Abstract

A strain of Desulfovibrio sp. sulfate-reducing bacteria (SRB) was isolated from a sludge sample. Novel immobilized SRB beads with microalgae (Chlorella vulgaris, Scenedesmus obliquus, Selenastrum capricornutum, and Anabaena spiroides) as the carbon source were prepared and then used to treat wastewater containing 60 mg/L Cu(II) and 600 mg/L sulfate in batch experiments. The microalgae were first degraded by co-existing fermentative bacteria into fatty acids, which then served as a carbon source for SRB. The solution chemical oxygen demand was significantly lower with microalgae substrates than with ethanol as a substrate. Different immobilization methods were evaluated with an orthogonal design, which indicated that the compositional parameters for preparing immobilized beads with an optimal sulfate reduction rate were polyvinyl alcohol (2%), sodium alginate (1%), calcium chloride (6%), silica sand (1%), and a 50-mL volume of SRB suspension. SRB activity in the immobilized beads was distinctly enhanced compared with that of suspended SRB. At an initial pH of 5.5, 72.4–74.4% of sulfate and over 91.7% of Cu(II) were removed, indicating that immobilized SRB beads with plentiful low-cost microalgae as a nutrient source may be an efficient method for acid mine drainage treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Copper (Cu) is a toxic metal commonly found in contaminated water, and it adversely impacts the environment and human health (Bilal et al. 2013). Copper exists mainly in the state of Cu(0), Cu(I), and Cu(II), of which Cu(II) is more carcinogenic and more difficult to remove than the other forms (Yan and Pan 2002). The maximum allowable limit of Cu(II) in drinking water is 2.0 mg/L according to the World Health Organization (Yuvaraja et al. 2012).

Industrial activities, particularly the copper mining and smelting process, discharge Cu(II) ions into wastewater (Seiler et al. 1988; Akbari et al. 2015). Highly acidic copper mining wastewater with elevated levels of sulfate and heavy metals is produced when sulfide-bearing material is exposed to oxygen and water (Fuge et al. 1993). Each year, a large amount of acid mine drainage is discharged into the surrounding environment, with devastating effects on terrestrial and aquatic ecosystems (Macías et al. 2012). This is particularly the case in China, which has the most abundant copper stocks in the world (Zhang et al. 2015). For example, the cadmium (Cd), Cu, and arsenic (As) levels in well water near the Tonglushan mine in Hubei, China were significantly higher than those in reference areas, and soils were so heavily contaminated with Cd (2.59 mg/kg), Cu (386 mg/kg), and As (35.4 mg/kg) that they were no longer suitable for crop production (Cai et al. 2015). Worse still, mine wastewater in some water shortage areas was used for agricultural irrigation, resulting in the accumulation of heavy metals (Cu, lead (Pb), chromium (Cr), and zinc (Zn)) in wheat crops (Ma et al. 2015). A pilot study in Western Uganda also found that the Kilembe copper mine released cobalt (Co), nickel (Ni), and Cu into the Nyamwamba River, a public water source, and 19% of Amaranthus vegetables sampled exceeded the European Community Cu thresholds (Mwesigye and Tumwebaze 2017). Therefore, developing cost-effective techniques for Cu(II) removal from acid mine drainage is critical.

Conventional techniques for treating acid mine drainage, including chemical precipitation, adsorption, coagulation/flocculation, ion exchange, and reverse osmosis, still suffer from certain disadvantages, such as high treatment costs, inefficient removal of metals, and secondary pollution problems (Hlabel et al. 2007; Madzivire et al. 2010; Yang et al. 2016). The use of sulfate-reducing bacteria (SRB) is an attractive method for the treatment of acid mine drainage. SRB use sulfate as the terminal electron acceptor in the metabolism of organic substrates under anaerobic conditions (Lens et al. 1998). The sulfide produced reacts with metals in solution and precipitates in the form of metal sulfides (McCauley et al. 2009). Many studies have indicated that over 99.9% of Cu, iron (Fe), aluminum (Al), Cr, Ni, Pb, and Zn in acid mine drainage can be removed by SRB (Costa et al. 2017; Kieu et al. 2011; Sahinkaya et al. 2011; Mothe et al. 2017). However, rich carbon sources must be added to the system, because organic matter in natural acid mine drainage is often insufficient (Li et al. 2016). The cost of lactate, acetate, or ethanol is high (Gonçalves et al. 2007; Pagnanelli et al. 2012), and it is difficult for SRB to use other organic wastes, which may lead to a high chemical oxygen demand (COD) in the effluent (Zhang and Wang 2014; Das et al. 2015). In addition, high metal concentrations can inhibit the activity of microorganisms, especially freely suspended SRB, and have a negative effect on remediation efficiency (Sheoran et al. 2010; Hao et al. 2014). Therefore, more valid strategies should be explored to solve these problems.

Microalgae are solar-driven autotrophic plants that exist in many habitats, ranging from marine to freshwater environments, and are widely available (Flores-Chaparro et al. 2017). They have been used as biosorbents of heavy metal ions on account of having different active sites in their cellular structures (Henriques et al. 2017). Bacterial sulfate reduction supported solely by the degradation of algal biomass was demonstrated at the laboratory scale using both Scenedesmus and Carteria microalgae biomass by Russell et al. (2003). Boshoff et al. (2004) also demonstrated the use of dried Spirulina biomass as a carbon source for biological sulfate reduction in an upflow anaerobic digestor. However, not all of the algal biomass was broken down, and only 31% was used by SRB. Even worse, the COD of the outflow was in the range of 3000–14,000 mg/L. Immobilized beads can protect the microorganisms against harmful substances, maintaining high microbial activity and therefore improving effluent quality (Quan et al. 2011; Zhang et al. 2016). Nevertheless, few studies thus far have reported the treatment of copper mine wastewater using immobilized SRB beads with microalgae biomass as the sole nutrient.

