Abstract

Improving energy and hydraulic performance of large-scale pressurized irrigation is now perceived as a very pressing need, after large budgets have been allocated into systems modernization. This paper tackles this priority area by developing a management oriented multi-step methodology, that integrates different existing models, to sector the system according to the pressure requirements of the hydrants, and to regulate the pumping station for i) a fixed and a variable pressure head control, and for ii) an enhanced performance. When applied to an on-demand system in the Sinistra Ofanto irrigation scheme of Foggia (Italy), this integrated approach showed potential for energy saving under the optimal scenario of 49 %, and noticeable improvement in the system performance in terms of hydrant pressure heads, as compared to the actual conditions. The monetary assessment demonstrates that the achieved energy saving amounts to 23,636 Euros per irrigation season, 45 % among which are due to sectoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Agriculture accounts for 70 percent of total global freshwater withdrawals, and a 10 percent increase is projected to exacerbate this situation by 2050 (FAO 2011).

Irrigation agencies and water users organizations are being questioned about the current levels of efficiency of water use, and are continuously asked to improve the performance of irrigation conveyance and delivery systems in the arid and semi-arid regions of southern Europe and of the Mediterranean (D’Urso 2001). As a matter of fact, the modernization of existing irrigation systems was carried out in several countries, and it mainly concerned the physical aspects of the infrastructure. Large investments were made to transform open-channel water delivery systems into pressurized systems, and in most cases, delivering water required energy (FAO 2014). Moreno et al. (2010a) and Lamaddalena and Khila (2011) reported that pumping water for distribution and groundwater extraction are the main energy consumers in pressurized irrigation networks.

With the increase of energy consumption, as a consequence of modernization, and with the ascending trend of energy prices, energy is becoming one of the main inputs for irrigators and a major challenge in the irrigation supply (Rodríguez Díaz et al. 2011; Córcoles et al. 2015).

Hence, the adoption of reliable and effective approaches able to manage trade-offs and build synergies between water and energy, allowing for a more integrated and cost-effective irrigation modernization, is a must.

Since the optimal design of a pressurized irrigation distribution system is based on the satisfaction in terms of pressure heads of the most unfavorable hydrant, an excess of pressure is usually manifested on several hydrants. To face this constraint and reduce energy consumption, several approaches and methodologies were developed and adopted. Optimizing the regulation of the pumping station and sectoring the irrigation network were particularly revealed to be key issues (Córcoles et al. 2016). Several authors have developed network sectoring methodologies and evaluated their potential impacts as one of the most effective energy saving measures, (Rodríguez Díaz et al. 2009; Jiménez-Bello et al. 2010; Moreno et al. 2010b; Navarro Navajas et al. 2012; Fernandez Garcia et al. 2013). Sectoring is the practice of grouping hydrants with similar pressure head requirements, to operate according to scheduled periods, in order to ensure a minimum pressure head at hydrant for appropriate operation of the on-farm system. It was proven that more than 20% of energy consumption could be saved by sectoring an irrigation system, but this is usually accompanied by a loss of flexibility, where a semi-arranged schedule is applied, rather than an on-demand system (Rodríguez Díaz et al. 2009). Energy consumption was reduced by nearly 30% by sectoring an irrigation district devoted to olive grove production in a mountainous area, and no negative impact of flexibility loss was registered, as a 13% increase in farmers' profits was achieved, as compared to a traditional on-demand system (Navarro Navajas et al. 2012). Actually, irrigation scheduling strategies are part of the complex problem of optimal water resources management (English et al. 2002) and could drive an optimal management of the irrigation network (González Perea et al. 2016).

The main novelty of the proposed methodology is represented by its holism, where existing tools are integrated to 1) sector the irrigation network; 2) optimally regulate the pumping station; and 3) analyze the performance of the network after implementing the proposed measures for minimizing energy consumption. These actions/steps influence one another, so by considering them simultaneously, coherent and optimal measures can be implemented to improve water and energy efficiency in collective irrigation distribution networks.

This novel methodology, applied on a case study in Southern Italy, considers i) the interaction between the irrigation system use and the energy consumption, and ii) the impact of different management techniques and their combinations on energy consumption, accounting for the hydraulic performance of the distribution system using Relative Pressure Deficit (RPD) and Reliability (Re) indicators at hydrant, as compared to the minimum required for an adequate service at farm level.

