Abstract

In this study the breadmaking potential of lupin flour from L. mutabilis after being debittered (DLF) and solid state fermented (FLF) was evaluated in lupin-wheat breads. Different levels of substitution (10, 15, 20%) were tested on dough rheology and the technological and nutritional (composition and in vitro digestibility indexes) properties of breads, as well as acceptability. Lupin weakened the dough during mixing, having shorter development time and stability, especially FLF. Less relevant was the effect of lupin flours along heating-cooling of the doughs recorded with the Mixolab. DLF and FLF significantly affected technological properties of the lupin-wheat breads at higher substitution (> 10%), particularly reducing bread volume, crust luminosity, crumb cohesiveness and resilience. Detrimental effects observed at the highest substitutions (20%) were diminished when using FLF, although breads received lower score due to the acidic taste detected by panelists. Both lupin flours provided lupin-wheat breads with rather similar composition, rising the average content of proteins, fat and dietary fiber by 0.8, 2.4, 6.5 %, respectively, compared to wheat breads. Likewise, lupin-wheat breads had significantly lower hydrolytic and glycemic indexes. Overall, debittered and fermented lupin could be used for enriching wheat breads, although better technological properties were observed with FLF.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wheat bread constitutes an important part of the diet and remains as staple food across the civilized world [1]. Nevertheless, sustainability issues and current consumers’ demands have driven the latest innovations in bakery towards sustainable and healthy foods made of either whole grains, alternative grains or even legumes as substitutes for refined wheat. Likewise, wheat replacement in bread recipes for other grains allows reducing wheat importation in non-wheat producers’ countries. Lupin (genus Lupinus) is an undervalued legume that some decades back was proposed for increasing the nutritional value of bread [2]. However, only some years ago lupin seeds awakened growing interest due to its high protein content [3], observing very little changes in product acceptability up to 6% addition [4, 5]. Increasing amounts of lupin flour (up to 20%) decrease the bread volume and the crumb texture quality [6], but allows increasing the content in protein and dietary fiber, apart from the content of bioactive compounds like phenols and carotenoids [7]. Most of the studies reported for bread enrichment with lupin have been carried out using L. angustifolius (Blue Lupine with narrow leaves) [8] or L. albus (White Lupine) [4]; although Lupinus mutabilis Sweet shows better adaptation to poor soils and extreme conditions and limited information exists about its application in breadmaking. Despite the high nutritional value of lupin seeds, its use is very limited due to the presence of bitter compounds, specifically alkaloids derived from quinolizidine [9]. The aqueous debittering process, consisting in several washings, reduces the alkaloids content to safe levels [10], but it is quite costly in water and time consuming. This process can be more efficient using thermal treatments [11] and saline solutions (0.5% (w/v) for seeds hydration and cooking [12]. Likewise, further nutritional improvement of lupin seeds could be obtained with the solid-state fermentation by using lactic acid bacteria [13] or fungi [14]. In fact, wholemeal lupin fermented with Lactobacillus sakei, Pediococcus pentosaceus or P. acidilactici could be added up to 10% as sourdough to wheat flour, improving the rheological properties of dough and wheat-lupine bread volume [13]. Regarding fungi, fermentation of lupin with Rhizopus oligosporus induced a further increase of protein levels [14], but there is no information about its potential application in breadmaking.

The objective of this research was to evaluate the impact of Lupinus mutabilis Sweet for wheat flour replacing in breadmaking, and to what extent the debittering and solid-state fermentation of lupin could affect the resulting dough and bread quality. With that purpose, different levels of lupin were tested and dough rheological properties as well as nutritional and technological quality of enriched breads were evaluated.

Materials and Methods

Materials

Lupinus mutabilis Sweet, variety INIAP-Andino 450, obtained by selection and evaluation from a germplasm population introduced from Peru in 1992, with the identification of ECU-2659. Commercial wheat flour (WF) for breadmaking (moisture content 14%, ash 0.73%, protein 14.30%, gluten content 33.11%) “Superior France” from Alsuperior S.A. (Quito, Ecuador) was used.

