Abstract

Anaerobic digestion of ethanol-based distillery wastewater (DWW) was conducted in an immobilized 2-L Erlenmeyer flask set in 120 rpm incubator shaker and at 40℃ thermophilic condition for 30 days. K1 moving bed biofilm carriers, with specifications of 10 mm diameter, 7 mm length, density of 0.96–0.98 g/cm3 and a specific biofilm surface area of > 800 m2/m3, were used for immobilization. With five batches of anaerobic digestion, pure and diluted DWW were observed. The control batch with no carriers and with pure DWW produced the least volume of biogas. Batch 5, whose volume dilution ratio is 7:3 (DWW: pure water), produced the highest volumetric yield of biogas of 2 L. Similarly, Batch 2, which is pure DWW with no plastic carriers produced almost the same volume of biogas (1850 L) as compared to that of Batches 3 through 5 with complete nutrients. Among the samples, Batch 5 has the highest degree of TSS reduction and has BOD/COD ratio of 0.23, which is closest to zero that practically implies perfect biodegradability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Solid Organic Waste (SOW) management still faces many challenges in developing countries, with food wastes, yard wastes, animal manure, waste activated sludge, and agricultural waste yield in an increasing annual rate. One of the most polluting organic wastes is wastewater from distilleries due to the 88% of its raw materials that is discharged into the environment [1]. Ethanol as a type of alcohol serves many purposes in various industries, such as in chemical and manufacturing. Ethanol industry is producing huge amounts of alcohol to supply to the society. However, large volume of this unwanted chemical liquid is emitted and posed a threat to the ecosystem as it contains high biological and chemical oxygen demand, salt contents, and heavy metals that makes it acidic [2]. There exist many methods to resolve this global issue by converting the waste into valuable products. The biofuel as a research area gives a promising solution in producing energy from these SOW, and simultaneously utilizing the remaining waste as a possible resource or raw material to a significant industry. With potential in treating various organic wastes, anaerobic digestion (AD) is used to transform these into biogas energy and a stabilized fertilizer known as digestate. However, limitations in anaerobic digestion originate from the inadequate amount of mono-substrate supply and lack of immobilization of the feedstock. For the AD to become an efficient process, there must be an optimal amount of nutrients such as carbon (C), nitrogen (N), phosphorus (P), and sulfur (S). However, if the substrate has an excessive or deficient C/N, it can cause incomplete conversion of carbon due to inability in producing enzymes or can accumulate ammonia from conversion of urea [3].

Microbial culture present during anaerobic digestion should be immobilized to maintain a low concentration of the intermediates. A moving bed biofilm reactor has proven its potential in wastewater treatment to reduce the harmful organic compounds present. In terms of cost effectiveness in maintaining a high rate AD, the need to use moving bed biofilm reactor system sustains the microbiological community by the growth of biofilm in the plastic media. To this date, no studies found in the previous researches in utilizing a moving bed biofilm reactor.

This study aims to achieve the following objectives: (1) to compare the methane yield of distillery wastewater digested under plastic media to that of recent studies and (2) to determine the physico-chemical characteristics of the final digestate: pH, intial and final BOD/COD, %TSS (Total Suspended Solids) reduction, and %TP (Total Phosphorus). This papers seeks to analyze the effects of biofilm formation in the improvement of biogas supply using a moving bed biofilm reactor. Further, this can provide new insights in determining the effects of added nutrients and other factors that may influence the biogas production.

2 Experimental Methodology

Distillery wastewater (DWW) samples were freshly taken from Batangas’ Absolut Distillers, Inc, whereas the cow manure was sourced from YGGACC HAI farms in Laguna. The latter was sealed and incubated at 40 \(^\circ{\rm C}\) anaerobically for seven (7) days before the experiment. Cow manure is used as the inoculum for the samples to generate bacteria immediately throughout the experiment. In this study, there are five samples containing distillery wastewater and pure water. Table 1 shows different parameters for each batch sample, where the DWW/water ratio, micronutrients, glucose, and media carrier are taken into consideration. The composition of the micronutrients used can be found in Table 2.

In order to immobilize the substrates, plastic carriers are used as the medium to contain the bacteria for anaerobic digesting upon integrating in the moving bed biofilm reactor. K1 moving bed biofilm carriers that were utilized has the following specifications of 10 mm diameter, 7 mm length, density of 0.96–0.98 g/cm3 and a specific biofilm surface area of > 800 m2/m3.

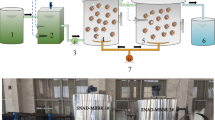

To remove the oxygen and promote AD in all the samples, nitrogen gas entered through a glass tube, submerged in the mixture, and was purged in each of the media bottle for 10 min. The oxygen that was initially present in the samples exit through the other glass tube. In order to collect the produced biogas, 2-L urine bags were connected to each of the media bottles though rubber tubes. The media bottles were exposed to a constant temperature of 37˚C inside an orbital shaker set at 120 rotations per minute in a duration of 4 weeks as shown in Fig. 1.

3 Results and Discussion

Figure 2 shows that using pure DWW produced the least biogas as the authors speculated less amount of carbon utilized by the anaerobes. Batches 2 and 5, meanwhile, produced the maximum volume of around two (2) L at day = 24; however, the former diffused from 2000 mL to 1850 mL at the last day. Both of them had nutrients and glucose that suit as optimal intake for the bacteria, which led the AD process to commence within a short period of time.

During the digestion process, there is a decrease in pH for all of the batch samples as there is a production of acetate and fatty acids [4]. The methanogenic bacteria can halt the biological reactions in the digestion due to its sensitivity in a very low pH environment. The optimal pH of final digestate ranges from 4.0 to 7.2 in anaerobic digestion [5].

