Abstract

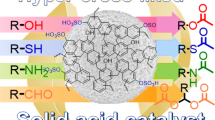

A sulfonate-functionalized N-heterocyclic carbene (NHC) was successfully attached to a hyper-cross-linked polymer via an external cross-linking reaction. The structure of Poly-BBIS was confirmed by FTIR spectroscopy, TEM, FESEM, and BET. The Poly-BBIS show a large surface areas (up to 563 m2 g−1) and hydrophilicity, as well as abundant micro-mesoporous, tunable and versatile active sites. The catalytic activity of the Pd derivative Poly-BBIS-Pd2+ was examined for Suzuki–Miyaura cross-coupling reactions in water, followed by an investigation of the reaction mechanism. The Poly-BBIS-Pd2+ gives a yield of 98% for the reaction between bromobenzene and phenylboronic acid with a loading of 0.057 mmol % Pd in water after approximately 2 h. Also, the catalyst can be reused for 5 times without significant loss of activity. This work highlights a low-cost route to the synthesis of heterogeneous catalysts based on hydrophilic sulfonate-functionalized NHC polymers for the Suzuki–Miyaura cross-coupling reaction in water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the most common reaction for the selective construction of biaryls, the palladium-catalyzed Suzuki–Miyaura cross-coupling reaction is often utilized in the synthesis of natural products, pharmaceuticals, and functional materials [1, 2]. Over the last decades, the C–C coupling reaction has attracted growing interest as a target for heterogeneous catalytic systems and environmentally friendly reaction media such as water [3]. The major aim of these efforts is to reduce the energy, time and cost of such reactions in line with the aims of green and sustainable chemistry [4, 5]. Water is the ideal solvent in view of its safety and abundance, with palladium-catalyzed cross-coupling reactions being widely applied to the synthesis of fine chemicals, functional materials, and industrial starting materials. However, achievement of both high catalytic activity and easy catalyst reuse in water without catalyst leaching [6] still remain prominent challenges for the development of green C–C bond formation reactions [7, 8].

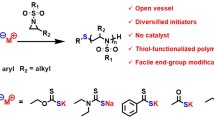

Based on the first example of the use of water in Pd-catalyzed cross-coupling reactions reported by Calabrese and co-workers in 1990 [9], a large number of water-soluble Pd catalysts bearing hydrophilic ligands have been synthesized, especially by modifying traditional P-donor ligand-supported Pd catalysts. However, most phosphine ligands are air and moisture sensitive, restricting the reuse of the catalyst and result in leaching of undesirable residues under aqueous reaction conditions [10]. Therefore, N-donor ligands have been regarded as promising candidates for Pd-catalyzed Suzuki–Miyaura cross-coupling reactions in water [11]. Compared with other ligands, NHCs have inherent advantages such as a strong donor ability, thermal and oxidative stability as well as electronic and steric tunability. Davis and co-workers [12] reported a modified protein as a support for catalytic Suzuki cross-coupling reactions with good yields of biphenyls. Wang and Chen [13] reported a water-soluble Pd-NHC for the cross-coupling of biomolecules under mild conditions in water.

In consideration of the high cost of palladium, many kinds of Pd-supported NHCs such as polymer-supported [14, 15], silica-supported [16, 17], nanoparticle-supported [18] and porous organic polymer-supported NHCs [19] have been prepared for various Pd-catalyzed cross-coupling reactions. With relatively high surface areas and abundant pore structures, porous polymer-supported NHC heterogeneous catalysts can show significant catalytic activities. Furthermore, microporous organic polymers can be readily prepared by conventional methods, making them attractive as heterogeneous catalyst substrates. Reported examples include NHCs on organic frameworks as heterogeneous organocatalysts [20], triptycene-based MOMPs bearing bis-(NHC)–palladium species and their catalytic applications in Suzuki–Miyaura coupling reactions [21], and porous organic polymers with NHC-gold(I) as catalysts in alkyne hydration reactions [22]. However, the advantages of NHCs supported by microporous organic polymers are not easily realized in the aqueous phase. The only successful example reported to date is a water-soluble polymeric Pd-NHC catalyst, which is able to catalyze Suzuki cross-coupling with excellent yields [23]. However, the synthesis of the Pd-NHC polymer is relatively complicated and the polymer itself is not easily characterized.