It underlines the importance to consider the energy impacts in any modernization process together with system performance and water use efficiency, in order to achieve a balance between the water and energy consumption, and to promote the design as well as management practices, with minimum impact on the farmer.

2 Materials and Methods

A multi-step methodology was developed and applied with the intent of meeting the objectives of this study. The following tools, developed by two research groups of the Regional Center of Water Research (CREA-UCLM) and the Land and Water Resources Management Department (L&W-MAIB), were integrated in order to implement a holistic approach capable of ensuring energy saving coupled with a proper network performance in pressurized irrigation systems operating on demand.

2.1 The Case Study

Irrigation district 1-a managed by the Consortium di Bonifica per La Capitanata in the Sinistra Ofanto irrigation scheme-Southern Italy, was selected as a case study to apply the multi-step methodology.

It covers a total area of 660 ha (564 ha irrigable land), with the main irrigated crops being asparagus (25.9%), tomato (45.3%), and other vegetables. It is served with an upstream pumping station and was designed for on-demand operation with a peak discharge of 300 ls-1. District 1-a is sub-divided into 8 smaller agronomic operational units that are composed of several grouped farms. The farms are served with 75 hydrants with a fixed nominal discharge of 10 ls-1 each and more than 200 outlets. The design minimum pressure head required to satisfy the on-farm irrigation systems was fixed to 20 m at all hydrants. Asbestos cement was used for the irrigation network main lines having large diameters of 300 mm and above, while PVC pipelines for the remainders.

The irrigation season at the Consortium starts approximately at the beginning of April and ends at the end of September. The system is operated according to a restricted-demand delivery schedule, where all farmers are served at their convenience within a maximum allowed flow rate of 10 ls-1, and not exceeding the maximum seasonal allocated shares out of the total water supply available from the Capacciotti Dam. The service-oriented operation of the distribution network being conducted by the Water Users’ Association (WUA) ensures a minimum pressure head of at least 20 m at each hydrant, which is suitable for trickle and micro-irrigation methods commonly used by farmers in the area.

The pumping station is composed of: 1) a small electrical base-pump that maintains the network under pressure when the water demand is low. This pump is characterized by a maximum flow rate of 65 ls-1, and a water pressure head of 64 m; 2) three horizontal axis pumps, each of them providing a maximum flow rate of 95 ls-1, at a pumping head of 60 m.

An ultrasound flow-meter and a pressure transducer are installed at the upstream end of the network, downstream from the pumping station. The flow-meter is connected to a computer; it communicates the discharge to the inverter which, accordingly, adjusts the speed of the pump in order to satisfy a pre-established fixed pressure head. In particular, when the demand discharge is lower than 30 ls-1, the base-pump operates by maintaining the network under pressure. When the demand exceeds 30 ls-1, the first horizontal pump operates by providing for each discharge a constant pressure head, Hm, computed to meet the peak discharge (Hm = 65 m for district 1a). When the network discharge exceeds the maximum capacity of the first pump, the second pump begins to operate at variable speed providing the same pressure head. Whenever the network demand discharge exceeds the maximum that could be provided by the operating pumps, a new pump starts to operate at variable speed while the others run at maximum speed. The pressure head at the upstream end of the network is always kept constant.

2.2 The Multi-Step Methodology

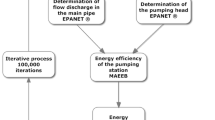

The multi-step methodology consists of 5 main steps that promote the reduction of energy consumption and facilitate the analysis of the network performance (Fig. 1). The 5 steps consist of 1) Sectoring the network by grouping hydrants with similar energy requirements; 2) Calculating the peak upstream discharge and generating the system curve for the whole network,and for the sectored network; 3) Generating for analysis the efficiency of the pumping station for each demand scenario (Q and H) ; 4) Generating the demand hydrographs during the entire irrigation season for the whole irrigation network and for the sectored network; and 5) Analyzing the performance of the irrigation distribution network once the pumping station regulation is optimized for the entire network and for separate sectors. Each step is described in detail in the following sub-sections.

