Abstract

The present work investigates the potential of two experimental field columns (FC-2 and FC-4) to reduce volatile organic compound (VOC) emissions from a municipal solid waste (MSW) landfill located in Quebec, Canada. The FC-2 and FC-4 were fed by raw biogas coming from the landfill site. The VOC were identified and quantified in emitted biogas and raw biogas. The emitted biogas was collected at the surface of FC-2 and FC-4, and the raw biogas was obtained directly from the well. The main groups of the VOC in the landfill biogas are BTEX (66 %), alkanes (19 %), cyclic compounds (10 %), and halogenated compounds (5 %). The concentration of VOC in the landfill raw biogas varies from below the limit of detection (BLD) to 22 ppmv, and that of the emitted biogas varies from BLD to 3.1 ppmv. The result of this study showed that the experimental field columns had a very high potential to reduce the VOC emissions from the investigated landfill. The effectiveness of the VOC emission removal for the FC-2 and FC-4 was shown to be practically 100 % for many compounds. The experimental field column elimination capacity of VOC emissions is in the range of 0.1 to 4.6 mg m−3 h−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

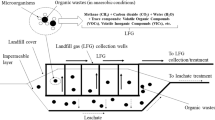

Waste disposal represents a serious problem if biogas emissions are not controlled (Mnif et al. 2012). Broadly, landfills are the most common, simple, and economic methods to dispose the wastes (Erses et al. 2008). This method produces biogas emissions into the atmosphere. Decomposition of solid wastes may cause environmental problems, more especially if the biogas emissions are not controlled. Over the last decade, much attention has been paid to the biogas emitted by municipal solid waste (MSW) landfills. MSW contains hazardous substances, vehicle maintenance products, mercury-containing waste, certain detergents, personal care products, pharmaceuticals, garden pesticides, batteries, and many other industrial wastes (Slack et al. 2005). Landfill biogas (LFG) is produced by microbial degradation of organic matter under anaerobic conditions (Beylot et al. 2012; Chiriac et al. 2007). Biogas is produced in different environments such as (i) in sewage sludge, (ii) in bio-waste digesters during anaerobic degradation of organic materials, and (iii) in landfills (Rasi et al. 2007). Biogas production depends on the waste features and age, the available organic biodegradable carbon content, and climatic conditions (Desideri et al. 2003; Manna et al. 1999). The LFG content is typically composed of 55–65 % v/v methane, 40–45 % v/v carbon dioxide, 5–15 % v/v nitrogen, and 1 % v/v for trace compounds (volatile organic compounds (VOC) and odorant compounds) (Albanna et al. 2007; Beylot et al. 2012; Durmusoglu et al. 2010; Johari et al. 2012; Ménard et al. 2012; Rasi et al. 2007, 2011; Schweigkofler and Niessner 1999; Shin et al. 2002; Tassi et al. 2009). According to Rasi et al. (2007), amounts of VOC and odorant compounds are low compared to methane. The formation or production of the VOC in landfill can be results from (i) either associated or competitive secondary reactions or reorganization of the organic matter during the humification and (ii) escaping of VOC present initially in the waste buried in landfill; the biogas is the emission vector (Staley et al. 2006). Many VOC are emitted from landfill (Scheutz et al. 2008). The LFG contained at least these classes of compounds: saturated and unsaturated hydrocarbons, acidic hydrocarbons and organic alcohols, aromatic hydrocarbons, halogenated compounds, sulfur compounds such as carbon disulfide and mercaptans, and inorganic compounds (Allen et al. 1997). The VOC concentrations depend on the quantity and composition of the solid waste dumped at the site (Mor et al. 2006). The VOC concentration in raw biogas of landfill can range from 0.05 to 1077 mg m−3 (Rasi et al. 2011). Benzene, toluene, ethylbenzene, and xylene isomers (known by BTEX compounds) form an important group of VOC found in landfill biogas (Durmusoglu et al. 2010; Hoque et al. 2008).

