Abstract

A mist bioreactor using a disposable bag as a culture chamber was used to propagate single nodal explants of Artemisia annua into rooted plantlets that were ready for soil using a single batch (one-step) culture. To vertically scale plant growth inside the mist reactor, poly-l-lysine (PLL)-coated 70 µm nylon mesh and solid polypropylene sheeting were used for explant attachment. Both manually chopped and blender-chopped (blenderized) shoot tissues were attached to PLL-coated substrates. Compared to blenderized shoots, manually chopped tissues were larger with better attachment to PLL-coated substrates. Regardless of substrates or explant preparation method, 80–95 % of initially attached shoot tissues remained attached to PLL-coated surfaces after being misted with culture medium for 24 h. New shoot proliferation increased about tenfold as the size of blenderized shoot tissue increased. To reduce callusing during shoot proliferation and thus stimulate root initiation, original shooting medium was reduced to half strength of phytohormone and Murashige and Skoog salts. The duration of shoot proliferation was also reduced from 2 to 1 week. Original rooting medium was then further improved with NAA or IBA. After successive shooting, rooting and in vitro acclimatization, the nodal explants attached to PLL-coated hanging strips and developed into fully rooted plantlets in the mist reactor. Although most of the large rooted plantlets detached from the hanging strips by the time of harvest, they had fully functional stomata and were later successfully established in the soil, suggesting this “hanging garden” technology may prove useful for micropropagation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Using plant cell, tissue and organ culture techniques, billions of commercially important plants are clonally produced annually through micropropagation (Singh and Shetty 2011). The traditional micropropagation process, which is based on non-scalable gelled medium, is labor intensive, requiring manual handling of a large number of single containers (Takayama and Akita 2006). To reduce labor, bioreactors are being developed to provide control of the in vitro microenvironment to secure the growth and physiological integrity of the plantlets (Steingroewer et al. 2013).

Existing bioreactors for micropropagation can be classified into liquid-phase bioreactors (e.g. airlift and balloon type bubble bioreactors), temporary immersion systems (TIS; e.g. RITA® and Twin flask) and gas-phase bioreactors (e.g. nutrient mist bioreactor) (Steingroewer et al. 2013; Weathers et al. 2010). In liquid-phase bioreactors, plant materials remain suspended in the culture medium. Although liquid suspension is ideal for culturing protocorm-like bodies and storage organs, shoots do not grow as well often developing physio-morphological abnormalities (i.e. hyperhydricity) caused by low oxygen and osmotic potential of the liquid medium (Afreen 2006; Dewir et al. 2014; Georgiev et al. 2014; Yang et al. 2010). A TIS, on the other hand, provides flexible nutrient feeding regimes with periodically altered gaseous growth environments. Thus, TIS reactors have been widely used for micropropagation of economically important species (Berthouly and Etienne 2005; González 2005; Watt 2012).

Traditionally, plant materials in TISs are horizontally placed on a supportive raft or net, creating a large footprint for each bioreactor. To save costly floor space, multi-tiered shelves have to be used in commercial production (Adelberg 2006; Adelberg and Fári 2010; Wilken et al. 2014). In mist reactors, plant materials have thus far been horizontally placed to receive nutrient mist fed top down, which limits yield per footprint area. To maximize batch yield and also minimize footprint, a vertical “hanging garden” style of culture could prove useful as suggested by Fei and Weathers (2014). This method requires rapid and predictable attachment of plant materials onto vertically hanging substrates within a bioreactor.

Surface attachment of plant materials has been primarily studied using plant cell cultures for production of secondary metabolites, bioconversion and biomanufacturing (Huang and McDonald 2012; Ruffoni et al. 2010; Tyler et al. 1995). Adhesion of plant cells to a surface is the result of interfacial tensions and electrostatics (Dicosmo et al. 1989), and is affected by hydrophobicity of substrates as well as pH and ionic strength of the liquid medium (Facchini et al. 1988a, 1989). Since plant cells have a net negative surface charge (Dicosmo et al. 1989; Facchini et al. 1988b) and many substrates used for immobilization are also negatively charged, poly-cation coating of substrates has the potential for reducing repulsion and enhancing attachment between plant tissues and substrates. Using poly-l-lysine (PLL) coated polypropylene and nylon as substrates, Fei and Weathers (2014) showed that pre-embryogenic carrot cells attached to vertically hung substrate strips and developed in situ into fully rooted embryos in a mist bioreactor. That study suggested a similar approach may work for culturing differentiated tissues (shoots and roots) via micropropagation. Although root tissues were shown to adhere to PLL-coated substrates via root hairs (Towler and Weathers 2003), it is unclear if shoot tissues can similarly bind. Using A. annua as a test species, attachment ability of leaf explants to PLL-coated substrates was investigated along with the potential of using manually chopped or blender chopped shoot tissues as inoculum for micropropagation. Also investigated was the feasibility of one step micropropagation that included shooting, rooting and acclimatization with tissue attaching to PLL-coated substrates hanging inside the mist reactor.