2.2.1 Sectoring of the Irrigation Network

In order to sector the irrigation network into groups of hydrants with similar energy requirements, the first step to undertake is the generation of peak demand scenarios of open hydrants. These are configurations of open hydrants corresponding to the demand occurring during the 10 days peak period, lasting from the 21st to the 30th of July in the case study area.

To this aim, the Random Daily Demand Curve Methodology (RDDC) (Moreno et al. 2007b) was implemented in Matlab™ which uses the EPANET calculation engine (Rossman 2000) through the EPANET toolkit. The RDDC generates demand scenarios of random configurations of open hydrants accounting for the irrigation parameters at plot level i.e. irrigation time, irrigation interval and number of sectors to irrigate, which define the probability of opening each hydrant. These factors depend on the cultivated crops and on the period of the irrigation season that is analyzed. Then, RDDC calculates the upstream flow distribution, and for each simulation, it calculates the upstream minimum head pressure required to ensure, a minimum pre-defined pressure and the actual pressure occurring at hydrant level; this last parameter constitutes the dataset for network sectoring. Actually, the pressure values generated at each hydrant, for different demand scenarios through the RDDC method and the EPANET software are 19200, corresponding to 200 iterations * 24 hrs * 4 intervals hr-1, where the operation time OT (24hr) of the network is divided into short intervals of 15 minutes (Moreno et al. 2007b).

Clustering techniques that gather data points with similar pressure values are applied on the dataset, and hydrants with similar pressure heads are grouped; and the irrigation network is sectored consequently. Specifically, k-means partitioned clustering was applied in order to establish similarities between the hydrants. In this segmentation study, the measure of association that underlies the partitioning process depends on the Euclidean distance. Hydrants were separated into groups with similar pressure demand which allowed for fitting the demand for pressure to the pressure supplied by the pumping station, and thus for saving energy.

2.2.2 Calculation of the Peak Upstream Discharge and Generation of the System Curves (Q-H)

After the sectors are well defined, the RDDC (Moreno et al. 2007b) is used again to calculate the peak period flow of the whole irrigation network and of the separate sectors.

The RDDC model allowed for the generation of several demand discharges and for the consequent calculation through the EPANET toolkit of the upstream required pressure head for each demand scenario, as described in step 1.

At this level, the system curve generation software (CD) is used to generate the system curve of the irrigation network where the opening/closing of a hydrant is randomly taken (Moreno et al. 2010b). Thus, for the same demand discharge, the required pumping head depends on the location of the open hydrants. A statistical analysis of the results can be performed to determine the pumping head that supplies enough pressure for a certain percentage of satisfaction of the possible scenarios of open hydrants, termed guarantee of supply. In order to draw the system curves, several scenarios should be considered, defining the curves of maximum and minimum demand, together with the curve that fits the guarantee of supply (a 95% guarantee was considered). The system curves were generated for the whole network (current management strategy) and for the sectored network, allowing to set the pressure head and to consider two management strategies at the pumping station level as follows:

-

1)

a fixed head control: it accounts for the maximum demand calculated with RDDC. It allows for the operation of the pumping station at a pre-calculated design pressure head, that guarantees a pre-determined minimum pressure at hydrant level in the most unfavorable operating conditions or;

-

2)

a dynamic control: it sets a pressure at the pumping station according to the system curve and corresponding to a range of demanded discharges recorded at the upstream flow meter. In a dynamic pressure head control, the upstream pressure head is not static; it changes according to the operating hydrants and the required pressure is guaranteed at any demanded flow. Using the system curves, it is possible to establish the pressure head required at the pumping station for each discharge and hence, to guarantee the minimum operating pressure at each flow intake (hydrant) by programming it into the control system. The speed of the pumps is regulated thanks to the variable speed drive according to the flow and pressure required.

Setting the required fixed or dynamic pressure head at each sector, with knowledge of the pumping station operation and its efficiency, allows to assess the energy requirement of the irrigation system.