The VOC emissions are prone to play an essential role in the photochemical processes, which are responsible for air pollution in the atmosphere (Wang et al. 2012; Yu et al. 2012). In the presence of NOx, the VOC compounds react with OH radicals to form ozone resulting in modifying the chemical reactions in the atmosphere (Hoque et al. 2008). The VOC are harmful to animals and plants, and they contribute to the greenhouse effect (Salvador et al. 2006). Some VOC despite their low concentrations may exert adverse effects on environment and human health (Durmusoglu et al. 2010; Mohan et al. 2006). According to Haque et al. (2012) and Mello et al.(2010), the chronic exposure to BTEX is linked to increased risk of cancer; central nervous system disorders; and damage to the blood, liver, and kidneys.

Control of VOC emissions from landfill facilities is becoming, therefore, one of the largest environmental challenges facing the municipal waste management to day. Many techniques are commonly employed to reduce the biogas emission from landfill sites, such as installation of daily and final covers and biogas collection systems. However, none of these systems are 100 % efficient (Spokas et al. 2006). Consequently, part of the generated landfill gas and associated VOC can escape to the atmosphere as fugitive emissions. The installation of properly designed biofilters appears to be a promising alternative to reduce fugitive and residual emissions of methane. It was hypothesized in the present study that biofilters could also be effective in reducing VOC emissions. The biotechnology approach is an efficient and potential alternative for the treatment of VOC compounds (Mello et al. 2010). The most common emission control technology in current use is the installation of biocover on landfill biogas. The microorganisms living in biological systems are the capacity to degrade VOC (Haque et al. 2012). According to Haque et al. (2012), many research studies remain to be carried out before this technology can be widely implemented. A review of the literature suggests that studies focused on the removal of VOC in landfill sites are rather limited (Allen et al. 1997; Durmusoglu et al. 2010; Haque et al. 2012; Scheutz et al. 2008). To enrich scientific research in this field, two experimental field columns FC-2 and FC-4 were installed on Saint-Nicephore (Quebec, Canada) landfill site and are fed by biogas coming from the biogas well. This paper documents with field data the reduction of VOC emissions by experimental field columns under the real meteorological conditions. The main objectives of the present work are concerned with the identification and quantification of VOC in raw biogas and emitted biogas collected at the surface of FC-2 and FC-4. The sub-objective is to study the VOC removal effectiveness and the elimination capacity of FC-2 and FC-4 to reduce VOC contained in LFG under the real conditions. This paper addresses the characterization of the composition of the LFG.

2 Materials and Methods

2.1 Description of the Field Columns

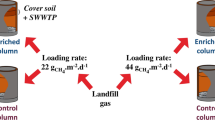

In June 2012, two experimental field columns (FC-2 and FC-4) were constructed in Saint-Nicephore (Quebec, Canada) landfill site (Fig. 1).

These experimental field columns are 0.90 m (L), 0.90 m (W), and 0.45 m (H). The FC-2 is composed of sand and top soil (Table 1). FC-4 is composed by sand, top soil, and compost (Table 1). The FC-2 and FC-4 characteristics are documented in Table 1. The natural media are the commonly used packing media in the biofilters due to their large surface area, high void fraction, and high microbial population density with sufficient nutrients (Galera et al. 2008; Singh et al. 2010).

The atmospheric conditions in Saint-Nicéphore landfill site were reported in Table 2.

FC-2 and FC-4 were fed by the biogas coming from a capture well. Columns were fed at different flow rates ranging from 12 to 18 L h−1 during the sampling period. The sampling period took place in Saint-Nicéphore (Quebec, Canada) from 14 August to 30 September 2012.

2.2 Collection of Samples and Analyses

2.2.1 Collection of Samples

To collect the emitted biogas from FC-2 and FC-4, a rectangular PVC flux chamber was used (Fig. 2). A peristaltic pump was used to collect a volume of 10 L of the emitted biogas in the flux chamber. Gas was pumped using a peristaltic pump at a flow rate adjusted to match the methane (CH4) surface flux (obtained previously to VOC sampling). The CH4 flux rate was estimated using Eq. 1 (Barlaz et al. 2004; Scheutz et al. 2008):

where (dC/dt) is the slope of a plot of methane concentration (ppmv) versus time (min), V (m3) is the volume, and A is the area (m2) of the flux chamber.