Hyper-cross-linked polymers (HCPs), consisting of purely organic elements, are a kind of porous material [24]. Besides characteristics of high surface area and low skeletal density, they also show advantages such as synthetic diversity, chemical and physical stability, and tunability of pore size and surface. The bottom-up approach for porous organic polymer synthesis allows for the design of polymer frameworks with various functionalities, which can be employed as catalysts or ligands [25, 26]. These catalysts can exhibit better stability and activity than traditional support materials under similar conditions for Suzuki cross-coupling reactions [27].

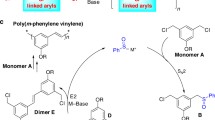

In this paper, based on a previous report on the general synthesis and catalytic performance of palladium carbine complexes [19], sulfonate-functionalized NHCs have been incorporated into the networks of an HCP by external cross-linking (Scheme 1). Metallization by post-synthesis modification allowed for incorporation of Pd2+ into the polymer, giving a highly active catalyst for Suzuki–Miyaura coupling reactions in water. This catalyst designated as Poly-BBIS-Pd2+ can be reused for five times with only moderate decreases in its catalytic efficiency.

Experimental section

Materials

Benzimidazole, benzyl chloride, 1,3-propane sultone, formaldehyde dimethyl acetal (FDA, 98%) Pd(OAc)2, FeCl3 (anhydrous), methanol and 1,2-dichloroethane (DCE) were obtained from Sinopharm Chemical Reagent Co., Ltd. and Adamas-beta®, all of which were of analytical grade and were used as received.

1-Benzyl-1H-benzimidazole (BBI) was synthesized following a reported procedure [28]. 1H NMR (400 MHz, DMSO-d6): 5.81 (s, 2H), 7.38 (m, 7H), 7.62 (m, 2H), 9.38 (s, 1H).

N, N-(benzyl) (propanesulfonate)imidazolium (BBIS) was synthesized based on the use of 1,3-propane sultone as an alkylating agent, as used for the preparation of sulfonate-functionalized NHCs [29]. 1H NMR (400 MHz, DMSO-d6): 2.11 (m, 2H), 2.59 (m, 2H), 4.88 (m, 2H), 5.51 (s, 2H), 8.02 (m, 9H), 9.25 (s, 1H).

The functionalized polymer precursors were synthesized by using external cross-linking of BBI and BBIS following a reported procedure [19, 30].

Synthesis of Poly-BBIS

Under a nitrogen atmosphere, BBIS (660 mg, 2 mmol) was dissolved in 1,2-dichloroethane (4 mL) with formaldehyde dimethyl acetal (1368 mg, 18 mmol). After complete dissolution of BBIS, anhydrous FeCl3 (2916 mg, 18 mmol) was added at room temperature. The resulting mixture was heated at 20 °C for 4 h, 40 °C for 8 h, 60 °C for 8 h, and finally 80 °C for 24 h. After cooling, the resulting solid was washed three times with methanol and further purified by Soxhlet extraction with methanol for 48 h, then dried under vacuum at 70 °C for 12 h. Elemental combustion analysis (%) was found: C: 82.01, H: 5.65, N: 0.12, S: 0.15. Poly-BBI was synthesized by the same method, BBI (418 mg, 2 mmol), formaldehyde dimethyl acetal (1368 mg, 18 mmol), anhydrous FeCl3 (2916 mg, 18 mmol) and 1,2-dichloroethane (4 mL). Elemental analysis (%) was found: C: 84.63, H: 6.65, N: 0.21.

