Abstract

Aquatic or land-based plastic pollution has raised serious concerns for ecosystems, and especially human and animal health worldwide. A variety of legislative instruments were developed to control, reduce, and manage the usage of plastics in day-to-day life to minimize the adverse outcomes brought by sending these plastic to landfill. Existing legislation heavily embraces levies, bans, and voluntary efforts through “reduce and reuse campaigns.” Thus, the present review highlights the pros and cons of the existing legislation and its implementation. It also assesses the need for the improvement of plastic legislation to better consider environmental and human health impacts. The paper proposes new efficient management strategies to aid in the development of plastic legislation which prevents increase of plastic pollution worldwide, the potential challenges that would arise from its implementation, and the mechanisms for overcoming these challenges. The paper proposes a conventional management strategy based on the current plastic management and legislation. It aims to improve the feasibility and effectiveness of the implementation of future plastic policies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

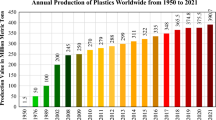

For over half a century, plastics have raised concerns due to their abundance, non-degradable and persistent nature, and their adverse impacts on biodiversity and the environment (Gall and Thompson 2015). The global production of plastic resins and fibers has increased from 2 to 381 metric tons from 1950 to 2015, with a total of 7800 metric tons over 65 years (PlasticsEurope 2008; PlasticsEurope 2016). The Asian region accounts for nearly 50% of global plastic production, with Europe and North America each producing around 18–19% (PlasticsEurope 2008; PlasticsEurope 2016). Similar trends exist for patterns of consumption. Plastic recovery ratios represent the proportion of plastic waste recovered and converted into reusable materials. While overall plastic recovery ratios remain at 70% for Europe and North America, such high levels of recovery are not found in Asian regions (Geyer et al. 2017) (Fig. 1).

Composition of marine litter according to 10 categories (period 2014–15) (OSPAR 2017)

When marine species ingest plastic, this can block the passage of food, resulting in a reduced nutritional intake, starvation, malnutrition, and even mortality (Derraik 2002). The microplastic could persist, transfer, and bioaccumulate along the trophic level, making it very difficult to remove (Arthur et al. 2009). Legislation promoting responsible plastic use has been evolving to minimize marine plastic pollution. However, despite efforts to reduce and effectively manage the production and disposal of plastic goods, the legacy of plastics has instead emerged as a magnified offshoot. During 2014–15, approximately 70–80% of marine litter was categorized as plastic litters (Fig. 1) (PlasticEurope 2017). Plastic particles less than 5 mm in size are termed as microplastics. Primary microplastics include small pellets and beads used in cosmetic and industrial applications, whereas secondary microplastics are those formed via the phytodegradation, mechanical degradation, or biodegradation of larger plastic debris (GESAMP 2015). Microplastics are composed of mostly six major types of petroleum-based polymers: polyethylene (PE), polypropylene (PP), and expanded polystyrene (PS) which are most likely to float, and polyvinyl chloride (PVC), polyamide (PA), also known as nylon and polyethylene terephthalate (PET) that are more likely to sink in the water column due to differences in their density (Lusher et al. 2017). The distribution of litter in the marine environment is determined by their relative density to marine water.

Moreover, plastic additives are another concern coinciding with plastic debris. The purpose of adding additives with plastic is to increase properties like durability and plasticity, or to decrease viscosity. However, these additives tend to leach out from the plastics and pollute the environment (Koelmans et al. 2014). For instance, nonylphenol (NP) which had migrated to water was detected in PVC and high-density polyethylene (HDPE) water containers (Loyo-Rosales et al. 2004). NP is an endocrine disruptor, generating concerns over human exposure. It is also an aquatic and freshwater pollutant impacting marine organisms by suppressing their growth and development (Zhang et al. 2017). As the main degradation product of NP, ethoxylates (NPEOs) mimic the effects of estrogen, inhibit the activity of antioxidant enzymes, cause tissue-specific effects, and cause baseline narcosis (Tollefsen et al. 2008; Watanabe et al. 2004; Wu et al. 2011; Zha et al. 2007). The common types of additive include plasticizer, flame retardant, heat stabilizer, filler, impact modifier, antioxidant, colorant, lubricant, and light stabilizer (Geyer et al. 2017). Plasticizers, fillers, and flame retardants represent nearly three quarters of all additive categories (Geyer et al. 2017).

In recent years, efforts have been made to develop legislative instruments which better manage and reduce the impacts of plastic waste. This article discusses how plastic pollution poses adverse impacts to ecosystems and human health. It also provides a comprehensive review of existing legislation on plastics and their implementation. It assesses the need to improve the legislative framework on plastics from an environmental and human health perspective. Hence, it combines various current plastic management strategies into one conventional method to tackle impacts brought by plastic wastes.

2 The Environmental and Human Health Impacts of Plastics

The adverse environmental and human health impacts discussed in the literature indicate that there is a need to implement legislation to minimize continual growing threats of plastic waste. As plastics have different physicochemical characteristics, they tend to produce a variety of toxic effects on aquatic and human health. Currently, there are five plastic types classified as carcinogenic (category 1A), or both carcinogenic and mutagenic (category 1B), including polyurethanes, polyacrylonitriles, polyvinyl chloride, epoxy resins, and styrenic copolymers (Lithner et al. 2011). The toxicity of these polymers is a result of their monomer constituents. The most hazardous monomers include 1,3-butadiene, acrylonitrile, epichlorohydrin, and vinyl chloride, which have carcinogenic and mutagenic abilities in their respective polymer compounds (Lithner et al. 2011). Production of such polymers has reached 37 t per year, raising concerns over their impact on the environment and potential human health risks (Lithner et al. 2011).

There are three stages in the production of plastic; the production of monomers, polymerization of resins, and the manufacturing of plastic goods (DeMatteo et al. 2012). Toxic components of plastic, such as styrene, may release during the manufacturing process, which poses a significant risk to workers through inhalation (Helal and Elshafy 2013). Low-dose exposure can cause irritation in the respiratory tract, while high-dose exposures (> 100 mg/m3) can cause chronic bronchitis and obstructive pulmonary changes (Helal and Elshafy 2013). The working environment is often heavily contaminated with dusts and fumes, creating occupational exposure to category 1A and 1B plastic chemicals, which can increase the risks posed by carcinogens and endocrine disruptors (DeMatteo et al. 2012). The life cycle of plastic (from production to disposal) must be accounted for before legislation is produced. Currently, there is a lack of policy and regulations to ensure a safe limit of exposure for workers within the plastics industry. A risk assessment of each stage of plastic production is yet to be performed.

Apart from the human health issues, the marine organisms posed adverse impacts as well (Table 1). Microplastic particles were found in many marine species, such as Mytilus edulis, Calanus helgolandicus, and Scleractinian corals. The adverse impacts included growth inhibition, energy depletion, decreased reproduction outputs, and respiration stress (von Moos et al. 2012; Wright et al. 2013, b; Cole et al. 2015; Green 2016; Green et al. 2016). The marine larva Tripneustes gratilla resulted in smaller post-oral arms after they were exposed to 300 microplastic particle/ml treatment (Kaposi et al. 2014). The embryo of Lytechinus variegatus also showed abnormal embryonic development while exposed to polyethylene microplastic pellets (Nobre et al. 2015). The energy costs of healthy egg productions are determined by their feeding which could lead to reproductive success of copepods (Cole et al. 2015). The copepod ingested microplastic suffered twofold greater energetic losses compared to ingestion of T. weissflogii (Cole et al. 2015). Hence, there would be less energy available for reproductive success after ingestion of microplastics. Another adverse physiological response was shown in European flat oyster (Ostrea edulis) (Green 2016). The oysters showed around 2.6 times higher respiration rates while exposed to polylactic acid (PLA) plastics (Green 2016). Different plastic materials demonstrated different levels of toxicity to the European flat oysters (Green 2016). High-density polyethylene (HDPE) had lower physiological effects than PLA to O. edulis (Green 2016).