Materials and methods

Plant materials for attachment experiments

Rooted Artemisia annua L. (clone SAM; Voucher MASS 00317314; Weathers and Towler 2012) shoots were grown in Magenta boxes containing 50 mL semi-solid hormone-free rooting medium (RTM): 20 g L−1 sucrose, 2.22 g L−1 Murashige (Murashige and Skoog 1962) and Skoog (MS) salts with vitamins, and 5 g L−1 Agargellan ™, pH 5.8 (Nguyen et al. 2013). All cultures were grown at 25 °C under continuous irradiation at 50 µmol m−2 s−1 with cool white fluorescent bulbs (GE brand, F15T8-CW) unless otherwise specified. Subculture was every 4 weeks by nodal cuttings. Leaf tissues of 4-week-old cultures were used in attachment experiments.

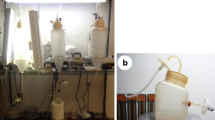

Mist reactor

Mist reactor preparation and set up was already detailed in Fei and Weathers (2014). Briefly, the reactor (Fig. 1) had an in-lab-built 7 L working volume disposable cylindrically shaped polypropylene (~0.2 mm thick) bag as a culture chamber with a stainless steel mesh platform for tissues. The disposable bag was fitted around a Nalgene bottle neck to be screw capped to the matching Nalgene cap with an inserted Sonotek mister head. Air was delivered via a pump and humidified using a Nafion tube (MH-110-48F-4, Perma Pure, Toms River, NJ). Nafion tubing basically enables a large amount of liquid to be passed via diffusion through a very porous tube into the gas passing into the reactor. Separate tubing connected the culture medium reservoir to the mister head and also between the culture bag and the reservoir.

Preparation of substrates and PLL coating

Pieces of polypropylene (PP) sheeting (~0.2 mm thick) and nylon mesh (70 µm; N70) were cut into 2 × 4 cm strips for binding experiments. PLL coating was done by soaking the PP sheet and N70 mesh in unshaken 0.01 % (w/v) PLL (70,000–150,000 mol wt, Sigma, P1274) solution for 0.5 h and then air dried (Fei and Weathers 2014; Towler and Weathers 2003). During the attachment phase tissue explants must not be disturbed as agitation prevents attachment. Binding experiments were done under non-sterile conditions for 1–24 h. Initially bound tissues within 12 h were considered “retained” since it was uncertain if they would remain bound for longer time. Initially retained tissues were considered truly “attached” after they remained on substrates for at least 24 h.

Retention of chopped leaf tissue by manual application

Leaf tissue of 4-week-old in vitro cultivated A. annua was randomly chopped into about 5 mm pieces and then incubated ±PLL onto PP sheeting or N70 mesh substrates in 30 g L−1 sucrose to maintain osmotic potential and avoid tissue desiccation. After unstirred, horizontal incubation for 1–6 h, the substrates were then held vertically and washed 10 times from top to bottom each time with 0.3 mL dH2O. Percent tissues retained on substrates were determined as:

Quick dip and retention of manually chopped versus blenderized leaf tissue

Small pieces of leaf tissue were produced either from manually chopped leaves as described above or chopped by using a 4-blade blender (blenderized; Hamilton Beach Commercial). The blender was filled with about 4 g of fresh leaf tissues and 200 mL of 30 g L−1 sucrose, and tissues blended for 30, one-second pulses, under low input power. The small pieces of tissue from manually chopped or blenderized leaves were then suspended in 30 g L−1 sucrose at various tissue FW concentrations (25, 33, 50, 100 g L−1) in Magenta boxes; each suspension was incubated with PP sheet and N70 mesh ± PLL for 5–10 s (quick dip). Then substrates were transferred from the tissue suspension, blotted dry, and measured for fresh weight (FW) of retained tissues by deducting the weight of substrate from the total weight of substrate and retained tissue.

Attachment of manually chopped versus blenderized leaf tissue after quick dip

Initially retained tissues from leaves either manually chopped or blenderized were hung inside the mist bioreactor and sprayed with hormone-free RTM (20 g L−1 sucrose and 2.22 g L−1 MS salts with vitamins, pH 5.8) for 24 h at a misting cycle of 0.3 min on/2.7 min off (300 mL h−1). The % attachment was measured and defined as:

Quick dip and attachment of various sizes of blenderized leaf explants

Blenderized leaf tissue was successively sieved through stainless steel screens of 1, 0.5, 0.35 and 0.15 mm to obtain four groups of tissues: 0.15–0.35, 0.35–0.5, 0.5–1 and >1 mm. At a biomass concentration of 1 g FW in 20 mL 30 g L−1 sucrose, each size was measured for instant retention on ±PLL N70 following the quick dip method previously described. Initially retained tissues were then misted with rooting medium for 24 h at a misting cycle of 0.3 min on/2.7 min off (300 mL h−1), and % attachment was measured (Eq. 2).

