Abstract

Seven full-scale wastewater treatment plants were investigated to highlight the effectiveness of each treatment stage on removing Escherichia coli. The primary sedimentation achieved an average E. coli removal efficiency of 30.5% which was much lower than the suspended solids (58%), thus, revealing the absence of a linear relationship between the two parameters. Biological processes proved to be very important in the removal of E. coli through adsorption inside the sludge flocs and complex decay (mortality). In biological processes with a long retention time, such as activated sludge denitrification-nitrification, the decay was very important, whereas in the more traditional activated sludge process, without nitrification, the contribution of adsorption and mortality was quite balanced. Overall, the mechanical-biological treatment achieved a removal efficiency of 91.8–96.5% depending on the process. Additional removal can be achieved by disinfection. The effectiveness of E. coli removal with sodium hypochlorite was strictly depended on the product of residual chlorine (C R) with the contact time (t). The experimental curve fitted the Collins model well, with a standard deviation of less than 7%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Escherichia coli (E. coli) is a group of facultative anaerobic, rod-shaped bacteria which colonize the intestinal tract of humans and warm-blooded animals. Thus, E. coli are members of the fecal coliform community. Most E. coli strains are harmless, but some are pathogenic, as they can cause illness both inside and outside the intestinal tract (U.S. Food and Drug Administration 2012). Sewage is the main source of fecal contamination of surface water and represents a serious disease risk due to pathogenic organisms excreted by infected individuals.

Such pathogenic organisms belong to the very large kingdoms of bacteria, protozoa, helminths, and viruses. These pathogens can occur in water and wastewaters in very low concentrations, thus, making them difficult to identify. The microbiological analysis of water and wastewaters therefore commonly refer to micro-organism indicators. Fecal coliforms have been used for many years, and in many countries, this parameter is still used as a typical indicator of fecal pollution (Frigon et al. 2013). More recently, E. coli was taken as a more specific indicator, thus, becoming the reference parameter for many international and local legislations.

Wastewater treatment plants play an important role in the removal of typical pollution parameters such as BOD5 (biological oxygen demand after 5 days of incubation), COD (chemical oxygen demand), and SS (suspended solids), but at the same time they are also very effective in removing microbiological pollution. The scientific literature is full of information on total and fecal coliforms and their removal efficiency (Tchobanoglous et al. 2003; Kazmi et al. 2008; Cavallini et al. 2013; Massana et al. 2015). Total coliforms are present in raw sewage in the range of 107–109 CFU 100 ml−1, while fecal coliforms are detected in the range of 106–108 CFU 100 ml−1 (George et al. 2002; Tchobanoglous et al. 2003; Raboni et al. 2015).

Mechanical-biological wastewater treatment plants can remove these indicators by 90–98%, and an effective additional removal of up to 99.999% can be achieved by a final disinfection process that becomes almost mandatory in case of wastewater reuse (Papa et al. 2016). However, the disinfection stage can also result in the formation of by-products that may adversely impact upon the environment, especially in case of chlorine use, both for wastewater treatment plants (EPA Victoria 2002; Pignata et al. 2012) and for drinking water treatment plants (Sorlini et al. 2015a, 2016). Thus, a methodological approach proposed by Sorlini et al. (2015b) for drinking water treatment plants, that could be applied for wastewater treatment plants, is very useful to verify the critical issues of a water treatment plant and, by means of experimental studies (at laboratory and/or full scale), optimize the operative conditions also for disinfection processes (Sorlini et al. 2015c).

Although there have been many studies on the presence of E. coli in waterbodies and the related health risk, there has been little coverage regarding E. coli in treatment plants (Hartman et al. 2006; Soller et al. 2010; Semenov et al. 2011; Carlos et al. 2012; Taegyu and Jong-In 2013; Landa-Cansigno et al. 2013).

We, thus, investigated seven full-scale wastewater treatment plants located in an area north of Milan (in northern Italy). Six of these plants carry out biological denitrification-nitrification and phosphorus removal, which are very well studied process and applied all over the world (USEPA 2010; Bautista-Toledo et al. 2015; Capodaglio et al. 2015; Copelli et al. 2015; Raboni et al. 2013a, b, 2014a, b, 2015; Viotti et al. 2015). The seventh plant carries out a biological process without nitrification. All plants are equipped with a disinfection unit.

