Abstract

Anaerobic digestion is a possibility for post-hydrothermal liquefaction wastewater (PHWW) treatment because this wastewater is rich in nutrients and organic compounds. However, the PHWW presents many toxic compounds. A strategy for the anaerobic treatment of toxic compounds is using biomass adhered to inert supports forming biofilms, which can offer more resistance to the microorganism and protection from such compounds. The continuous treatment of PHWW is the essential key to obtaining a sustainable hydrothermal liquefaction process. In this work, the use of immobilized biomass was evaluated for the anaerobic degradation of PHWW from Spirulina in batch assays and continuous treatment. Higher methane production potential and volatile fatty acid mass balance showed the advantages of using biomass immobilized in polyurethane foam. Continuous treatment in a horizontal-flow anaerobic immobilized biomass (HAIB) reactor reached chemical organic demand (COD) removal efficiencies of 67% and 58% for volumetric organic load rates of 0.8 and 1.6 g COD.L−1.d−1, respectively. After 200 days of continuous treatment, Anaerobaculum and Coprothermobacter, fermentative proteolytic genera of bacteria with potential for hydrogen production, were favored.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bio-crude oil can be produced by converting organic materials through a hydrothermal liquefaction (HTL) process. Through HTL, the wet feedstock is subjected to high temperatures and pressures to be converted into bio-crude oil, which can be used as biofuel after the refining process. The conversion simulates the natural geological processes that produce our current fossil fuel reserves (Toor et al. 2011; Roberts et al. 2013; Chen et al. 2014). The possibility of using wet raw materials as feedstock is one of the main advantages of this process compared to other thermochemical processes such as gasification and pyrolysis (Behrendt et al. 2008; Chen et al. 2015; Jena and Das 2011). In the hydrothermal liquefaction, the drying step known to be energy-consuming is not needed (Costa and de Moraes 2011). In addition, the lipid content of the feedstock is not a restriction for bio-crude oil production by HTL, making fast-growing low-lipid content algae and cyanobacteria suitable feedstock for producing bio-crude oil via HTL processes (Tian et al. 2014).

One critical challenge of the HTL process is its problematic liquid by product (referred to here as post-hydrothermal liquefaction wastewater, PHWW) which is formed in large amounts, with high concentrations of organic matter and toxic compounds. Due to such characteristics, the treatment and reuse of this effluent are essential to obtain an economically viable HTL process. According to Elliott et al. (2015), the treatment of PHWW is the key to obtaining sustainable production of renewable fuel through HTL.

Anaerobic biodegradation has been evaluated for treating PHWW from different feedstocks: mixtures of algae (Tommaso et al. 2015), swine manure (Zhou et al. 2015), Spirulina (Bueno et al. 2020; Quispe-Arpasi et al. 2018; Zheng et al. 2017), food waste (Posmanik et al. 2017), and cornstalk (Si et al. 2018). Those studies verified the possibility of methane production; however, they also observed high toxic potential to the anaerobic consortium. Phenols, N-heterocyclic compounds, and furans were considered the main potential inhibitors in the PHWW from Spirulina (Quispe-Arpasi et al. 2018; Gai et al. 2015). In a previous study, Bueno et al. (2020) verified the complete inhibition of methane production in anaerobic batch tests using granular sludge degrading PHWW from Spirulina at initial concentrations higher than 11 g COD.L−1.

Results regarding continuous PHWW treatment are still scarce in the literature. Fernandez et al. (2018) evaluated semi-continuous anaerobic digestion to degrade the organic fraction of wastewater streams from HTL of microalgae (Tetraselmis and Chlorella) and clarified manure as a co-substrate. Si et al. (2018) reported continuous anaerobic digestion of PHWW of cornstalk via an up-flow anaerobic sludge bed reactor (UASB) and packed bed reactor (PBR). Yang et al. (2020) operated an anaerobic biofilm reactor, packed with granular activated carbon and polyethylene rings for treating PHWW of swine manure. Reactors with immobilized sludge offer several advantages over reactors with suspended cells, such as the capacity of biodegrading different organic substrates simultaneously and promoting the stability of microorganisms that would not survive in suspended systems (Langer et al. 2014; Girijan and Kumar 2019). Biofilms usually provide microorganisms greater protection to toxic components due to their complex structure, thus providing more tolerance to high concentrations of pollutants (Cohen 2001; Mah and O’Toole 2001). Also, the high cell density facilitates the exchange of metabolites, improving cell viability for the biodegradation of pollutants (Langer et al. 2014; Girijan and Kumar 2019).

There are several possible support materials for biofilm formation, and the roughness, porosity, and pore size affect the microbial colonization rate of the support. Polyurethanes have interesting characteristics, such as density, high internal porosity, stability to hydrolysis, and non-biodegradability (Pascik 1990). Zheng et al. (2017) observed satisfactory results using immobilized sludge in polyurethane foams treating PHWW of hydrothermal liquefaction from Spirulina compared to granular biomass.

Several reactor configurations with immobilized sludge can be used in biological wastewater treatment systems (Girijan and Kumar 2019). Studies have pointed to the horizontal-flow anaerobic immobilized biomass (HAIB) reactor as an excellent option for treating wastewater containing toxic compounds (Cattony et al. 2005; Damianovic et al. 2009; Oliveira et al. 2019). The HAIB reactor was efficiently applied to treat water containing BTEX (Gusmão et al. 2007; Ribeiro et al. 2013) and gasoline (de Nardi et al. 2005). Aromatic compounds such as benzene, toluene, ethylbenzene, and xylenes, collectively known as BTEX, are contaminants present in petroleum products (Pruden et al. 2003) and can also be found in PHWW of hydrothermal liquefaction (Chen et al. 2014; Pham et al. 2013). For those reasons, this research aimed to evaluate the use of polyurethane foam matrices as immobilization support for biomass growth in PHWW generated for HTL conversion of Spirulina, as well as continuous anaerobic treatment in a HAIB reactor. 16S rDNA sequencing analysis was used to increase the understanding of the data obtained during the continuous treatment and to identify essential microorganisms involved in the studied process.

2 Materials and Methods

2.1 PHWW Generation and Characteristics

The PHWW used was generated following instructions in Vardon et al. (2011) and Tang et al. (2016). The HTL process was carried out at 260°C for 60 min in a 7-L stainless steel reactor equipped with graphite gasket and magnetic stirring (Parr-4575 A), operated in batch mode. The reactor was fed with 900 g of Spirulina powder in addition to 4.5 L of distilled water, resulting in an initial solid content of 20% (w/w). Before the reaction, the reactor was subjected to a nitrogen atmosphere and 1200 psi of pressure. The PHWW was vacuum filtered with 0.45-μm pore membrane. The physical-chemical characteristics are presented in Table 1. The organic compounds measured corresponded to 12 g. L−1 of organic matter expressed in chemical oxygen demand (COD), which corresponded only to 10% of the total measured COD in the PHWW according to Table 1.