3 Plastic Degradation in Marine Environment and Microplastic Types

Plastic has high stability and durability which result in long degradation times and tend to accumulate in the environment (Barnes et al. 2009). The oceanic hydrodynamic and wind transport plastic litters in the oceans, and it beak down as it ages (Noone et al. 2013; Gewert et al. 2015). Plastic degradation is defined as a decline of polymer properties through physical and chemical reaction breakdown of the materials (Yousif and Haddad 2013). The degradation processes can occur in the marine environment through abiotic or biotic pathways (Vasile and Pascu 2005; Gewert et al. 2015). Abiotic plastic degradation is initiated by thermally, hydrolytically, and UV radiative processes (Andrady 2011). This degradation process can break down plastic materials into smaller polymer fragments (Andrady 2011). The biotic degradation is defined as the degradation involved with microorganism activities (Shah et al. 2008). The microorganisms excrete extracellular enzymes onto plastic polymers to activate the biodegradation process (Shah et al. 2008). Hence, the plastic degradation mostly occurs on the polymer surface where the area exposes to chemical and enzymatic attack (Gewert et al. 2015). The degradation mechanisms of different plastic materials are summarized in Table 2.

Microplastics are classified as either primary microplastics or secondary microplastics. Primary microplastics include preproduction resin pellets and microbeads while secondary microplastics are formed by degradation of large plastic debris in the environment. The Government of the Netherlands has banned microbeads (primary microplastic), such as scrub, toothpaste soap, and bath and shower gel in 2015 due to their appearance in wastewater. Current processes used by Wastewater treatment plants are unable to filter out microbeads, which can be causing pollution when treated water is released into the environment (Fela 2014).

4 Primary Microplastics

Primary microplastics are defined as manufacturer-produced microplastic purposefully. Majority of the primary microplastics produced commercially often ends up in aquatic or marine bodies as an emerging pollutant. (Li et al. 2016). Even though the wastewater treatment plants are capable to reduce 99% of microplastic of effluent water, the microplastic still leak out into the environment due to their massive amount in the wastewater discharges (Li et al. 2016). A California wastewater treatment study found that one microfiber per liter was discarded into the Pacific Ocean (Browne et al. 2011). The fibers are thought to be from laundry (Li et al. 2016). The other type of primary microplastic is scrubbers, which are used in many cosmetic products (Li et al. 2016). Thus, there is no sufficient research on the effectiveness and occurrence of microplastic released into the natural environment through wastewater, but the adverse outcomes are emerging. It needs to minimize the pollution source through reducing the consumption and even establishing bans.

5 Microfibers

Despite some countries enacting legislation to limit or eradicate microbeads, another significant source of microplastic pollution takes the form of microfibers. A study that surveyed 18 shorelines worldwide found that 78% of polyester fibers and 22% of acrylic fibers originated from domestic washing machine discharges (Browne et al. 2011). The microfibers were found in sediments, macroinvertebrates, and shorebirds from wetlands along the Eastern Atlantic (Lourenco et al. 2017). The concentrations of microfiber were found to be higher around highly pressured with anthropogenic pressure (Lourenco et al. 2017). The pristine sites were also found to have relatively high microfiber concentration (Lourenco et al. 2017). This indicated the spreading ability in the ocean and caused wide area pollution. Developing legislation to manage this source is challenging without knowing the microfiber load or degree of environmental impact made by domestic wastewaters compared with effluents from the textile industry.

6 Secondary Microplastics

The secondary microplastic pollution has been found in terrestrial and aquatic environments. In the terrestrial environment, agroecosystems were polluted by the microplastic that was the breakdown of larger plastic debris, such as plastic mulch films and greenhouse materials and soil conditioners (e.g., polyurethane foam and polystyrene flakes) (Duis and Coors 2016; Koelmans et al. 2015; Rillig 2012). This may decrease agricultural food quality and increase food safety concerns. In aquatic environments, secondary microplastic (fragmentation of large plastics into micro-sized debris) is generated through physical, biological, and chemical processes that decrease the structural integrity of the polymer (Browne et al. 2007). As a newly emerging contaminant, detailed eco-toxicological knowledge is not available to evaluate their impacts on both the environment and human health, making it challenging to develop new legislation to manage plastic pollution issues. The uncertainties include the fate of microplastics, pollution sources, distribution, bioavailability, and toxicity to humans and other organisms. Additionally, knowledge gaps exist for both short- and long-term effects. The short-term effects of plastic pollution include direct impacts to the environment and biota following their release, while long-term or secondary effects are anticipated to result from the additive chemicals, such as the bioaccumulation of persistent organic pollutants (POPs) (Li et al. 2016). While some toxic substances like bisphenol A (BPA) have successfully been banned from use in food and beverage containers, additional case studies on plastic additives are necessary to help reduce the associated environmental and human health risks.

Risk assessments are an important tool for evaluating the risks associated with plastic pollution. Assessments should be wide in their scope, focusing on pollution, degradation products, additive, and mixed toxic effects. The results of assessment should conclude the comparison of plastic substance to develop a practical tool as a reference for the development of legislations and management plans.

7 Current Plastic Litter Legislation

Globally, the development of legislation has occurred over the last three decades to manage the risks and impacts of macroplastics and larger plastic debris. Plastic wastes are managed mostly depending on their size: micro-, medium-, or macroplastics. An early plastic-related policy was implemented in Germany in 1991 with the aim to reduce plastic bag consumption.

Firstly, levies (a fee for using or dispensing) and bans have been a successful strategy to control plastic pollution at regional levels. Reduction in the use of low-density polyethylene (LDPE) bags is one of the key achievements of this strategy. In 2002, Bangladesh implemented a ban on LDPE bags, with a further 65 countries following their lead (Mourshed et al. 2017). Recently, Kenya introduced a 38,000 USD fine and punishment of up to 4 years in prison for the use, manufacture, and import of plastic bags (Rayne 2008). In Wales, it was the first country in the UK to implement 5 pence charges on single-use plastic bag (Poortinga et al. 2013).

The South African government implemented legislation concerning the use of disposable polythene shopping bags (Dikgang et al. 2012). This legislation placed a total ban on plastics < 30 μm thick, with bags > 30 μm attracting a levy in 2002. This strategy failed to reduce the demand for plastic bags, which the authors attributed to customers accepting to pay the low levy put in place, and eventually the steady increase in demand for plastic bags suggests that the plastic littering issue will persist on the litter stream in South Africa (Dikgang et al. 2012). Conversely, there are many cases worldwide demonstrating success in implementing bans (Supplementary Table 1). The supermarkets in Switzerland, Germany, Sweden, Norway, Netherlands, and Spain charge customers for the use of plastic bags (Luis and Spinola 2010). In Portugal, a plastic bag tax was implemented since 2015 and consequently reduced 74% of consumption (Martinho et al. 2017). The general public approved the implementation of plastic bag tax, and hypermarkets and supermarkets provided alternatives of reusable plastic bags which brought the success in managing plastic bag consumption (Martinho et al. 2017). This comparison indicates the success of Germany’s plastic bag legislation to manage consumers’ behavior. Ireland introduced a levy in 2002 which reduced the consumption of plastic bags by more than 90%, resulting in a decrease in both littering and adverse landscape effects (Convery et al. 2007). There were two positive outcomes of the levy implementation, firstly, improved consumer behavior, and secondly, the acceptance of the charges by stakeholders and consumers allowing the levy to be implemented (Convery et al. 2007).

