Abstract

The reaction pathways and shear-induced kinetics of methyl thiolate and ethyl thiolate species on copper are measured using in situ and ex situ techniques in ultrahigh vacuum. The in situ techniques consist of measuring the gas-phase products using a mass spectrometer placed in-line-of-sight of the rubbing interface while monitoring the variation in friction coefficient of an alkyl thiolate-covered surface as a function of the number of times it is rubbed (referred to in the paper as “number of scans”). The rubbed surfaces are analyzed using Auger spectroscopy as a function of the number of scans. The experiments are carried out for a tungsten carbide ball covered by a copper transfer film on copper surface at a normal load of 0.44 N and a sliding speed of 4 mm/s. The shear-induced reaction occurs as RS(ads) → S(ads) → S(subsurface), where RS(ads) is an adsorbed alkyl thiolate species, S(ads) is adsorbed atomic sulfur, and S(subsurface) is subsurface sulfur formed by shear-induced surface-to-bulk transport. The rate constants for the sequential reaction steps are found by fitting an analytical kinetic model to the yield of gas-phase products and Auger signals as a function of the number of scans over the surface. The validity of the kinetic parameters is confirmed by comparison with the variation in friction coefficient as a function of the number of scans. The analysis reveals that both ethyl and methyl thiolate species decompose under shear at approximately the same rate and that the rate of surface-to-bulk transport is higher than for thiolate decomposition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tribochemical reactions occur at a buried solid–solid interface so that obtaining information on the elementary steps in the reaction pathway and their rates becomes a particular challenge due to the lack of surface-sensitive techniques available for analyzing the nature of such a buried interface. In some cases, the sliding interface can be analyzed using optical techniques as long as the material of one of the counterfaces is transparent [1–5]. However, many tribochemical reactions involve the surfaces as either reactants or catalysts, therefore limiting the reactions studied to ones with transparent interfaces means that many systems of interest cannot be investigated. While direct, in situ analyses, defined as the analysis of the sliding interface during rubbing, are the most valuable for determining reaction pathways and their kinetics, such techniques are sparse and must be supplemented by ex situ analyses. The latter is the most common approach to analyze tribofilms. Ex situ analyses are most often carried out by removing the sample from the tribometer. This has the advantage that a number of different techniques can be used to analyze the same region to obtain a full picture of the nature and structure of the boundary film. However, this type of ex situ analysis potentially suffers from two problems. First, the surface may change either with time or due to atmospheric exposure; second, the evolution of the nature of the boundary film as a function of time or the number of scans cannot be obtained using such ex situ analyses since it is essentially impossible to replace the sample into the tribometer at exactly the same location. Thus, more revealing ex situ analyses are those that are performed in the same location as a function of the number of scans with the sample always inside the tribometer. The rubbed regions in the majority of tribometers are narrow, since they usually involve a ball sliding on a flat sample, and therefore, such analytical techniques should have reasonably good spatial resolution and be surface sensitive. Issues of atmospheric contamination are also important in such experiments and are addressed in this work by using an ultrahigh vacuum (UHV) tribometer to minimize and hopefully eliminate such effects.

Because of the lack of access of spectroscopic probes (e.g., photons or electrons) to a non-transparent solid–solid interface, there are, as far as we are aware, only three in situ techniques available for studying chemical reactions and their rates at such interfaces. The first is to measure the change in friction force as a surface reaction proceeds. By arguing that the different intermediates and products have different characteristic frictional properties, the time dependence of the friction force (or friction coefficient) reflects the kinetics of the surface reaction. Thus, if there are several reactants, intermediates and products on the surface, and if the ith component has a relative, time-dependent coverage \(\varTheta_{i} (t)\), with an associated friction coefficient μ i , then the time evolution of the friction coefficient μ(t) can be written as:

This approach is particularly useful in the case of a simple, first-order reaction, A(ads) → B(ads) since μ A and μ B can be measured before and after reaction to obtain the time-dependent coverages and has recently been used to follow shear-induced reactions in an atomic force microscope (AFM) [6].

The second approach is to measure the electrical contact resistance while sliding [7–10]. This technique tends to be more useful for thicker films, but is often difficult to interpret unless the film structure and its conductivity are known. The final approach is to measure the gas-phase products evolved during rubbing using a mass spectrometer. Since the amount of product formed from such a small contact is relatively low, these experiments are carried out under high [11, 12] or ultrahigh vacuum [13]. This approach allows both the reaction kinetics to be measured and the nature of the gas-phase products to be monitored.

