Abstract

The removal of total petroleum hydrocarbons (TPHs) from contaminated mining soil was carried out under in vitro conditions. The aerobic consumption of TPH in the slow bioremediation stage via biostimulation with native microorganisms and biostimulation-bioaugmentation with autochthonous fungal isolates was evaluated. The initial TPH concentration was 70,880 ± 975 mg TPH/kg soil, soil was amended with nutrients at a C:N:P ratio of 100:15:1, the water content was adjusted to the soil field capacity, and batch microcosm reactors were incubated at room temperature (20.5 ± 3.1°C) for 90 days. The bioaugmentation process was tested using four hydrocarbonoclastic fungal strains isolated from the same contaminated mining soil individually and a mixed culture of the four isolates. The molecular characterization of the isolated fungi was based on sequence analysis of 18S rRNA, and the fungi were identified as Aspergillus niger MT786339.1, Aspergillus fumigatus MT786338.1, Aspergillus terreus MT786341.1, and Aspergillus flavus MT786340.1. The best TPH removal was achieved by inoculation with the fungal consortium (57 ± 1.97%) at 45 days (slow stage) after initiating the biostimulation process, followed by inoculation with Aspergillus niger (49 ± 1.2%), Aspergillus terreus (44 ± 0.67%), Aspergillus fumigatus (35 ± 0.98%), and Aspergillus flavus (32 ± 0.38%), while the degradation rate achieved with native microorganisms was only 21.6 ± 1.5%; statistical analysis of the results showed significant differences.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The importance of the mining industry in Mexico is such that it is positioned as the world leader in silver production, the ninth largest producer of gold, and the seventh in copper production, according to 2018 statistics (ITA 2020). On the other hand, the mining industry negatively impacts the environment; it contributes to noise pollution, soil compaction and loss of fertility, habitat destruction, contamination of aquifers, and visual deterioration of the landscape. Among the contaminants discharged by mining activities that negatively impact soils are TPHs from accidental or intentional spills of crude oil, gasoline, oil, and lubricants.

TPH is a term used to describe a family of thousands of compounds that come from crude oil, among which aliphatic and aromatic compounds stand out. Specifically, the high hydrophobicity and low solubility of these compounds confer their recalcitrance to the soil matrix, which affects ecosystems (flora and wildlife). These compounds usually have C6 to C35 carbon chains like gasoline, diesel, and oil, and as there are many compounds present in crude oil, it is recommended that they be quantified as TPHs (ATSDR 2020). There are many examples that highlight the presence of TPHs in the environment; those caused by anthropogenic activities can be emphasized as the most prevalent, such as vehicle fleet and machinery maintenance, accidental spills and leakage from underground storage tanks (UST), and spills during the extraction and transport of hydrocarbons (Lee et al. 2007), causing soil and groundwater pollution. Hence, it is necessary to have adequate methods for handling this type of compound to avoid spillage into the environment as well as practical solutions for recovery and removal of these contaminants (Suppen et al. 2006). It is important to mention that contamination of the soil in the facilities of Mexican mining companies, and many other cases worldwide, has resulted from accidental TPH spills, mainly of diesel, gasoline, and residual oils. When spills occur, the soil must be confined for subsequent treatment; hence, it is essential to offer treatment alternatives to comply with the maximum permissible limits (MPL) set by the current Mexican legislation (DOF 2013).

Recovery of soils can be performed using bioremediation technologies, a well-known and commonly used biological process that is sustainable, environmentally friendly, inexpensive, and easy to apply, using indigenous organisms of the contaminated site or other sites (exogenous) organisms (Aniefiok and Udo 2019). Bioremediation is a biological technology that can be performed by different microorganisms (mostly fungi and bacteria) under aerobic (O2 as an electron acceptor, ea−) or anaerobic (without O2; different ea−is utilized) conditions where the substrate-carbon source (TPH) is oxidized, degraded, and/or mineralized to CO2, H2O, and biomass. The efficiency in the removal of pollutants is a function of different factors, such as the substrate availability, electron donor (ed−), carbon source, ea−, micro- and macronutrients, inoculum concentration, moisture, and environmental conditions (Kauppi et al. 2011; Kensa 2011).

Bioremediation can be carried out through three different processes: bioattenuation or natural degradation, biostimulation, and bioaugmentation. In natural attenuation, the degradation of pollutants (substrate, carbon source, and ed−) takes place in the presence of an electron acceptor (ea−) due to the activity of indigenous microorganisms. In biostimulation, micro- and macronutrients and ea− are required in the system to accelerate the biodegradation of the substrate (carbon source and ed−), and a greater removal efficiency is achieved than that with natural attenuation. For bioaugmentation, degradation of contaminants occurs at an even greater rate because of the inoculation of microorganisms into the system; these added microorganisms must be as efficient as the natives and capable of degrading the target contaminants (Abena et al. 2019; Essabri et al. 2019; Safdari et al. 2018; Mrozik and Piotrowska-Seget 2010; Aleer et al. 2010). This involves the removal and/or microbial transformation of hydrocarbons into safe or less toxic metabolic compounds to the ecosystem through aerobic or anaerobic metabolic pathways, which depend on the chemical composition of the pollutant and the microbial species present in the contaminated soil (Prenafeta-Boldú et al. 2018; Etuk et al. 2012; Abdulsalam et al. 2011; Alisi et al. 2009).

Some studies have evaluated the ability of axenic cultures (only one type of microorganism from a single cell) of soil fungi to remove TPHs with outstanding results and even higher efficiencies than mixed cultures. Some of the fungal isolates (pure or mixed) reported were as follows: a mixed culture of Aspergillus fumigatus, Aspergillus niger, Penicillium funiculosum, and Fusarium solani showed the lowest removal efficiency of 70%; a mixed culture of Aspergillus fumigatus and Aspergillus niger removed 90% of hydrocarbons; and Aspergillus niger (axenic) had the highest degradation rate of 95% (Al-Jawhari 2014). Bioremediation may use indigenous organisms typical of the contaminated site with the required nutrients (biostimulation) or exogenous and native isolated organisms (bioaugmentation) and can be performed in situ or ex situ (Kaczyńska et al. 2015; Moliterni et al. 2011; Xu and Lu 2010; Bento et al. 2005). Studies conducted by Essabri et al. (2019) reported TPH removal via bioaugmentation and biostimulation by three hydrocarbonoclastic fungal strains: Penicillium ochrochloron, Aspergillus niger, and Trichoderma viride. These eukaryotic microorganisms were isolated from olive oil effluent and used to degrade the hydrocarbons—as the sole carbon source—present in contaminated soil in in vitro experiments.

The selection of technologies for the recovery of contaminated soils depends on the pollutant composition, concentration, physicochemical characteristics, and the risk that the pollutant poses to ecosystem health (Kaczyńska et al. 2015; Semple et al. 2001; Brohon and Gourdon 2000). Usually, the degradation of hydrocarbons requires the incorporation of molecular oxygen into its molecules through the contribution of monooxygenase enzymes, while the degradation of aromatic pollutants by the addition of two oxygen molecules in the ring is catalyzed by dioxygenases (Madigan et al. 2015; Parales and Ju 2011; Arora et al. 2010).

