Abstract

Plastic waste is an ever-growing global challenge, perhaps second only to climate change in its scope and impact. Unmanaged plastic waste can be found on every continent and every ocean, from mountaintops to the seafloor. In addition to the plastic we can see, over time, plastics break down into smaller and smaller pieces called microplastics, and in that form, plastic has worked its way into the food chain—from plankton to humans. Plastics have been touted as recyclable, but in practice, recycling is difficult and has not proven to be an effective solution. Additionally, current laws and regulations are not sufficient in slowing the use—and misuse—of plastic. However, there is reason for optimism. New technologies like chemical recycling and new manufacturing approaches aim to make the process of recycling plastic easier and new and proposed regulations around the world are beginning to take a radically different approaches to addressing and recognizing the potential harm to the environment and human health done by plastics. In this review, we will address the current state of plastic waste management from a technical and policy perspective and look forward to potential changes and innovations on the horizon.

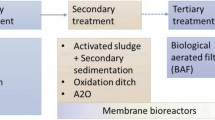

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the 1950s, the world’s appetite for all things plastic has been steadily growing. The largest single market for non-fiber plastic is packaging (Geyer et al. 2017). Due to a global shift from reusable to single-use containers the share of plastics in municipal solid waste (by mass) increased from less than 1% in 1960 to more than 10% by 2005 in middle- and high-income countries (Geyer et al. 2017). Nearly half of the plastic produced is only used once then discarded (UN Environment Program 2021b), while microplastic from sources such as tires, synthetic fibers and coatings is shed during use and never captured. (NASEM 2021). Plastic is inexpensive to produce, is endlessly formable, lightweight, strong, and durable. However, these beneficial qualities, have also led to serious environmental problems. Because plastic persists in the environment for decades or even centuries, virtually every piece of plastic ever made is still around. Researchers estimate that by 2030, annual emissions of plastic waste may reach 53 million metric tons annually, exceeding all efforts to mitigate its migration to the environment (Borrelle et al. 2020).

To complicate matters further, plastic doesn't simply remain in its original manufactured form. While they do not chemically degrade, manufactured plastic items do fracture into smaller and smaller bits eventually creating microplastic. Apart from fracturing of larger plastic pieces, much of the microplastic pollution is released directly from consumer products as they are used, such as tires, synthetic fibers and coatings. These microplastics are never captured. (NASEM 2021). The microplastic form can cause the most harm (Jambeck et al. 2015). Microplastics are often mistaken for food by microorganisms, and because the plastic doesn’t break down as part of a metabolic process, it makes its way up the food chain, eventually to humans, where the long-term health hazards aren’t well understood. Microplastic, when fracturing into nanoplastic, can become small enough to cross the blood brain and placental barriers and even enter cells, behaving like free radicals and causing oxidative stress (Hu and Palić 2020; Ternes 2020). Such nanoplastics have been shown to even change the secondary nature of proteins, affecting the folding of proteins similar to those encountered in the prion disease bovine spongiform encephalopathy (i.e., “mad cow disease”) (Holicoczki and Fehrke 2019). Thus, nanoplastics are recognized as inducing “significant cellular and thereby ecological damages,” (Holicoczki and Fehrke 2019).

Although in principle, plastic should be easy to recycle, it isn’t, even first assuming waste plastic can be captured before it enters the environment and thus can be directed toward recycling. Post-use plastic collected for recycling contains more than 10,000 additives which are used in the manufacture of plastic that allow it to be transformed into the products we use every day (Wiesinger et al. 2021). Unfortunately, this massive variety makes recycling difficult due to the uncertainty of composition when manufacturing goods from post-consumer plastic waste. Additionally, over 2400 of these additives are known to be potentially hazardous (Weisinger et al. 2021).

