Abstract

Laundry wastewater has a high amount of dirt from the washed items and chemical additives used in washing process. Aiming the primary treatment of this type of wastewater, three different natural coagulants (Tanfloc POP, Tanfloc SL, and Tanfloc SG) were evaluated in the removal of color and turbidity by the coagulation/flocculation/sedimentation process (C/F/S). The results showed that the time between 5 and 10 min was sufficient for the sedimentation of the flakes, with a time of 10 min being adopted for further studies. The statistical analysis and the cost of acquiring the coagulant were decisive in the selection of the best natural coagulant. The maximum values of color (88.7%) and turbidity (92.8%) removal efficiency occurred at a concentration of 120 mg L−1 (concentration determined by the Fischer LSD test) and the lowest cost (0.75$) obtained for the Tanfloc POP coagulant. The volume of sludge generated was higher in the treated effluent sample compared to the control sample, which proves the removal of total solids present in the effluent. The Tanfloc POP coagulant showed a high performance in removing color and turbidity from industrial laundry wastewater; it has been as a promising coagulant in the primary treatment of wastewater in this service sector.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The combating of air, soil, and water pollution over the years has been a major challenge for humans. In the aquatic environment, pollution has several origins, such as industrial effluents, significant use of pesticides and fertilizers in agriculture, and residues of pharmaceutical and domestic origin (Natarajan et al., 2018; Zahrim et al., 2013).

Among industrial wastewaters, that of laundries has in its composition high levels of suspended solids, COD, color, surfactants, and organic matter. These parameters can alter the characteristics of the water and lead to the occurrence of the eutrophication phenomenon (Al-Gheethi et al., 2017; Choobar et al., 2019). They are generally parameters that are in greater proportions than the legislation allows for disposal or reuse, which confirms the need for treatment of this type of wastewater (Turkay et al., 2017).

Color and turbidity are among the main parameters that indicate water quality. The presence of color in the aquatic environment reduces the passage of light through the water, leading to a change in the photosynthetic activity and consequent natural imbalance of flora and fauna, while turbidity indicates the presence of suspended solids such as organic particles and soluble in water. These are factors that in addition to causing a poor appearance of the water, are also capable of inducing microbial resistance (Collivignarelli et al., 2019; Momeni et al., 2018).

The main methods used for the treatment of laundry wastewater are as follows: coagulation/flocculation/sedimentation (C/F/S), adsorption, flotation, and membrane separation processes (Kim et al., 2014), with the C/F/S process being widely used in the primary treatment of effluents, due to its ability to remove organic matter, turbidity, and color (Muthuraman & Sasikala, 2014).

The C/F/S process has the main purpose to remove the particles of impurities and the color of the water, and for that, it requires the addition of coagulants to the samples of wastewater to be treated, in order to destabilize and agglomerate the small particles, making it easier to removal of flakes formed (Freitas et al., 2015).

According to Kim (2016), some factors influence the efficiency of the C/F/S process, such as the type of coagulant used and its dosage, the pH value of the water to be treated, speed and stirring time, operating temperature, and retention time.

Coagulation is the physical and chemical reaction that occurs between the alkalinity of the water and the added coagulant, which results in the formation of flakes. Flocculation is the movement controlled by the agitation of the effluent that leads to the formation of settleable flakes of 20 to 50 µm in size (Ciabatti et al., 2009; Manda et al., 2016).

The sedimentation process occurs by solid/liquid separation influenced by gravity, allowing the heavier flakes to settle faster than the dispersed particles, in order to settle in the bottom of the solution. Thus, the aim is to obtain the shortest time of sedimentation to achieve a viable and efficient process that reduces the operation time of treatment plants (Mohamad et al., 2021; Ortiz et al., 2021).

The coagulants used in the wastewater treatment can be of the inorganic type or of natural origin. Inorganic coagulants can be formed based on aluminum, such as aluminum sulfate, sodium aluminate, and potassium alum, and also based on iron, such as ferric sulfate and ferric chloride (Manda et al., 2016).

The use of inorganic coagulants in large quantities leads to a high production of residues, which are not biodegradable and exhibit toxicity to the environment (Ang et al., 2015). The aluminum sulfate, widely used in C/F/S processes, when present in high dosages in the human body can cause diseases that affect motor coordination, such as Alzheimer’s disease (Saritha et al., 2019).