The choice of these wastewater treatment plants (WWTPS) as a case study can be considered significant due to these aspects: (i) treatment plant is at full-scale, (ii) the capacity of WWTPS is very wide (from 5600 to 250,000 population equivalent), (iii) the process schemes of WWTPS (even with tertiary treatment) are widely used not only in the local situation of northern Italy.

We assessed the effects of individual treatment steps (primary sedimentation, biological and tertiary treatments, and disinfection), as well as the correlation between E. coli removal efficiency and the removal of BOD5 and SS. We also assessed the incidence of residual chlorine and retention time on the performance of the disinfection unit.

2 Materials and Methods

2.1 The Wastewater Treatment Plants

The investigation regards seven full-scale wastewater treatment plants, located in an area north of Milan. Table 1 reports the main features of each individual plant.

All plants treat domestic wastewater with various industrial wastewaters (from 5 to 20% in terms of PE (Population Equivalent) n) (Torretta and Katsoyiannis 2013). For the purposes of the investigation, it is important to highlight the following:

-

Plant 1 consists of a primary sedimentation (after pretreatment) and an oxidative biological-activated sludge process which run at a medium food-to-mass (F:M) ratio (about 0.22 Kg BOD5 Kg SS−1 day−1). The plant does not carry out nitrification.

-

Plant 2 does not have a primary sedimentation, and the pretreated sewage directly feeds the biological-activated sludge process complete with denitrification-nitrification.

-

Plants 3, 4, and 5 involve a similar process. All these plants carry out a primary sedimentation (after pretreatment) and a biological-activated sludge process complete with denitrification-nitrification.

-

Plant 6 is similar to plant 2, with an additional tertiary treatment (coagulation-flocculation with ferric chloride)

-

Plant 7 is similar to plants 3, 4, and 5, with an additional tertiary treatment (microfiltration)

-

Plants 1 to 6 carry out a final disinfection with sodium hypochlorite, while plant 7 carries out the disinfection by a pre-dosage of sodium hypochlorite and a final ozonation.

-

All plants are run in full compliance with the discharge limits issued by the Italian legislation (Italian Parliament Legislative Decree 152/2006 and further modification/integration): BOD5 = 25 mg L−1, SS = 35 mg L−1, TN (total nitrogen) = 10 mg L−1, TP (total phosphorous) = 1 mg L−1; E. coli = 5000 CFU 100 mL−1.

The aim of the investigation was to highlight the fate of E. coli through the different treatment steps.

2.2 Sampling and Analysis

The investigation lasted 6 months, and 20 sampling campaigns (about one per week) were carried out on each plant. The sampling points were the following:

-

Raw wastewater

-

After primary sedimentation

-

After biological + tertiary treatment

-

Final effluent (after disinfection)

Mean daily samples were collected at each point, and E. coli, BOD5, and SS were analyzed. E. coli was enumerated by the membrane filtration technique, and the results were expressed in colony-forming units (CFU) per 100 mL−1. In addition, various operating data of the plants (such as flow rate, temperature and pH of wastewater and treated effluent, dissolved oxygen in the oxidizing biological reactor, and chlorine residual) were collected.

Moreover, E. coli was measured in primary sludge and excess sludge; to extract bacteria from flocs and sludge, the samples were left to settle for 15 min. Then, bacteria from the settled phase were extracted by sonication and recovered.

The measures of E. coli in primary and excess sludge, as well as the E. coli determination in the sampling points reported above, allow to carry out a mass balance to try to assess the E. coli removal phenomena in the different stage of WWTP.

Sampling and analyses were carried out in accordance with the official analytical methods of the Italian legislation, issued by the IRSA-Institute for Water Research of the Italian National Research Council and APAT-Agency for the protection of the Environment and Technical Services (IRSA and APAT 2003).

During this analytical campaign, a specific search on plants 1, 4, and 6 was also carried out to verify the correlation of the E. coli removal efficiency with C R⋅t (product of residual chlorine at the end of the disinfection reactor with the contact time). Thus, 60 instantaneous samples (20 samples for each plant) were collected for the E. coli count, while the residual chlorine was detected with a portable HI series HI711 analyzer using a fixed wavelength LED and silicon photo detector, in the range 0–3.00 mg L−1, resolution = 0,01 mg L−1. These measures were compared with the residual chlorine amperometric analyzers mounted on line at each plant.