Despite these challenges, new technologies are being developed that can potentially address the plastic waste crisis. Technologies like chemical recycling, conversion to fuel oil, as well as the development of new synthetic and bioplastics that are easier to recycle, or naturally biodegradable are on the horizon. Additionally, new policies and regulations around the world have been enacted to help stem the flow of plastic waste into the environment. While the United States has some catching up to do on the policy front, globally the United Nations, European Union, China and other countries are making great progress in developing regulatory structures that ban unnecessary uses of plastic, mandates recycling content and ensures circularity. (Ternes 2020). Given the developing research regarding harm to human health and the environment from exposure to microplastic and to toxic chemicals that can leach from larger pieces of plastic waste material, more rigorous legal mandates and related litigation will certainly follow. Thus, industry has significant incentive to propose plastic product approaches designed to mitigate these risks. Industry can assist in developing strategies to avoid use of plastic where possible. Where plastic use is deemed necessary, then industry can help develop strategies employing extended producer responsibility to support capture and recycling and as well as general strategies that support circularity to prevent plastic from entering the environment.

Challenges to traditional recycling

According to Vogt et al. (2021) the historically low recycling rates are not by accident but rather are a consequence of a variety of economic and technical challenges that disincentivize recycling. Due to the general poor miscibility of polymer blends, effective sorting of the waste is critical to the quality of products obtained from mechanical recycling (Vogt et al. 2021). This sorting is an economic challenge. Plastics are produced in two broad categories, thermoplastics and thermoset plastics. In principle, thermoplastics plastics are easily recyclable. In fact, pre-consumer thermoplastics are recycled at a high rate. Unfortunately, in practice, the process is significantly more challenging. Innovation and increased complexity of plastic-containing products is evolving faster than recycling facilities and systems can adapt, adding to the difficulty in collecting and sorting post-consumer plastic waste (Bennett et al. 2021). Most plastics products are produced from a formulation that includes additives like colors and dyes, fillers, UV protectants, fire retardants, reinforcements, and plasticizers, among many others (Vogt et al. 2021). The presence of these additives means that post-consumer recycled plastics differ significantly from virgin resins, making them unsuitable for many applications. Additionally, mechanical recycling processes not only fail to remove additives, but work by shredding the plastics before remelting, meaning that the polymer chains are shortened in the process. Unlike metals, which are essentially endlessly recyclable, shredding leads to a degradation in quality with each recycling. Over time, the plastic becomes unrecyclable and must be discarded or used for its heating value. This problem is compounded in the developing world, where the infrastructure to collect and sort plastic waste is often insufficient or unavailable (Browning et al. 2021). Furthermore, thermoset plastics like polyesters, polyurethanes, silicones, and epoxy cannot be remelted and remolded after they have been formed due to their crosslinked structure. Post-consumer thermoset plastics are typically not recyclable at all.

In addition to the technical challenges, the economic challenges to traditional recycling are significant as well. Currently, for post-consumer plastic, only relatively pure waste plastic streams such as polyethylene terephthalate and high-density polyethylene bottles are commercially recycled, while potentially recyclable plastics like polystyrene, polypropylene, polyethylene films and mixed polyolefins are typically discarded (Larrain et al. 2021). Additionally, low oil prices also effect the recycling market by reducing the cost of virgin resin. The need for policies that would increase the demand of recycled products, such as imposing minimal recycled content targets are therefore critical to the economic viability to recycling operations (Larrain et al. 2021).

