Abstract

In this paper, the focus was on the study of the management of irrigation networks, and a tool was implemented in the MATLAB® environment and developed using the EPANET® toolkit to minimize the energy costs at the pumping station. The tool was validated in an on-demand irrigation network located in Tarazona de La – Mancha (Albacete, Spain). Several scenarios were developed to determine the starting time for each irrigation event and hydrant. The results from the proposed methodology, based on a dynamic pressure regulation, were compared to the current irrigation management practice that used the pressure head as a constant value. On a daily basis, the energy savings achieved ranged from 4 to 8 %, whereas 13–36 % was saved in energy costs. On a festival day, without a high energy rate period, obtaining energy and cost savings close to 7–8 %, and 8–11 %, respectively was possible. Additionally, the savings obtained using the proposed methodology were increased with the use of two variable speed pumps activated sequentially, with the rest of the pumps as fixed, which improved the energy efficiency at the pumping station.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The recently formed European Innovation Partnership (EIP) on water aims to contribute to the discussion on addressing the global challenges facing water availability. Among the priorities stated by the EIP for water use, the water-energy nexus priority states that the water distribution systems and the wastewater treatments must be included in the smart management of regional energy. Thus, the efficient use of energy in the water distribution networks is a primary priority in the European objectives related to water use (Rodríguez-Díaz et al. 2007).

Examples of the management of several irrigation networks include rotational schedules or on-demand irrigation networks. The lack of flexibility, reliability and predictability are some of the primary concerns highlighted in the scheduled rotation networks (Nassim et al. 2003). In most cases, the irrigation schedules are not followed, and the farmers tend to irrigate as much as possible (Moreno et al. 2010). An on-demand schedule provides users with flexibility in the frequency and duration of delivery (Burt and Plusquellec 1992; Khadra and Lamaddalena 2006) and delivers the exact quantity of water at the correct time because the farmers decide when to irrigate. In spite of the on-demand schedule, the energy efficiency use may be low in some on-demand irrigation networks (Rodríguez-Díaz et al. 2009) because the upstream pressure head of the on-farm network can be subjected to high and continuous fluctuations depending on the number of hydrants being simultaneously opened (Daccache et al. 2010). By contrast, rotational schedule networks typically result in higher energy efficiency, when the sectors are properly selected.

Several methodologies were developed that focused on irrigation networks. The Clément methodology is the most commonly used model, although it can produce different levels of flow underestimation (Planells et al. 2001). Moreno et al. (2007a) developed a Random Daily Demand Curve (RDDC) method to determine the design flow based on the generation of demand scenarios in on-demand irrigation networks. Another methodology is the sectoring of the irrigation networks (Jiménez-Bello et al. 2011, 2015), which is based on genetic algorithms combined with a hydraulic network model. Rodríguez-Díaz et al. (2009) developed the OPTIEN algorithm, which minimizes the energy consumption with a sectoring of the network. Carrillo-Cobo et al. (2010) proposed a methodology for optimal sectoring that used cluster analyses and dimensionless coordinates. Several other researchers (Navarro Navajas et al. 2012; Rodríguez-Díaz et al. 2012; Fernández-García et al. 2013, 2014a) developed methodologies for the sectoring of irrigation networks. Fernández-García et al. (2014b) developed a model to optimize the sectoring operation and the pressure head based on the location of critical points to reduce energy consumption, and with this model, they obtained energy savings of up to 26 %.

Other studies developed several algorithms that focused on minimizing the total energy costs of the pumping stations (Moradi-Jalal et al. 2004; Planells et al. 2005). The performance of the pumping stations depends largely on real performance conditions, not only on the conditions considered in the design process. Thus, the development of pumping station analysis models that simulate the performance of the pumping stations is necessary to help optimize the regulation and management strategy for the pumping stations. Moreno et al. (2007b) developed a Model for Energy Analysis of Pumping stations (MAEEB), with the aim to improve the energy efficiency of the pumping stations.

The proper regulation of the pumping systems is a key step in matching the energy consumption to the current energy demand. Lamaddalena and Khila (2012) demonstrated that energy savings of 27 to 35 % were achieved using appropriate average speed regulation in two Italian on-demand irrigation districts.