Shoot regeneration of blenderized leaf tissue

Shoot tissues of different sizes generated from 30 pulses of blending were cultured for 6 weeks on gelled shooting medium (SHM): 30 g L−1 sucrose, 4.43 g L−1 MS salts with vitamins, 0.25 µmol L−1 α-naphthaleneacetic acid (NAA), 2.5 µmol L−1 N-6-benzyladenine (BA), and 5 g L−1 Agargellan ™, pH 5.8 (Nguyen, et al. 2013). All cultures were grown under 25 °C and continuous light at 50 µmol m−2 s−1. The shooting percentage of leaf tissues in each size group was then measured as follows:

Each of the four sizes of tissue was loaded in 3 replicate wells in a 12-well plate with four replicate plates.

Improved shooting medium to reduce callus formation and enable root development

To reduce callus formation and thus enable root development, SHM was improved by altering plant growth regulators (PGRs) and MS salts. BA and NAA were proportionally reduced to 10, 20, 40, 60 and 80 % of the starting concentration with either full or ½ strength MS salts (Table S1). Single nodal cuttings were inoculated into Magenta boxes filled with the different SHM to induce shoots, and then to induce roots, explants with new shoots were transferred onto hormone-free rooting medium (RTM) at day 7 and 14, respectively. New shoots that developed on explants from each tested shooting medium were recorded at the time of transfer and after 3 weeks of cultivation and rooting percentage calculated (Eq. 4). Each tested shooting medium had 6 explants in each of three Magenta boxes. Rooting percentage was defined as:

Addition of auxin into rooting medium to enhance root initiation after shoot proliferation

To further improve rooting percentage, hormone-free RTM was changed by testing two types of auxin: NAA and indole-3-butyric acid (IBA). Single nodal cuttings were first cultured for 7 days on ½ strength shooting medium (SHM50: 30 g L−1 sucrose, 2.22 g L−1 MS salts with vitamins, 0.125 µmol L−1 NAA, 1.25 µmol L−1 BA, pH 5.8), and then transferred to Magenta boxes each filled with a different RTM (Table S1). Rooting percentage was measured after 3 weeks. Each RTM had 12 explants and the experiment was repeated three times.

One-step micropropagation of A. annua by attachment to PLL-coated substrates

Shoot tissues from 4-week-old cultures in hormone-free rooting medium (RTM) were manually chopped into single nodes and then suspended in 30 g L−1 sucrose solution at the ratio of 1 g FW per 20 mL. N70 and PP sheet were cut into 4 × 20 cm strips, and every two strips were connected by fish line (Tom Mann, CS-65) at the top. The strips were hot seamed using an impulse sealer every 3 cm lengthwise to create a zig-zag shape in a side view to facilitate tissue retention longitudinally along the hanging strips. A front view of the zig-zag strips is shown in Fig. 5a. The strips were then autoclaved and coated with PLL as described in Fei and Weathers (2014). Air dried PLL-coated strips were subsequently soaked in a suspension of shoot tissues for 5 min prior to inoculation into the mist reactor and misted for 7 days with SHM50 (Table S1) followed by misting for another 21 days with RTM1y (Table S1) at 50 µmol m−2 s−1 light intensity and 25 °C. Reactor ventilation was 0.1 vvm (700 mL min−1 gas flow rate) of 0.16 % (v/v) CO2 enriched air. Unless otherwise specified, CO2 enriched air was humidified using a Nafion tube connected with a 0.2 µm sterile filter prior to entry into the mist reactor. Gelled medium controls had the same ventilation and light conditions as the mist reactor.

During the 7-day shooting stage, the mist cycle was 0.75 min on/59.25 min off with medium flow rate of 40 mL min−1 to deliver 30 mL h−1. After 7 days of shoot proliferation, RTM1y (Table S1) was switched into the feeding line to initiate root development. The misting cycle was 0.25 min on/14.75 min off during the first 12 days for root induction, and then switched to 0.5 min on/29.5 min off during the remaining 9 days of culture for acclimatization. Volumetric medium delivery was maintained at 30 mL h−1 during the 21 days of culture in RTM1y. Ventilation during acclimatization was 0.1 vvm of 0.16 % (v/v) CO2 enriched air with about 52 % relative humidity.

Plantlets from mist reactor and gelled medium controls were measured for their shooting percentage (Eq. 3), number of new shoots per plantlet (# shoots), rooting percentage (Eq. 4), number of primary roots per plantlet (# roots), and hyperhydricity percentage (Eq. 5). Detached 3–6th fully expanded leaves were sampled and imprints of their abaxial side were made with clear nail polish to measure stomatal function as detailed by (Correll et al. 2001). Stomatal function was scored as open, partially open, closed (Fig. 2). Closed stomata were deemed functional. Counts were made at 400× magnification at 5 positions on each sampled leaf, and 2 leaves were sampled from each plantlet. The average of these 10 counts was then taken to represent each plantlet, and the average of 10 plantlets was taken to represent each reactor plantlet harvested from mist reactors and gelled medium controls. Plantlets were transplanted to soil:perlite (2:1 V/V) pots and ex vitro survival was measured after 1 week.

The percent of shoots that were hyperhydric was the result of numerically scoring for 6 features including swollen and glassy appearance, brittle texture, dark color, narrow and elongated shape, and curling edges. In Eq. (5), a, b, c, d, e, f are the number of explants developing new shoots that showed 1, 2, 3, 4, 5, and all 6 of the hyperhydric features, respectively.