Microplastic in the environment

Microplastics are defined as plastic particles smaller than 5 mm in diameter. Due to their small size, they are easily transported throughout the environment (Jambeck et al. 2015). Researchers have recently found microplastic particles from North America and Africa at an elevation of over 9000 ft above sea level in the French Pyrenees mountains, indicating that these particles can be transported globally via the atmosphere (Jaynes 2021). Additionally, recent studies have shown that due to its ability to migrate up the food chain, nearly all of us have microplastics in our bodies (Carrington 2021). Microplastics are especially problematic because they are nearly impossible to remove from the ecosystem. Microplastics are created from fracturing of larger pieces of waste plastic in the environment. But microplastics are also shed from tires and marine coatings are released directly to the environment through use and cannot be recovered. Microplastics from synthetic fabrics are shed when they’re worn (particularly from loosely woven fibers like “fleece”), but a significant amount of microfibers, can be captured by wastewater treatment systems and concentrated in treatment plant sludges. Yet when wastewater treatment plant sludge is applied to field in agricultural operations (in the United States, applied as biosolids pursuant to 40 C.F.R. Part 503), the microfibers are released again. Synthetic textile fabrics like nylon, polyester, and acrylic are known sources of microfibers. (NASEM 2021). The best approach to preventing microplastic environmental pollution is simply to keep plastic, and thus the inevitable fate of environmental waste plastic, microplastic, out of the environment to begin with. This means mitigating plastic waste, regulating products that shed plastic and avoiding use of plastic in outdoor applications, such as building materials.

Recent advancements in chemical recycling

Due to the previously mentioned challenges with traditional (mechanical) recycling, new techniques are needed. One of the recent advances in recycling techniques is chemical recycling (Kol et al. 2021; Volmer et al. 2020). Mechanically recycled plastics often have deteriorated physical properties compared with virgin plastics because they are broken down by the recycling process itself (Lee et al. 2021). Selective solvent extraction is one of the more promising technologies. This process involves matching solvents with polymers to separate the plastics from the additives used to enhance their properties. This process results in recycled material that is indistinguishable from virgin material. However, the feasibility of additives removal depends strongly on the type of additive and plastic and also on the extraction conditions (Ügdüler 2021).

Converting post-consumer plastic waste into liquid fuel is another technology that can remove plastic from the environment (Li et al. 2022). Plastic can be thermally decomposed by pyrolysis into liquid fuels with similar properties to traditional diesel fuel or kerosene (Joshi and Seay 2020). On a life cycle basis, this technology can produce fuels with a lower carbon dioxide footprint than the well-to-tank emissions from producing traditional fuels (Joshi and Seay 2020). Additionally, plastic derived fuel oils are sulfur-free thus minimizing pollution-causing sulfur oxide emissions when combusted (Joshi and Seay 2020). Another technology known as hydrothermal processing uses supercritical water to convert post-consumer polyolefins into clean, low sulfur fuels and waxes (Chen et al. 2019; Jin et al. 2020). Hydrothermal carbonization can convert waste products link biomass and plastic into products like hydrochar at relatively low processing temperatures (Shen 2020).

As the challenges of plastics recycling become more apparent, researchers have been thinking about how plastics are made in the first place, to develop polymers that are more easily recycled (Boehner 2021). A team of chemists recently developed a new polyacetyl polymer that can be easily broken down into its base monomers with the addition of a strong acid (Abel et al. 2021). This process even allows the monomer to be recovered from a mixture of plastics (Abel et al. 2021).

Chemical recycling has the potential to positively influence greenhouse gas emissions through avoided emissions. A report commissioned by the European Chemical Industry Council reviewed 4 studies, each indicating that chemical recycling could potentially reduce annual CO2 emissions in the EU compared with the production of virgin resin (Cefic 2022).

Recent advances in bioplastics

Bioplastics are another area where technology may be able to address the growing plastic waste crisis. Bioplastics are simple plastic polymers made from renewable, biobased feedstocks, as opposed to crude oil, like traditional plastics. However, being bio-based does not necessarily mean being environmentally friendly. When considering the potential environmental impacts of plastic in the environment, the source of the carbon is inconsequential. In order to truly be environmentally friendly, bioplastic must also be biodegradable within a short time frame—typically weeks or months. The commonly produced bioplastic polylactic acid (PLA) is not naturally biodegradable. There are, however, some bioplastics that meet this description. One bioplastic that can naturally biodegrade is polyhydroxyalkanoate (PHA). Research shows that PHAs such as poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) are biodegradable in all aerobic and anaerobic environments and can be used to make completely compostable, and soil and marine biodegradable products (Meereboer et al. 2020). Despite these advances, it should be noted there is no bioplastic currently available that can meet global demand at a cost lower than traditional crude oil derived plastics.