2.2 Inoculum

The inoculum used in anaerobic biodegradability tests and in the continuous reactor was composed of three anaerobic sludge: S1, S2, and S3. S1 was a granular sludge obtained from a UASB reactor treating corn processing wastewater (Ingredion Brasil–Ingredients Industrials Ltda, Mogi Mirim, SP), S2 was a granular sludge obtained from a UASB reactor treating poultry slaughterhouse wastewater (Dacar, Ltda, Mogi Mirim, SP), and S3 was a flocculent sludge obtained from a UASB reactor treating domestic sewage (ETE-Laranja Azeda, Pirassununga, SP). The mixture was made at a rate of 2:2:1 in terms of volume for S1, S2, and S3, respectively. The composed sludge was enriched in a sequential batch reactor fed with a solution of acetic, propionic, and valeric acids and methanol, according to Bueno et al. (2020). Specific methanogenic activity (SMA) assays was carried out according to Aquino et al. (2007) with a proportion of 0.25 g COD/gTVS by using a mixture of volatile fat acids (VFA) that consisted of acetate (C2), propionate (C3), and butyrate (C4). The COD resulted from the mix of VFAs had a proportion of 24.3:34.4:41.3 for C2, C3, and C4, respectively. Nutrients supplementation was performed according to Zehnder et al. (1980). The sludge, which had 66.42 g. L−1 of total volatile solid, presented a specific methanogenic activity of 0.15 g CH4-COD.(gTVS.d) −1. This value is considered adequate according to Angelidaki et al. (2009), whose preconize minimum values of SMA of 0.1 g CH4-COD.(gTVS.d) −1 and 0.3 g CH4-COD.(gTVS.d) −1 for sludge and granular sludge, respectively.

2.3 Anaerobic Biodegradability Tests

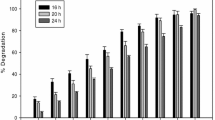

This essay aimed to evaluate the degradation of PHWW from conversion of Spirulina using immobilized sludge compared to suspended sludge in terms of organic matter removal, methane production, and intermediate metabolites production. For that, two sets of fifteen bottles (120 mL) were incubated, one set containing suspended sludge and the other containing immobilized sludge. Polyurethane matrices were used as support for the biomass immobilized according to Zaiat et al. (1996). The polyurethane matrices had 0.5 cm of sides and density of 23 Kg.m−3. The initial organic matter concentration expressed in COD was based on Bueno et al. (2020) and set at 10 g.L−1. Due to the sludge immobilization and volume occupied by polyurethane matrices, the concentration of solids could not be the same for both tested conditions. Therefore, the ratio between organic matter concentration and total volatile solids was kept constant at 0.4 g COD. g TVS−1 by adding 0.5 g of COD and 1.33 g of TVS in the flasks with suspended sludge and 0.4 g of COD and 1 g of TVS in the flasks with immobilized biomass. Basal medium containing macro- and micronutrients was provided according to Angelidaki et al. (2009), and the pH was corrected to 7.5 using 10% HCl solution. Three flasks of each set were opened weekly, and their liquid phases were analyzed, for the quantification of VFA and COD. Three negative control bottles (without PHWW) were also incubated for both conditions. The test lasted 35 days (840 h) and was interrupted when net accumulated methane production tended to stabilize.

The Gompertz model (Eq. 1) was adjusted to the values of the net methane production obtained discounting the control production corresponding to the endogenous methane production. From this adjustment, it was possible to estimate the maximum methanogenic production rate (k) and the duration of the latency phase (λ) of the processes. The model was adjusted using the Levemberg-Marquardt method (Microsoft Origin 9.0). All the parameters estimated in this study are apparent since they were obtained under the influence of mass transfer resistances. The values obtained for k were divided by the volatile suspended solids (VSS) provided in each assay to obtain the maximum specific methanogenic production rate expressed in NmLCH4.g−1VSS.h−1.

2.4 Continuous Anaerobic Treatment

To study the continuous anaerobic treatment of PHWW, a bench-scale HAIB reactor was used. The experiment was divided into four phases: I, II, II, and IV, differentiated by the applied organic loading rates (OLR). The applied OLRs were 0.8, 1.6, 3.2, and 0.8 gCOD.L−1d−1 in phases I, II, III, and IV, respectively. The HAIB reactor was built in glass with a length of 100 cm and an internal diameter of 5 cm, resulting in a ratio of length to diameter (L/D) of 20 and a total volume of 2 L. Polyurethane foam cubes with 0.5 cm of sides were used as support material. For sludge immobilization, 17 g of polyurethane foams were used, resulting in 2.7 g TVS. (g foam) −1. After introducing the inoculated matrices in the reactor, its porosity was estimated by 40% through liquid volume direct measure. The reactor was equipped with four equidistant sampling ports along its length and a gas collector at its surface. It was kept in a thermostatic chamber with a temperature of 37°C ± 2°C. The substrate reservoir was maintained at a temperature below 4°C to minimize biochemical reactions. Before entering the reactor, the substrate was heated to 37°C using a water bath. The HRT chosen was 24 h, based on OLRs used by Tommaso et al. (2013).

2.5 Analytical Methods

2.5.1 PHWW Characterization

Chemical oxygen demand (COD), Kjeldahl nitrogen (total and ammoniacal), concentration solids (gravimetric method), and phosphorus (spectrophotometric method) were performed all according to the Standard Methods for the Examination of Water and Wastewater (APHA 2017). The pH value was measured with a calibrated potentiometer. Bicarbonate alkalinity and total volatile acid content were determined according to Ripley et al. (1986) and DiLallo and Albertson (1961), respectively. The content of total phenolic compounds was analyzed using Folin-Ciocalteu reagent and was expressed in terms of gallic acid equivalents (GAE) (Singleton et al. 1999). The PHWW obtained was also analyzed in terms of important target organic compounds (Table 1) by gas chromatography (GC) (Agilent Tech 7890A, USA) equipped with a flame ionization detector (FID) and a capillary HP-FFAP column size of 25 m × 0.32 mm × 0.50 μm (Agilent 19091F-112, USA). The GC temperatures were maintained at 225°C for the detector and 240°C for the injector. The FID was used with helium as the carrier gas (pressure = 11 psi, flow rate = 2.45 mL min−1). For the sample preparation, 750 μL of the sample was transferred to a 1.5 mL vial, and 750 μL of pentanol was added for dilution and acted as an internal standard; also, 10 μL of formic acid (98%) was added for acidification.

2.5.2 Batch and Continuous Treatment

Both batch tests and continuous treatment were evaluated using the following analyses: COD, solids, alkalinity (total, partial, and intermediate) concentration of volatile acids, and biogas methane content. COD and solid analyses were performed based on methods 5220 and 2540, respectively, from Standard Methods for the Examination of Water and Wastewater (APHA 2017). The VFA concentrations were determined according to the methodology described by Adorno et al. (2014) on a gas chromatograph equiped (2014, Shimadzu, Japan) with a flame ionization detector and a 30-m HP INNOWAX column with 0.25 mm (inner diameter) and 0.25 μm (film thickness) columns. Alkalinity analyses were performed according to Ripley et al. (1986). The content of TVS of the polyurethane matrices was measured according to Tommaso et al. (2013). According to the procedure, five polyurethane matrices were placed in a sealed glass flask (50 mL) with 5.0 mL of phosphate-buffered saline and 2.5 g of glass beads. The flask was agitated manually for 20min. The liquid containing biomass was separated, and the matrices were washed nine more times with the same volume of buffer solution, which was also collected. The resultant liquid phase was then analyzed according to APHA (2017) for obtaining the total volatile solids.

Biogas production obtained in the batch tests was quantified by a pressure transducer (model Data Logger GN200) with detection limit 15 psi. Biogas was collected when the pressure in the flask reached a maximum of 10 psi. After each biogas collection, the pressure in the reactor flasks was relieved. The CH4 biogas content was measured by a gas chromatograph equipped with a thermal conductivity detector (2014, Shimadzu, Japan) and a 30-m Carboxen 1010 PLOT column with an inner diameter of 0.53 mm. Helium gas was used as the gas carrier, with a flow rate of 10 mL/min. The injector was kept at 100°C. The column was initially held at 40°C for 3 min and increased at a rate of 60°C/min to a final temperature of 150°C and held for 1 min. A standard containing CH4 and CO2 (50.032: 49.968) was injected periodically to obtain the conversion factor between the area of the peaks and the mass of methane in the samples.