Statistics

All experiments were nonfactorial. All attachment experiments had four replicates. Medium adjustment and one-step micropropagation experiments had three replicates. Data with two groups were subjected to Student’s t test. Data from all experiments with more than two groups were subjected to one-way ANOVA, and Duncan’s multiple range analysis by SPSS.

Results and discussion

Retention of manually chopped and applied leaf tissue

It was initially uncertain if small pieces of leaf tissue could attach to PLL-coated strips. Using manually chopped and applied leaf pieces, there was a significant increase in retention percentage with PLL-coated PP sheets and N70 mesh compared to controls lacking PLL (Fig. 3a). Regardless of PLL coating, leaf tissue retention rate was higher on N70 than on PP sheets (Fig. 3a). Tissue binding kinetics showed a nearly linear increase in retention on both substrates as incubation time increased from 1 to 6 h (Fig. 3b). This was different from the kinetics of cell binding, which showed a rapid interaction between cells and PLL (Davis et al. 2004; Fei and Weathers 2014). After 1 h of binding incubation, more than twice as many leaf tissues were retained on N70 mesh than on PP sheets (Fig. 3a). This was in contrast to the results using manually applied carrot cells (Fei and Weathers 2014).

Retention of leaf tissue on substrates ±PLL. a Retention percentage of manually applied leaf explants with 1 h incubation after 10 successive vertical washes; #compares +PLL versus −PLL; *compares PP sheet versus N70 mesh, N = 4, ±SE, p ≤ 0.05; b kinetics of leaf piece retention. Letters compare across different incubation times PP sheet (a, b, c) and N70 mesh (x, y, z), *compares PP sheet versus N70 mesh, N = 4, ±SE, p ≤ 0.05; c leaf tissue attached to +PLL substrate via filamentous trichome (arrow), bar 250 µm

Unlike spherical cells, differentiated tissues like leaves consist of complicated structures, so the retention of a piece of leaf tissue is a function of binding force of the structures interacting with the PLL-coated surface and the weight of the tissue piece. Microscopic observation showed that the A. annua leaf pieces were at least in part attached to substrates via their filamentous trichomes (Fig. 3c), which was similar to root attachment to PLL-coated substrates by root hairs (Towler and Weathers 2003). A. annua leaves have two types of trichomes: T-shaped filamentous and 10-cell glandular trichomes (Duke et al. 1994). The T-shaped filamentous trichomes are long outgrowths on the leaf surface and give rise to a slightly hairy appearance of leaves (Fig. 3c). The higher tissue retention on N70 mesh than on PP sheet was thus probably because fine openings in the N70 mesh structure further facilitated trichome anchorage.

Quick dip retention versus attachment: manually chopped versus blenderized leaf tissue

Since adherence of leaf tissue on PLL-coated substrates was deemed feasible, a “hanging garden” style of culture through quick dip inoculation was envisioned. Using manually chopped or blenderized leaf pieces, there was a significant increase of initially retained leaf FW with PLL-coated PP sheet and N70 mesh compared to controls lacking PLL (Table S2). Generally there was no difference in initially retained leaf FW between PP sheet and N70 mesh for both chopping methods (Table S2). However, there was greater retention of blenderized tissue pieces at higher tissue concentrations (100 and 50 g L−1) than at lower tissue concentrations (33 and 25 g L−1) (Table S2). Tissue concentration of manually chopped tissues did not seem to affect their initial retention on PLL-coated N70 mesh. Regardless of substrate type, PLL coating or tissue concentration, blenderized tissue showed significantly fewer initially retained tissues than manually chopped tissue (Table S2).

Compared to controls lacking PLL, there was significantly more attachment of the initially retained tissues on PLL-coated substrates (Table S3). Most retained tissues on PLL-coated substrates remained attached after 24 h of misting regardless of substrate type or chopping method, suggesting the retained tissues were likely to remain on PLL-coated hanging strips during cultivation in a bioreactor (Table S3). For controls lacking PLL, attachment was greater on N70 mesh than on PP sheet, and tissues that were manually chopped also showed greater attachment than those from the blender (Table S3). The main difference between manually chopped and blenderized leaves was size, so variation in attachment was likely due to tissue size.

Quick dip, attachment and shoot regeneration of various sized shoot tissues

To determine if the smaller size of blenderized leaf tissue correlated with its lower retention compared to manually chopped leaves, quick dip retention and attachment experiments were conducted using the four leaf sizes shown in Table 1. The tissue concentration for quick dip was 50 g FW L−1, and N70 was used as the binding substrate. As shown in Table 1, the retention FW on N70 + PLL was greatest in the >1 mm group, but was significantly reduced once the size decreased to <0.5 mm. The finest pieces (0.15–0.35 mm) showed lowest % attachment to N70 + PLL (Table 1).

The blenderized leaf tissue was actually a mixture of the four sizes of tissues, so the initially retained FW of blenderized tissue was estimated by summing the fraction of each size group. Using the numbers in Table 1, the calculated overall retained FW on PLL-coated N70 mesh was about 160 mg, which was close to the experimental result (126 mg) under the same tissue concentration of 50 g FW L−1 during the quick dip (Table S2). It was posited that this reduced retention was likely the result of the smaller pieces having fewer intact filamentous trichomes. The regeneration ability of leaf explants also progressively decreased as explant size decreased (Table 1), possibly due to mechanical damage during blending.