The removal efficiencies of each treatment unit and of the whole plant were calculated as follows:

or

where Xo represents the value of tested parameters (E. coli, BOD5, and SS) at the inlet and X at the outlet.

3 Results and Discussion

3.1 E. coli in Raw Sewage and Discharged Effluent

Figure 1 shows the average E. coli concentration in the raw sewage and discharged effluent of the seven wastewater treatment plants. The standard deviations (SDs) of the concentrations are also reported. The average concentration in the raw sewage varied in the range 5.60–7.11 E + 06 CFU 100 mL−1. In each individual plant, the fluctuation in concentration was characterized by a CV (coefficient of variation) in the order of 23–38% of the average concentrations. The average concentration of E. coli in the treated effluent was affected by the specific disinfectant dosage and varied in the range of 0.91–2.60 E + 03 CFU 100 mL−1, while the SD of each individual plant fluctuated in the narrower range of 1.95–4.04 E + 2.0 CFU 100 mL−1 (CV = 15.5–23.0% of the average concentrations).

The removal efficiency is determined by the combined actions of the individual treatment units whose contribution is highlighted in the following sections.

Figure 2 shows the average specific loads of E. coli as a function of the plant size, in terms of the sewered population. These loads show a tendency to increase with the plant size; the equations concerning the increase of E. coli (both for concentrations and specific load) with respect plant capacity were reported in Fig. 2. Indeed, some authors have reported that in the sewer network, the bacteria can multiply and their growth depends on the mean residence time in the sewer, thus, approximately on the plant size (George et al. 2002). This hypothesis may be plausible; however, we believe that the data collected in this research are not sufficient to give scientific certainty to this correlation. Moreover, this possible multiplicative effect may depend on several factors such as the temperature of the wastewater and the hydraulics features of the sewer network (slope, mean residence time). In addition, the specific loads are negatively affected by the old septic tanks of isolated houses (also connected to the sewer), as mainly observed in small sewered communities in the area. Finally, it also seems reasonable to consider that a very long retention time in the sewer (typical of large communities) and the progressive cooling of the wastewater may promote the decay of fecal coliform, rather than their multiplication.

3.2 E. coli Removal by Primary Treatment Alone

Figure 3 shows the E. coli log10 removal by primary sedimentation, as a function of SS removal. SS results were considerably reduced by this treatment (on average by 58%), while E. coli were removed to a much lower extent (average 36.7%). The figure highlights the lack of a significant linear relationship between the removal of SS and the removal of E. coli. In particular, the findings suggest that highest amount of E. coli is flushed-out with the supernatant of the primary sedimentation, while a smaller amount remains trapped in the settled sludge. As a useful comparison, the removal of fecal coliforms in primary sedimentation occurs in varying degrees of between 20 and 50% (Tchobanoglous et al. 2003).

3.3 E. coli Removal by the Whole Treatment (Except Disinfection)

Figure 4 shows the E. coli removal efficiency of the seven plants. The data prove that secondary and tertiary treatments are much more efficient in eliminating E. coli than primary settling. On average, the whole treatment (primary sedimentation—if present; biological process, tertiary treatment—if present) achieved a 94.2% efficiency, but with a considerable difference between plants; efficiency was greater in plants with high retention times in the biological reactors and equipped with tertiary treatments. Thus, the order of increasing performance for the four different types was: plant 1 = plant 2 < plants 3, 4, and 5 < plants 6 and 7.

The E. coli removal efficiency for plants equipped with primary sedimentation was equal to (i) 38.3% for plant 1, (ii) 29.1% for plant 3, (iii) 38.7% for plant 4, (iv) 32.5% for plant 5, and (v) 45% for plant 7.

Plants 7 and 6 performed best (96.5 and 96.1% respectively) due to the combined effect of primary sedimentation (only in plant 7), high retention time in biological denitrification-nitrification reactors, and the tertiary treatment. A comparison of plants 7 and 6 with plants 3, 4, and 5 proves that the tertiary treatment adds about two percentage points to the removal efficiency.

Figures 5 and 6 show the E. coli removal efficiency of the seven plants against the removal efficiency of SS and BOD5 which are the two most common analytical parameters to assess the performance of a wastewater treatment plant. The data show that E. coli is generally better removed than SS and BOD5, thus, confirming the additional action of the biological and tertiary treatments. In particular, as concerns the tertiary treatments, the dots related to plants 6 and 7 are much higher than the equivalence line.