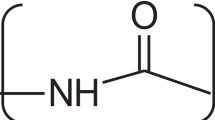

These problems have stimulated the interest in the development and use of natural coagulants, which can be extracted from plants and animals (Graham et al., 2008). To replace the synthetic inorganic or organic polymers or even aluminum and iron salts, the use of cationic polymers prepared from natural products has been proposed, for example, the tannin that is extracted from the husk of Acacia-negra (Acacia mearnsii). In Brazil, this tree is cultivated only in Rio Grande do Sul, and the Tanac S.A. company owns an area of more than 30 thousand hectares (Mangrich et al., 2014).

The cationic organic polymer is prepared by the Mannich reaction, which consists of the polymerization of tannin by the addition of formaldehyde, ammonium chloride, and hydrochloric acid. This type of process is conducted in patents, including the specific process for Tanfloc (Hameed et al., 2016). Tanfloc coagulants are widely used to treat effluents from different industries, and have shown efficiency in removing parameters such as color and turbidity, as reported in the work of Lopes et al. (2019). The authors used the C/F process to treat synthetic textile wastewaters, adding the concentration of 80 mg L−1 of dye and using Tanfloc SG (concentration: 50 to 200 mg L−1) under the conditions of 3 min of rapid mixing at 150 rpm and 15 min of slow mixing at 20 rpm with 15 min for the flakes sedimentation time and obtained the total removal of turbidity and color in the treated effluent.

In the study of Dos Santos et al. (2018), different coagulants of natural origin were evaluated in the treatment of the wastewater from the cassava processing industry (manipueira) for a sedimentation time of 15 min. The Tanfloc SL (480 mg L−1) and Acquapol S5T (320 mg L−1) coagulants showed the highest efficiencies, with turbidity and color removal around 87% and 77%, respectively, for both coagulants. Vaz et al. (2010) obtained removal of 96.77% for color and 99.38% for turbidity in the treatment of electroplating effluent with the use of the natural coagulant Tanfloc SG (concentration: 400 mg L−1) for a sedimentation time of 50 min.

Based on the promising applications of natural coagulants in different effluents, including Tanfloc, the present work was encouraged to evaluate the efficiency of three natural coagulants (Tanfloc POP, Tanfloc SG, and Tanfloc SL) in the treatment of industrial laundry effluent. Therefore, we sought to determine the best coagulant dosage and the shortest sedimentation time for the flakes that would result in the highest removal of color and turbidity of the effluent. The analysis of the acquisition cost of the coagulants was carried out together with the statistical analysis to choose the best coagulant in relation to the efficiency in the process.

2 Materials and Methods

2.1 Wastewater and Analytical Methodology

The raw wastewater was collected in the equalization tank of an industrial laundry in the western region of Paraná, Brazil, and stored in polypropylene gallons with a capacity of 5 and 20 L in a refrigerator for use in subsequent tests. As informed by the laundry, approximately 800 kg of items is washed daily, such as professional uniforms from a fish fridge, blankets, comforters, carpets and curtains of domestic and hotel management origin, and sofas and armchairs. In this washing process, around 8 m3/day of wastewater from the activity is produced.

The wastewater was destined to its characterization and to the C/F/S assays using different natural coagulants to determine the most efficient range in the removal of color and turbidity of the wastewater.

The characterization of the wastewater followed the methodologies of Standard Methods for the Examination of Water and Wastewater (APHA, 1998) and all the analyses were performed in duplicate. The analyses of Total Organic Carbon (TOC-5310C) and total nitrogen, which followed the methodology of American Society for test Method´s D5176 (ASTM, 2015), were analyzed in a TOC-L equipment (brand: Shimadzu). The conductivity (2510-B) was quantified using a conductivity meter (Tecnal R-TEC-04P-MP). Apparent color (8025) and Chemical Oxygen Demand (COD 5220D) were analyzed using a Hach Spectrophotometer (DR 3900). The pH (4500_H+ B) was measured using a pH meter (Digimed DM-22), and temperature was measured using a thermometer Icoterm (ASTM 8C-86 IMM) (APHA-255B). Turbidity (2130B) was quantified using a turbidimeter (Model 2100 P), and the analyses of Total Dissolved Solids and Total Solids were performed following the TDS-2540C and TS-2540B procedures (APHA, 1998) respectively.