Alternatives to plastic

One of the reasons that plastics are so ubiquitous is that they are lightweight, low cost, and endlessly formable. Traditional materials like metals, glass, cardboard, and cloth simply cannot compete from a cost perspective. In addition, there are certainly other environmental concerns with all of the potential alternatives. Metals must be mined which can cause land-use concerns and refined which is highly energy-intensive. Although metals can be recycled, the collection and transport of post-consumer use metals do require both energy and infrastructure. In addition to being prone to breaking during transport, glass is primarily made from sand, which is in a global short supply. According to the UN Environment Program’s Global Sand Observatory Initiative, use of sand (along with gravel and other aggregates) has tripled over the last two decades, leading to a potential shortage (UN Environment Programme 2021a). Cardboard can of course be used for packaging and can be made from post-consumer recycled material. In addition, cardboard biodegrades in the environment. Despite its suitability for packaging, plastic is still the superior option for food preservation and storage. Finally, reusable natural fiber cloth bags are often cited as an effective alternative to plastic bags, however, the pesticides and herbicides used in the growing of the fibers used in cloth manufacture can often be environmentally damaging. Organically produced cotton fiber cloth bags actually have a greater environmental impact due to the larger amount of water needed when growing and the reduced crop yield per acre (Cho 2020). In short, there is no currently available product that can replace plastic on a global scale unless the cost of plastic includes the cost of ensuring complete circularity.

Legal authority addressing plastic waste

Over the past seventy years, environmental law has become among the most durable fixtures in developed nations, as well as the bases for global consensus regarding mitigation of environmental impacts from industrialization. Before such legal mandates, which dictate that prospective operations comply with specific requirements to prevent environmental pollution, resolution of harm caused by environmental pollution was left to the judicial system. The courts would decide retroactively, and on a case-by-case basis, whether the defendant caused environmental pollution, whether the environmental pollution caused the alleged harm, such as property damage and wrongful death, whether the harm was redressable (i.e., whether the court could effectively provide a remedy through a decision mandating actions by the defendant that would cure the alleged harm), including the amount of damages and any further relief. This case-by-case approach did not curb pollution from prospective industrial operations and thus only perpetuated environmental degradation which continued to result in human fatalities. However, during the peace following World War II, human fatalities from environmental pollution were recognized generally and the cause was then identified as industrial sources of combustion emissions. Legal mandates dictating environmental controls to mitigate these impacts and avoid human fatalities were adopted in the form of national legislation. In the United States, this national legislation grew in scope to address more causes of human fatalities and incorporated ways to mitigate environmental degradation, represented now by the environmental statutes implemented primarily by the United States Environmental Protection Agency and delegated state agencies. This bedrock legal construct of preventing loss of human life through environmental protection is now utilized globally and considered a human rights issue. Environmental legal authority, whether adopted by single nations or incorporated into global treaties or enforceable agreements between countries, has driven a revolution in technological innovation developed to meet environmental quality standards (Schnelle et al. 2016).

Over the past decade, there has been a significant global trend in adopting environmental legal authority to mitigate waste plastic in the environment. This global trend is based upon both the obvious environmental damage caused by large pieces of waste plastic in the environment as well as the negative impacts to human health from exposure to microplastic based on developing research on waste plastic fate and transport in the environment and human health risk studies. Plastic waste in the environment, as well as products such as tires, coatings, and fibers, are recognized as not degrading sufficiently in the environment. Yet, while not degrading, this waste does fracture into micro and nanoplastic, which has been proven to pose significant risk to human health. For these reasons, the risk waste plastic poses to human health will continue to drive development of technology and policy approaches necessary to mitigate this risk to human health and meet any new legal mandates adopted to mitigate this risk.