The aim of this paper was to show that a tool developed in the MATLAB® environment with the EPANET® toolkit (Rossman 2001) could minimize the energy cost of the pumping stations in on-demand irrigation networks with the organization of the starting irrigation times for each hydrant. To achieve this objective, one of the novelties of this tool is that it is based on an analysis model that simulates the performance of the pumping station with consideration of the effect of the efficiency of the frequency speed drive. With this tool, the efficiency of the pumping station for each pressure head and flowing discharge combination for each scenario was determined. Hence, it was possible to analyse the influence of the use of different types of regulation of the pumping station, such as the use of one or two variable speed drives. Additionally, a comparison was conducted of the results obtained using manometric regulation or a variable pressure head.

2 Methodology

2.1 Case Study

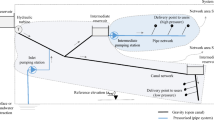

The proposed methodology was applied to the SORETA irrigated area, which is located in Tarazona de La Mancha (Albacete) in the southeast of Spain. The irrigation network, which has 550 ha irrigated, is composed of 323 hydrants. The primary irrigation system (94 % of the total area) is sprinkler irrigation, with maize, onions and vineyards as the most relevant crops. The primary water source is underground water resources (Jucar Basin, Hydrogeologic Unit 08.29), with the water pumped to a reservoir (23,000 m3) from three wells. From the reservoir, a pumping station composed of ten pumps (140 HP) supplied water to an on-demand irrigation network. The current management scenario allowed the users to irrigate whenever they chose, with an operating time (DOT) of 24 h. One of the pumps had a frequency speed drive, with the rest of the pumps having fixed speed drives. Conducted with a 60 m pressure head, manometric regulation guaranteed a pressure head of 45 m in all the hydrants of the network. To achieve manometric regulation of the pumping station, a pressure transducer was installed in the pumping collector, which controlled the sequence of activation of the variable and fixed-speed pumps to maintain the set pressure.

Depending on the hourly range, the electricity pricing distribution was different (Table 1). According to this distribution, during a day, three energy rate periods (low, medium and high) were highlighted. In the case of a festival day, two energy periods were identified (low and medium), with the low rate period as the most representative (18 h in length).

2.2 Irrigation Network Model

The first step was the implementation of the irrigation network model in the EPANET® software (Rossman 2001), which has a dynamic link to a library of functions for the customization of the EPANET computational engine with the software developed in this paper.

The information on pipes, related to the distribution, design and diameter or length, among other characteristics, was obtained from the irrigation society database, which was complemented with field verification. With regard to the nodes of the irrigation network, the crop distribution was obtained for each property, which was used to obtain the base demand for each node. The hydraulic network used was calibrated with the methodology developed by Moreno et al. (2008). The elevations of all hydrants and all key points in the network (e.g., pumping stations and valves, among others) were measured using high-precision GPS equipment (with an error of less than 1 cm).

2.3 Description of the Method

Before implementing the proposed methodology (Fig. 1), a random selection of hydrants was conducted with the Random Daily Demand Curve (RDDC) method (Moreno et al. 2007a). This tool was used taking into account the irrigation parameters of each plot, which depend on the crop. RDDC was used with the aim to reproduce a current scenario for open hydrants during a day in the peak period of the irrigation season. Hence, the probability of a hydrant opening was calculated with consideration of the irrigation time (IT), the irrigation interval (In), the number of sectors (Ns) of the irrigation system in the plot and the daily operating time of the network (DOT).

For each hydrant selected, the starting time of the irrigation event was computed with consideration of the defined characteristics for each hydrant and the daily operating time of the network (DOT). Thus, the available hours for irrigation were computed based on the total duration of each irrigation event. Therefore, for each hydrant, based on the available hours to irrigate per day, randomized scenarios for the starting time were conducted. As a first case, the proposed methodology was conducted based on a DOT = 24 h, which included the high, medium and low energy rate periods (Table 1).