In this study, to solve the problems of nutrient sources and adverse environmental conditions for SRB, novel immobilized SRB-microalgae spheres were prepared and evaluated for effective remediation of copper-containing wastewater. Our efforts comprised four main objectives: (1) isolation and identification of SRB; (2) assessment of the sulfate reduction rate and discharged COD in wastewater using four different microalgae species (Chlorella vulgaris, Scenedesmus obliquus, Selenastrum capricornutum, and Anabaena spiroides) as the carbon source for SRB; (3) preparation and characterization of immobilized SRB-microalgae beads under optimal conditions; and (4) investigation of copper-containing wastewater disposal by the immobilized SRB-microalgae beads in a batch experiment.

2 Materials and Methods

2.1 Isolation and Identification of SRB

The mixed culture of SRB used in this study was initially collected in anaerobic sludge from a cattle farm in Yanqing City, China. A 20% sludge solution was added into 500-mL serum bottles filled with Postgate C medium (Postgate 1984). The initial pH of the nutrient medium was adjusted to 7.2. After purging with pure nitrogen for 30 min to reduce dissolved oxygen, the bottles were sealed and incubated at 30 °C for 7 days. The growth of SRB can be directly assessed by the generation of black precipitate (iron sulfide). An enriched SRB culture was obtained by repeating this process three times. Next, the enriched culture was diluted into seven gradient concentrations (10−1, 10−2, 10−3, 10−4, 10−5, 10−6, and 10−7), and SRB were screened by the Hungate roll-tube technique (Hungate and Macy 1973). After cultivation for 2 days at 30 °C, single black colonies were selected and the procedure was repeated three times before the cultures were deemed pure. At the same time, colonies were transferred into solution to determine sulfate reduction activity. All incubations were performed in the dark.

Genomic DNA from the isolated strain with the highest rate of sulfide production was extracted using the method described by Weisburg et al. (1991). PCR amplification of the 16S ribosomal DNA (rDNA) gene was carried out using the universal primers 27F and 1492R (Lane 1991). The amplified fragments were purified using a MagExtractor PCR and Gel Clean-up kit (Toyobo, Osaka, Japan) according to the manufacturer’s instructions, and then sequenced by Beijing Sunbiotech Co., Ltd. The sequenced 16S rDNA gene of the isolated strain was compared with sequences in the GenBank database (Benson et al. 1999) and the EzTaxon Server (http://www.ezbiocloud.net/eztaxon), and the sequences of six closely related type strains were selected. The 16S rDNA sequences of the isolated strain and the reference strains were used to construct a phylogenetic tree using a software package (Tamura et al. 2011).

2.2 Cultivation of Microalgae

C. vulgaris, S. obliquus, S. capricornutum, and A. spiroides were purchased from the Institute of Hydrobiology, Chinese Academy of Sciences. All microalgae used in batch experiments were cultivated in flasks filled with 1000 mL solution containing BG-11 medium. All cultivation operations were performed under sterile conditions, and all chemicals were of analytical grade or better.

2.3 Effect of Microalgae on Sulfate Reduction by Free SRB

C. vulgaris, S. obliquus, S. capricornutum, and A. spiroides biomasses were harvested from nutrient solution after cultivating for 5 days, washed three times with deionized water, and centrifuged at 5000 rpm for 20 min to remove extraneous materials and salts. These microalgae were further sterilized in an autoclave for 20 min to be used as a carbon source for SRB. A solution of 5 g/L K2SO4 was prepared as synthetic wastewater that did not contain heavy metals. The initial pH of the solution was adjusted to 7.0 and boiled to remove oxygen. The experiments were carried out in six 650-mL anaerobic bottles designated R1–R6 (Table 1), which contained 78 mL K2SO4 solution, 2 mL soil supernatant, and 20 mL of SRB inoculum of log phase cells. Equal amounts of the four microalgae biomasses were added to the bottles, respectively, and then filled with deionized water. Simple organism ethanol as carbon source was fed to a bottle at the same reaction condition. A control test in the presence of sulfate solution without an external carbon source was also carried out. The utility of C. vulgaris, S. obliquus, S. capricornutum, and A. spiroides biomass as potential carbon sources to promote microbial sulfate reduction activity was evaluated with batch experiments at 30 °C in a vapor-bathing vibrator for 51 days. Liquid samples were removed at predefined intervals and filtered through a 0.45-μm filter and analyzed for sulfate and COD in solution. Dissolved micro-molecular organics resulting from fermentation for 5 days were also analyzed.

