Abstract

Reaction–diffusion processes in multiscale catalytic porous media are found in a wide range of scientific areas as, for example, electrochemical energy conversion and storage devices, geological systems and bioengineering. The dependency of effective transport properties on reaction rate has been long debated in the literature, and traditionally ignored in emerging fields, such as polymer electrolyte fuel cells (PEFCs). In this work, a 1D upscaling method is presented to evaluate the effective properties (effective diffusivity and catalyst utilization) of PEFC catalyst layers featuring first-order kinetics. Unlike Whitaker’s closure method, the present algorithm is easy to implement and well suited for porous media with arbitrarily complex 3D geometries. The numerical results show that the normalized effective diffusivity and catalyst utilization are not passive geometrical properties but are influenced by the reaction–diffusion coupling when the Thiele modulus is higher than 1. This effect can be important at high current densities in the cathode catalyst layer of state-of-the-art PEFCs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Polymer electrolyte fuel cells (PEFCs) are promising electrochemical devices to replace traditional internal combustion engines with the advantage of zero emission and high energy density (Debe 2012; Steinbach et al. 2018). The cathode catalyst layer is one of the most critical components of PEFCs due to the sluggishness of the oxygen reduction reaction. State-of-the-art catalyst layers are composed of dispersed electrocatalyst nano-particles onto high surface area carbon bound together by ionomer phase and with pore space for gas transport. In order to improve cell performance and durability, a better understanding of the coupled mass, charge and heat transport processes that occur in catalyst layers is necessary (García-Salaberri et al. 2017a; Zenyuk et al. 2016; Weber et al. 2014). Due to computational limitations, it is virtually impossible to perform direct numerical simulation (DNS) on the entire catalyst layer (Tanno et al. 2013; Wang et al. 2006a, b). Instead, macroscopic continuum models are widely used alternative, where effective transport properties account for the pore-scale phenomena within the porous medium (Zenyuk et al. 2016; Weber et al. 2014; Fang et al. 2018; Bosomoiu et al. 2015; Salejova et al. 2011). Agglomerate models of catalyst account for inter carbon diffusion but struggle with the idealizations of ideal spherical geometries and agglomerate size approximations (Sun et al. 2005; Epting and Litster 2012). It is also a challenge to incorporate agglomerate models with effective properties for pore-scale phenomena obtained with DNS. Overall, the necessary effective transport properties are rather difficult to determine in practice due the thin (thickness ~ 10 µm) and heterogeneous nature of catalyst layers (García-Salaberri et al. 2017b). For example, the effective diffusivity used in Fick’s law of diffusion depends on the porosity and the tortuosity factor of the catalyst layer (García-Salaberri et al. 2015a, b, 2018; Karaki et al. 2017; Zarandi et al. 2018). While the former can be determined relatively easy, the latter is challenging to obtain. In catalyst layers, diffusion and reaction are tightly coupled, as oxygen needs to reach active sites to electrochemically react. The electrocatalyst sites can be located within larger carbon agglomerates (~ 200 nm) and also on the surface of these agglomerates. The reaction–diffusion front is highly dependent on operating conditions (temperature, current density, pressure), but it also depends on catalyst layer morphology (porosity, tortuosity, electrocatalyst accessibility).

Reaction–diffusion phenomena in porous media are present in a wide range of engineering areas, including, among others, energy conversion and storage (PEFCs, redox flow batteries, metal–air batteries, electrolyzers, etc.), geological systems (composition of natural waters, formation and dissolution of rocks and minerals, mobility of radionuclides in waste repositories, etc.) and bioengineering (enzymatic reactions, biofilms, etc.) (Bear and Buchlin 1991; Whitaker 1999; Weber et al. 2011, 2014). Numerous experimental, numerical and analytical works have studied the effective diffusivity under reactive conditions, but results are still controversial. Some studies claim that the effective diffusivity is influenced by reaction rate (Wakao et al. 1969; Toei et al. 1973; Park and Kim 1984; Sahimi 1988; Sadeghi et al. 2017), while others show that the effective diffusivity does not have reaction rate dependency (García-Ochoa and Santos 1994; Ryan et al. 1980). There is also a discussion of volumetric vs. surface sink terms for reaction rates. Dadvar and Sahimi (2007) used pore network and continuum models to study the effective diffusivity in porous media with and without a nonlinear reaction rate term. They found that the effective diffusivity can vary a few orders of magnitude depending on the reaction rate. Valdes-Parada and Alvarez-Ramirez (2010; Lugo-Méndez et al. 2015) used the method of volume averaging (Whitaker 1999) to study the effective diffusivity of porous media with volumetric reaction rates, and they observed that the effective diffusivity increases with the Thiele modulus (i.e., when the ratio of the reaction rate to the diffusion rate increases). These studies suggest that the effect of reaction on the effective diffusivity cannot be, in general, neglected (Dadvar and Sahimi 2007; Valdes-Parada and Alvarez-Ramirez 2010).

The influence of the reaction rate on the effective diffusivity has been traditionally neglected in the fuel cell community. Kim and Pitsch (2009) reconstructed catalyst layers by using simulated annealing and determined the effective diffusivity using the lattice Boltzmann method. Lange et al. (2010) studied the effective diffusivity of the cathode catalyst layer by performing pore-scale simulations on a stochastically reconstructed sphere-shaped microstructure. Mukherjee and Wang (2006) performed DNS on a 3D stochastically reconstructed microstructure using statistical information from 2D transmission electron microscopy (TEM) images to analyze the effective properties of the cathode catalyst layer. Litster et al. (2013) examined the effective diffusivity of catalyst layers by simulating gas diffusion on a 3D geometry from nano X-ray computed tomography (CT). All these works treated the effective diffusivity as a property that is only dictated by the geometry of the material (and the bulk diffusivity), but neglected the potential effect of reaction on the effective diffusivity.

The aim of this work is to examine the impact of reaction rate on the effective transport properties, namely effective diffusivity and catalyst utilization, of multiscale reactive porous media, such as catalyst layers of PEFCs. The structure of the paper is as follows: in Sect. 2, three different approaches to determine the effective diffusivity of porous media are presented, including the traditional 1D upscaling method for non-reactive conditions and Whitaker’s closure method for reaction–diffusion conditions (Whitaker 1999; Lugo-Méndez et al. 2015). The inconveniences of these two methods when applied to catalytic porous media with complex 3D geometries are summarized. Next, the 1D upscaling method proposed here is described, which allows the calculation of the effective diffusivity and utilization factor of arbitrary porous media with first-order kinetics. In Sect. 4, the results of our 1D upscaling method are validated against the closure method using a simple 2D square-shaped unit cell. In Sect. 5, the method is applied to the 3D microstructure of a PEFC catalyst layer determined from nano X-ray CT, as well as an idealized 3D catalytic porous medium with low tortuosity. A thorough discussion of the influence of the Thiele modulus on the effective diffusivity and catalyst utilization is carried out. Lastly, a critical current density study is presented to show at what PEFC operating conditions the reaction rates cannot be neglected when computing effective transport properties.

2 Methods

2.1 Traditional Method

The traditional method considers the definition of effective diffusivity under passive diffusion conditions. In this method, the effective diffusivity depends only on the geometry of the porous medium and the bulk diffusivity, neglecting any effect of reaction. Laplace’s equation is solved at the pore scale in the fluid space, using Dirichlet boundary conditions at the inlet (surface 1) and the outlet (surface 2). No-flux boundary conditions are prescribed at the remaining interfaces. The pore-scale governing equation is given by:

where \( c \) is the pore-scale species concentration and D is the bulk diffusivity. The average superficial flux through the porous medium, N, is directly obtained from the pore-scale simulations, so, by analogy with the 1D macroscopic diffusion equation, the effective diffusivity is equal to:

where ΔC = c1 − c2 is the superficial concentration difference between inlet and outlet, and L is the thickness of the sample. Here, \( D_{\text{eff}} \) is the component of the effective diffusivity in the direction of interest from the inlet to the outlet, which is equal in all directions for an isotropic material. For the general case of an anisotropic material, \( D_{\text{eff}} \) varies with the direction examined, so diffusion is characterized (in 3D) by a second-order tensor, \( {\mathbf{D}}_{\text{eff}} \), whose diagonal and non-diagonal components can be determined by changing the direction of interest in the calculations (see, e.g., García-Salaberri et al. 2015a, b and references therein). For simplicity, hereafter we shall refer to the effective diffusivity as the principal component in one specific direction, e.g., the zz-component of the effective diffusivity tensor.