The main mechanisms involved in the removal of E. coli and other fecal coliforms by activated sludge is the mortality due to protozoa predation, the lytic action of certain bacteria, and the adverse effects of the physical-chemical environment of the mixed-liquor (temperature, dissolved oxygen, substrates, pH, salinity, rH, toxics).

It is also worth highlighting the sorption action of activated sludge flocs. The action of activated sludge in removing E. coli (and other coliforms) follows a two-step process: first E. coli is rapidly adsorbed into the sludge flocs, after which they are slowly eliminated by the mortality mechanisms (van der Drift et al. 1977; Hwang 2012; Orruño et al. 2014). Therefore, a plant with a low retention time in the biological process (such as plant 1) is expected to exhibit a relatively low E. coli decay and a relatively high transport in excess sludge.

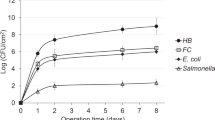

During the investigation, seven samples of primary sludge and excess sludge of the seven plants were analyzed for E. coli determination. These data combined with those previously mentioned meant that the average E. coli balance of the investigated mechanical-biological plants could be plotted (Fig. 7). This figure shows the fundamental role of the decay mechanism inside the biological reactors, which ranges between 37 and 66% depending on the type of plant. For plant 1, the role of decay is roughly comparable to the role of primary sedimentation and of entrapping in excess sludge, due to its short retention time in the biological treatment. Instead, plants 2 and 6 (without primary sedimentation and with a high retention time in the biological system) achieve a very high removal by decay (66–69%) and the contribution of the removal with excess sludge is still significant. The role of decay is also very important in plants 3, 4, and 5, thus, confirming that this mechanism is the main cause of E. coli removal in plants with a high retention time in the biological treatment. On the other hand, lower retention times favor greater removal with excess sludge. Anyway, almost all the cited mechanisms contribute significantly to E. coli removal, as only tertiary treatment has a low percentage of less than 3%.

3.4 E. coli Removal by Disinfection

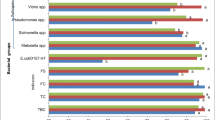

Data on disinfection were collected for all the plants; however, a more detailed investigation was carried out for plants 1, 4, and 6 as these three are representative examples of the different types of plant. In the various plants, the sodium hypochlorite dosage is set to obtain a concentration of E. coli in the final effluent of less than 5000 CFU 100 mL−1 (recommended limit according to Italian legislation). Thus, the dosage in plants 1 to 6 varied in the range of 2–5 mg L−1 (as Cl2). Plant 1 had the highest dosage because of the high concentrations of ammonia and SS in the influent of the disinfection reactor. Plant 6 had the lowest dosage due to the complete nitrification of the ammonia and the tertiary treatment, which allows a low SS concentration at the disinfection inlet. The E coli removal efficiency achieved by the disinfection amounted to 99.64–99.93%.

The efficiency of disinfection with chlorine and its derivatives is mainly affected by the chlorine residual C R and the contact time t. Increasing values of these parameters lead to increased efficiency. These relationships were studied in plants 1, 4, and 6 by plotting the experimental value Eo/E (E. coli inlet disinfection/E. coli outlet disinfection) against the product C R⋅t. The choice of the ratio Eo/E led to a better comparison of the experimental data with two of the most commonly used models to describe the performance of the chlorine disinfection of secondary effluents (Tchobanoglous et al. 2003):

-

$$ \mathrm{Collins}\ \mathrm{model}\ \mathrm{E}\mathrm{o}/\mathrm{E} = {\left(1 + 0,23\ {\mathrm{C}}_{\mathrm{R}}\cdot t\right)}^3 $$(3)

-

$$ \mathrm{White}\ \mathrm{model}\ \mathrm{E}\mathrm{o}/\mathrm{E} = {\left[\left({\mathrm{C}}_{\mathrm{R}}\cdot t\right)/b\right]}^n $$(4)

where the typical values of the constants, for fecal coliforms, are b = 3.0 and n = 2.8.

Figure 8 shows the experimental points and their regression line, which demonstrate a similar exponential growth; however, their best mathematical representation is given by a polynomial series with a coefficient of determination of R 2 = 0.96. A comparison with the cited models proves that the experimental curve fits the Collins model well, with a standard deviation lower than 7.0%.