The CH4 production obtained in the continuous treatment was measured by liquid displacement using a 5% NaOH solution. Thymol Blue was used as an indicator. The yields were calculated taking into account the CH4 volume produced per gram of COD provided. The COD balance was calculated according to the daily methane produced and the daily removed COD. The effluent COD was added to the COD from methane produced and divided by the value of the influent COD. Through this calculation, it was possible to estimate the percentage of the supplied COD that has not been converted to methane.

2.6 Analysis of the Microbial Community

The inoculum and the sludge collected from the HAIB reactor were submitted to molecular biology analyses to analyze the microbial community. When coming from the HAIB reactor, the samples of polyurethane matrices with biomass were collected in the first sampling port, (L/D =2). The biomass was detached from the polyurethane matrices according to Tommaso et al. (2013). The biological samples were submitted to 16S rDNA sequencing for the taxonomic characterization of the microbial communities. The sludge samples were washed using TAE solution (20 mM tris-acetate (pH 7.4), 10 mM acetate, 0.5 mM Na2EDTA), and the DNA extraction was performed according to Griffiths et al. (2000) modified by the addition of glass beads. An illustra GFX PCR DNA and Gel Band Purification (GE Healthcare) kit was used to purify the sample. The DNA purity and quantification were evaluated using NanoDrop and agarose gel electrophoresis. 16S rDNA sequencing was performed at Genome dx (Rio de Janeiro, RJ, Brazil) using the Illumina high-throughput sequencer with paired-end sequencing methodology, according to the Illumina manufacturer’s guidelines. The software FLASH (Magoč and Salzberg 2011), QIIME (version 1.7.0) (Caporaso et al. 2010), and UCHIME algorithm (Edgar et al. 2011) were used for merging paired-end reads to obtain high-quality clean tags and identify and remove chimera sequences, respectively. For operational taxonomic units (OTUs), sequences with similarity higher than or equal to 97% were assigned using UPARSE software (Edgar 2013), while taxonomic classification was performed using the Green Gene Database based on RDP (Wang et al. 2007). Richness (Chao-1) diversity (Shannon) and Good’s coverage indexes were determined with QIIME (Version 1.7.0), and the graphs were generated with R software (Version 2.15.3). The sequencing reads were deposited at the Sequence Read Archive (SRA) database (http://www.ncbi.nlm.nih.gov/sra) under the project PRJNA 639546 for the inoculum and PRJNA 639527 for the reactor sample.

2.7 Statistics

The Student’s t-test was applied at the 95% confidence level using Minitab (Version 18, Minitab, Inc., PA, USA) to evaluate the values of methanogenic production and kinetic parameters obtained in batch tests. The organic matter removal efficiency values throughout the operation phases of the HAIB reactor were also subjected to the test.

3 Results and Discussion

3.1 Anaerobic Biodegradability Assay for Biomass Evaluation

The net accumulated methane production obtained from the PHWW anaerobic degradation using immobilized and granular sludge is presented in Fig. 1a. A production of 177±12 NmL of CH4 was observed using immobilized sludge, which was 68.6% superior to that obtained by granular sludge, 105±8 NmL. Similar results were observed by Zheng et al. (2017) using lower initial COD concentrations. According to the authors, besides to being a support material, the polyurethane foam could temporarily store nutrients and toxic compounds and then slowly release them to the microbes, contributing to higher methane production. In addition, immobilized microorganisms can degrade different organic substrates simultaneously and have more resistance to toxic compounds than free cells (Girijan and Kumar 2019; Langer et al. 2014).

Net CH4 production was fit to a modified Gompertz model to estimate λ and k. The Student’s t-test confirmed that the difference between the CH4 production of these two assays (granular and immobilized biomass) was statistically significant (p < 0.05). Although the λ predicted by the modified Gompertz model was lower using immobilized sludge (154 ± 38 h) than using granular sludge (228 ± 9 h), according to Student’s t-test, the difference between both assays λ was not statistically significant (p > 0.05). Regarding the specific maximum methane production rate, the immobilized sludge presented 1.02 ± 0.2 NmL CH4. (g VSS.h)−1, which was more than double the value obtained for granular sludge, 0.48 ± 0.1 NmL CH4. (g VSS.h)−1. According to the Student’s t-test, that difference λ was statistically significant (p > 0.05).

When immobilized sludge was used, the maximum COD removal was observed at 504 h (54.16±3.41 %), followed by an increase in organic matter concentration in the liquid medium. When granular sludge was used, the maximum COD removal occurred at 672 h (39.64±1.53 %). Then an increase in the concentration of organic matter in the liquid medium was observed. Consequently, the maximum organic matter removal rate was observed at 504 h using immobilized sludge (0.03±0.0075 g COD.L−1. d−1) and at 672 h using granular sludge (0.022±0.01 g COD.L−1. d−1).

The increase in COD concentration after 500 h of testing using immobilized sludge and after 672 h using granular sludge could be attributed to compounds that were initially resistant to oxidation by dichromate, the COD detection method used, but later degraded, such as some nitrogenous aromatic compounds including pyridine (Vogel et al. 2000). Numerous N-containing compounds were previously observed in PHWW from microalgae (Zhou et al. 2015). According to Tommaso et al. (2015), N-heterocyclic compounds corresponded to approximately 30–40% of the compounds present in PHWW from microalgae. Quispe-Arpasi et al. (2018) also identified N-heterocyclic compounds in PHWW from Spirulina. In the present study, the COD of these compounds may not have been detectable until after being cleaved into smaller compounds by specific microorganisms.

Similar behavior was also observed for VFA concentrations obtained over time (Fig. 1b). Using granular biomass, concentrations of acetic and valeric acids increased over time, while butyric and propionic acids showed a non-defined trend but at lower concentrations. After 672 h, levels of butyric and propionic acids were significantly reduced, while very high production of acetic and valeric acid was observed. The accumulation of valeric acid was verified by Zheng et al. (2017) in the anaerobic digestion of PHWW from microalgae, indicating that this acid’s conversion may be a rate-limiting step. According to Pind et al. (2003), the accumulation of valeric acid indicates inhibition because, in the acetogenesis stage, it can be degraded into propionic acid and then into acetic acid by methanogenic microorganisms. Indeed, lower propionic acid concentrations were observed when valeric acid accumulation started. Acetic acid accumulation indicated that methanogenesis did not occur properly. On the other hand, when immobilized sludge was used, all compounds appeared in lower concentrations, almost half of the concentration observed in the test with granular sludge. The reduction of each compound was observed up to 504 h, at which point accumulation of acetic acid was observed.

Late VFA production probably occurred due to the breakdown of the previously discussed N-heterocyclic compounds, which, in addition to the increase in the COD concentration, caused destabilization in the acetogenesis step, VFA accumulation, and inhibition of methanogenesis. However, the use of immobilized sludge was clearly more appropriate than granular sludge for PHWW anaerobic biodegradation. According to Wang et al. (2020), the biofilm structure formed in the material support, in this case, the polyurethane foam, allows the microbial cells to optimally use all nutrients in the liquid phase, providing faster substrate transport. Additionally, the biofilms’ cellular structure gives microorganisms more effective resistance mechanisms to adverse situations, becoming more tolerant of changing environmental conditions and less vulnerable to toxic substances (Girijan and Kumar 2019; Żur et al. 2020). Inhibition of acetogenesis was not verified when immobilized sludge was used, since there was little to no valeric acid accumulation observed. Additionally, a lower concentration of accumulated acetic acid was observed using immobilized sludge, inferring that acid’s consumption occurred.