For each simulation (combination of starting times for each hydrant), the flow discharge was determined in the primary pipe using the EPANET® software (Rossman 2001). Additionally, the pressure head for each hydrant was obtained, which was required to calculate the required pressure head at the pumping station, to supply the minimum required pressure of 45 m at the most restrictive node.

In each simulation, using MAEEB (Moreno et al. (2007b), the energy efficiency of the pumping station was computed, and therefore, the energy consumed by the pumping station was obtained. To compute the energy efficiency, the MAEEB model was required to specify a pumping station regulation. Thus, the current pumping station regulation (with one pump as a frequency speed drive and the rest as fixed speed drives) in the irrigation network was used. Following this specification of the regulation, for each simulation, the energy costs per day were calculated, depending on the energy rate period (Table 1) of the irrigation district. With regard to this calculation, to check the versatility of the proposed methodology, it was calculated for two types of days, normal and festival days.

An iterative process, using 100,000 iterations, was conducted to obtain several simulations with different combinations of irrigation event starting times. Following completion of the iterations, the scenario (starting time for each hydrant) that minimized the energy costs per day during the peak period was selected.

After the application of the proposed methodology, the results for the selected scenario were compared with the current on-demand irrigation network scenario (the manometric regulation using a pressure head of 60 m as a constant value). The comparison was conducted using the same hydrant selection used with the proposed methodology. The current on-demand irrigation scenario (using DOT = 24 h) was obtained by selecting at random one of the scenarios originated by the proposed methodology, one that simulated accurately the behaviour of the on-demand irrigation networks (Moreno et al. 2007a). For this current scenario, the flow discharge, the energy consumed, the energy efficiency and the energy costs were computed in the same way as indicated with the proposed methodology.

To analyse the influence of the different energy rate periods during a day, the current on-demand irrigation scenario was compared with the scenario obtained using the proposed methodology with a different DOT. Hence, two additional DOTs were used (18 and 8 h). The use of a DOT = 18 h was an attempt to avoid the high rate period in a normal day (Table 1) and to include the number of hours for the low and medium energy rate periods on a festival day. A DOT = 8 h was used to account for the hours only in the low energy rate period (Table 1).

Finally, with the aim of comparing the results from the other types of pumping station regulation, the proposed methodology was conducted using two variable speed pumps activated sequentially, with the rest of the pumps as fixed speed drives. Additionally, the three DOTs (24, 18 and 8 h) were used. The results obtained with the use of this type of regulation were compared with the results obtained with the current on-demand irrigation scenario. The simulations conducted in this paper are shown in Table 2.

2.4 Pumping Station Efficiency

To determine the energy efficiency of the pumping station for each flow discharge scenario analysed, the Model for Energy Analysis of Pumping stations (MAEEB) was used. This software, implemented in MATLAB®, calculated the efficiency of the pumping stations for the different types of pumping station regulation, accounting for the frequency of the discharges during the irrigation season (Moreno et al. 2007b) and the characteristic curves of the pumps (pressure head and efficiency). Thus, the model returned the flow discharge-efficiency curve for each demanded flow of the pumping station.

3 Results and Discussion

The results obtained in this paper were based on the random selection of 43 open hydrants, which represented a current scenario of open and closed hydrants for when farmers in the irrigated area applied for an irrigation event during a day in the peak period of the irrigation season. Hence, the same hydrants were used in all the cases analysed.

3.1 Comparison Between Current Scenario and Scenarios Obtained Using Simulation A

Using the RDDC methodology (current scenario with 24 h as the DOT), the flow rate distribution for any one irrigation day (normal or festival) is shown in Fig. 2a. In this case, the highest accumulated flow rate was concentrated in the time between 6 a.m. and 3 p.m., with the highest flow rates close to 550 l/s. Moreover, some discharges were released during the high-energy rate period (10 a.m. to 4 p.m.) (Table 1).

Using the same hydrants as in the RDDC methodology, the flow rate distributions for a normal and a festival day (Fig. 2a) of the peak period were generated using the proposed software, which minimized the energy costs. The greatest differences in the flow rate distribution occurred during a normal day, in comparison with the current scenario. Thus, during a normal day, the period between 4 and 10 a.m. had the highest flow discharge values (close to 600 l/s), with the flow rate distribution not as uniform as in the RDDC scenario. Moreover, most of the flow discharges were concentrated during that range of time, which coincided with the low and medium energy cost periods (Table 1).