2.2.3 Improvement of the Pumping Station Management: Efficiency Analysis

After the system curves are generated, the efficiencies of the couples discharge-pressure head (Q-H) are calculated and then the MAEEB (Model for Energy Analysis of Pumping stations) (Moreno et al. 2007a) is used to analyze the energy efficiency of the pumping station. Actually, the model facilitates the selection of the best combination of number and type of pumps to operate and the modulation strategy, when a variable demand of flow and pressure head is required by the irrigation network. For each Q-H, MAEEB searches to minimize the activation costs, by selecting the most appropriate strategy for pumps regulation based on the characteristic and efficiency curves (Q–H and Q–μ), which consider the pumps and the motors efficiency together with the frequency drive efficiency. The model simulates the behavior of the variable-speed pumps by using affinity laws and the working points for the fixed pumps. The motor efficiency does not vary greatly when it operates near its design load and is considered a fixed value of 90%, while the variable speed drive efficiency is dependent on the frequency drive supplying to the motor (Moreno et al. 2009).

When the efficiency versus Q curve for the whole range of pumping station discharges is defined, the configuration of the pumping station that minimizes the energy consumption is determined and its efficiency is calculated based on the active pumps efficiency.

2.2.4 Generation of the Demand Hydrograph along the Irrigation Season Using WINGENERA

In order to perform the energy consumption analysis, it is important to define the discharge distribution throughout the irrigation season (the hydrograph) and not only during the peak period as performed with RDDC. To this aim, WINGENERA model (Khadra and Lamaddalena 2006) was used. This model, among other properties, allows for the generation of the upstream hydrographs of on-demand pressurized irrigation systems, based on the simulation of the water budget at the level of each single hydrant (deterministic component) and of the farmer’s management strategy (stochastic component). When the simulations are completed, the model aggregates upwards all the flows of the open hydrants, thus tracing the upstream demand hydrograph. WINGENERA was calibrated and validated on an irrigation network located in the same area of the present case study (Khadra and Lamaddalena 2006).

2.2.5 Performance Analysis Using AKLA Model

Water system operational status is described as either satisfactory or unsatisfactory, where unsatisfactory (failure) corresponds to a drop in pressure head (and/or discharge) at the hydrant below the minimum required for on-farm irrigation. The next phase consists of reproducing the hydraulic behavior and thus analyzing the performance of the system under the simulated flow configurations that result from the demand hydrograph previously generated. The flow configurations (of open hydrants) are inputs to the AKLA model (Lamaddalena and Sagardoy 2000) which achieves the performance analysis. The AKLA model consists of a multiple random generation of K hydrants simultaneously opened among the R total number. Each generation produces a hydrant configuration corresponding to a discharge configuration or a flow regime (Khadra and Lamaddalena 2010). The state of satisfaction of each hydrant under different regimes is analysed and the critical zones of the scheme are identified using the Relative Pressure Deficit (RPD) and Reliability (Re) as performance indicators. Both indicators are defined in mathematical terms at hydrant level (Lamaddalena and Sagardoy 2000). AKLA was used to test the performance of the irrigation system as a whole, and in different sectors.

2.3 Calculation of Energy Saving and Absorbed Power for Different Scenarios

Defining the discharge distribution throughout the irrigation season, and the efficiency of activation of the pumping station at each discharge for a defined pressure head, allowed to perform the energy consumption analysis.

The energy used by the pumping plant is calculated through the equation

Where: E is the energy (kWh), T is the operation time (h) and \( \overline{N_{abs}} \) is the average absorbed power (kW) by the pumping station.

The pumping station absorbed power \( \overline{N_{abs}} \) being calculated as follows

Where fi is the frequency of occurrence of Qi,, the total flow of the pumping station (m3.s-1); Hi is the pressure head (m) in the flow interval i (constant for manometric regulation); and μi is the total efficiency for the flow interval i.

The energy consumption and hydraulic performance of the irrigation network are simulated for the upstream demanded discharges, when a minimum pressure of 20 m at hydrant level is required. Several scenarios are built and compared to the current situation. The differentiation criteria among these scenarios are i) the pumping station regulation modalities that may be static or dynamic depending on the pressure head control and ii) the irrigation network sectoring.

Finally, a simplified economic analysis is performed to assess the feasibility of the sectoring and the regulation options proposed. The benefit in monetary value of the energy saving achieved due to sectoring in the optimal scenario over the entire irrigation season is calculated, and then compared to the total district income.