3.2 PHWW Continuous Treatment

The HAIB reactor using immobilized sludge was operated for approximately 200 days. COD, alkalinity, and acidity analyses were performed weekly. Figure 2 a presents the COD removal efficiencies obtained during the HAIB operation at each phase over time. The dispersion degree, data obliquity, and outliers are indicated by the spaces between the different parts of the box. The variability outside the upper and lower quartiles is indicated by the whisker extending horizontally from the box. The outliers are plotted as individual points, as seen in phase II. It is possible to notice the variation of COD removal at phases I and III. In contrast, phase II had more stability, presenting less variability and higher COD removal efficiencies.

As stability was not observed in phase III, the OLR was reduced to the same value used in phase I as an attempt to recover the previously obtained efficiencies. The reactor was operated for an additional 40 days (phase IV); therefore, the COD removal efficiencies increased compared to phase III. The process stability and the COD removal efficiency previously obtained at phase I were not achieved during the last monitoring period, probably due to the intoxication of part of the microbial consortium by the organic load rate applied at phase III. Indeed, 2.7 g TVS.g foam −1 was provided in the inoculation process, and, at the end of the operation, 1.5 g TVS. g foam −1 were observed, indicating loss of biomass, which corroborates the hypothesis of microbial intoxication due to the applied organic load in phase III.

The Student’s t-test was used to analyze the COD removal values obtained in phases I, II, and III. In general, COD removal efficiencies decreased when the organic load rate was increased. The average COD removal efficiency in phase I was 66.8% (varying from 64 to 69.6%). Additionally, Student’s t-test showed (with 95% reliability) that COD removal was above 60%. In phase II, the COD removal average was 58.16% (varying from 53 to 63.3%). The Student’s t-test also showed (with 95% reliability) that COD removal was above 50%. In phase III, in which a higher organic load rate was applied, the average COD removal efficiency was 36.8% (varying from 32.6 to 40.9%). In this phase, the Student’s t-test showed (with 95% reliability) that COD removal was above 30%. In phase IV, the dynamic equilibrium state was not achieved; thus, statistical analysis could not be applied.

The HAIB reactor has been successfully used in the removal of recalcitrant compounds. Oliveira et al. (2019) used the HAIB reactor to evaluate sulfamethazine (sulfonamide) anaerobic biodegradability and reached COD removal efficiencies between 90 and 95%, using OLR of 1.0 g COD.L−1.d−1. Ribeiro et al. 2013 obtained an average COD removal of 86% by treating BTEX with ethanol as a co-substrate in a HAIB reactor. Damianovic et al. (2009) obtained COD removal efficiencies of up to 98% using HAIB reactors treating pentachlorophenol (PCP). According to the authors, the high COD removal efficiencies could be explained by the maintenance of high methanogenic activity inside the reactor and the predominance of microorganisms capable of converting organic compounds to acetate.

The lower COD removal efficiencies (approximately 60%) obtained in the present study may be related to the fact that the PHWW used was derived from Spirulina. In addition, presenting a relatively high organic nitrogen content, this effluent contains several potentially toxic N and O-heterocyclic compounds, as discussed in the “Anaerobic Biodegradability Assay for Biomass Evaluation” section. Pham et al. (2013) identified several of such compounds and demonstrated that they conferred high toxicity. Besides, a synergistic cytotoxicity effect among most of these compounds was observed. Thus, their mixture found in PHWW from Spirulina presented more toxicity than single compounds, as treated by Damianovic et al. (2009) and Oliveira et al. (2019).

Furthermore, the PHWW used in this work was produced at 260°C, and according to Tommaso et al. (2015), the characteristics of PHWW are directly related to the variations of the conditions applied in the HTL process. The authors evaluated the effects of HTL temperatures (260–320° C) on the anaerobic degradability of PHWW from microalgae and verified that PHWW obtained at lower temperatures presented lower anaerobic biodegradability. Gai et al. (2015) observed that HTL using Chlorella pyrenoidosa as feedstock at 280 and 300°C had higher concentrations of organic acids. However, at 260°C, higher concentrations of N and O-heterocyclic cyclic compounds were found. The compounds measured from the PHWW produced (Table 1) correspond to 12 g COD. L−1, which represented only 10% of the total COD in the PHWW. This implies that many other compounds are responsible for the COD of PHWW, such as nitrogenous compounds and other acids and phenolic compounds not detected by the method used.

PHWW derived from other lower nitrogen feedstock produced lower total nitrogen PHWW and probably presented different toxicity effects on anaerobic digestion due to the absence of N and O-heterocyclic compounds. In this way, Si et al. (2018) obtained a COD removal efficiency of approximately 67%; however, the feedstock used in the HTL process was cornstalk. The results were obtained in an up-flow anaerobic sludge bed reactor (UASB) and packed bed reactor (PBR) under an organic loading rate of 8 g COD.L−1. d−1, after an acclimatization period of 25 days using a synthetic substrate with glucose as the carbon source. In the same sense, Yang et al. (2020) obtained 80% of COD removal treating PHWW of swine manure at a concentration of 10 g COD.L−1, using an anaerobic biofilm reactor under a 1.7 d HRT.

Methane production was measured over the reactor operating time by liquid displacement. Figure 2 b presents the methane yield obtained from phase I to the end of phase III. In every phase change, which meant increasing the OLR, an initial reduction in methane yield was observed. Table 2 presents average daily methane production and the results of COD balance. Although a decrease in COD removal was verified with an increase in organic load, methanogenic daily output increased. This production, however, was not stable, and the methane yields were low. All the calculated COD balances resulted in values smaller than 1, which means that part of the removed COD was not converted into methane gas. The missing COD could have been either initially adsorbed or converted into other products besides methane. The COD balance results were increasing throughout the phases, inferring that the COD adsorption happened at the beginning of the reactor operation. After such a period, an equilibrium was established, and the COD flow was dependent on the concentrations found in the bulk liquid. According to Zhou et al. (2015), the adsorption process generally requires minutes to days to achieve equilibrium, depending on the adsorbent, which is significantly faster than the net rates for anaerobic digestion. Thus, in phase I, the polyurethane matrices and the attached biofilm as well may have acted as a sink for toxic compounds, helping microorganism survival or adaptation. Later on, in phases II and III, higher conversion levels could be observed, corroborated by the COD balance results. Another explanation for the unaccounted-for COD could be that it was converted into a product such as acids and H2. H2 was not monitored in this experiment; however, the 16S rDNA sequencing results (item 3.3) can support this assumption. It is also important to consider that the method used for methane measurement (basic solution displacement), which provided a trap only for carbon dioxide, could have also quantified the hydrogen production.

The alkalinity to bicarbonate was higher in the effluent compared to the influent throughout the experiment, except at phase IV, in which the alkalinity value can be assumed the same in the influent and effluent if the standard deviation is considered. This analysis indicates the system’s ability to neutralize acids, preventing pH decrease due to an increased concentration of acids. Thus, the alkalization capacity of the reactor is an indication that anaerobic digestion was occurring adequately. According to Ripley et al. (1986), the relationship between intermediate alkalinity (IA), which is related to volatile acids, and partial alkalinity (PA), which is the alkalinity to bicarbonate, higher than 0.3 is indicative of instability of the process. However, due to each effluent’s characteristics, some reactors may not show instability, even presenting IA/PA greater than 0.3 (Pereira et al. 2009), as occurred in phases I and II. The IA/PA was equal to or higher than 0.3, considering the standard deviation, as shown in Table 3.

Samples along the HAIB reactor length were collected at the end of each phase for COD and VFA analysis. The spatial variation of the filtered COD is presented in Fig. 3a, and the spatial variation of VFA concentration in terms of COD throughout the reactor during phase I and phase II is shown in Fig. 3b. In phases III and IV, the acid peaks obtained were below the calibration curve; therefore, it was impossible to present these data.