The degradation of hydrocarbons requires the synergistic participation of microbial consortia (Wackett et al. 2001), from which two removal stages are distinguished, fast (FS) and slow (SS), assuming that in the first stage (FS), the hydrocarbons are easily degraded and mainly consumed, while in the second stage (SS), the degradation is slower. It is also considered that the degradation rate is linked not only to the growth of microorganisms present in the contaminated soil but also to the contaminant concentration, and in some cases, the biodegradation of TPH by indigenous bacterial populations in mining soil takes place in the presence of a surfactant (López-Miranda et al. 2018; De la Cueva et al. 2016; Walter et al. 1997). According to early considerations, the aim of this work was to demonstrate that autochthonous hydrocarbonoclastic fungal strains, Aspergillus niger MT786339.1, Aspergillus terreus MT786341.1, Aspergillus fumigatus MT786338.1, and Aspergillus flavus MT786340.1, isolated from the same contaminated mining soil and a mixed culture formed by the four strains, may favor aerobic TPH degradation via bioaugmentation when they are inoculated at the beginning of the slow bioremediation stage (SS).

2 Materials and Methods

2.1 Reactants

The following chemicals were purchased from the Jalmek Company (Monterrey, Mexico): (NH4)2SO4 (batch 16-0703-11A57) and K2HPO4 (batch 15-1510-06P51); H2SO4 (batch 733341) was procured from the Monterrey Chemical Products Fermont Company (Monterrey, Mexico); and FeSO4 7H2O (batch 46) was obtained from CIVEQ Company (Guadalajara, Mexico).

2.2 Soil

The contaminated mining soil used was provided by a mining facility located in San Dimas Tayoltita, Durango, Mexico, and its concentration was 70,880 ± 975 ppm TPH (mg TPH/kg soil). Actual contaminated soil was used to isolate hydrocarbonoclastic filamentous fungi and to conduct biodegradation experiments via biostimulation and biostimulation-bioaugmentation.

2.3 Experimental Procedure

2.3.1 Isolation and Identification of Autochthonous Hydrocarbonoclastic Eukaryotic Microorganisms

Fungal strains were isolated according to the sequential dilution method: A mixture of 1 g of soil sample and 99 mL of sterile physiological solution was magnetically stirred for 1 h (Cisneros-de la Cueva et al. 2016). Aliquots were taken and diluted serially on Petri dishes containing agar-agar (16 mg/mL), streptomycin sulfate (550 mg/L), rose bengal dye (200 mg/L), chloramphenicol (100 mg/L), and mineral salt solution containing (g/L) NaCl (12.3), MgSO4·7H2O (3.15), MgCl2·6H2O (2.53), (NH4)2SO4, (2.0), K2HPO4 (1.55), NaH2PO4·2H2O (0.85), CaCl2·2H2O (0.73), KCl (0.33), NaHCO3 (0.09), ZnSO4·7H2O (0.002), FeSO4·7H2O (0.005), MnCl2·2H2O (0.001), H3BO3 (0.001), KI (0.0005), KAl(SO4)2·12H2O (0.0005), NiCl2·6H2O (0.0005), CoCl2·6H2O (0.0004), Na2MoO4·2H2O (0.0002), and CuSO4·5H2O (0.0002) at a final pH of 5.5 ± 0.1. A sterile filter paper (Whatman No. 1) saturated with diesel, used as the carbon source and electron donor (ed−), was placed in the cover of the Petri dish according to the technique described by Thijsse and Van der Linden (1961). Petri dishes were incubated at 28°C for 2 weeks. Individual fungal colonies with different macroscopic morphological characteristics were purified, and colonies were transferred to potato dextrose agar (PDA) supplemented with 0.5 mg/L streptomycin (Etuk et al. 2012).

The isolated fungal species were grown in 5 mL of Sabouraud dextrose agar in a 50 mL flask at 37°C for 48 h (Fredricks et al. 2005). DNA extraction was performed in duplicate according to the bead-beating method (Yeates et al. 1998). The amplification of DNA was conducted by PCR using a set of primers that target highly conserved regions of the 18S rRNA ribosomal gene, NS1 (5-GTAGTCATATGCTTGTCTC-3) and GCfung (5-GCATTCCCCGTTACCCGTTG-3) (May et al. 2001; White et al. 1990). In each reaction mixture, a total volume of 25 μL was used, containing 1 μL of deoxynucleoside triphosphate (10 mM), 0.25 μL of Taq DNA polymerase (5 u/μL) (PROMEGA Bio, USA), 0.5 μL of each primer, 5 μL of Buffer 5X, 0.5 μL of template DNA (38.7 ng/μL), 1 μL of MgCl2 (25 mM), and 16.25 mL of nuclease-free water. Conditions for the PCR were as follows: initial DNA denaturation at 95°C for 1 min followed by 10 denaturation cycles at 95°C for 30 s, annealing at 65 to 60°C for 30 s, a reduction in temperature of 0.5°C per cycle, and extension at 72°C for 1 min. Additionally, 20 cycles at 95°C for 30 s, 60°C for 30 s, and 72°C for 1 min, with a final extension at 72°C for 7 min, were performed with a gradient PCR/Techne Thermal Cycler (Model TC-5000, USA). The extracted DNA and PCR products were analyzed by agarose gel electrophoresis and ethidium bromide staining. The PCR products were purified using the DNA Clean-up and Concentrator Kits (Zymo Research, USA); subsequently, these products were sequenced by Biotechnology Institute (UNAM, Cuernavaca-Morelos, Mexico).

2.3.2 TPH Analysis

The concentration of residual total petroleum hydrocarbons in contaminated soil [TPH]R was measured by the EPA 821-B-94-004 and EPA 3540C methods (US EPA 1995; US EPA 1996). Samples of 10 g of soil from sacrificed reactors were taken in duplicate at 0, 15, 30, 45, 60, 75, and 90 days for extraction and quantification of hydrocarbons with a detection limit of 30 mg/kg dry soil. The results were expressed as mg of TPH/kg of dry soil (ppm), while the viable microorganism count, expressed as colony forming units contained in a gram of soil (CFU/g soil), was quantified by the serial dilution method (Krüger et al. 2009) using potato dextrose agar (PDA) as the culture medium. One gram of soil was suspended in 9 mL of sterile distilled water, and then 1 mL of the first dilution was taken and transferred to a new dilution tube. The serial dilution was continued until the desired dilution was obtained (10−8); plates were inoculated by surface extension and incubated at 28°C for 7 days.

2.3.3 Inoculum Preparation and Fungal Growth

This stage was conducted using axenic cultures. Fungal microorganisms were inoculated by surface extension in inclined 50 mL tubes containing 25 mL of PDA as a culture medium and were incubated for 7 days at 28°C. Conidia were harvested with 15 mL of sterile water, and their concentration was determined in a Neubauer chamber; this concentration was used to calculate the volume needed to produce inoculum with a concentration of 106 conidia/g soil.