2.4 Preparation of Immobilized SRB-Microalgae Beads

Polyvinyl alcohol (PVA) and sodium alginate, which are less toxic and less expensive than other materials, were used as a conventional gel matrix for the immobilized beads (Hsu et al. 2010). Silicon sand, which increases the compression strength of the formed beads, was also added. The preparation process was executed in an anaerobic box. First, soil supernatant, PVA, and sodium alginate were added to deionized water and heated to 80 °C until the solution was completely dissolved. Then silicon sand, sodium alginate, and 0.1 g deactivated microalgae were slowly added, and the mixture was air-cooled (30–40 °C) and mixed with SRB (1 × 108 colony forming units/mL) suspension. The resulting gel was added drop-wise into a crosslinker solution (saturated boric acid and calcium chloride) with a syringe and maintained at room temperature for 24 h to form gel beads. Finally, the beads were washed with saline three times to remove boric acid and stored at 4 °C for subsequent experiments.

2.5 Performance Test of Immobilized Beads

Different immobilization methods were evaluated in this work. Mechanical strength, sulfate reduction rate, and mass transfer were the evaluation parameters for the preparation of immobilized SRB-microalgae beads. Five key factors, the concentrations of PVA, sodium alginate, calcium chloride, and silica sand, and the volume of SRB suspension, were investigated and labeled as A, B, C, D, and E (Table 2). An orthogonal design table L16 was designed using Orthogonal Design Assistant II software (Sharetop Software Studio). For example, various SRB-S. obliquus beads were made based on the above criteria (Table 2). Randomly selected beads were added to a 100-mL glass syringe, and a certain pressure was applied to the beads, and the damage was observed to qualitatively describe mechanical strength. If all beads could keep the appearance integrity, the mechanical strength was marked as superb. If less than five beads cracked, it was labeled as good. If more than five beads cracked, the mechanical strength was marked as bad. Several immobilized beads were immersed in methylene blue solution, and the mass transfer of the beads was evaluated by observing the uptake of methylene blue into the beads. If the beads center became blue in 5 min, the mass transfer of beads was marked as superb. If the beads center changed to blue in 10 min, it was marked as good. If the beads center became blue in 20 min or longer, the mass transfer ability was marked as bad. Equal amounts of beads were fed into 100 of 600 mg/L SO42− solution, and the sulfate reduction rates were examined.

2.6 Treatment of Copper-Containing Wastewater with Immobilized SRB-Microalgae Beads

Immobilized SRB-microalgae beads were prepared using the optimized conditions. A comparable amount of immobilized beads were fed into sealed 650-mL anaerobic bottles (designated R1–R6 in Table 1) to examine the removal ability of copper-containing wastewater. At the same time, Cu(II) removal by immobilized SRB with ethanol as a carbon source was also carried out. Immobilized SRB beads were first put into the bottom of the bottles to a height of approximately 2–3 mm, and the bottles were filled with solution containing 60 mg/L Cu(II) and 600 mg/L sulfate. The initial pH of all treatments was adjusted to 5.5. Finally, the bottles were placed in a 100 rpm vibrator at 30 °C. Samples were collected and filtered through 0.45-μm filter membrane to determine sulfate, COD, and Cu(II) concentrations in solution.

2.7 Analytical Methods

The diameter of the beads was measured using vernier calipers. The pH determination was performed immediately using an E-201-C multi-glass electrode (Hanna Instruments, Limena, Italy). Sulfate levels were determined using barium chromate spectrophotometry. COD analysis was conducted using the potassium bichromate method (APHA-AWWA-WEF 1998). The concentrations of soluble Cu were determined with flame atomic absorption spectrometry (AA-7000, Shimadzu Corp., Kyoto, Japan). Volatile fatty acids were analyzed using gas chromatography and mass spectrometry (QP2010, Shimadzu Corp.). All sample analyses were carried out in quadruplicate and the average results are reported.

3 Results and Discussion

3.1 Phylogenetic Analysis, G + C Content, and DNA–DNA Hybridization

The isolated strain was designated GSRB. The GenBank accession number for the 16S rDNA sequence of strain GSRB is MF521825. The 16S rDNA gene sequences of GSRB and six closely related Desulfovibrio-type strains were used to construct a neighbor-joining phylogenetic tree (Fig. 1). These data indicated that the GSRB strain should be assigned to the genus Desulfovibrio. The homology of GSRB to the nucleotide sequence of Desulfovibrio sp. KRS1 was 83%; however, they did not belong to the same branch.

3.2 Effect of Microalgae on Biological Sulfate Reduction of Free SRB

The use of microalgae as a carbon source for free SRB in sulfate reduction was studied. On the first day of the experiment, obvious evidence of SRB activity was observed in R5 by the formation of visible black precipitate and the classic odor of hydrogen sulfide (H2S). However, no obvious evidence of SRB activity was observed in R1–4 or R6 until the third day. The pH, sulfate concentration, and COD in the solutions were monitored as reaction progressed.