As recognized globally, to fully mitigate risk to human health from plastic pollution, plastic policies must not only mandate collection and recycling, but also product restrictions including manufacturing and extended producer responsibility and mitigation strategies contemplating the potential fate of all types of plastic waste. In the past, policies have been adopted and legislative authority enacted to address critical pollutant issues arising from the broad incorporation of materials with previously unrecognized hazards into consumer products. For example, in the United States asbestos had been used to produce a wide variety of consumer products, including the snowflakes used in the Wizard of Oz “field of poppies” scene and cigarette filters, before legislative action was taken to authorize federal agencies to regulate asbestos products. Chlorofluorocarbons and other specific ozone-depleting substances had been used widely as refrigerants until their manufacture was banned internationally by the 1987 Montreal Protocol. It is time for the United States to address the urgent matter of environmental plastic waste and the products and uses that result in plastic waste to mitigate further avoid widespread harm to human health and the global environment. While emphasis in chemical engineering publications often focuses on recycling technology, a critical prerequisite to recycling is capture of post-use plastic. In the United States, there is no specific federal plastic waste pollution regulation and no national bans on production of any type of plastic, much less the form of plastic most likely to end up in the environment, e.g., fast food straws and utensils. And there is no broad federal mandate requiring capture and recycling of post-use plastic. Yet, the United States has been identified as clearly the largest contributor to global ocean plastic waste, with 42 million tons of plastic waste in 2016. This is more than the 28 countries of the European Union combined, almost twice as much as India (26 million) and China (22 million). (NASEM 2021).

There is a clear gap in United States environmental law that has allowed plastic to escape regulation. Federal environmental laws in the United States focus on mitigating harm from release to the environment of either general pollutants from certain activities or specific pollutants based upon the anticipated hazard, prioritized by overall production volumes and hazard characteristics, including toxicity, reactivity, ignitability, and corrosivity. These specific pollutants are regulated for their hazards in each media specific statute. For example, in air, the Clean Air Act regulates emissions of “criteria pollutants” including combustion gases (e.g., particulate matter, carbon monoxide, nitrogen oxide) as well as specific Hazardous Air Pollutants (e.g., tetrachloroethylene, regulated for its toxicity). In water, the Clean Water Act regulates discharges of “conventional pollutants” including stormwater runoff constituents (e.g., total suspended solids, fecal coliform, oil, and grease) as well as toxic pollutants (e.g., again, tetrachloroethylene). In waste, the Resource Conservation and Recovery Act regulates management of hazardous waste that are specifically listed, or nonetheless exhibit one or more of the four hazard characteristics (e.g., again, tetrachloroethylene). Originating from a product designed for durable use, such as to preserve food and drinking water for human consumption, plastic waste is, of course, inert and exhibits none of these hazardous characteristics. Thus, plastic waste is regulated as “municipal waste.” Federal municipal waste programs are delegated to state agencies for implementation which do not uniformly prioritize or otherwise enforce restrictions regarding plastic waste (though some states and municipalities do attempt to address the issue of plastic waste with bans and recycling mandates with their own state specific law and municipal ordinances). At most, airborne microplastic could be recognized for its physical presence as particulate matter regulated pursuant to the Clean Air Act as “PM2.5.” Plastic present in navigable waters could be regulated for its physical presence as total suspended solid pursuant to the Clean Water Act, and if microplastic, as turbidity pursuant to the Safe Drinking Water Act.

While the United States Legislature has introduced a number of bills intended to directly address plastic waste, the United States has enacted only two statutes, each addressing marine debris. In 2018, the United States enacted the Save Our Seas Act, which requires the National Oceanic and Atmospheric Administration (NOAA) to respond to severe marine debris events, which can include removing marine debris as plastic waste from the oceans. Then, in 2020, the United States enacted the Save Our Seas Act 2.0 which goes further and requires exploration into possible international agreements regarding mitigation of marine debris.