\( D_{\text{eff}} \) is customarily expressed as the product of the molecular diffusivity, D, and the porosity, \( \varepsilon \), divided by the tortuosity factor, \( \tau \):

The porosity is simply given by the ratio of the fluid to total volume, ε = Vfluid/Vtotal, while the tortuosity factor is equal to the square of tortuosity (Epstein 1989), i.e.,

where \( L_{\text{eff}} \) is the length of the tortuous pathways. In practice, however, the tortuosity factor is usually calculated a posteriori as a fitting parameter of Eq. (3) to match the computed or measured values of \( D_{\text{eff}} \):

The relationships existing between superficial, interstitial and pore-scale fluxes and how these variables are related to the tortuosity factor are presented in Supplemental Material.

2.2 Closure Method

The closure method takes into account the effect of reaction rate on the effective diffusivity using Whitaker’s volume-averaging technique (Whitaker 1999; Lugo-Méndez et al. 2015). Here, we consider the case of a porous medium with first-order homogenous reaction in the fluid space for comparative purposes with our method (see the validation results in Sect. 4). A detailed description of the simplifications made in the development of the volume-averaging method with closure, including the well-known separation between pore and macroscopic length scales, can be found elsewhere (Whitaker 1999). The governing equation of the macroscopic model in the closure method is

where R is the reaction rate and \( \left\langle c \right\rangle^{\gamma } \) is the volume-averaged concentration in the \( \gamma \)-phase (the fluid space), i.e., the interstitial concentration. The effective diffusivity tensor, \( {\mathbf{D}}_{\text{eff}} \), can be determined as

where \( {\mathbf{I}} \) is the second-order unit tensor, \( {\mathbf{x}} \) is the position vector from the origin to the center of the modeled domain, \( {\mathbf{r}} \) is the position vector from the origin to any point in the domain, \( A_{\gamma \kappa } \) is the fluid–solid interface, and \( {\mathbf{n}}_{\gamma \kappa } \) is the unit normal vector directed from the fluid to the solid phase. The first term on the right-hand side of Eq. (7), \( {\mathbf{D}}_{\text{diff}} \), is the geometrical diffusivity tensor, which is only affected by the microstructure of the porous medium (and the bulk diffusivity) and is independent of reaction, whereas the second term, \( {\mathbf{D}}_{rx} \), is a diffusion-like coefficient that depends on the reaction rate. The closure variable, \( {\mathbf{b}} \), is determined from the corresponding closure problem:

where \( \varOmega_{\gamma } \) is the fluid domain, \( \partial \varOmega_{\gamma \kappa } \) is the fluid–solid interface, and \( {\mathbf{l}}_{i} \) is the unit cell lattice vector, whose magnitude is equal to the length of the side of the domain. The volume-averaging method considers that the macro-scale domain is composed of spatially periodic representative regions, where each microscale representative region is a unit cell used in the closure method. Therefore, the boundary conditions at the unit cell boundary are periodic boundary conditions i.e., same Dirichlet (concentration) and Neumann (flux) boundary conditions at opposite points.

For first-order kinetics, i.e., \( R(c) = - kc \), \( {\mathbf{b}} \) can be decomposed as \( {\mathbf{b}} = - k{\mathbf{b}}_{rx} + {\mathbf{b}}_{\gamma } \), where \( k \) is the reaction rate coefficient. The component \( {\mathbf{b}}_{rx} \) solves the following boundary-value problem, which depends on the reaction rate:

The boundary-value problem for \( {\mathbf{b}}_{\gamma } \) does not depend on the reaction rate and can be written as follows:

As can be seen in the above equations, the closure method requires the application of local boundary conditions and the evaluation of integrals along the entire fluid–solid interface. Therefore, Whitaker’s closure method is usually useful for simple geometries, but becomes tedious and complicated for complex porous media, such as catalyst layers.

2.3 Present Method

The present method extends the traditional 1D approach for passive diffusion presented in Sect. 2.1 to reactive conditions. The method solves the pore-scale reaction–diffusion equation, considering first-order kinetics. Dirichlet boundary conditions are prescribed at the inlet (surface 1) and the outlet (surface 2), while a no-flux boundary condition is set at the sidewalls of the domain. The governing equation at the pore scale is:

Similarly, the 1D upscaled reaction–diffusion equation can be written as

where C is the superficial concentration, and \( D_{\text{eff}} \) and \( k_{\text{eff}} \) are the effective diffusivity and reaction rate coefficient, respectively. Introducing the dimensionless variables C* = C/c1 and z* = z/L, Eq. (12) can be expressed as

where the only governing parameter is the effective Thiele modulus, \( \phi_{\text{eff}} = L\sqrt {k_{\text{eff}} /D_{\text{eff}} } \), which measures the relative importance of reaction and diffusion rates. The dimensionless boundary conditions at the inlet and the outlet are given by

The analytical solution to Eq. (13) subject to boundary conditions (14.a)–(14.b) can be written as

So, the dimensional superficial flux, \( N = - \left( {D_{\text{eff}} c_{1} /L} \right){\text{d}}C^{ * }/{\text{d}}z^{ * } \), is

This equation can be used to get expressions for \( \phi_{\text{eff}} \), \( D_{\text{eff}} \) and \( k_{\text{eff}} \) as a function of the inlet/outlet concentrations and fluxes, (c1, N1) and \( \left( {c_{2} ,N_{2} } \right) \), and the thickness of the porous medium, L. The resulting relationships are as follows:

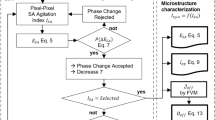

As shown in Fig. 1, the set of Eqs. (17.a)–(17.c) is used to determine the effective properties \( \phi_{\text{eff}} \), \( D_{\text{eff}} \) and \( k_{\text{eff}} \) upon knowledge of the inlet and outlet average superficial fluxes, N1 and N2, computed in the pore-scale simulations. Summarizing, the steps of the 1D upscaling algorithm are as follows:

Schematic of the 1D upscaling method proposed in this work to determine the effective properties (\( \phi_{\text{eff}} \), \( D_{\text{eff}} \), \( k_{\text{eff}} \)) of multiscale catalytic porous media featuring first-order kinetics. The method takes the pore-scale Thiele modulus as an input, \( \phi = L\sqrt {k/D} \), and solves the reaction–diffusion equation at the pore scale with Dirichlet boundary conditions in the direction of interest. The inlet and outlet superficial fluxes, N1 and N2, obtained from the pore-scale simulations are then used to determine the effective properties through Eqs. (17.a)–(17.c). The fluid and permeable solid regions of the catalyst layer are indicated

-

1)

Set the value of the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D} \), and apply the concentration boundary conditions in the pore-scale model.

-

2)

Solve Eq. (11.a) numerically on the pore-scale geometry of the porous medium.

-

3)

Extract both the inlet and outlet average superficial fluxes, N1 and N2, from the pore-scale simulations.

-

4)

Determine the effective properties \( \phi_{\text{eff}} \), \( D_{\text{eff}} \) and \( k_{\text{eff}} \) using Eqs. (17.a)–(17.c).