As shown in Fig. 2, the pH in R1–4 decreased slowly over the first 7 days. As the reaction progressed, it increased slightly, although there was a slight fluctuation throughout the experiment. At the end of the experiment, the pH in R1–R4 was in the range of 6.09–6.26, which was slightly lower than at the beginning. Generally, SRB are unable to use complex substrates as a carbon source for sulfate reduction (Liamleam and Annachhatre 2007). These complex substrates are first degraded to simple molecules by co-existing fermentative bacteria, and then used by SRB (Wakeman et al. 2010; Martins et al. 2011). In this study, fatty acids were measured after 5 days as an indicator of soluble organic content in the reaction solution (Table 3). This indicated that microalgae were broken down into small molecule organic acids by the actions of co-existing anaerobic fermentative bacteria which may come from air or soil supernatant during the experiment. Further, more than half of the S. capricornutum biomass was converted into carbonic acid, while the main fermentation product of the other three microalgae was propanoic acid. Decreased pH and fatty acid levels measured in the samples during the first 5 days indicated that more fatty acids were produced from the readily degradable constituents of microalgae by fermentative bacteria than were consumed through sulfate reduction. After the early stages of the experiment, the SRB gradually adapted to the reactor environment, and the increasing rate of consumption of fermentation products and the alkalinity produced by the sulfate reduction process were gradually balanced with the rate of fatty acid production; thus, no significant changes were observed in reactors R1–R4 at the end of the experiment. However, there was a significant decline in pH in R5 compared with the other reactors. This may be due to the conversion of ethanol, which cannot be completely oxidized, to acetic acid by SRB, and its accumulation in the terminal liquid products (Liu et al. 2004; Sánchez-Andrea et al. 2014).

Sulfate reduction using different types of microalgae and ethanol as carbon sources is shown in Fig. 3. The initial sulfate concentrations ranged from 690.18 to 706.20 mg/L in R1–R4, and the sulfate concentrations ranged from 430.22 to 451.20 mg/L after the reaction. The removal efficiency of sulfate was 34.7–39.4%. The sulfate removal rate in reactor R2 was slightly lower than in reactors 1, 3, and 4. The products of the fermentative culture of the different microalgae varied, and therefore, the reduction efficiencies of reactors 1–4 were slightly different. Ten grams of three organic wastes (chicken manure, dairy manure, and sawdust) was also assessed as carbon sources to promote sulfate-reducing activity, and the sulfate reduction reached 50.27–79.04% on 35th day (Zhang and Wang 2014), which was higher than that in this study. However, more organic wastes were added which may lead to organic pollution. In R5, the sulfate concentration decreased rapidly after 5 days and was less than 8 mg/L (the detection limit of barium chromate spectrophotometry) at day 46. Although the ethanol used in R5 as an electron donor for sulfate reduction was suitable for SRB growth, as documented in some studies (Costa et al. 2009), Cao et al. (2012) also indicated that volatile fatty acids are better electron donors for SRB than are easily degradable ethanol because ethanol utilization often generates abundant acetate, which can increase competition between SRB and other microbial groups and decrease the sulfate-reducing rate. In addition, the residual amount of sulfate in R6 declined slightly after the reaction, mainly because the biological activity of SRB was low, as only 2 mL of soil supernatant was added.

As indicated in Fig. 4, the initial COD in R1–4 was approximately 122–198 mg/L, whereas it was 1428 mg/L in R5. During the first 3 days, the SRB were still in a lag phase, but the COD value in all bottles began to increase, especially in the reaction using ethanol as a substrate. This was because the complex microalgae substrates were first degraded to simple molecules by fermentative bacteria. Zhang et al. (2016) suggested that the cooperative relationship between SRB and fermentative bacteria may be the key factor for the use of complex organic substrates as a carbon source for sulfate reduction to achieve effective bioremediation. Once SRB adapt to the environment, the simple molecules are used by Desulfovibrio sp. After 51 days, R5 was characterized by high COD values (1700 mg/L); thus, a second stage of treatment should be designed to treat the effluent to meet standard discharge requirements. Apparently, ethanol was not suitable for wastewater remediation. Although the masses of microalgae and ethanol used as substrates were identical, the COD levels in R1–4 were far lower than that in R5. This demonstrates that although microalgae cannot be completely oxidized, the use of microalgae guaranteed efficient sulfate reduction and produced relatively low COD that did not require further treatment. A bench scale anaerobic upflow reactor was used by Boshoff et al. (2004) to study the growth of a mixed culture of SRB, and the results demonstrated that dried Spirulina spp. biomass can serve as a carbon source for biological sulfate reduction, but only 31% of the microalgal biomass was used by SRB. The highest sulfate removal rate reached 90.3%, with an influent COD/SO42− ratio of 8:1. This conversion was high compared to the results obtained in our study, partly because the anaerobic upflow reactor was continuously fed inorganic media, which was helpful for SRB growth, and also partly because excess dried Spirulina spp. biomass was fed to the anaerobic upflow reactor, as can be seen through the high COD (3000–5600 mg/L) in the outflow. Overall, from day 5 to day 51, the four types of microalgae substrates all performed well as carbon sources for SRB, as evidenced by low COD discharge.

3.3 Optimization of Immobilized Beads

Table 4 presents the results obtained for the different immobilization methods evaluated by the orthogonal experiment and shows the influence of the concentrations of PVA (A), sodium alginate (B), CaCl2 (C), silica sand (D), and the volume of SRB-microalgae suspension (E) on bead formation. The optimized embedding conditions included bead shape, mechanical strength, and mass transfer. We then targeted the sulfate reduction rate as the main factor to further determine the optimal conditions for immobilized beads. For example, when the factor was A, the level was 1 (2%), and the evaluation index was the sulfate reduction rate, such that K1 was mathematically expressed by K1 = (90.5% + 93.4% + 81.1% + 88.5%) / 4 = 88.4%, which represented the mean value of the average sulfate reduction rate for factor A at level 1. By comparing the different K values, the optimal level of factors for immobilized beads can be achieved. Further, the difference between the maximum and the minimum K values was represented by R, which denoted the range in K values, and reflected the significance of this level on sulfate reduction ability. According to this definition, the maximum value of R corresponded to the most important factor (Tang et al. 2016).