On a festival day (Fig. 2a), the flow discharge distribution was very similar to the current on-demand irrigation scenario. In this case, the scenario obtained did not lead to a concentration of the irrigation events during the irrigation day. Hence, the highest flow discharges occurred between 6 a.m. and 6 p.m., which was a longer period of time than in a normal day because the energy rate on a festival day did not include a high cost period (Table 1), which increased the time available to irrigate. Additionally, during a festival day, the low cost energy period ended at 6 p.m. (Table 1), which explained why most of the irrigation events were concentrated in the period between 12 a.m. and 6 p.m.

The pressure head obtained, for both a normal and a festival day, was between 45 and 55 m, which was lower than the current regulation scenario (60 m). Other authors analysed the effects of a dynamic pressure mode, such as Rodríguez-Díaz et al. (2009), who reported that to improve energy efficiency, an adaption of the pumping stations to dynamic pressure head management was required.

According to the flow discharge and pressure head values during a day, the energy efficiency was between 50 and 70 % (Fig. 2b), with the average energy efficiency values close to 60 %. These efficiencies were slightly lower than the current scenario using manometric regulation (average energy efficiency close to 64 %) (Fig. 2b). During the irrigation, the variability in energy efficiency was noteworthy. Hence, Rodríguez-Díaz et al. (2009), analysing the energy saving scenarios for on-demand pressure irrigation networks, obtained an efficiency at the pumping station higher than that obtained in this study (close to 75 %). This result could be explained because the authors did not account for the variability in the efficiency with flow rates, and they assumed a constant value. The tendency of the efficiency values obtained in this paper was very similar to the results of Moreno et al. (2007b) and Carrillo-Cobo (2009), who reported that efficiency values were high for high flow rates but were low when less water was pumped.

Regarding the energy consumed, the distribution was very similar to the distribution of the flow rate (Fig. 2a). During a normal day, the highest energy consumption (Fig. 2c) was observed between 3 a.m. and 10 a.m., which represented a peak area in that period of time. For the case of a festival day, the energy distribution was uniform and was very similar to that of the current on-demand irrigation scenario (Fig. 2c). Using the proposed methodology, savings in energy consumption were attained. Thus, for a normal day, the energy consumption was 7 % lower than in the current scenario, and the consumption was close to 8 % lower for a festival day. Carrillo-Cobo et al. (2010) analysed two irrigation districts in Cordoba (Spain) and obtained energy savings that were very similar (close to 5 and 8 %), using a methodology for the optimal sectoring in pressurized irrigation networks.

For a normal day, the scenario that minimized the energy costs showed that these costs were higher during the period between 8 and 11 a.m. (Fig. 2d). The distribution obtained might be explained because the proposed scenario attempted to avoid the energy high period (Table 1), with most of the flow discharges concentrated in the period between 4 and 10 a.m. (low and medium energy rate periods) (Table 1). By contrast, for the current scenario, the energy cost distribution was more uniform, with the period with the highest energy cost values between 8 a.m. and 3 p.m. (Fig. 2d). In comparison to the current scenario of the irrigation network, the use of the proposed methodology that minimized energy costs produced energy cost savings close to 13.5 %.

For a festival day (Fig. 2d), the differences in the distributions of energy costs were not as large as during a normal day. Additionally, the current on-demand irrigation scenario showed a similar energy cost distribution to the ones obtained using the proposed methodology. A possible explanation was that because during a festival day there was no high energy rate period (Table 1), which led to the irrigation time being distributed throughout the day. Although there was not a high energy rate period, with the proposed methodology, it was possible to save in energy costs on a festival day (11 % lower than the current scenario).

3.2 Comparison Between Current Scenario and Scenarios Obtained Using Simulation B

Representing the flow discharge for a normal and a festival day (Fig. 3a), the highest values were close to 725 and 650 l/s, respectively. These values were greater than those obtained using a DOT = 24 h (simulation A) (Fig. 2a) because the availability of irrigation time during the day was reduced. Using a DOT = 18 h (simulation B), most of the irrigation events were concentrated in the periods from 8 p.m. to 1 a.m. (normal day) and from 8 p.m. to 2 a.m. (festival day).

