Abstract

A survey of Australian grain growers was conducted to gauge grower attitudes to crop and soil sensing and their role in nitrogen fertilizer management. The technologies considered were yield monitors, remote and proximal crop sensing, high resolution soil survey, soil moisture sensing and digital elevation models (DEM). Whereas Australian grain growers have readily adopted machine guidance and autosteer, and a majority have access to yield monitoring, the rate of use of many crop and soil sensors remains comparatively low. However, the survey results suggest a positive effect on sensor adoption through present use of yield mapping. Access to yield maps was significantly associated with the use of remotely sensed imagery, high resolution soil survey, soil moisture sensing, DEM and variable rate application of fertilizers and/or soil amendments. There is some support for proximal crop sensing, albeit with low present rates of use; the use of soil water sensors and DEM is presently very low. For the further development of precision agriculture (PA), the results make clear that expending effort in enhancing the adoption and use of yield maps would be valuable as a lever to gain ‘buy-in’ from growers to sensing and PA more broadly. Since growers use many sources of information to support fertilizer decision-making, any new fertilizer decision aid needs to establish a point of difference from, but be complementary to, existing tools. One way of achieving this would be to use sensors, supported by locally derived algorithms, as a key input to fertilizer decision support.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In a recent survey, 60% of farmers from EU countries (France, Germany, Poland and the UK) expressed a belief that by 2030, precision agriculture (PA) will be widely adopted (Corsini et al. 2015), enabled by the increased use of sensors, software and wireless connectivity on farming implements. Conversely, recent assessments of PA adoption in Australia (Robertson et al. 2012; Llewellyn and Ouzman 2015) and USA (Schimmelpfennig and Ebel 2011; Miller et al. 2017) suggest that the rates of uptake of some PA technologies will need to increase greatly for this EU prediction to be realised in western farming systems more broadly. In Australia, recent studies (Keogh and Henry 2016; Leonard et al. 2017 and the underpinning reports referenced therein) have identified numerous issues which need to be addressed for ‘Digital agriculture’ and ‘Big data’ (Sonka 2014) to become the trusted norm; PA contributes to these. In particular, a greater need for leadership, governance and cross industry collaboration was identified, along with issues of trust in technology and service providers, internet connectivity, digital literacy (throughout the agricultural value chain, not just on farm), the availability of appropriate data and a need for new tools for data analysis and decision support (Leonard et al. 2017). Importantly, the value proposition for producers to change to digital agriculture was reported as “unclear” to producers. Many of these issues no doubt apply in other countries; for example, Mark et al. (2016) have identified internet connectivity as a major constraint to digital agriculture in the USA and noted the similarities between USA and Australia in this regard.

‘Future Farm’ is a new initiative focussed on the Australian grains and cotton sectors established to develop research in automation. It was structured around the themes of sensing, decisions and delivery platforms, with nitrogen (N) fertilizer management chosen as the first exemplar farm operation for research and development focus. It was founded on the premise that farmer adopters of PA are seeking greater automation in their farming operations, especially in terms of the process of acquiring and then using data to make decisions and, indeed, in implementing these through a chosen management action. But what do Australian farmers think of sensing, automation and decision support tools? What are their attitudes towards adoption of such technologies? These are important questions given the apparent reluctance, as noted above, of some farmers to adopt digital technologies. They are also important given the suggestion (Leonard et al. 2017) that ‘unconstrained decision agriculture’ could lead to an increase in the gross value of production in the Australian grains industry of 51%. In making this claim, Leonard et al. (2017) defined ‘decision agriculture’ as a “conclusion or action resulting from the application of knowledge and/or information that may be derived from digital agriculture.” Thus, ‘unconstrained decision agriculture’ infers a situation where digital technologies, along with more conventional sources, provide all the information that a farmer might need in order to make a beneficial business decision. This paper reports on a survey that was undertaken to assess Australian grain grower attitudes to the use of sensors in the operation of their farm businesses. It was conducted to assist in setting the direction for the early phase of Future Farm, a program with potential to facilitate moves towards an ‘unconstrained decision agriculture’.

Methods and materials

A questionnaire comprising over 40 questions was developed using the ‘Survey Monkey’ platform (https://www.surveymonkey.com/). These were grouped to enable assessment of different components of PA, albeit with particular focus on N management. The questions are reproduced in Table 1 to facilitate comparative studies. For brevity, a reference in this paper to question 16, for example, is simply denoted by ‘(q16)’ rather than ‘(question 16; Table 1).

The survey was made ‘open’ to approximately 49,000 growers on the mailing list of the Australian Grains Research and Development Corporation (GRDC) via emails sent by GRDC on January 12, 2017, with a reminder sent to the same list on January 31, 2017. The survey remained open until 25 February, 2017, although the overwhelming majority of responses were received within 24 h of these emails being sent. Note that response to the survey was voluntary. Note also that all Australian grain growers pay a levy to GRDC and as such, the email list used to distribute the survey was sent to every grower with an email address; we are confident that those growers without an email address represent a very small proportion of the total grain growing population.