Apart from implementing levies, taxes, and bans, another strategy used to manage plastic litter is voluntary campaigns, which have been successful in certain places to reduce consumption of plastic carrier bags (Supplementary Table 2). For instance, 37% of supermarkets in Portugal voluntarily abolished the distribution of free plastic bags. Meanwhile, alongside an applied levy of 0.02 euro from “2007 – 2009,” these methods demonstrated that a potential of 64% reduction in use could be achieved (Luis and Spinola 2010). This voluntary levy changed customers’ shopping behaviors, as 52% of clients that pay for plastic bags use them until they are almost full; however, only 17% of clients do the same when the plastic bags are given for free (Luis and Spinola 2010). Australian retailers adopted a voluntary approach to reduce plastic bags in October 2003 (Australian Retailers Associations 2004). A Code of Practice for the Management of Plastic Bags was agreed between the Australian Retailers Association (ARA) and the Environment Protection and Heritage Council (EPHC) (Australian Retailers Associations 2004). The Code required supermarkets and non-supermarkets to participate, by setting out targets that aim to reduce and recycle plastic bags by the end of 2005 (Australian Retailers Associations 2005). The ARA Code of Practice final report indicated that the supermarkets participating in the initiative achieved a 26.9% reduction; moreover, a reduction was shown in participating non-supermarkets too (Australian Retailers Associations 2004; Australian Retailers Associations 2005). Retailers in Germany, Portugal, Hungary, and the Netherlands charge fees on single-use plastic carrier bags (Ayalon et al. 2009; European Commission 2013). In the UK, the town of Modbury implemented an initiative to ban plastic bags. Other towns have followed with a similar initiative which resulted in a 48% reduction of plastic bag consumption in 2009 (Ayalon et al. 2009). Smaller businesses can voluntarily charge levy which encourages customers to use reusable carrier bags to reduce the consumption of single-use carrier bags (Xanthos and Walker 2017).

One way to reduce plastic pollution is to decrease the consumption of plastics. Recycling of the plastic materials is another avenue. Recycling plastic materials back to the market could utilize the plastic resources and prolong their lifespans. The plastic wastes could be converted into recovered plastic materials for manufacturing new products. (Hopewell et al. 2009). Plastic waste is classified as organic material which can be expanded to generate energy, where the calorific value of the waste is optimized by combustion (Hopewell et al. 2009). Life cycle assessment (LCA) indicates that replacing new virgin polymer by recycled plastic polymer can reduce oil consumption and emissions of greenhouses gasses directly (Hopewell et al. 2009).

European countries have implemented an effective plastic waste management (Jambeck et al. 2015) (Fig. 2). The European Association of Plastics Recycling and Recovery Organizations (EPRO) stated that 40% of plastic products on the market are items used for packaging, forming 62% of the overall plastic waste mass and 81% of recycled plastics (Waste + Water Management Australia 2015). The plastic recycling schemes in Europe successfully increased the recycling rate from 34.7 to 39.5% within a 2-year period (2012–2014) (Waste + Water Management Australia 2015). This successful recycling was evident as every member country met the national targets through the implemented law or covenant (Waste + Water Management Australia 2015). In Australia during 2009 and 2010, the major sources of plastic waste were mainly packaging (37%), building (26%), furniture, houseware, leisure, and clothing (10%) (Brulliard et al. 2012). Among these plastic wastes, the major plastic types are polyethylene terephthalate (PET), high-density polyethylene (HDPE), low-density polyethylene, and polypropylene (PP) (Brulliard et al. 2012). Polystyrene was recycled at a significant recovery rate, but was produced in lesser quantities (Brulliard et al. 2012). From 2008 to 2009, nearly 1.8 million tonnes of plastic waste was generated and only about 287,600 t of plastic waste was recycled (a 16% recycling rate) (Brulliard et al. 2012). PET, HDPE, LDPE, and PP contributed more than 85% of reprocessed plastic wastes in Australia (Brulliard et al. 2012).

Global distribution of produced and mismanaged plastic waste (modified from Pravettoni 2018)

The reprocessing of plastic waste reduces the amount of plastic waste being sent to landfill, and is determined by its chemical properties (Kutz 2011). Plastic products are constituted of different types of blended plastic, making the reprocessing of plastics a complex process (Kutz 2011). The recycled plastic wastes can be reprocessed into high-quality “food grade” plastics as well as structural and hard plastics (Kutz 2011). In 2008, it was estimated that approximately 40% of plastic waste was exported for reprocessing from Victoria and 23% from South Australia (Sustainability Victoria 2010; Brulliard et al. 2012). The exported plastic market for reprocessing is mainly China (Brulliard et al. 2012). It has been growing since 2008, with Chinese buyers decreasing their plastic waste quality requirement (Brulliard et al. 2012).

Moreover, energy recovery is another way to utilize plastic waste, by transforming it into energy (Waste + Water Management Australia 2015), and thereby reducing the volume of plastic litter going to landfill (Hopewell et al. 2009). The conversion may bring negative impacts to the environment, such as emission of air pollutants including CO2, NOx, and SOx, generation of VOCs, smoke, heavy metals, etc. (Zhou et al. 2015). Contrarily, there are some advantages brought by the energy recovery. Pyrolysis of plastic waste is the process of converting plastic into liquid fuel (Sharuddin et al. 2017). The obtained liquid fuel has high calorific value around 40 MJ/Kg and with the existence of a catalyst, the impurities and water content in the plastic waste could be eliminated (Sharuddin et al. 2017). Australian plastic waste data showed nearly 80% of plastic packaging waste was recovered for transformation into energy in 2014 (Waste + Water Management Australia 2015). European countries recovered more than 50% of their plastic waste into energy in 2014, and combined simultaneously with the regular recycling rate, more than 90% pf plastic waste was recovered (Waste + Water Management Australia 2015). This indicates less than 10% of plastic wastes ended up in landfill which gradually reduced the environmental impacts of plastic waste. Although energy recovery from plastic waste cannot reduce global fossil fuel demand (Hopewell et al. 2009), the utilization of plastic materials through energy recovery can prolong plastic material lifespan or even convert it into energy in the form of different products. It also provides environmental sustainability measures, by reducing the environmental impacts brought by plastic wastes to landfill and burning fossil fuels.

8 Current Microplastic Legislation

Microplastics pose a threat to the marine environment and potentially to human health (Browne et al. 2007; Browne et al. 2011; Van Cauwenberghe and Janssen 2014). Research shows that marine organisms cannot distinguish between food and plastic particles; therefore, the uptake of microplastics via filtration and ingestion can result in impacts on the food chain (Cole et al. 2011; Wright et al. 2013, b). For example, the commercially important blue mussel (Mytilus edulis) was shown to be contaminated with microplastics, which has implications for human health via dietary exposure (von Moos et al. 2012; Van Cauwenberghe and Janssen 2014). The United Nations Environment Program stated that the amount of microbeads in a typical exfoliating gel could be equal to the amount of plastic materials used to produce the packaging, at 137,000–2,800,000 microbeads per bottle (Napper et al. 2015; Beat the Microbead 2018).

In Australia, industry and government have begun to take action to reduce the impacts of microbeads on the marine environment (NSW EPA 2016). Microbeads were found present in over 100 personal care products on the market (NSW EPA 2016). The presence of microbeads in cosmetic products has prompted the enactment of legislation to reduce the production and consumption of plastic materials, thereby reducing any adverse impacts to the environment and potential human health risks. Recently, the US Federal Government brought in the Microbead-Free Water Act 2015, which aims to prohibit the manufacture and sale of microbeads in cosmetic products from July, 2018. The Canadian parliament passed legislation to prohibit the manufacture of microbeads in June, 2017. The Australian Microplastics Working Group was established to seek voluntary agreement from industry to phase out microbeads in personal care, cosmetic, and cleaning products (Council of the European Union 2014; Legislative Assembly of Ontario 2015; NSW EPA 2016).