A volume of 10 L of the raw and emitted biogases was collected directly from the biogas well (Fig. 3). Bags for colleting the biogas were made of Tedlar. Tedlar bags have been widely used as a container for the collection of biogas/air samples (Mariné et al. 2012). Prior to their usage, these bags were ventilated with compressed and filtered ambient air for 12 h. These bags were then closed with a septum. To ensure accuracy of the results, the bags were checked for background VOC before sampling the biogas. In the field, before connecting the bag to the biogas well, the pipe was flushed for a few minutes. For the emitted biogas at the surface of FC-2 and FC-4, air was allowed to pass through the pipe (Fig. 2) for 30 min.

The FC-2 and FC-4 performances were determined with two main parameters: the VOC removal efficiency, RE (%), and the VOC elimination capacity, EC (g m−3 h−1), as follows:

where Q is the biogas flow rate (m3 h−1), V is the field column bed volume (m3, including void space), and C RB and C EB are the VOC concentrations (g m−3) in raw biogas and emitted biogas, respectively.

2.2.2 Analyses

A solid-phase micro-extraction (SPME) fiber (Carboxen/PDMS, 85 μm) was used to extract VOC from the collected samples (Cai et al. 2006; Tassi et al. 2009). The fiber was cleaned each time following the same method to treat samples. When using the fiber for the first time, a conditioning step was performed by putting the fiber in the gas chromatography (GC) injector for 60 min at a temperature of 300 °C. Then, the SPME fiber was introduced into the sampling bag containing the biogas for 30 min to adsorb VOC. Finally, the fiber was placed in the GC injector for 5 min at a temperature of 290 °C to desorb VOC prior to analysis.

For the detection and quantification of VOC, a GC (G1800A, Hewlett–Packard) equipped with an electron ionization detector [MS] and an HP-5 MS-fused silica column (30 m × 0.25 mm i.d., 0.25 mm film thickness, Hewlett–Packard) were used.

Analysis was conducted in full-scan mode over an m/z range of 50 to 450 amu. Helium was used as carrier gas at a flow rate of 1.20 mL min−1. The column was held at 35 °C for 6 min then the temperature increased to 225 °C at a rate of 20 °C min−1, and it was finally increased to 300 °C at a rate of 30 °C min−1 and held for 6 min.

For the quantification of BTEX group, the GC was calibrated by the same method that was used by Wang et al. (1996) and Wu et al. (2004).

Besides BTEX group, four groups (Table 3) of VOC are identified and quantified. The concentration of this groups was expressed in “toluene equivalent” (Chiriac et al. 2011) because of the high number of the VOC identified and quantified and our analytical possibilities. The BTEX limit of detection (ppbv) was 1.8, 38.1, 4.1 and 24.5 for benzene, toluene, ethylbenzene and xylene, respectively.

3 Results and Discussions

The raw biogas collected at Saint-Nicephore landfill site contained the following groups: (i) BTEX, (ii) alkanes, (iii) aromatic compounds (BTEX excluded), (iv) cyclic compounds, and (v) halogenated compounds. The BTEX compounds are the dominant group in raw biogas (Fig. 4). The results obtained in this study are generally comparable with others reported earlier in the literature (Durmusoglu et al. 2010; Scheutz et al. 2008; Tassi et al. 2009).

The VOC concentrations in the raw biogas and the emitted biogas were summarized in Table 3. In the raw biogas, VOC concentration (ppmv) was in the range of below the limit of detection (BLD) to 22, 0.5 to 3.1, 0.6 to 2.2, and BLD to 1.7 for BTEX, alkanes, cyclic compounds, and halogenated compounds, respectively. Aromatic compound (BTEX excluded) concentrations are below the limit of detection in the raw biogas.