Since the information available from the in situ techniques described above is sparse, it must be supplemented with ex situ analyses as a function of the number of times that the surface is rubbed (referred to in the following as “the number of scans”) within the wear track. This approach requires surface-sensitive (electron-based) spectroscopic techniques with reasonable spatial resolution to allow the nature of the worn and unworn regions to be compared. X-ray photoelectron spectroscopy is perhaps the most chemically sensitive surface analysis technique [14] but is often difficult to incorporate directly into the UHV chamber and is usually included in a separate analytical chamber. Techniques based on excitation by high-energy electron beams are experimentally easier since the electron source is more compact than an X-ray source and does not need to be as close to the sample. There are several electron-based spectroscopic techniques that can be used, notably Auger spectroscopy [14], which provides elemental information, and electron energy loss spectroscopy, which can be chemically specific [15, 16].

The approach is illustrated in this work by using shear-induced boundary layer formation from the reaction of dialkyl disulfides on copper in ultrahigh vacuum [17].

2 Experimental

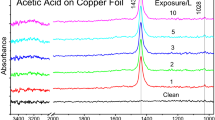

Tribological measurements were carried out in a stainless steel, UHV chamber operating at a base pressure of ~2 × 10−10 Torr following bakeout, which has been described in detail elsewhere [18]. Briefly, the chamber was equipped with a UHV-compatible tribometer, which simultaneously measures the normal load, lateral force and contact resistance between the tip and substrate and the experimental conditions and the data collection were controlled by a LabView program. Previous work has demonstrated that the maximum interfacial temperature rise for a copper sample under the experimental conditions used (4 × 10−3 m/s sliding speed, 0.44 N normal load) is much less than 1 K [13]. All experiments were carried out by initially rubbing the tribopin (1.27 x 10−2 m diameter tungsten carbide covered by a copper transfer film) against the clean copper sample until a constant friction coefficient was obtained, a process that usually required ~50 scans. The reactants were dosed through a leak valve connected to a dosing tube (with an internal diameter of 4 × 10−3 m) directed toward the sample so that the pressure at the sample surface is enhanced compared to the measured background pressure. The chamber was also equipped with a single-pass cylindrical-mirror analyzer (CMA) for Auger analysis and an argon ion bombardment source for sample cleaning and depth profiling. A high-resolution electron gun with a beam energy of 5 kV and a channeltron secondary electron detector were also incorporated into the system. This allowed scanning electron microscopy (SEM) images and Auger profiles of the wear scars to be collected. Finally, the chamber also included a quadrupole mass spectrometer for leak checking, detecting gas-phase products formed during rubbing and for gauging reactant purity.

The copper samples (Alfa Aesar, 99.99 % pure, 1 mm thick) were polished to a mirror finish using 1-µm diamond paste and then rinsed with deionized water and ultrasonically degreased in acetone. Once in UHV, the copper foils were cleaned using a standard procedure, which consisted of argon ion bombardment (~1 kV, ~2 µA/cm2) and annealing cycles up to ~850 K. The cleanliness of the samples was monitored using Auger spectroscopy, where only Auger peaks due to copper were detected after cleaning.

The dimethyl disulfide (DMDS, Aldrich, 99.0 % purity) and diethyl disulfide (DEDS, Aldrich, 99.0 % purity) were transferred to glass bottles and attached to the gas-handling systems of the vacuum chamber, where they were subjected to several freeze–pump–thaw cycles. The purity of the compounds was monitored using mass spectroscopy.

3 Results

The shear-induced reaction pathways of DMDS and DEDS were explored on clean copper foils in UHV [19]. A substantial amount of previous work has been carried out on DMDS, where it was shown that methane is the predominant reaction product, although some ethylene and ethane are formed so that all carbonaceous species are removed from the surface [13, 17], similar to the thermally formed products at higher temperatures [20]. Repeated rubbing creates a clean surface by removing the outermost layers [17], and it has been shown that shear causes the resulting adsorbed sulfur to penetrate the bulk of the sample [21], in a mechanism proposed to occur by the formation of Kelvin–Helmholtz instabilities at the sliding surface [22–28].