Comprehensive legislation to limit the inclusion of microplastics in cosmetics are operational in the USA, Canada, and the UK (Xanthos and Walker 2017) (Supplementary Table 3). Examples from different nations demonstrate both success and failures, which can be used to implement future policies more effectively. As the microplastics legislation has only recently been employed, there is a lack of environmental data or relevant quantitative information to state the outcomes. However, some qualitative data such as public and political actions have been undertaken to stop using microbead-related cosmetic products. On the other hand, some NGOs, such as Greenpeace, the World Wildlife Fund, and World Conservation Union have been playing influential actors within public community governance, particularly in marine litters within their oceans activities (Vince and Hardesty 2016). The other NGO parties acted more on issue-specific strategy, such as an organization called Beat the Microbead was developed and reported which products may contain microbeads and is accessible through their website or phone application (Vince and Hardesty 2016). Different NGO organizations targeted different groups, set different aims, and implement different strategies in order to tackle various aspects of marine litter issues (Vince and Hardesty 2016). There was positive impact brought by the NGOs and resulted in significant change to government regulations and policies, such as microbead bans have been implemented in many countries (Vince and Hardesty 2016).

Microfibers are another form of microplastics which could be a major pollution source emitted from plastic and textile factories or laundry wastewater from domestic origins (De Falco et al. 2018). Microfibers emerge from wastewater contaminated by synthetic fibers from washing clothes (De Falco et al. 2018). The number of microfibers released from 5-kg loads of synthetic fiber clothing could reach over 6 million microfibers, depending on the type of detergent used (De Falco et al. 2018). The powder type detergent contains inorganic compounds insoluble in water, such as zeolite, that potentially increase friction with fibers, and hence increase the amount of microfibers released into wastewater (De Falco et al. 2018) Moreover, the pH property of the detergent is related to the amount of microfibers released, as alkaline-based detergents can induce chemical damage on polyester fabrics through slow surface hydrolysis (Bishop 1995; De Falco et al. 2018). A study by De Falco et al. (2018) found that among woven polyester, knitted polyester, and woven polypropylene, the highest amount of microfibers leached out are woven polyester due to its fabric characteristics. The length of the fibers that compose the yarn is critical in determining the amount of microfibers released during the washing process (De Falco et al. 2018). The usage of softener could reduce 35% of microfiber release during laundering processes, due to its ability to decrease the friction between fibers (De Falco et al. 2018). From this research, policy could be established based on the microfiber generation mechanisms and the fibric types and detergents involved, such as encouraging the usage of longer length of fibric yarn, and use of liquid detergent rather than powder form. A tax could apply for fibric materials with shorter lengths of yarns, and for detergents which generate the release of more microfibers. These measured could effectively reduce the origins of pollution.

9 Mechanisms for Implementing Legislation on Plastics

It is necessary to implement legislation which limits or bans certain types of plastics from both producer and consumer use. There is no specific strategy for international plastic legislation and plastic waste management. Generally, there are two current plastic management approaches which aim to reuse plastic materials and reduce sending plastic waste to landfill. These two approaches work independently without any interactions with each other. Here, we propose a closed-loop, conventional approach in managing plastic materials. It combines three isolated current plastic management strategies into a conventionally/circular connected strategy (Fig. 3.). This approach requires cooperation at all levels of society, from governments and plastic manufacturers, to industry consumers and individual consumers, waste management organizations, and researchers (Worm et al. 2017). This national cooperation must first be exhibited as an integration of efforts at the national level, before extending to a global scale. In order to achieve better cooperation at the global level, an institutional setting needs to be devised with a multilateral agency or initiative, to integrate national efforts and promote the global policy agenda. This could be the United Nations Clean Seas Campaign (United Nations (UN) News Centre 2017) that has strongly advocated for the implementation of plastic reduction policies, encouraged industry to minimize plastic packaging and redesign products, and urged consumers to change behaviors with regard to disposable plastic products. For example, the campaign suggested a ban on microbeads and single-use carrier bags. (United Nations (UN) News Centre 2017).

When plastic waste is generated by producers and consumers, it should be recycled or transformed in a way which would minimize any adverse environmental impacts. If the plastic waste ends up in landfill or the ocean, then environmental risk/impact assessments need to be implemented to evaluate the environmental impacts and potential human health risks. These risk assessments will be used to evaluate current plastic legislation, and to develop new plastic legislation concerning single-use cutlery, plastic resin pellets, and microplastics (Fig. 3 and Table 3).

This generalized conventional plastic waste management model includes recycling and the production of clean energy from plastic waste. It aims to recycle plastic and extend their lifespan by converting them into other plastic products that return to the market. Two alternative recycling methods exist: physical recycling and feedstock recycling (Brems et al. 2012). Physical recycling reprocesses plastic waste into new products, generally of lesser quality, whereas feedstock recycling transforms plastic waste into their constituent monomers, or a hydrocarbon feedstock and crude oil (Brems et al. 2012). Energy recovery aims to be eco-friendly by turning plastic into energy resources which provide alternative options to fossil fuels. Plastic-containing waste could be transferred into clean energy production via the process of dehalogenation, followed by thermochemical conversion (Shen et al. 2016). The suggested conventional plastic waste management could gradually decrease the environmental impacts, while increasing the efficiency of plastic consumption by turning them into clean energy. Hence, conventional plastic legislation should be responsible for setting targets on increasing overall recovery percentage through recycling and energy recovery.

The EU Plastic Strategy (EuPC) suggested a new, conventional and circular business model (Messenger 2017). The model compiled four key measures to utilize and prolong the lifespan of plastic products, from production to end of life (Messenger 2017). The four key measures include the improvement of the economics and quality of recycled plastics, the reduction of plastic waste volumes, the increase in innovation and investment in plastic materials, and the promotion of initiatives on plastics at the global level (Anon 2018). The EuPC’s model aims to ensure that all of the plastic packaging will be either reusable or recyclable on the market in a cost-effective manner by 2030 (Anon 2018). The intended outcome is to provide a prosperous, sustainable, and circular plastics economy within European countries (Anon 2018).

10 Challenges and Future Directions for Plastic Policies

The existing legislation and initiatives on plastics discussed in the above sections illustrate how management of plastic wastes still need to be improved and extended to cover the different types of plastic products. Similar strategies have been used by different countries to handle different varieties of plastics. For macroplastics and microplastics (including the microbead), waste management has reduced the amount of plastic waste generated, due to the implementation of plastic legislation (Beat the Microbead 2018; European Commission 2013). Voluntary commitments and their success in achieving the targets are limited by external factors. Similarly, the success of recycling will depend on how profitable it is. Legislation can be a driving factor that influences voluntary commitments and enables better outcomes in recycling. Despite progress made in terms of legislation and voluntary initiatives on plastics, there are still challenges in the implementation of legislation. The future directions for the effective management of plastics require focusing on three aspects: that is the producer, the consumer, and the government.