The energy efficiency during a normal and a festival day reached average values close to 59 % and ranged from 38 to 74 % (normal day) and from 51 to 72 % (festival day). The average values of 52 and 51 m for normal and festival days, respectively were obtained with consideration of the flow discharges and the pressure head in the pumping station.

For the distribution of the energy consumed (Fig. 3a), for a normal day, the highest values of energy consumed were between 8 p.m. and 1 a.m. On a festival day, the highest values of energy consumption were concentrated in the period between 9 p.m. and 2 a.m. Both energy distributions were similar to the flow discharge distributions for a normal and a festival day (Fig. 3a). The energy savings reached on a normal and a festival day were close to 4 and 7 %, respectively, in comparison with the current on-demand irrigation scenario.

With regard to the distribution of energy costs (Fig. 3a), using the proposed methodology for a normal and a festival day, savings in energy costs were reached in comparison with the current scenario. The most relevant savings were highlighted for a normal day (close to 20 %) and were 12 % for a festival day. For a normal day, although the energy savings were lower than that using the proposed methodology with a DOT of 24 h (simulation A), the energy cost savings were higher because with a DOT = 24 h, some irrigation events occurred during the high energy rate period. In an analysis of an irrigation district in Córdoba (Spain), Rodríguez-Díaz et al. (2009) reported that energy savings of more than 20 % could be achieved when operating by sectors and concentrating the irrigation events into 12 h instead of 24 h.

3.3 Comparison Between Current Scenario and Scenarios Obtained Using Simulation C

The results obtained using the proposed methodology were identical for a normal and a festival day because during the available hours to irrigate, the energy costs were similar for both cases (Table 1).

With regard to the flow discharge distribution (Fig. 3b), the maximum flow discharges were higher than when using a DOT = 24 h (simulation A; Fig. 2a) or a DOT = 18 h (simulation B; Fig. 3a). Moreover, the flow discharge was homogenous for 8 h, when most of the irrigation events were concentrated.

During the irrigations, the average pressure head was close to 63 m, with values that ranged from 60 to 66 m. According to the flow discharge and pressure head values, the average energy efficiency was close to 66 %, which was slightly higher than the energy efficiency obtained with the current scenario (64 %).

Although the energy consumed was slightly higher during the irrigation time using a DOT = 8 h (Fig. 3b) in comparison with the results of a DOT = 24 h (simulation A) and of a DOT = 18 h (simulation B), it was also possible to obtain energy savings. Regarding these savings, it should be noted that using the scenario based on a DOT = 8 h resulted in a lack of time to irrigate all the plots, and in some plots, the number of irrigated sectors was lower than in the other analysed scenarios. The savings obtained were close to 8.5 %, with the same scenario for a normal and a festival day. Additionally, the energy cost savings were noteworthy (Fig. 3b). Hence, the scenario obtained using the proposed methodology showed that the energy costs during a normal day were close to 36 % lower than with the current on-demand scenario. For a festival day, the energy cost savings were close to 12 %.

3.4 Results Obtained Using the Proposed Methodology Considering Simulations D, E and F

During a normal and a festival day, the scenarios that minimized the energy costs were very similar to the ones obtained using one pump with a variable speed drive and the rest of pumps as fixed. These similarities are shown in the flow discharge distributions (Fig. 4a and b). For a normal day, most of flow discharges were concentrated between 5 and 11 a.m. (DOT = 24 h, simulation D), 8 p.m. and 1 a.m. (DOT = 18 h, simulation E) and 12 a.m. and 6 a.m. (DOT = 8 h, simulation F). This distribution was similar for a festival day, except for the scenario of DOT = 24 h (7 a.m. and 3 p.m.).