Immobilized beads with a high sulfate reduction rate are better for bioremediating acid mine drainage (Li et al. 2017); consequently, the value of K should be as large as possible. Table 4 shows that the silica sand played an important role in sulfate reduction ability, followed by the concentrations of PVA and CaCl2, the volume of SRB suspension, and sodium alginate concentration. The compositional parameters for obtaining immobilized beads with an optimal sulfate reduction rate were A1 (2%), B2 (1%), C3 (6%), D2 (1%), and E4 (50 mL).

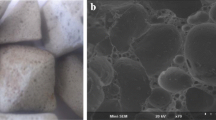

Figure 5a shows the morphology of the immobilized SRB-microalgae beads prepared using the optimized parameters. Immobilized SRB-microalgae beads were approximately 3 mm wide. The beads did not crack after soaking in water for 14 days (Fig. 5b), which showed that the immobilized beads exhibit high mechanical strength.

3.4 Treatment of Copper-Containing Wastewater Using Immobilized Beads in Batch Experiments

Immobilized SRB beads were freshly prepared according to the optimized conditions and then used to remediate simulated wastewater. Biological sulfate reduction was observed on the second day as indicated by a strong smell of H2S. However, SRB were not activated until the third day when free microalgae were used as a carbon source. SRB in immobilized beads were more easily adaptable to the environment than were free SRB. The Cu(II) and sulfate removal abilities of the immobilized beads throughout the experiment are illustrated in Fig. 6.

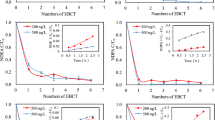

As shown in Fig. 6a, the sulfate reduction in R1–4 could be divided into three stages: period I (days 0–3), period II (days 4–10), and period III (days 11–45). In period I, sulfate reduction efficiency reached 58.9–62.6% on the first day and increased quickly to 68.6–71.8% by the third day. However, SRB growth did not occur before the second day. Therefore, sulfate removal was mainly attributed to adsorption onto materials initially present in the beads. While sulfate reduction efficiency showed some fluctuation during period II, likely due to the hydrolysis of microalgae, the adsorbed sulfate was released back into the solution. During period III, the sulfate reduction rate increased slowly as a result of the enrichment and activity of SRB. Compared with the use of ethanol as the nutrient source in R5, sulfate reduction with microalgae as the nutrient source in R1–4 was effective throughout the experiment, and the maximum sulfate reduction rate reached 72.4–74.4%, which is comparable to other results in the literature (Sahinkaya and Yucesoy 2010).

More importantly, sulfate reduction efficiency of immobilized SRB increased by about 33–40% than that of free SRB. There are several reasons for this observation. First, PVA and sodium alginate had good adsorption capacity for sulfate. Second, SRB efficiently used the carbon source, because micro-molecular organics from the degradation of microalgae were in the vicinity of the SRB. SO42−/COD had a known significant effect on sulfate reduction. The reduction of 1 g SO42− by SRB theoretically consumed 0.67 g COD under standard conditions (Choi and Rim 1991). Das et al. (2015) found that sulfate removal efficiency increased with sweetmeat waste as a nutrient supplement, with a COD/SO42− ratio up to 4, at which maximum sulfate removal (99%) was achieved. In the present study, the initial COD/SO42− ratio ranged from 0.19 to 0.33 for free microalgae. However, some of the sulfate was adsorbed onto immobilized SRB beads, and the released carbon source was mainly in the interior of the beads. Therefore, the COD/SO42− ratio for immobilized SRB increased significantly, resulting in effective sulfate reduction.

The variation in Cu(II) concentrations in the water was monitored throughout the experiment, and the removal rate is illustrated in Fig. 6b. The Cu(II) removal rate in R1–4 was 40.6–52.7% on the first day, increased to 78.3–91% after 10 days, and ultimately reached 91.7–98.2%. Although the adsorption of Cu(II) by immobilized SRB-microalgae beads was not investigated, adsorption surely contributed to metal removal, particularly during the period of SRB adaptation, which can be concluded from the analysis of Fig. 6a. More specifically, Bayramoğlu and Arica (2009) showed that the maximum Cu(II) adsorbed onto bare Ca alginate/PVA beads and microalgae (Scenedesmus quadricauda) entrapped in alginate/PVA composite beads at pH 6.0 were 0.534 ± 0.023 and 0.970 ± 0.028 mmol/g, respectively, and the biosorption process was spontaneous. Moreover, Cu(II) removal did not show similar fluctuations to sulfate during the experiment, likely because the beads had a higher binding capacity for Cu(II). Algal biomass possesses high binding capacity for heavy metals, since abundant polysaccharides and proteins in their extracellular polymeric substances contain functional groups such as amino, hydroxyl, carboxyl, and sulfate groups (Xiao and Zheng 2016; Henriques et al. 2017). Besides, sodium alginate, which is a linear polysaccharide composed of b-d-mannuronic (M) and a-l-guluronic acid (G) residues, is known to strongly bind metal ions and is currently used for heavy metal adsorption (Wang et al. 2013). After acclimation, the SRB were suited to their environment, and sulfate was reduced to S2− with concurrent formation of copper sulfide (CuS). After 45 days, residual Cu(II) concentrations were in the range of 1.08–4.99 mg/L. At the end of the experiment, Cu(II) was not completely removed, which may indicate that SRB activity was inhibited due to insufficient (only 0.142 g) microalgae. Furthermore, the solubility product constant (Ksp = 6.3 × 10−36) of copper sulfide is significantly lower and the dissolution of CuS did not occur, as evidenced by the steady removal of Cu(II) over a long period.

