Abstract

Condensation of (−)-isopulegol with acetone was investigated at 25–40 °C over clay based materials (K10, cloisite Na+ and halloysite nanotubes) modified with sulfonic acid groups by one-pot sulfonation with chlorosulfonic acid or via organosilylation with 2-(4-chlrosulfonylphenyl)-ethyltrimethoxysilane. The target product was the R diastereomer of dimethyl-substituted octahydro-2H-chromen-4-ol with exhibits antiviral activity. The catalysts were characterized by a range of physico-chemical methods. The effect of the initial isopulegol concentrations on the yield of ketone-derived chromenols and the R/S isomers ratio was studied for the first time. The best catalyst was a highly acidic, large pore K10-clay modified by sulfonic acid. Varying the initial concentration of the reagents allows to find a balance between dehydration by-products and a side etherification reaction. A high yield (73%) of the desired chromenols was reached using 0.52 mol/l initial (−)-isopulegol concentration after 240 min at 87% substrate conversion and reaction temperature 25 °C. The yield exceeded that of other previously reported in the open literature catalysts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, the synthesis of pharmaceuticals starting from abundant naturally occurring compounds (i.e. terpenes) using heterogeneous catalysts is very interesting being an environmentally friendly and potentially a cheaper process than alternatives with an easy catalyst reuse and recycling. One important reaction in this context is the Prins cyclization of aldehydes or ketones with alkenes [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15]. Typically, Prins cyclization is performed by reacting a homoallylic alcohol and carbonyl compounds over acidic catalysts to produce tetrahydropyrans.

The Prins reaction of (−)-isopulegol with aldehydes has been already investigated in several publications [1,2,3,4,5,6, 8,9,10, 12,13,14,15] in the presence of acid catalysts giving octahydro-2H-chromen-4-ol (as 4R and 4S diastereoisomers) and its dehydration products. The yield of chromenols and the 4R/4S isomer ratio depends on the structure of the aldehyde and the catalyst used. The 4R diastereoisomer of chromenol obtained by condensation of (−)-isopulegol with thiophene-2-carbaldehyde has a pronounced prolonged (14 h) analgesic effect superior to diclofenac used for comparison [9]. Another interesting reaction is (−)-isopulegol condensation with acetone (Fig. 1), because the 4R isomer of chromenol 212 exhibits antiviral properties against H1N1 and H2N2 influenza [7]. At the same time, the 4S diastereomer practically did not show any anti-virus effect [7].

Although the condensation of isopulegol with aldehydes has been well studied, much less attention has been paid to ketones utilization for the synthesis of chromenols [7, 11]. In [11], iodine was used as a homogeneous catalyst in this reaction in dichloromethane as a solvent. When applying a heterogeneous K10 clay per se as a catalyst, the total yield of chromenols was 21% with the R/S ratio of 9:1 after 1 h at room temperature [7]. In addition an acid modified K10 clay gave 57% yield of chromenol with R/S ratio of only 3:1 in 2.5 h at room temperature. Very recently, halloysite nanotubes (HNT) pretreated with HCl were applied for synthesis of ketones-derived chromenols [16], which in the case of acetone made it possible to increase of the chromenols yield to 78% with the R/S ratio equal to 8.4. The result was explained by presence of weak acid sites in HNT. Formation of the target chromenols occurs through addition of water to the cyclic intermediate. In parallel to this, interactions of the intermediate with isopulegol lead to stereoselective formation of an ester of chromene, which after hydrolysis gives chromenols [16]. However, such parameters as the reaction temperature, the concentration of reagents that may affect the yield of the target product have not been studied.

Considering that the sulfonated clay based solids with different acidity demonstrated high selectivity in the condensation of isopulegol with benzaldehyde [15], their study for synthesis of acetone-derived chromenol with approved antiviral activity is an actual task. Herein, sulfonic acid-functionalized K-10 and cloisite Na+ (CLOI) clay and halloysite nanotubes (HNT) from natural montmorillonites were used as solid acid catalysts for condensation of (−)-isopulegol with acetone.