Experiments were also carried out to detect the desorption products from a surface exposed to DEDS using a mass spectrometer placed in-line-of-sight of the sample. A typical plot of the mass spectrometer signal at 26 amu is shown in Fig. 1, plotted as a function of the number of scans after saturating the surface (by exposure to 0.7 L of DEDS) that had been previously rubbed 50 times to create a wear track. The experiment was carried out as follows. The pin was brought into contact at a preset load of 0.44 N, where the load was controlled by the LabView software. The sample was rubbed once while continually monitoring the mass spectrometer signal, and gas-phase species were detected only during rubbing, giving rise to the pulses as shown in Fig. 1. After the surface had been rubbed, the pin was brought out of contact, and then brought into contact once again to ensure that the loads were identical for each pass over the substrate. This procedure was repeated until no more gas-phase products were detected. The lack of signal when the surface was not being rubbed indicates that the gas-phase products are formed by rubbing, not by thermal decomposition of the adsorbate. Finally, since the time for the pin to approach the surface varies somewhat for each pass, the time interval between the pulses is not uniform. The data were collected using a sliding speed of 4 mm/s at a normal load of 0.44 N for a distance of 1 cm. The background pressure in the chamber remained constant during these experiments because of the small amount of gas-phase products formed during sliding. The plot shows distinct gas pulses that decrease in intensity as the surface becomes depleted of ethyl thiolate species [29] due to rubbing. Since reaction occurs along the contact between the pin and the copper substrate, the total amount of gas-phase products detected will depend on sliding distance, but the decay in the signal as a function of the number of scans will be independent of sliding distance. Furthermore, since the sliding distance is much larger than the size of the contact between the pin and substrate, the contribution to the signal from the surface of the pin is negligible.

Similar results have been found when rubbing a methyl thiolate-covered surface formed by dosing DMDS, to form methyl thiolate species on the surface, under the same sliding conditions [13], and show a similar exponential decay in the intensity of the methane desorption pulses as a function of the number of scans, p. Experiments carried out by rubbing while continually dosing the surface showed only sulfur in subsequent Auger spectroscopy analysis, but essentially no carbon on the surface and in the subsurface region of the sample indicating that carbon is completely removed as gas-phase products [17]. The reaction time during sliding t(p) is proportional to the number of scans, so that t(p) = t C p, where t C is the time that a chemical species on the surface spends in the contact. An exponential decay in signal intensity indicates that the methyl thiolate species decomposes via a first-order process [13] with a rate constant k 1, so that the thiolate coverage Θ th is given by:

Note that the coverage Θ is taken to be the relative coverage, that is, the number of adsorbates per surface copper atom ratioed to the maximum number of adsorbates that can be accommodated per surface atom, so that 0 ≤ Θ ≤ 1. A fit to the experimental data for methyl thiolate decomposition gives k 1 t C = 0.63 ± 0.03 [13].

Auger analyses of the sulfur coverage in the worn region show that the amount of sulfur decreases as a function of the number of scans (Fig. 2). Here the clean copper was rubbed 50 times to create an initial wear track. The sample was then exposed to DMDS to create a saturated methyl thiolate overlayer and rubbed under a load of 0.44 N at a sliding speed of 4 mm/s; Auger spectra were collected in the same position at various intervals. In addition, it was found that redosing the surface with DMDS after rubbing a saturated thiolate-covered surface ~8 times, until the methane desorption had decreased to zero, leads to the evolution of an identical amount of methane as found after the first dose [13]. This indicates that a clean surface is formed after ~8 scans due to the shear-induced transport of practically all of the absorbed sulfur into the copper substrate [17, 21].

Plot of relative coverage of the sulfur in the wear track measured by small-spot-size Auger spectroscopy as a function of the number of scans for a methyl thiolate overlayer on the surface, where the sulfur peak-to-peak intensity is normalized to that of the copper substrate. The normal load was 0.44 N, the sliding speed was 4 mm/s, and the surface was precovered with thiolate species after a wear track had been created by rubbing the clean copper surface 50 times. The line through the data is a fit to the kinetic model

As discussed above, the variation in friction coefficient can be used to monitor the change in the nature of the surface due to shear-induced reactions. The resulting plot of friction coefficient as a function of the number of scans is shown in Fig. 3 for a methyl thiolate-covered surface rubbed at a sliding speed of 4 mm/s under a load of 0.44 N. Here the friction coefficient increases from an initial value of ~0.25 up to a final value of ~0.5, similar to the value previously found for clean copper [17]. The line in the figure is a fit to the data, discussed in greater detail below.

