Abstract

Aeration strategy is an important factor for the formation and maintenance of aerobic granular sludge (AGS), but aeration is also the most energy-consuming part in the biological wastewater treatment system. In order to optimize the aeration strategy of AGS reactor at low temperature, short- and long-term effects of dissolved oxygen (DO) concentration and aeration intensity (AI) were investigated at 10 ℃ in this study. The results showed that the carbon and phosphorus removal performance of AGS exhibited high resistance to the short-term changes of DO and AI, while the nitrogen removal was greatly influenced. The optimum DO and AI were 4 mg/L and 0.25 cm/s, corresponding to 82.7% and 81.4% of total inorganic nitrogen removal efficiencies, respectively. Long-term operation experiment showed that the properties of AGS kept stable under 4 mg/L DO concentration, but the overgrowth of filamentous bacteria and reduction of extracellular polymeric substance under 0.25 cm/s AI led to a large amount of granule disintegration, which could not be recovered with the prolonged operation. These findings might provide guidance for the operation optimization of AGS system at low temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Aerobic granular sludge (AGS) is an efficient biological wastewater treatment technology, which is formed by self-immobilization of microorganisms under high selective pressure (Nguyen Quoc et al., 2021). Compared with the traditional activated sludge process, AGS has the advantages of compact structure and excellent sedimentation performance, which is conductive to improving the biomass concentration of the reactors (Zitomer et al., 2007). In addition, the special layered structure due to the diffusion limitation of dissolved oxygen (DO) in AGS makes it possible to simultaneously remove nitrogen, phosphorus, and organic matter in a single system (Mosquera-Corral et al., 2005). To date, AGS technology has been successfully applied in the treatment of municipal sewage and industrial wastewater containing toxic substances, showing high pollutant removal rate, strong impact load resistance, and low operating cost (Pronk et al., 2015; Sadri Moghaddam & Alavi Moghaddam, 2016; Wei et al., 2016).

The aeration strategy is an important factor that influences the formation and performance of AGS, by providing dissolved oxygen (DO) and shear force (Gao et al., 2013; de Sousa Rollemberg et al., 2018). It has been confirmed that the cultivation and stable operation of AGS was easier to realize under high DO concentration and high shear force due to the high secretion rate of extracellular polymeric substance (EPS) (Muhammad Sajjad 2015). However, Mosquera-Corral et al. (2005) found that the nitrogen removal efficiency in AGS reactor increased from 8 to 45% while reducing the saturation of DO from 100 to 40%. This system ran stably for 150 days under 75% DO saturation, but collapsed soon under 40% DO saturation, which was speculated to be caused by the degradation of EPS in the core of granules. Gao et al. (2013) studied the impact of aeration intensity (AI) on mature AGS and found that the apparent half rate constant and the COD removal rate were similar under high and low AI. In considering that aeration is the main energy consumption part in biological wastewater treatment processes, it is necessary to optimize the aeration strategy, not only to improve the pollutant removal efficiency, but also to reduce the wastewater treatment cost. However, most relative studies were carried out at room temperature. Few studies pay attention to the optimization of aeration strategies at low temperature, in spite of the fact that the same aeration strategy can not be applied to room and low-temperature environments at the same time, because of the difference in the DO transfer rate, water viscosity, and microbial activity (Chen et al., 2017; Winkler et al., 2012).

To optimize the aeration strategy of AGS system at low temperature, the present study investigated the short- and long-term effects of DO concentration and AI on the performance of AGS at 10 ℃, respectively. The aeration strategy was first determined by batch tests and then substituted into the reactor for verification. The nutrient removal efficiency, granule morphology, and EPS content were simultaneously detected to identify the operational stability of AGS under different aeration strategies. It is expected to provide useful information for further reducing the energy consumption of AGS reactors.

2 Materials and Methods

2.1 Reactor Setup

Long-term experiments were carried out in a cylindrical sequencing batch reactor (R0). The effective working volume was 3.0 L, with an inner diameter of 7.4 cm and a height of 70 cm. Compressed air was introduced via a bubble stone at the bottom of the reactor. The original aeration flux was 160 L/h, which led to an AI of 1.0 cm/s and a DO concentration of 10.5 mg/L during aeration period. The operation temperature was controlled at 10 ± 0.5 ℃ by a precise cryogenic thermostat throughout the experiment. A 4-h operation cycle was applied, which consisted of 60-min feeding, 152-min aeration, 3-min settling, 5-min effluent withdrawal, and 20-min idle time. The volumetric exchange ratio was 50%, corresponding to a hydraulic residence time of 8 h. The excess sludge was discharged regularly to control the sludge retention time at 30 days.