During the sampling period, 14 August to 30 September, 2012, FC-2 and FC-4 are fed with a controlled debit varying from 12 to 18 L h−1. The concentration of the emitted biogas at the surface of FC-2 and FC-4 was measured for the following chemical groups: BTEX, alkanes, aromatic compounds (BTEX excluded), cyclic compounds, and halogenated compounds. The BTEX concentration varied from BLD to 1.1 and from BLD to 3.1 for biogas collected at the surface of FC-2 and FC-4, respectively. Alkane concentrations (ppmv) in the emitted biogas are in the range of BLD to 0.9 for FC-2 and from BLD to 1.1 for FC-4. For cyclics and halogenated groups, concentrations are below the limit of detection. For different controlled debits varying from 12 to 18 L h−1 and during the sampling period, a higher concentration value obtained in the present work is for xylene in raw biogas and for toluene in the emitted biogas (Table 3).

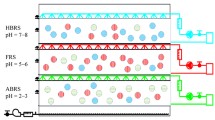

According to Leson and Winer (1991) and Singh et al.(2006), the RE and EC of biofilters varied with the type of media, airflow rate, inlet loading, and the type of VOC to be removed. Only airflow was varied in this study. As shown in Table 4, FC-2 and FC-4 are efficient to reduce the VOC emissions. FC-2 and FC-4 efficiency of the VOC emission are in the range of 54 % to practically 100 %. The VOC removal effectiveness (RE) is in the range of 69 to 100 % and 54 to 100 % for BTEX and alkane. For other groups identified and quantified in LFG, RE is practically 100 % (Table 4).

A number of studies have shown that biofiltration is an efficient biotechnology to reduce VOC emissions (Zarook et al. 1997). High removal efficiency of aromatic hydrocarbons from air can be achieved using biofilters (Zilli et al. 2001). The BTEX removal efficiency of a biofilter composed by coarse sand was 29 % (Haque et al. 2012). In the case of biofilter composed by compost, its removal efficiency to reduce toluene, ethylbenzene, and xylene was in the range of 43 to 94 % (Haque et al. 2012). According to Singh et al. (2010), the biofilter removal efficiency for toluene is in the range of 68.2 to 99.9 %.

As shown in Table 1, the organic matter (OM) content was determined in FC-2 and FC-4. OM boosts the development of the ubiquitous microorganisms (are not identified in the present work) that can oxidize VOC compounds. The high rates of biofilter efficiencies to reduce VOC emissions obtained can be influenced by a number of factors such as (i) the moisture and the temperature in the biofilter, (ii) the soil pH (Lu et al. 2002), and (iii) the organic nutriments available in the biofilter soil (Cho et al. 2009; Gaudin et al. 2008; Lu et al. 2002). The organic matter content indicates the presence of nutrients for growth of bacteria (Ait-Benichou et al. 2009; Czepiel et al. 1995). For example, it was reported that a biofilter composed of natural packing materials like compost demonstrated better performance in the VOC removal compared to soil amendment (Cho et al. 2009). The compost is a desired material for landfill biocovers because it retains moisture for microbial activity (Mostafid et al. 2012). During the sampling period, the atmospheric temperature at the Saint-Nicéphore landfill site varied from 6 to 22 °C. Over the same period, the soil temperature at 10 cm in the FC-2 and FC-4 ranged from 8 to 24 °C. According to Cho et al. (Cho et al. 2009), the suitable temperature in biofilters to remove BTEX ranged from 23 to 33 °C.

The FC-2 and FC-4 elimination capacity (EC) was summarized in Table 4. EC (mg m−3 h−1) varied from 0.1 to 4.6, 0.1 to 0.5, 0.1 to 0.4, and 0.1 to 0.3 for BTEX, alkane, cyclic compounds, and halogenated compounds, respectively. The RE of a biofilter packed with compost and ceramic beads is in the range of 40 to 95 %, and its EC (g m−3 h−1) ranging from 3.5 to 128 was observed depending upon the initial loading rates (Rene et al. 2005; Singh et al. 2006).