3 Results and Discussion

3.1 Network Sectoring

After generating the upstream demand scenarios and the corresponding pressure heads at hydrant level, clustering techniques were applied. They allowed for the division of the irrigation system into 2 sectors: sector 1 with 20 hydrants and sector 2 with 51 hydrants. Most of the hydrants fell in the group of lower pressure requirements which indicates a good opportunity to save energy. Four hydrants showed very high pressure requirements and thus were excluded from the 2 sectors and considered separately.

The number of sectors defines the new operation time of each sector; since two sectors are defined, the operation time per sector is fixed to 12h over 24h. Consequently, a semi-arranged demand schedule was established, reducing the farmer’s freedom and access to water by 50% and thus inducing farmers to apply higher flows to match the irrigation requirements.

Figure 2 shows the sectoring layout of the 75 hydrants of district 1a, specifically sectors 1 and 2 and the excluded hydrants.

3.1.1 Calculation of the Peak Upstream Discharge and Generation of the System Curves (Q-H)

The upstream discharge obtained as an output of the RDDC model is 190 ls-1, 95 ls-1 and 222 ls-1 when the whole network, sector 1 and sector 2, are considered respectively. The difference between the design upstream peak discharge (300 ls-1) and the newly calculated upstream peak discharge when the whole network is considered, is mainly due to the large physical changes in the irrigation network. Actually, many hydrants were definitely eliminated, and a change in the cropping pattern occurred, knowing that the RDDC methodology was proven to well estimate the upstream discharge (Moreno et al. 2007b). Moreover, the upstream discharge at sector 2 is higher than the one occurring upstream the whole network. The operation time is divided by two as compared to the initial one while the number of hydrants of sector 2 represents more than 50% of the total number of hydrants. In conclusion, the system is supposed to supply the demand in less time with a higher flow.

The definition of the irrigation sectors allowed for the use of the CD software to generate the system curves that apply to: 1) the whole network, 2) sector 1 and 3) sector 2. The output of the software is represented with the system curves functions. Once the system curves are defined and the upstream discharges calculated, the pressure head required at the pumping station, to satisfy a minimum pressure at hydrant level of 20 m is calculated for: 1) a fixed head regulation and resulting in an upstream required pressure head of 55 m, 49 m and 58 m when the whole network, sector 1 and sector 2 are considered, respectively; and 2) a dynamic control, ensuring that the pumping station is supplying the required flow and pressure head with the maximum operating efficiency.

3.2 Efficiency Analysis: Regulating the Pumping Station

At this stage, the pumping station simulation model MAEEB is used to reproduce the behavior of all the pumps by generating their efficiencies for the different couples of head and discharge (Q-H); thus, it is possible to draw the characteristic curve of each of the 3 main pumps and of the supply pump. Different regulations of the main pumps were accounted for: i) 1 main pump is operating at a variable speed, and ii) the 3 main pumps are operating at a variable speed, which represents the current situation. The efficiencies of the supply pump were generated assuming a variable speed operation. Under the current regulation, the supply pump is just used to maintain the network under pressure when the demand is low; once the demand is higher than 30 l.s-1 the supply pump is disrupted and the main pumps are activated one by one according to the required discharge.

The Q-H and efficiency matrix was analyzed for a fixed head control. After a simple analysis of the pumping system, it was noted that the efficiency of the supply pump is higher than the one of the main pumps for low discharges. It was proven that the best regulation to adopt is to operate the supply pump and one of the main pumps on variable speeds, and the remaining 2 main pumps on a fixed speed, as shown in Fig 3. Finally, the efficiency of the whole pumping station was calculated under the current regulation and the proposed new regulations.

The whole irrigation network was analyzed for the current and the new regulations. Efficiency-discharge curves were obtained for 2 different pressure heads, i.e. 65 m to represent the current network design and operation, and 55 m to represent the pressure head necessary to deliver the demand discharge effectively required and calculated using RDDC methodology. Figure 3 compares the current and optimal efficiency curves for the whole irrigation network considering a pressure head of 55 m. It can be observed that managing the pumping station according to the optimal efficiency accomplishes higher efficiencies for any demand discharge.