2.3.4 Soil Preparation for In Vitro Experiments

Mining-contaminated soil was sieved, and the soil that passed through a US standard sieve number 10 was collected, while the soil was retained in sieve number 12 to achieve a particle size of 2 mm. The concentration of C:N:P was adjusted to a 100:15:1 ratio using the Tchobanoglous & Vigil method for nutrient balance with a mineral solution (10.63 g (NH4)2SO4/kg soil and 0.70 g K2HPO4/kg soil); the soil moisture was adjusted to 70% of its field capacity (185 mL H2O/kg soil) (Eweis et al. 1998). For all treatments evaluated, experiments were carried out using sacrificed batch reactors in duplicate: P1 (14), P2 (56), and P3 (70) (Tchobanoglous and Vigil 1993).

2.3.5 TPH Consumption by Microorganisms via Biostimulation and Biostimulation-Bioaugmentation

A series of three treatments were established to evaluate the behavior of native microorganisms vs isolated fungal strains (each of the 4 isolated fungi and a mixed culture of the four) in terms of TPH consumption. Natural attenuation-biostimulation (P1) was used as a control, and only nutrients were added; biostimulation-bioaugmentation (P2) was performed using inoculation of single fungal strains at the beginning of the process where fast degradation takes place (Fs = 0 d); and biostimulation-bioaugmentation (P3) was performed by inoculation at the beginning of the slow bioremediation (Ss = 45 d) stage. According to the above, the experimental design, formulation, and ID of the four fungal strains used are summarized in Table 1.

P1: Biostimulation with Indigenous Microorganisms.

The biostimulation experiments were carried out in duplicate in 220-mL loose-lid flasks with the following conditions: 100 g of contaminated soil (TPH as carbon source-substrate-electron donor), 18.5 mL of mineral solution as source of micro- and macronutrients, and the field capacity of the soil was adjusted to 70%. The flasks were incubated at room temperature (20.5 ± 3.12°C) for 90 days. Changes in the concentration of TPH were recorded, reactors were sacrificed every 15 days (t = 0, 15, 30, 45, 60, 75, and 90 days) taking samples of 10 g of soil for analysis of the total residual hydrocarbon content and the viable count of microorganisms as colony forming units (CFU)/g soil.

P2: Biostimulation-Bioaugmentation with Inoculum Added at 0 days.

Bioaugmentation experiments in the fast degradation stage (Fs) were carried out in duplicate in 220-mL loose-lid flasks with the following conditions: 100 g of sterilized contaminated soil (UV rays for 1 h in an ESCO AVC-D2 laminar flow hood), 18.5 mL of mineral solution as source of micro- and macronutrients, and the field capacity of the soil was adjusted to 70%. Batch reactors were inoculated with each of the four isolated strains individually at a concentration of 1×106 conidia/g soil (Table 1); flasks were incubated at room temperature (20.5 ± 3.12°C) for 90 days. The change in the concentration of TPH was measured, and duplicate reactors were sacrificed every 15 days (t = 0, 15, 30, 45, 60, 75, and 90 days). Samples of 10 g of soil were taken for analysis of the residual TPH content, and the viable count of microorganisms was recorded as colony forming units (CFU)/g soil.

P3: Biostimulation-Bioaugmentation with Fungal Inoculum Added at 45 days.

Experiments in the slow degradation stage (Ss) were conducted to evaluate the influence of the isolated fungal microorganisms on the degradation of TPH as the sole carbon source-substrate-electron donor. Duplicate 220-mL loose-lid flasks were established containing 100 g of contaminated soil and 18.5 mL of mineral solution, and the field capacity of the soil was adjusted to 70%; flasks were incubated at room temperature (20.5 ± 3.12°C) for 45 days (biostimulation of native microorganisms); at this time, flasks were inoculated with 1×106 conidia/g soil for each single pure culture and with the consortium (mixed fungal culture, each of the four fungal strains was in equal proportion) (bioaugmentation). The change in the concentration of TPH was measured and duplicate reactors were sacrificed every 15 days (t = 45, 60, 75, and 90 days). Samples of 10 g of soil were taken for analysis of the residual TPH content and the viable count of microorganisms (CFU/g soil).

2.3.6 TPH Removal Efficiency by Hydrocarbonoclastic Microorganisms

To determine the removal efficiency of each process (R), TPH was consumed by the fungal strains as an electron donor-substrate-carbon source in an aerobic process where the electron acceptor O2 was not limited throughout the entire process. This efficiency was estimated as the difference in the TPH content at time zero (TPHo) and at 90 days (TPHt), as shown in Eq (1).

2.3.7 Evaluation of the Biodegradation Rate Constant and Half-Life Time

The first-order biodegradation rate constant (k) was determined by evaluating the slope of the best fit line on a plot of concentration vs time using Eq. (2).

where Co is the initial concentration of hydrocarbons (mg TPH/kg soil) and C is the concentration of hydrocarbons at time (t) (Abbassi and Shquirat 2008). On the other hand, the half-life time (t1/2) was estimated from the derivative of Eq. (3) (Suarez and Rifai 2010).

2.4 Statistical Analysis

The experimental results were analyzed by one-way analysis of variance (ANOVA) to validate the differences by comparisons of means between groups using Tukey HSD (honest significant difference) with Statistica 12 software. The experimental design was a single factor with 3 levels and two replicates, having as a response variable the change in TPH concentration at a significance level (α) value of 0.05.

3 Results and Discussion

3.1 Molecular Characterization of Isolated Autochthonous Hydrocarbonoclastic Fungi

Four hydrocarbonoclastic fungal strains were isolated from TPH-contaminated mining soil and selected on the basis of their fast reproduction. Molecular identification was based on sequence comparison of the 18S rRNA gene, and the sequences of the fungal strains were deposited in GenBank, with the following accession numbers: Aspergillus niger accession number MT786339.1, Aspergillus fumigatus accession number MT786338.1, Aspergillus terreus accession number MT786341.1, and Aspergillus flavus accession number MT786340.1.

3.2 Degradation of TPH by Native Consortium and Isolated Fungal Microorganisms

P1: Consumption of TPH by Biostimulation with Native Microorganisms.

Figure 1 depicts the kinetics of TPH biodegradation for all three processes evaluated in the present research based on normalized concentration values, and its trend was expected to decrease with time. In P1, rapid degradation took place (FS) from 0 to 45 days; after that, TPH consumption slowed down (SS) and remained almost constant until the end of the experiment. In this treatment (P1), a 21.58 ± 1.50% removal of TPH was achieved for the 90-day period. This result is even higher than that reported by Benyahia and Shams Embaby (2016), who achieved 23% consumption of TPH in a period of 156 days in a biostimulation process with indigenous microorganisms in a biopile system of desert soil, in which the average TPH initial concentration was similar to the concentration in the present study.