Plot of the friction coefficient as a function of the number of scans while rubbing a methyl thiolate-covered copper surface at a normal load of 0.44 N and a sliding speed of 4 mm/s. The line shows a fit to the data (see Sect. 4)

Similar kinetic experiments were carried out for copper dosed with DEDS, which forms ethyl thiolate species on the surface [29]. These experiments also yielded pulses of gas-phase products during sliding as shown in Fig. 1 measured while monitoring 26 amu. In order to establish how the amount of evolved gas from ethyl thiolate species on the surface depends on DEDS exposure, the integrated area of the mass spectrometer signal during the first pass at 26 amu was measured as a function of DEDS exposure in Langmuirs (1 Langmuir (L) = 1 × 10−6 Torr s). The results are displayed in Fig. 4, and a line is plotted through the data as a guide to the eye. It is observed that the yield of gas-phase products increases with DEDS exposure, but saturates at an exposure of ~0.2 L. Note, however, that exposures were measured from the background pressure in the vacuum chamber, while the local pressure at the sample is higher. Exposures of 0.7 L were used for subsequent experiments to ensure that the surface was saturated.

Experiments were carried out to monitor the gas-phase products formed during sliding for an ethyl thiolate-saturated sample obtained by dosing with DEDS, similar to the results displayed in Fig. 1, by monitoring mass spectrometer signals at 2, 15, 16, 26, 29, 30 and 58 amu; no signals were detected at 2, 16 and 58 amu, indicating that no hydrogen, methane or C4 hydrocarbons were produced at the sliding interface. The 28 amu signal was not measured because of the large intensity at this mass due to residual carbon monoxide in the vacuum chamber; these results are displayed in Fig. 5, which plots the integrated peak areas for each desorption pulse at various masses as a function of the number of scans. This shows that the yield at all masses decreases in a similar manner as each other as a function of the number of scans. The signals at 30, 29 and 15 amu are due to ethane, and their relative intensities, along with others, are in good agreement with the mass spectrometer ionizer fragmentation pattern of ethane, measured in the same mass spectrometer used to collect the data in Fig. 5. The 26 amu signal is mainly due to ethylene formation, but also contains contributions from the fragmentation of ethane in the mass spectrometer ionizer. The amount of ethylene produced during rubbing is calculated by subtracting the mass spectrometer contribution at 26 amu due to ethane using its fragmentation pattern. The ethane and ethylene yields as a function of the number of scans are shown as an inset in Fig. 5. Plots of ln(Yield) versus \(p - 1\) were linear and yielded essentially identical values of k 1 t C (0.60 ± 0.14 for ethane formation and 0.74 ± 0.04 for ethylene formation). This suggests a common rate-limiting step for both reactions which, based on density functional theory calculations for methyl thiolate species on copper, is proposed to be due to shear-induced C–S bond scission to form alkyl species and sulfur on the surface [13].

Plot of the variation in integrated intensities of the 15 (■), 26 (●), 29 (▲) and 30 (▼) amu signals as a function of the number of scans, after saturating a copper surface, that had previously been rubbed 50 times, with an exposure of 0.8 L of DEDS; a sliding speed of 4 mm/s and a normal load of 0.44 N were used. Shown as an inset is a plot of the integrated area per pulse for ethane (■) and ethylene (●) formation. The ethane signal is calculated by subtracting the contribution due to ethane fragmentation using the fragmentation pattern for ethane measured using the same mass spectrometer as used to collect the shear-induced desorption data

Finally, a plot of friction coefficient as a function of the number of scans for an ethyl thiolate-covered surface is shown in Fig. 6, at a sliding speed of 4 mm/s at a load of 0.44 N. The line is a fit to the data, discussed in greater detail below.