The proposed method is easy and straightforward to implement compared to the closure method described in Sect. 2.2. It is best suited to study 3D porous media with complex geometries. Besides, it can be efficiently used to characterize the local effective properties in large-scale multiscale simulations involving heterogeneous materials at various length scales.

An aspect that deserves further attention is the singularity that arises in Eq. (17.a) when the denominator \( c_{2} N_{1} + c_{1} N_{2} \) vanishes, or even becomes negative, as \( \phi \) is significantly higher than 1. As shown in Fig. 2a, this limitation of the method was examined considering a 1D bulk domain without internal features, so \( \phi_{\text{eff}} = \phi \), \( D_{\text{eff}} = D \), and \( k_{\text{eff}} = k \). As can be seen in Fig. 2b, when \( c_{1} ,c_{2} \ne 0 \) and \( \phi \gg 1 \), the reaction–diffusion process is concentrated in the regions close to the inlet and the outlet, so the concentration in one side has no effect on the other side; the solution in the middle region is simply given by \( c \simeq 0 \). Hence, the concentration at the opposite side that is effectively seen from either the inlet or the outlet can be treated as zero. Under this condition, the inlet/outlet concentrations and fluxes, i.e., \( \left( {c_{1} ,N_{1} } \right) \) and \( \left( {c_{2} ,N_{2} } \right) \), tend to form similar pairs but with different signs. For the 1D bulk domain, this can be easily checked using Eq. (16). If we set the outlet concentration \( c_{2} = 0 \) in Eq. (16), the inlet flux \( N_{1} \) (z* = 0) becomes:

a Schematic of the 1D bulk domain used to investigate the singularity that arises in Eq. (17.a), \( c_{2} N_{1} + c_{1} N_{2} \) vanishes, or it can even become negative when \( c_{1} ,c_{2} \ne 0 \) and \( \phi \gg 1 \). b Example of similar pairs formed at the inlet and the outlet in the simulations of the 1D bulk domain when \( \phi = 50 \)

Similarly, introducing the inlet concentration \( c_{1} = 0 \) in Eq. (16), the outlet flux \( N_{2} \) (z* = 1) is:

Therefore, combining Eqs. (18)–(19) yields:

where it can be seen that \( c_{2} N_{1} + c_{1} N_{2} \) vanishes, and thus Eq. (17.a) becomes singular when \( \phi \) is exceedingly high. Here, this issue was solved by setting the outlet concentration \( c_{2} = 0 \) in all calculations, so the expression \( c_{2} N_{1} + c_{1} N_{2} \) is reduced to \( c_{1} N_{2} \). Since \( c_{1} N_{2} \ge 0 \) for any case of interest, the singularity is successfully removed. Further details considering a 2D case are presented in Supplemental Material.

3 Numerical Modeling

3.1 Geometry and Materials

A platinum group metal-free (PGM-free) Fe–N–C catalyst layer was studied in this work. The preparation, characterization and operation of the catalyst layer in a PEFC can be found in our earlier works (Serov et al. 2018; Normile et al. 2018). Nano X-ray CT images of the catalyst layer were acquired at Advanced Photon Source (beamline 32-ID) with a resolution of 60 nm/voxel. A thorough description of the imaging setup is presented in (Serov et al. 2018; Zenyuk et al. 2016). Image reconstruction was performed in TomoPy (Gürsoy et al. 2014), while ImageJ (Schneider et al. 2012a, b) was used for image cropping and thresholding. Since meso-pores with a size below 60 nm and the carbon particles below this threshold could not be distinguished in the images, the catalyst phase (which shows up in image analysis as solid phase) was effectively treated as a permeable catalytic region. The first-order reaction on the surface of the electrocatalyst was modeled as a locally homogeneous (i.e., volumetric) reaction term in the permeable solid region. Hereon, we will refer to this meso-porous domain as ‘solid’ region. Figure 3a, b shows the analyzed domain that was extracted from the main sample, indicating the fluid and permeable solid phases in white and black, respectively. The thickness of the domain is 12.8 µm, and the widths in x- and y-direction are equal to 9 µm and 7 µm, respectively. The porosity is \( \varepsilon = 0.52 \). This porosity does not include internal porosity of the catalyst domain.

a 2D slice and b 3D voxelized domain from nano X-ray CT of the PGM-free catalyst layer, showing the fluid and permeable catalytic solid regions in white and black, respectively. c Idealized geometry made up of an array of straight cylindrical permeable catalytic regions (solid phase), embedded inside a fluid region

Additionally, as shown in Fig. 3c, an idealized geometry was created to examine the effect of the pore-scale structure of the porous medium on the effective diffusivity. The idealized geometry was made up of straight cylindrical catalytic regions (i.e., the permeable solid phase) with a radius of 815.5 nm embedded inside a fluid region. To make the results comparable, the thickness and porosity of this geometry were set equal to those of the catalyst layer. In addition, the side of the square cross section was fixed to 8 µm to make the total volume similar.

3.2 Model Setup

Prior to the simulations, the binary images were converted into a distribution of local diffusivities, i.e., \( D = D_{\text{bulk}} \) or \( D = D_{\text{solid}} \) according to the fluid or solid label of each voxel. Then, the computational domain was meshed as desired and the local diffusivities were assigned to each element according to the previously generated distribution function. The simulations were performed using the Transport of Dilute Species module of COMSOL Multiphysics 5.1, using the Live-Link interface with MATLAB to generate the diffusivity distributions, evaluate fluxes and automatize the set-up and post-processing operations. The inlet and outlet concentrations were set to \( c_{1} = 1\;{\text{mol}}/{\text{m}}^{3} \) and \( c_{2} = 0\;{\text{mol}}/{\text{m}}^{3} \) throughout the work, while the bulk gas diffusivity was calculated using the following correlation for the oxygen–nitrogen gas pair (Bird et al. 2002):

The temperature was set to 80 °C. In addition, the solid-phase diffusivity was set to 5% of that in the pore space, i.e., \( D_{\text{solid}} = 0.05D_{\text{bulk}} \), to account for diffusive transport through the meso-pores that were not resolved in the images (\( d_{\text{pore}} { \lesssim }60\;{\text{nm}} \)) (Litster et al. 2013). The pore-scale reaction rate coefficient \( k \) in the permeable catalytic solid region was varied to analyze the impact of the Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \).

Steady-state simulations were run on a workstation equipped with 64 GB RAM and Intel i7-6900 K 3.2 GHz 2-core processors. The geometry of the catalyst layer was meshed using a mapped grid with 915,975 elements, while a free tetrahedral grid with 1,522,642 elements was used for the idealized array of cylinders. In both cases, a refined boundary layer was included in the region adjacent to the inlet and the outlet to improve the accuracy of the calculations.

4 Method Validation

Before proceeding further, the predictions of the present method were compared against those of the closure method. As shown in Fig. 4, to reproduce the conditions in Lugo-Méndez et al. (2015), a simple 2D square-shaped unit cell with a solid central region was used in the simulations. Furthermore, the solid-phase diffusivity was set to zero, and the homogeneous reaction term was modeled in the fluid region instead of the solid region. Different porosities are achieved by varying the size of the solid central region, while maintaining symmetry. Three different porosities were examined: \( \varepsilon = 0.3 \), 0.5 and 0.7.