Improved shooting and rooting media to eliminate manual transfer between shoot proliferation and rooting stages

The goal of one-step micropropagation in the mist reactor was to accomplish shoot proliferation, root development and in vitro acclimatization in one batch culture by manipulating the nutrient medium and culture conditions. There would be no manual transfers. Unfortunately, the initial trials of one-step micropropagation in the mist reactor yielded callused shoot stems during the shoot proliferation stage and roots did not form unless the callus was excised prior to switching to the hormone-free rooting medium (RTM). Compact callus at the bottom of stems also inhibited root induction in Artemisia absinthium (Zia et al. 2007). Others have shown that cytokinins (e.g. BA) in the medium generally inhibited root induction (Jarvis 1986) and having both BA and NAA in the medium induced callus formation on shoots (Jamaleddine et al. 2013; Sudha et al. 2012; Zia et al. 2007). Root initials originate in stem but not callus tissue (Lane 1979), so root induction may be improved by reducing callus formation during shoot proliferation. To reduce callus formation and improve root induction, the phytohormone and salt composition of shooting medium was changed. In addition, the exposure time to different shooting media was investigated.

As shown in Table S4, neither the strength of MS salts nor the incubation time for shoot proliferation affected the production of new shoots. Shoot proliferation remained constant as long as the phytohormones were ≥40 % of the original concentration (Table S4).

On the other hand, none of the new shoots from full strength MS SHM had roots after 3 weeks regardless of time of transfer (Table S5). Root development only happened with those explants previously cultured on ½ strength MS SHM with <60 % of the original SHM phytohormones and transferred on day 7 (Table S5). The majority of new shoots transferred on day 14 had formed callus at the time of transfer and few roots were observed later on RTM, suggesting the duration of exposure to BA and NAA during shoot proliferation also played a role in subsequent root induction. Taken together, results from Tables S4 and S5, shooting time was adjusted to 7 days on ½ strength SHM in order to enhance root development without reducing shoot proliferation. The sucrose concentration of the adjusted shooting medium remained at 30 g L−1.

To further improve rooting, NAA and IBA were tested in RTM. Both auxins were reported to effectively induce root development in various cultivars of A. annua (Alam and Abdin 2011; Gopinath et al. 2014; Hailu et al. 2014; Han et al. 2005; Hong et al. 2009; Janarthanam et al. 2012; Lin et al. 2011; Sharma and Agrawal 2013). As indicated in Table S6, 0.25 µmol L−1 of NAA and both concentrations of IBA improved root initiation. There was no difference in root induction efficiency between the two IBA concentrations (Table S6).

One-step micropropagation of A. annua by attachment to PLL-coated substrates

Propagation by attachment to PLL-coated strips was successfully achieved through somatic embryogenesis of carrot (Fei and Weathers 2014). When this concept was tested using A. annua nodal explants followed by shooting, rooting and acclimatization (Fig. 4), the majority of plantlets grew large and unfortunately fell off the strips when harvested 28 days after inoculation (Fig. 5a). The adherent force between these large plantlets (Fig. 5b) and PLL-coated strips was not adequate to retain their increased weight. The zig-zag design of strips marginally helped plantlet retention. In contrast, when inoculated with embryogenic cells, the binding force was strong enough and resulting plantlet weight was low enough to enable retention of rooted plantlets (Fei and Weathers 2014).

One-step micropropagation of A. annua in mist reactor by attachment to PLL-coated strips. a Rooted plantlets harvested on PLL-coated polypropylene strip with zig-zag seam; b rooted plantlets harvested from the mist reactor after one-step culture; c rooted plantlets harvested from gelled medium control; d representative photo of stomata on abaxial side of harvested leaf from mist reactor; e representative photo of stomata on abaxial side of harvested leaf from gelled medium. Bars in d and e 50 µm

Although the process still requires optimization, one-step culture in the mist reactor is feasible and plantlets grew better than in gelled medium controls (Fig. 5b, c; Table 2). Compared to gelled medium controls, better growth in the mist reactor was probably due to increased availability of nutrients in liquid medium as suggested by other reactor systems (Adelberg and Fári 2010). Regardless of similar stomatal developmental status (Fig. 5d, e; Table 2), ex vitro survival from the mist reactor also appeared greater than from gelled medium controls (p = 0.08). This was probably because plantlets from gelled medium were too small to survive transplant into soil, suggesting that in vitro culture duration on gelled medium needs to be longer than in the mist reactor.

When considering bioreactors for shoot cultures, a TIS is frequently used because it yields high amounts of biomass with high quality (Adelberg 2006; Hahn and Paek 2005; Roels et al. 2005, 2006; Welander et al. 2014; Yan et al. 2010, 2013; Yang and Yeh 2008). Similar to a TIS, the mist reactor offers an alternative for micropropagation as shown in this and prior studies (Correll et al. 2001).