2.2 Coagulant Solution and C/F/S Tests

The natural coagulants Tanfloc POP, Tanfloc SG, and Tanfloc SL used in the C/F/S tests for the treatment of the laundry wastewater were provided by the company Tanac S.A. These coagulants are produced by the process of extracting the tannin from the husk of Acacia-negra (Acacia mearnsii), and operate in a pH range between 4.5 and 8. The solutions of the natural coagulants (Tanfloc POP, SG, and SL) were prepared with distilled water according to the desired concentration (80, 100, 120, 140, and 160 mg L−1) in the C/F/S assays. These tests were carried out in order to select among the three natural coagulants tested, the one that had the best color and turbidity removals, associated with the best coagulant dosage and sedimentation time of the flakes.

The assays were performed in Jar Test equipment (JT102-Milan) containing tanks with a capacity of 1 L of wastewater each. Experiments without addition of coagulant (control) in wastewater sample were performed simultaneously in C/F/S process. The pH of the wastewater was adjusted to 7.5 by adding NaOH 1 mol L−1 and HCl 0,1 mol L−1 solutions, to meet the pH range of the coagulants (between 4.5 and 8). All assays were performed in duplicate and at room temperature at 26 °C, establishing the operating conditions of 120 rpm for rapid mixing velocity (RMV) and 2 min for rapid mixing time (RMT) and 20 rpm for slow mixing velocity (SMV) and 15 min for slow mixing time (SMT).

After the start of the sedimentation time of the flakes, aliquots of the supernatant were collected in each tank in the interval of 5 min until the total time of sedimentation was completed for 20 min. The collected samples were evaluated regarding the removal of color and turbidity parameters and the pH was also measured.

After the C/F/S step, the best coagulant and its best dosage were defined. C/F/S assays were repeated exclusively to determine the sludge produced, with all content present in tank (1 L) being transferred to the Imhoff cone and after 60 min of sedimentation the settleable solids were read directly (in the cone) and the volume of sludge was quantified.

The removal efficiency of color and turbidity parameters for the C/F/S process was determined by Eq. 1:

The statistical analyses were performed using the Statistica 7® software, in relation to the calculated efficiency values for the color and turbidity parameters. The ANOVA analysis of variance allowed to evaluate which treatments were significant considering a significance level of 5%. The comparison of the averages of color and turbidity removal for the three coagulants tested in the different concentrations was performed by the Fisher LSD test, in the established sedimentation time of 10 min.

The choice of the best coagulant was based on the analysis of the highest percentages of color and turbidity removal together with an analysis of acquisition cost of the coagulants.

3 Results and Discussion

3.1 Characterization of the Laundry Wastewater

The average values of the physicochemical parameters obtained in the present study and in some studies in the literature for the characterization of laundry wastewater are shown in Table 1.

The value of the total organic carbon represents the amount of organic matter present in the wastewater. In this study, the value of the parameter was lower than that obtained by Mozia et al. (2016) for the raw laundry wastewater, a fact that is due to the soiling of the washed parts and chemicals used in washing.

The conductivity (480 ± 2 µS cm−1) showed lower value than the one obtained by other studies in the characterization of laundry wastewater. According to Mozia et al. (2016), this parameter is an indicative of the presence of ions in the wastewater, which come from the products used in the washing.

The color parameter comes from the chemicals used in the process and the coloring that some fabrics lose during washing, which implies a variability among the values depending on the demand for the services.

In all characterizations of the laundry wastewater, with the exception of the authors Braga and Varesche (2014), the pH of the wastewater showed an alkaline characteristic, similarly to that obtained in the present study. These pH results support the statement of Shang et al. (2015) that the high pH value presented by laundry wastewaters is due to the use of phosphates, silicates, and other chemical components present in soaps and detergents.

The turbidity parameter is an indication of the presence of suspended particles and organic matter in wastewater (Pichler et al., 2012). In the present work, the turbidity value was lower in relation to the others, except for Huang et al. (2019). COD is another indicator of the presence of organic matter in the wastewater, with the value obtained in the present study lower than the found by Choobar et al. (2019), Braga and Varesche (2014), and Shang et al. (2015). According to Al-Gheethi et al. (2017), the detergent compounds present in the wastewater contribute to the increment in the COD and turbidity, due to the fact that they raise the organic load of the medium and cause an increase in the chemical reactions among the organic substances.