Production of Debittered Lupin Flour (DLF) and Fermented Lupin Flour (FLF)

The grains were debittered following the aqueous heat process [12]. One part of debittered grain (5 kg) was then dried in an air convection cabinet (Labolan HS122A, Navarra, Spain) at 50oC for 6 h, it was cooled down to room temperature and ground in a mill using a 100 µm sieve (Retsch KG -5657 Haan Remscheid, Germany), obtaining the debittered lupin flour (DLF). Other part of debittered grain (5 kg) was subjected to solid state fermentation following the procedure described by Villacrés et al. [14]. Fermented grains were then dried and ground as above described, to obtain fermented lupin flour (FLF).

Physical Characteristics and Chemical Composition of Flours

pH and total titratable acidity (TTA) were determined after homogenizing 10 g of flour with 90 ml of distilled water, and expressed as milliliters of 0.1 m NaOH needed to reach pH 8.3. Standard methodologies of the AOAC was used to assess: humidity (925.09), protein (total N x 6.25) (955.39), fat (920.39), dietary fiber (991.43) and ash (942.05) [15]. The mineral content was determined by atomic absorption spectrophotometry in AA-7000 atomic absorption spectrophotometer (Shimadzu, Kyoto, Japan) following AOAC method 985.35, except for phosphorus that was colorimetrically analyzed [15].

Dough Characterization

Mixolab (Chopin, Villeneuve-la-Garenne Cedex, France) was used to characterize the rheology of the doughs following the standard method AACC (54-60.01) [16]. The impact of the lupin flours (DLF and FLF) was evaluated by replacing wheat flour at three levels 10, 15 and 20%. pH and total titratable acidity (TTA) of lupin-wheat doughs were assessed as described previously for flours.

Bread Making

Bread recipe, based on 100 g flour, was: 5 g sugar, 2 g salt, 9 g sunflower seeds oil, 4 g compressed yeast, 3 g dairy powder and the required water assessed in the Mixolab. Ingredients were mixed together in a mixer (Planetaria VFICB7B, Lombardía, Italy) for 7 min. Dough was proofed in a cabinet at 37 °C and 90% relative moisture for 20 min, then dough was divided (̴ 170 g), shaped and placed into previously greased stainless steel trays, which were fermented for 1 h at 37 °C. Baking was carried out at 190oC for 25 min in an electric oven (Maquipan UHC-1, Florida, USA). Loaves were cooled down at room temperature for 30 min.

Bread Characterization

Chemical composition of breads was assessed as described previously for flours. The texture was performed 24 h after the breads were baked, following the AACC method 74 − 09 [18] using a texturometer TA-XT2i, Stable Micro Systems, Godalming, UK. The crust and crumb color were performed using a Portable Spectrophotometer (Lange Spectro-Color d/8° model LZM 268, Chelmsford, United Kingdom) based on the CIE L*, a*, b* color system. The following attributes of visual sensation were measured: L* (luminosity), C* (chromatism) and H* (hue). The determination of specific volume was made according to the method AACC 10-05.01 [16], the hydrolytic and glycemic index by the method described by Goñi et al. [17].

For sensory acceptability, breads were placed on coded white plastic plates and served randomly. Test was performed with twenty seven trained panelists (14 females and 13 male, ranging in age between 20 and 40 year) working at the Santa Catalina Experimental Station, INIAP (Quito, Ecuador). Previous group discussion was carried out to define bread characteristics and scores. A 7-point hedonic scale (1 – disliked extremely, 2 – much disliked, 3 – disliked, 4 – liked and did not like, 5 – liked, 6 –a lot, 7 – liked extremely) [18].

Statistical Analysis

All analyses were performed in triplicate, the results are given as the mean ± standard deviation. The data were analyzed by applying multifactorial ANOVA, using INFOSTAT statistical software package (Universidad de Córdoba, Argentina), to compare the means with respect to flour type and substitution level. The Tukey’s multiple range test was applied to determine significant differences at the 5% level.