Most of the organic matter was consumed in the first part of the reactor length. It was also observed in previous studies using a HAIB reactor at similar organic loading rates as in the present study (Damianovic et al. 2009; Tommaso et al. 2013). Despite this, peaks of acids were identified in the middle of the length. The VFA profiles from phases I and II presented similar behaviors. This behavior may be related to the late detection of part of the COD, as was discussed earlier. The maximum accumulated concentration of propionic and valeric acids decreased by approximately half when the OLR was increased. This difference in VFA concentrations in phases I and II can be explained by the difference in the applied organic load. In phase II, the organic load rate was higher; therefore, in addition to the recalcitrant compounds, simple organic matter such as carbohydrates and amino acids was also present in greater concentration than in phase I. This simple organic matter was present in concentrations enough to support the process and obtain less accumulation of acids. The acetic acid concentration, however, was practically the same under both conditions, indicating that acetoclastic methanogenesis was impaired. Despite the decrease in methanogens, it can be inferred that it still occurred, even if slowly.

3.3 Microbial Profile

Biomass samples were collected from the foams at the first sampling point of the HAIB (L/D = 2) at the end of phase III, where the major part of the organic matter removal was happening. The results obtained were compared with the results obtained from the inoculum. Sludge samples were also collected at the final operation in phase IV; nevertheless, they did not have sufficient DNA quality to be sequenced.

Through 16S rDNA sequencing of the inoculum and the sludge from the reactor, 47360 and 42491 sequences were obtained, which were grouped into 423 and 311 OTUs, respectively. High coverage was observed (99%) for both samples. The average lengths of effective tags were 403 and 406 for the inoculum and the reactor’s sludge. The results indicated that after the HAIB operation treating PHWW from Spirulina, the sludge’s diversity and richness decreased. The diversity index (Shannon) was higher for the inoculum (4.8) than for the sample from the reactor (3.11). The same trend was observed for the richness estimation (Chao-1); the inoculum presented a higher index (460.6) compared to that observed for samples of the reactor’s sludge (376.7). In addition, a remarkable change in the microbial community occurred during the PHWW continuous treatment in the HAIB reactor. While 54.3% of the inoculum microorganisms were Archaea, and 45.7% were Bacteria, after the continuous process, the sludge presented 90.8% of Bacteria and only 9.2% Archaea.

Methanosaetaceae was the most representative archaeal family in the inoculum, followed by Methanosarcinaceae. The most representative bacterial families found in the inoculum were Kosmotogaceae, Porphyromonadaceae, Lentimicrobiaceae, Thermoplasmatales, Spirochaetaceae, and Syntrophaceae. After the continuous operation, Synergistaceae and Thermodesulfobiaceae were the most representative families in the reactor, followed by Methanosaetaceae, Fervidobacteriaceae, Hydrogenophilaceae, Methanobacteriaceae, and Thermoanaerobacteraceae.

The genera identified in the inoculum at relative abundances higher than 1% were Methanosaeta (43.21%), Methanomethylovorans (5.36%), Mesotoga (2.49%), Macellibacteroides (2.21), Smithella (2.11%), Lentimicrobium (1.99%), Methanomassiliicoccus (1.74%), Syntrophobacter (1.59%), and Methanolinea (1.43%) (Fig. 4). The most abundant bacterial genus identified in the inoculum was acetogenic bacteria, Mesotoga, with a potential role in the degradation of halogenated aromatic compounds (Ben Hania et al. 2011); fermentative bacteria, Macellibacteroides and Lentimicrobium, which produce mainly acetate, hydrogen, and butyrate (Jabari et al. 2012; Zhang et al. 2019); and syntrophic substrate-oxidizing bacteria, Smithella and Syntrophobacter, which are related to the syntrophic association with methanogenic archaea in acid bioconversion into methane (Narihiro et al. 2018).

After the reactor operation, the genera identified in the sludge with relative abundances higher than 1% were Anaerobaculum (39.5%), Coprothermobacter (31.2%), Methanosaeta (7.34%), Fervidobacterium (3.9%), and Methanobacterium (1.64%) (Fig. 4). Although fermentative bacteria were still favored, the community presented a different profile. Coprothermobacter and Anaerobaculum were the genera with the highest relative abundance and are part of the phylogenetic groups Firmicutes and Synergistetes, respectively. They are described as proteolytic bacteria or peptide fermenters (Menes and Muxí 2002; Rainey and Stackebrandt 1993). Both genera were found in microbial cultures enriched with LCFAs (Hatamoto et al. 2007; Palatsi et al. 2011). Nevertheless, some authors justify their presence by using protein substrates, resulting from deteriorated cells (Sousa et al. 2009), which could have happened during phase III.

Anaerobaculum is reported in the literature as a moderately thermophilic microorganism, organic acid fermenter, and great hydrogen producer (Ben Hania et al. 2016; Maune and Tanner 2012; Menes and Muxí 2002). The reactor operation was kept at mesophilic temperatures (37°C); however, this genus was also found in an anaerobic lagoon treating wool-scouring wastewater (Menes and Muxí 2002), which is typically kept at environmental temperatures, and in anaerobic sludge treating protein-rich wastewater 35°C. (Palatsi et al. 2011). Anaerobaculum was also identified in a methanogenic packed-bed reactor treating protein solid waste (Sasaki et al. 2007) and petroleum reservoirs (Gieg et al. 2010). Anaerobaculum is from the Synergistaceae family. Si et al. (2018) found microorganisms from the Synergistaceae family present in the sludge of reactors (PBR and UASB) used for the continuous treatment of PHWW from cornstalk. Interestingly, the highest percentage of microorganisms in this family were found in the PBR, which used microorganisms immobilized in polyurethane rings.

Coprothermobacter is described in the literature as an anaerobic, proteolytic, and thermophilic bacterium associated with hydrogen production (Etchebehere and Muxí 2000; Gagliano et al. 2015; Kawagoshi et al. 2005; Tandishabo et al. 2012). Although it is a thermophilic microorganism, its growth range is 35 to 75°C, and it has been isolated from a methanogenic mesophilic reactor treating protein-rich wastewater (Etchebehere et al. 1998; Ollivier et al. 1985; Palatsi et al. 2011). Coprothermobacter was observed in nonconventional anaerobic systems as in petroleum reservoirs (Nazina et al. 2006), which have similar compounds also found in PHWW. Tatara et al. (2008) found that biofilms are an important niche for Coprothermobacter; thus, the HAIB reactor treating PHWW from Spirulina seems to have provided conditions for Coprothermobacter growth. The hydrogen production potential by Anaerobaculum and Coprothermobacter could also explain the instability in the methane production and COD balance values, which were found to be inferior to 1, indicating that the methanogenic route was not the only route used.

The inoculum used was methanogenic once Methanosaeta was the predominant genus, followed by Methanomethylovorans and Methanomassiliicoccus archaea, methylotrophic methanogens that can directly convert methanol into methane (Florencio et al. 1995). In contrast, after the continuous operation, in the biomass from the HAIB reactor, the fermenting microorganisms were favored, reinforcing the assumption of possible hydrogen production. The only methanogenic archaea identified in relative abundance higher than 1% was Methanosaeta, but still in lower abundance (7.34%) compared to the inoculum (43.25%). The archaea from the Methanosaetaceae family were found in higher abundance by Si et al. (2017) in continuous treatment of PHWW from cornstalk in PBR and UASB reactors. Differently, results obtained here indicate that the conditions applied to the PHWW continuous treatment using the HAIB reactor did not favor methanogenic archaea’s growth, causing significant transformations in the microbial population. Further studies considering the production of hydrogen and volatile fat acids should be carried out.