The obtained TS presented a value of 447 mg L−1, which indicates that most of the solids present in the wastewater are dissolved (TDS = 409 mg L−1). This TDS value is close to the value obtained by Kim et al. (2014) and more than ten times smaller than that presented by Choobar et al. (2019). The high value for TDS in the work of Choobar et al. (2019) is attributed to the presence of high amounts of detergents (in powder and liquid) used in the washing cycle and by the organic matter present in the wastewater (grease, oil, and dirt).

According to Mozia et al. (2016), laundry wastewaters have low value of total nitrogen, being in your work added nitrogen (14 mg L−1) to balance the proportion of nutrients in wastewater. In the present study, the value of 4.8 mg L−1 was obtained, a higher value than that presented by Šostar-Turk et al. (2005), of 2.7 mg L−1.

Temperature is a relevant parameter that must be monitored, since it interferes in the ionic interactions between adsorbents and surfactants (Ho et al., 2021). Its value depends on the climate at the time of collection and the process in which the wastewater is subjected to the treatment plants (Šostar-Turk et al., 2005). In the present work, the temperature of wastewater at the time of collection was 26.1 °C.

The values presented by physicochemical parameters evaluated indicate the necessity of an effective treatment to remove the contaminants and organic matter present in laundry wastewater before the discharge into water springs.

3.2 C/F/S Experiments: Choice of the Coagulant

The value of pH measured in all the assays remained around 7.5 ± 0.2. According to Lopes et al. (2019), tannin does not change the pH of the water as it does not consume alkalinity in the medium, which is an advantage presented by natural coagulants. In their work using the coagulant Tanfloc SG in the C/F process for the treatment of synthetic textile effluents, the pH varied at most by 0.3 pH units.

The color and turbidity removal curves of the laundry wastewater for the three coagulants evaluated in the assays are shown in Fig. 1a–f).

Color removal curves (a, b, c) and turbidity removal curves (d, e, f) for the different coagulant dosages in relation to the sedimentation time using the Tanfloc POP, SG, and SL coagulants, respectively (mean initial color = 560 mgPt-Co L−1; mean initial turbidity = 87 NTU), pH = 7.5, RMT = 2 min, RMV = 120 rpm, SMT = 15 min, SMV = 20 rpm, temperature = 26 °C. Legend:

The raw wastewater (Fig. 1a–f) used in the control tests, when submitted to the same operational conditions (pH, velocity, and time of mixing), presented a natural sedimentation of the suspended particles in the wastewater, reducing the color from an initial value of 560 to 419 mgPt-Co L−1 and turbidity from 87 to 40 NTU in the sedimentation time of 20 min. However, the effectiveness with the addition of natural coagulants can be observed, since the three coagulants were able to reduce the color and turbidity of the wastewater (Fig. 1a–f) in the different concentrations evaluated when compared with the control sample (without coagulant) in the C/F/S process.

The results indicated a sedimentation time between 5 and 10 min as sufficient to perform the C/F/S step of laundry wastewater treatment under the experimental conditions studied, so the sedimentation time of 10 min was determined to posterior assays.

The reduction in turbidity of laundry wastewater in relation to the sedimentation time of the flakes was studied by Kim et al. (2014) using different polymers as coagulant. These authors obtained removals higher than 95% of the suspended particles for a time of 10 min of sedimentation.

The assays using the three natural coagulants presented a greater reduction in the parameters of color and turbidity of the wastewater with an increase in the concentration of coagulant. At coagulant dosage of 160 mg L−1 and 10 min of sedimentation, a reduction in color from 438 to 49.5 mgPt-Co L−1 and turbidity from 53 to 3.9 NTU were obtained for Tanfloc POP. Under these same conditions, a color reduction from 423 to 32.5 mgPt-Co L−1 and from 50 to 3 NTU for turbidity was obtained for the Tanfloc SG coagulant. The Tanfloc SL coagulant showed the smallest removals for both parameters, reducing from 424 to 131.5 mgPt-Co L−1 for color and 40 to 16.5 NTU for turbidity.

In the study conducted by Hameed et al. (2016), the effect of variations in the concentration of Tanfloc coagulant (0 to 45 mg L−1), mixing velocity (60 to 100 rpm), and mixing time (2 to 30 min) for the treatment of municipal effluent by C/F maintaining the rapid mixing velocity at 200 rpm for 1 min, was evaluated. The highest efficiency (90%) in the removal of turbidity was obtained with the dosage of 35 mg L−1 of coagulant in the time of 10 min of agitation and 100 rpm of velocity.