Results and Discussion

Characteristics of Debittered and Fermented Lupin Flours and Wheat-lupin Doughs

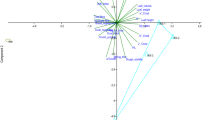

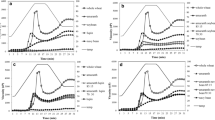

There were significant differences (P < 0.05) on the proximate and minerals composition of the lupin flours (Table 1). The solid-state fermentation significantly increased the protein and fat, with a concomitant reduction in crude fiber, carbohydrate content and minerals (with exception of copper), likely due to the metabolic activity of Rhizopus oligosporus [14]. It must be stressed that the protein content was much higher than the one reported by Mubarak [4] for deffated lupin flour from Lupinus albus, which could be associated to the lupin variety or the debittering process that can greatly affect the nutritional profile of the flours [7]. Regarding pH and acidity, FLF significantly decreased the pH and increased the TTA (Table 1). Three levels of wheat replacement with lupin flours (DLF, FLF) were tested in the breadmaking process. When dough rheological properties were evaluated with the Mixolab, the type of lupin flour significantly affected, the development time, dough stability during mixing and heating (C4) and dough consistency after cooling (C5) (Table 2). Water absorption values were in the range reported by Mubarak [4]. DLF progressively decreased the development time when increasing the substitution level, whereas FLF decreased that parameter independently on the level. Despite the gluten reduction when decreasing the relative amount of WF, dough had similar stability to wheat dough or even increased with DLF. Moreover, C2 was higher in lupin-wheat doughs at the highest level tested. Results suggested that lupin proteins might be incorporated into the gluten matrix and remained entrapped, giving some consistency during heating. Islam et al. [19] suggested that β-conglutins of lupin could be trapped within gluten matrix even after baking, whereas the higher thermal stability of the α-conglutins might explain their no structural integration. Starch gelatinization related to C3 and its stability during heating (C4) decreased in the presence of DLF but the opposite effect was observed in FLF, in spite of the lower carbohydrate content of this flour (Table 1), thus starch performance might be affected by the other flour constituents like the high content of proteins [20]. Again, FLF increased the dough consistency after cooling (C5) and a tendency to decrease it when increasing the level of the FLF flour was envisaged, but the opposite effect was observed with DLF. An increase in C5 has been described when increasing amounts of debittered lupin flour (up to 25%) were blended with wheat, which was related to the interactions between wheat amylose and lupin lipids (one of the major constituents) [20]. Divergences observed in the present study with DLF might be due to the adapted hydration of the doughs used in this study. Nevertheless, considering the possible role of lipids in dough consistency after cooling, it seems that the different lipid profile of DLF and FLF might be responsible of their diverse performance [14].

Breads Technological Properties and Acceptability

Lupin treatment significantly affected the specific volume and all color parameters of the crumb, being the effect more marked for breads containing FLF (Table 3). Nevertheless, no significant effect on specific volume was observed with 10% replacement with either of the lupin flours. Higher replacements induced a significant reduction of the specific volume. These results agree with previous findings, attributing that reduction to the gluten replacement by lupin proteins and the level of fiber [21, 6].

Wheat substitution with lupin significantly reduced the luminosity of the crust, and that effect was intensified when increasing the levels of lupin, significantly in the case of FLF (Table 3). Similar observations have been reported with other lupin-wheat breads [21]. Crumb chroma (C*) significantly increased with both lupin flours, but a steady increase was observed when augmenting the level of FLF, which could be attributed to its higher carotenoids content (544.78 µg/100 g) [14]. Similarly, Dervas et al. [22] reported darker crust and yellowish crumbs at levels of substitution higher than 10% with L. albus.