Experimental

Catalyst synthesis and characterization

Sulfonic acid functionalized clays were prepared either by direct sulfonation with chlorosulfonic acid (CSA) or by one-pot organosilylation with 2-(4-chlorosulfonylphenyl)-ethyltrimethoxysilane (CSP), as efficient and economically sustainable methodologies to prepare sulfonic acid solid catalysts (Fig. S1) according to previous publications [15, 17, 18] and also presented in supporting information (SI).

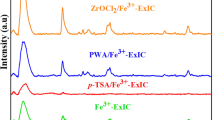

The catalysts were also extensively characterized as reported in the previous publications [15, 17, 18]. The following methods were used: determination of acidity via potentiometric titration and pyridine adsorption–desorption by FTIR, specific surface area and pore sizes by nitrogen adsorption, sulfur content on the catalyst surface by XPS and total sulfur content via elemental analysis. In addition, the crystallographic structure was studied by XRD while morphology and texture were evaluated by TEM and SEM/EDS. In addition, the surface groups were analyzed with FTIR (see more details in SI, Fig. S2).

Experimental setup

The Prins cyclization of (−)-isopulegol (Sigma Aldrich, 98.9%) was performed in a batch reactor equipped with a reflux cooler. Prior to experiments the catalyst (50 mg) was dried overnight at 110 °C. The catalyst was added into a three-necked glass reactor and the reactor was flushed with argon (AGA, 99.999%) during 10 min under intensive stirring (390 rpm) to remove moisture. Thereafter (−)-isopulegol in 25 ml of acetone (VWR Chemicals, 100%, as reactant and solvent) was added into the reactor. When the desired temperature was reached, the reaction was started by turning on the motor stirrer. The stirring speed of 375 rpm was used together with small catalyst particles in order to suppress external and internal mass transfer limitations. Samples were taken periodically and analyzed by a gas chromatograph (HP 6890) equipped with HP-5 column (length 30 m, diameter 0.32 mm, film thickness 0.5 µm) using the following temperature programme: 100 °C (5 min)–10 °C/min–280 °C (thereafter 10 min holding time). Such a program made it possible to completely separate all products. (Fig. S3). The reactant and chromenols as well as dehydration products were calibrated using the standards prepared of Novosibirsk Institute of Organic Chemistry. Standards were synthesized according to the procedure described in [7] using of K10 clay. The products were confirmed by GC–MS (Agilent Technologies 6890 N).

Stability of R- and S-chromenols was investigated using the Forcite, Conformers and DMol3 modules in Materials Studio 2019 software [19, 20]. The most stable conformers were optimized by density functional theory with B3LYP hybrid functional [21,22,23,24]. The Grimme method in DMol3 SEDC module was implemented for DFT-D (dispersion) correction [25]. Dielectric coefficient of acetone, 20.7 was used with Conductorlike Screening Model (COSMO) [26].

Results and discussion

Catalyst characterization results

Catalyst characterization results have been recently reported in [15], in which Prins cyclization was performed with (−)-isopulegol and benzaldehyde. The most important catalyst properties, such as specific surface area, pore sizes, elementary analysis and XPS results for sulfur as well as acidities are shown in Tables 1 and 2. These results revealed that the highest specific surface area for sulfur modified catalyst was observed for K10 clay organosilylated with 2-(4-chlorosulfonylphenyl)-ethyltrimethoxysilane and noted as K10-CSP, followed by K10 clay sulfonated with chlorosulfonic acid and denoted as K10-CSA. Noteworthy is also the pore sizes for K10-CSA and HNT-CSP which were much higher than for other catalysts.

The sulfur content on the catalyst surface determined by XPS (Table 1) was the highest for K10-CSA, followed by sulfur modified HNT catalysts. The lowest sulfur content on the catalyst surface was observed for K10-CSP. The concentration of Brønsted acid sites, which is an important parameter for the studied reaction [15, 16], decreased as follows: K10-CSA > CLOI-CSP > K10-CSP > HNT-CSA > HNT-CSP (Table 2) and the ratio Brønsted acid/Lewis acid as follows: K10-CSA (only Brønsted acid sites) > HNT-CSP > HNT-CSA > CLOI-CSP > CLOI-CSA > K10-CSP. The acid sites concentration determined by potentiometric titration was also the highest for K10-CSA.