With regard to the pressure head required by the pumping station, the average pressure obtained was very similar to the results obtained using one variable speed drive pump. The primary differences between both types of regulations were related to the pumping station efficiency. In all the analysed cases, the energy efficiency was slightly higher using two variable speed pumps activated sequentially than one (Fig. 5). Consistent with this result, Moreno et al. (2007b) analysed three types of pumping station regulation in Tarazona de La –Mancha and found that when the pumping station was oversized, the regulation with two pumps activated sequentially improved the energy efficiency. As demonstrated by the authors in their research, this type of regulation was the most efficient.

Finally, regarding the energy consumed and costs, the savings were higher than with the other type of regulation that used different DOTs. Hence, the savings for energy consumed were between 11 and 17 % (Fig. 6), which was slightly higher than that for the energy costs (range from 13 to 38 %). The energy cost savings related to a DOT = 8 h were also related to the lack of time to irrigate all sectors in some of the plots. In the same area analysed in this study, Moreno et al. (2007b) obtained an energy cost savings of 16 % using the sequence of pump activation in which two variable speed pumps worked sequentially. Rodríguez-Díaz et al. (2009), using scenarios based on dynamic pressure head and type of regulation using six pumps activated sequentially, reported that an energy savings close to 2.6 % were obtained, with a required pressure of 30 m for the open hydrants.

4 Conclusions

This study presents a methodology that attempts to minimize the energy costs in irrigation networks, which is very important in on-demand irrigation networks in which the energy expenses are very high in comparison with the other types of irrigation management.

This application might be useful as a Decision Support System to help irrigation network managers to organize the irrigation scheduling based on the determination of the time to start an irrigation event for each user. With this tool, using management of irrigation networks based on a variable pressure head at the pumping station, it was possible to reduce the pressure head at the pumping station and obtain values between 15 and 20 % lower than with the current irrigation management (manometric regulation).

The proposed methodology resulted in energy and cost savings in all analysed cases. Using the most extended operating times in the area of the study (24 and 18 h), the results showed energy savings between 4 and 7 % on a normal day. Additionally, this tool provided energy savings close to 8 %, even on festival days, which were characterized by no high energy rate periods. In these cases, the energy cost savings were also relevant in comparison with the current scenario, with savings that ranged from 13 to 20 % for a normal day and that were close to 11 % for a festival day.

The proposed methodology showed that the irrigation management in the area could be conducted with 8 h as the operating time. According to the results, energy savings close to 8 % were reached for a normal and a festival day. The most relevant energy cost savings were for a normal day. Moreover, with the irrigation events concentrated into 18 and 8 h, the savings were close to 19 and 36 %, respectively, which were higher than the savings obtained with a DOT = 24 h (13 %). Thus, the recommendation might be to reduce the flexibility in the management of the irrigation network and reduce the operating time to 18 or 8 h.

In all the scenarios analysed, the type of regulation that used two variable speed pumps activated sequentially and the rest of the pumps as fixed had energy efficiencies that were slightly higher than the regulation with one variable speed pump and the rest as fixed. With regard to this outcome, the energy savings reached in this case ranged from 11 to 15 % for a normal day and were close to 10 to 16 % for a festival day. Additionally, a reduction in the energy costs might be achieved with this type of regulation, with energy cost savings that reached 13–17 % (festival day) and 22–36 % (normal day).

References

Burt CM, Plusquellec HL (1992) Water delivery control. In: Hoffman G, Howell T, Solomon K (eds) Management of farm irrigation systems, Am Soc Agric Eng, Michigan, pp 373–423

Carrillo-Cobo MT (2009) Uso racional del agua y la energía en la Comunidad de Regantes de Fuente Palmera. Dissertation, University of Córdoba, Spain

Carrillo-Cobo MT, Rodríguez-Díaz JA, Montesinos P, López R, Camacho E (2010) Low energy consumption seasonal calendar for sectoring operation in pressurized irrigation networks. Irrig Sci 29:157–169

Daccache A, Lamaddalena N, Fratino U (2010) On-demand pressurized water distribution system impacts on sprinkler network design and performance. Irrig Sci 28:331–339

Fernández-García I, Rodríguez-Díaz JA, Camacho E, Montesinos P (2013) Optimal operation of pressurized irrigation networks with several supply sources. Water Resour Manag 27:2855–2869