Synthesis of Pd2+-containing polymer network (Poly-BBIS-Pd2+)

Poly-BBIS (0.1 g) was added to an HCl solution (4 ml, 0.1 mol/L) of Pd(OAc)2 (11.2 mg, 0.05 mmol), and the mixture was stirred under a nitrogen atmosphere at 80 °C for 12 h. The solid catalyst was centrifugally separated and washed three times, followed by Soxhlet extraction with ethanol to remove Pd2+ species physically absorbed on the surface. The final catalyst was dried at 70 °C under vacuum, and the as-prepared catalyst was denoted as Poly-BBIS-Pd2+. Poly-BBI-Pd2+ was synthesized by the same method.

Characterization

FTIR spectra were recorded between 4000 and 400 cm−1 using a Bruker VERTEX 70 FTIR Spectrometer. Polymer morphologies were investigated with an FEI Quanta FEG field emission scanning electron microscope (FESEM). Polymer surface areas, N2 adsorption isotherm (77.3 K), and pore size distribution were measured using a V-Sorb 2800TP surface area and porosity analyzer. Before analysis, the samples were degassed at 110 °C for 8 h under vacuum (10−5 bar). Surface chemical composition was determined by X-ray photoelectron spectroscopy (XPS) on a VG ESCALAB 250 spectrometer (Thermo Electron, UK), using a nonmonochromatized Al Ka X-ray source (1486 eV).

Suzuki cross-coupling reactions

Typically, Suzuki–Miyaura cross-coupling reactions were carried out as follows. Bromobenzene (1 mmol), phenylboronic acid (1.2 mmol) and base (1.5 mmol) were added to deionized water (2 ml) in a flat-bottomed reaction flask (10 ml). The flask was then heated in an oil bath at 80 °C under vigorous stirring. After the reaction was complete, 1 ml ethyl acetate was added and the catalyst was separated by centrifugal filtration. The product was obtained by preparative TLC using a mixture of ethyl acetate and petroleum ether (1:10, v/v) as eluting solvent. The products were characterized by 1H NMR. For the recycling experiments, 20 mg Poly-BBIS-Pd2+ was used. After reaction, the mixture was quickly separated by centrifugation, the biaryl product was extracted twice with ethyl acetate, and the solid catalyst was washed three times with deionized water, dried under vacuum, and reused in the next run.

Results and discussion

The FTIR spectra of Poly-BBIS and Poly-BBI (Fig. 1) display a series of bands ranging from 1250 to 950 and 900 to 600 cm−1, respectively, which can be attributed to aromatic ring skeleton stretching and C–H bending. The sulfonyl groups give rise to bands around 1190, 1068, and 620 cm−1 of Poly-BBIS, confirming successful introduction of the sulfonate-functionalized NHC into the polymer framework. Water solubility tests show that the Poly-BBIS disperses well in water (Fig. S1), while Poly-BBI only floats on the surface of water after stirring for 1 h, indicating that Poly-BBIS has an excellent hydrophilic performance.

XPS was employed to investigate the elemental composition of the surface and coordination states of Pd species. XPS images for Poly-BBIS-Pd2+ (Fig. 2) revealed the presence of palladium (II), corresponding to binding energies (BE) of 338.6 and 343.8 eV for the Pd 3d5/2 and 3d3/2 levels, respectively. The fitted results also reveal shoulder peaks at 342.5 and 336.6 eV which are attributed to Pd(0); however, the ratio of Pd(0) is only a small fraction of the total palladium peak area. Compared to PdCl2 (337.9 and 343.1 eV) [31], the Pd2+ binding energy in Poly-BBI-Pd2+ and Poly-BBIS-Pd2+ was shifted negatively by 0.2 and 0.5, 0.7 and 0.7 eV, respectively, which can be attributed to the strong electron-donation of the heteroatom functional group doped in the networks. These results confirm that Pd2+ was successfully immobilized on the Poly-BBIS by coordination to NHC functional groups, rather than by physical adsorption of Pd2+ on the surface.