Producers need to take responsibility for the adverse impacts of plastic products to the environment and human health. They have to ensure the plastic products comply with safety standards, such as the AS/NZS 2070 Australian Standard for food-grade plastic products. This could include the reduction of harmful substances and waste, the prevention of plastic pellet loss, the reuse and recycling of plastic products, and transparency about ingredients and production processes (GESAMP 2015). A report published in cooperation with Polymer Comply Europe Sarl assessed the current and future usage of recycled plastic materials (rPM) in the European plastic conversion organizations (Messenger 2017). It concluded that nearly 60% of the European plastic converting companies claimed that it was a challenge for them to get supply of rPM in an acceptable quality (Messenger 2017). Only 27% of customers of European plastic converting companies were aware of the benefits and needs to choose rPM, which indicated rPM did not get enough support from the customers (Messenger 2017). About 60% of European plastic converting companies stated that the current EU regulations were not suitable to support rPM in the future. This implies that the regulatory framework needs to be adapted to adequately support the use of rPM (Messenger 2017). Furthermore, the plastic processors require large quantities of recycled plastics and strict specification in manufacturing plastic products (Nkwachukwu et al. 2013); consequently, their production budgets may be more expensive than plastic products produced by virgin plastic. Price may be an important factor for a plastic company to choose between virgin plastic and recycled plastic materials for the manufacturing of their products. Moreover, not all of the plastic can be recycled; there are four types of plastics commonly recycled which included low-density and high-density polyethylene (LDPE and HDPE), plypropylene, polystyrene, and polyvinyl chloride (Nkwachukwu et al. 2013). There is another challenge in the recycling of plastic, which is the level of purity of the plastic (Nkwachukwu et al. 2013). Plastics are manufactured by more than one type of polymer or may be infused with an additive to increase the strength. This means it could be complicated to extract desired plastic materials (Nkwachukwu et al. 2013). Moreover, the development of sustainable alternative plastic materials such as biodegradable plastic (BDP) and bioplastic (BP) products which could be less harmful and less persistent in the environment could minimize the current issues of using common plastic materials. The BDP is constituted of polyhydroxyalkanoate (PHA) which is similar to conventional plastics (petroleum-based plastic) in all properties with additional advantages, such as being able to naturally decompose and break into natural and safe byproducts (Koushal et al. 2014; Song et al. 2009). The BDP could decompose through biological process and reduce the total quantities of plastic waste to landfill (Song et al. 2009). Additionally, the composts of BDP can contribute to improve soil quality functions and provide additional ecological services (Song et al. 2009).

Further development on recycling of the BDP and BP could benefit the management of fossil-based convention plastics. BP is made from polymers derived from sugar cane, potato starch, cellulose from trees, straw and cotton, and other biological resources but not crude oil (Koushal et al. 2014). BP degrades in the air and industrial composting plant aided by bacteria, fungi, and enzymes (Koushal et al. 2014). The development of policy to encourage the use of bioplastics as an alternative to conventional plastic is recommended in order to minimize the environmental impacts and health risks of plastic use. If widely accepted, it could gradually reduce the present environmental impacts and human health risks by decomposing along with food and other non-recyclable materials in the natural environment in a less toxic way (Siotto et al. 2011).

The consumer sector contains a wide array of parties, such as the general public, fishing industries, and commercial salespeople, etc. (Worm et al. 2017). Although there are different types of consumers and their consumption vary, they all need to follow, reduce, recycle, and reuse (3Rs). This strategy aims to reduce plastic generation and inputs into landfill or marine environment (GESAMP 2015; Worm et al. 2017). For instance, choosing replacements for alternative products which are reusable rather than single-use plastic could gradually reduce the amount of waste generated. Consumers play a major role in the generation of plastic waste. Responsible waste handling is the social awareness and behavior to accomplish an effective recycling scheme. The willingness to participate in plastic pollution, cleanups, and boycotts against emerging plastic issues (such as microbead-containing cosmetic products) could substantially increase the efficiency of plastic waste management (Thevenon et al. 2014; Worm et al. 2017).

Governments should reclassify plastic materials into different classes. This reclassification needs to be based on the evidence of impacts of plastics on the environment and human health, and could be used to establish a new international convention to trace and manage problematic plastic pollution (Worm et al. 2017). The plastic materials should also be classified as priority hazardous substances like other priority pollutants, as defined under the US Clean Water Act (Rochman et al. 2013; Worm et al. 2017). These priority pollutants are used in establishing water quality standards and effluent limitations, particularly for wastewater. Consistent analyzing protocols and discharge limits should be determined (Worm et al. 2017). Ongoing monitoring and reporting is necessary to measure the environmental outcomes following the lag time between announcing legislation and the implementation date. This could be used to project the future plastic waste generation rate and revise the legislative strategy in order to increase feasibility of plastic material management. Furthermore, international monitoring efforts to gather and synthesize data would improve management practices by providing a solid foundation for introducing legislation surrounding plastic waste. A declaration of ingredients in plastics, including any additives they contain, could warn consumers about potential adverse impacts to their health and the environment (Worm et al. 2017). Legislation should form part of a compulsory policy framework on a national scale. It can also provide information for researchers to study their eco-toxicity effects on the environment, and more importantly, the human health risks carried by the products. In addition, this could improve waste management practices and avoid buildup of plastic waste in the environment.

References

Andrady, A. L. (2011). Microplastics in the marine environment. Marine Pollution Bulletin, 62, 1596–1605.

Anon. (2018). EU: plastics strategy will hinge on public concern (p. 1). Oxford: Analytica Daily Brief Service.

Arthur, C., Baker, J., Bamford, H., (2009). In Proceedings of the International Research Workshop on the occurrence, effects and fate of microplastic marine debris. NOAA technical memorandum NOS- OR & R-30.NOAA, silver spring, September 9-11, 2008, 530.

Australian Retailers Associations (2004). ARA code of practice for the management of plastic bags 2004 end of year report. Australian Retailers Associations. Available from: http://www.nepc.gov.au/system/files/resources/0c513e54-d968-ac04-758b-3b7613af0d07/files/ps-pbag-rpt-ara-cop-endofyear-200412.pdf. Accessed 5 Jan 2018.

Australian Retailers Associations (2005). Australian Retailers association Code of Practice for the Management of Plastic Bags Final Report December 2005. Australian Retailers Associations. Available from: http://www.nepc.gov.au/system/files/resources/0c513e54-d968-ac04-758b-3b7613af0d07/files/ps-pbag-rpt-ara-cop-endofyear-200512.pdf. Accessed 5 Jan 2018.

Ayalon, O., Goldrath, T., Rosenthal, G., & Grossman, M. (2009). Reduction of plastic carrier bag use: an analysis of alternatives in Israel. Waste Management, 29, 2025–2032. https://doi.org/10.1016/j.wasman.2009.02.016.

Barnes, D. K. A., Galgani, F., Thompson, R. C., & Barlaz, M. (2009). Accumulation and fragmentation of plastic debris in global environments. Philosophical Transactions of the Royal Society B: Biological Sciences, 364, 1985–1998.

Beat the Microbead. (2018). Results so far. Beat the Microbead. http://www.beatthemicrobead.org/results-so-far/. Accessed 15 Jan 2018.

Bishop, D. (1995). Physical and chemical effects of domestic laundering processes. In C. M. Carr (Ed.), Chemistry of the textiles industry (pp. 125–172). New York: Springer.

Brems, A., Baeyens, J., & Dewil, R. (2012). Recycling and recovery of post-consumer plastic solid waste in a European context. Thermal Science, 16, 669–685.

Browne, M. A., Crump, P., Niven, S. J., Teuten, E., Tonkin, A., Galloway, T., & Thompson, R. (2011). Accumulation of microplastic on shorelines woldwide: sources and sinks. Environmental Science and Technology, 45, 9175–9179. https://doi.org/10.1021/es201811s.

Browne, M. A., Dissanayake, A., Galloway, T. S., Lowe, D. M., & Thompson, R. C. (2008). Ingested microscopic plastic translocates to the circulatory system of the mussel, Mytilus edulis (L.). Environmental Science and Technology, 42, 5026–5031.