4 Conclusions

Two field columns are constructed in Saint-Nicephore landfill site. These field columns are fed by a raw biogas coming directly from the waste mass and under the real meteorological conditions. Saint-Nicéphore LFG contained at least these groups of VOC: (i) BTEX, (ii) aromatics (BTEX excluded), (iii) cyclics, (iv), alkanes, and (v) halogenated compounds. Among these VOC goups, the BTEX is the dominant. The VOC concentrations ranged from BLD to 22 ppmv. The present work shows that the field columns FC-2 and FC-4 are efficient to reduce VOC emissions. The VOC removal efficiency for FC-2 and FC-4 is in the range of 54 to 100 %. The FC-2 and FC-4 elimination capacity is in the range of 0.1 to 4.6 mg m−3 h−1. It can be concluded that the field column behaviors to reduce VOC are practically similar. This work documents with field data the reduction of VOC by experimental field columns under the real conditions. FC-2 and FC-4 represent an interesting technology to reduce VOC emissions from landfill sites.

Globally, it can be concluded that the results obtained during this study show the potential of field columns to reduce VOC emissions from a landfill. However, additional data are required to support the results obtained in the present work. For example, a biologic part should be addressed.

References

Ait-Benichou, S., Jugnia, L.-B., Greer, C. W., & Cabral, A. R. (2009). Methanotrophs and methanotrophic activity in engineered landfill biocovers. Waste Management, 29, 2509–2517.

Albanna, M., Fernandes, L., & Warith, M. (2007). Methane oxidation in landfill cover soil; the combined effects of moisture content, nutrient addition, and cover thickness. Journal of Environmental Engineering and Science, 6, 191–200.

Allen, M. R., Braithwaite, A., & Hills, C. C. (1997). Trace organic compounds in landfill gas at seven U.K. waste disposal sites. Environmental Science & Technology, 31, 1054–1061.

Barlaz, M. A., Green, R. B., Chanton, J. P., Goldsmith, C. D., & Hater, G. R. (2004). Evaluation of a biologically active cover for mitigation of landfill gas emissions. Environmental Science and Technology, 38, 4891–4899.

Beylot, A., Villeneuve, J., & Bellenfant, G. (2012). Life Cycle Assessment of landfill biogas management: sensitivity to diffuse and combustion air emissions. Waste Management, 33, 401–411.

Cai, L., Koziel, J. A., Lo, Y.-C., & Hoff, S. J. (2006). Characterization of volatile organic compounds and odorants associated with swine barn particulate matter using solid-phase microextraction and gas chromatography-mass spectrometry-olfactometry. Journal of Chromatography A, 1102, 60–72.

Chiriac, R., Carre, J., Perrodin, Y., Fine, L., & Letoffe, J.-M. (2007). Characterisation of VOCs emitted by open cells receiving municipal solid waste. Journal of Hazardous Materials, 149, 249–263.

Chiriac, R., De Araujos Morais, J., Carré, J., Bayard, R., Chovelon, J. M., & Gourdon, R. (2011). Study of the VOC emissions from a municipal solid waste storage pilot-scale cell: comparison with biogases from municipal waste landfill site. Waste Management, 31, 2294–2301.

Cho, E., Galera, M. M., Lorenzana, A., & Chung, W.-J. (2009). Ethylbenzene, o-xylene, and BTEX removal by Sphingomonas sp. D3K1 in rock wool-compost biofilters. Environmental Engineering Science, 26, 45–52.

Czepiel, P. M., Crill, P. M., & Harriss, R. C. (1995). Environmental factors influencing the variability of methane oxidation in temperate zone soils. Journal of Geophysical Research, [Atmospheres], 100, 9359–9364.

Desideri, U., Di Maria, F., Leonardi, D., & Proietti, S. (2003). Sanitary landfill energetic potential analysis: a real case study. Energy Conversion and Management, 44, 1969–1981.

Durmusoglu, E., Taspinar, F., & Karademir, A. (2010). Health risk assessment of BTEX emissions in the landfill environment. Journal of Hazardous Materials, 176, 870–877.

Erses, A. S., Onay, T. T., & Yenigun, O. (2008). Comparison of aerobic and anaerobic degradation of municipal solid waste in bioreactor landfills. Bioresource Technology, 99, 5418–5426.