In the research work of Dos Santos et al. (2018), different concentrations (160 to 800 mg L−1) of the coagulants Tanfloc SL and Tanfloc SG were evaluated in relation to the color and turbidity removal of the starch effluent in an interval of sedimentation of the flakes from 0 to 20 min. The greatest efficiencies were achieved at the concentration of 320 mg L−1 of the coagulant and the sedimentation time of 15 min.

Figure 2a–c shows the percentages of color and turbidity removal for the sedimentation time of 10 min using the coagulants Tanfloc POP, Tanfloc SG, and Tanfloc SL in the tested concentrations.

Among the three evaluated coagulants, Tanfloc POP and Tanfloc SG showed the highest percentage of color removal (88.7% and 92.3%, respectively) and turbidity (92.8% and 94.0%, respectively) at a concentration of 160 mg L−1. The Tanfloc SL coagulant showed the lowest removal efficiency for both the color (69.0%) and turbidity (58.6%) parameters at the same concentration evaluated, a fact that indicates less intensity of the interactions of this coagulant with suspended solids present in the laundry wastewater (Saritha et al., 2019).

In the study conducted by Huang et al. (2019) for the treatment of laundry wastewater using the same natural coagulant (Tanfloc POP®) in operating pH of 7.5 and sedimentation time of 10 min, the best removal of color (79.68%) and turbidity (83.64%) of wastewater were obtained to coagulant concentration of 140 mg L−1.

The presented value of increase in percentage refers to the average value of color and turbidity removal using the coagulants dosages of 100 and 160 mg L-1. These additions in removal are equivalent to an increase of 60 mg L−1 of coagulant used to treat 1 L of wastewater, which increases treatment costs. This fact justifies an analysis of the cost of acquiring the coagulant and variance (ANOVA) to assess the significance of the concentration of coagulant in the efficiency of color and turbidity removal.

3.3 Cost of Coagulants and Statistical Analysis of Removal Efficiency

In order to associate the efficiency of the C/F/S process in wastewater with the lower operating cost of the treatment unit, a price survey was carried out for each natural coagulant with the manufacturer (TANAC). Table 2 shows the values of the coagulants quoted in February 2021.

As shown in Table 2, the Tanfloc POP coagulant has the lowest acquisition cost (R$ 4.09) in relation to the others, as well as demonstrating the highest efficiency in color removal (88.7%) and turbidity (92.8%) of the laundry wastewater; therefore, it was selected as the best coagulant for the process under study.

To evaluate the significance of the coagulant concentration in the removing of color and turbidity for 10 min of sedimentation, an analysis of variance (ANOVA) was performed for a significance level of 5%. The ANOVA table and the Fisher LSD test for the Tanfloc POP are shown in Tables 3 and 4 respectively.

The analysis of variance (ANOVA) presented in Table 3 shows for a significance level of 5% that the type of treatment (concentration in mg L−1 of coagulant) was significant (p-value < 0.05); i.e., the variation in concentration influences the efficiency of color and turbidity removal in the C/F/S process of laundry wastewater.

The Fisher LSD test (Table 4) allowed for an analysis to compare the means of the percentage of color and turbidity removal obtained by the treatments and through the p-value to evaluate the difference among it.

The results of the statistical analysis (Table 4), considering a significance level of 5%, demonstrate that the means are statistically equal (p-value > 0.05) for the treatments of 120, 140, and 160 mg L−1; i.e., there is no significant difference for both color and turbidity removal, which implies the same efficiency in removing these parameters when using any of these concentrations.

The values of the means of color and turbidity removal obtained for Fisher’s test are shown in Table 5.

The statistical analysis demonstrated that the means of color and turbidity removal are equal for a significance level of 5% at concentrations of 100, 120, and 140 mg L−1, as well as the means obtained with the concentrations of 120, 140, and 160 mg L−1. Therefore, the concentration of 120 mg L−1 of Tanfloc POP coagulant achieves a satisfactory removal of the color and turbidity parameters of the wastewater.

3.4 Sludge Production in C/F/S Process

Sludge production in the C/F/S is an important factor to evaluate the efficiency of the process, and its volume should be reduced as much as possible (Beltrán-Heredia & Sánchez-Martín, 2009).