Browne, M. A., Galloway, T., & Thompson, R. (2007). Microplastic—an emerging contaminant of potential concern? Integrated Environmental Assessment and Management, 3, 559–561. https://doi.org/10.1002/ieam.5630030412.

Brulliard, C., Cain, R., Do, D., Dornom, T., Evans, K., Lim, B., Olesson, E., & Young, S. (2012). Netbalance tomorrow’s agenda. Report No.: MMPJ11DWH048, Department of Sustainability, Environment, Water, Population and Communities (DSEWPaC) The Australian recycling sector.

Chanda, M., & Roy, S. K. (2006). Plastics technology handbook, fourth edition. Baton Rouge: CRC Press.

Cole, M., Lindeque, P., Fileman, E., Halsband, C., & Galloway, T. S. (2015). The impact of polystyrene microplastics on feeding, function and fecundity in the marine copepod Calanus helgolandicus. Environmental Science and Technology, 49, 1130–1137. https://doi.org/10.1021/es504525u.

Cole, M., Lindeque, P., Fileman, E., Halsband, C., Goodhead, R., Moger, J., & Galloway, T. S. (2013). Microplastic ingestion by zooplankton. Environmental Science and Technology, 47, 6646–6655.

Cole, M., Lindeque, P., Halsband, C., & Galloway, T. S. (2011). Microplastics as contaminants in the marine environment: a review. Marine Pollution Bulletin, 62, 2588–2597. https://doi.org/10.1016/j.marpolbul.2011.09.025.

Convery, F., McDonnell, S., & Ferreira, S. (2007). The most popular tax in Europe? Lessons from the Irish plastic bags levy. Environmental and Resource Economics, 38, 1–11. https://doi.org/10.1007/s10640-006-9059-2.

Council of the European Union (2014). Elimination of microplastics in products—an urgent need. Information from the Belgian, Dutch, Austrian and Swedish Delegations. No. 16263/14 of 3 December 2014 on Environment Council meeting. Council of the European Union. http://register.consilium.europa.eu/doc/srv?l=EN&f=ST%2016263%202014%20INIT. Accessed 17 Jan 2018.

De Falco, F., Gullo, M. P., Gentile, G., Di Pace, E., Cocca, M., Gelabert, L., Brouta-Agnesa, M., Rovira, A., Escudero, R., Villalba, R., Mossotti, R., Montarsolo, A., Gavignano, S., Tonin, C., & Avella, M. (2018). Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environmental Pollution, 236, 916–925. https://doi.org/10.1016/j.envpol.2017.10.057.

DeMatteo, R., Keith, M. M., Brophy, J. T., Wordsworth, A., Watterson, A. E., Beck, M., Ford, A. R., Gilbertson, M., Pharityal, J., Rootham, M., & Scott, D. N. (2012). Chemical exposures of women workers in the plastics industry with particular reference to breast cancer and reproductive hazards. New Solution, 22, 427–448. Environmental and Resource Economics. https://doi.org/10.2190/NS.22.4.

Derraik, J. G. B. (2002). The pollution of the marine environment by plastic debris: a review. Marine Pollution Bulletin, 44, 842–852. https://doi.org/10.1016/S0025-326X(02)00220-5.

Dikgang, J., Leiman, A., & Visser, M. (2012). Analysis of the plastic-bag levy in South Africa. Resources. Conservation and Recycling, 66, 59–65. https://doi.org/10.1016/j.resconrec.2012.06.009.

Duis, K., & Coors, A. (2016). Microplastics in the aquatic and terrestrial environment: sources (with a specific focus on personal care products), fate and effects. Environmental Science Europe, 28. https://doi.org/10.1186/s12302-015-0069-y.

European Commission (2013). Impact assessment for a proposal for a directive of the European Parliament and of the Council amending Directive 94/62/EC on packaging and packaging waste to reduce the consumption of lightweight plastic carrier bags. No. L 115/11. European Commission.

Fela, J. (2014). Dutch lead EU in microbead ban. Frontiers in Ecology and the Environment, 12(10), 541.

Gall, S. C., & Thompson, R. C. (2015). The impact of debris on marine life. Marine Pollution Bulletin, 92, 170–179. https://doi.org/10.1016/j.marpolbul.2014.12.041.

GESAMP (2015). Sources, fate and effects of microplastics in the marine environment: a global assessment. No. IMO/FAO/UNESCO-IOC/UNIDO/WMO/IAEA/UN/UNEP/UNDP. Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection.

Gewert, B., Plassmann, M. M., & MacLeod, M. (2015). Pathways for degradation of plastic polymers floating in the marine environment. Environmental Science: Processes & Impacts, 17, 1513–1521.

Geyer, R., Jambeck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advance, 3. https://doi.org/10.1126/sciadv.1700782.

Graham, E. R., & Thompson, J. T. (2009). Deposit- and suspension-feeding sea cucumbers (Echinodermata) ingest plastic fragments. Journal of Experimental Marine Biology and Ecology, 368, 22–29.

Green, D. S. (2016). Effects of microplastics on European flat oysters, Ostrea edulis and their associated benthic communities. Environmental Pollution, 216, 95–103.

Green, D. S., Boots, B., Sigwart, J., Jiang, S., & Rocha, C. (2016). Effects of conventional and biodegradable microplastics on a marine ecosystem engineer (Arenicola marina) and sediment nutrient cycling. Environmental Pollution, 208, 426–434.

Gurman, J. L., Baier, L., & Levin, B. C. (2018). Polystyrenes: a review of the literature on the products of thermal decomposition and toxicity. Fire and Materials, 11, 109–130.

Hall, N. M., Berry, K. L. E., Rintoul, L., & Hoogenboom, M. O. (2015). Microplastic ingestion by scleractinian corals. Marine Biology, 162, 725–732.

Hämer, J., Gutow, L., Köhler, A., & Saborowski, R. (2014). Fate of microplastics in the marine isopod idotea emarginata. Environmental Science and Technology, 48, 13451–13458.

Helal, S. F., & Elshafy, W. S. (2013). Health hazards among workers in plastic industry. Toxicology and Industrial Health, 29, 812–819.

Hopewell, J., Dvorak, R., & Kosior, E. (2009). Plastics recycling: challenges and opportunities. Philosophical Transactions of the Royal Society B, 364, 2115–2126. https://doi.org/10.1098/rstb.2008.0311.

Jambeck, J. R., Geyer, R., Wilcox, C., Siegler, T. R., Perryman, M., Andrady, A., Narayan, R., & Law, K. L. (2015). Plastic waste inputs from land into the ocean. Science, 347, 768–771. https://doi.org/10.1126/science.1260352.

Jones, P. H., Prasad, D., Heskins, M., Morgan, M. H., & Guillet, J. E. (1974). Biodegradability of photodegraded polymers. I. Development of experimental procedures. Environmental Science and Technology, 8, 919–923.

Kaposi, K. L., Mos, B., Kelaher, B. P., & Dworjanyn, S. A. (2014). Ingestion of microplastic has limited impact on a marine larva. Environmental Science and Technology, 48, 1638–1645.

Koelmans, A. A., Besseling, E., & Foekema, E. M. (2014). Leaching of plastic additives to marine organisms. Environmental Pollution, 187, 49–54. https://doi.org/10.1016/j.envpol.2013.12.013.

Koelmans, A. A., Besseling, E., & Shim, W. J. (2015). Nanoplastics in the aquatic environment. In M. Bergmann, L. Gutow, & M. Klages (Eds.), Critical review BT—marine anthropogenic litter (pp. 325–340). Cham: Springer International Publishing. https://doi.org/10.1007/978-3-319-16510-3_12.

Koushal, V., Sharma, R., Sharma, M., Sharma, R., & Sharma, V. (2014). Plastics: issues challenges and remediation. International Journal of Waste Resources, 04, 134. https://doi.org/10.4172/2252-5211.1000134.