Catalytic results

Effect of structure and surface acidity of clay catalyst: comparison of K10-CSA and CLOI-CSA catalysts

Preliminary experiments were performed using the most acidic K10-CSA in the Prins cyclization of (−)-isopulegol with acetone at 30 °C using initial (−)-isopulegol concentration of 0.013 mol/l and 50 mg catalyst (Table 3, entry 1). The reaction exhibited a very high rate under these conditions giving after 30 min complete conversion of (−)-isopulegol. This highly acidic K10-CSA resulted in relatively low R/S ratio, which also decreased with increasing conversion from 4.3 to 3.3. When comparing this result with the data for the Prins cyclization of (−)-isopulegol with benzaldehyde [15], performed with the same catalyst under the same conditions, it can be stated that in the latter case (−)-isopulegol converted already after 1 min during heating the reactor subsequently (−)-isopulegol reaction with benzaldehyde was faster than with acetone, as expected, since a keto group in acetone is less reactive than a primary carbonyl group in benzaldehyde. The corresponding R/S ratio decreased in (−)-isopulegol with benzaldehyde reaction analogously with increasing conversion from 3.6 to 3.2 indicating that while this catalyst was active, it was, however, not very selective, when using a low initial reactant concentration. The chromenol yield with K10-CSA using 0.013 mol/l initial (−)-isopulegol concentration at 30 °C was in the current case 83%, being higher than the one reported in [7]. Since the above mentioned conditions resulted in too high conversion, it was appropriate to study the Prins cyclization of (−)-isopulegol with acetone over different catalysts using higher substrate concentrations.

A comparative study of K10-CSA, K10-CSP, CLOI-CSP and CLOI-CSA catalysts was performed at 25 °C using the initial concentration of (−)-isopulegol of 0.52 mol/l (Table 3, entries 4, 8 and 10). CLOI-CSP with an intermediate concentration of Brønsted acid sites was also not active, most probably due to its low content surface sulfonic groups (Table 1) [15]. The initial rate and conversion for K10-CSA were much higher than those for CLOI-CSA (Table 3, Fig. 2a), which can be related to higher acidity. CLOI-CSA exhibited a low initial reaction rate because of its low acid site concentration (Table 2). In addition, CLOI-CSA catalyst has also rather small pores, 3.6 nm, which are much smaller than those of K10-CSA (Table 1). When taking into account formation of products with a relatively large size, especially at a high initial (−)-isopulegol concentration (Table 3), catalyst deactivation by pore blocking is not surprising. On the other hand, CLOI-CSA exhibited high activity and a high R/S ratio in benzaldehyde cyclization with (−)-isopulegol [15].

The selectivity to the desired chromenols was higher for K10-CSA catalysts than for CLOI-CSA (Fig. 2b). For CLOI-CSA with a very low acid site concentration giving a low reaction rate, the chromenol selectivity was maximally about ca. 50% and approximately the same selectivity was obtained for dehydration products (Table 3).

The R/S ratio of the reaction products is a very important parameter, because biological activity of R is much higher than of the S diastereomer [7]. This ratio was the highest among the studied catalysts for K10-CSA when using 0.65 mol/l initial (−)-isopulegol concentration (Fig. S5a). CLOI-CSA gave the lowest R/S ratio due to its low amount of Brønsted acid site concentration. In Prins cyclization of (−)-isopulegol with benzaldehyde [15], the highest R/S ratio was obtained with mild Brønsted and Lewis acidic catalysts, while the opposite is valid in the current case.

When plotting concentration of dehydration products as a function of the concentration of chromenols (Fig. S5b) in the Prins cyclisation of (−)-isopulegol with acetone over different catalysts, it can be clearly seen that K10-CSA is a better catalyst for producing chromenols in comparison to CLOI-CSA and the ratio between the rates for formation of dehydration products to chromenols decreased for these catalysts in the following order: 2.1 (CLOI-CSA) > 0.12 (K10-CSA).

Other products formed over K10-CSA at 25 °C with 0.52 mol/l initial (−)-isopulegol concentration were dehydration products (3–5 in Fig. 1) and ether (6 in Fig. 1), which were confirmed by GC–MS (Fig. S4). The kinetic analysis of the results is presented below.