2.2 Inoculum and Wastewater

The reactor was seeded with mature aerobic granules collected from a lab-scale AGS-SBR system (Xu et al., 2018), which has been operated stably for over 300 days at 10 ± 0.5 ℃. The mixed liquor suspended solids (MLSS) concentration of the reactor after inoculation was about 6.0 g/L. The feed to the reactor was synthetic wastewater simulating municipal sewage, which was consisted of the following: COD (NaAc) 400 mg/L, NH4+-N (NH4Cl) 50 mg/L, TP (K2HPO4 and KH2PO4) 18 mg/L, Mg2+ (MgSO4) 8 mg/L, KCl 32.5 mg/L, and 1 mL/L of trace element solution (described by Beun et al. (2000)).

2.3 Analytical Methods

The wastewater parameters, including COD, NH4+-N, NO2−-N, NO3−-N, TP, MLSS, and MLVSS, were measured according to standard method (APHA, 2005). DO and pH were detected by HQ 30d and HI 8424 pH meters. Thermal extraction was utilized to extract EPS from sludge (Li & Yang, 2007). The contents of protein (PN) and polysaccharide (PS) in EPS were measured using modified Lowry method (Frølund et al., 1996) and phenol–sulfuric acid method (Gerhardt et al., 1994), respectively. The extracted EPS was qualitatively analyzed by FP-6500 fluorescence spectrophotometer (3D-EEM). The excitation wavelength was 220–450 nm and the emission wavelength was 220–650 nm. The morphology of AGS was obtained using digital camera and stereomicroscope (TM-2M45-B2).

2.4 Batch Test

After R0 (described above) had been operated stably, batch tests were conducted to investigate the short-term effect of DO and AI on AGS performance. At the beginning of each test, mixed liquor (500 mL) was collected from R0 at the end of aeration, and then transferred to a minified version SBR reactor with the same working volume. The minified SBR was operated at the same condition (except for DO and AI) with R0 for 2 days. Samples were taken out regularly at the last cycle to investigate the conversion process of the pollutants. When studying the effect of DO, AI was kept steady while introducing nitrogen gas (N2, 99% purity) into the reactor. DO was firstly aerated to the target concentrations (2, 4, 6, and 8 mg/L) within 10 min and then kept steady by changing the air to N2 ratio, which was accomplished by DO detector, mass flow controller, and high-pressure solenoid valve. When studying the effect of AI, the aeration flux was adjusted to maintain the AI at 0.25, 0.5, and 0.75 cm/s. The variation of DO during the last cycles was also detected to identify the influence degree of DO and AI respectively.

3 Results and Discussion

3.1 Start-up of AGS-SBR Reactor

Due to the same operating conditions with source reactor, R0 entered a stable state rapidly. As shown in Table 1, the average diameter of AGS at phase I was about 4.5 mm, with a settling velocity of 75 m/h. The PN and PS contents in EPS were 79.30 and 26.86 mg/g VSS, respectively, corresponding to a PN/PS ratio of 2.95. In order to further clarify the components of EPS in AGS, 3D-EEM was conducted. As shown in Fig. 1a, 4 peaks were detected, representing humic acid–like substances (peaks A and C), tryptophan protein (peak B), and aromatic protein (peak D) (Ni et al., 2017). The high fluorescence intensity of tryptophan indicated that the granules might exhibit high hydrophobicity, which has been proved favorable for promoting the cell-to-cell interaction and then improving the stability of AGS (Campo et al., 2018).