TPH degradation kinetics of native microorganisms vs isolated fungal strains for the different processes evaluated. (a) Biostimulation of native MOs (P1) and pure individual fungal MOs (P2). (b) Biostimulation of native MOs (P1) vs bioaugmentation with isolated fungal strains, individual and mixed culture, inoculated at 45 days (P3)

Based on the results observed in the P1 process, 45 days was chosen as the time point to conduct further tests with inoculation of the 4 isolated fungal strains (pure and mixed culture) under bioaugmentation conditions (P3, Fig. 1b). Several authors have pointed out that successful bioremediation of TPH-contaminated soils by biostimulation (addition of appropriate nutrients, N and/or P) results in better metabolic activity of native microorganisms and, therefore, accelerates the degradation of hydrocarbons (Ghaly et al. 2013; Suja et al. 2014; Smith et al. 2015).

P2: Bioaugmentation in Sterile Soil with Isolated Fungal Strains (Inoculation at 0 day).

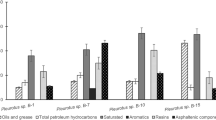

The kinetic profiles of TPH degradation carried out in sterile soil by the isolated hydrocarbonoclastic fungal microorganisms added at time zero are also shown in Fig. 1a. As shown, the degradation rates for the P2 process under the treatments were close for all fungal strains tested but higher than those for P1; values ranged from 1.14- to 1.33-fold those of P1. However, statistical analysis showed that there were significant differences (p<0.05) only for Aspergillus niger (p = 0.01695) and Aspergillus flavus (p = 0.04701) but not for the other two strains. These results clearly show that there was little influence of the inoculum when added to sterile soil at time zero, probably because enzyme activity was not triggered at the early stage of the process (Fig. 2).

P3: Biostimulation with Native MOs vs Bioaugmentation with Isolated Fungal Strains (Inoculation at 45 days).

Although an increase in the TPH removal rate was observed in the fast degradation stage, a bioaugmentation experiment was conducted at the slow degradation stage, wherein contaminated native soil was inoculated with the isolated fungal strains (single and mixed) at day 45. The untreated soil was only biostimulated with micro- and macronutrients present in the mineral solution. Bioremediation by the native microorganisms was allowed for 45 days; at this time, the soil was inoculated, in separate experiments, with the four strains of fungi individually and with a mixture of the four strains in equal proportions, and the experiment was continued for another 45 days (Fig. 1b).

As shown, bioaugmentation offered a much higher degradation rate than the biostimulation with native microorganisms (Fig. 3). TPH removal increased from 1.6- to 3.3-fold with the addition of each fungal strain individually and 4.2-fold with the consortium, with the mixed fungal culture offered the best degradation rate. Accordingly, statistical analysis showed that there were significant differences (p<<0.05) in all cases as follows: Aspergillus niger (p = 0.000225), Aspergillus flavus (p = 0.003413), Aspergillus terreus (p = 0.000225), Aspergillus fumigatus (p = 0.000431), and the mixed fungal culture (0.0000225). These results undoubtedly show that there was a significant influence of the inoculum when added at 45 days, supporting the fact that enzyme activity was properly exhibited at this stage of the process, showing that the native microflora favors the removal of contaminants, due to the fact that they release mono- and dioxygenase enzymes, responsible for the reduction of aliphatic and aromatic compounds (Alvarez and Illman 2006). The highest percentage of degradation was obtained with the consortium, achieving a TPH degradation efficiency of 57 ± 1.97%, and the rates ranged from 35 ± 0.98 to 49 ± 1.19% for the individual fungal strains when compared to that of P1 (Tables 2 and 3).

Table 2 summarizes the results for the aerobic degradation of TPH for all processes conducted, and degradation rates are presented from highest to lowest. It is clear that the bioaugmentation process (P3) offered the best removal, with higher degradation constants and significantly lower half-life times: fungal mixed culture (9.76×10−3 ± 7.07 ×10−6 1/d and 71.06 ± 0.05 days, respectively) offered the best degradation followed by A. niger MT786339.1, A. terreus MT786341.1, A. fumigatus MT786338.1, and A. flavus MT786340.1 as compared to P2 and P1; native microorganisms (P1) yielded the lowest degradation constant rate (2.35 × 10−3 ± 7.07 × 10−5 1/day) and longest half-life time (295.09 ± 8.88 days). Several studies report that the participation of microbial consortia has advantages over individual species in efficiently degrading hydrocarbon mixtures, because the microbial communities evolved together to survive in contaminated soil (Zafra et al. 2017).

Table 3 shows the comparison among all processes (P1, P2, and P3) and microorganisms (native, isolated fungi, and mixed fungal culture) for the aerobic degradation of TPH in mining-contaminated soil; experiments were conducted at the same initial TPH concentration and under the same conditions for a period of 90 days. Values can be read by row and column to compare 2 microorganisms under different processes. For instance, the last row shows that the mixed fungal culture (P3) produced a higher degradation rate of TPH in all cases when compared to any other microorganism treatment (columns), e.g., a 4.2-fold greater degradation than native microorganisms (MOs) (Sakineh et al. 2012).

Several authors have reported negative effects on the cell induced by high hydrocarbon concentrations, mechanical stress, and an increase in temperature caused by cellular accumulation of TPHs in the acyl chains of the phospholipid monolayers of the cell membrane, which is why the structure of the cell membrane is affected and changes such as increased permeability with increased proton flux are observed (Sikkema et al. 1995; White et al. 1981; McIntosh et al. 1980).

The results in this research can be compared to those reported by Benyahia and Shams Embaby (2016). The desert soil biopile system was bioaugmented with Amnite P-300 (containing 10 strains belonging predominantly to the Pseudomonas genus, including both aerobic and facultative organisms, and the total viable count was not less than 5.0 x 108 CFU/g) (Cbio 2020). The results showed a 77% TPH reduction over a period of 156 days, whereas the system with polyoxyethylene (20) sorbitan monooleate (Tween 80) gave a TPH removal rate of 56%, while in the present research, a 57.01 ± 1.97% removal was achieved in 90 days.

Different studies report the use of either bacteria or fungi to degrade several petroleum hydrocarbons in biostimulation or bioaugmentation processes. Abena et al. (2019) conducted studies with a consortium of five exogenous bacteria under natural attenuation with nutrients (biostimulation) and bioaugmentation with nutrients (biostimulation) to degrade TPH in highly contaminated soils. They found that the bioaugmentation treatment showed better degradation of TPH (48.10%) than the natural attenuation-biostimulation process. Suja et al. (2014) worked with crude oil-contaminated soil in a microcosm tank experiment (2 kg soil samples), and the combination of bioaugmentation (Acinetobacter sp. and Pseudomonas sp.) and biostimulation (mineral salt solution was added) gave the highest degradation rate, with 79% removal of TPH. Iheanacho et al. (2014) isolated indigenous fungal species from an oil exploration zone and tested their hydrocarbon degradation potentials. Yarrowia lipolytica ATCC 9773 (> 82%) and Zygorrhinchus sp. (2) (>83%) achieved removal via biodegradation within 14 days, demonstrating that these fungal species are potential degraders to be used in the treatment of oil-polluted farmlands (soil).