4 Conclusions

Batch tests have shown that the use of immobilized biomass in polyurethane foams can be more appropriate than granular biomass to degrade PHWW from Spirulina. Higher methane production potential and less volatile fatty acid accumulation were obtained using immobilized biomass in polyurethane foam. The continuous treatment of PHWW of Spirulina in the HAIB reactor achieved COD removal efficiencies of 67% and 58% for volumetric organic load rates of 0.8 and 1.6 g COD. L-1. d-1, respectively. However, the HAIB reactor did not favor methanogenic archaeal development and did not show stability in volumetric organic load rates higher than 1.6 g COD. L−1. d−1. In the other hand, the HAIB reactor treating PHWW from Spirulina showed potential for hydrogen production once it favored the growth of hydrogen producing microorganisms, Anaerobaculum and Coprothermobacter. Since experiments on the continuous treatment of effluent from the hydrothermal liquefaction process are scarce in the literature, the study contributes to the anaerobic treatment of algae HTL effluent, supporting future studies aiming to implement this process for obtaining renewable and alternative fuels. Future studies aiming at different operational conditions or different reactor configurations and different compounds as co-substrates must also be carried out.

References

Adorno, M. A. T., Hirasawa, J. S., & Varesche, M. B. A. (2014). Development and validation of two methods to quantify volatile acids (C2-C6) by GC/FID: Headspace (automatic and manual) and liquid-liquid extraction (lle). American Journal of Analytical Chemistry, 05, 406–414.

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J. L., Guwy, A. J., Kalyuzhnyi, S., Jenicek, P., & Van Lier, J. B. (2009). Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Science and Technology, 59, 927–934.

APHA. (2017). Standard methods for the examination of water and wastewater. American Public Health Association. Am. Water Work. Assoc. Water Environmental, 23.

Aquino, S. F., Chernicharo, C. A. L., De, M., Florêncio, L., Santos, D., & Monteggia, L. O. (2007). Methodologies for determining the specific methanogenic activity (SMA) in anaerobic sludges. Engenharia Sanitária e Ambiental., 12, 192–201.

Behrendt, F., Neubauer, Y., Oevermann, M., Wilmes, B., & Zobel, N. (2008). Direct liquefaction of biomass. Chemical Engineering and Technology, 31, 667–677.

Ben Hania, W., Bouanane-Darenfed, A., Cayol, J. L., Ollivier, B., & Fardeau, M. L. (2016). Reclassification of Anaerobaculum mobile, Anaerobaculum thermoterrenum, Anaerobaculum hydrogeniformans as Acetomicrobium mobile comb. nov., Acetomicrobium thermoterrenum comb. nov. and Acetomicrobium hydrogeniformans comb. nov., respectively, and emendati. International Journal of Systematic and Evolutionary Microbiology, 66, 1506–1509.

Ben Hania, W., Ghodbane, R., Postec, A., Brochier-Armanet, C., Hamdi, M., Fardeau, M. L., & Ollivier, B. (2011). Cultivation of the first mesophilic representative (“Mesotoga”) within the order Thermotogales. Systematic and Applied Microbiology, 34, 581–585.

Bueno, B. E., Soares, L. A., Quispe-Arpasi, D., Sakamoto, I. K., Zhang, Y., Varesche, M. B. A., Ribeiro, R., & Tommaso, G. (2020). Anaerobic digestion of aqueous phase from hydrothermal liquefaction of Spirulina using biostimulated sludge. Bioresource Technology. https://doi.org/10.1016/j.biortech.2020.123552.

Caporaso, J. G., Kuczynski, J., Stombaugh, J., Bittinger, K., Bushman, F. D., Costello, E. K., Fierer, N., Peña, A. G., Goodrich, J. K., Gordon, J. I., Huttley, G. A., Kelley, S. T., Knights, D., Koenig, J. E., Ley, R. E., Lozupone, C. A., McDonald, D., Muegge, B. D., Pirrung, M., Reeder, J., Sevinsky, J. R., Turnbaugh, P. J., Walters, W. A., Widmann, J., Yatsunenko, T., Zaneveld, J., & Knight, R. (2010). QIIME allows analysis of high-throughput community sequencing data. Nature Methods, 7, 335–336.

Cattony, E. B. M., Chinalia, F. A., Ribeiro, R., Zaiat, M., Foresti, E., & Varesche, M. B. A. (2005). Ethanol and toluene removal in a horizontal-flow anaerobic immobilized biomass reactor in the presence of sulfate. Biotechnology and Bioengineering, 91, 244–253.

Chen, W. T., Zhang, Y., Zhang, J., Yu, G., Schideman, L. C., Zhang, P., & Minarick, M. (2014). Hydrothermal liquefaction of mixed-culture algal biomass from wastewater treatment system into bio-crude oil. Bioresource Technology, 152, 130–139.

Chen, Y., Wu, Y., Hua, D., Li, C., Harold, M. P., Wang, J., & Yang, M. (2015). Thermochemical conversion of low-lipid microalgae for the production of liquid fuels: Challenges and opportunities. RSC Advances, 5, 18673–18701.

Cohen, Y. (2001). Biofiltration – the treatment of fluids by microorganisms immobilized into the filter bedding material: A review. Bioresource Technology, 77, 257–274.

Costa, J. A. V., & de Morais, M. G. (2011). The role of biochemical engineering in the production of biofuels from microalgae. Bioresource Technology, 102, 2–9.

Damianovic, M. H. R. Z., Moraes, E. M., Zaiat, M., & Foresti, E. (2009). Pentachlorophenol (PCP) dechlorination in horizontal-flow anaerobic immobilized biomass (HAIB) reactors. Bioresource Technology, 100, 4361–4367.

de Nardi, I. R., Ribeiro, R., Zaiat, M., & Foresti, E. (2005). Anaerobic packed-bed reactor for bioremediation of gasoline-contaminated aquifers. Process Biochemistry, 40, 587–592.

DiLallo, R., Albertson, O. E. (1961) Volatile acids by direct titration. Journal of Water Pollution Control Federation, 33, 356–65. http://www.jstor.org/stable/25034391.

Edgar, R. C. (2013). UPARSE: Highly accurate OTU sequences from microbial amplicon reads. Nature Methods, 10, 996–998.

Edgar, R. C., Haas, B. J., Clemente, J. C., Quince, C., & Knight, R. (2011). UCHIME improves sensitivity and speed of chimera detection. Bioinformatics, 5, 2194–2200.

Elliott, D. C., Biller, P., Ross, A. B., Schmidt, A. J., & Jones, S. B. (2015). Hydrothermal liquefaction of biomass: Developments from batch to continuous process. Bioresource Technology, 178, 147–156. https://doi.org/10.1016/j.biortech.2014.09.132.

Etchebehere, C., & Muxí, L. (2000). Thiosulfate reduction and alanine production in glucose fermentation by members of the genus Coprothermobacter. Antonie van Leeuwenhoek International Journal of General and Molecular Microbiology, 77, 321–327.

Etchebehere, C., Pavan, M. E., Zorzópulos, J., Soubes, M., & Muxí, L. (1998). Coprothermobacter platensis sp. nov., a new anaerobic proteolytic thermophilic bacterium isolated from an anaerobic mesophilic sludge. International Journal of Systematic Bacteriology, 48, 1297–1304.

Fernandez, S., Srinivas, K., Schmidt, A. J., Swita, M. S., & Ahring, B. K. (2018). Anaerobic digestion of organic fraction from hydrothermal liquefied algae wastewater byproduct. Bioresource Technology, 247, 250–258.

Florencio, L., Field, J. A., & Lettinga, G. (1995). Substrate competition between methanogens a n d acetogens during the degradation of methanol in UASB reactors. Water Research, 29(3), 915–922.