The particle morphology of the Poly-BBIS was investigated by SEM and TEM (Fig. 3). Figure 3a shows high-magnification SEM images indicating that the samples were composed of small quasi-spherical particles with an average diameter of 50 nm. The surface of the particles has a rough, loose and porous structure, with the smaller particles tending to aggregate together, rather different to our previously reported observations on Poly-NHC-2 [19]. Figure 3b shows an SEM image of Poly-BBIS-Pd2+; it is clear that the surface morphology and structure are not changed much after incorporation of Pd2+. Composition analysis by energy-dispersive X-ray spectroscopy (EDS) (Fig. 3c) shows the presence of Pd, C, and N in the catalyst Poly-BBIS-Pd2+, and the content of Pd2+ is ca. 0.6% as determined by atomic absorption spectroscopy (AAS). Figure 3d shows a high-magnification TEM image of Poly-BBIS, indicating abundant porous structures in the sample.

Figure 4a shows the nitrogen adsorption and desorption isotherms and pore size distribution of Poly-BBI and Poly-BBIS. Both exhibit typical type-I isotherms at 77 K with a steep increase at low pressure (P/P0 < 0.001), indicating the coexistence of micropores in the framework [32]. A sharp rise in the high-pressure region (P/P0 = 0.9–1.0) implies the formation of abundant macropores in the networks of Poly-BBI and Poly-BBIS, with the confirmation calculated using DFT methods of pore size as micro-, meso- and macropores (Figure 4b, c). After incorporation of the Pd2+ species, the surface areas of Poly-BBI and Poly-BBIS are decreased to 25 and 21 m2 g−1, respectively (Table 1). The may be due to palladium species occupying parts of the micro- and mesoporous structure. Nevertheless, the type of absorption curves and pore size distribution remain almost the same (Figure 4a).

Following characterization of these new catalysts, the Suzuki–Miyaura cross-coupling was chosen as a model reaction for study under various conditions. First, we investigated the activities of Poly-BBI-Pd2+ and Poly-BBIS-Pd2+ in water, finding that the catalyst Poly-BBIS-Pd2+ gives a yield above 98% for the reaction of bromobenzene with phenylboronic acid. In contrast, the yield for Poly-BBI-Pd2+ as catalyst is only 23%. As shown by the data in Table 1, the surface area and Pd loading of the two catalysts is almost the same; the difference in yields can therefore be explained by the different water solubilities of the two materials. In a mixed system with organic substrate and inorganic base in water, the more hydrophilic catalyst is better dispersed in the reaction mixture. Hence, this work demonstrates that the microporous polymer backbone derivatized with NHC and SO3H moieties can efficiently disperse Pd2+ and improve hydrophilicity to promote the catalytic activity in the aqueous phase [33]. Accordingly, Poly-BBIS-Pd2+ was selected as catalyst for subsequent experiments.

Next, we studied the effects of solvent and base on the yield of product for Poly-BBIS-Pd2+ as catalyst. The catalytic activity is high in polar solvents, including water (Table 2, entries 1–4), but much poorer in less polar solvents such as CH3CN and CH2Cl2, with yields only around 30% (Table 2, entries 5–6). Overall, from the point view of green chemistry, water was chosen as the best solvent. Further experiments on the choice of base showed that inorganic bases gave the desired product in excellent yields, except for NaOH (Table 2, entry 7–13). However, organic bases such as NEt3 and DBU afforded lower yields of 38 and 33%, respectively (Table 2, entries 14–15), which according to our assumption, can be attributed to the fact that inorganic bases are more easily dispersed in the water phase [34]. In view of these results, K3PO4·3H2O was chosen as the optimal base for further studies.