According to Justina et al. (2018), the sludge formed by processes that use natural coagulants based on tannins has the advantage of being biodegradable and does not pose risks to human health. In their work, the effects caused on the soil by the addition of sludge from the C/F process using Tanfloc SL in the treatment of dairy effluent were studied. The results showed that there was no release of pollutants in the soil, and the acidity of the soil was neutralized, proving the promising results in the use of natural coagulants.

The volume of sludge obtained for assays using the concentration of 120 mg L−1 of coagulant Tanfloc POP presented a value of 40 ± 2.8 mL L−1 h−1, against only 3.4 ± 0.5 mL L−1 h−1 in the control sample. This increase in volume of sludge generated by the treated wastewater with Tanfloc POP coagulant is due the amount of organic matter, total solids in suspension, and the compounds formed from the coagulant (Aguilar et al., 2002).

The results obtained for the C/F/S process using the natural coagulant Tanfloc POP (lower cost) for the treatment of laundry wastewater proved to be satisfactory and promising in relation to the reduction of color and turbidity parameters, in addition to forming a biodegradable volume of sludge (without metals) susceptible to further studies for future applications.

4 Conclusion

The three natural coagulants (Tanfloc POP, Tanfloc SL, and Tanfloc SG) demonstrated efficiency in reduction of the color and turbidity parameters of the laundry wastewater, in addition to not changing the pH of the treated wastewater. The results showed that the sedimentation time of 10 min was sufficient for the clarification of the sample. The removal of color and turbidity obtained for the coagulant Tanfloc POP (color: 88.7%; turbidity: 92.8%) and Tanfloc SG (color: 92.3%; turbidity: 94%) were greater compared to Tanfloc SL (color: 69%; turbidity: 58.6%). The coagulant selected among those tested was Tanfloc POP (0.75 $/kg) based on the efficiency of removal of parameters and the lowest cost. The analysis of variance ANOVA showed that the variation in the concentration of Tanfloc POP coagulant influences the removal of color and turbidity parameters at a significance level of 5%, and the Fischer LSD test indicated the concentration of 120 mg L−1 as the most suitable for carrying out the process. The Tanfloc POP coagulant showed a high performance in removing color and turbidity from industrial laundry wastewater, presenting itself as a promising coagulant in the primary treatment of wastewater in this service sector.

Data availability

The datasets supporting the conclusions of this article are included within the article.

References

Aguilar, M. I., Saéz, J., Lloréns, M., Soler, A., & Ortuño, J. F. (2002). Nutrient removal and sludge production in the coagulation – flocculation process. Water Research, 36, 2910–2919.

Al-Gheethi, A., Mohamed, R. M. S. R., Wurochekke, A. A., Nurulainee, N. R., Rahayu, J. M., & Hashim, M. K. A. (2017). Efficiency of Moringa oleifera seeds for treatment of laundry wastewater. MATEC Web of Conferences, 103, 1–8.

Ang, W. L., Mohammad, A. W., Hilal, N., & Leo, C. P. (2015). A review on the applicability of integrated/hybrid membrane processes in water treatment and desalination plants. Desalination, 363, 2–18. https://doi.org/10.1016/j.desal.2014.03.008

APHA. (1998). APHA: Standard methods for the examination of water and wastewater. American Public Health Association/American Water Works Association/Water Environment Federation,.

ASTM (American Society for Testing and Materials): 2015, ASTM D5176–08 standard test method for total chemically bound nitrogen in water by pyrolysis and chemiluminescence detection (Vol. 11.). Water and Environmental Technology.

Beltrán-Heredia, J., & Sánchez-Martín, J. (2009). Municipal wastewater treatment by modified tannin flocculant agent. Desalination, 249(1), 353–358. https://doi.org/10.1016/j.desal.2009.01.039

Braga, J. K. & Varesche, M. B. A. (2014). Commercial laundry water characterisation. American Journal of Analytical Chemistry, 5(1), 8–16. https://doi.org/10.4236/ajac.2014.51002

Choobar, B. G., Shahmirzadi, M. A. A., Kargari, A., & Manouchehri, M. (2019). Fouling mechanism identification and analysis in microfiltration of laundry wastewater. Journal of Environmental Chemical Engineering, 7(2), 103030. https://doi.org/10.1016/j.jece.2019.103030

Ciabatti, I., Cesaro, F., Faralli, L., Fatarella, E., & Tognotti, F. (2009). Demonstration of a treatment system for purification and reuse of laundry wastewater. Desalination, 246(1–3), 78–86. https://doi.org/10.1016/j.desal.2009.02.008