Bioreactors usually save labor by increased culture scale and also by circumventing otherwise piecemeal handling in gelled medium (Alister et al. 2005; Lorenzo et al. 1998; Takayama and Akita 2006). In an estimation of production efficiency, one-step micropropagation in the mist reactor took 40 % less time to produce soil-ready plants than the traditional method (Table 2). By using more vertical space in the reactor, greater productivity should also be possible.

Current attachment technology mainly relies on electrical attraction between negatively charged plant tissues and positively charged substrates through the PLL-coating. When plant shoots grow well and large, the adhesive force may not be strong enough to counteract gravity. Physical entrapment can be used to enhance plant tissue retention. For example, the polypropylene strips can be hot-seamed with pockets or small slashes to “catch” explants during inoculation by tissue immersion and then hold the inoculum until they develop into plants (Fig S1). Plants can also grow on a spiral support hanging inside the mist reactor (Fig S1). Use of a spiral support provides each plant with a slight horizontal plane with a small angle, and thus plants may be better retained.

Conclusions

Leaf tissues of A. annua attached to PLL-coated polypropylene sheeting and nylon mesh. Filamentous trichomes on leaves appeared to contribute to the attachment. Most of the initially retained tissue remained attached to the substrate after a 24 h misting treatment in the mist reactor, suggesting the feasibility of a “hanging garden” style of culture. Although automation of leaf tissue preparation by blending is possible, the timing has to be carefully controlled to prevent over production of very fine tissue pieces < 0.5 mm, which have a reduced capacity for both attachment and shoot regeneration. On the other hand, sufficiently large leaf explants will bind to PLL-coated materials and produce shoots and roots, thereby enabling development of alternative cultivation technologies for possible use in micropropagation. In a final test of one-step micropropagation through attachment to PLL-coated strips, single node explants attached to PLL-coated strips and developed into acclimatized rooted plantlets ready for direct transplant into soil. This proof of concept study should further automation of this labor intensive industrial process.

References

Adelberg J (2006) Agitated, thin-films of liquid media for efficient micropropagation. In: Gupta SD, Ibaraki Y (eds) Plant tissue culture engineering, vol 6. Focus on biotechnology. Springer, Netherlands, pp 101–117

Adelberg J, Fári MG (2010) Applied physiology and practical bioreactors for plant propagation. Propag Ornam Plants 10:205–219

Afreen F (2006) Temporary immersion bioreactor-engineering considerations and applications in plant micropropagation. In: Dutta Gupta S, Ibaraki Y (eds) Plant tissue culture engineering, vol 6. Focus on biotechnology. Springer, Heidelberg, pp 187–201

Alam P, Abdin MZ (2011) Over-expression of HMG-CoA reductase and amorpha-4,11-diene synthase genes in Artemisia annua L. and its influence on artemisinin content. Plant Cell Rep 30:1919–1928. doi:10.1007/s00299-011-1099-6

Alister BM, Finnie J, Watt MP, Blakeway F (2005) Use of the temporary immersion bioreactor system (RITA®) for production of commercial Eucalyptus clones in Mondi forests (SA). In: Hvoslef-Eide A, Preil W (eds) Liquid culture systems for in vitro plant propagation. Springer, Netherlands, pp 425–442

Berthouly M, Etienne H (2005) Temporary immersion system: a new concept for use liquid medium in mass propagation. Liquid culture systems for in vitro plant propagation. Springer, Netherlands, pp 165–195

Correll MJ, Wu Y, Weathers PJ (2001) Controlling hyperhydration of carnations (Dianthus caryophyllus L.) grown in a mist reactor. Biotechnol Bioeng 71:307–314. doi:10.1002/1097-0290(2000)71:4<307:AID-BIT1019>3.0.CO;2-9

Davis HE, Rosinski M, Morgan JR, Yarmush ML (2004) Charged polymers modulate retrovirus transduction via membrane charge neutralization and virus aggregation. Biophys J 86:1234–1242. doi:10.1016/S0006-3495(04)74197-1

Dewir Y, Indoliya Y, Chakrabarty D, Paek K-Y (2014) Biochemical and physiological aspects of hyperhydricity in liquid culture system. In: Paek K-Y, Murthy HN, Zhong J-J (eds) Production of biomass and bioactive compounds using bioreactor technology. Springer, Netherlands, pp 693–709

Dicosmo F, Facchini PJ, Neumann AW (1989) Plant cell adhesion to polymer surfaces as predicted by a thermodynamic model and modified by electrostatic interaction. Colloids Surf 42:255–269. doi:10.1016/0166-6622(89)80195-7

Duke MV, Paul RN, Elsohly HN, Sturtz G, Duke SO (1994) Localization of artemisinin and artemisitene in foliar tissues of glanded and glandless biotypes of Artemisia annua L. Int J Plant Sci 155:365–372

Facchini P, DiCosmo F, Radvanyi L, Giguere Y (1988a) Adhesion of Catharanthus roseus cells to surfaces: effect of substrate hydrophobicity. Biotechnol Bioeng 32:935–938. doi:10.1002/bit.260320716