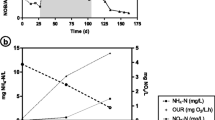

In terms of pollutant removal performance, R0 achieved nearly 92.5% and 99.5% removal efficiencies of COD and TP at the beginning of operation, due to the high concentration of inoculated AGS. As shown in Fig. 2, the effluent TIN concentration was about 20 mg/L, corresponding to 60% TIN removal efficiency. The nutrient removal processes in a typical cycle at day 30 was tested. The results showed that the anaerobic phosphorus release after feeding was 68 mg/L (Fig. S1a). During aerobic period, the phosphorus accumulating organisms (PAO) accumulated phosphorus rapidly. Almost all phosphorus was removed within 100 min of aeration. Nitrogen conversion process is illustrated in Fig. S1b. It can be seen that the concentration of NH4+-N in liquid phase was only 14.5 mg/L rather than 25.0 mg/L. Considering that no anaerobic ammonium-oxidizing bacteria were detected in the source SBR, the loss of NH4+-N might be caused by the adsorption of AGS, which has been confirmed in previous study (He & Xu, 2018). The trend of NO3−-N concentration shows that the traditional denitrifying bacteria might play less role in the nitrogen removal process, since the NO3−-N concentration in the liquid phase was 10.2 mg/L after feeding, nearly no reduction occurred, indicating that mostly of the NO3−-N was reduced during aeration period by denitrifying polyphosphate-accumulating organism (DPAO).

3.2 Short-Term Effect of Aeration Strategies

3.2.1 DO

DO plays an important role in the process of simultaneous nitrogen and phosphorus removal in AGS system. Under the same other conditions, the aerobic zone in AGS increases with the increase of DO concentration, and the corresponding anoxic zone and anaerobic zone decrease accordingly (Chiu et al., 2007). Therefore, appropriate DO concentration is helpful to adjust the functional zone of AGS so as to improve the removal efficiency of pollutants.

The removal processes of nitrogen and phosphorus in the last cycle of each batch experiment under different DO concentrations is shown in Fig. 3. It can be observed that DO concentration had a significant effect on the conversion process of nitrogen, especially nitrite oxidation and denitrification. When DO concentration decreased from 10.5 to 2 mg/L, the accumulation rate of NO3−-N in liquid phase decreased gradually, and the concentration of NO3−-N in effluent decreased from 20 to 3.04 mg/L, with a slight increase of NO2−-N (0–0.5 mg/L). Linear fitting of NO3−-N concentration during aeration (Table S1) shows that when DO concentration was above 8 mg/L, the nitrite oxidation rate had no significant change, for the nitrate accumulation rate was both 0.12 mgNO3−-N·L−1 min−1. NH4+-N could be effectively removed in the studied DO concentrations, except for 2 mg/L, at which NH4+-N in effluent increased to about 9 mg/L. The reason for this result can also be explained from the regulation of DO on AGS functional zoning: functional flora related to nitrogen removal in AGS mainly distributed in the peripheral aerobic and anoxic zones, with AOB → NOB → denitrifying bacteria from surface to inert core (Guimarães et al., 2017). The penetration depth of DO in AGS decreased alongside liquid DO concentration, resulting in the compression of aerobic zone and the outward migration of anoxic zone. The NOB was affected firstly while the oxidation rate of NO2−-N decreased. More NO2−-N was directly reduced to N2 rather than oxidized to NO3−-N. In addition, due to the short-cut denitrification process which required fewer carbon source, more NOx could be reduced under the same COD concentration, thereby improving the TIN removal efficiency (Yang & Yang, 2011). The highest TIN removal efficiency in this experiment was 82.7%, which was obtained at 4 mg/L DO. This was consistent with the partial nitrification study of Wang et al. (2020), in which the ammonium oxidation rate was kept stable when the DO concentration was greater than 4 mg/L at 15℃. When DO concentration decreased to 2 mg/L, the aerobic zone decreased dramatically and the activity of AOB was inhibited, resulting in the residue of NH4+-N. Therefore, although the effluent NO3−-N concentration continued to decline, the removal efficiency of TIN decreased accordingly.

In terms of phosphorus removal, AGS system showed strong resistance to the change of DO, for more than 96% of phosphorus removal could be obtained at each cycle (as shown in Fig. 3f). In AGS systems, the biological removal of phosphorus is mainly performed by PAO and DPAO. Unlike traditional PAO, DPAO can use NO2−-N or NO3−-N instead of DO as electronic donors to accumulate phosphorus under anoxic conditions (Lee & Yun, 2014). Considering the performance of NO3−-N reduction, DPAO might account for a large proportion in the total microbial community, which could adapt to various DO environments. It is noteworthy that although phosphorus could be removed adequately, its accumulation rates decreased with the decrease of DO concentration. This might be due to the compression of aerobic zone and the outward migration of anoxic zone in granules, which led to the decrease of phosphorus uptake rate of traditional PAO. It can also be found that when DO concentration in the system was at a low level, NO3−-N decreased continuously in the first 40 min of aeration. Considering that there was only a small amount of carbon source residue in the system at this period, the cause for this phenomenon might be the faster denitrifying phosphorus removal rate than the nitrite oxidation rate.