Variation of the normalized effective diffusivity, \( \varepsilon D_{\text{eff}} /D \), with the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \), as predicted by the present implementation of the closure method (curves) and previous results presented in the literature (Lugo-Méndez et al. 2015) (dots) corresponding to different porosities: \( \varepsilon = 0.3,\;0.5\;{\text{and}}\;0.7 \). The inset shows the 2D unit cell used in the validation study (Lugo-Méndez et al. 2015)

Figure 4 shows the computed effective diffusivity as a function of the pore-scale Thiele modulus. As can be seen, the present results obtained with the closure method closely reproduce the results of Lugo-Méndez et al. 2015. According to Eq. (7), the effective diffusivity is composed of two parts: \( D_{\text{diff}} \), which is independent of the reaction rate and is only influenced by the geometry of the porous medium and the bulk diffusivity, and Drx, which depends on the reaction rate. In Fig. 5, the two components of the effective diffusivity are plotted as a function of the pore-scale Thiele modulus. It can be seen that \( D_{\text{diff}} \) remains constant regardless of the value of the Thiele modulus, whereas \( D_{rx} \) shows a sigmoid-like dependency with the Thiele modulus. When \( \phi \) is lower than 1, the relative importance of reaction over diffusion is small, so that \( D_{rx} \) is virtually zero and the impact of reaction can be neglected. However, when \( \phi \) is between 1 and 100, \( D_{rx} \) sharply increases with \( \phi \) due to the higher influence of reaction. Finally, when \( \phi \) is exceedingly high and the problem is strongly dominated by the reaction term, \( D_{rx} \) approaches a constant value asymptotically. Specifically, the effective diffusivity becomes equal to the bulk diffusivity, i.e., \( \varepsilon D_{\text{eff}} /D = \varepsilon \), since species are completely consumed in the inlet region and the geometry of the porous medium does not affect the reaction–diffusion process.

Variation of a the reaction-independent, \( \varepsilon D_{\text{diff}} /D \), and b the reaction-dependent, \( \varepsilon D_{rx} /D \), components of the normalized effective diffusivity with the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \), as predicted by the closure method for different porosities of the 2D geometry used in the validation study (Lugo-Méndez et al. 2015): \( \varepsilon = 0.4,\;0.6\;{\text{and}}\;0.8 \)

The results of our upscaling method are compared to those of the closure method in Fig. 6. Note that \( k_{\text{eff}} \) was set equal to \( k \) in our algorithm, as this assumption is used in the closure method. Accordingly, Eq. (17.a) was used to calculate \( \phi_{\text{eff}} \), while the effective diffusivity was directly determined as \( D_{\text{eff}} = kL^{2} /\phi_{\text{eff}}^{2} \) instead of using Eq. (17.b). When \( \phi \) is either small (\( \phi = 0.1 - 1 \)) or large (\( \phi = 10 - 100 \)), the effective diffusivities predicted by both methods are almost the same. However, they slightly differ in the intermediate range \( \phi = 1 - 10 \), especially for low porosities. This difference is explained by the 2D effects that arise around the upper constriction of the fluid space when \( \phi = 1 - 10 \), which helps diffusive transport across the material. As a result, the effective diffusivity predicted by our 1D upscaling formulation is somewhat higher compared to that of the 2D upscaling formulation of the closure method. In other words, all 2D pore-scale transport effects in our 1D upscaling method are collected in the value of the effective diffusivity. By contrast, in the closure method part of the 2D pore-scale transport effects is preserved in the 2D macroscopic equation; hence, the corresponding effective diffusivity is lower.

Variation of the normalized effective diffusivity, \( \varepsilon D_{\text{eff}} /D \), with the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \), as predicted by the closure method (curves) and the present method (dots) for different porosities of the 2D geometry used in the validation campaign (Lugo-Méndez et al. 2015): \( \varepsilon = 0.4,\;0.6\;{\text{and}}\;0.8 \)

The above situation is further illustrated in Fig. 7, which shows the dimensionless concentration distribution for \( \varepsilon = 0.4 \), corresponding to three different values of the Thiele modulus: ϕ = 0.1, 5 and 50. When ϕ = 0.1, diffusion is fast compared to reaction, so the local diffusive flux through the porous medium is almost 1D. Similarly, when ϕ =50 the reaction rate is very high and species transport takes place only in the inlet bulk region, and thus the diffusive flux is 1D again. However, in the case of ϕ = 5, both reaction and diffusion play a relevant role, and the diffusive flux shows noticeable 2D effects around the contractions/expansions of the porous medium. In particular, the significant flux in x-direction around the lower contraction promotes diffusive transport toward the lateral bulk regions, which, in turn, enhances transport in z-direction. Consequently, the effective diffusivity computed by our 1D method is somewhat higher compared to that of the 2D closure method, as discussed earlier. The differences between the two methods decrease for higher porosities because species transport is less affected by the internal solid obstacle and the pathways become more 1D. For instance, \( D_{\text{eff}} /D = 1 \) when \( \varepsilon = 1 \) regardless of the value of ϕ, as shown in Supplemental Material. The overall good agreement of the results was considered fair enough to confirm the proper functioning of the present method.

Dimensionless pore-scale concentration distribution, \( c/c_{1} \), in the simple 2D geometry used for the validation of the present method (Lugo-Méndez et al. 2015), corresponding to different values of the pore-scale Thiele modulus: a\( \phi = 0.1 \), b\( \phi = 5 \), and c\( \phi = 50 \). The porosity is \( \varepsilon = 0.4 \)

5 Results and Discussion

The influence of the reaction rate on the effective diffusivity of the catalyst layer and the idealized catalyst layer (array of cylinders) is illustrated in Fig. 8. Figure 8a, d shows the local diffusivity distributions, which range between D = 2.83 × 10−5 m2/s in the fluid region and D = 1.41 × 10−6 m2/s in the permeable solid region. In addition, Fig. 8b, c, e, f shows the computed reaction rate distributions in the catalytic solid region and the transport pathways for the case ϕ = 1. It can be clearly seen that the transport pathways in the catalyst layer are significantly more tortuous than those in the idealized geometry, where they are nearly straight lines.

Figure 9a shows the variation of the effective diffusivity of the catalyst layer and the idealized catalyst layer in a wide range of Thiele moduli, spanning from ϕ =10−2 to ϕ =105. We shall discuss first the results of the catalyst layer. As can be seen, when \( \phi { \lesssim }1 \), the effect of reaction is negligible and Deff remains almost constant. However, Deff strongly changes with the Thiele modulus when \( \phi { \gtrsim }1 \): Deff decreases first in the range \( \phi = 1 - 200 \) and then increases when \( \phi { \gtrsim }200 \). Note that the variation of Deff in the range ϕ =103–105 is somewhat noisy because of the strong impact of reaction and the complex geometry of the catalyst layer. Eventually, when ϕ =104–105, the effective diffusivity tends to a constant value. The corresponding variation of the tortuosity factor τ for the catalyst layer is shown in Fig. 9b. When ϕ < 1, \( \tau \) remains approximately constant regardless of the reaction rate with a value around 1.2. In this region, the traditional method is applicable, as species diffusion depends primarily on catalyst layer morphology. When ϕ > 1, the reaction term influences diffusive transport; hence, τ is no longer a reaction-independent parameter and the traditional method can no longer be used to compute the effective diffusivity. Despite the slight increase of τ in the range \( \phi = 1 - 200 \), diffusion is facilitated by reaction in the remaining range when \( \phi { \gtrsim }200 \), reaching a value somewhat lower than 1 for \( \phi = 10^{4} \). If the effective diffusivity would be calculated based on geometrical factors only, then the lower limit of the tortuosity factor would be 1. Here, the geometrical effects are counterbalanced by the local high reaction fluxes. Examining the results of the idealized geometry, the effective diffusivity is higher (τ is lower) than that of the catalyst layer, even though the results are qualitatively similar in both cases. For small values of ϕ, \( \tau \) remains close to 1 according to the nearly straight pathways prevailing for this geometry, see Fig. 8f. This value then decreases to 0.8 when ϕ is high enough because diffusion is facilitated by reaction.