Plot of the friction coefficient as a function of the number of scans while rubbing an ethyl thiolate-covered copper surface at a normal load of 0.44 N at a sliding speed of 4 mm/s. The line shows a fit to the data (see Sect. 4)

4 Discussion

The shear-induced reaction pathways for DMDS and DEDS are summarized in Scheme 1. At room temperature, both DMDS and DEDS react on copper by S–S bond scission to form alkyl thiolate species on the surface [20, 29]. They decompose at ~300 K under the influence of shear via a first-order reaction, with rate constant k 1 to produce hydrocarbons, predominantly methane with some C2 hydrocarbons in the case of methyl thiolate species, and ethylene and ethane in the case of ethyl thiolate, along with adsorbed sulfur. The adsorbed sulfur is then transported into the bulk under the influence of shear [17, 21, 30] to form a sulfur-containing boundary film. This reforms a clean copper surface that allows the reaction cycle to proceed once again. The reaction pathway (Scheme 1) consists of a sequence of two shear-induced reactions: RS(ads) → S(ads) → S(subsurface), where the rate constant for the first reaction is k 1 and for the second is denoted as k 2. The first-order decomposition of the alkyl thiolates yields a coverage as a function of the number of scans p given by Eq. (2). If the coverage of adsorbed sulfur, S(ads) formed by this reaction is denoted Θ s then, from the sequential reaction shown in Scheme 1, adsorbed sulfur is formed by alkyl thiolate decomposition and removed by surface-to-bulk transport:

where it is assumed that surface-to-bulk transport occurs via a first-order process, and this will be discussed in greater detail below. The time variation in alkyl thiolate coverage Θ th is given by Eq. (2) so that substituting in Eq. (3) gives:

This can be solved analytically to give:

Writing this as a function of the number of scans p gives:

Since the Auger analyses (Fig. 2) measure the sulfur from both adsorbed sulfur species and alkyl thiolate species, the coverage of all sulfur-containing species is calculated as \(\varTheta_{\text{S}} ({\text{tot}}) = \varTheta_{\text{S}} + \varTheta_{\text{th}}\), and this gives:

However, it should be noted that the sampling depth in Auger spectroscopy depends on the electron escape depth and will thus also detect signals from subsurface sulfur, S(subsurface); strategies for addressing this issue are discussed below. Finally, the coverage of the clean surface, Θ clean is calculated from:

Surface-to-bulk transport kinetics have previously been analyzed [17, 21, 30] following a model proposed by Rigney [22–25, 27, 28, 31, 32] in which Kelvin–Helmholtz instabilities cause the atoms at the surface to move into the subsurface region. The film penetrates a distance d(p) into the subsurface region as a function of the number of scans as: d(p) = d p p x, where d p is the distance that the sulfur penetrates the subsurface region per pass. The exponent x depends on the strain-rate sensitivity of the substrate which is expected to be approximately zero for a metal. While the value of the strain-rate sensitivity is likely to evolve as the mechanical properties change during sliding, the sulfur depth distribution and the variation in the Auger signal as a function of number of scans have been found previously to be consistent with x ~ 1 [30]. If the initial film thickness at t = 0 is d 0 (corresponding to the thickness of the original saturated sulfur overlayer), then during shear for a time in the contact \(\delta t\), the width of the shear-induced region increases by δz. A value of x = 1 implies that δz ∝ δt so that:\(\frac{{{\text{d}}z}}{{{\text{d}}t}} = k\) where k is a constant to be determined. If the initial (sulfur) coverage is Θ 0 with a thickness of d 0 and, since the number of atoms is conserved, when sulfur is transported into the substrate, the sulfur coverage is reduced such that \(\varTheta_{\text{S}} d = {\text{constant}} = \varTheta_{0} d_{0}\). Thus, during a time δt the coverage changes by \(\delta \varTheta\) where:

to give \(\frac{{{\text{d}}\varTheta_{\text{S}} }}{{{\text{d}}t}} = - \frac{{k\varTheta_{\text{S}} }}{{d_{0} }}\). If the number of scans over the surface is p, and the contact time is t C, then over p scans the total contact time is pt C and, from the above equation, the film will spread a distance d p p. Integrating \(\frac{{{\text{d}}z}}{{{\text{d}}t}} = k\) shows that \(k = \frac{{d_{\text{p}} }}{{t_{\text{C}} }}\). Thus, the surface-to-bulk transport rate equation is:

which is a first-order reaction with respect to Θ s, as assumed in the above analysis. Writing k 1′ = k 1 t C yields the following equation for the sulfur coverage, modified from Eq. (6) as:

However, surface spectroscopies, including Auger spectroscopy, not only are sensitive to adsorbates but also include signals from the subsurface region [14, 33]. It has been previously shown that the Auger signal due to subsurface sulfur varies as 1/p [30] so that the Auger signal contribution arising from subsurface sulfur is taken to be \(\propto \frac{{\varTheta_{\text{subsurface}} }}{p + 1}\) where \(\varTheta_{\text{subsurface}}\) is the subsurface sulfur coverage and p + 1 is used to avoid a singularity at p = 0. Therefore, the sulfur Auger signal I Auger(p) is given by:

where α is a constant. Since \(\varTheta_{\text{subsurface}} = 1 - \varTheta_{\text{th}} - \varTheta_{\text{S}}\), this yields:

which is normalized to the initial Auger signal of the clean surface.