It can be concluded that K10 clay is a better support for the Prins cyclization of (−)-isopulegol with acetone due to better accessibility of organic molecules to its pores. Furthermore, strongly acidic K10-CSA exhibited much higher rate and conversion in comparison to CLOI-CSA.

Comparison of K10-X and HNT-X systems: effect of structure and surface acidity

A comparative study of K10-CSA, K10-CSP, HNT-CSA and HNT-CSP for Prins cyclization was performed at 25 °C using 0.52 mol/l initial (−)-isopulegol concentration. The initial reaction rate calculated as moles of converted (−)-isopulegol between 1 and 30 min per mass of catalysts increased for K10-CSA being 3.6 fold of that obtained with K10-CSP when increasing the initial (−)-isopulegol concentration (Table 3, entry 4 and 8). The high activity of K10-CSA is due to its high acidity. On the other hand, no conversion was obtained with halloysite nanotubes modified with CSA and CSP, i.e. HNT-CSP, HNT-CSA, which exhibit a low concentration of Brønsted acid sites and thus were not active in the Prins cyclization of (−)-isopulegol with a ketone, acetone, which has a steric hindrance and a lower reactivity in comparison to benzaldehyde [15].

One reason for a lower catalyst activity of K10-CSP was formation of isopulegol ether of chromenol at a high initial (−)-isopulegol concentration in cyclization of (−)-isopulegol with benzaldehyde [15]. This product exhibiting a size of 1.1 nm, being close to the interlamellar space between the fibre bundles in K10-CSP of only 1–2 nm, probably blocks an access of reactants to the active sites [15]. A similar explanation of the decreased rate after prolonged reaction times in the current study with K10-CSP can be also suggested.

The yield of the target product on K10-CSA (73%) was much higher than that obtained with K10-CSP (23%). In addition, the yield of chromenols over K10-CSA was higher than that obtained earlier [16] on the strongly acidic (1.7 mmol/l) Amberlyst-15 resin (62%). It can be concluded that K10-CSA has an adequate amount of Brønsted acid centers, which is sufficient for high selectivity to acetone-derived chromenol. Note that according to work [16], in the case of isopulegol condensation with acetone at 30 °C without any solvent, weakly acid halloysite nanotubes (45 µmol/g) allowed 77% selectivity for the sum of R and S isomers. K10-CSP produced also more dehydration products in comparison to K10-CSA (Table 3, entries 4 and 8), most probably due to the slow rate of reaction. Thus, it can be stated that clay structure has a major role determining the product distribution in Prins cyclization.

Catalytic properties of K10-materials

Effect of initial (−)-isopulegol concentration for K10-CSA catalyst

The effect of the initial (−)-isopulegol concentration was investigated for K10-CSA catalyst at three different concentrations (Fig. 3a, Table 3). The results show that the initial rate increased by a factor 2.3 when the initial (−)-isopulegol concentration was increased fivefold. The overall conversion after 4 h decreased.

Comparison of the effect of the initial isopulegol (IP) concentration on the performance of K10-CSA. a Conversion as a function of time and b selectivity to chromenols as a function of conversion in Prins cyclization with acetone using 50 mg K10-CSA catalyst. Symbols: (filled rectangle) 0.013 mol/l, (filled circle) 0.52 mol/l and (filled triangle) 0.65 mol/l (−)-isopulegol at 25 °C

Chromenol selectivity over K10-CSA catalyst decreased only slightly with increasing initial (−)-isopulegol concentration at 25 °C (Fig. 3b, Table 3, entries 3–5). On the other hand, the R/S ratio was the lowest when using the lowest initial (−)-isopulegol concentration (Fig. S6a). When comparing selectivity to dehydration products and the ether at the same conversion level (70%) it can be seen (Table 3, entries 3–5) that selectivity to dehydration products was not much affected by different initial (−)-isopulegol concentrations. It is also interesting to investigate kinetics for formation of chromenols and dehydration products via plotting the concentration of dehydration products as a function of chromenol concentration (Fig. S6b). The results revealed that these products are formed in the parallel fashion for the initial (−)-isopulegol concentrations between 0.013 and 0.52 mol/l with the rate ratio for dehydration to chromenols of 0.17, while at a higher initial (−)-isopulegol concentration formation of the dehydration product is more prominent.