a Effective diffusivity and b tortuosity factor as a function of the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \), corresponding to the nano X-ray CT image of the catalyst layer and the idealized array of cylinders. The value of the Thiele modulus, \( \phi = 1 \), for which the effect of reaction on the effective diffusivity starts to be important (i.e., the critical current density) is indicated in a. c–g From left to right, pathways computed in the idealized geometry for \( \phi = 10^{ - 2} ,\;1,\;10,\;10^{2} ,\;10^{4} \)

Figure 9c–g shows the flux lines computed for the idealized geometry, corresponding to five different Thiele moduli: (c) \( \phi = 10^{ - 2} \), (d) \( \phi = 1 \), (e) \( \phi = 10 \), (f) \( \phi = 10^{2} \) and (g) \( \phi = 10^{4} \). The four regions identified in Fig. 9a for the variation of the effective diffusivity can be visualized with the transport pathways. Thus, when the effect of reaction on diffusion is negligible (\( \phi = 10^{ - 2} \)), the pathways are almost straight lines through the fluid phase. However, when \( \phi = 1 \), the pathways start to deviate toward the solid phase due the reaction sink. Since the solid-phase diffusivity is 5% of the bulk diffusivity, the effective diffusivity of the porous medium starts to decrease. When \( \phi = 10 \), species mostly pass through the solid phase to cross the porous domain and the effective diffusivity reaches the smallest value at this point. The reason for the gas species to transport through the meso-pores of the carbon material, rather than the exterior void region, is that the high volumetric reaction sink term is a strong driving force for the species to diffuse into the catalyst domain. Note that the minimum effective diffusivity (maximum tortuosity) is reached at different Thiele moduli for the catalyst layer and the idealized geometry. This is because the solid domains have different sizes. The cylinders in the idealized geometry have a radius of 815.5 nm, whereas the mean radius of the solid region in the catalyst layer is 211 nm (see Supplementary Material). Smaller agglomerates in the catalyst layer result in larger reaction rates and Thiele moduli needed to ensure that transport mostly takes place through the catalyst domain and not the external void space. In other words, with smaller agglomerates, the traditional method can approximate effective diffusivity for a larger range of Thiele moduli. For \( \phi = 10^{2} \), the reaction rate is significantly faster than diffusion, so species are mostly consumed at the interface near the inlet. As a result, the portion of the solid phase that is accessed decreases, leading to a high increase in the effective diffusivity. Finally, when \( \phi = 10^{4} \), the reaction rate is extremely fast, so species are completely consumed near the solid surface facing the inlet, and the effective diffusivity approaches a constant value.

5.1 Effect of the Diffusivity of the Permeable Solid Region

The diffusivity in the solid region can vary significantly in catalyst layers with different meso-porosities. In this section, the effect of the solid-phase diffusivity on the effective diffusivity of the catalyst layer is examined. Figure 10a shows the results of the effective diffusivity when the solid-phase diffusivity is 5–30% of the bulk diffusivity. Two regimes can be distinguished in all cases: (1) a first region (\( \phi { \lesssim }200 \)) where the effective diffusivity increases with the solid-phase diffusivity, and (2) a second region (\( \phi { \gtrsim }200 \)) where the effective diffusivity is no longer influenced by the solid-phase diffusivity, and all the curves collapse onto a single curve. Note that in the intermediate range \( \phi = 1 - 200 \), the descent of the effective diffusivity is more pronounced when the solid-phase diffusivity is high. Again, for \( \phi \) < 1 the effective diffusivity does not depend on the reaction rate and the traditional method can be used. In this regime, effective diffusivity strongly depends on porosity and tortuosity. The scenarios associated with the above two regimes are shown as schematics in Fig. 10b, c. As can be seen, the reaction rate is rather slow in Regime 1, so species are transported through the catalytic solid region and consumed therein. Consequently, the effective diffusivity increases with the solid-phase diffusivity. By way of contrast, the reaction rate is high enough in Regime 2, so transport through the catalytic region is negligible and species are mostly consumed on the surface. Hence, the effective diffusivity does not depend on the solid-phase diffusivity when ϕ is large enough (\( \phi { \gtrsim }200 \)). To translate these findings into the porous catalytic layer design: internal carbon meso- and micro-porosity of catalyst agglomerates becomes negligible at high reaction rates. Figure 10 shows that at the interception of Regime 1 and Regime 2 for \( \phi \) ~ 200 the effective diffusivity to molecular diffusivity ratio is 0.35 for all diffusivities in the solid phase. The rational design of catalytic media should ensure that most of the electrocatalyst sites are on the surface of carbon agglomerates. We discuss more practical applications in the next sections.

a Normalized effective diffusivity, \( D_{\text{eff}} /D \), as a function of the pore-scale Thiele modulus, \( \phi = L\sqrt {k/D_{\text{bulk}} } \), corresponding to different diffusivities of the solid phase: Dsolid/Dbulk = 5–30%. b, c Schematic of transport pathways in the two regimes indicated in a

5.2 Utilization Factor

As discussed earlier, only the part of the catalyst layer that is close to the inlet is utilized when the Thiele modulus is significantly high. This effect can be examined by comparing the effective and pore-scale or intrinsic reaction rate coefficients, \( k_{\text{eff}} \) and \( k \), respectively. A catalyst utilization factor can be defined as

where \( (1 - \varepsilon ) \) is the volume fraction of the catalytic solid phase. Introducing this term, \( U_{\text{eff}} \approx 1 \) when the entire catalyst layer is utilized. Further details about the derivation of this expression can be found in Supplemental Material (O'Hayre et al. 2016).

Figure 11a shows the variation of the utilization factor as a function of the Thiele modulus. As expected, when \( \phi { \lesssim }1 \), species diffusion is high enough to reach the active catalyst sites, so the entire catalyst layer is utilized and \( U_{\text{eff}} \) remains around 1. However, when \( \phi { \gtrsim }1 \), the strength of diffusion is relatively smaller than that of reaction, and only part of the catalyst layer is utilized. In this region, the effective diffusivity decreases due to the influence of reaction, and hence the utilization factor decreases. This situation is intensified for higher values of \( \phi \), where only the narrow catalytic region close to the inlet is utilized and, therefore, \( U_{\text{eff}} \) drops to zero. Note that the utilization factor slightly increases for higher solid-phase diffusivities due to the facilitated transport of species toward the active catalytic sites. Figure 11b shows the variation of the effective Thiele modulus as a function of the pore-scale Thiele modulus. The relative importance of the macroscopic reaction rate over the diffusion rate increases from 0.01 to 70 in the range ϕ = 0.01–200 owing to the increase in the intrinsic reaction rate. For higher values of \( \phi \), the effective Thiele modulus saturates at around 70, since species are consumed voraciously at the solid surface near the inlet, and the ratio \( k_{\text{eff}} /D_{\text{eff}} \) does not longer change.

5.3 Critical Current Density

As shown in the previous sections, \( D_{\text{eff}} \) is affected by reaction when \( \phi { \gtrsim }1 \). Therefore, it is pertinent to ask about the value of the PEFC’s critical current density for which \( \phi = 1 \), that is, \( k = D_{\text{bulk}} /L^{2} \). Essentially, we are interested in understanding under what operating conditions the traditional method for extracting effective properties is inaccurate. The current density is related to the oxygen reaction rate, \( R_{\text{ORR}} = - k_{\text{eff}} c_{{{\text{O}}_{2} }}^{\text{cl}} \approx - \left( {1 - \varepsilon } \right)U_{\text{eff}} kc_{{{\text{O}}_{2} }}^{\text{cl}} \), by Faraday’s law:

where \( F \) is Faraday’s constant and \( c_{{{\text{O}}_{2} }}^{\text{cl}} \) is the average oxygen concentration in the catalyst layer, which can be estimated using the overall oxygen mass transport resistance between the channel inlet and the catalyst layer, \( R_{{{\text{O}}_{2} }} \). Given that the diffusive flux of oxygen is \( N_{{{\text{O}}_{2} }} = j_{\text{critical}} /4F \), we have that

Therefore, considering that \( U_{\text{eff}} \sim1 \) when \( \phi \sim 1 \), the combination of Eqs. (23)–(24) yields the following expression for the critical current density

Moreover, since \( {LkR}_{{{\text{O}}_{2} }} \left( {1 - \varepsilon } \right) \) is typically much higher than 1, Eq. (25) can be simplified to

As can be seen from Eq. (26), the critical current density is mostly determined by the inlet oxygen concentration and the overall transport resistance, while the effect of the reaction rate coefficient \( k \) is small. The inlet oxygen concentration \( c_{{{\text{O}}_{2} }}^{\text{in}} \) can be determined as

where \( p_{\text{g}} \), \( T \), and RH are the operating pressure, temperature and relative humidity, respectively; \( p_{{{\text{H}}_{2} {\text{O}}}}^{\text{sat}} \) is the vapor pressure of water (García-Salaberri et al. 2017a). The gas constant is denoted as \( R_{\text{u}} \) here to differentiate it from the reaction rate.