Moreover, the efficiency-discharge curve was obtained for both sectors for an upstream pressure head of 49 m and 58 m, corresponding to the upstream required pressure head at sector 1 and sector 2 respectively, under the proposed new regulation. The analysis of these curves demonstrate that the proposed regulation fits better the system operation, and yields a better efficiency as previously stated. For example, by weighing the pumping station efficiency according to the frequency of discharges occurring along the irrigation season, when the new regulation is applied on the network as a whole for a pressure head of 65m, it is proved that the total pumping station efficiency increased from 64.2% to 71.5%.

3.3 Generation of the Demand Hydrograph along the Irrigation Season

In order to analyze the energy consumption of the irrigation system, according to i) the delivered upstream pressure head and discharge, ii) the efficiency of the pumping station, and iii) the different demand scenarios, the hydrograph of frequencies throughout the irrigation season was generated using the model WINGENERA (Khadra and Lamaddalena 2006), as no reliable registered data was available for the case study.

3.4 Analysis of the Hydraulic Performance

The analysis for multiple flow regimes was performed using the AKLA model, integrated into the COPAM package. The primary analysis considered the whole network with a total number of 150 randomly generated configurations, each corresponding to an upstream discharge of 300 ls-1 and an upstream piezometric elevation of 60 m. The RPD at each operating hydrant within each randomly generated configuration is calculated. The resulting cloud of points can be enclosed between a lower and an upper envelope. Intermediate envelopes are also possible to define. The 90% envelope curve, excluding the 10% of less favourable events, is usually used to describe the hydraulic state of a hydrant (Khadra and Lamaddalena 2010). The 90% envelope curve of the system clearly demonstrates the poor performance in terms of RPD at hydrant level. Actually, more than 90% of hydrants show negative pressure.

When the same number of configurations was generated for an upstream discharge Q = 190 ls-1 and an upstream piezometric elevation of 55 m (Output of RDDC Model), a slight improvement was registered, however, the performance of the system failed to be acceptable, since most of the hydrants continued showing negative relative pressure deficits. Adding to this alarming situation, the Re of many hydrants was low, denoting a persistent RPD and low Re.

A substantial increase in performance occurred at sector 1, where the same number of configurations was generated for an upstream discharge of 95 ls-1 and an upstream piezometric elevation of 49 m. Actually, excess pressure was registered on all hydrants, and a Re of 100% occurred, denoting a time-lasting condition. Sector 2 analyzed for the same number of configurations corresponding to an upstream discharge of 222 ls-1 and for an upstream piezometric elevation of 58 m showed the same results as for sector 1, except for the case of 5 hydrants located at the extreme end of the network (Fig. 4). However, the Re of most hydrants was equal to 100%, and in the worst case 78%, demonstrating that the frequency of occurrence of this deficit is very low.

These results demonstrate that the reduction of the operation time by 50% had no negative effect. Instead, performance was enhanced to a very large extent. This can be explained by the fact that the effective irrigation time, still much shorter than the 12 hours operating time implied by sectoring.

3.5 Energy Consumption of the Irrigation System under Different Scenarios

The average absorbed power (Nabs) was calculated for the whole network and for the separate sectors, taking into account the upstream discharges delivered at the pumping station, their frequency of occurrence, the head required to satisfy the upstream discharge and a minimum pressure of 20 m to guarantee at hydrant level, as well as the operating pumps’ total efficiency. The current situation and the different proposed scenarios were considered as shown in Table 1, where: M.P. and S.P. represent respectively the main and the supply pumps, Q is the upstream design discharge and H is the upstream pressure head required to satisfy Q and a minimum pressure of 20 m at hydrant level. The results of power and energy calculations are shown in Table 2.

The cost of energy is 10 cent€/kWh in the consortium of Capitanata (Lamaddalena and Khila 2011). When scenario 6 and scenario 4 are compared, it can be concluded that an extra 22.9 % of energy saving is achieved if sectoring is applied in addition to a dynamic head control; the new regulation applied in scenario 4 saved 25.91% of the total energy consumed under the current situation. During one irrigation season 22,535 euro can be saved if the optimal scenario (number 6) is applied, out of which 10,573 euro are saved due to sectoring.