Following download of the survey results from ‘Survey Monkey’, data management and analysis were done using Excel (Microsoft Office Professional Plus 2013, Microsoft Corporation, Redmond, WA, USA) and JMP (v. 11.0, SAS Institute Inc, Cary, NC, USA). Since most of the data were categorical, the significance of associations between the factors surveyed was tested using contingency analysis and the ‘likelihood ratio’ Chi squared test (SAS Institute Inc. 2013). Continuous data were analysed using one-way analysis of variance with the significance of differences tested using the Tukey–Kramer test.

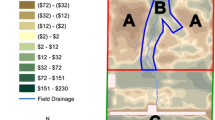

To enable comparison with other recent surveys (Llewellyn and Ouzman 2015; Robertson et al. 2012), the analysis was structured on the basis of GRDC region (Fig. 1), farm size, rainfall, whether or not a grower uses an agronomic consultant and current practice in terms of yield mapping. Note that the northern GRDC region encompasses the grain growing areas in Queensland and New South Wales and has relatively high seasonal rainfall and more diversity of production (both summer and winter crops and a range of crop types) than the other regions. It is the largest source of Australia’s premium hard high protein wheat. The southern region encompasses Victoria, Tasmania and South Australia and is focussed on winter cropping with yield potential strongly driven by seasonal rainfall, with many enterprises also engaged in livestock production. The western region is confined to Western Australia. This is the lowest yielding of the Australian grain regions (ABARES 2017) with production conducted over large scale as a consequence; as in the southern region, yields are dependent on seasonal rainfall. Further information is available at https://grdc.com.au/about/our-industry/growing-regions and in ABARES (2017). Because of the water-limited nature of Australian grain growing, it was of interest to know whether being either severely or relatively un-constrained in this regard impacted on survey responses. Accordingly, respondents receiving less than 350 mm annual rainfall were regarded as being in ‘low’ rainfall areas, with those receiving more than 500 mm regarded as being from ‘higher’ rainfall locations. Similarly, those cropping more than 2500 ha were regarded as having ‘large’ operations and those cropping less than 2500 ha were treated as ‘small’.

Results and discussion

Respondents, demographics and background information

A total of 203 survey responses were received; 30.5, 43.8 and 25.6% were from the northern, southern and western GRDC regions, respectively. The farm size of respondents varied from 100 to 27,000 ha with a median farm size of 2500 ha. The median cropping percentage was 77% of arable land. When examined on a regional basis, the median farm size in both the southern (range of 220–11,500 ha) and northern (100–27,000) regions (2000 ha) was approximately half that seen in the western region (median size of 4139 ha; range of 1000–14,000 ha).

The survey respondents were dominated by grain growers who had been farming for more than 25 years, with no significant between-region differences in grower experience (P > 0.05). This is an interesting result if time spent farming is treated as a surrogate for farmer age, given the common assumption that younger farmers are likely to be more comfortable with modern technology. Note that, since the survey did not ask about the ages of different family members involved in the farm business, we assume here that the time spent farming/farmer age refers to the person filling out the survey and that this person was the primary decision maker in terms of farm management.

Unsurprisingly, there were significant (P < 0.05) between-region differences in reported annual rainfall with means of 569, 432 and 375 mm in the northern, southern and western regions respectively. However, whilst reported growing season rainfall followed the same trend (326, 297 and 281 mm), there were no significant between-region differences in growing season rainfall (P > 0.05) amongst the survey cohort.

Data management, agronomic advice and possible survey bias

Of the 200 respondents who answered q6, 156 (78%) use an agronomic consultant; of the 104 respondents with yield maps (q17, 18), 85 (82%) also used a consultant. This result is consistent with those from previous surveys (Robertson et al. 2012; Llewellyn and Ouzman 2015), which highlighted the importance of a grower having a paid agronomic consultant to their likelihood of earlier adoption of some PA practices. However, of the issues canvassed in this survey, having a consultant only had a significant positive relationship with adoption of soil moisture sensing (P < 0.01). These results likely reflect the voluntary nature of the survey and points towards the self-selected respondents being biased towards those likely to be interested in PA and sensing. Since the survey purpose was to assist in setting a direction for a research and development project, this is no bad thing, but it does nevertheless place a caveat on the results.

Notwithstanding familiarity with or interest in technology, ‘paper format’ remains the dominant mode of record keeping (q7) with only approximately 30% of those surveyed managing their farm data either in a spreadsheet or using some form of dedicated farm management software, with many of these respondents also using paper format. Interestingly, the number of years spent farming had no significant impact (P > 0.05) on the mode of record keeping, with the exception of a significant positive relationship (P < 0.01) between time spent farming and spreadsheet use.