Figure 12 shows the variation of the critical current density as a function of the cell temperature for an operating pressure \( p_{\text{g}} = 1 {\text{bar}} \) and relative humidity, \( {\text{RH}} = 0.9 \). Four different oxygen mass transport resistances, \( R_{{{\text{O}}_{2} }} = 1,2,3\;{\text{and}}\;4\;{\text{s}}/{\text{cm}} \), are considered according to the values reported in previous experimental works for state-of-the-art PEFCs (Wang et al. 2017; Baker et al. 2009; Hao et al. 2015; Owejan et al. 2014; Pavlicek et al. 2018). These are oxygen transport resistances that are outside the catalyst layer. The critical current density decreases with the oxygen mass transport resistance owing to the lower oxygen concentrations reached in the catalyst layer, resulting in a range of 1–3 A/cm2. Nowadays, the progress achieved in PEFCs has led to current densities as high as 3–4 A/cm2 (Kamitaka et al. 2018; Eller et al. 2017; Gröger et al. 2015), so the effect of reaction on the effective diffusivity should not be neglected. Furthermore, the local current density can be notably higher than the average current density due to the spatial variations of the oxygen concentration over the cell active area. Accordingly, the impact of reaction on the effective diffusivity can be important in certain regions of the catalyst layer, even if the average output current density is not significantly high. Agglomerate models of the catalyst layer can capture the effectiveness factor dependency on Thiele modulus; however, it is not clear how to use these models in DNS, which becomes more prevalent due to availability of morphological data.

Estimation of the critical current density, \( j_{\text{critical}} \), as a function of the cell temperature, \( T \), for different oxygen mass transport resistances: \( R_{{{\text{O}}_{2} }} = 1,\;2,\;3\;{\text{and}}\;4\;{\text{s}}/{\text{cm}} \). The operating pressure and relative humidity are equal to \( p_{\text{g}} = 1 {\text{bar}} \) and \( {\text{RH}} = 0.9 \), respectively

6 Conclusions

In this work, the effect of reaction rate on the effective properties (effective diffusivity and catalyst utilization factor) of porous media, such as catalyst layers of polymer electrolyte fuel cells (PEFCs), was examined. This aspect has been commonly ignored in the PEFC literature, where effective properties are usually determined under passive diffusion condition. This simplification can be removed by using Whitaker’s volume-averaging method with closure. However, this technique is tedious and challenging to apply to complex 3D geometries. As an alternative, a 1D upscaling method has been presented here to determine the effective diffusivity and utilization factor of catalytic porous media. The proposed method makes use of the 1D macroscopic reaction–diffusion equation with first-order kinetics to derive expressions for the effective properties in terms of only the inlet/outlet superficial concentrations and fluxes, and the thickness of the material. The algorithm is composed of three main steps: (1) to set the value of the Thiele modulus and apply the concentration boundary conditions in the pore-scale model; (2) to solve the reaction–diffusion equation on the pore-scale geometry of the porous medium; and (3) to extract both the inlet/outlet average superficial fluxes from the pore-scale simulations, and determine the effective properties using the derived expressions. This method is versatile and easy to implement, and can significantly reduce the computational time in multiscale simulations.

The proposed method was validated using a simple square-shaped 2D unit cell, resulting in similar results to those of Whitaker’s closure method. The method was then used to explore the variation of the effective diffusivity and catalyst utilization factor as a function of the Thiele modulus. Two different geometries were examined: a catalyst layer with microstructure determined from nano X-ray computed tomography, and an idealized catalyst layer, simulated with an array of straight cylindrical catalytic regions. The results have shown that the effective diffusivity and the utilization factor cannot be treated as reaction-independent properties when the Thiele modulus is higher than 1. For instance, diffusion is facilitated by reaction and the utilization factor is drastically reduced for high values of the Thiele modulus. The critical current density for which reaction starts to affect the effective properties was examined for various fuel cell operating conditions. The results revealed that this effect can be important at high current densities in state-of-the-art PEFCs (1–3 A/cm2). These are the current densities where mass transport resistances are significant. Previous works used agglomerate model for catalyst layer to capture the effect of reaction rate on diffusion (Sun et al. 2005). Our upscaling method circumvents the agglomerate model and provides a unified solution that captures transport dependency on both morphology and reaction rate.

Future work should consider the implementation of different reaction orders in the 1D upscaling method. In particular, the double-trap kinetics, which can be considered as a half-order reaction rate, is worth exploring to improve the modeling of the oxygen reduction reaction in the cathode catalyst layer of PEFCs.

Abbreviations

- \( A_{\gamma \kappa } \) :

-

Solid–fluid interface

- \( {\mathbf{b}} \) :

-

Closure variable vector solves Eq. (8) (m)

- \( {\mathbf{b}}_{rx} \) :

-

Closure variable vector solves Eq. (9) (m)

- \( {\mathbf{b}}_{\gamma } \) :

-

Closure variable vector solves Eq. (10) (m)

- \( c \) :

-

Mole concentration (mol/m3)

- \( C \) :

-

Macroscopic superficial concentration (mol/m3)

- \( c^{*} \) :

-

Dimensionless concentration

- \( \left\langle c \right\rangle^{\gamma } \) :

-

Volume-averaged concentration in \( \gamma \) phase (mol/m3)

- \( c_{{{\text{O}}_{2} }}^{\text{cl}} \) :

-

Oxygen concentration in catalyst layer (mol/m3)

- \( c_{{{\text{O}}_{2} }}^{\text{in}} \) :

-

Oxygen concentration in the inlet of the channel (mol/m3)

- \( c_{\text{g}} \) :

-

Overall gas concentration in the inlet of the channel (mol/m3)

- \( c_{{{\text{H}}_{2} {\text{O}}}} \) :

-

Vapor concentration in the inlet of the channel (mol/m3)

- \( D \) :

-

Bulk diffusivity (m2/s)

- \( D_{\text{solid}} \) :

-

Diffusivity in solid phase (m2/s)

- \( D_{\text{eff}} \) :

-

Effective diffusivity (m2/s)

- \( {\mathbf{D}}_{\text{diff}} \) :

-

Passive effective diffusion coefficient which is independent of reaction (m2/s)

- \( {\mathbf{D}}_{\text{eff}} \) :

-

Effective diffusivity tensor (m2/s)

- \( {\mathbf{D}}_{rx} \) :

-

Diffusion-like coefficient which depends on reaction rate (m2/s)

- \( F \) :

-

Faraday’s constant (C/mol)

- \( {\mathbf{I}} \) :

-

Identity tensor

- \( j \) :

-

Current density (A/m2)

- \( j_{\text{critical}} \) :

-

Critical current density (A/m2)

- \( k \) :

-

Reaction rate coefficient (s−1)