3.2.2 AI

The effect of AI on AGS is not only reflected in promoting floc aggregation and maintaining granular stability, but also closely related to the removal rate of pollutants (He et al., 2018). As reported, the diffusion coefficients of NaAc, DO, and ammonium are 2.5 × 10−9, 1.67 × 10−9, and 1.01 × 10−9 m2 s−1, respectively (Liu & Liu, 2006). The mass transfer resistance of substrates in AGS is much higher than that in liquid phase, so a higher AI is needed to improve the mass transfer rate of substrates (Zhu et al., 2015). Figure S2 shows the variation of DO concentration in typical cycles under different AI. It can be seen that the rising rate of DO concentration increased with the increase of AI, which might be related to the increase of the gas–liquid oxygen transfer rate (Garcia-Ochoa & Gomez, 2009). Data also show that when AI was 1.0 and 0.75 cm/s, DO in the systems could both reach saturation state, but 0.75 cm/s AI took longer time to achieve. When AI was 0.5 and 0.25 cm/s, DO in the system was increased throughout the aeration period, which could reach 8.45 and 5.94 mg/L eventually.

The conversion processes of nitrogen and phosphorus are shown in Fig. 4. It can be seen that although the changes of AI had little effect on ammonium oxidation rate and nitrate accumulation rate due to the high DO concentration (> 5.9 mg/L), the NO3−-N concentration in effluent decreased gradually. The TIN removal efficiency increased from 60 to 81.4% while the AI decreased from 1.0 to 0.25 cm/s. This result might be caused by the increase of denitrifying rate at the first 20 min of aeration, for the concentration of NO3−-N continued to decrease at this period. In previous research, the variation of DO concentration was considered to be the main reason for the effect of AI on the pollutant removal of AGS (He et al., 2019). However, when comparing the effects of DO and AI at the same time, it can be observed that even if DO concentration was close, the denitrification capacity of the system was different under different AI. Such as Fig. 3d and Fig. 4b, the final DO concentrations of the two systems were 8 and 8.5 mg/L, but the concentrations of NO3−-N in the effluent were 17.33 and 12.54 mg/L, and the corresponding TIN removal efficiency was 65.34% and 74.92%, respectively. There might be two reasons for this phenomenon. One of them is the increase rate of DO was different between these two conditions. In the experiment of DO effect, the DO in system was not controlled until it reached the desired concentration. That is to say, the duration of DO concentration below 8 mg/L in aeration stage was less than 5 min. However, in the AI effect experiment, DO did not reach 8 mg/L until 90 min of aeration, resulting in higher denitrification rate in the majority aeration time than the former. The other reason might be that the mass transfer rate under DO experiment was higher, so the solid–liquid surface of AGS could catch more DO and substrate than low AI system. Therefore, DO could penetrate deeper in AGS under high AI, leading to the decrease of the anoxic zone and denitrification efficiency.

In the aspect of phosphorus removal, the effect of AI showed similar trends with DO, that is, the phosphorus accumulation rate decreased with the AI. It is noteworthy that in the DO effect experiments, the aerobic phosphorus uptake rate had little change before DO concentration dropped to 4 mg/L, and the phosphorus could be fully removed within 160 min. However, in the AI effect experiments, the phosphorus uptake rate slowed down obviously with the decrease of AI, and the time of the complete removal of phosphorus was delayed to 180, 200, and 220 min, respectively, even though the DO concentration was higher (Fig. 4d). This phenomenon indicated that the mass transfer rate controlled by AI might have a greater impact on the pollutant removal than DO.