Etherification reaction was, as expected, more prominent at a high initial (−)-isopulegol concentration (Table 3, entry 4 and 5). An even larger value of selectivity to the ether (14%) was observed in the previous work [16] over acid-treated halloysite without any solvent i.e. using a more concentrated substrate. According to the reaction network, proposed in [16], the ether is an intermediate product and is formed as a result of acetone reaction two isopulegol molecules. The reaction order in this reaction pathway exceeds that for the direct formation of chromenols from the reactants. The current data on the increase in ether selectivity with increasing initial isopulegol concentration are in line with the reaction scheme described in [16].

Concentration profiles for all products in the Prins cyclization of (−)-isopulegol over the best catalyst, K10-CSA at 0.52 mol/l initial (−)-isopulegol concentration at 25 °C are shown in Fig. 4 illustrating formation of chromenols, dehydration products and (−)-isopulegol ether of chromenol. Overall the performance of this catalyst was very good and the effect of initial (−)-isopulegol concentration is summarized in Fig. 5. The reaction mechanism involves protonation of acetone similar to the reaction mechanism reported for aldehydes [14] followed by addition of the protonated ketone to (−)-isopulegol forming chromenol. In the consecutive step chromenol can be dehydrated to chromenes (as shown in Figs. 1 and 5) over strong Brønsted acid sites. In addition, isopulegol ether of chromenol (as a single R isomer) was formed in the current work over Brønsted acidic sites. Thus, varying the initial concentration of the reagents allows to find a balance between formation of dehydration by-products while decreasing the R/S ratio (lower concentration of the substrate) and the formation of ether.

Concentration of (filled rectangle) (−)-isopulegol, (filled circle) R-chromenol, (open circle) S-crhomenol, (filled triangle) dehydration products and (asterisk) isopulegol chromenol ether formed in Prins cyclization of (−)-isopulegol with acetone over K10-CSA at 25 °C using 0.52 mol/l (−)-isopulegol in acetone

The best result over K10-CSA was obtained using 0.52 mol/l initial (−)-isopulegol concentration, the substrate conversion was 87% after 240 min over K10-CSA with the main products were chromenols with the yield of 73% and the yield of R-chromenol was 53%. The second largest compounds are dehydration products while formation of the ether was not that high (Table 3). Note that selectivity to the desired R-chromenol was slightly higher than that using a weakly acidic halloysite nanotubes (69%) [16].

In order to elucidate the reason for a high R/S ratio for K10-CSA catalyst, stability of different products was analyzed by quantum chemical calculations. The results revealed (Fig. S7, Table S1) that the S diastereomer of chromenol exhibited only a slightly higher Gibbs free energy in comparison to the R diastereomer. This small difference alone cannot explain a high ratio of R/S. This result indicates that the adsorption mode of molecules on the catalyst surface (as described in [14]) and kinetics leading to different stereomers have thus a major impact on R/S ratio, and not thermodynamics. An insignificant difference in Gibbs energies between the R ether formed as compared with the hypothetical S ether (Table S1) can indicate steric difficulties in the formation of the latter on the catalyst surface.

Effect of reaction temperature and initial (−)-isopulegol concentration for K10-CSP catalyst

The effect of the reaction temperature was investigated with K10-CSP catalyst using two different initial (−)-isopulegol concentrations (Table 3, entries 6–9). The results show that although the initial reaction rate was very high at 25 °C, at 40 °C an induction period was observed and the reaction rate started to increase only after a prolonged reaction time (ca. 30 min) (Fig. 6a). In order to further investigate the reason for this phenomenon, in particular strong adsorption of the reactant, only (−)-isopulegol was added into the reactor with the same catalyst using an inert solvent, hexane. The results showed that (−)-isopulegol concentration remained constant showing that it was not strongly adsorbed on this catalyst. An explanation of the induction period can be adsorption of the products at 40 °C when using a low initial (−)-isopulegol concentration. Interestingly, such induction period was absent at 40 °C with a higher (0.52 mol/l) initial (−)-isopulegol concentration.