Kutz, M. (2011). Applied plastics engineering handbook: processing and materials. Oxford, UK: Elsevier. Legislative Assembly of Ontario, 2015. Bill 75, Microbead Elimination and Monitoring Act, 2015.

Legislative Assembly of Ontario (2015). Bill 75, Microbead Elimination and Monitoring Act, 2015.

Li, W. C., Tse, H. F., & Fok, L. (2016). Plastic waste in the marine environment: a review of sources, occurrence and effects. Science of the Total Environment, 566, 333–349. https://doi.org/10.1016/j.scitotenv.2016.05.084.

Lithner, D., Larsson, A., & Dave, G. (2011). Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Science of the Total Environment, 409, 3309–3324. https://doi.org/10.1016/j.scitotenv.2011.04.038.

Lourenco, P. M., Serra-Goncalves, C., Ferreira, J. L., Catry, T., & Granadeiro, J. P. (2017). Plastic and other microfibers in sediments, macroinvertebrates and shorebirds from three intertidal wetlands of southern Europe and West Africa. Environmental Pollution, 231, 123–133.

Loyo-Rosales, J. E., Rosales-Rivera, G. C., Lynch, A. M., Rice, C. P., & Torrents, A. (2004). Migration of nonylphenol from plastic containers to water and a milk surrogate. Journal of Agricultural and Food Chemistry, 52, 2016–2020.

Luis, I. P., & Spinola, H. (2010). The influence of a voluntary fee in the consumption of plastic bags on supermarkets from Madeira Island (Portugal). Journal of Environmental Planning and Management, 53, 883–889. https://doi.org/10.1080/09640568.2010.490054.

Lusher A, Hollman PCH, Mendoza-Hill JJ. (2017). Microplastics in fisheries and aquaculture—status of knowledge on their occurrence and implications for aquatic organisms and food safety. Italy: Food and Agriculture Organization of the United Nations (FAO). Report No.: No.615. http://www.fao.org/3/a-i7677e.pdf. Accessed 14 Jan 2018.

Martinho, G., Balaia, N., & Pires, A. (2017). The Portuguese plastic carrier bag tax: the effects on consumers ‘behavior’. Waste Manage, 61, 3–12.

Messenger, B. (2017). EuPC survey on the use of recycled plastics materials. Waste Management World, 25 Oct. https://waste-management-world.com/a/eupc-survey-on-the-use-of-recycled-plastics-materials. Accessed 17 Jan 2018.

Mor, R., & Sivan, A. (2008). Biofilm formation and partial biodegradation of polystyrene by the actinomycete Rhodococcus ruber. Biodegradation, 19, 851–858.

Mourshed, M., Masud, M. H., Rashid, F., & Joardder, M. U. H. (2017). Towards the effective plastic waste management in Bangladesh: a review. Environmental Science and Pollution Research, 24, 27021–27046. https://doi.org/10.1007/s11356-017-0429-9.

Nakajima-Kambe, T., Shigeno-Akutsu, Y., Nomura, N., Onuma, F., & Nakahara, T. (1999). Microbial degradation of polyurethane, polyester polyurethanes and polyether polyurethanes. Applied Microbiology and Biotechnology, 51, 134–140.

Napper, I. E., Bakir, A., Rowland, S. J., & Thompson, R. C. (2015). Characterisation, quantity and sorptive properties of microplastics extracted from cosmetics. Marine Pollution Bulletin, 99, 178–185. https://doi.org/10.1016/j.marpolbul.2015.07.029.

Nicholson, J. (2006). The chemistry of polymers, The Royal Society of Chemistry, i-178 pp.

Nkwachukwu, O. I., Chima, C. H., Ikenna, A. O., & Albert, L. (2013). Focus on potential environmental issues on plastic world towards a sustainable plastic recycling in developing countries. International Journal of Industrial Chemistry, 4. https://doi.org/10.1186/2228-5547-4-34

Nobre, C. R., Santana, M. F. M., Maluf, A., Cortez, F. S., Cesar, A., Pereira, C. D. S., & Turra, A. (2015). Assessment of microplastic toxicity to embryonic development of the sea urchin Lytechinus variegatus (Echinodermata: Echinoidea). Marine Pollution Bulletin, 92, 99–104.

Noone, K. J., Sumaila, U. R., & Diaz, R. J. (2013). Managing ocean environments in a changing climate: sustainability and economic perspectives. Burlington: Elsevier.

NSW EPA (2016). Plastic microbeads in products and the environment. Environment Protection Authority.

OSPAR (2017). Beach litter—abundance, composition and trends. OSPAR Intermediate Assessment 2017. https://oap.ospar.org/en/ospar-assessments/intermediate-assessment-2017/pressures-human-activities/marine-litter/beach-litter/. Assessed 15 April 2018.

PlasticEurope. (2017). Plastics Europe Operation Clean Sweep Report. 2017: Plastics Europe. Association of Plastics Manufacturers. PlasticEurope. https://www.plasticseurope.org/en/newsroom/press-releases/plasticseurope-presents-operation-clean-sweepr-report-pellet-containment-european-plastics-industry-reinforces-its-commitment-fi. Accessed 25 January 2018.

PlasticsEurope (2008). The compelling facts about plastics: an analysis of plastic production, demand and recovery for 2006 in Europe (PlasticsEurope, 2006). PlasticEurope. https://www.plasticseurope.org/application/files/2815/1689/9283/2006compelling_fact_PubJan2008.pdf. Accessed 25 Jan 2018.

PlasticsEurope (2016). Plastics—the facts 2016: an analysis of European plastics production, demand and waste data (PlasticsEurope, 2016). PlasticEurope. https://www.plasticseurope.org/application/files/4315/1310/4805/plastic-the-fact-2016.pdf. Accessed 25 Jan 2018.

Poortinga, W., Whitmarsh, L., & Suffolk, C. (2013). The introduction of a single-use carrier bag charge in Wales: attitude change and behavioural spillover effects. Journal of Environmental Psychology, 36, 240–247.

Pravettoni, R. (2018). Plastic waste produced and mismanaged. Grid Arendal. http://www.grida.no/resources/6931. Assessment 15 April 2018.

Rayne, S. (2008). The need for reducing plastic shopping bag use and disposal in Africa. African Journal of Environmental Science and Technology, 3(3).

Rillig, M. C. (2012). Microplastic in terrestrial ecosystems and the soil? Environmental Science and Technology, 46, 6453–6454. https://doi.org/10.1021/es302011r.

Rochman, C. M., Browne, M. A., Halpern, B. S., Hentschel, B. T., Hoh, E., Karapanagioti, H. K., Rios-Mendoza, L. M., Takada, H., Teh, S., & Thompson, R. C. (2013). Classify plastic waste as hazardous. Nature, 494, 169–171. https://doi.org/10.1038/494169a.

Setälä, O., Fleming-Lehtinen, V., & Lehtiniemi, M. (2014). Ingestion and transfer of microplastics in the planktonic food web. Environmental Pollution, 185, 77–83.

Setälä, O., Norkko, J., & Lehtiniemi, M. (2016). Feeding type affects microplastic ingestion in a coastal invertebrate community. Marine Pollution Bulletin, 102, 95–101.

Shah, A. A., Hasan, F., Hameed, A., & Ahmed, S. (2008). Biological degradation of plastics: a comprehensive review. Biotechnology Advances, 26, 246–265.

Sharuddin, S. D. A., Abnisa, F., Daud, W. M. A. W., & Aroua, M. K. (2017). Energy recovery from pyrolysis of plastic waste: study on non-recycled plastics (NRP) data as the real measure of plastic waste. Energy Conversion and Management, 148, 925–934.