It is worth noting that in Fig. 6b, the sulfate reduction rate in R5 was smaller than that in R1–4. The most important reason was that less Cu(II) was adsorbed onto immobilized SRB-ethanol beads, and more Cu(II) in solution inhibited SRB activity. In short, the microalgae promoted SRB activity under high concentrations of heavy metals by providing a carbon source and shelter for SRB growth. Moreover, immobilization prevented cell washout and increased biomass in the bioreactor. We preliminarily demonstrated that immobilized SRB-microalgae beads can be used for the effective bioremediation of acid mine drainage.

4 Conclusions

Sulfate reduction by SRB using four microalgae biomass as carbon sources was investigated. Immobilized SRB beads were successfully prepared and applied in copper-containing wastewater. The results indicated that S. capricornutum, C. vulgaris, S. obliquus, and A. spiroides are suitable for promoting sulfate reduction, with lower COD released. These complex microalgae substrates were first degraded to propanoic acid, butanoic acid, and pentanoic acid by co-existing fermentative bacteria and then used by SRB. The compositional parameters for producing immobilized beads with an optimal sulfate reduction rate were PVA (2%), sodium alginate (1%), calcium chloride (6%), silica sand (1%), and 50 mL SRB suspension. It was evident that the immobilized SRB nutrient beads had better remediation efficiency than free cells, because the beads not only protected SRB against heavy metal toxicity but also enhanced the COD/SO42− ratios. After 45 days, the Cu(II) and sulfate removal rates ranged from 91.7 to 98.2% and from 72.4 to 74.4%, respectively. The excellent efficiency and stability of this immobilized SRB-microalgae bead provide a promising strategy for dealing with heavy metal pollution. Further work should be carried out in a continuous test to fully assess the regeneration of the immobilized beads.

References

Akbari, M., Hallajisani, A., Keshtkar, A. R., Shahbeig, H., & Ghorbanian, S. A. (2015). Equilibrium and kinetic study and modeling of Cu(II) and Co(II) synergistic biosorption from Cu(II)-Co(II) single and binary mixtures on brown algae C. indica. Journal of Environmental Chemical Engineering, 3, 140–149.

APHA-AWWA-WEF. (1998). Standard methods for examination of water and wastewater (20th ed.). Washington DC: American Public Health Association.

Bayramoğlu, G., & Arica, A. M. (2009). Construction a hybrid biosorbent using Scenedesmus quadricauda and Ca-alginate for biosorption of Cu(II), Zn(II) and Ni(II): kinetics and equilibrium studies. Bioresource Technology, 100, 186–193.

Benson, D. A., Boguski, M. S., Lipman, D. J., Ostell, J., Ouellette, B. F., Rapp, B. A., & Wheeler, D. L. (1999). GenBank. Nucleic Acids Research, 27, 12–17.

Bilal, M., Shah, J. A., Ashfaq, T., Gardazi, S. M. H., Tahir, A. A., Pervez, A., Haroon, H., & Mahmood, Q. (2013). Waste biomass adsorbents for copper removal from industrial wastewater—a review. Journal of Hazardous Materials, 263, 322–333.

Boshoff, G., Duncan, J., & Rose, P. D. (2004). The use of micro-algal biomass as a carbon source for biological sulphate reducing systems. Water Research, 38, 2659–2666.

Cai, L. M., Xu, Z. C., Qi, J. Y., Feng, Z. Z., & Xiang, T. S. (2015). Assessment of exposure to heavy metals and health risks among residents near Tonglushan mine in Hubei, China. Chemosphere, 127, 127–135.

Cao, J. Y., Zhang, G. J., Mao, Z. S., Li, Y. Y., Fang, Z. H., & Yang, C. (2012). Influence of electron donors on the growth and activity of sulfate-reducing bacteria. International Journal of Mineral Processing, 106-109, 58–64.

Choi, E., & Rim, J. M. (1991). Competition and inhibition of sulfate reducers and methaneproducers in anaerobic treatment. Water Science and Technology, 23, 1259–1264.

Costa, M. C., Santos, E. S., Barros, R. J., Pires, C., & Martins, M. (2009). Wine wastes as carbon source for biological treatment of acid mine drainage. Chemosphere, 75, 831–836.

Costa, J. M., Rodriguez, R. P., & Sancinetti, G. P. (2017). Removal sulfate and metals Fe+2, Cu+2, and Zn+2 from acid mine drainage in an anaerobic sequential batch reactor. Journal of Environmental Chemical Engineering, 5, 1985–1989.

Das, B. K., Roy, S., Dev, S., Das, D., & Bhattacharya, J. (2015). Improvement of the degradation of sulfate rich wastewater using sweetmeat waste (SMW) as nutrient supplement. Journal of Hazardous Materials, 300, 796–807.

Flores-Chaparro, C. E., Ruiz, L. F. C., Torre, M. C. A. D. L., Huerta-Diaz, M. A., & Rangel-Mendez, J. R. (2017). Biosorption removal of benzene and toluene by three dried macroalgae at different ionic strength and temperatures: algae biochemical composition and kinetics. Journal of Environmental Management, 193, 126–135.