Effect of temperature and initial (−)-isopulegol concentration on a conversion and selectivity to chromenols as a function of chromenols in Prins cyclization over K10-CSP catalyst at 25 °C (triangle) and 40 °C (circle) using 0.013 mol/l (solid symbol) and 0.52 mol/l (open symbol) initial (−)-isopulegol concentration

Selectivity to chromenols decreased from 63 to 40% over K10-CSP catalyst at 0.013 mol/l initial (−)-isopulegol concentration (Fig. S6b), when increasing the temperature from 25 °C to 40 °C. At the same time the R/S ratio was only slightly decreased (Fig. S8a) indicating the R-diastereomer reacted further.

The concentration of the dehydration products plotted as a function of the concentration of chromenols for K10-CSP (Fig. S8b, Table 3, entries 6–9) shows much higher concentrations of dehydration products are formed at 40 °C. The ratio between the initial rates for formation of these products is 1.33 and 0.4 at 40 °C and at 25 °C, respectively. It is important to note that when significantly lower initial concentrations of isopulegol (0.013 mol/l) were used, selectivity to dehydration products was higher over K10-CSP (Table 3, entry 7), and the R/S ratio was lower than in concentrated solutions. This may indicate an increase of the ratio between the rate of monomolecular dehydration of chromenols and chromenols formation, which obviously has a large molecularity [12]. In addition, dehydration products can also be formed directly from substrates [16]. Note that in the case of low initial concentrations, ether was not observed (Table 3, entry 6, 7).

Stability of K10-CSA catalyst

For the best catalyst, K10-CSA, a filtrate test was performed as follows: the reaction was started in the presence of catalyst, which was filtrated away at 9 min and the reaction in the absence of catalyst was continued after 30 min in the reactor under stirring. The results showed that sulfur was not leached into the liquid phase eliminating a possible homogeneous reaction (Fig. 7), because (−)-isopulegol was not reacting further in the absence of a catalyst.

Filtration test using K10-CSA in Prins cyclization of (−)-isopulegol with acetone at 25 °C using 0.65 mol/l initial (−)-isopulegol concentration. Symbols: (filled rectangle) reaction in the presence of catalyst, (filled triangle) filtration of the catalyst and (open rectangle) reaction in the absence of a catalyst

Reaction mechanism

A plausible mechanism for the Prins cyclization of (−)-isopulegol with acetone has been proposed in Fig. 1. The carbonyl group of acetone is first protonated and attacked by the hydroxyl group of (−)-isopulegol. The subsequent proton transfer and removal of water leads to the oxocarbenium ion 1. This is followed by an attack of the carbon–carbon double bond to the oxacarbenium ion 1 forming the tetrahydropyranyl tertiary carbocation 2. The nucleophiles (water or (−)-isopulegol) presented in the reaction medium can attack the tertiary carbocation 2 to give products with a molecular mass of 212 g/mol (denoted as 4). Elimination of a proton from the carbocation 2 leads to formation of olefins (3–5). Moreover, dehydration of chromenols 212 may take place to produce the same olefins 3–5.

Conclusions

Prins condensation of (−)-isopulegol with acetone as a reactant and a solvent was investigated over sulfonated K10, cloisite Na+ and halloysite nanotubes based on montmorillonite natural clays. The reaction was performed in the temperature range of 25–40 °C giving R-diastereomer of chromenol as the main and desired product. The initial (−)-isopulegol concentration was varied in the range of 0.013–0.65 mol/l. Halloysite nanotubes were inactive in this reaction due to their mild acidity. The reaction rate after prolonged times decreased especially for organosilylated cloisite clay which has a rather narrow interlamellar space between fibre bundles and exhibited also a rather mild acidity. One potential explanation is formation of a large isopulegol ether of chromenol at a high initial (−)-isopulegol concentration blocking an access of the reactants.

The best results were obtained with a highly acidic sulfonic acid modified K10 clay giving high activity and high selectivity (78–88%) to chromenol at a 78–100% conversion of (−)-isopulegol. High activity of this catalyst can be ascribed to high acidity and a large pore size.