4 Conclusions

The investigation carried out on seven full-scale wastewater treatment plants highlighted the efficiency in terms of E. coli removal of the individual treatment units.

-

The primary sedimentation achieved an average E. coli removal efficiency of 36.7% with a wide fluctuation depending on the design criteria. The removal of E. coli was much lower than the suspended solids (58.0% removal efficiency), thus, highlighting the absence of a linear relationship between the two parameters. The largest amount of E. coli (69.5%) in the raw sewage is transported to the biological process with the sedimentation supernatant.

-

The removal of E. coli in the biological treatment proved to be highly effective, more so than removing BOD5 and suspended solids. E. coli can be removed by adsorption inside the sludge flocs and subsequently by complex decay phenomenon (mortality). In biological processes with a long retention time, such as activated sludge denitrification-nitrification, the decay is highly important, whereas in the more traditional activated sludge process, without nitrification, the contribution of adsorption and mortality is quite balanced. A count balance of a treatment plant with primary sedimentation followed by a biological process with denitrification-nitrification leads to the following average E. coli removal percentages: 31% by primary sedimentation, 53% through decay, and 16% by adsorption (and subsequent extraction with excess sludge). A similar plant but without nitrification had the following removal percentages: 33.0% by primary sedimentation, 37% through decay, and 30% by adsorption. One of the plants without primary sedimentation and with biological denitrification-nitrification gave a 30.5% removal by adsorption and 67% by decay.

-

Tertiary treatment, despite its great importance in removing suspended solids, BOD5, and COD, is not very effective in E. coli removal (less than 3% of the total removal).

-

Overall, the mechanical-biological treatment achieved an E. coli removal efficiency of 91.8–96.5% depending on the type of process. Additional removal can be achieved by disinfection. The use of sodium hypochlorite as a disinfectant agent was investigated in three typical plants. The results highlight the key role of the factor C R⋅t (i.e., the product of the residual chlorine with the contact time). The Eo/E ratio, between E. coli at the inlet and outlet of the disinfection reactor, can be expressed by an exponential equation that fits the Collins model well with a standard deviation lower than 7%.

The knowledge of the fate of E. coli in wastewater treatment plants allows a more accurate assessment of the risks connected to the disposal and reuse of sludge and wastewater at different degrees of treatment. Further case of studies related to various types of treatment processes, such as membrane bioreactor (MBR) and process based on attached growth biomass, and different operating conditions (i.e., different F/M ratio, etc.,) may implement and enforce the results of this research.

References

Bautista-Toledo, M. I., Espinosa-Iglesias, D., Carrasco-Marin, F., Pérez-Cardenas, A. F., & Maldonado, F. I. (2015). Influence of the physicochemical properties of inorganic supports on the activity of immobilized bacteria for water denitrification. Journal of Environmental Management, 156, 81–88. doi:10.1016/j.jenvman.2015.03.031.

Capodaglio, A.G., Hlavínek, P., & Raboni, M. (2015). Physico-chemical technologies for nitrogen removal from wastewaters: a review. Revista Ambiente & Agua, 481–498 (2015). doi:10.4136/ambi-agua.1618.

Carlos, C., Alexandrino, F., Stoppe, N. C., Sato, M. I. Z., & Ottoboni, L. M. M. (2012). Use of Escherichia coli BOX-PCR fingerprints to identify sources of fecal contamination of water bodies in the State of São Paulo, Brazil. Journal of Environmental Management, 93, 38–43. doi:10.1016/j.jenvman.2011.08.012.

Cavallini, G. S., de Campos, S. X., de Souza, J. B., & Vidal, C. M. D. (2013). Evaluation of the physical-chemical characteristics of wastewater after disinfection with peracetic acid. Water, Air, and Soil Pollution, 224(10), 1–11. doi:10.1007/s11270-013-1752-5.

Copelli, S., Raboni, M., & Urbini, G. (2015). Water pollution: biological oxidation and natural control techniques. In J. Reedijk (Ed.), Reference module in chemistry, molecular sciences and chemical engineering (pp. 1–28). Elsevier. doi:10.1016/B978-0-12-409547-2.11419-2.

EPA Victoria (2002). Guidelines for environmental management—disinfection of treated wastewater. Publication 730, September. ISBN 0 7306 7623 4.