3.3 Long-Term Effect of Aeration Strategies

The long-term effects of DO and AI on AGS were sequenced conducted under 4.0 mg/L DO concentration and 0.25 cm/s AI, which have been proved to be the most conducive condition for the simultaneous removal of pollutants by short-term experiments, respectively. As shown in Fig. 2 (phase II, days 30–60), the removal performance of COD, NH4+-N, and TP remained stable at this stage, while the average TIN removal efficiency increased to 82% soon after the reduction of DO, accompanied by the significant decrease of effluent NO3−-N. Granules could be divided into two types: white and pale yellow. Different from the study conducted under room temperature, in which AGS soon disintegrated due to the overgrowth of filamentous bacteria when the DO saturation decreased from 100 to 40% (Mosquera-Corral et al., 2005), the reduction of DO in this study had little effect on the stability of AGS, but the white to yellow ratio changed obviously. The succession of microbial community structure might be the main reason for the different granular morphology. As reported by Barr et al. (2010), the white granules in AGS system was dominated by Candidatus Accumulibacter, which is a typical DPAO, while the yellow granules was dominated by Candidatus Competibacter, which is a typical denitrifying glycogen-accumulating organisms (DGAO). It has been confirmed that PAOs have an advantage over GAOs at low DO levels, as PAOs have a higher DO affinity (Carvalheira et al., 2014). Therefore, the change of white to yellow ratio might be due to the enrichment of DPAO. The content of PN and PS in EPS also kept stable at this period (Table 1). However, the 3D-EEM spectra shows that the fluorescence intensity of humic acid–like substances increased significantly, indicating that the degree of cell lysis inside granules increased with the increase of anaerobic zone (Burdon, 2001).

In practice, high AI in biological reactor operation usually results in huge energy consumption. Therefore, reducing AI can not only improve nutrient removal, but also reduce operating costs. During days 60–90, the long-term effect of AI on AGS system was investigated without DO controlling. As shown in Fig. 2 (phase III), the performance of AGS could be divided into two phase. The first was days 60–70, during which granules kept stable and no obvious change occurred. TIN removal efficiency decreased gradually with the recovery of NOB activity, which might be due to the increase of DO concentration. However, from day 70, filamentous bacteria began to accumulate in the system and quickly occupied a dominant position. The surface of AGS turned into fluffy and the settling speed decreased to 15 m/h within 5 days, which directly led to a large amount of sludge discharged with the effluent. It has been reported that low temperature was not favorable for the amplification of filamentous bacteria, due to a higher temperature coefficient than floc-forming bacteria (Liu & Liu, 2006). However, the special layered structure of AGS and the decrease of mass transfer rate increased the substrate gradient inside granules (including DO), which might provide a suitable environment for filamentous bacteria (Castellanos et al., 2021). At the end of phase III, a significant granule disintegration occurred, which directly caused the collapse of the system. As a chain reaction, the nutrient removal performance deteriorated rapidly. Ammonium oxidation rate and nitrite oxidation rate decreased simultaneously, which caused the accumulation of NH4+-N and NO2−-N. The TIN, COD, and TP removal efficiencies dropped to 55%, 78%, and 65% respectively, which could not be recovered with the prolong of operation. It is noteworthy that, during studying the effect of AI on AGS system at room temperature, granules exhibited similar performance under 0.58 and 0.14 cm/s (Gao et al., 2013). In addition, Yuan and Gao (2010) found that the optimal DO (achieved by reducing AI) for AGS was 2.5 mg/L at 30℃. However, in this study, the fluidization of AGS was poor when the AI was below 0.25 cm/s, which might be due to the higher water viscosity at low temperature. Besides, the inhibitation of low temperature on functional microorganisms could also lead to the different performance of AGS. In order to figure out the main reason for system collapse except for filamentous bacteria overgrowth, the characteristics of EPS at day 90 were investigated. It can be seen that the PN and PS contents in EPS decreased 38.81% and 16.03% compared to day 60, which resulted in a 27.3% decrease of PN/PS. The fluorescence intensity of tryptophan and aromatic-like proteins decreased accordingly, and the peak E, which belonged to soluble microbial products, appeared at this period. As described by Franca et al. (2018), the degradation of EPS could cause the formation of cavity structure and reduce the stability of AGS. Besides, a lower EPS secretion rate under low AI has also been confirmed (He et al., 2019). Therefore, the decrease of EPS content, especially PN, might also be a main reason for the collapse of AGS while reducing AI. How to select the optimized AI that can simultaneously improve the nutrient removal ability and maintain the stability of AGS at low temperature needs further research.

4 Conclusion

In this study, short- and long-term effects of aeration strategies on AGS at low temperature were investigated. The results showed that the AGS had strong resistance to the short-term changes of DO and AI. The optimized conditions were 4 mg/L DO and 0.25 cm/s AI, corresponding to 82.7% and 81.4% of TIN removal efficiencies, respectively. The long-term reduction of DO had little effect on the performance of AGS. However, the reduction of AI caused the excessive growth of filamentous bacteria and the decrease of EPS content, which eventually led to the disintegration of granules. These results suggest that the relatively high AI and low DO might be more suitable for AGS operation, which could be realized through adjusting the aeration mode, such as changing microporous aerator to perforated aerator.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request. All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

APHA (2005) Standard methods for the examination of water and wastewater. In, American Public Health Association, Washington, DC, New York.