Crude oil is made from a mixture of different compounds, and individual microorganisms metabolize only a limited range of hydrocarbon substrates; therefore, biodegradation of petroleum hydrocarbons requires a mixture or consortia of different bacterial and fungal strains (Al-Saleh et al. 2009; Bordenave et al. 2007). Microorganisms have the necessary enzymes to achieve optimal results and degrade a wide range of hydrocarbons (Leahy and Colwell 1990). D’Annibale et al. (2006) carried out the bioremediation of contaminated soil with aromatic hydrocarbons and confirmed that the isolation of nine indigenous fungi (Allescheriella sp. strain DABAC 1, Stachybotrys sp. strain DABAC 3, and Phlebia sp. strain DABAC 9, among others) followed by their reinoculation at the same source could be a beneficial remediation strategy.

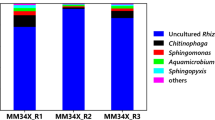

3.3 Fungal Growth and TPH Mass balance

According to the microbial kinetics of the native microorganisms (biostimulation), the four individual fungal strains isolated, and the mixed fungal culture, at 90 days, the mixed fungal culture had the greatest growth, followed by A. niger, A. terreus, A. fumigatus, A. flavus, and the native microorganisms; this corresponded to the degradation (%) of TPHs, since reproduction of microorganisms or their biosynthesis (anabolism) is directly related to the consumption of substrate-ed--carbon source (TPH). The initial average microbial count in all treatments corresponded to 1×103 CFU/g soil, and the addition of micro- and macronutrients biostimulated the growth of the native microorganisms during the first 45 days (fast stage, Fs). Afterwards, at the beginning of the slow degradation stage (day 45), 1×106 conidia/g soil of each of the four fungal strains and their mixture were inoculated in separate treatments. Growth was measured at all sampling points, and it was observed that the microbial counts peaked at day 45 of the bioremediation process and decreased to their lowest value at day 60; this behavior explains the presence of the slow bioremediation stage. However, in all treatments for the P3 process, ascendant growth behavior was observed during the final 30 days of experimentation, as seen in Fig. 4. We suggest that a longer experimental period should be examined to confirm whether better results can be achieved.

Viable microbial count per gram of soil for the P3 process where fungal strains were inoculated at 45 days after the biostimulation of native microorganisms was started. The initial average microbial count in all treatments corresponded to 1×103 CFU/g soil, and at day 45, 1×106 conidia/g soil was added

The mass balances for all three processes evaluated are summarized in Table 4 in terms of TPH removal (%), TPH mass degraded (mg), and residual TPH (HR) mass (mg). Inoculation in the slow rate stage (at 45 d) gave the best results; the highest degradation removal (57 ± 1.97%) was achieved in P3 with the mixed fungal culture, and the lowest corresponded to P1 with the native microorganisms (22 ± 1.50).

4 Overall Discussion and Conclusions

Hydrocarbonoclastic fungal strains were isolated from TPH-contaminated mining soil, four of which were selected on the basis of their fast growth and identified based on sequence comparison of their 18S rRNA. Native microorganisms were tested for the removal of TPH (ed-) under aerobic conditions (ea-: O2) via biostimulation and compared to biostimulation-bioaugmentation systems by inoculation with the 4 isolated fungal strains (in pure and mixed culture). The inoculation of fungal strains at the beginning of the slow bioremediation stage (SS) significantly improved the removal efficiency of TPHs from the soil. This phenomenon is attributed to the increased concentration of microorganisms and the presence of enzymes, just at the time where the indigenous microbial activity was decreasing considerably. Extended exposure of viable microorganisms to a strongly nonpolar environment modifies the permeability of their cell membranes and decreases the concentration of viable microorganisms. As a result, inoculation with fresh fungal cells accelerates the breakdown of the remaining complex hydrocarbons. Regarding the four isolated fungal strains tested in this study and inoculated individually, Aspergillus niger MT786339.1 exhibited the greatest degradation of TPH (49 ± 1.2%), followed by Aspergillus terreus MT786341.1 (44 ± 0.67%), Aspergillus fumigatus MT786338.1 (35 ± 0.98%), and Aspergillus flavus MT786340.1 (32 ± 0.38%); however, the best results were achieved when the mixed fungal consortium (all four fungal strains in equal proportion) was used for inoculation (57 ± 1.97%). George-Okafor et al. (2009) conducted isolation studies and found that 8 strains showed potential to biodegrade hydrocarbons: Aspergillus versicolor, Aspergillus niger, Aspergillus flavus, Syncephalastrum spp., Trichoderma spp., Neurospora sitophila, Rhizopus arrhizus, and Mucor spp. Of these eight strains, A. niger and A. versicolor presented the highest biodegradation efficiency, which agrees with the results obtained in the present work. Adekunle and Adeniyi (2015) studied the biodegradation of petroleum diesel by bioaugmentation with fungi, where Aspergillus niger showed a 20.93% removal rate. In the present work, isolated A. niger achieved a TPH degradation rate of 49 ± 1.2%, a 2.34-fold increase for the same strain. It is worth mentioning that in a similar study on the removal of diesel by Aspergillus terreus, reported by Cisneros-de la Cueva et al. (2016), for an initial diesel concentration of 50,000 mg diesel/kg soil with inoculation at time zero (fast degradation rate), the reaction rate constant was 0.002 ± 7.07E-05 1/day, and the half-life time was 308.2 ± 9.69 days, close to the values found in the present study. However, when inoculation was performed at 45 days, the rate constant showed a 2.66-fold degradation rate, even when the initial concentration of TPH was 1.42 times higher (70,880 ± 975 mg TPH/kg), confirming the influence that bioaugmentation has when inoculation is performed in the slow degradation stage. Other authors have shown that the addition of exogenous microorganisms promotes significant changes in the composition of the soil microbial community (Festa et al. 2016), so better efficiency is accomplished in the bioremediation process (Agnello et al. 2016; Kadali et al. 2012; Li et al. 2012; Tang et al. 2010). On the other hand, it has been demonstrated that the microbial count and type of microorganisms present in the system influence the concentration and type of hydrocarbons removed, and a strong association exists between TPH chemical composition and microorganisms associated with degradation (López-Miranda et al. 2018; De la Cueva et al. 2016). Fungi, for the most part, can break down some of the largest molecules present in nature (Fernández-Luqueño et al. 2011); therefore, fungi have been shown to degrade hydrocarbons better than bacteria. The overall results in the present study support that isolated fungal strains were able to degrade TPHs at a faster rate, with a better performance, when fresh cells were reinoculated as a consortium at the slow remediation stage; further experiments are suggested to determine the maximum degradation rate in biostimulation-bioaugmentation experiments at a larger scale.