Frigon, D., Biswal, B. K., Mazza, A., Masson, L., & Gehr, R. (2013). Biological and physicochemical wastewater treatment processes reduce the prevalence of virulent Escherichia coli. Applied and Environmental Microbiology, 79(3), 835–844. doi:10.1128/AEM.02789-12.

George, I., Crop, P., & Servais, P. (2002). Fecal coliform removal in wastewater treatment plants studied by plate counts and enzymatic methods. Water Research, 36, 2607–2617.

Hartman, L. J., Grimsley, G. A., Martin, A. E., & Register, K. M. (2006). A long-term study comparing membrane filtration with Colilert® defined substrates in detecting fecal coliforms and Escherichia coli in natural waters. Journal of Environmental Management, 80, 191–197. doi:10.1016/j.jenvman.2005.08.024.

Hwang, S.W. (2012). Optimizing Pathogen Destruction during Urban Wastewater Treatment to Provide for More Sustainable Effluent Disinfection. Proceedings of 1st Civil and Environmental Engineering Student Conference, Imperial College London, 25–26 June.

IRSA-Institute for Water Research of the National Research Council, APAT-Agency for the protection of the Environment and Technical Services (2003). Analytical methods for water-Report 29/2003, Rome, Italy.

Italian Parliament (2006). Legislative Decree No. 152 approving the Code on the Environment. Official Gazette of the Italian Republic No. 88, 14th April 2006.

Kazmi, A. A., Tyagi, V. K., Trivedi, R. C., & Kumar, A. (2008). Coliforms removal in full-scale activated sludge plants in India. Journal of Environmental Management, 87, 415–419. doi:10.1016/j.jenvman.2007.01.017.

Landa-Cansigno, O., Durán-Álvarez, J. C., & Jiménez-Cisneros, B. (2013). Retention of Escherichia coli, Giardia lamblia cysts and Ascaris lumbricoides eggs in agricultural soils irrigated by untreated wastewater. Journal of Environmental Management, 128, 22–29. doi:10.1016/j.jenvman.2013.04.049.

Massana, A. C., Gómez-Doñate, M., Sánchez, D., Belanche-Muñoz, L. A., Muniesa, M., & Blanch, A. R. (2015). Predicting fecal sources in waters with diverse pollution loads using general and molecular host-specific indicators and applying machine learning methods. Journal of Environmental Management, 151, 317–325. doi:10.1016/j.jenvman.2015.01.002.

Orruño, M., Garaizabal, I., Bravo, Z., Parada, C., Barcina, I., & Arana, I. (2014). Mechanisms involved in Escherichia coli and Serratia marcescens removal during activated sludge wastewater treatment. MicrobiologyOpen, 3(5), 657–667. doi:10.1002/mbo3.196.

Papa, M., Bertanza, G., & Abbà, A. (2016). Reuse of wastewater: a feasible option, or not? A decision support system can solve the doubt. Desalination and Water Treatment, 57(19), 8670–8682. doi:10.1080/19443994.2015.1029532.

Pignata, C., Fea, E., Rovere, R., Degan, R., Lorenzi, E., de Ceglia, M., Schilirò, T., & Gilli, G. (2012). Chlorination in a wastewater treatment plant: acute toxicity effects of the effluent and of the recipient water body. Environmental Monitoring and Assessment, 184, 2091–2103. doi:10.1007/s10661-011-2102-y.

Raboni, M., Torretta, V., Viotti, P., & Urbini, G. (2013a). Experimental plant for the physical-chemical treatment of groundwater polluted by Municipal Solid Waste (MSW) leachate, with ammonia recovery. Revista Ambiente & Agua, 8, 22–32. doi:10.4136/ambi-agua.1250.

Raboni, M., Torretta, V., & Urbini, G. (2013b). Influence of strong diurnal variations in sewage quality on the performance of biological denitrification in small community wastewater treatment plants (WWTPs). Sustainability, 5, 3679–3689. doi:10.3390/su5093679.

Raboni, M., Torretta, V., Viotti, P., & Urbini, G. (2014a). Pilot experimentation with complete mixing anoxic reactors to improve sewage denitrification in treatment plants in small communities. Sustainability., 6, 112–122. doi:10.3390/su6010112.