Barr, J. J., Cook, A. E., & Bond, P. L. (2010). Granule formation mechanisms within an aerobic wastewater system for phosphorus removal. Applied and Environment Microbiology, 76(22), 7588–7597.

Beun, J. J., Loosdrecht, M. C. M., & v. and Heijnen J. J. (2000). Aerobic granulation. Water Science and Technology, 41, 41–48.

Burdon, J. (2001). Are the traditional concepts of the structures of humic substances realistic? Soil Science, 166, 752–769.

Campo, R., Corsino, S. F., Torregrossa, M., & Di Bella, G. (2018). The role of extracellular polymeric substances on aerobic granulation with stepwise increase of salinity. Separation and Purification Technology, 195, 12–20.

Carvalheira, M., Oehmen, A., Carvalho, G., Eusébio, M., & Reis, M. A. M. (2014). The impact of aeration on the competition between polyphosphate accumulating organisms and glycogen accumulating organisms. Water Research, 66, 296–307.

Castellanos, R. M., Dias, J. M. R., Dias, B. I., Dezotti, M., & Bassin, J. P. (2021). Effect of sludge age on aerobic granular sludge: Addressing nutrient removal performance and biomass stability. Process Safety and Environmental Protection, 149, 212–222.

Chen, Y., Lan, S., Wang, L., Dong, S., Zhou, H., Tan, Z., & Li, X. (2017). A review: Driving factors and regulation strategies of microbial community structure and dynamics in wastewater treatment systems. Chemosphere, 174, 173–182.

Chiu, Z. C., Chen, M. Y., Lee, D. J., Wang, C. H., & Lai, J. Y. (2007). Oxygen diffusion and consumption in active aerobic granules of heterogeneous structure. Applied Microbiology and Biotechnology, 75(3), 685–691.

de Sousa, R. S. L., Mendes, B. A., & R., Milen Firmino P. I. and Bezerra Dos Santos A. (2018). Aerobic granular sludge: Cultivation parameters and removal mechanisms. Bioresour Technol, 270, 678–688.

Frølund, B., Palmgren, R., Keiding, K., & Nielsen, P. H. (1996). Extraction of extracellular polymers from activated sludge using a cation exchange resin. Water Research, 30, 1749–1758.

Franca, R. D. G., Pinheiro, H. M., van Loosdrecht, M. C. M., & Lourenco, N. D. (2018). Stability of aerobic granules during long-term bioreactor operation. Biotechnology Advances, 36(1), 228–246.

Gao, D. W., Liu, L., & Liang, H. (2013). Influence of aeration intensity on mature aerobic granules in sequencing batch reactor. Applied Microbiology and Biotechnology, 97(9), 4213–4219.

Garcia-Ochoa, F., & Gomez, E. (2009). Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnology Advances, 27(2), 153–176.

Gerhardt, P., Murray, R. G. E., Wood, W. A., & Krieg, N. R. (1994). Methods for general and molecular bacteriology. American Society for Microbiology.

Guimarães, L. B., Mezzari, M. P., Daudt, G. C., & da Costa, R. H. R. (2017). Microbial pathways of nitrogen removal in aerobic granular sludge treating domestic wastewater. Journal of Chemical Technology & Biotechnology, 92(7), 1756–1765.

He, J., & Xu, J. (2018). The characteristics of heat-driven ammonium adsorption in aerobic granular sludge. Water Science and Technology, 78(7), 1466–1475.

He, Q., Chen, L., Zhang, S., Chen, R., & Wang, H. (2019). Hydrodynamic shear force shaped the microbial community and function in the aerobic granular sequencing batch reactors for low carbon to nitrogen (C/N) municipal wastewater treatment. Bioresource Technology, 271, 48–58.

He, Q., Chen, L., Zhang, S., Wang, L., Liang, J., Xia, W., Wang, H., & Zhou, J. (2018). Simultaneous nitrification, denitrification and phosphorus removal in aerobic granular sequencing batch reactors with high aeration intensity: Impact of aeration time. Bioresource Technology, 263, 214–222.

Lee, H., & Yun, Z. (2014). Comparison of biochemical characteristics between PAO and DPAO sludges. Journal of Environmental Sciences (china), 26(6), 1340–1347.