Collivignarelli, M. C., Abbà, A., Carnevale Miino, M., & Damiani, S. (2019). Treatments for color removal from wastewater: State of the art. Journal of Environmental Management, 236, 727–745. https://doi.org/10.1016/j.jenvman.2018.11.094

Dos Santos, J. D., Veit, M. T., Juchen, P. T., da Cunha Gonçalves, G., Palácio, S. M., & Fagundes-Klen, M. (2018). Use of different coagulants for cassava processing wastewater treatment. Journal of Environmental Chemical Engineering, 6(2), 1821–1827. https://doi.org/10.1016/j.jece.2018.02.039

Freitas, T. K. F. S., Oliveira, V. M., De Souza, M. T. F., Geraldino, H. C. L., Almeida, V. C., Fávaro, S. L., & Garcia, J. C. (2015). Optimization of coagulation-flocculation process for treatment of industrial textile wastewater using okra ( A. esculentus ) mucilage as natural coagulant. Industrial Crops & Products, 76, 538–544. https://doi.org/10.1016/j.indcrop.2015.06.027

Graham, N., Gang, F., Fowler, G., & Watts, M. (2008). Characterisation and coagulation performance of a tannin-based cationic polymer: A preliminary assessment. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 327(1–3), 9–16. https://doi.org/10.1016/j.colsurfa.2008.05.045

Hameed, Y. T., Idris, A., Hussain, S. A., & Abdullah, N. (2016). A tannin-based agent for coagulation and fl occulation of municipal wastewater : Chemical composition, performance assessment compared to Polyaluminum chloride, and application in a pilot plant. Journal of Environmental Management, 184, 494–503. https://doi.org/10.1016/j.jenvman.2016.10.033

Ho, K. C., Teow, Y. H., Sum, J. Y., Ng, Z. J., & Mohammad, A. W. (2021). Water pathways through the ages: Integrated laundry wastewater treatment for pollution prevention. Science of the Total Environment, 760, 143966. https://doi.org/10.1016/j.scitotenv.2020.143966

Huang, A. K., Veit, M. T., Juchen, P. T., Gilberto, C. G., Palácio, S. M., & Cardoso, C. D. O. (2019). Sequential process of coagulation / flocculation / sedimentation- adsorption - microfiltration for laundry effluent treatment. Journal of Environmental Chemical Engineering, 7(4), 103226. https://doi.org/10.1016/j.jece.2019.103226

Justina, M. D., Alves, M. V., & Skoronski, E. (2018). Applying different doses of tannin coagulated dairy sludge in soil: Influences on selected pollutants leaching and chemical agronomic attributes. Agricultural Water Management, 209(January), 11–19. https://doi.org/10.1016/j.agwat.2018.07.005

Kim, H. C., Shang, X., Huang, J. H., & Dempsey, B. A. (2014). Treating laundry waste water: Cationic polymers for removal of contaminants and decreased fouling in microfiltration. Journal of Membrane Science, 456, 167–174. https://doi.org/10.1016/j.memsci.2014.01.028

Kim, S. (2016). Application of response surface method as an experimental design to optimize coagulation – flocculation process for pre-treating paper wastewater. Journal of Industrial and Engineering Chemistry, 38, 93–102. https://doi.org/10.1016/j.jiec.2016.04.010

Lopes, E. C., Santos, S. C. R., Pintor, A. M. A., Boaventura, R. A. R., & Botelho, C. M. S. (2019). Evaluation of a tannin-based coagulant on the decolorization of synthetic effluents. Journal of Environmental Chemical Engineering, 7(3), 103125. https://doi.org/10.1016/j.jece.2019.103125

Manda, I. K. M., Chidya, R. C. G., Saka, J. D. K., & Biswick, T. T. (2016). Comparative assessment of water treatment using polymeric and inorganic coagulants. Physics and Chemistry of the Earth, 93, 119–129. https://doi.org/10.1016/j.pce.2015.09.008

Mangrich, A. S., Doumer, M. E., Mallmann, A. S., & Wolf, C. R. (2014). Química Verde no Tratamento de Águas : Uso de Coagulante Derivado de Tanino de Acacia mearnsii. Revista Virtual De Química, 6(1), 2–15. https://doi.org/10.5935/1984-6835.20140002