The total agricultural income deriving from the irrigated crops of the whole district is 1,368,283 euro. A break-even point between money gained (given by the value of the energy saved due to sectoring in scenario number 6) and the percentage of loss in yield (given by the reduction in the agricultural income) is the critical point for this analysis and will be addressed in future research.

The benefits from energy saving due to sectoring correspond to 0.772% of the total district income. Any loss of yield because of sectoring can make scenario 6 unfeasible, and a shift to scenario 4 without sectoring a better option. However, this is an unlikely possibility as a great enhancement of the performance due to sectoring was achieved at hydrant level. As a matter of fact, the correlation between hydrant performance in terms of actual pressure, and on-farm system uniformity and application adequacy was investigated in a detailed analysis, conducted in the Sinistra Ofanto Scheme (Lamaddalena et al. 2007; Daccache et al. 2009 and 2010; Khadra et al. 2013). This analysis demonstrated the positive impact of enhanced performance at hydrant level on the on-farm system behavior, allowing to set up an adequate irrigation schedule strategy, able to match the crop requirements.

4 Conclusion

Irrigation modernization has improved water use efficiency, but has increased energy cost dramatically. To overcome this challenge, a reliable and effective approach able to manage trade-offs and build synergies between water and energy is defined and applied to a case study in Southern Italy.

The results demonstrated that combining sectoring with a new regulation and a dynamic head control at the pumping station can save energy by about 49%, as compared to the actual situation. It also shows the positive impact on the hydraulic performance of the irrigation system, at hydrant level.

This substantial improvement of performance, positively impacts uniformity and application adequacy at farm level, allowing to set up irrigation schedule strategies able to match the crop requirements as demonstrated in several studies.

References

Córcoles JI, Tarjuelo JM, Carrión PA, Moreno MÁ (2015) Methodology to minimize energy costs in an on-demand irrigation network based on arranged opening of hydrants. Water Resour Manag 29:3697–3710. doi:10.1007/s11269-015-1024-9

Córcoles JI, Tarjuelo JM, Moreno MA (2016) Pumping station regulation in on-demand irrigation networks using strategic control nodes. Agric Water Manag 163:48–56. doi:10.1016/j.agwat.2015.09.001

D’Urso G (2001) Simulation and management of on-demand irrigation systems: a combined agrohydrological and remote sensing approach. Wageningen University

Daccache A, Lamaddalena N, Fratino U (2009) On-demand pressurized water distribution system impacts on sprinkler network design and performance. Irrig Sci 28:331–339. doi:10.1007/s00271-009-0195-7

Daccache A, Lamaddalena N, Fratino U (2010) Assessing pressure changes in an on-demand water distribution system on drip irrigation performance-case study in Italy. J Irrig Drain Eng 136(4):261–270. doi:10.1061/(ASCE)IR.1943-4774.0000170

English MJ, Solomon KH, Hoffman GJ (2002) A paradigm shift in irrigation management. J Irrig Drain Eng 128:267–277

FAO (2011) The state of the world’s land and water resources for food and agriculture (SOLAW) – managing systems at risk. Food and agriculture Organization of the United Nations. Rome and Earthscan, London

FAO (2014) The water-energy-food nexus - a new approach in support of food security and sustainable agriculture. Food and Agriculture Organization of the United Nations, Rome

Fernandez Garcia I, Rodriguez Diaz JA, Camacho Poyato E, Montesinos P (2013) Optimal operation of pressurized irrigation networks with several supply sources. Water Resour Manag 27:2855–2869. doi:10.1007/s11269-013-0319-y

González Perea R, Camacho Poyato E, Montesinos P, Rodríguez Díaz JA (2016) Optimization of irrigation scheduling using soil water balance and genetic algorithms. Water Resour Manag. doi:10.1007/s11269-016-1325-7

Jiménez-Bello MA, Martínez Alzamora F, Bou Soler V, Ayala HJB (2010) Methodology for grouping intakes of pressurised irrigation networks into sectors to minimise energy consumption. Biosyst Eng 105:429–438. doi:10.1016/j.biosystemseng.2009.12.014