The lupin treatment significantly affected the textural parameters, with exception of springiness, whereas the level of substitution significantly affected hardness, chewiness and resilience (Table 3). Specifically, flours type significantly increased the crumb hardness at levels > 10% and reduced resilience. The flour type also affected significantly the crumb cohesiveness. Compared to wheat bread, DLF gave similar crumb hardness in the lupin-wheat breads up to 10% substitution, but higher level of substitution resulted in great crumb hardening. Similar hardness has been reported for lupin-wheat breads at those levels of substitution and it has been explained based on gluten dilution [20], which has been also observed with lupin protein isolates (10%) that gave more compact crumbs [23]. Conversely, 10% FLF substitution gave softer crumbs, and although higher substitution resulted in crumb hardening, it was lower than that of DLF. Some authors studying different varieties of lupins observed that their lipid and protein profile might be responsible of attaining some textural properties similar to wheat breads [6]. Cohesiveness of the crumbs was reduced with the lupin flours but no trend was observed with the level of substitution. Chewiness was even reduced in lupin-wheat breads, compared to wheat bread and only DLF at 20% replacement resulted in a significant increase. Considering that chewiness is inversely related to the easiness of chewing, FLF allowed obtaining more chewy protein enriched wheat breads. Crumbs resilience was significantly reduced with the lupin flours, compared to wheat bread, and the effect was slightly more noticeable with FLF. This decrease could be related to the low specific volume of the breads, having denser crumbs with lower number of gas cells, in consequence the crumb structure takes longer to recover after compression [24]. The sensory analysis carried out with those breads to check acceptability indicated that only the lupin treatment significantly affected the acceptability, which was similar to wheat bread when using DLF for substitution, but decreased for FLF (Table 3). Panelists attributed the lower acceptance of the FLF-wheat bread due to their acidic taste and flavor. The aroma of lupin-wheat breads has been associated to oxidative degradation of fatty acids or thermal reactions [5], thus the different fatty acids profile of DLF and FLF [14] might explain their sensory differences. Changes in aroma and taste have been previously reported at 15% substitution with L. albus [25]. Even lower levels of deffated lupin (9%) has been reported to decrease the overall quality of lupin-wheat breads due to low scoring in texture, crumb color and flavor [4].

Nutritional Characteristics of Lupin-wheat Bread

Bread composition in macro and micronutrients is displayed in Table 4. The multiple factor analysis of variance indicated significant differences (P˂0.05) promoted by flour type (debittering, fermentation) of lupin flour on moisture, ash, fat, crude fiber, protein and carbohydrates content, whereas the level of wheat substitution by lupin additional resulted in significant variation (P˂0.05) in most nutritional component, except in copper (data not showed). Compared to wheat bread, breads containing lupin, whatever treatment, had lower moisture content, higher protein, fat and fiber content, which increased with the level of wheat replacement. Despite the higher fiber content, lupin-wheat breads retained less moisture, likely due to the high fat content. Higher moisture content has been reported for breads made with lupin previously fermented with lactic acid bacteria and used as sourdough [13]. For the same level of wheat substitution (20%), lupin enriched breads had similar composition in protein and ash than the one previously reported by [7] when compared breads made with debittered lupin from different varieties of L. angustifolius, but higher levels of fat and crude protein are obtained in the present study with L. mutabilis. Unexpectedly, although FLF had higher protein content than DLF, that difference was not observed in the lupin-wheat breads. Compared to wheat breads, lupin-wheat breads with FLF increased the protein content by 14.71, 29.75 and 30.53% when the level of substitution was 10, 15 and 20%, respectively, versus 20.31, 30.0 and 32.48% obtained with same substitution of DLF. Possibly, nitrogen compounds in FLF were more accessible to yeast during fermentation reducing the theoretical increase. Therefore, initial differences in the nutrient composition of the debittered and fermented lupin flours were not really noticeable in the resulting breads. Regarding the mineral content (Table 4), the flour type and level of substitution affected significantly the amount of all minerals, with exception of copper (results not shown). Nevertheless, compared with the wheat bread, lupin-wheat breads had significantly higher content of calcium, phosphorus, magnesium (only FLF), iron, manganese and zinc, which agrees with the high mineral content of lupin flour [26]. Again, despite the significant differences observed in the lupin flours composition, no great differences were observed between the resulting lupin-wheat breads.