Mohamad, N. A., Hamzah, S., Che Harun, M. H., Ali, A., Rasit, N., Awang, M., et al. (2021). Integration of copperas and calcium hydroxide as a chemical coagulant and coagulant aid for efficient treatment of palm oil mill effluent. Chemosphere, 281, 130873. https://doi.org/10.1016/j.chemosphere.2021.130873

Momeni, M. M., Kahforoushan, D., Abbasi, F., & Ghanbarian, S. (2018). Using Chitosan/CHPATC as coagulant to remove color and turbidity of industrial wastewater: Optimization through RSM design. Journal of Environmental Management, 211, 347–355. https://doi.org/10.1016/j.jenvman.2018.01.031

Mozia, S., Janus, M., Brożek, P., Bering, S., Tarnowski, K., Mazur, J., & Morawski, A. W. (2016). A system coupling hybrid biological method with UV/O3oxidation and membrane separation for treatment and reuse of industrial laundry wastewater. Environmental Science and Pollution Research, 23(19), 19145–19155. https://doi.org/10.1007/s11356-016-7111-5

Muthuraman, G., & Sasikala, S. (2014). Removal of turbidity from drinking water using natural coagulants. Journal of Industrial and Engineering Chemistry, 20(4), 1727–1731. https://doi.org/10.1016/j.jiec.2013.08.023

Natarajan, S., Bajaj, H. C., & Tayade, R. J. (2018). Recent advances based on the synergetic effect of adsorption for removal of dyes from waste water using photocatalytic process. Journal of Environmental Sciences, 65, 201–222. https://doi.org/10.1016/j.jes.2017.03.011

Ortiz, A., García-Galán, M. J., García, J., & Díez-Montero, R. (2021). Optimization and operation of a demonstrative full scale microalgae harvesting unit based on coagulation, flocculation and sedimentation. Separation and Purification Technology, 259, 118171. https://doi.org/10.1016/j.seppur.2020.118171

Pichler, T., Young, K., & Alcantar, N. (2012). Eliminating turbidity in drinking water using the mucilage of a common cactus. Water Science and Technology: Water Supply, 12(2), 179–186. https://doi.org/10.2166/ws.2012.126

Saritha, V., Karnena, M. K., & Dwarapureddi, B. K. (2019). “Exploring natural coagulants as impending alternatives towards sustainable water clarification” – A comparative studies of natural coagulants with alum. Journal of Water Process Engineering, 32(August), 100982. https://doi.org/10.1016/j.jwpe.2019.100982

Shang, X., Kim, H. C., Huang, J. H., & Dempsey, B. A. (2015). Coagulation strategies to decrease fouling and increase critical flux and contaminant removal in microfiltration of laundry wastewater. Separation and Purification Technology, 147, 44–50. https://doi.org/10.1016/j.seppur.2015.04.005

Šostar-Turk, S., Petrinić, I., & Simonič, M. (2005). Laundry wastewater treatment using coagulation and membrane filtration. Resources, Conservation and Recycling, 44(2), 185–196. https://doi.org/10.1016/j.resconrec.2004.11.002

Turkay, O., Barışçı, S., & Sillanpää, M. (2017). E-peroxone process for the treatment of laundry wastewater : A case study. Journal of Environmental Chemical Engineering, 5(5), 4282–4290. https://doi.org/10.1016/j.jece.2017.08.012

Vaz, L. G. D. L., Klen, M. R. F., Veit, M. T., Da Silva, E. A., Barbiero, T. A., & Bergamasco, R. (2010). Avaliação da eficiência de diferentes agentes coagulantes na remoção de cor e turbidez em efluente de galvanoplastia. Eclética Química, 35(4), 45–54. https://doi.org/10.26850/1678-4618eqj.v35.4.2010.p45-54

Zahrim, A. Y., Hilal, N., & Tizaoui, C. (2013). Tubular nano fi ltration of highly concentrated C . I . Acid Black 210 dye. Water Science & Technology, 67(4), 901–906. https://doi.org/10.2166/wst.2012.638

Funding

The present work was financially supported by the Brazilian research funding agency CAPES (Federal Agency for the Support and Improvement of Higher Education).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Consent for Publication

All authors consent to the submission and publication in the journal.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Oliveira Cardoso Nascimento, C., Veit, M.T., Palácio, S.M. et al. Use of Natural Coagulants in the Removal of Color and Turbidity from Laundry Wastewater. Water Air Soil Pollut 232, 300 (2021). https://doi.org/10.1007/s11270-021-05253-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-021-05253-6