4.1 Analysis of Methyl Thiolate Kinetics

The above kinetic equations allow the rates of the shear-induced elementary reaction steps of alkyl thiolates on copper to be analyzed. We start with the decomposition of methyl thiolate species for which k 1 t C = k 1′ = 0.63 ± 0.03 as obtained above. In order to obtain d p/d 0, the sulfur Auger data (Fig. 2) are fit to Eq. (13) to yield values of α = 0.9 ± 0.1 and d p/d 0 = 2.5 ± 0.5. The results are verified by fitting to the friction data in Fig. 3 by rewriting Eq. (1) as:

where μ th, μ S and μ clean are the characteristic friction coefficients of the thiolate-covered, sulfur-covered and clean surfaces, respectively. Here, the rate constants were constrained to be in the range determined above and μ clean was allowed to vary between 0.45 and 0.55 found for sliding on clean copper. The fit to the data is shown as a solid line in Fig. 3 and yields μ th = 0.07 ± 0.02, μ S = 0.39 ± 0.06, and μ clean = 0.47 ± 0.05. The resulting plot of the adsorbate coverages as a function of the number of scans for an initially methyl thiolate-saturated surface, at a load of 0.44 N and a sliding speed of 4 mm/s, is shown in Fig. 7. This shows that a clean surface is indeed produced after ~8 scans, since the clean surface coverage (▲) becomes almost unity after this number of scans, thereby allowing the tribochemical cycle to be repeated to eventually form a sulfur-containing boundary film. In addition, as a consequence of d p/d 0 being much larger than k 1′, the sulfur is transported into the subsurface region almost as quickly as it is formed on the surface resulting in the adsorbed sulfur coverage always remaining less than 0.2 monolayers (●).

4.2 Analysis of Ethyl Thiolate Kinetics

A similar analysis was carried out for the shear-induced decomposition of ethyl thiolate species formed from DEDS on copper. The values of \(k_{1} t_{\text{C}} \left( {k_{1}^{'} } \right)\) are 0.60 ± 0.14 for ethane formation and 0.74 ± 0.04 for ethylene production (Fig. 5) and therefore are similar to the values found for methyl thiolate species, consistent with the rate-limiting steps for both reactions being similar. These kinetic parameters are used to fit to the variation in friction coefficient as a function of the number of scans to verify that the kinetic measurements are consistent with in situ measurements of the shear-induced chemistry (Fig. 6). The fit to the data yields a value of d p/d 0 = 2.5 ± 0.5, identical to that found for methyl thiolate decomposition, and yields an optimum value of \(k_{1} t_{\text{C}} \left( {k_{1}^{'} } \right) = \, 0.50 \, \pm \, 0.05\), slightly lower than the corresponding value for methyl thiolate species on copper. The best fit to the experimental data (shown as a line in Fig. 6) is obtained with characteristic friction coefficients of μ th = 0.15 ± 0.04, μ S = 0.43 ± 0.06, and μ clean = 0.50 ± 0.05. As expected, the last two values, μ S and μ clean, are in good agreement with those for a methyl thiolate-covered surface. However, the friction coefficient for a saturated layer of ethyl thiolate species on copper is somewhat larger (~ 0.15) than that found for methyl thiolate species (~0.07).

The resulting plot of adsorbate coverages for shear-induced ethyl thiolate decomposition as a function of the number of scans is displayed in Fig. 8 which, because of the similar rate constants for the various shear-induced processes, is similar to that found for methyl thiolate species (Fig. 7). In particular, a clean surface is formed after ~8 scans since the clean surface coverage approaches unity (▲), and the sulfur coverage remains low because of the relatively larger value of d p/d 0 than k 1′ (●).