Farm size had no significant impact on whether a consultant was used (P > 0.05); 84% of respondents from larger farms (> 2500 ha) and 74% from smaller farms (< 2500 ha) use a consultant. By comparison, a 2014 unbiased survey reported by Llewellyn et al. (2016) indicated that 58% of grain growers “pay for cropping advice”; Llewellyn and Ouzman (2015) predicted that this figure would rise to 63% by 2017. The present survey did not specify that “consultants” should be paid and it is possible that use of agronomists linked to retailers could have been included amongst the responses received to the present survey. Llewellyn and Ouzman (2015) noted that the use of unpaid advisers from retail outlets was high (~ 60%) in some regions, especially in parts of New South Wales, Victoria and South Australia; paid consultant use was greatest in Western Australia.

Table 2 summarises the statistical significance of the various factors canvassed in the survey on adoption of sensing technologies.

Yield monitoring/mapping

Production of yield maps (q15–18), rather than just use of a yield monitor, was used as an indicator of the level of adoption of PA given that most new headers sold in Australia now come with a yield monitor already installed. Thus, 87% of survey respondents have access to a yield monitor (q15) and 88% of those who do, use it when harvesting (q16). However, only 57% of those with a yield monitor generate yield maps (q15, 17), either themselves (the majority) or with the assistance of a consultant (26% of those who obtain maps).

Farm size had a significant impact (P < 0.01) on whether a farm has a yield monitor and on whether or not yield maps are produced (P < 0.001). Of the 71 farmers on ‘large’ farms who have yield monitors, 54 produce maps (76%) whereas only 50% of growers on smaller farms who have yield monitors generate yield maps. Of 77 southern region respondents with a yield monitor, 57 generate yield maps (74%). This is a higher rate of yield map production than in either the western (58% of those with a yield monitor) or northern region (43%). However, and in spite of the western region being the driest, 72% of low rainfall growers with a yield monitor generate maps compared to 50% in the higher rainfall areas; this result could be a reflection of the northern regional difference given that the northern region has a greater proportion of higher rainfall growers than the other regions.

Farm size was also significantly associated with the number of years for which yield maps had been produced (P < 0.01) with large farms having yield maps for 8.9 years compared to 5.7 years for small farms. This result is no doubt associated with a significant regional effect, with yield mapping in the western region (9.9 years) having a significantly longer history than either the southern (6.6 years; P < 0.05) or northern (5.9 years; P < 0.05) regions; the northern and southern regions were not significantly different (P > 0.05). The longer history of yield mapping in the west is likely a reflection of much of the early Australian PA research being conducted in Western Australia (Cook et al. 1996; Cook and Bramley 1998; Adams et al. 1999). This regional effect is also likely the reason for the significant effect of rainfall on yield mapping; farms classified as ‘dry’ (< 350 mm/year) had a significantly larger (P < 0.05) number of years of yield maps (8.4) compared to farms in wetter areas (> 500 mm/year; 5.5 years of yield maps).

Of the 105 growers with yield maps, 65 (62%) use them to assist in management zone delineation (q18). Conversely, one could say that in spite of typically having yield maps for 5–7 years, 38% of growers have not made use of them for decision-making relating to targeting management. Given the frequent anecdotal reporting that farmers ‘don’t know what to do with their maps’, it is suggested that the development of easy-to-use tools, which automate the process of map generation and analysis, would be useful.

Farm survey and machine guidance

A key platform underpinning PA implementation, including the production of robust yield maps and identification of management zones (e.g. Taylor et al. 2007), is some form of spatial farm survey (q8). Overall, of the 197 respondents who answered q8, 158 (80%) had conducted some form of farm survey; 100 of these had used GPS to do the survey whilst 50 had used ‘Google Earth’. Of those who had not surveyed their farm, 10 were from ‘large’ farms (13% of ‘large’ farms not surveyed), whilst 27 were from ‘smaller’ farms (22% of ‘smaller’ farms not surveyed); this difference was not significant (P > 0.05). Unsurprisingly, farm boundary surveys were significantly more common amongst those with yield maps than those without (87.5% compared to 67.4%; P < 0.01); that 12.5% of growers who have produced yield maps do not have farm boundaries surveyed is perhaps of some concern since it indicates that the maps are not being interpolated onto raster grids defined by the field boundaries. Such data processing is necessary for data overlay and robust zone delineation (e.g. Taylor et al. 2007).