It was established that the R/S ratio of isomers increased, and the selectivity to the dehydration products decreased with increasing initial concentration of isopulegol. The highest yield of chromenols was 73% obtained over K10 clay sulfonated with chlorosulfonic acid using 0.52 mol/l initial (−)-isopulegol concentration at 87% substrate conversion after 240 min. Sulfonic acid modified K10 clay did not show any leaching of sulfonic groups. Thus, this material is promising for use as a catalyst for the selective synthesis of ketone-based chromenols.

References

Nazimova EV, Shtro AA, Anikin VA, Patrusheva OS, Il'ina IV, Korchagina DV, Zarubaev VV, Volcho KP, Salakhutdinov NF (2017) Influenza antiviral activity of Br-containing [2R,4R(S),4aR,7R,8aR]-4,7-dimethyl-2-(thiophen-2-yl)octahydro-2H-chromen-4-ols prepared from (–)-isopulegol. Chem Nat Comp 53:260–264

Timofeeva MN, Volcho KP, Mikhalchenko OS, Panchenko VN, Krupskaya VV, Tsybulya SV, Gil A, Vicente MA, Salakhutdinov NF (2015) Synthesis of octahydro-2H-chromen-4-ol from vanillinand isopulegol over acid modified montmorillonite clays: effect ofacidity on the Prins cyclization. J Mol Cat A Chem 398:26–34

Timofeeva MN, Panchenko VN, Gil A, Zakusin SV, Krupskaya VV, Volcho KP, Vicente MA (2015) Effect of structure and acidity of acid modified clay materials on synthesis of octahydro-2H-chromen-4-olfrom vanillin and isopulegol. Catal Commun 5:234–238

Stekrova M, Mäki-Arvela P, Kumar N, Behvaresh E, Aho A, Balme Q, Volcho KP, Salakhutdinov NF, Murzin DYu (2015) Prins cyclization: Synthesis of compounds with tetrahydropyran moietyover heterogeneous catalysts. J Mol Catal A 410:260–270

Kholkina E, Mäki-Arvela P, Lozachmeuer C, Barakov R, Shcherban N, Murzin DYu (2019) Prins cyclisation of (-)-isopulegol with benzaldehyde over ZSM-5 based micro-mesoporous catalysts for production of pharmaceuticals. Chin J Catal 40:1713–1720

Sidorenko AYu, Kravtsova AV, Aho A, Heinmaa I, Volcho KP, Salahutdinov NF, Agabekov VE, Murzin DYu (2018) Acid-modified halloysite nanotubes as a stereoselective catalyst for synthesis of 2H-chromene derivatives by the reaction of isopulegol with aldehydes. ChemCatChem 10:3950–3954

Ilyina IV, Zarubaev VV, Lavrentina IN, Shtro AA, Esaulkova IL, Korchagina DV, Borisevich SS, Volcho KP, Salakhutdinov NF (2018) Highly potent activity of isopulegol-derived substituted octahydro-2H-chromen-4-ols against influenza A and B viruses. Bioorg Medicin Chem Lett 28:2061–2067

Yadav JS, SubbaReddy BV, Ganesh AV, Narayana GC, Kumar KS (2010) Sc(OTf)3-catalyzed one-pot ene-Prins cyclization: a novel synthesis of octahydro-2H-chromen-4-ols.Tetrahedr Lett 51:2963–2966

Nazimova E, Pavlova A, Michalchenko O, Il'ina I, Korchagina D, Tolstikova T, Volcho K, Salakhutdinov N (2016) Discovery of highly potent analgesic activity of isopulegol-derived(2R,4aR,7R,8aR)-4,7-dimethyl-2-(thiophen-2-yl)octahydro-2H-chromen-4-ol. Med Chem Res 25:1369–1383

Timofeeva MN, Panchenko VN, Volcho KP, Zakusin SV, Krupskaya VV, Gil A, Mikhalchenko OS (2016) Effect of acid modification of kaolin and metakaolin on Brønsted acidity and catalytic properties in the synthesis ofoctahydro-2H-chromen-4-olfrom vanillin and isopulegol. J Mol Catal A 414:160–166

Kishore KR, Reddy K, Silva LF Jr (2013) Iodine-catalyzed Prins cyclization of aliphatic and aromatic ketones. J Braz Chem Soc 24(9):1414–1419