5 Conclusions

The shear-induced reaction pathways and the elementary step kinetics for sliding-induced decomposition of alkyl thiolate species on copper are explored using in situ and ex situ techniques. The shear-induced reaction pathways are preceded by a thermal reaction that involves S–S bond scission to deposit alkyl thiolate species on the copper surface. Shear induces thiolate decomposition to evolve gas-phase hydrocarbons, followed by rapid shear-induced surface-to-bulk transport of absorbed sulfur to produce subsurface sulfur. This process recreates a clean surface that allows the cycle to be repeated so that the dialkyl disulfides act as gas-phase lubricants. While ex situ experiments, by definition, do not necessarily reflect the nature of the contacting interface during rubbing, carrying out such experiments in ultrahigh vacuum minimizes the possibility of atmospheric reactions with the surface. In addition, the results can be validated by comparing the results of ex situ measurements with in situ measurements of friction force. It is thus expected that such an approach will be generally useful for determining shear-induced reaction pathways and their kinetics.

Since, in the case of the shear-induced alkyl thiolate reactions, the rate of surface-to-bulk transport is higher than the rate of thiolate decomposition, it is essentially a single rate-limiting-step reaction, RS(ads) → S(subsurface). This offers the possibility of following the shear-induced reaction kinetics for a well-defined reaction pathway, in this case, alkyl thiolate decomposition, just by measuring the evolution in friction force using an AFM.

References

Fraenkel, R., Butterworth, G.E., Bain, C.D.: In situ vibrational spectroscopy of an organic monolayer at the sapphire–quartz interface. J. Am. Chem. Soc. 120(1), 203–204 (1998)

Piras, F.M., Rossi, A., Spencer, N.D.: Growth of tribological films: in situ characterization based on attenuated total reflection infrared spectroscopy. Langmuir 18(17), 6606–6613 (2002)

Scharf, T.W., Singer, I.L.: Monitoring transfer films and friction instabilities with in situ Raman tribometry. Tribol. Lett. 14(1), 3–8 (2003)

Dvorak, S., Wahl, K., Singer, I.: In situ analysis of third body contributions to sliding friction of a Pb–Mo–S coating in dry and humid air. Tribol. Lett. 28(3), 263–274 (2007)

Sawyer, W.G., Wahl, K.J.: Accessing inaccessible interfaces. In situ approaches to materials tribology. MRS Bull. 33(12), 1145–1150 (2008)

Felts, J.R., Oyer, A.J., Hernández, S.C., Whitener Jr, K.E., Robinson, J.T., Walton, S.G., Sheehan, P.E.: Direct mechanochemical cleavage of functional groups from graphene. Nat. Commun. 6, 6467 (2015)

Tonck, A., Martin, J.M., Kapsa, P., Georges, J.M.: Boundary lubrication with anti-wear additives: study of interface film formation by electrical contact resistance. Tribol. Int. 12(5), 209–213 (1979)

Jiang, J., Stott, F.H., Stack, M.M.: Some frictional features associated with the sliding wear of the nickel-base alloy N80A at temperatures to 250 °C. Wear 176(2), 185–194 (1994)

Wahl, K.J., Belin, M., Singer, I.L.: A triboscopic investigation of the wear and friction of MoS2 in a reciprocating sliding contact. Wear 214(2), 212–220 (1998)

Miller, B., Kotvis, P., Furlong, O., Tysoe, W.: Relating molecular structure to tribological chemistry: borate esters on copper. Tribol. Lett. 49(1), 21–29 (2013)

Mori, S., Morales, W.: Tribological reactions of perfluoroalkyl polyether oils with stainless steel under ultrahigh vacuum conditions at room temperature. Wear 132(1), 111–121 (1989)

Minami, I., Kubo, T., Fujiwara, S., Ogasawara, Y., Nanao, H., Mori, S.: Investigation of tribo-chemistry by means of stable isotopic tracers: TOF-SIMS analysis of Langmuir–Blodgett films and examination of their tribological properties. Tribol. Lett. 20(3–4), 287–297 (2005)

Adams, H.L., Garvey, M.T., Ramasamy, U.S., Ye, Z., Martini, A., Tysoe, W.T.: Shear-induced mechanochemistry: pushing molecules around. J. Phys. Chem. C 119(13), 7115–7123 (2015)

Briggs, B., Seah, M.P.: Practical Surface Analysis: Auger and X-ray Photoelectron Spectroscopy. Wiley, New York (1996)