Facchini P, Neumann A, DiCosmo F (1988b) Thermodynamic aspects of plant cell adhesion to polymer surfaces. Appl Microbiol Biotechnol 29:346–355. doi:10.1007/BF00265818

Facchini PJ, Wilhelm Neumann A, DiCosmo F (1989) Adhesion of suspension-cultured Catharanthus roseus cells to surfaces: effect of pH, ionic strength, and cation valency. Biomaterials 10:318–324. doi:10.1016/0142-9612(89)90072-0

Fei L, Weathers P (2014) From cells to embryos to rooted plantlets in a mist bioreactor. Plant Cell, Tissue Organ Cult 116:37–46. doi:10.1007/s11240-013-0380-5

Georgiev V, Schumann A, Pavlov A, Bley T (2014) Temporary immersion systems in plant biotechnology. Eng Life Sci 14:607–621. doi:10.1002/elsc.201300166

González E (2005) Mass propagation of tropical crops in temporary immersion systems. In: Hvoslef-Eide A, Preil W (eds) Liquid culture systems for in vitro plant propagation. Springer, Netherlands, pp 197–211

Gopinath B, Gandhi K, Saravanan S (2014) In vitro propagation of an important medicinal plant Artemisia annua L. from axillary bud explants. Adv Appl Sci Res 5:254–258

Hahn EJ, Paek KY (2005) Multiplication of Chrysanthemum shoots in bioreactors as affected by culture method and inoculation density of single node stems. In: Hvoslef-Eide A, Preil W (eds) Liquid culture systems for in vitro plant propagation. Springer, Netherlands, pp 143–153

Hailu T, Abera B, Mariam G (2014) In vitro mass propagation of Artemisia (Artemisia annua L.) cv: anamed. Plant Tissue Cult Biotechnol 23:165–176. doi:10.3329/ptcb.v23i2.17518

Han J, Wang H, Ye H, Liu Y, Li Z, Zhang Y, Zhang Y, Yan F, Li G (2005) High efficiency of genetic transformation and regeneration of Artemisia annua L. via Agrobacterium tumefaciens-mediated procedure. Plant Sci 168:73–80. doi:10.1016/j.plantsci.2004.07.020

Hong G, Hu W, Li J, Chen X, Wang L (2009) Increased accumulation of artemisinin and anthocyanins in Artemisia annua expressing the Arabidopsis blue light receptor CRY1. Plant Mol Biol Rep 27:334–341. doi:10.1007/s11105-008-0088-6

Huang TK, McDonald KA (2012) Bioreactor systems for in vitro production of foreign proteins using plant cell cultures. Biotechnol Adv 30:398–409. doi:10.1016/j.biotechadv.2011.07.016

Jamaleddine Z, Lyam P, Fajimi O, Giwa A, Aina A, Lawyer E, Okere A, Odofin W (2013) In vitro growth response of Artemisia annua seeds to different concentrations of plant growth regulators. Afr J Biotechnol 10:17841–17844. doi:10.5897/AJB10.1289

Janarthanam B, Rashmi P, Sumathi E (2012) Rapid and efficient plant regeneration from nodal explants of Artemisia annua L. Plant Tissue Cult Biotechnol 22:33–39. doi:10.3329/ptcb.v22i1.11257

Jarvis BC (1986) Endogenous control of adventitious rooting in non-woody cuttings. In: Jackson M (ed) New root formation in plants and cuttings, vol 20. Developments in Plant and Soil Sciences. Springer, Netherlands, pp 191–222

Lane WD (1979) Regeneration of pear plants from shoot meristem-tips. Plant Sci Lett 16:337–342. doi:10.1016/0304-4211(79)90046-4

Lin X, Zhou Y, Zhang J, Lu X, Zhang F, Shen Q, Wu S, Chen Y, Wang T, Tang K (2011) Enhancement of artemisinin content in tetraploid Artemisia annua plants by modulating the expression of genes in artemisinin biosynthetic pathway. Biotechnol Appl Biochem 58:50–57. doi:10.1002/bab.13

Lorenzo J, González B, Escalona M, Teisson C, Borroto C (1998) Sugarcane shoot formation in an improved temporary immersion system. Plant Cell, Tissue Organ Cult 54:197–200. doi:10.1023/a:1006168700556

Murashige T, Skoog F (1962) A revised medium for rapid growth and bio assays with tobacco tissue cultures. Physiol Plant 15:473–497. doi:10.1111/j.1399-3054.1962.tb08052.x

Nguyen K, Towler M, Weathers P (2013) The effect of roots and media constituents on trichomes and artemisinin production in Artemisia annua L. Plant Cell Rep 32:207–218. doi:10.1007/s00299-012-1355-4

Roels S, Escalona M, Cejas I, Noceda C, Rodriguez R, Canal MJ, Sandoval J, Debergh P (2005) Optimization of plantain (Musa AAB) micropropagation by temporary immersion system. Plant Cell, Tissue Organ Cult 82:57–66. doi:10.1007/s11240-004-6746-y