Gagliano, M. C., Braguglia, C. M., Petruccioli, M., & Rossetti, S. (2015). Ecology and biotechnological potential of the thermophilic fermentative Coprothermobacter spp. FEMS Microbiology Ecology, 91, 1–12.

Gai, C., Zhang, Y., Chen, W. T., Zhou, Y., Schideman, L., Zhang, P., Tommaso, G., Kuo, C. T., & Dong, Y. (2015). Characterization of aqueous phase from the hydrothermal liquefaction of Chlorella pyrenoidosa. Bioresource Technology, 184, 328–335.

Gieg, L. M., Davidova, I. A., Duncan, K. E., & Suflita, J. M. (2010). Methanogenesis, sulfate reduction and crude oil biodegradation in hot Alaskan oilfields. Environmental Microbiology, 12, 3074–3086.

Girijan, S., & Kumar, M. (2019). Immobilized biomass systems: an approach for trace organics removal from wastewater and environmental remediation. Current Opinion in Environmental Science and Health., 12, 18–29.

Griffiths, R. I., Whiteley, A. S., Anthony, G., Donnell, O., & Bailey, M. J. (2000). Rapid method for coextraction of dna and rna from natural environments for analysis of ribosomal DNA- and rRNA-based microbial community composition. Applied and Environmental Microbiology, 66, 1–5.

Gusmão, V. R., Chinalia, F. A., Sakamoto, I. K., & Varesche, M. B. A. (2007). Performance of a reactor containing denitrifying immobilized biomass in removing ethanol and aromatic hydrocarbons (BTEX) in a short operating period. Journal of Hazardous Materials, 139, 301–309.

Hatamoto, M., Imachi, H., Yashiro, Y., Ohashi, A., & Harada, H. (2007). Diversity of anaerobic microorganisms involved in long-chain fatty acid degradation in methanogenic sludges as revealed by RNA-based stable isotope probing. Applied and Environmental Microbiology, 73, 4119–4127.

Jabari, L., Gannoun, H., Cayol, J. L., Hedi, A., Sakamoto, M., Falsen, E., Ohkuma, M., Hamdi, M., Fauque, G., Ollivier, B., & Fardeau, M. L. (2012). Macellibacteroides fermentans gen. nov., sp. nov., a member of the family Porphyromonadaceae isolated from an upflow anaerobic filter treating abattoir wastewaters. International Journal of Systematic Bacteriology, 62, 2522–2527.

Jena, U., & Das, K. C. (2011). Comparative evaluation of thermochemical liquefaction and pyrolysis for bio-oil production from microalgae. Energy and Fuels, 25, 5472–5482.

Kawagoshi, Y., Hino, N., Fujimoto, A., Nakao, M., Fujita, Y., Sugimura, S., & Furukawa, K. (2005). Effect of inoculum conditioning on hydrogen fermentation and pH effect on bacterial community relevant to hydrogen production. Journal of Bioscience and Bioengineering, 100, 524–530.

Langer, S., Schropp, D., Bengelsdorf, F. R., Othman, M., & Kazda, M. (2014). Dynamics of biofilm formation during anaerobic digestion of organic waste. Anaerobe, 29, 44–51.

Magoč, T., & Salzberg, S. L. (2011). FLASH: Fast length adjustment of short reads to improve genome assemblies. Bioinformatics., 27, 2957–2963.

Mah, T.-F. C., & O’Toole, G. A. (2001). Mechanisms of biofilm resistance to antimicrobial agents. Trends in Microbiology, 9, 34–39.

Maune, M. W., & Tanner, R. S. (2012). Description of Anaerobaculum hydrogeniformans sp. nov., an anaerobe that produces hydrogen from glucose, and emended description of the genus Anaerobaculum. International Journal of Systematic Bacteriology, 62, 832–838.

Menes, R. J., & Muxí, L. (2002). Anaerobaculum mobile sp. nov., a novel anaerobic, moderately thermophilic, peptide-fermenting bacterium that uses crotonate as an electron acceptor, and amended description of the genus Anaerobaculum. International Journal of Systematic Bacteriology, 52, 157–164.

Narihiro, T., Nobu, M. K., Bocher, B. T. W., Mei, R., & Liu, W. T. (2018). Co-occurrence network analysis reveals thermodynamics-driven microbial interactions in methanogenic bioreactors. Environmental Microbiology Reports, 10, 673–685.

Nazina, T. N., Shestakova, N. M., Grigor’yan, A. A., Mikhailova, E. M., Tourova, T. P., Poltaraus, A. B., Feng, C., Ni, F., & Belyaev, S. S. (2006). Phylogenetic diversity and activity of anaerobic microorganisms of high-temperature horizons of the Dagang oil field (P. R. China). Microbiology., 75, 55–65.

Oliveira, C. A., Penteado, E. D., Tomita, I. N., Santos-Neto, Á. J., Zaiat, M., da Silva, B. F., & Lima Gomes, P. C. F. (2019). Removal kinetics of sulfamethazine and its transformation products formed during treatment using a horizontal flow-anaerobic immobilized biomass bioreactor. Journal of Hazardous Materials, 365, 34–43.

Ollivier, B. M., Mah, R. A., & Ferguson, T. J. (1985). Emendation of the genus thermobacteroides: Thermobacteroides proteolyticus sp. nov., a proteolytic acetogen from a methanogenic enrichment. International Journal of Systematic Bacteriology, 35, 425–428.

Palatsi, J., Viñas, M., Guivernau, M., Fernandez, B., & Flotats, X. (2011). Anaerobic digestion of slaughterhouse waste: Main process limitations and microbial community interactions. Bioresource Technology, 102, 2219–2227.

Pascik, I. (1990). Modified polyurethane carriers for biochemical waste water treatment. Water. Science and Techonology., 22, 33–42.

Pereira, E. L., Campos, C. M. M., & Monterani, F. (2009). Effects of pH, acidity and alkalinity on the microbiota activity of an anaerobic sludge blanket reactor (UASB) treating pig manure effluents. Revista Ambiente e Água, 4(3), 157–168.

Pham, M., Schideman, L., Scott, J., Rajagopalan, N., & Plewa, M. J. (2013). Chemical and biological characterization of wastewater generated from hydrothermal liquefaction of Spirulina chemical and biological characterization of wastewater generated from hydrothermal liquefaction of Spirulina. Environmental Science & Technology, 47, 2131–2138.

Pind, P. F., Angelidaki, I., Ahring, B. K. (2003). Dynamics of the anaerobic process: Effects of volatile fatty acids. Biotechnology Bioengineering, 82, 791–801. https://doi.org/10.1002/bit.10628.

Posmanik, R., Labatut, R. A., Kim, A. H., Usack, J. G., Tester, J. W., & Angenent, L. T. (2017). Coupling hydrothermal liquefaction and anaerobic digestion for energy valorization from model biomass feedstocks. Bioresource Technology, 233, 134–143.

Pruden, A., Sedran, M., Suidan, M., & Venosa, A. (2003). Biodegradation of MTBE and BTEX in an aerobic fluidized bed reactor. Water Science and Technology, 47, 123–128.

Quispe-Arpasi, D., de Souza, R., Stablein, M., Liu, Z., Duan, N., Lu, H., Zhang, Y., de Oliveira, A. L., Ribeiro, R., & Tommaso, G. (2018). Anaerobic and photocatalytic treatments of post-hydrothermal liquefaction wastewater using H2O2. Bioresource Technology Reports., 3, 247–255.