Fuge, R., Pearce, F. M., Pearce, N. G., & Perkins, W. T. (1993). Geochemistry of Cd in the secondary environment near abandoned metalliferous mines, Wales. Applied Geochemistry, 8, 29–35.

Gonçalves, M. M., da Costa, A. C., Leite, S. G., & Sant'Anna Jr., G. L. (2007). Heavy metal removal from synthetic wastewaters in an anaerobic bioreactor using stillage from ethanol distilleries as a carbon source. Chemosphere, 69, 1815–1820.

Hao, T., Xiang, P., Mackey, H. R., Chi, K., Lu, H., Chui, H., van Loosdrecht, M. C. M., & Chen, G. H. (2014). A review of biological sulfate conversions in wastewater treatment. Water Research, 65, 1–21.

Henriques, B., Rocha, L. S., Lopes, C. B., Figueira, P., Duarte, A. C., Vale, C., Pardal, M. A., & Pereira, E. (2017). A macroalgae-based biotechnology for water remediation: simultaneous removal of Cd, Pb and Hg by living Ulva lactuca. Journal of Environmental Management, 191, 275–289.

Hlabel, P., Maree, J., & Bruinsma, D. (2007). Barium carbonate process for sulphate and metal removal from mine water. Mine Water and the Environment, 26, 14–22.

Hsu, H. F., Jhuo, Y. S., Kumar, M., Ma, Y. S., & Lin, J. G. (2010). Simultaneous sulfate reduction and copper removal by a PVA-immobilized sulfate reducing bacterial culture. Bioresource Technology, 101, 4354–4361.

Hungate, R. E., & Macy, J. (1973). The roll-tube method for cultivation of strict anaerobes. Bulletins from the Ecological Research Committee, 3, 123–126.

Kieu, H. T. Q., Müller, E., & Horn, H. (2011). Heavy metal removal in anaerobic semi-continuous stirred tank reactors by a consortium of sulfate-reducing bacteria. Water Research, 45, 3863–3870.

Lane, D. J. (1991). 16S/23S rRNA sequencing. In E. Stackebrandt & M. Goodfellow (Eds.), Nucleic acid techniques in bacterial systematics (pp. 115–175). New York: Wiley.

Lens, P. N. L., Visser, A., Janssen, A. J. H., Pol Hulshoff, L. W., & Lettinga, G. (1998). Biotechnological treatment of sulfate-rich wastewaters. Critical Reviews in Environmental Science and Technology, 28, 41–88.

Li, Y. C., Hu, X. X., & Ren, B. Z. (2016). Treatment of antimony mine drainage: challenges and opportunities with special emphasis on mineral adsorption and sulfate reducing bacteria. Water Science and Technology, 73, 2039–2051.

Li, X., Dai, L. H., Zhang, C., Zeng, G. M., Liu, Y. G., Zhou, C., Xu, W. H., Wu, Y., Tang, X. Q., Liu, W., & Lan, S. M. (2017). Enhanced biological stabilization of heavy metals in sediment using immobilized sulfate reducing bacteria beads with inner cohesive nutrient. Journal of Hazardous Materials, 324, 340–347.

Liamleam, W., & Annachhatre, A. P. (2007). Electron donors for biological sulphate reduction. Biotechnology Advances, 25, 452–463.

Liu, G. M., Ren, N. Q., Wang, A. J., Wang, X., Du, D. Z., & Chen, M. (2004). The fermentation type of acidogenic bacteria and their cooperation with SRB in an acidogenic sulfate-reducing reactor. Acta Scientiae Circumstantiae, 24, 782–788.

Ma, S. C., Zhang, H. B., Ma, S. T., Wang, R., Wang, G. X., Shao, Y., & Li, C. X. (2015). Effects of mine wastewater irrigation on activities of soil enzymes and physiological properties, heavy metal uptake and grain yield in winter wheat. Ecotoxicology and Environmental Safety, 113, 483–490.

Macías, F., Caraballo, M. A., Nieto, J. M., Rötting, T. S., & Ayora, C. (2012). Natural pretreatment and passive remediation of highly polluted acid mine drainage. Journal of Environmental Management, 104, 93–100.

Madzivire, G., Petrik, L. F., Gitari, W. M., Ojumu, T. V., & Balfour, G. (2010). Application of coal fly ash to circumneutral mine waters for the removal of sulphates as gypsum and ettringite. Minerals Engineering, 23, 252–257.

Martins, M., Faleiro, M. L., Silva, G., Chaves, S., Tenreiro, R., & Costa, M. C. (2011). Dynamics of bacterial community in up-flow anaerobic packed bed system for acid mine drainage treatment using wine wastes as carbon source. International Biodeterioration & Biodegradation, 65, 78–84.

McCauley, C. A., O’Sullivan, A. D., Milke, M. W., Weber, P. A., & Trumm, D. A. (2009). Sulfate and metal removal in bioreactors treating acid mine drainage dominated with iron and aluminum. Water Research, 43, 961–970.

Mothe, G. K., Pakshirajan, K., & Das, G. (2017). Heavy metal removal from multicomponent system by sulfate reducing bacteria: mechanism and cell surface characterization. Journal of Hazardous Materials, 324, 62–70.

Mwesigye, R. A., & Tumwebaze, B. S. (2017). Water contamination with heavy metals and trace elements from Kilembe copper mine and tailing sites in western Uganda; implications for domestic water quality. Chemosphere, 169, 281–287.