Roels S, Noceda C, Escalona M, Sandoval J, Canal MJ, Rodriguez R, Debergh P (2006) The effect of headspace renewal in a temporary immersion bioreactor on plantain (Musa AAB) shoot proliferation and quality. Plant Cell, Tissue Organ Cult 84:155–163. doi:10.1007/s11240-005-9013-y

Ruffoni B, Pistelli L, Bertoli A, Pistelli L (2010) Plant cell cultures: bioreactors for industrial production. In: Giardi M, Rea G, Berra B (eds) Bio-farms for nutraceuticals, vol 698. Advances in experimental medicine and biology. Springer, US, pp 203–221

Sharma G, Agrawal V (2013) Marked enhancement in the artemisinin content and biomass productivity in Artemisia annua L. shoots co-cultivated with Piriformospora indica. World J Microbiol Biotechnol 29:1133–1138. doi:10.1007/s11274-013-1263-y

Singh G, Shetty S (2011) Impact of tissue culture on agriculture in India. Biotechnol Bioinform Bioeng 1:279–288

Steingroewer J, Bley T, Georgiev V, Ivanov I, Lenk F, Marchev A, Pavlov A (2013) Bioprocessing of differentiated plant in vitro systems. Eng Life Sci 13:26–38. doi:10.1002/elsc.201100226

Sudha CG, George M, Rameshkumar KB, Nair GM (2012) Improved clonal propagation of Alpinia calcarata Rosc., a commercially important medicinal plant and evaluation of chemical fidelity through comparison of volatile compounds. Am J Plant Sci 3:930. doi:10.4236/ajps.2012.37110

Takayama S, Akita M (2006) Bioengineering aspects of bioreactor application in plant propagation. In: Gupta SD, Ibaraki Y (eds) Plant tissue culture engineering, vol 6. Focus on biotechnology. Springer, Netherlands, pp 83–100

Towler MJ, Weathers PJ (2003) Adhesion of plant roots to poly-l-lysine coated polypropylene substrates. J Biotechnol 101:147–155. doi:10.1016/S0168-1656(02)00319-X

Tyler RT, Kurz WGW, Paiva NL, Chavadej S (1995) Bioreactors for surface-immobilized cells. Plant Cell, Tissue Organ Cult 42:81–90. doi:10.1007/BF00037685

Watt MP (2012) The status of temporary immersion system (TIS) technology for plant micropropagation. Afr J Biotechnol 11:14025–14035. doi:10.5897/AJB12.1693

Weathers PJ, Towler MJ (2012) The flavonoids casticin and artemetin are poorly extracted and are unstable in an Artemisia annua tea infusion. Planta Med 78:1024–1026

Weathers PJ, Towler MJ, Xu JF (2010) Bench to batch: advances in plant cell culture for producing useful products. Appl Microbiol Biotechnol 85:1339–1351. doi:10.1007/s00253-009-2354-4

Welander M, Persson J, Asp H, Zhu LH (2014) Evaluation of a new vessel system based on temporary immersion system for micropropagation. Sci Hortic 179:227–232. doi:10.1016/j.scienta.2014.09.035

Wilken D, Gonzalez EJ, Gerth A, Gómez-Kosky R, Schumann A, Claus D (2014) Effect of immersion systems, lighting, and TIS designs on biomass increase in micropropagating banana (Musa spp. cv’.Grande naine’AAA). In Vitro Cell Dev Biol Plant 50:582–589. doi:10.1007/s11627-014-9605-5

Yan H, Liang C, Li Y (2010) Improved growth and quality of Siraitia grosvenorii plantlets using a temporary immersion system. Plant Cell, Tissue Organ Cult 103:131–135. doi:10.1007/s11240-010-9752-2

Yan H, Yang L, Li Y (2013) Improved growth and quality of Dioscorea fordii Prain et Burk and Dioscorea alata plantlets using a temporary immersion system. Afr J Biotechnol 10:19444–19448. doi:10.5897/AJB11.2684

Yang SH, Yeh DM (2008) In vitro leaf anatomy, ex vitro photosynthetic behaviors and growth of Calathea orbifolia (Linden) Kennedy plants obtained from semi-solid medium and temporary immersion systems. Plant Cell, Tissue Organ Cult 93:201–207. doi:10.1007/s11240-008-9363-3

Yang J, Piao X, Sun D, Lian M (2010) Production of protocorm-like bodies with bioreactor and regeneration in vitro of Oncidium‘Sugar Sweet’. Sci Hortic 125:712–717. doi:10.1016/j.scienta.2010.05.003

Zia M, Rehman R, Chaudhary MF (2007) Hormonal regulation for callogenesis and organogenesis of Artemisia absinthium L. Afr J Biotechnol 6:1874–1878. doi:10.5897/AJB2007.000-2281

Acknowledgments

The authors thank WPI for supporting L Fei and to the Society for In Vitro Biology for travel awards to L Fei. Advice from Dr. Melissa Towler, and Profs. Elizabeth Ryder and Samuel Politz of the Department of Biology and Biotechnology at WPI was also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fei, L., Weathers, P. From leaf explants to hanging rooted plantlets in a mist reactor. Plant Cell Tiss Organ Cult 124, 265–274 (2016). https://doi.org/10.1007/s11240-015-0890-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-015-0890-4