The hydrolytic and glycemic indexes evaluated by in vitro methods were affected by both factors, the flour type and the level of substitution (data not shown), with major impact promoted by FLF. Those indexes were significantly lower than the ones obtained for wheat breads, confirming the reduced digestion of the starchy compounds in lupin-wheat breads [17]. The hypoglycemic effect of the lupin-wheat breads has already been reported and associated to the type of proteins, particularly the γ-conglutins [27]. The effect on hydrolytic index was significantly more accentuated in FLF breads and a progressive reduction was observed increasing lupin levels.

Other highly appreciated aspect in breads is the content in dietary fiber and lupin-wheat breads had significantly higher fiber content than wheat bread, particularly in the case of DLF-wheat breads. The DLF flour had significantly higher content of fiber than FLF flour (Table 1). Fiber is reduced during the solid-state fermentation process because R. oligosporus partly used it to synthesize fats and bioactive compounds required for its metabolism [14].

Concluding Remarks

Debittered and fermented lupin flours from L. mutabilis showed good breadmaking performance at dough and bread level when blended with wheat flour. Lupin-wheat breads without any significant impact on the technological properties could be obtained with 10% wheat substitution. Nevertheless, to further increase the quantities of protein, dietary fiber and minerals in lupin-wheat breads, substitution could be increased up to 20%, although with some detrimental effect on crust luminosity, specific volume, crumb hardness, cohesiveness and resilience. Despite the different proximate composition of debittered and solid-state fermented lupin flours, barely differences were evidenced in the nutritional composition of the lupin-breads, but FLF could be used up to 20% with less impact on textural properties, and greater reduction on the hydrolytic index, although the acidic taste detected by panelists should be masked.

References

Betoret E, Rosell C (2020) Enrichment of bread with fruits and vegetables: Trends and strategies to increase functionality. Cereal Chem 97:9–19

Ballester D, Zacari I, Yhlez E (1984) Baking studies and nutritional value of bread supplemented with full-fat sweet lupine flour (L. albus cv Multolupa). J Food Sci 49:14–16

Villarino C, Jayasena V, Coorey R, Chakrabarti-Bell S, Johnson S (2016) Nutritional, health, and technological functionality of lupin flour addition to bread and other baked products: benefits and challenges. Crit Rev Food Sci 56:835–857

Mubarak A (2001) Chemical, nutritional and sensory properties of bread supplemented with lupin seed (Lupinus albus) products. Nahrung 45:241–245

Paraskevopoulou A, Chrysanthou A, Koutidou M (2012) Characterisation of volatile compounds of lupin protein isolate-enriched wheat flour bread. Food Res Int 48:568–577

Villarino C, Jayasena V, Coorey R, Chakrabarti-Bell S, Johnson S (2015a) Optimization of formulation and process of Australian sweet lupin (ASL)-wheat bread. Food Sci Technol-Leb 61:359–367

Villarino C, Jayasena V, Coorey R, Chakrabarti-Bell S, Foley R, Fanning K, Johnson S (2015b) The effects of lupin (Lupinus angustifolius) addition to wheat bread on its nutritional, phytochemical and bioactive composition and protein quality. Food Res Int 76:58–65

Villarino C, Jayasena V, Coorey R, Chakrabarti-Bell S, Johnson S (2014) The effects of bread‐making process factors on Australian sweet lupin‐wheat bread quality characteristics. Int J Food Sci Tech 49:2373–2381

Frick K, Kamphuis L, Siddique K, Singh K, Foley R (2017) Quinolizidine alkaloid biosynthesis in lupins and prospects for grain quality improvement. Front Plant Sci 8:87

Cortés-Avendaño P, Tarvainen M, Suomela J, Glorio-Paulet P, Yang B, Repo-Carrasco-Valencia R (2020) Profile and content of residual alkaloids in ten ecotypes of Lupinus mutabilis sweet after aqueous debittering process. Plant Foods Hum Nutr 75:184–191

Jiménez-Martínez C, Campos‐Mendiola R, Sánchez‐Espíndola M, Jiménez‐Aparicio A, Gutiérrez‐López G, Dávila‐Ortiz G (2009) Microstructural changes in Lupinus campestris seed in response to three thermal debittering treatments. J Sci Food Agric 89:2399–2404