Galera, M. M., Cho, E., Tuuguu, E., Park, S.-J., Lee, C., & Chung, W.-J. (2008). Effects of pollutant concentration ratio on the simultaneous removal of NH3, H2S and toluene gases using rock wool-compost biofilter. Journal of Hazardous Materials, 152, 624–631.

Gaudin, F., Andres, Y., & Le Cloirec, P. (2008). Packing material formulation for odorous emission biofiltration. Chemosphere, 70, 958–966.

Haque, F., De Visscher, A., & Sen, A. (2012). Biofiltration for BTEX removal. Critical Reviews in Environmental Science and Technology, 42, 2648–2692.

Hoque, R. R., Khillare, P. S., Agarwal, T., Shridhar, V., & Balachandran, S. (2008). Spatial and temporal variation of BTEX in the urban atmosphere of Delhi, India. Science of the Total Environment, 392, 30–40.

Johari, A., Ahmed, S. I., Hashim, H., Alkali, H., & Ramli, M. (2012). Economic and environmental benefits of landfill gas from municipal solid waste in Malaysia. Renewable and Sustainable Energy Reviews, 16, 2907–2912.

Leson, G., & Winer, A. M. (1991). Biofiltration: an innovative air pollution control technology for VOC emissions. Journal of the Air & Waste Management Association, 41, 1045–1054.

Lu, C., Lin, M.-R., & Chu, C. (2002). Effects of pH, moisture, and flow pattern on trickle-bed air biofilter performance for BTEX removal. Advances in Environmental Research, 6, 99–106.

Manna, L., Zanetti, M. C., & Genon, G. (1999). Modeling biogas production at landfill site. Resources, Conservation and Recycling, 26, 1–14.

Mariné, S., Pedrouzo, M., Maria Marcé, R., Fonseca, I., & Borrull, F. (2012). Comparison between sampling and analytical methods in characterization of pollutants in biogas. Talanta, 100, 145–152.

Mello, J. M. M., de Lima Brandão, H., de Souza, A. A. U., da Silva, A., & de Souza, S. M. A. G. U. (2010). Biodegradation of BTEX compounds in a biofilm reactor—modeling and simulation. Journal of Petroleum Science and Engineering, 70, 131–139.

Ménard, C., Ramirez, A. A., Nikiema, J., & Heitz, M. (2012). Biofiltration of methane and trace gases from landfills: a review. Environmental Reviews, 20, 40–53.

Mnif, S., Zayen, A., Karray, F., Bru-Adan, V., Loukil, S., Godon, J. J., Chamkha, M., & Sayadi, S. (2012). Microbial population changes in anaerobic membrane bioreactor treating landfill leachate monitored by single-strand conformation polymorphism analysis of 16S rDNA gene fragments. International Biodeterioration & Biodegradation, 73, 50–59.

Mohan, R., Spiby, J., Leonardi, G. S., Robins, A., & Jefferis, S. (2006). Sustainable waste management in the UK: the public health role. Public Health, 120, 908–914.

Mor, S., Ravindra, K., De Visscher, A., Dahiya, R. P., & Chandra, A. (2006). Municipal solid waste characterization and its assessment for potential methane generation: a case study. Science of the Total Environment, 371, 1–10.

Mostafid, M. E., Shank, C., Imhoff, P. T., & Yazdani, R. (2012). Gas transport properties of compost-woodchip and green waste for landfill biocovers and biofilters. Chemical Engineering Journal, 191, 314–325.

Rasi, S., Veijanen, A., & Rintala, J. (2007). Trace compounds of biogas from different biogas production plants. Energy, 32, 1375–1380.

Rasi, S., Läntelä, J., & Rintala, J. (2011). Trace compounds affecting biogas energy utilisation—a review. Energy Conversion and Management, 52, 3369–3375.

Rene, E. R., Murthy, D., & Swaminathan, T. (2005). Performance evaluation of a compost biofilter treating toluene vapours. Process Biochemistry, 40, 2771–2779.

Salvador, S., Kara, Y., & Commandré, J. M. (2006). Factors influencing pollutant gas emissions of VOC recuperative incinerators—large-scale parametric study. Applied Thermal Engineering, 26, 1640–1651.