Li, X. Y., & Yang, S. F. (2007). Influence of loosely bound extracellular polymeric substances (EPS) on the flocculation, sedimentation and dewaterability of activated sludge. Water Research, 41(5), 1022–1030.

Liu, Y., & Liu, Q. S. (2006). Causes and control of filamentous growth in aerobic granular sludge sequencing batch reactors. Biotechnology Advances, 24(1), 115–127.

Mosquera-Corral, A., de Kreuk, M. K., Heijnen, J. J., & van Loosdrecht, M. C. (2005). Effects of oxygen concentration on N-removal in an aerobic granular sludge reactor. Water Research, 39(12), 2676–2686.

Muhammad, K. S. K. (2015). Studies on the interactions of Ca2+ and Mg2+ with EPS and their role in determining the physicochemical characteristics of granular sludges in SBR system. Process Biochem, 50, 966–972.

Nguyen, Quoc B., Wei, S., Armenta, M., Bucher, R., Sukapanpotharam, P., Stahl, D. A., Stensel, H. D., & Winkler, M.-K.H. (2021). Aerobic granular sludge: Impact of size distribution on nitrification capacity. Water Res, 188, 116445.

Ni, L., Li, D., Rong, S., Su, L., Zhou, W., Wang, P., Wang, C., Li, S., & Acharya, K. (2017). Characterization of extracellular polymeric substance (EPS) fractions produced by Microcystis aeruginosa under the stress of linoleic acid sustained-release microspheres. Environmental Science and Pollution Research, 24(26), 21091–21102.

Pronk, M., de Kreuk, M. K., de Bruin, B., Kamminga, P., Kleerebezem, R., & van Loosdrecht, M. C. (2015). Full scale performance of the aerobic granular sludge process for sewage treatment. Water Research, 84, 207–217.

Sadri Moghaddam, S., & AlaviMoghaddam, M. R. (2016). Aerobic granular sludge for dye biodegradation in a sequencing batch reactor with anaerobic/aerobic cycles. CLEAN - Soil, Air, Water, 44(4), 438–43.

Wang, J., Yang, H., Liu, X., Wang, J., & Chang, J. (2020). The impact of temperature and dissolved oxygen (DO) on the partial nitrification of immobilized fillers, and application in municipal wastewater. RSC Advances, 10, 37194–37201.

Wei, D., Li, M., Wang, X., Han, F., Li, L., Guo, J., Ai, L., Fang, L., Liu, L., Du, B., & Wei, Q. (2016). Extracellular polymeric substances for Zn (II) binding during its sorption process onto aerobic granular sludge. Journal of Hazardous Materials, 301, 407–415.

Winkler, M. K. H., Bassin, J. P., Kleerebezem, R., van der Lans, R. G. J. M., & van Loosdrecht, M. C. M. (2012). Temperature and salt effects on settling velocity in granular sludge technology. Water Research, 46(16), 5445–5451.

Xu, J., He, J., Wang, M., & Li, L. (2018). Cultivation and stable operation of aerobic granular sludge at low temperature by sieving out the batt-like sludge. Chemosphere, 211, 1219–1227.

Yang, S., & Yang, F. (2011). Nitrogen removal via short-cut simultaneous nitrification and denitrification in an intermittently aerated moving bed membrane bioreactor. Journal of Hazardous Materials, 195, 318–323.

Yuan, X., & Gao, D. (2010). Effect of dissolved oxygen on nitrogen removal and process control in aerobic granular sludge reactor. Journal of Hazardous Materials, 178(1–3), 1041–1045.

Zhu, L., Zhou, J., Yu, H., & Xu, X. (2015). Optimization of hydraulic shear parameters and reactor configuration in the aerobic granular sludge process. Environmental Technology, 36(13–16), 1605–1611.

Zitomer, D. H., Duran, M., Albert, R., & Guven, E. (2007). Thermophilic aerobic granular biomass for enhanced settleability. Water Research, 41(4), 819–825.

Funding

This research was supported financially by the Key Research and Development Program of Shandong Province (No. 2020CXGC011202) and the Natural Science Foundation of Shandong Province (No. ZR2021QE274).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, J., Ju, H., He, J. et al. The Performance of Aerobic Granular Sludge Under Different Aeration Strategies at Low Temperature. Water Air Soil Pollut 233, 43 (2022). https://doi.org/10.1007/s11270-022-05506-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-022-05506-y