To examine the scope of application of Poly-BBIS-Pd2+ in the Suzuki reaction, various aryl halides were coupled with different phenylboronic acid derivatives in water in the presence of 10 mg Poly-BBIS-Pd2+ using K3PO4·3H2O as base, giving the results as shown in Table 3. For iodobenzene, good yields (> 99%) of the products were observed within 1 h (Table 3, entries 1–2). Gratifyingly, we found that the coupling reaction of both activated and deactivated phenylboronic acids with bromobenzene also gives the desired products with excellent yields (Table 3, entries 3–9, 11–14). It is worth noting that the sterically hindered coupling partners gave the corresponding biaryl products with excellent yields (Table 3, entry 6), and even more challenging hindered substrates such as 3,5-difluorophenylboronic acid coupled with bromobenzene to give the product with a yield of 82% (Table 3, entry 9). However, for the more sterically hindered 2,6-dimethylphenylboronic acid, the yield is negligible in spite of extending the reaction time to 15 h (Table 3, entry 10).

Reuse of Poly-BBIS-Pd2+

Another important issue concerning the use of a solid catalyst is its reusability and stability under the reaction conditions. To gain insight into this issue, recycling studies on Poly-BBIS-Pd2+ were performed for the Suzuki coupling of bromobenzene with phenylboronic acid. After each reaction, the solid was separated by centrifugation and washed several times with water and ethanol. Good product yields (> 94%) were achieved after five such recycling experiments (Table 4), confirming the high stability and reusability of the catalyst. The kinetic curve for the recycled catalyst (Fig. S2) showed a very similar kinetic process as in the first run, although a longer time was required to reach yields above 90%. In order to investigate whether the coupling reaction was catalyzed by heterogeneous Poly-BBIS-Pd2+ or leached homogeneous palladium species, a hot filtration experiment was carried out. After 20 min, the reaction of bromobenzene with 4-methylphenylboronic acid was stopped, by removing the solid catalyst from the reaction mixture. The yield obtained was 50% by GC. The mother liquor was allowed to react for another 40 min under the same conditions, but the final yield remained at 50%; no obvious increase was observed. This result indicates that the active phase was not dissolved palladium species leached from the support. Therefore, it is fair to conclude that the observed catalysis is heterogeneous in nature.

Conclusions

Sulfonate-functionalized Poly-BBIS, a new material, was found to be a microporous polymer with hydrophilic nature. Its palladium derivative had high activity for catalytic Suzuki–Miyaura cross-coupling reactions at 80 °C in water, with short reaction times. The electronically rich environment for palladium provided by this support gives a distinct enhancement in the stabilization and accessibility of the metal centers toward organic substances in aqueous solution [35]. Using this catalyst, biphenyl products were obtained in high yields without side products. The activity of the catalyst remained high after reusing five times, with the TON reaching 4291. Moreover, the ability to use water as a green solvent in these reactions provides an environmentally friendly strategy for the Suzuki–Miyaura cross-coupling reaction.

References

Gholinejad M, Seyedhamzeh M, Razeghi M, Najera C, Kompany-Zareh M (2016) ChemCatChem 8(2):441–447

Clave G, Pelissier F, Campidelli S, Grison C (2017) Green Chem 19(17):4093–4103

Zhong R, Pöthig A, Feng Y, Riener K, Herrmann WA, Kühn FE (2014) Green Chem 16(12):4955–4962

Han J, Liu Y, Guo R (2009) J Am Chem Soc 131(6):2060–2061

Uozumi Y, Yamada YMA (2009) Chem Rec 9(1):51–65

Crabtree RH (2012) Chem Rev 112(3):1536–1554

Chatterjee A, Ward TR (2016) Catal Lett 146(4):820–840

Park G, Lee S, Son SJ, Shin S (2013) Green Chem 15(12):3468

Calabrese JC, Casalnuovo AL (1990) J Am Chem Soc 112:4324–4330

Pahlevanneshan Z, Moghadam M, Mirkhani V, Tangestaninejad S, Mohammadpoor-Baltork I, Loghmani-Khouzani H (2016) J Organomet Chem 809:31–37