In a previous publication, Ternes (2020), described that internationally, many nations are making much more progress mitigating the generation of unnecessary plastic waste. The trend became clear in 2018, when China announced its “National Sword” policy which banned many categories of plastic waste imports and eliminated 99% of its plastic waste imports. In 2019, the European Union issued its Proposal for a Directive on the Reduction of the Impact of Certain Plastic products on the Environment (now final). And in May 2019, the United Nations parties of the 1989 Basel Convention on Transboundary Movements of Hazardous Wastes and their Disposal adopted amendments listing for the first time plastic waste presumed to be “hazardous waste,” effective January 1, 2021.

The European Union has been leading the way on sustainability and circularity. On March 11, 2020, the EU adopted its new Circular Economy Action Plan, covering: electronics, batteries, vehicles, packaging, plastics, textiles, construction, buildings, food, water, nutrients. This new Plan is intended to: ensure less waste and more value, enhance waste policy to support waste prevention and circularity in a toxic free environment, create a secondary raw materials market, address waste exports, and lead efforts at the global level and monitoring progress. This measure specifically targets microplastics as well, particularly from unintentionally released microplastics from tires and textiles. Goals include: risk assessment regarding microplastics in the environment, drinking water and foods; sourcing, labeling and use of bio-based plastics ensuring genuine environmental benefits beyond mere reduction of fossil fuel; and ensuring biodegradable and compostable labeling does not mislead consumers “to dispose of it in a way that causes littering or pollution due to unsuitable environmental conditions or insufficient time for degradation.”

The European Green Deal was introduced on December 11, 2019. This package of measures is meant to deal with the challenges posed by climate change and environmental degradation, which create an “existential harm” for Europe and the rest of the world. Several strategies and action plans resulted from the European Green Deal, including the Chemical Strategy for Sustainability, which was published on October 14, 2020. The Chemical Strategy for Sustainability aims to reach a toxic-free environment and expressly targets plastics.

The 2020 Circular Economy Action Plan relies on a June 5, 2019 Directive mandating reduction of the impact of certain plastic products on the environment, as well as the 2018 Strategy for Circular Economy (COM (2018) 28 final). The 2019 Directive launched rules mandating reductions in single-use plastics including: cotton buds, cutlery, plates, straws, drink stirrers and sticks for balloons, drink containers. The 2019 Directive also mandates consumption reduction targets, where producers are to reduce the costs of waste management for food containers, packets, wrappers, drinks containers, cups, tobacco products with filters, wet wipes, balloons and lightweight plastic bags. Further the 2019 Directive sets: collection target of 90% for drinks bottles by 2025; labeling requirements for sanitary towels, wipes and balloons; requirement that collection cost of fishing gear be placed on producers of gear.

China, in addition to its 2018 “National Sword” policy, has further committed to ban or restrict single-use non-degradable plastic products in five plastic consuming sectors within five years. China expects to ban the production and sale of disposable foam plastic tableware and plastic cotton swabs and prohibit the production of household chemicals incorporating plastic microbeads, both by the end of 2020 (Liqiang 2020). Future phases of China’s plastic ban will target nondegradable plastic bags, phasing out their use in various sectors and locations through 2022. Significantly, China has adopted a national standard for biodegradable plastic shopping bags and is prepared for wide-scale production. Also, China will seek e-commerce and on-demand service platforms, such as food and goods delivery, to reduce use of disposable plastic products and find suitable substitutes, while cooperating with waste management and recycling companies to collect packaging.

Regarding other countries, in its December 5, 2018 report entitled “Legal Limits on Single-Use Plastics and Microplastics: A Global Review of National Laws and Regulations,” the United Nations summarized as follows: 127 out of 192 countries reviewed have adopted some form of legislation to regulate plastic bags most commonly restricting free retail distribution. Twenty-seven countries assess taxes on the manufacture and production of plastic bags; 30 countries charge consumer fees for plastic bags. In addition, 27 countries have banned or limited the production of specific products (e.g. plates, cups, straws, packaging) and materials (e.g. polystyrene). Forty-three countries have included elements of extended producer responsibility for plastic bags; 63 countries mandate extended producer responsibility for single-use plastics, including deposit-refunds, product take-back, and recycling targets. Several countries have banned microbeads and the European Union has started a process to restrict the intentional addition of microplastics to consumer and professional use products. (UN Environment Programme 2018).