References

Abbassi, B. E., & Shquirat, W. D. (2008). Kinetics of indigenous isolated bacteria used for ex-situ bioremediation of petroleum contaminated soil. Water, Air, and Soil Pollution, 192, 221–226.

Abdulsalam, S., Bugaje, I. M., Adefila, S. S., & Ibrahim, S. (2011). Comparison of biostimulation and bioaugmentation for remediation of soil contaminated with spent motor oil. International Journal of Environmental Science and Technology, 8, 187–194. https://doi.org/10.1007/BF03326208.

Abena, M. T. B., Li, T., Shah, M. N., & Zhong, W. (2019). Biodegradation of total petroleum hydrocarbons (TPH) in highly contaminated soils by natural attenuation and bioaugmentation. Chemosphere., 234, 864–874. https://doi.org/10.1016/j.chemosphere.2019.06.111.

Adekunle, A. A., & Adeniyi, A. O. (2015). Biodegradation of petroleum oil by fungi isolated from Treculia africana (Dec'ne) seeds in Nigeria. African Journal of Environmental Science and Technology, 9(2), 126–135.

Agnello, A. C., Bagard, M., van Hullebusch, E. D., Esposito, G., & Huguenot, D. (2016). Comparative bioremediation of heavy metals and petroleum hydrocarbons co-contaminated soil by natural attenuation, phytoremediation, bioaugmentation and bioaugmentation-assisted phytoremediation. Science of the Total Environment, 563-564, 693–703. https://doi.org/10.1016/j.scitotenv.2015.10.061.

Aleer, S., Adetutu, E. M., Makadia, T. H., Patil, S., & Ball, A. S. (2010). Harnessing the hydrocarbon-degrading potential of contaminated soils for the bioremediation of waste engine oil. Water, Air, & Soil Pollution, 218(1-4), 121–130. https://doi.org/10.1007/s11270-010-0628-1.

Alisi, C., Musella, R., Tasso, F., Ubaldi, C., Manzo, S., Cremisini, C., & Sprocati, A. R. (2009). Bioremediation of diesel oil in a cocontaminated soil by bioaugmentation with a microbial formula tailored with native strains selected for heavy metals resistance. Science of the Total Environment, 407, 3024–3032. https://doi.org/10.1016/j.scitotenv.2009.01.011.

Al-Jawhari, I. F. H. (2014). Ability of some soil fungi in biodegradation of petroleum hydrocarbon. Journal of Applied & Environmental Microbiology, 2(2), 46–52 Available online at http://pubs.sciepub.com/jaem/2/2/3 DOI:10.12691/jaem-2-2-3.

Al-Saleh, E., Drobiova, H., & Obuekwe, C. (2009). Predominant culturable crude oil-degrading bacteria in the coast of Kuwait. International Biodeterioration and Biodegradation, 63(4), 400–406. https://doi.org/10.1016/j.ibiod.2008.11.004.

Alvarez, P. J. J., & Illman, W. A. (2006). Bioremediation and natural attenuation: Process. fundamentals and mathematical model. New York: Wiley. https://doi.org/10.1002/047173862X.

Aniefiok, E. I., & Udo, J. I. (2019). Role of plants and microbes in bioremediation of petroleum hydrocarbons contaminated soils, International Journal of Environmental Bioremediation & Biodegradation., 7(1), 1–19. https://doi.org/10.12691/ijebb-7-1-1.

Arora, P. K., Srivastava, A., & Singh, V. P. (2010). Application of monooxygenases in dehalogenation, desulphurization, denitrification, and hydroxylation of aromatic compounds. Journal of Bioremediation & Biodegradation, 1, 112. https://doi.org/10.4172/2155-6199.1000112.

ATSDR (2020). Agency for toxic substances and disease registry. Toxicological Profile for Total Petroleum Hydrocarbons TPH. Available in: https://www.atsdr.cdc.gov/substances/toxsubstance.asp?toxid=75. Accessed: December 10th, 2020.

Bento, F. M., Camargo, F. A. O., Okeke, B. C., & Frankenberger, W. T. (2005). Comparative bioremediation of soils contaminated with diesel oil by natural attenuation, biostimulation and bioaugmentation. Bioresource Technology, 96(9), 1049–1055. https://doi.org/10.1016/j.biortech.2004.09.008.

Benyahia, F. & Shams Embaby, A. (2016). Bioremediation of crude oil contaminated desert soil: Effect of biostimulation, bioaugmentation and bioavailability in biopile treatment systems. Int. J. Environ.

Bordenave, M., Goñi-Urriza, S., Caumette, P., & Duran, R. (2007). Effects of heavy fuel oil on the bacterial community structure of a pristine microbial mat. Applied and Environmental Microbiology, 73(19), 6089–6097.

Brohon, B., & Gourdon, R. (2000). Influence of soil microbial activity level on the determination of contaminated soil toxicity using Lumistox and MetPlate bioassays. Soil Biology and Biochemistry, 32(1), 853–857. https://doi.org/10.1016/S0038-0717(99)00216-3.

Cbio (2020). Cleveland Biotech Ltd. Amnite - Model P300 - Aliphatic and aromatic chemicals degrading product. Available in: https://www.environmental-expert.com/products/amnite-model-p300-aliphatic-and-aromatic-chemicals-degrading-product-141878. Accessed: December 9th, 2020.

Cisneros-de la Cueva, S., Martínez-Prado, M. A., López-Miranda, J., Rojas-Contreras, J. A., & Medrano-Roldán, H. (2016). Aerobic degradation of diesel by Aspergillus terreus KP862582. Revista Mexicana de Ingeniería Química, 15, 347–360 http://www.redalyc.org/pdf/620/62046829005.pdf.

D’Annibale, A., Rosetto, F., Leonardi, V., Federici, F., & Petruccioli, M. (2006). Role of autochthonous filamentous fungi in bioremediation of a soil historically contaminated with aromatic hydrocarbons. Applied and Environmental Microbiology, 72(1), 28–36. https://doi.org/10.1128/AEM.72.1.28-36.2006.

De la Cueva, S. C., Rodríguez, C. H., Cruz, N. O. S., Contreras, J. A. R., & Miranda, J. L. (2016). Changes in bacterial populations during bioremediation of soil contaminated with petroleum hydrocarbons. Water, Air, & Soil Pollution, 227, 91. https://doi.org/10.1007/s11270-016-2789-z.

DOF (2013). Diario Oficial de la Federación. NOM-138-SEMARNAT/SS-2003. Norma Oficial Mexicana. Límites máximos permisibles de hidrocarburos en suelos y las especificaciones para su caracterización y remediación. Diario Oficial de la Federación. Marzo 29-2005. Available in: https://www.dof.gob.mx/nota_detalle.php?codigo=5313544&fecha=10/09/2013. Accessed: January 15th, 2021.