- \( k_{\text{eff}} \) :

-

Effective reaction rate coefficient (s−1)

- \( {\mathbf{l}}_{i} \) :

-

Unit cell lattice vectors, \( i \) = 1, 2, 3 (m)

- \( L \) :

-

Thickness between inlet and outlet boundaries (m)

- \( L_{\text{eff}} \) :

-

Length of the tortuous pathway (m)

- \( {\mathbf{n}}_{\gamma \kappa } \) :

-

Unit normal vector directed from the fluid to the solid phase

- \( M \) :

-

Molecular weight (kg/mol)

- \( N \) :

-

Superficial diffusive flux (mol/m2s)

- \( N_{{{\text{O}}_{2} }} \) :

-

Diffusive oxygen flux (mol/m2s)

- \( p_{\text{g}} \) :

-

Gas pressure (Pa)

- \( p_{{{\text{H}}_{2} {\text{O}}}}^{\text{sat}} \) :

-

Vapor pressure of water (Pa)

- \( {\mathbf{r}} \) :

-

Position vector directed from the origin to a point in the averaging domain (m)

- \( R \) :

-

Reaction rate (mol/m3s)

- \( R_{{{\text{O}}_{2} }} \) :

-

Overall oxygen mass transport resistance between inlet of the channel and the catalyst layer (s/m)

- \( R_{u} \) :

-

Gas constant (J/mol K)

- \( T \) :

-

Temperature (K)

- \( U_{\text{eff}} \) :

-

Utilization factor

- \( V_{\text{total}} \) :

-

Total volume of the porous material (m3)

- \( V_{\text{fluid}} \) :

-

Volume of fluid space (m3)

- \( V_{\gamma } \) :

-

Volume of \( \gamma \) phase (m3)

- \( {\mathbf{x}} \) :

-

Position vector directed from the origin to the averaging domain center (m)

- \( z \) :

-

Coordinate in z-direction (m)

- \( z^{*} \) :

-

Dimensionless z-coordinate

- \( \rho \) :

-

Gas mixture density (kg/m3)

- \( \omega \) :

-

Mass fraction

- ε :

-

Porosity

- \( \tau \) :

-

Tortuosity factor

- \( \phi \) :

-

Thiele modulus

- \( \phi_{\text{eff}} \) :

-

Effective Thiele modulus

- \( \varOmega_{\gamma } \) :

-

Domain occupied by \( \gamma \) phase

- \( \partial \varOmega_{\gamma \kappa } \) :

-

Domain occupied by solid–fluid interface

References

Baker, D.R., Caulk, D.A., Neyerlin, K.C., Murphy, M.W.: Measurement of oxygen transport resistance in PEM fuel cells by limiting current methods. J. Electrochem. Soc. 156, B991–B1003 (2009)

Bear, J., Buchlin, J.-M. (eds.): Modelling and Applications of Transport Phenomena in Porous Media. Kluwer Academic Publishers, Dordrecht (1991)

Bird, R.B., Lightfoot, E.N., Stewart, W.E.: Transport Phenomena. Wiley, New York (2002)

Bosomoiu, M., Tsotridis, G., Bednarek, T.: Study of effective transport properties of fresh and aged gas diffusion layers. J. Power Sources 285, 568–579 (2015)

Dadvar, M., Sahimi, M.: The effective diffusivities in porous media with and without nonlinear reactions. Chem. Eng. Sci. 62, 1466–1476 (2007)

Debe, M.K.: Electrocatalyst approaches and challenges for automotive fuel cells. Nature 486, 43 (2012)

Eller, J., Roth, J., Marone, F., Stampanoni, M., Büchi, F.N.: Operando properties of gas diffusion layers: saturation and liquid permeability. J. Electrochem. Soc. 164, F115–F126 (2017)

Epstein, N.: On tortuosity and the tortuosity factor in flow and diffusion through porous media. Chem. Eng. Sci. 44, 777–779 (1989)

Epting, W.K., Litster, S.: Effects of an agglomerate size distribution on the PEFC agglomerate model. Int. J. Hydrogen Energy 37, 8505–8511 (2012)

Fang, W.-Z., Tang, Y.-Q., Chen, L., Kang, Q.-J., Tao, W.-Q.: Influences of the perforation on effective transport properties of gas diffusion layers. Int. J. Heat Mass Transf. 126, 243–255 (2018)

García-Ochoa, F., Santos, A.: Effective diffusivity under inert and reaction conditions. Chem. Eng. Sci. 49, 3091–3102 (1994)

García-Salaberri, P.A., Hwang, G., Vera, M., Weber, A.Z., Gostick, J.T.: Effective diffusivity in partially-saturated carbon-fiber gas diffusion layers: effect of through-plane saturation distribution. Int. J. Heat Mass Transf. 86, 319–333 (2015a)

García-Salaberri, P.A., Gostick, J.T., Hwang, G., Weber, A.Z., Vera, M.: Effective diffusivity in partially-saturated carbon-fiber gas diffusion layers: effect of local saturation and application to macroscopic continuum models. J. Power Sources 296, 440–453 (2015b)

García-Salaberri, P.A., Sánchez, D.G., Boillat, P., Vera, M., Friedrich, K.A.: Hydration and dehydration cycles in polymer electrolyte fuel cells operated with wet anode and dry cathode feed: a neutron imaging and modeling study. J. Power Sources 359, 634–655 (2017a)

García-Salaberri, P.A., Gostick, J.T., Zenyuk, I.V., Hwang, G., Vera, M., Weber, A.Z.: On the limitations of volume-averaged descriptions of gas diffusion layers in the modeling of polymer electrolyte fuel cells. ECS Trans. 80, 133–143 (2017b)

García-Salaberri, P.A., Zenyuk, I.V., Shum, A.D., Hwang, G., Vera, M., Weber, A.Z., Gostick, J.T.: Analysis of representative elementary volume and through-plane regional characteristics of carbon-fiber papers: diffusivity, permeability and thermal/electrical conductivity. Int. J. Heat Mass Transf. 127, 687–703 (2018)

Gröger, O., Gasteiger, H.A., Suchsland, J.-P.: Review—electromobility: batteries or fuel cells? J. Electrochem. Soc. 162, A2605–A2622 (2015)

Gürsoy, D., De Carlo, F., Xiao, X., Jacobsen, C.: TomoPy: a framework for the analysis of synchrotron tomographic data. J. Synchrotron Radiat. 21, 1188–1193 (2014)

Hao, L., Moriyama, K., Gu, W., Wang, C.-Y.: Modeling and experimental validation of pt loading and electrode composition effects in PEM fuel cells. J. Electrochem. Soc. 162, F854–F867 (2015)

Kamitaka, Y., Takeshita, T., Morimoto, Y.: MgO-templated mesoporous carbon as a catalyst support for polymer electrolyte fuel cells. Catalysts 8, 230 (2018)

Karaki, M., Hallal, A., Younes, R., Trochu, F., Lafon, P., Hayek, A., Kobeissy, A., Fayad, A.: A comparative analytical, numerical and experimental analysis of the microscopic permeability of fiber bundles in composite materials. Int. J. Compos. Mater. 7, 82–102 (2017)

Kim, S.H., Pitsch, H.: Reconstruction and effective transport properties of the catalyst layer in PEM fuel cells. J. Electrochem. Soc. 156, B673–B681 (2009)

Lange, K.J., Sui, P.-C., Djilali, N.: Pore scale simulation of transport and electrochemical reactions in reconstructed PEMFC catalyst layers. J. Electrochem. Soc. 157, B1434–B1442 (2010)

Litster, S., Epting, W.K., Wargo, E.A., Kalidindi, S.R., Kumbur, E.C.: Morphological analyses of polymer electrolyte fuel cell electrodes with nano-scale computed tomography imaging. Fuel Cells 13, 935–945 (2013)