Despite recognition of the plastic waste crisis and its urgency, which has turned appropriate focus to improved recycling approaches, recent scientific studies have confirmed the significant contribution of environmental plastic resulting from microplastic shed from products in use where no capture is contemplated or practically possible, as discussed above. (NASEM 2021). These contributions that cannot be captured will likely need to be mitigated through specific regulation regarding the manufacture and use of these products, such as prohibiting or requiring modification of these products (e.g., enforcing a maximum “shed rate” for synthetic fibers; finding an alternative to current synthetic plastic content in tires and marine coatings), or limiting the use of these products to mitigate microplastic shedding into the environment.

Conclusions

In conclusion, although plastics have without question made our modern society possible, unmanaged post-consumer plastic waste presents a significant global challenge. In fact, the global plastic waste challenge maybe second only to climate change in its potential to adversely affect life on earth. The use of plastic products is accelerating and unless steps are taken, the amount of plastic entering the environment will overwhelm humanity’s ability to mitigate it. Despite this looming challenge, technological advances, along with new policies and regulations provide hope that a solution will be found. Only through focused and sustained effort can we avoid the potential harm plastic in the environment can cause.

Data availability

There is no data affiliated with this review article.

References

Abel BA, Snyder RL, Coates GW (2021) Chemically recyclable thermoplastics from reversible-deactivation polymerization of cyclic acetals. Science 373(6556):783–789. https://doi.org/10.1126/science.abh0626

Bennett EM, Alexandridis P (2021) Informing the public and educating students on plastic recycling. Recycling 6:69. https://doi.org/10.3390/recycling6040069

Boerner, LK (2021) Plastics recycling rocketed forward. Chemical and Engineering News, December 13/20

Borrelle SB, Ringma J, Law KL, Monnahan CC, Lebretona L, McGivern L, Murphy E, Jambeck J, Leonard GH, Hilleary MA, Eriksen M, Possingham HP, De Frond H, Gerber LR, Polidoro B, Tahir A, Bernard M, Mallos N, Barnes M, Rochman CM (2020) Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 369(6510):1515–1518. https://doi.org/10.1126/science.aba3656

Browning S, Beymer-Farris B, Seay J (2021) Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr Op Chem Eng. https://doi.org/10.1016/j.coche.2021.100682

Carrington D (2021) Microplastics cause damage to human cells, study shows, The Guardian, https://www.theguardian.com/environment/2021/dec/08/microplastics-damage-human-cells-study-plastic

Chen WT, Jin K, Wang N-H (2019) Use of supercritical water for the liquefaction of polypropylene into oil. ACS Sustain Chem Eng 7(4):3749–3758

Cho R (2020) Plastic, paper or cotton: Which shopping bag is best?. State of the Planet - News from the Columbia Climate School, April 30, 2020. https://news.climate.columbia.edu/2020/04/30/plastic-paper-cotton-bags/

European Chemical Industry Council (Cefic) (2022) Chemical recycling: greenhouse gas emission reduction potential of an emerging waste management route. Online resource: Accessed 03 Febuary 2022), https://cefic.org/app/uploads/2020/12/CEFIC_Quantis_report_final.pdf

Geyer R, Jambeck J, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv. https://doi.org/10.1126/sciadv.1700782

Holicoczki O and Fehrke S (2019) Nanoplastics can change the secondary structure of proteins. Scientific Reports, 9, Article Number 16013, at: https://www.nature.com/articles/s41598-019-52495-w

Hu M, Palić D (2020) Micro- and nano-plastics activation of oxidative and inflammatory adverse outcome pathways. Redox Biol. https://doi.org/10.1016/j.redox.2020.101620

Larrain M, Van Passel S, Thomassen G, Van Gorp B, Nhu TT, Huysveld S, Van Geem KM, De Meester S, Billen P (2021) Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2021.105607