Azua A, Sanz S, Peris E (2010) Organometallics 29(16):3661–3664

Gao Z, Gouverneur V, Davis BG (2013) J Am Chem Soc 135(37):13612–13615

Ma X, Wang H, Chen W (2014) J Org Chem 79(18):8652–8658

Kim Y-H, Shin S, Yoon H-J, Kim JW, Cho JK, Lee Y-S (2013) Catal Commun 40(Supplement C):18–22

Lambert R, Coupillaud P, Wirotius A-L, Vignolle J, Taton D (2016) Macromol Rapid Commun 37(14):1143–1149

Pucino M, Mougel V, Schowner R, Fedorov A, Buchmeiser MR, Copéret C (2016) Angew Chem Int Ed 55(13):4300–4302

Martinez A, Krinsky JL, Penafiel I, Castillon S, Loponov K, Lapkin A, Godard C, Claver C (2015) Catal Sci Technol 5(1):310–319

Baquero EA, Tricard S, Flores JC, de Jesús E, Chaudret B (2014) Angew Chem Int Ed 53(48):13220–13224

Xu S, Song K, Li T, Tan B (2015) J Mater Chem A 3(3):1272–1278

Rose M, Notzon A, Heitbaum M, Nickerl G, Paasch S, Brunner E, Glorius F, Kaskel S (2011) Chem Commun 47(16):4814–4816

Zhang Y, Riduan SN (2012) Chem Soc Rev 41(6):2083–2094

Wang W, Zheng A, Zhao P, Xia C, Li F (2014) ACS Catal 4(1):321–327

Karimi B, Fadavi Akhavan P (2011) Chem Commun (Camb) 47(27):7686–7688

Tan L, Tan B (2017) Chem Soc Rev 46:3322–3356

Song K, Liu P, Wang J, Tan B, Li T (2016) J Porous Mater 23(3):725–731

Yang Z-Z, Zhao Y, Zhang H, Yu B, Ma Z, Ji G, Liu Z (2014) Chem Commun 50(90):13910–13913

Tan L, Tan B (2017) Chem Soc Rev 46(11):3322–3356

Kore R, Srivastava R (2011) J Mol Catal A Chem 345(1–2):117–126

Godoy F, Segarra C, Poyatos M, Peris E (2011) Organometallics 30(4):684–688

Wang S, Song K, Zhang C, Shu Y, Li T, Tan B (2017) J Mater Chem A 5(4):1509–1515

Guan Z, Hu J, Gu Y, Zhang H, Li G, Li T (2012) Green Chem 14(7):1964–1970

Zhang C, Zhu P-C, Tan L, Liu J-M, Tan B, Yang X-L, Xu H-B (2015) Macromolecules 48(23):8509–8514

Velazquez HD, Verpoort F (2012) Chem Soc Rev 41(21):7032–7060

Liu L, Dong Y, Tang N (2014) Green Chem 16(4):2185

Duan L, Fu R, Zhang B, Shi W, Chen S, Wan Y (2016) ACS Catal 6(2):1062–1074

Acknowledgements

This work was supported by National Undergraduate Training Program for Innovation and Entrepreneurship (201710638031), the Key Project Funds of Science and Technology Department of Sichuan Province (2017JY0015), Fundamental Research Funds of China West Normal University (17C038) and Meritocracy Research Funds of China West Normal University (17YC031).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

11243_2018_255_MOESM1_ESM.docx

Details of the catalysts prepared and NMR spectrum of the products associated with this article can be found in the supporting information (DOCX 1517 kb)

Rights and permissions

About this article

Cite this article

Fu, YF., Song, KP., Zou, ZJ. et al. External cross-linked sulfonate-functionalized N-heterocyclic carbenes: an efficient and recyclable catalyst for Suzuki–Miyaura reactions in water. Transit Met Chem 43, 665–672 (2018). https://doi.org/10.1007/s11243-018-0255-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11243-018-0255-z