Rainey, F. A., & Stackebrandt, E. (1993). Transfer of the type species of the genus Thermobacteroides to the genus Thermoanaerobacter as Thermoanaerobacter acetoethylicus (Ben-Bassat and Zeikus 1981) comb. nov., description of Coprothermobacter gen. nov., and reclassification of Thermobacteroides. International Journal of Systematic Bacteriology, 43, 857–859.

Ribeiro, R., de Nardi, I. R., Fernandes, B. S., Foresti, E., & Zaiat, M. (2013). BTEX removal in a horizontal-flow anaerobic immobilized biomass reactor under denitrifying conditions. Biodegradation., 24, 269–278.

Ripley, L. E., Boyle, W. C., & Converse, J. C. (1986). Improved alkalimetric monitoring for anaerobic digestion of high-strength wastes. Journal Water Pollution., 58(5), 406–411.

Roberts, G. W., Fortier, M.-O. P., Sturm, B. S. M., & Stagg-Williams, S. M. (2013). Promising pathway for algal biofuels through wastewater cultivation and hydrothermal conversion. Energy & Fuels, 27(2), 857–867.

Sasaki, K., Haruta, S., Ueno, Y., Ishii, M., & Igarashi, Y. (2007). Microbial population in the biomass adhering to supporting material in a packed-bed reactor degrading organic solid waste. Applied Microbiology and Biotechnology, 75, 941–952.

Si, B., Li, J., Zhu, Z., Shen, M., Lu, J., Duan, N., Zhang, Y., Liao, Q., Huang, Y., & Liu, Z. (2018). Inhibitors degradation and microbial response during continuous anaerobic conversion of hydrothermal liquefaction wastewater. The Science of the Total Environment, 630, 1124–1132.

Singleton, V., Orthofer, R., & Lamuela-Raventós, R. (1999). Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods in Enzymology, 299, 152–178.

Sousa, D. Z., Smidt, H., Alves, M. M., Stams, A. J. M. (2009). Ecophysiology of syntrophic communities that degrade saturated and unsaturated long-chain fatty acids. FEMS Microbiology Ecology, 68, 257–272. https://doi.org/10.1111/j.1574-6941.2009.00680.x.

Tandishabo, K., Nakamura, K., Umetsu, K., & Takamizawa, K. (2012). Distribution and role of Coprothermobacter spp. in anaerobic digesters. Journal of Bioscience and Bioengineering, 114, 518–520.

Tang, X., Zhang, C., Li, Z., & Yang, X. (2016). Element and chemical compounds transfer in bio-crude from hydrothermal liquefaction of microalgae. Bioresource Technology, 202, 8–14.

Tatara, M., Makiuchi, T., Ueno, Y., Goto, M., & Sode, K. (2008). Methanogenesis from acetate and propionate by thermophilic down-flow anaerobic packed-bed reactor. Bioresource Technology, 99, 4786–4795.

Tian, C., Li, B., Liu, Z., Zhang, Y., & Lu, H. (2014). Hydrothermal liquefaction for algal biorefinery: A critical review. Renewable and Sustainable Energy Reviews, 38, 933–950.

Tommaso, G., Chen, W. T., Li, P., Schideman, L., & Zhang, Y. (2015). Chemical characterization and anaerobic biodegradability of hydrothermal liquefaction aqueous products from mixed-culture wastewater algae. Bioresource Technology, 178, 139–146.

Tommaso, G., Domingues, M. R., Ribeiro, R., Varesche, M. B. A., Zaiat, M., & Foresti, E. (2013). Anaerobic degradation of protein: Simplified kinetic modelling and microbial dynamics. Water, Air and Soil Pollution. 224. https://doi.org/10.1007/s11270-013-1554-9.

Toor, S. S., Rosendahl, L., & Rudolf, A. (2011). Hydrothermal liquefaction of biomass: A review of subcritical water technologies. Energy., 36(5), 2328–2342.

Vardon, D. R., Sharma, B. K., Scott, J., Yu, G., Wang, Z., Schideman, L., Zhang, Y., & Strathmann, T. J. (2011). Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresource Technology, 102, 8295–8303.

Vogel, F., Harf, J., Hug, A., & Von Rohr, P. R. (2000). The mean oxidation number of carbon (MOC) - A useful concept for describing oxidation processes. Water Research, 34, 2689–2702.

Wang, J., Liang, J., Sun, L., Li, G., Temmink, H., & Rijnaarts, H. H. M. (2020). Granule-based immobilization and activity enhancement of anammox biomass via PVA/CS and PVA/CS/Fe gel beads. Bioresource Technology, 309, 123448. https://doi.org/10.1016/j.biortech.2020.123448.

Wang, Q., Garrity, G. M., Tiedje, J. M., & Cole, J. R. (2007). Naïve Bayesian classifier for rapid assignment of rRNA sequences into the new bacterial taxonomy. Applied and Environmental Microbiology, 73, 5261–5267.

Yang, L., Si, B., Zhang, Y., Watson, J., Stablein, M., Chen, J., Zhang, Y., Zhou, X., & Chu, H. (2020). Continuous treatment of hydrothermal liquefaction wastewater in an anaerobic biofilm reactor: potential role of granular activated carbon. Journal of Cleaner Production, 276, 122836. https://doi.org/10.1016/j.jclepro.2020.122836.

Zaiat, M., Cabral, A. K. A., & Foresti, E. (1996). Cell wash-out and external mass transfer resistance in horizontal-flow anaerobic immobilized sludge reactor. Water Research, 30, 2435–2439.

Zehnder, A. J. B., Huser, B. A., Brock, T. D., & Wuhrmann, K. (1980). Characterization of an acetate-decarboxylating, non-hydrogen-oxidizing methane bacterium. Archives of Microbiology, 24, 1–11.

Zhang, F., Zhang, W., Qian, D. K., Dai, K., van Loosdrecht, M. C. M., & Zeng, R. J. (2019). Synergetic alginate conversion by a microbial consortium of hydrolytic bacteria and methanogens. Water Research, 163, 114892. https://doi.org/10.1016/j.watres.2019.114892.

Zheng, M., Schideman, L. C., Tommaso, G., Chen, W. T., Zhou, Y., Nair, K., Qian, W., Zhang, Y., & Wang, K. (2017). Anaerobic digestion of wastewater generated from the hydrothermal liquefaction of Spirulina: Toxicity assessment and minimization. Energy Conversion and Management, 141, 420–428.

Zhou, Y., Schideman, L., Zheng, M., Martin-Ryals, A., Li, P., Tommaso, G., & Zhang, Y. (2015). Anaerobic digestion of post-hydrothermal liquefaction wastewater for improved energy efficiency of hydrothermal bioenergy processes. Water Science and Technology, 72, 2139–2147.

Żur, J., Piński, A., Michalska, J., Hupert-Kocurek, K., Nowak, A., Wojcieszyńska, D., & Guzik, U. (2020). A whole-cell immobilization system on bacterial cellulose for the paracetamol-degrading Pseudomonas moorei KB4 strain. International Biodeterioration and Biodegradation, 149, 104919. https://doi.org/10.1016/j.ibiod.2020.104919.

Acknowledgements

The authors are grateful to the São Paulo Research Support Foundation (FAPESP, process number 2017/12486-6) for financial support. The first author is grateful to the Coordination for the Improvement of Higher Education Personnel (CAPES)-Finance Code 001 for the Ph.D. fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bueno, B.E., Quispe-Arpasi, D., Soares, L.A. et al. Continuous Anaerobic Treatment of the Aqueous Phase of Hydrothermal Liquefaction from Spirulina Using a Horizontal-Flow Anaerobic Immobilized Biomass (HAIB) Reactor. Water Air Soil Pollut 232, 97 (2021). https://doi.org/10.1007/s11270-021-05025-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-021-05025-2