Raboni, M., Torretta, V., Viotti, P., & Urbini, G. (2014b). Calculating specific denitrification rates in pre-denitrification by assessing the influence of dissolved oxygen, sludge loading and the mixed-liquor recycle. Environmental Technology, 35, 2582–2588. doi:10.1080/09593330.2014.913690.

Raboni, M., Gavasci, R., & Viotti, P. (2015). Influence of denitrification reactor retention time distribution (RTD) on dissolved oxygen control and nitrogen removal efficiency. Water Science and Technology, 72, 45–51. doi:10.2166/wst.2015.188.

Semenov, A. V., van Overbeek, L., Termorshuizen, A. J., & van Bruggen, A. H. C. (2011). Influence of aerobic and anaerobic conditions on survival of Escherichia coli O157:H7 and Salmonella enterica serovar Typhimurium in Luria–Bertani broth, farm-yard manure and slurry. Journal of Environmental Management, 92, 780–787. doi:10.1016/j.jenvman.2010.10.031.

Soller, J., Embrey, M., Tuhela, L., Ichida, A., & Rosen, J. (2010). Risk-based evaluation of Escherichia coli monitoring data from undisinfected drinking water. Journal of Environmental Management, 291, 2329–2335. doi:10.1016/j.jenvman.2010.06.017.

Sorlini, S., Collivignarelli, M. C., & Canato, M. (2015a). Effectiveness in chlorite removal by two activated carbons under different working conditions: a laboratory study. Journal of Water Supply: Research and Technology-AQUA, 64(4), 450–461. doi:10.2166/aqua.2015.132.

Sorlini, S., Collivignarelli, M. C., Castagnola, F., Crotti, B. M., & Raboni, M. (2015b). Methodological approach for the optimization of drinking water treatment plants’ operation: a case study. Water Science and Technology, 71(4), 597–604. doi:10.2166/wst.2014.503.

Sorlini, S., Biasibetti, M., Collivignarelli, M. C., & Crotti, B. M. (2015c). Reducing the chlorine dioxide demand in final disinfection of drinking water treatment plants using activated carbon. Environmental Technology, 36(12), 1499–1509. doi:10.1080/09593330.2014.994043.

Sorlini, S., Biasibetti, M., Gialdini, F., & Collivignarelli, M. C. (2016). How can drinking water treatments influence chlorine dioxide consumption and by-product formation in final disinfection? Water Science and Technology: Water Supply, 16(2), 333–346. doi:10.2166/ws.2015.142.

Taegyu, K., & Jong-In, H. (2013). Fast detection and quantification of Escherichia coli using the base principle of the microbial fuel cell. Journal of Environmental Management, 130, 267–275. doi:10.1016/j.jenvman.2013.08.051.

Tchobanoglous, G., Burton, F. L., & Stensel, H. D. (2003). Wastewater engineering—treatment and reuse (4th ed.). New York: Mc Graw Hill.

Torretta, V., & Katsoyiannis, A. (2013). Occurrence of polycyclic aromatic hydrocarbons in sludges from different stages of a wastewater treatment plant in Italy. Environmental Technology, 34(7), 937–943. doi:10.1080/09593330.2012.722693.

U.S. Food & Drug Administration (2012). Bad Bug Book—Handbook of Foodborne Pathogenic Microorganisms and Natural Toxins (2nd Ed.), Center for Food Safety and Applied Nutrition (CFSAN) of the Food and Drug Administration (FDA), U.S. Department of Health and Human Services.

US-EPA, United States Environmental Protection Agency (2010). Nutrient Control Design Manual. Report EPA/600/R‐10/100. Office of Research and Development / National Risk Management Research Laboratory, Cincinnati, USA.

van der Drift, C., van Seggellen, E., Stumm, C., Hol, W., & Tuinte, J. (1977). Removal of Escherichia coli in wastewater by activated sludge. Applied and Environmental Microbiology, 34(9), 315–319.

Viotti, P., Collivignarelli, M. C., Martorelli, E., & Raboni, M. (2015). Oxygen control and improved denitrification efficiency by dosing ferrous ions in the anoxic reactor. Desalination and Water Treatment. doi:10.1080/19443994.2015.1089200.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Raboni, M., Gavasci, R. & Torretta, V. Assessment of the Fate of Escherichia coli in Different Stages of Wastewater Treatment Plants. Water Air Soil Pollut 227, 455 (2016). https://doi.org/10.1007/s11270-016-3157-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-016-3157-8