Essabri, A. M. A., Aydinlik, N. P., & Williams, N. E. (2019). Bioaugmentation and biostimulation of total petroleum hydrocarbon degradation in a petroleum-contaminated soil with fungi isolated from olive oil effluent. Water, Air, and Soil Pollution, 230, 76. https://doi.org/10.1007/s11270-019-4127-8.

Etuk, C. U., John, R. C., Ekong, U. E., & Akpan, M. M. (2012). Growth study and hydrocarbonoclastic potential of microorganisms isolated from aviation fuel spill site in Ibeno, Nigeria. United States Department of Agriculture. Bulletin of Environmental Contamination and Toxicology, 89, 727–732. https://doi.org/10.1007/s00128-012-0796-3.

Eweis, J. B., Ergas, S. J., Chang, D. P., & Schroeder, E. D. (1998). Bioremediation Principles. McGraw-Hill Book Company Europe. 296pp.

Fernández-Luqueño, F., Valenzuela-Encinas, C., Marsch, R., Martínez-Suárez, C., Vázquez-Núñez, E., & Dendooven, L. (2011). Microbial communities to mitigate contamination of PAHs in soil -possibilities and challenges: A review. Environmental Science and Pollution Research, 18, 12–30. https://doi.org/10.1007/s11356-010-0371-6.

Festa, S., Coppotelli, B. M., & Morelli, I. S. (2016). Comparative bioaugmentation with a consortium and a single strain in a phenanthrene-contaminated soil: Impact on the bacterial community and biodegradation. Applied Soil Ecology, 98, 8–19. https://doi.org/10.1016/j.apsoil.2015.08.025.

Fredricks, D. N., Smith, C., & Meier, A. (2005). Comparison of six DNA extraction methods for recovery of fungal DNA as assessed by quantitative PCR. Journal of Clinical Microbiology, 43, 5122–5128. https://doi.org/10.1128/JCM.43.10.5122-5128.2005.

George-Okafor, U., Tasie, F., & Muotoe-Okafor, F. (2009). Hydrocarbon degradation potentials of indigenous fungal isolates from petroleum contaminated soils. Journal of Physical and Natural Sciences, 3(1), 1–6.

Ghaly, A. E., Yusran, A., & Dave, D. (2013). Effects of biostimulation and bioaugmentation on the degradation of pyrene in soil. Journal of Bioremediation & Biodegradation, S7(005), 1–13. https://doi.org/10.4172/2155-6199.S7-005.

Iheanacho, C. C., Okerentugba, P. O., Orji, F. A., & Ataikiru, T. L. (2014). Hydrocarbon degradation potentials of indigenous fungal isolates from a petroleum hydrocarbon contaminated soil in Sakpenwa community, Niger Delta. Global Advanced Research Journal of Environmental Science and Toxicology (ISSN: 2315-5140), 3(1), 006–011.

ITA (2020). International Trade Administration. Helping US Companies Export. Mexico - M. Mining and Minerals. Available in https://www.export.gov/article?id=Mexico-Mining-and-Minerals. Accessed: December 8th, 2020.

Kaczyńska, G., Borowik, A., & Wyszkowska, J. (2015). Soil Dehydrogenases as an Indicator of Contamination of the Environment with Petroleum Products. Water, Air, and Soil Pollution, 226, 372. https://doi.org/10.1007/s11270-015-2642-9.

Kadali, K. K., Simons, K. L., Sheppard, P. J., & Ball, A. S. (2012). Mineralisation of weathered crude oil by a hydrocarbonoclastic consortia in marine mesocosms. Water, Air, & Soil Pollution, 223(7), 4283–4295. https://doi.org/10.1007/s11270-012-1191-8.

Kauppi, S., Sinkkonen, A., & Romantschuk, M. (2011). Enhancing bioremediation of diesel-fuel-contaminated soil in a boreal climate: Comparison of biostimulation and bioaugmentation. International Biodeterioration & Biodegradation, 65(2). https://doi.org/10.1016/j.ibiod.2010.10.011.

Kensa, V. M. (2011). Bioremediation - An overview. Journal of Industrial Pollution Control. ISSN (0970-2083). Available in: https://www.icontrolpollution.com/articles/bioremediation%2D%2Dan-overview-.php?aid=37408 Accessed: October 25th, 2020.

Krüger, D., Sharma, M., & Varma, A. (2009). Assessing the mycorrhizal diversity of soils and identification of fungus fruiting bodies and axenic cultures. Soil Biology. Symbiotic Fungi: Principles and Practice, 18, 159–188 Springer ISBN: 978-3-540-95893-2.

Leahy, J. G., & Colwell, R. R. (1990). Microbial degradation of hydrocarbons in the environment. Microbiological Reviews, 54(3), 305–315.

Lee, S. H., Lee, S., Kim, D. Y., & Kim, J. G. (2007). Degradation characteristics of waste lubricants under different nutrient conditions. Journal of Hazardous Materials, 143, 65–72. https://doi.org/10.1016/j.jhazmat.2006.08.059.

Li, X., Wu, Y., Lin, X., Zhang, J., & Zeng, J. (2012). Dissipation of polycyclic aromatic hydrocarbons (PAHs) in soil microcosms amended with mushroom cultivation substrate. Soil Biology and Biochemistry, 47, 191–197. https://doi.org/10.1016/j.soilbio.2012.01.001.

López-Miranda, J., Cisneros-de la Cueva, S., Páez-Lerma, J. S., Rojas-Contreras, J. A., & Soto-Cruz, N. O. (2018). Changes in hydrocarbon composition and autochthonous microorganism growth of contaminated mining soil during bioremediation. Water, Air, & Soil Pollution, 229, 165. https://doi.org/10.1007/s11270-018-3798-x.

Madigan, M. T., Martinko, J. M., Bender, K. S., Buckley, D.H., & Stahl, D. A. (2015). Brock Biology of Microorganisms. Pearson Education, Inc. Fourteenth edition.

May, L. A., Smiley, B., & Schmidt, M. G. (2001). Comparative denaturing gradient gel electrophoresis of fungal communities associated with whole plant corn silage. Canadian Journal of Microbiology, 47, 829–841 In: Molecular Identification of Fungi, (Youssuf Gherb & Kerstin Voigt, eds.). Springer.

McIntosh, T. J., Simon, S. A., & MacDonald, R. C. (1980). The organization of n-alkanes in lipid bilayers. Biochimica et Biophysica Acta, Biomembranes, 597, 445–463. https://doi.org/10.1016/0005-2736(80)90219-9.

Moliterni, E., Rodriguez, L., Fernández, F. J., & Villaseñor, J. (2011). Feasibility of different bioremediation strategies for treatment of clayey and silty soils recently polluted with diesel hydrocarbons. Water, Air, & Soil Pollution, 223(5), 2473–2482. https://doi.org/10.1007/s11270-011-1040-1.

Mrozik, A., & Piotrowska-Seget, Z. (2010). Bioaugmentation as a strategy for cleaning up of soils contaminated with aromatic compounds. Microbiological Research, 165(5), 363–375. https://doi.org/10.1016/j.micres.2009.08.001.