Reihl, B., Baer, Y., Crescenzi, M.D., Diociaiuti, M., Lozzi, L., Picozzi, P., Santucci, S.: Local structure of graphite by EELFS spectroscopy: influence of multiple plasmons and orientational dependence. Surf. Sci. 189, 628–635 (1987)

De Crescenzi, M., Piancastelli, M.N.: Electron Scattering and Related Spectroscopies. World Scientific, Singapore; River Edge (1996)

Furlong, O.J., Miller, B.P., Kotvis, P., Tysoe, W.T.: Low-temperature, shear-induced tribofilm formation from dimethyl disulfide on copper. ACS Appl. Mater. Interfaces 3(3), 795–800 (2011)

Gao, F., Kotvis, P.V., Tysoe, W.T.: The friction, mobility and transfer of tribological films: potassium chloride and ferrous chloride on iron. Wear 256(11–12), 1005–1017 (2004)

Furlong, O., Miller, B., Tysoe, W.T.: Shear-induced boundary film formation from dialkyl sulfides on copper. Wear 274–275, 183–187 (2012)

Furlong, O.J., Miller, B.P., Li, Z., Walker, J., Burkholder, L., Tysoe, W.T.: The surface chemistry of dimethyl disulfide on copper. Langmuir 26(21), 16375–16380 (2010)

Furlong, O.J., Miller, B.P., Tysoe, W.T.: Shear-induced surface-to-bulk transport at room temperature in a sliding metal–metal interface. Tribol. Lett. 41(1), 257–261 (2011)

Rigney, D.A.: Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 245(1–2), 1–9 (2000)

Karthikeyan, S., Kim, H.J., Rigney, D.A.: Velocity and strain-rate profiles in materials subjected to unlubricated sliding. Phys. Rev. Lett. 95(10), 106001 (2005)

Emge, A., Karthikeyan, S., Kim, H.J., Rigney, D.A.: The effect of sliding velocity on the tribological behavior of copper. Wear 263(1–6), 614–618 (2007)

Kim, H., Kim, W., Falk, M., Rigney, D.: MD simulations of microstructure evolution during high-velocity sliding between crystalline materials. Tribol. Lett. 28(3), 299–306 (2007)

Emge, A., Karthikeyan, S., Rigney, D.A.: The effects of sliding velocity and sliding time on nanocrystalline tribolayer development and properties in copper. Wear 267(1–4), 562–567 (2009)

Karthikeyan, S., Agrawal, A., Rigney, D.A.: Molecular dynamics simulations of sliding in an Fe–Cu tribopair system. Wear 267(5–8), 1166–1176 (2009)

Rigney, D., Karthikeyan, S.: The evolution of tribomaterial during sliding: a brief introduction. Tribol. Lett. 39(1), 3–7 (2010)

Furlong, O., Miller, B., Li, Z., Tysoe, W.T.: The surface chemistry of diethyl disulfide on copper. Surf. Sci. 605(5–6), 606–611 (2011)

Miller, B., Furlong, O., Tysoe, W.: The kinetics of shear-induced boundary film formation from dimethyl disulfide on copper. Tribol. Lett. 49(1), 39–46 (2013)

Fu, X.-Y., Rigney, D.A., Falk, M.L.: Sliding and deformation of metallic glass: experiments and MD simulations. J. Non-Cryst. Solids 317(1–2), 206–214 (2003)

Kim, H.J., Karthikeyan, S., Rigney, D.: A simulation study of the mixing, atomic flow and velocity profiles of crystalline materials during sliding. Wear 267(5–8), 1130–1136 (2009)

Cumpson, P.J.: Angle-resolved XPS and AES: depth-resolution limits and a general comparison of properties of depth-profile reconstruction methods. J. Electron Spectrosc. Relat. Phenom. 73(1), 25–52 (1995)

Acknowledgments

We gratefully acknowledge the Chemistry Division of the National Science Foundation under Grant Number CMMI-1265742 and CMMI-1265594.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adams, H., Miller, B.P., Kotvis, P.V. et al. In Situ Measurements of Boundary Film Formation Pathways and Kinetics: Dimethyl and Diethyl Disulfide on Copper. Tribol Lett 62, 12 (2016). https://doi.org/10.1007/s11249-016-0664-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0664-0