In Fig. 3, Sample 4, which has the lowest decrease of pH, resulted to low biogas yield, whereas the remaining batch samples gave a consistent change of pH. The BOD/COD ratio in percentage depends upon the biodegradability of organic matter, which ranges from 0% (completely non-biodegradable) to 100% (completely biodegradable). Generally, it decreases before to after digestion (AD) due to presence of high proportion of non-degradable materials [5]. The optimal BOD/COD before undergoing to AD spans a range from 0.39 to 0.55, based on literature [6]. Generally, data points show that biodegradation took the most effect on the sample of diluted distillery wastewater mixed with nutrients, glucose, and media, thereby providing a place for colonies of bacteria to grow. Data of the change in BOD to COD ratio are well-matched with the AD principle by showing the largest difference between the initial and the final values. The BOD/COD ratio in Sample 5 is approaching to zero implying that degradation took place in an effective manner, with the possibility of projecting a hitting peak state wherein biodegradation stopped.

Also, Sample 5 showed the greatest reduction of suspended solids, indicating that AD took the greatest effect on it by means of biodegradability that was also observed in BOD/COD ratio. This only indicates that higher % reduction value of TSS resulted to greater volume of biogas yield. In this study, the optimum TSS to generate greater volume of biogas should be in the range of 938 to 1,456 mg/L. On the other hand, the data for both biogas yield and total phosphorus shows no consistent trend and thus implies no correlation.

It is noteworthy that only Batch 5 was the only sample the researchers observed with the formation of biofilm as seen in Fig. 4. This phenomenon could be attributed to the enhanced metabolic processes due to coordinated interactions between individual microbes that exist in a single culture of mixed microbes. Applicable for Sample 5, the microbial cultures in the biofilm seemingly digest the nutrients such as phosphorous and nitrogen-containing complexes during AD.

Table 3 summarizes the quantitative biogas yield from the initial volumetric amount of the substrates used. The volume of the feed is constant for all the samples, which is 1.4 L pure distillery wastewater. However, the biogas yield differs as there is an addition of nutrients, glucose, and carriers. The ratio of distillery wastewater and pure water also influenced the amount of biogas produced through anaerobic digestion. It is shown in this study that a mixture of distillery wastewater and pure water with added nutrients, glucose, and utilization of plastic carriers produced the highest yield among the other samples for about 2 L. It is also to highlight that with a mono-substrate of distillery wastewater with nutrients and glucose only generated the second highest volume of biogas of 1.85 L.

4 Conclusion

In this batch experimental study, indicators such as pH level, BOD/COD ratio and total suspended solids are considered in the study on anaerobic digestion of sugarcane distillery wastewater and are compared from the volumetric biogas yield pH levels must be around the setpoint value of 5.0 for the sample to undergo anaerobic digestion. Potential candidates tend not to change pH drastically during AD due to the buffer capacity supplied by ion bicarbonate equilibrium that should exist in the sample. A ratio of BOD to COD approaching to zero practically implies perfect biodegradability. Among the samples, Sample 5 has the BOD/COD ratio closest to zero and is also the sample that yields the most biogas. Meanwhile, a reduction of suspended solids almost always resulted from the proceeding of anaerobic digestion.

This experimental study shows that a combination of cobalt, magnesium, iron, and zinc makes AD proceed faster. Another way for making anaerobic digestion more efficient is by employing packing materials, or a media to allow more interaction between the microbes and the substrate. It is also noted, that a blend of microbes is better than just having a culture of one kind of microbes. This is because a coordinated metabolic processing makes anaerobic digestion proceed better than just having one kind of microbes do the entirety of the metabolic processing. Although some parameters need to take account such as Volatile Suspended Solid (VSS) reduction, overall, this study gives better insights of digesting sugarcane distillery wastewater in an anaerobic environment with the aid of plastic media containing a culture of multiple types of microbes.

References

Kharayat, Y.: Distillery wastewater: bioremediation approaches. J. Integrative Environ. Sci. 9(2), 69-91 (2012). https://doi.org/10.1080/1943815X.2012.688056

Ratna, S., Rastogi, S., Kumar, R.: Current trends for distillery wastewater management and its emerging applications for sustainable environment. J. Environ. Manage. 290,(2021)

Gerardi, M.H.: The Microbiology of Anaerobic Digesters. John Wiley and Sons, Inc. Chapter 7, pp. 51–59 (2003)

Lindorfer, G., Ahring, B., Verstraete, W.: Pre-treatment technologies for enhanced energy and material recovery of agricultural and municipal organic wastes in anaerobic digestion. In: Proceedings on Future of Biogas in European Biogas Workshop, pp. 79–85 (2003)

Menon, A., Wang, J., Giannis, A.: Optimization of micronutrient supplement for enhancing biogas production from food waste in two-phase thermophilic anaerobic digestion. Waste Manage. 59, 465–475 (2017)

Janke, L., Leite, A., Wedwitschka, H., Schmidt, T., Nikolausz, M., Stinner, W.: Biomethane production integrated to the brazilian sugarcane industry: the case study of São Paulo State. In: Proceedings of the 22nd European Biomass Conference and Exhibition, Hamburg, Germany, vol. 2326, p. 2326 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Almendrala, M., Villaflor, S.M., Tizon, Z.A., Doma, B., Evidente, R.C. (2023). Immobilized Anaerobic Digestion of Molasses-Based Distillery Wastewater in Moving Bed Biofilm Reactor. In: Chen, X. (eds) Proceedings of the 2022 12th International Conference on Environment Science and Engineering (ICESE 2022). ICESE 2022. Environmental Science and Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-1381-7_3

Download citation

DOI: https://doi.org/10.1007/978-981-99-1381-7_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1380-0

Online ISBN: 978-981-99-1381-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)