Parales, R. E. & Ju, K. S. (2011). Rieske-type dioxygenases: Key enzymes in the degradation of aromatic hydrocarbons. In: Comprehensive biotechnology, vol 6: Environmental Biotechnology and Safety, 2nd Edition, 115–134.

Prenafeta-Boldú, F. X., de Hoog, G. S., & Summerbell, R. C. (2018). Fungal Communities in Hydrocarbon Degradation. In T. McGenity (Ed.), Microbial communities utilizing hydrocarbons and lipids: Members, metagenomics and ecophysiology. Handbook of Hydrocarbon and Lipid Microbiology. Cham: Springer. https://doi.org/10.1007/978-3-319-60063-5_8-2.

Safdari, M. S., Kariminia, H. R., Rahmati, M., Fazlollahi, F., Polasko, A., Mahendra, S., Wildinga, W. V., & Fletcher, T. H. (2018). Development of bioreactors for comparative study of natural attenuation, biostimulation, and bioaugmentation of petroleum-hydrocarbon contaminated soil. Journal of Hazardous Materials, 342, 270–278. https://doi.org/10.1016/j.jhazmat.2017.08.044.

Sakineh, L., Gunale, V. R., & Rajurkar, N. S. (2012). Assessment of petroleum hydrocarbon degradation from soil and tarball by fungi. Bioscience Discovery, 3(2), 186–192.

Semple, K. T., Reid, B. J., & Fermor, T. R. (2001). Impact of composting strategies on the treatment of soils contaminated with organic pollutants. Environmental Pollution, 112, 269–283.

Sikkema, J., De Bont, J. A. M., & Poolman, B. (1995). Mechanisms of membrane toxicity of hydrocarbons. Microbial Reviews, 59, 201–222.

Smith, E., Thavamani, P., Ramadass, K., Naidu, R., Srivastava, P., & Megharaj, M. (2015). Remediation trials for hydrocarbon-contaminated soils in arid environments: Evaluation of bioslurry and biopiling techniques. International Biodeterioration and Biodegradation, 101, 56–65. https://doi.org/10.1016/j.ibiod.2015.03.029.

Suarez, M. P., & Rifai, H. S. (2010). Biodegradation rates for fuel hydrocarbons and chlorinated solvents in groundwater. Bioremediation Journal, 8, 37–41.

Suja, F., Rahim, F., Taha, M. R., Hambali, N., Razali, M. R., Khalid, A., & Hamzah, A. (2014). Effects of local microbial bioaugmentation and biostimulation on the bioremediation of total petroleum hydrocarbons (TPH) in crude oil contaminated soil based on laboratory and field observations. International Biodeterioration and Biodegradation, 90, 115–122. https://doi.org/10.1016/j.ibiod.2014.03.006.

Suppen, N., Carranza, M., Huerta, M., & Hernández, M. A. (2006). Environmental management and life cycle approaches in the Mexican mining industry. Journal of Cleaner Production, 14(12–13), 1101–1115. https://doi.org/10.1016/j.jclepro.2004.12.020.

Tang, J., Wang, R., Niu, X., & Zhou, Q. (2010). Enhancement of soil petroleum remediation by using a combination of ryegrass (Lolium perenne) and different microorganisms. Soil and Tillage Research, 110(1), 87–93. https://doi.org/10.1016/j.still.2010.06.010.

Tchobanoglous, G. T. H. & Vigil, S. (1993). Integrated solid waste management. Engineering principles and Management Issues. Mc. Graw-Hill. Singapore. 684-704, 992 pp.

Thijsse, G. J. E., & Van Der Linden, A. C. (1961). Iso-alkane oxidation by a Pseudomonas Part I. – Metabolism of 2-Methylhexane. Antonie Van Leeuwenhoek, 27, 171–179. https://doi.org/10.1007/BF02538437.

US EPA (1995). United States Environmental Protection Agency. EPA 821-B-94- 004. Method 1664: n-hexane extractable material and silica gel. Treated n-hexane extractable material (SGT-HEM) by extraction and gravimetry (oil and grease and total petroleum hydrocarbons).

US EPA (1996). United States Environmental Protection Agency. Method 3540C. Soxhlet extraction, part of test methods for evaluating solid waste, physical/chemical methods. Available in: https://www.epa.gov/sites/production/files/2015-12/documents/3540c.pdf. Accessed: December 6th, 2020.

Wackett, L., Lawrence, P., Hershberger, C., & Douglas, C. (2001). Biocatalysis and biodegradation. microbial transformation of organic compounds. ASM Pres. USA. 5:178-187.

Walter, M. V., Nelson, E. C., Firmstone, G., Martin, D. G., Clayton, M. J., Simpson, S., & Spaulding, S. (1997). Surfactant enhances biodegradation of hydrocarbons: Microcosm and field study. Journal of Soil Contamination, 6(1), 61–77.

White, S. H., King, G. I., & Cain, J. E. (1981). Location of hexane in lipid bilayers determined by neutron diffraction. Nature, 290, 161–163.

White, T. J., Bruns, T., Lee, S., & Taylor, J. (1990). Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In M. A. Innis, D. H. Gelfand, J. J. Sninsky, & T. J. White (Eds.), PCR Protocols: A Guide to Methods and Applications (pp. 315–322). New York: Academic Press.

Xu, Y., & Lu, M. (2010). Bioremediation of crude oil-contaminated soil: Comparison of different biostimulation and bioaugmentation treatments. Journal of Hazardous Materials, 183(1-3), 395–401. https://doi.org/10.1016/j.jhazmat.2010.07.038.

Yeates, C., Gillings, M. R., Davison, A. D., Altavilla, N., & Veal, D. A. (1998). Methods for microbial DNA extraction from soil for PCR amplification. National Center for Biotechnology Information. Biological Procedures Online, 1, 40–47.

Zafra, G., Absalón, A. E., Anducho-Reyes, M. A., Fernandez, F. J., & Cortés-Espinosa, D. V. (2017). Construction of PAH-degrading mixed microbial consortia by induced selection in soil. Chemosphere, 172, 120–126. https://doi.org/10.1016/j.chemosphere.2016.12.038.

Funding

Financial support was provided by Durango State Science and Technological Council (COCYTED), project number FOMIX-144259, and experiments were carried out at the facilities of Tecnológico Nacional de México-Instituto Tecnológico de Durango. We are grateful to the National Council of Science and Technology of Mexico (CONACyT) for the scholarship awarded (312904). The listed authors are highly obliged to their respective departments, institutes, and universities for providing literature services.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hernández-Adame, N.M., López-Miranda, J., Martínez-Prado, M.A. et al. Increase in Total Petroleum Hydrocarbons Removal Rate in Contaminated Mining Soil Through Bioaugmentation with Autochthonous Fungi During the Slow Bioremediation Stage. Water Air Soil Pollut 232, 95 (2021). https://doi.org/10.1007/s11270-021-05051-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-021-05051-0