Khadra R, Lamaddalena N (2006) A simulation model to generate the demand hydrographs in large-scale irrigation systems. Biosyst Eng 93:335–346. doi:10.1016/j.biosystemseng.2005.12.006

Khadra R, Lamaddalena N (2010) Development of a decision support system for irrigation systems analysis. Water Resour Manag 24:3279–3297. doi:10.1007/s11269-010-9606-z

Khadra R, Lamaddalena N, Inoubli N (2013) Optimization of on-demand pressurized irrigation networks and on-farm constraints. Procedia Environ Sci 19:942–954. doi:10.1016/j.proenv.2013.06.104

Lamaddalena N, Khila S (2011) Energy saving with variable speed pumps in on-demand irrigation systems. Irrig Sci 30:157–166. doi:10.1007/s00271-011-0271-7

Lamaddalena N, Sagardoy JA (2000) Performance analysis of on-demand pressurized irrigation systems. Irrigation and drainage paper no. 59. FAO, Rome, p. 132

Lamaddalena N, Fratino U, Daccache A (2007) On-farm sprinkler irrigation performance as affected by the distribution system. Biosyst Eng 96:99–109. doi:10.1016/j.biosystemseng.2006.09.002

Moreno MA, Carrión PA, Planells P, et al. (2007a) Measurement and improvement of the energy efficiency at pumping stations. Biosyst Eng 98:479–486. doi:10.1016/j.biosystemseng.2007.09.005

Moreno MA, Planells P, Ortega JF, Tarjuelo J (2007b) New methodology to evaluate flow rates in on-demand irrigation networks. J Irrig Drain Eng 133:298–306. doi:10.1061/(ASCE)0733-9437(2007)133:4(298)

Moreno MA, Planells P, Córcoles JI, et al. (2009) Development of a new methodology to obtain the characteristic pump curves that minimize the total cost at pumping stations. Biosyst Eng 102:95–105. doi:10.1016/j.biosystemseng.2008.09.024

Moreno MA, Córcoles JI, Tarjuelo JM, Ortega JF (2010a) Energy efficiency of pressurised irrigation networks managed on-demand and under a rotation schedule. Biosyst Eng 107:349–363. doi:10.1016/j.biosystemseng.2010.09.009

Moreno MA, Ortega JF, Córcoles JI, et al. (2010b) Energy analysis of irrigation delivery systems: monitoring and evaluation of proposed measures for improving energy efficiency. Irrig Sci 28:445–460. doi:10.1007/s00271-010-0206-8

Navarro Navajas JM, Montesinos P, Camacho Poyato E, Rodríguez Díaz JA (2012) Impacts of irrigation network sectoring as an energy saving measure on olive grove production. J Environ Manag 111:1–9. doi:10.1016/j.jenvman.2012.06.034

Rodríguez Díaz JA, López Luque R, Carrillo Cobo MT, et al. (2009) Exploring energy saving scenarios for on-demand pressurised irrigation networks. Biosyst Eng 104:552–561. doi:10.1016/j.biosystemseng.2009.09.001

Rodríguez Díaz JA, CamachoPoyato E, BlancoPérez M (2011) Evaluation of water and energy use in pressurized irrigation networks in southern Spain. J Irrig Drain Eng 137:644–650. doi:10.1061/(ASCE)IR.1943-4774.0000338

Rossman L A (2000) EPANET 2: users manual. US Environ Prot Agency, Washington, D.C. EPA/600/R-00/057, 2000

Acknowledgments

This research was developed in the framework of a master thesis funded by CIHEAM-Mediterranean Agronomic Institute of Bari (MAIB), Italy and conducted in collaboration with the University of Castilla-La Mancha, Spain. The authors would like to express their gratitude to the Division of Land and Water Resources Management at CIHEAM-MAIB, to the University of Castilla-La Mancha, Spain, to the Water Users Organization “Consorzio di bonifca della Capitanata”, which together made this research work possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khadra, R., Moreno, M.A., Awada, H. et al. Energy and Hydraulic Performance-Based Management of Large-Scale Pressurized Irrigation Systems. Water Resour Manage 30, 3493–3506 (2016). https://doi.org/10.1007/s11269-016-1365-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-016-1365-z