Sidorenko AYu, Kravtsova AV, Wärnå J, Aho A, Heinmaa I, Il'ina IV, Volcho KP, Salakhutdinov NF, Murzin DYu, Agabekov VE (2018) Preparation of octahydro-2H-chromen-4-ol with analgesic activity from isopulegol and thiophene-2-carbaldehyde in the presence of acid-modified clays. Mol Catal 453:139–148

Baishya G, Sarmah B, Hazarika N (2013) An environmentally benign synthesis of octahydro-2 H-chromen-4-ols via modified montmorillonite K10 catalyzed Prins cyclization reaction. Synlett 24:1137–1141

Sidorenko AYu, Kravtsova AV, Aho A, Heinmaa I, Wärnå J, Pazniak H, Volcho KP, Salakhutdinov NF, Murzin DYu, Agabekov VE (2019) Highly selective Prins reaction over acid-modified halloysite nanotubes for synthesis of isopulegol-derived 2H-chromene compounds. J Catal 374:360–377

Li-Zhulanov N, Mäki-Arvela P, Laluc M, Peixoto AF, Kholkina E, Sandberg T, Aho A, Volcho K, Salakhutdinov N, Freire C, Sidorenko AY, Murzin DY (2019) Prins cyclization of (-)-isopulegol with benzaldehyde for production of chromenols over organosulfonic clays. Mol Catal 478:110569

Sidorenko AYu, Kravtsova AV, Il'ina IV, Wärnå J, Korchagina DV, Galitov YuV, Volcho KP, Salakhutdinov NF, Murzin DYu, Agabekov VE (2019) Clay nanotubes catalyzed solvent-free synthesis of octahydro-2H-chromenols with pharmaceutical potential from (-)-isopulegol and ketones. J Catal 380:145–152

Silva SM, Peixoto AF, Freire C (2018) HSO3-functionalized halloysite nanotubes: New acid catalysts for esterification of free fatty acid mixture as hybrid feedstock model for biodiesel production. Appl Catal A 568:221–230

Silva SM, Peixoto AF, Freire C (2020) Organosulfonic acid functionalized montmorillonites as solid catalysts for (trans) esterification of free fatty acids and (waste) oils. Renew Energy 146:2416–2429

Delley B (1990) An all-electron numerical method for solving the local density functional for polyatomic molecules. J Chem Phys 92:508–517

Delley B (2000) From molecules to solids with the approach. J Chem Phys 113:7756–7764

Becke AD (1993) Density-functional thermochemistry. III. The role of exact exchange. J Chem Phys 98:5648–5652

Lee C, Yang W, Parr RG (1988) Development of the Colle–Salvetti correlation-energy formula into a functional of the electron density. Phys Rev B 37:785–789

Vosko SH, Wilk L, Nusair M (1980) Accurate spin-dependent electron liquid correlation energies for local spin density calculations: a critical analysis. Can J Phys 58:1200–1211

Stephens PJ, Devlin FJ, Chabalowski CF, Frischet MJ (1994) Ab Initio calculation of vibrational absorption and circular dichroism spectra using density functional force fields. J Phys Chem 98:11623–11627

McNellis ER, Meyer J, Reuter K (2009) Azobenzene at coinage metal surfaces: Role of dispersive van der Waals interactions. Phys Rev B 80:205414

Delley B (2006) The conductor-like screening model for polymers and surfaces. Mol Simul 32:117–123

Muthuvel I, Krishnakumar B, Swaminathna M (2012) Novel Fe encapsulated montmorillonite K10 clay for photo-Fenton mineralization of acid yellow 17. Ind J Chem 51A:800–806

Acknowledgements

Open access funding provided by Abo Akademi University (ABO).

Funding

A part of this work was funded by Fundação para a Ciência e a Tecnologia (FCT): PTDC/BII-BIO/30884/2017, UID/QUI/50006/2019 and DL57/2016—Norma transitória (AFP).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Laluc, M., Mäki-Arvela, P., Peixoto, A.F. et al. Catalytic synthesis of bioactive 2H-chromene alcohols from (−)-isopulegol and acetone on sulfonated clays. Reac Kinet Mech Cat 129, 627–644 (2020). https://doi.org/10.1007/s11144-020-01740-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01740-9