Villacrés E, Álvarez J, Rosell C (2020) Effects of two debittering processes on the alkaloid content and quality characteristics of lupin (Lupinus mutabilis Sweet). J Sci Food Agric 100:2166–2175

Bartkiene E, Schleining G, Rekstyte T, Krungleviciute V, Juodeikiene G, Vaiciulyte-Funk L, Maknickiene Z (2013) Influence of the addition of lupin sourdough with different lactobacilli on dough properties and bread quality. Int J Food Sci Tech 48:2613–2620

Villacrés E, Quelal M, Jácome X, Cueva G, Rosell C (2020b) Effect of debittering and solid-state fermentation processes on the nutritional content of lupin (Lupinus mutabilis Sweet). Int J Food Sci Tech 55:2589–2598

AOAC (Association of Official Analytical Chemestry) (1995, 2000, 2005) Official Methods of Analysis

AACC Approved methods of the American Association of Cereal Chemistry (2003) 10th. St. Paul, Minnesota, U.S.A

Goñi I, Garcia-Alonso A, Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycemic index. Nutr Res 17:427–437

Watts B, Ylimaki G, Jeffery L, Elías L (1992) Basic methods for food evaluation. Ottawa, International Development Research. CIID, Ottawa, 159 p

Islam S, Ma W, Yan G, Gao L, Appels R (2011) Differential recovery of lupin proteins from the gluten matrix in lupin–wheat bread as revealed by mass spectrometry and two-dimensional electrophoresis. J Agric Food Chem 59:6696–6704

Rosell C, Cortez G, Repo-carrasco R (2009) Breadmaking use of Andean crops Quinoa, Kañiwa, Kiwicha and Tarwi. Cereal Chem 86:386–392

Pollard N, Stoddard F, Popineau Y, Wrigley C, Macritchie F (2002) Lupin Flours as Additives: Dough Mixing, Breadmaking, Emulsifying, and Foaming. Cereal Chem 79:662–669

Dervas G, Doxastakis G, Hadjisavva-zinoviadi S, Trianta N (1999) Lupin flour addition to wheat flour doughs and effect on rheological properties. Food Chem 66:67–73

López E, Goldner M (2015) Influence of storage time for the acceptability of bread formulated with lupine protein isolate and added brea gum. Food Sci Technol-Leb 64:1171–1178

Matos M, Sanz T, Rosell C (2014) Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocolloid 35:150–158

Campos J, El Dash A (1978) Effect of addition of full fat sweet lupine flour on rheological properties of dough and baking quality of bread. Cereal Chem 55:619–625

Ertaş N (2015) Technological and chemical characteristics of breads made with lupin sprouts. Qual Assur Saf Crop 7:313–319

Sedláková K, Straková E, Suchý P, Krejcarová J, Herzig (2016) Lupin as a perspective protein plant for animal and human nutrition–a review. Acta Vet Brno 85:165–175

Acknowledgements

The authors would like to acknowledge the financial support of the Cooperative Program for the Regional Agricultural Technology Fund (FONTAGRO) (Project FTG/RF-14893-RG, 2016–2018), Spanish Ministry of Science and Innovation (RTI2018-095919-B-C21), Generalitat Valenciana (Prometeo 2017/189) and the European Regional Development Fund (FEDER).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest regarding this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• L. mutabilis flour could be used as ingredient for making wheat breads.

• Debittering and solid-state fermentation lead to lupin flours with good breadmaking performance.

• Up to 10% wheat replacement with lupin does not affect bread properties.

• Lupine-wheat breads with fermented lupin flour (20%) presented an improved nutritional profile.

Rights and permissions

About this article

Cite this article

Villacrés, E., Cueva, P., Díaz, M. et al. Replacing Wheat Flour with Debittered and Fermented Lupin: Effects on Bread’s Physical and Nutritional Features. Plant Foods Hum Nutr 75, 569–575 (2020). https://doi.org/10.1007/s11130-020-00844-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-020-00844-w