Fernández-García I, Moreno MA, Rodríguez-Díaz JA (2014a) Optimum pumping station management for irrigation networks sectoring: case of Bembezar MI (Spain). Agric Water Manag 144:150–158

Fernández-García I, Montesinos P, Camacho E, Rodríguez-Díaz JA (2014b) Methodology for detecting critical points in pressurized irrigation networks with multiple water supply points. Water Resour Manag 28:1095–1109

Jiménez-Bello MA, Martínez-Alzamora F, Castel JR, Intrigliolo D (2011) Validation of a methodology for grouping intakes of pressurized irrigation networks into sectors to minimize energy consumption. Agric Water Manag 102:46–53

Jiménez-Bello MA, Royuela A, Manzano J, García Prats A, Martínez-Alzamora F (2015) Methodology to improve water and energy use by proper irrigation scheduling in pressurized networks. Agric Water Manag 149:91–101

Khadra R, Lamaddalena N (2006) A simulation model to generate the demand hydrograph in large scale irrigation systems. Biosyst Eng 93:335–346

Lamaddalena N, Khila S (2012) Energy saving with variable speed pumps in on-demand irrigation systems. Irrig Sci 30:157–166

Moradi-Jalal M, Rodin SI, Mariño MA (2004) Use of genetic algorithm in optimization of irrigation pumping stations. J Irrig Drain Eng 130:357–365

Moreno MA, Planells P, Ortega JF, Tarjuelo JM (2007a) New methodology to evaluate flow rates in on-demand irrigation networks. J Irrig Drain Eng 133:298–306

Moreno MA, Carrión PA, Planells P, Ortega JF, Tarjuelo JM (2007b) Measurement and improvement of the energy efficiency at pumping stations. Biosyst Eng 98:479–486

Moreno MA, Planells P, Ortega JF, Tarjuelo JM (2008) Calibration of on-demand irrigation network models. J Irrig Drain Eng 134:36–42

Moreno MA, Córcoles JI, Tarjuelo JM, Ortega JF (2010) Energy efficiency of pressurized irrigation networks managed on-demand and under a rotation schedule. Biosyst Eng 107:349–363

Nassim A, Emad S, Jumah A (2003) Modeling a rotation supply system in a pilot pressurized irrigation network in the Jordan Valley. Jordan Irrig Drain Syst 17:163–177

Navarro Navajas JM, Montesinos P, Camacho E, Rodríguez-Díaz JA (2012) Impacts of irrigation network sectoring as an energy saving measure on olive grove production. J Environ Manag 111:1–9

Planells P, Tarjuelo JM, Ortega JF, Casanova MI (2001) Design of water distribution networks for on-demand irrigation. Irrig Sci 20:189–201

Planells P, Carrión PA, Ortega JF, Moreno MA, Tarjuelo JM (2005) Pumping selection and regulation for water distribution networks. J Irrig Drain Eng 131:273–281

Rodríguez-Díaz JA, Camacho E, López R (2007) Model to forecast maximum flows in on-demand irrigation distribution networks. J Irrig Drain Eng 133:222–231

Rodríguez-Díaz JA, López R, Carrillo-Cobo MT, Montesinos P, Camacho Poyato E (2009) Exploring energy saving scenarios for on-demand pressurised irrigation networks. Biosyst Eng 104:552–561

Rodríguez-Díaz JA, Montesinos P, Camacho E (2012) Detecting critical points in on-demand irrigation pressurized networks – A new methodology. Water Resour Manag 26:1693–1713

Rossman LA (2001) EPANET 2. Users Manual. Water supply and Water Resources Division National Risk Management Research Laboratory. Cincinati, USA

Acknowledgments

The authors wish to express their gratitude to the Ministry of Education and Science (MEC) of Spain for funding the project, “Sprinkler irrigation: water application, agronomy and return flows (AGL2010-21681-C03-02)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Córcoles, J.I., Tarjuelo, J.M., Carrión, P.A. et al. Methodology to Minimize Energy Costs in an On-Demand Irrigation Network Based on Arranged Opening of Hydrants. Water Resour Manage 29, 3697–3710 (2015). https://doi.org/10.1007/s11269-015-1024-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-015-1024-9