Lee J, Kwon EE, Lam SS, Chen W-H, Rinklebe J, Park Y-K (2021) Chemical recycling of plastic waste via thermocatalytic routes. J Clean Prod. https://doi.org/10.1016/j.jclepro.2021.128989

Li N, Liu H, Cheng Z, Yan B, Chen G, Wang S (2022) Conversion of plastic waste into fuels: a critical review. J Hazardous Mater. https://doi.org/10.1016/j.jhazmat.2021.127460

Liqiang H (2020) Rules for plastic products aim to curb urban pollution. China Daily, January 20

Jambeck JR, Andrady A, Geyer R, Narayan R, Perryman M, Siegler T, Wilcox C, Lavender Law K (2015) Plastic waste inputs from land into the ocean. Science 347:768–771

Jaynes CH (2021) Microplastics from Africa and North America Found 9,439 Feet Above Sea Level in French Pyrenees. Ecowatch, Dec. 23. https://www.ecowatch.com/microplastics-french-pyrenees-2656109647.html.

Jin K, Vozka P, Kilaz G, Chen W-T, Wang N-H (2020) Conversion of polyethylene waste into clean fuels and waxes via hydrothermal processing (HTP). Fuel. https://doi.org/10.1016/j.fuel.2020.117726

Joshi C, Seay J (2020) Total generation & combustion emissions of plastic derived fuels: a trash to tank approach. Environ Progr Sustain Energy. https://doi.org/10.1002/ep.13151

Kol R, Roosen M, Ügdüler S, Van Geem KM, Ragaert K, Achilias DS and De Meester S (2021) Recent advances in pre-treatment of plastic packaging waste [Online First], IntechOpen. https://doi.org/10.5772/intechopen.99385. Available from: https://www.intechopen.com/online-first/77840

Meereboer KW, Misra M, and Mohanty AK (2020) Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chemistry, Issue 17

National Academy of Sciences, Medicine and Engineering (2021) Reckoning with the U.S. Role in Global Ocean Plastic Waste, National Academies Press

Schnelle KB, Dunn RF and Ternes ME (2016) Air pollution control technology handbook 2nd Edition, CRC Press

Shen Y (2020) A review on hydrothermal carbonization of biomass and plastic wastes to energy products. Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2020.105479

Ternes ME (2020) Plastics: global outlook for multinational environmental lawyers. ABA Natural Resources and Environment, Oct. 5

Ügdüler S, Van Geem KM, Roosen M, Delbeke EIP, De Meester S (2021) Challenges and opportunities of solvent-based additive extraction methods for plastic recycling. Waste Manage 104:148–182. https://doi.org/10.1016/j.wasman.2020.01.003

UN Environment Programme (2018) Legal Limits on Single-Use Plastics and Microplastics - A Global Review of National Laws and Regulations. https://wedocs.unep.org

UN Environment Programme (2021a) Global Sand Observatory Initiative, https://unepgrid.ch/en/activity/sand

UN Environment Programme (2021b) Our planet is drowning in plastic pollution—it's time for change!, https://www.unep.org/interactive/beat-plastic-pollution/

Vogt BD, Stokes KK, Kumar SK (2021) Why is recycling of postconsumer plastics so challenging? ACS Appl Polym Mater 3:4325–4346

Vollmer I, Jenks MJF, Roelands MCP, White RJ, van Harmelen T, de Wild P, van der Laan GP, Meirer F, Keurentjes JTF, Weckhuysen BM (2020) Beyond mechanical recycling: giving new life to plastic waste. Angew Chem 2020(59):15402–15423

Wiesinger H, Wang Z, Hellweg S (2021) Deep dive into plastic monomers, additives, and processing aids. Environ Sci Technol 55(13):9339–9351. https://doi.org/10.1021/acs.est.1c00976

Funding

No funding was utilized for this review article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seay, J., Ternes, M.E. A review of current challenges and legal advances in the global management of plastic waste. Clean Techn Environ Policy 24, 731–738 (2022). https://doi.org/10.1007/s10098-022-02289-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02289-y