Scheutz, C., Bogner, J., Chanton, J. P., Blake, D., Morcet, M., Aran, C., & Kjeldsen, P. (2008). Atmospheric emissions and attenuation of non-methane organic compounds in cover soils at a French landfill. Waste Management, 28, 1892–1908.

Schweigkofler, M., & Niessner, R. (1999). Determination of siloxanes and VOC in landfill gas and sewage gas by canister sampling and GC-MS/AES analysis. Environmental Science and Technology, 33, 3680–3685.

Shin, H.-C., Park, J.-W., Park, K., & Song, H.-C. (2002). Removal characteristics of trace compounds of landfill gas by activated carbon adsorption. Environmental Pollution, 119, 227–236.

Singh, R. S., Agnihotri, S. S., & Upadhyay, S. N. (2006). Removal of toluene vapour using agro-waste as biofilter media. Bioresource Technology, 97, 2296–2301.

Singh, R. S., Rai, B. N., & Upadhyay, S. N. (2010). Removal of toluene vapour from air stream using a biofilter packed with polyurethane foam. Process Safety and Environmental Protection, 88, 366–371.

Slack, R. J., Gronow, J. R., & Voulvoulis, N. (2005). Household hazardous waste in municipal landfills: contaminants in leachate. Science of the Total Environment, 337, 119–137.

Spokas, K., Bogner, J., Chanton, J. P., Morcet, M., Aran, C., Graff, C., Golvan, Y. M.-L., & Hebe, I. (2006). Methane mass balance at three landfill sites: what is the efficiency of capture by gas collection systems? Waste Management, 26, 516–525.

Staley, B. F., Xu, F., Cowie, S. J., Barlaz, M. A., & Hater, G. R. (2006). Release of trace organic compounds during the decomposition of municipal solid waste components. Environmental Science & Technology, 40, 5984–5991.

Tassi, F., Montegrossi, G., Vaselli, O., Liccioli, C., Moretti, S., & Nisi, B. (2009). Degradation of C2-C15 volatile organic compounds in a landfill cover soil. Science of the Total Environment, 407, 4513–4525.

Wang, Y., Raihal, S., T., Jackman, P., A., & John, S., R. (1996). Use of Tedlar bags in VOC testing and storage: evidence of significant VOC losses. Environment Science Technology, 30, 3115–3117.

Wang, Y., Ren, X., Ji, D., Zhang, J., Sun, J., & Wu, F. (2012). Characterization of volatile organic compounds in the urban area of Beijing from 2000 to 2007. Journal of Environmental Sciences, 24, 95–101.

Wu, C.-H., Feng, C.-T., Lo, Y.-S., Lin, T.-Y., & Lo, J.-G. (2004). Determination of volatile organic compounds in workplace air by multisorbent adsorption/thermal desorption-GC/MS. Chemosphere, 56, 71–80.

Yu, J., Cai, W., Chen, J., Feng, L., Jiang, Y., & Cheng, Z. (2012). Conversion characteristics and mechanism analysis of gaseous dichloromethane degraded by a VUV light in different reaction media. Journal of Environmental Sciences, 24, 1777–1784.

Zarook, S. M., Shaikh, A. A., Ansar, Z., & Baltzis, B. C. (1997). Biofiltration of volatile organic compound (VOC) mixtures under transient conditions. Chemical Engineering Science, 52, 4135–4142.

Zilli, M., Palazzi, E., Sene, L., Converti, A., & Borghi, M. D. (2001). Toluene and styrene removal from air in biofilters. Process Biochemistry, 37, 423–429.

Acknowledgment

Support for this research was provided by Natural Sciences and Engineering Research Council of Canada (NSERC) and Waste Management (WM Quebec Inc.). The authors acknowledge Jean Guy Lemelin, Serge Bérubé, Marlon Capanema, and Adnane Filali for their support and help to realize this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lakhouit, A., Cabral, A.R. & Cabana, H. Two Novel Biofilters to Remove Volatile Organic Compounds Emitted by Landfill Sites. Water Air Soil Pollut 227, 113 (2016). https://doi.org/10.1007/s11270-016-2813-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-016-2813-3