Pagnanelli, F., Cruz Viggi, C., Cibati, A., Uccelletti, D., & Palleschi, C. (2012). Biotreatment of Cr(VI) contaminated waters by sulphate reducing bacteria fed with ethanol. Journal of Hazardous Materials, 199-200, 186–192.

Postgate, J. R. (1984). The sulfate-reducing bacteria (2nd ed.). Cambridge: Cambridge Univ. Press.

Quan, L. M., Khanh, D. P., Hira, D., Fujii, T., & Furukawa, K. (2011). Reject water treatment by improvement of whole cell anammox entrapment using polyvinyl alcohol/alginate gel. Biodegradation, 22, 1155–1167.

Russell, R. A., Holden, P. J., Wilde, K. L., & Neilan, B. A. (2003). Demonstration of the use of Scenedesmus and Carteria biomass to drive bacterial sulfate reduction by Desulfovibrio alcoholovorans isolated from an artificial wetland. Hydrometallurgy, 71, 227–234.

Sahinkaya, E., & Yucesoy, Z. (2010). Biotreatment of acidic zinc-and copper-containing wastewater using ethanol-fed sulfidogenic anaerobic baffled reactor. Bioprocess and Biosystems Engineering, 33, 989–997.

Sahinkaya, E., Gunes, F. M., Ucar, D., & Kaksonen, A. H. (2011). Sulfidogenic fluidized bed treatment of real acid mine drainage water. Bioresource Technology, 102, 683–689.

Sánchez-Andrea, I., Sanz, J. L., Bijmans, M. F., & Stams, A. J. (2014). Sulfate reduction at low pH to remediate acid mine drainage. Journal of Hazardous Materials, 269, 98–109.

Seiler, H. G., Sigel, H., Sigel, A., & Townshend, A. (1988). Handbook on toxicity of inorganic compounds. New York: Marcel Dekker.

Sheoran, A. S., Sheoran, V., & Choudhary, R. P. (2010). Bioremediation of acid-rock drainage by sulphate-reducing prokaryotes: a review. Minerals Engineering, 23, 1073–1100.

Tamura, K., Peterson, D., Peterson, N., Stecher, G., Nei, M., & Kumar, S. (2011). MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Molecular Biology and Evolution, 28, 2731–2739.

Tang, J. C., Gong, G. C., Su, H., Wu, F. H., & Herman, C. L. (2016). Performance evaluation of a novel method of frost prevention and retardation for air source heat pumps using the orthogonal experiment design method. Applied Energy, 169, 696–708.

Wakeman, K. D., Erving, L., Riekkola-Vanhanen, M. L., & Puhakka, J. A. (2010). Silage supports sulfate reduction in the treatment of metals-and sulfate-containing waste waters. Water Research, 44, 4932–4939.

Wang, W., Kang, Y., & Wang, A. (2013). One-step fabrication in aqueous solution of a granular alginate based hydrogel for fast and efficient removal of heavy metal ions. Journal of Polymer Research, 20, 101–111.

Weisburg, W. G., Barns, S. M., Pelletier, D. A., & Lane, D. J. (1991). 16S ribosomal DNA amplification for phylogenetic study. Journal of Bacteriology, 173, 697–703.

Xiao, R., & Zheng, Y. (2016). Overview of microalgal extracellular polymeric substances (EPS) and their applications. Biotechnology Advances, 34, 1225–1244.

Yan, H., & Pan, G. (2002). Toxicity and bioaccumulation of copper in three green microalgal species. Chemosphere, 49, 471–476.

Yang, W. C., Tang, Q. Z., Wei, J. M., Ran, Y. J., Chai, L. Y., & Wang, H. Y. (2016). Enhanced removal of Cd(II) and Pb(II) by composites of mesoporouscarbon stabilized alumina. Applied Surface Science, 369, 215–223.

Yuvaraja, G., Subbaiah, M. V., & Krishnaiah, A. (2012). Caesalpinia bonducella leaf powder as biosorbent for Cu(II) removal from aqueous environment: Kinetic and isotherms. Industrial & Engineering Chemistry Research, 51, 11218–11225.

Zhang, M. L., & Wang, H. X. (2014). Organic wastes as carbon sources to promote sulfate reducing bacterial activity for biological remediation of acid mine drainage. Minerals Engineering, 69, 81–90.

Zhang, L., Cai, Z. J., Yang, J. M., Yuan, Z. W., & Chen, Y. (2015). The future of copper in China—a perspective based on analysis of copper flows and stocks. Science of the Total Environment, 536, 142–149.

Zhang, M. L., Wang, H. X., & Han, X. M. (2016). Preparation of metal-resistant immobilized sulfate reducing bacteria beads for acid mine drainage treatment. Chemosphere, 154, 215–223.

Funding

This work is financially supported by the National Water Pollution Control and Treatment Science and Technology Major Project in China (2014ZX07510-001 and 2015ZX07103-007) and the National Natural Science Foundation of China (No. 41471399, 41101474 and 51504094).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Yang, X. & Geng, B. Preparation of Immobilized Sulfate-Reducing Bacteria-Microalgae Beads for Effective Bioremediation of Copper-Containing Wastewater. Water Air Soil Pollut 229, 54 (2018). https://doi.org/10.1007/s11270-018-3709-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-018-3709-1