Shen, Y. F., Zhao, R., Wang, J. F., Chen, X. M., Ge, X. L., & Chen, M. D. (2016). Waste-to-energy: dehalogenation of plastic-containing wastes. Waste Management, 49, 287–303. https://doi.org/10.1016/j.wasman.2015.12.024.

Singh, B., & Sharma, N. (2008). Mechanistic implications of plastic degradation. Polymer Degradation and Stability, 93, 561–584.

Siotto, M., Tosin, M., Innocenti, F., & Mezzanotte, V. (2011). Mineralization of monomeric components of biodegradable plastics in preconditioned and enriched sandy loam soil under laboratory conditions. Water Air and Soil Pollution, 221, 245–254.

Skarja, G. A., & Woodhouse, K. A. (2001). In vitro degradation and erosion of degradable, segmented polyurethanes containing an amino acid-based chain extender. Journal of Biomaterials Science, Polymer Edition, 12, 851–873.

Song, J. H., Murphy, R. J., Narayan, R., & Davies, G. B. H. (2009). Biodegradable and compostable alternatives to conventional plastics. Philosophical Transactions of the Royal Society B, 364, 2127–2139. https://doi.org/10.1098/rstb.2008.0289.

Sussarellu, S., Suquet, M., Thomas, Y., Lambert, C., Fabioux, C., Pernet, M. E. J., Le Goic, N., Quillien, V., Mingant, C., Epelboin, Y., Corporeau, C., Guyomarch, J., Robbens, J., Paul-Pont, I., Soudant, P., & Huvet, A. (2016). Oyster reproduction is affected by exposure to polystyrene microplastics. Proceedings of the National Academy of Sciences of the United States of America, 113, 2430–2435.

Sustainability Victoria (2010). Annual survey of Victorian recycling industries 2008–2009. State Government of Victoria. file:///D:/For%20Dell%20E6320/Publications%20Annual%20Survey%20of%20Victorian%20Recycling%20Industries%202009%2010.pdf. Accessed 15 Jan 2018.

Thevenon, F., Carroll, C., & Sousa, J. (2014). Plastic debris in the ocean: the characterization of marine plastics and their environmental impacts, situation analysis report. Gland: International Union for Conservation of Nature. https://doi.org/10.2305/IUCN.CH.2014.03.en.

Thomas, S., & Visakh, P. M. (2011). Engineering and specialty thermoplastics: polyethers and polyesters: state-of-the-art, new challenges and opportunities. Handbook of engineering and speciality thermoplastics: polyethers and polyesters, volume 3, chapter 1,pp. 1–14.

Tollefsen, K. E., Blikstad, C., Eikvar, S., Farmen Finne, E., & Katharina Gregersen, I. (2008). Cytotoxicity of alkylphenols and alkylated non-phenolics in a primary culture of rainbow trout (Onchorhynchus mykiss) hepatocytes. Ecotoxicology and Environmental Safety, 69, 64–73.

United Nations (UN) News Centre, (2017). UNdeclares war on ocean plastic. UN Environment. http://web.unep.org/newscentre/un-declares-war-ocean-plastic. Accessed 17 Nov 2017.

Van Cauwenberghe, L., & Janssen, C. R. (2014). Microplastics in bivalves cultured for human consumption. Environmental Pollution, 193, 65–70. https://doi.org/10.1016/j.envpol.2014.06.010.

Vasile, C., & Pascu, M. (2005). Practical guide to polyethylene. Smithers Rapra Technology.

Venkatachalam, S. (2012). Degradation and recyclability of poly (ethylene terephthalate). In S. G. Nayak (Ed.), (pp. Ch. 4-Ch. 4). Rijeka, IntechOpen.

Vince, J. Z. & Hardesty, B. D. (2016). Plastic pollution challenges in marine and coastal environments: From local to global governance. Restoration Ecology, 25(1). https://doi.org/10.1111/rec.12388.

von Moos, N., Burkhardt-Holm, P., & Kohler, A. (2012). Uptake and effects of microplastics on cells and tissue of the blue mussel Mytilus edulis L. after an experimental exposure. Environmental Science and Technology, 46, 11327–11335. https://doi.org/10.1021/es302332w.

Waste + Water Management Australia. (2015). European plastic packaging waste statistics 2014: 39.5% recycling, 38.5% energy recovery and 22% landfill. Waste + Water Management Australia, 42(4), 4–6.

Watanabe, H., Suzuki, A., Goto, M., Lubahn, D. B., Handa, H., & Iguchi, T. (2004). Tissue-specific estrogenic and non-estrogenic effects of a xenoestrogen, nonylphenol. Journal of Molecular Endocrinology, 33, 243–252.

Watts, A. J. R., Urbina, M. A., Corr, S., Lewis, C., & Galloway, T. S. (2015). Ingestion of plastic microfibers by the crab Carcinus maenas and its effect on food consumption and energy balance. Environmental Science and Technology, 49, 14597–14604.

Watts, A. J. R., Urbina, M. A., Goodhead, R., Moger, J., Lewis, C., & Galloway, T. S. (2016). Effect of microplastic on the gills of the shore crab Carcinus maenas. Environmental Science and Technology, 50, 5364–5369.

Worm, B., Lotze, H. K., Jubinville, I., Wilcox, C., & Jambeck, J. (2017). Plastic as a persistent marine pollutant. Annual Review of Environment and Resources, 42, 1–26. https://doi.org/10.1146/annurev-environ-102016-060700.

Wright, S. L., Rowe, D., Thompson, R. C., & Galloway, T. S. (2013). Microplastic ingestion decreases energy reserves in marine worms. Current Biology, 23, R1031–R1033.

Wright, S. L., Thompson, R. C., & Galloway, T. S. (2013). The physical impacts of microplastics on marine organisms: a review. Environmental Pollution, 178, 483–492. https://doi.org/10.1016/j.envpol.2013.02.031.

Wu, M., Xu, H., Shen, Y., Qiu, W., & Yang, M. (2011). Oxidative stress in zebrafish embryos induced by short-term exposure to bisphenol A, nonylphenol, and their mixture. Environmental Toxicology and Chemistry, 30, 2335.

Xanthos, D., & Walker, T. R. (2017). International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): a review. Marine Pollution Bulletin, 118, 17–26. https://doi.org/10.1016/j.marpolbul.2017.02.048.

Yousif, E., & Haddad, R. (2013). Photodegradation and photostabilization of polymers, especially polystyrene: review. SpringerPlus, 2, 1–32.

Zha, J. M., Wang, Z. J., Wang, N., & Ingersoll, C. (2007). Histological alternation and vitellogenin induction in adult rare minnow (Gobiocypris rarus) after exposure to ethynylestradiol and nonylphenol. Chemosphere, 66, 488–495.

Zhang, L., Wei, C., Zhang, H., & Song, M. (2017). Criteria for assessing the ecological risk of nonylphenol for aquatic life in Chinese surface fresh water. Chemosphere, 184, 569–574.

Zheng, Y., Yanful, E. K., & Bassi, A. S. (2005). A review of plastic waste biodegradation. Critical Reviews in Biotechnology, 25, 243–250.

Zhou, Y., Guan, J., Wang, J., Wu, W., & Zhang, C. (2015). Life cycle analysis on regenerating and energy recovery of plastic solid waste management in Shanghai. Applied Mechanics and Materials, 768, 426–433.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 57 kb)

Rights and permissions

About this article

Cite this article

Lam, CS., Ramanathan, S., Carbery, M. et al. A Comprehensive Analysis of Plastics and Microplastic Legislation Worldwide. Water Air Soil Pollut 229, 345 (2018). https://doi.org/10.1007/s11270-018-4002-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-018-4002-z