Lugo-Méndez, H.D., Valdés-Parada, F.J., Porter, M.L., Wood, B.D., Ochoa-Tapia, J.A.: Upscaling diffusion and nonlinear reactive mass transport in homogeneous porous media. Transp. Porous Media 107, 683–716 (2015)

Mukherjee, P.P., Wang, C.-Y.: Stochastic microstructure reconstruction and direct numerical simulation of the PEFC catalyst layer. J. Electrochem. Soc. 153, A840–A849 (2006)

Normile, S.J., Sabarirajan, D.C., Calzada, O., De Andrade, V., Xiao, X., Mandal, P., Parkinson, D.Y., Serov, A., Atanassov, P., Zenyuk, I.V.: Direct observations of liquid water formation at nano- and micro-scale in platinum group metal-free electrodes by operando X-ray computed tomography. Mater. Today Energy 9, 187–197 (2018)

O’Hayre, R., Cha, S.-W., Prinz, F.B., Colella, W.: Fuel Cell Fundamentals. Wiley, New York (2016)

Owejan, J.P., Trabold, T.A., Mench, M.M.: Oxygen transport resistance correlated to liquid water saturation in the gas diffusion layer of PEM fuel cells. Int. J. Heat Mass Transf. 71, 585–592 (2014)

Park, S.H., Kim, Y.G.: The effect of chemical reaction on effective diffusivity within biporous catalysts—I: theoretical development. Chem. Eng. Sci. 39, 523–531 (1984)

Pavlicek, R., Barton, S.C., Leonard, N., Romero, H., McKinney, S., McCool, G., Serov, A., Abbott, D., Atanassov, P., Mukerjee, S.: Resolving challenges of mass transport in non Pt-group metal catalysts for oxygen reduction in proton exchange membrane fuel cells. J. Electrochem. Soc. 165, F589–F596 (2018)

Ryan, D., Carbonell, R.G., Whitaker, S.: Effective diffusivities for catalyst pellets under reactive conditions. Chem. Eng. Sci. 35, 10–16 (1980)

Sadeghi, M.A., Aghighi, M., Barralet, J., Gostick, J.T.: Pore network modeling of reaction-diffusion in hierarchical porous particles: the effects of microstructure. Chem. Eng. J. 330, 1002–1011 (2017)

Sahimi, M.: Diffusion-controlled reactions in disordered porous media—I. Uniform distribution of reactants. Chem. Eng. Sci. 43, 2981–2993 (1988)

Salejova, G., Grof, Z., Solcova, O., Schneider, P., Kosek, J.: Strategy for predicting effective transport properties of complex porous structures. Comput. Chem. Eng. 35, 200–211 (2011)

Schindelin, J., Arganda-Carreras, I., Frise, E., Kaynig, V., Longair, M., Pietzsch, T., Preibisch, S., Rueden, C., Saalfeld, S., Schmid, B., Tinevez, J.-Y., White, D.J., Hartenstein, V., Eliceiri, K., Tomancak, P., Cardona, A.: Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012)

Schneider, C.A., Rasband, W.S., Eliceiri, K.W.: NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 9, 671–675 (2012)

Serov, A., Shum, A.D., Xiao, X., De Andrade, V., Artyushkova, K., Zenyuk, I.V., Atanassov, P.: Nano-structured platinum group metal-free catalysts and their integration in fuel cell electrode architectures. Appl. Catal. B Environ. 237, 1139–1147 (2018)

Steinbach, A.J., Allen, J.S., Borup, R.L., Hussey, D.S., Jacobson, D.L., Komlev, A., Kwong, A., MacDonald, J., Mukundan, R., Pejsa, M.J., Roos, M., Santamaria, A.D., Sieracki, Spernjak D., Zenyuk, I.V., Weber, A.Z .: Anode-design strategies for improved performance of polymer-electrolyte fuel cells with ultra-thin electrodes. Joule 2, 1297–1312 (2018)

Sun, W., Peppley, B.A., Karan, K.: An improved two-dimensional agglomerate cathode model to study the influence of catalyst layer structural parameters. Electrochim. Acta 50, 3359–3374 (2005)

Tanno, K., Kurose, R., Michioka, T., Makino, H., Komori, S.: Direct numerical simulation of flow and surface reaction in de-NOx catalyst. Adv. Powder Technol. 24, 879–885 (2013)

Toei, R., Okazaki, M., Nakanishi, K., Kondo, Y., Hayashi, M., Shiozaki, Y.: Effective diffusivity of a porous catalyst with and without chemical reaction. J. Chem. Eng. Jpn. 6, 50–58 (1973)

Valdes-Parada, F.J., Alvarez-Ramirez, J.: On the effective diffusivity under chemical reaction in porous media. Chem. Eng. Sci. 65, 4100–4104 (2010)

Wakao, N., Kimura, H., Shibata, M.: Kinetic studies and effective diffusivities in para to ortho hydrogen conversion reaction. J. Chem. Eng. Jpn. 2, 51–54 (1969)

Wang, G., Mukherjee, P.P., Wang, C.-Y.: Direct numerical simulation (DNS) modeling of PEFC electrodes: part I. Regular microstructure. Electrochim. Acta 51, 3139–3150 (2006a)

Wang, G., Mukherjee, P.P., Wang, C.-Y.: Direct numerical simulation (DNS) modeling of PEFC electrodes: part II. Random microstructure. Electrochim. Acta 51, 3151–3160 (2006b)

Wang, C., Cheng, X., Lu, J., Shen, S., Yan, X., Yin, J., Wei, G., Zhang, J.: The experimental measurement of local and bulk oxygen transport resistances in the catalyst layer of proton exchange membrane fuel cells. J. Phys. Chem. Lett. 8, 5848–5852 (2017)

Weber, A.Z., Mench, M.M., Meyers, J.P., Ross, P.N., Gostick, J.T., Liu, Q.: Redox flow batteries: a review. J. Appl. Electrochem. 41, 1137 (2011)

Weber, A.Z., Borup, R.L., Darling, R.M., Das, P.K., Dursch, T.J., Gu, W., Harvey, D., Kusoglu, A., Litster, S., Mench, M.M., Mukundan, R., Owejan, J.P., Pharoah, J.G., Secanell, M., Zenyuk, I.V.: A critical review of modeling transport phenomena in polymer-electrolyte fuel cells. J. Electrochem. Soc. 161, F1254–F1299 (2014)

Whitaker, S.: The Method of Volume Averaging. Springer, Dordrecht (1999)

Zarandi, M.A.F., Pillai, K.M., Barari, B.: Flow along and across glass-fiber wicks: testing of permeability models through experiments and simulations. AIChE J. 64, 3491–3501 (2018)

Zenyuk, I.V., Das, P.K., Weber, A.Z.: Understanding impacts of catalyst-layer thickness on fuel-cell performance via mathematical modeling. J. Electrochem. Soc. 163, F691–F703 (2016a)

Zenyuk, I.V., Parkinson, D.Y., Connolly, L.G., Weber, A.Z.: Gas-diffusion-layer structural properties under compression via X-ray tomography. J. Power Sources 328, 364–376 (2016b)

Acknowledgements

The work was supported by NSF CAREER award #1652445. This research used resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Pablo A. García-Salaberri thanks support from Project ENE2015-68703-C2-1-R (MINECO/FEDER, UE), the research grant ‘Ayudas a la Investigación en Energía y Medio Ambiente’ of the Spanish Iberdrola Foundation and the US-Spain Fulbright Commission.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, J., García-Salaberri, P.A. & Zenyuk, I.V. The Impact of Reaction on the Effective Properties of Multiscale Catalytic Porous Media: A Case of Polymer Electrolyte Fuel Cells. Transp Porous Med 128, 363–384 (2019). https://doi.org/10.1007/s11242-019-01252-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-019-01252-8