The rate of adoption of controlled traffic or machine guidance was high at 84% (q9) with the majority of adopters (65%) using higher accuracy (20 mm) auto-steer systems (q10). This result is consistent with the 77% rate of autosteer adoption in 2012 noted by Llewellyn and Ouzman (2015), suggesting further adoption since the 2012 survey. Here, farm size was found to have a significant association (P < 0.05) with adoption of guidance, which is used on 92% of large farms compared to 80% of smaller farms; 74% of large farms use higher accuracy (20 mm) systems compared to 44% of small farms (P < 0.0001). Several growers noted the use of systems of varying accuracy (20, 100, 150, 200, 500 mm) on different machines, with some using the high accuracy systems (20 mm) without auto-steer. In spite of the association between farm size and adoption of this technology and the larger farm size in the western compared to the northern and southern regions, there was no significant regional difference in the adoption of guidance/auto-steer technology per se (P > 0.05). However, region did have a significant impact (P < 0.05) on the use of higher accuracy (20 mm) systems, which are used by 62% northern growers, 61% southern growers, but only 39% western growers.

Given the frequent demonstration of the utility of a digital elevation model (DEM) to understanding field-scale variation in crop performance, in the PA literature (i.e. by researchers such as Bramley and Trengove 2013) and at grower technical meetings (i.e. by consultants; Michael Wells, PCT-Ag—pers. comm.), it was surprising that only 37% of machine guidance users had used their guidance system to generate a DEM of their farm (q11). This was especially so since having machine guidance had a significant positive effect on adoption of at least one of the sensing technologies canvassed in this survey (P < 0.01). However, farm size had a significant bearing (P < 0.01) on possession of a DEM; 46% of large farms have a DEM compared to 26% of small farms. Anecdotal evidence, including that obtained in other industry sectors (e.g. sugar), suggests that there is a low level of awareness amongst Australian farmers of the ability to obtain a DEM from a machine guidance system. However, there was a highly significant (P < 0.0001) effect of having yield maps on whether or not a DEM had been generated. Fifty-two percent of survey respondents who have yield maps and use auto-steer have obtained a DEM; only 15% of growers who do not have yield maps have generated a DEM and this figure only increases to 18% when confined to growers without yield maps but who do use auto-steer.

An even smaller proportion (26%) of respondents have acquired a high-resolution soil survey (e.g. using an electromagnetic sensor or gamma radiometrics) on their farm (q12) with no significant regional, farm size or rainfall effect on adoption (P > 0.05). However, the likelihood of having acquired high-resolution soil survey was significantly associated (P < 0.001) with also having yield maps. Only 11% of growers without yield maps have acquired high resolution soil survey, whilst amongst growers who have yield maps, 37% have also acquired high resolution soil survey. Amongst this cohort of respondents, use of an agronomic consultant had no effect on use of high-resolution soil survey (P > 0.05).

Electromagnetic sensing (e.g. EM38) remains the dominant form of high-resolution soil survey used (q13) albeit amongst a small pool of users (n = 50). Gamma radiometrics has been used by only 7 respondents and 4 of these were from the western region where EM38 has limitations for distinguishing between sandy and gravelly soils and where gamma radiometrics has been shown to have particular utility (Wong et al. 2008). These results, along with comments made by those who replied to q13 with ‘Other’, tend to suggest that the level of understanding of this technology, and/or perceptions of its relative utility, is low. Previous surveys (Robertson et al. 2012; Llewellyn and Ouzman 2015) have indicated that use of EM38 has been greatest in regions such as the Victorian and South Australian Mallee where it has correlated well with important and obvious changes in soil type (Llewellyn et al. 2008). However, there may not be on-going extensive high use in these regions due to increasing grower understanding of the relationship between EM38 and landscape position in the Mallee’s relic dune-swale systems and the impact of landscape position on yield (Whitbread et al. 2008; McBeath et al. 2015). However, those who have acquired high resolution soil survey clearly find it useful: a majority (88%) had used it to assist in guiding fertilizer management, whilst 49% used it to assist with crop choice decisions and 31% to guide seed rate (q14).

Crop sensing

Over 40% of all survey respondents have accessed remotely sensed imagery of their farms (q20) with 88% of users sourcing this from satellite-based platforms (q21). There was no significant difference (P > 0.05) between the regions in remote sensing usage, nor between ‘wet’ and ‘dry’ farms. However, of 193 respondents, growers from large farms were significantly more likely (P < 0.05) to have accessed remote sensing than those from smaller farms (58% compared to 40%). Whereas 49% of growers using an agronomic consultant had accessed imagery, only 33% of those who do not have a consultant had done so, albeit with this consultant effect not being statistically significant (P > 0.05). However, the biggest effect on acquisition of remotely sensed imagery was possession of yield maps (P < 0.001); 60% of growers who have yield maps have accessed imagery whereas only 28% of growers without yield maps have done so. In spite of all the present hype, unmanned aerial vehicles (UAVs) or drones do not yet seem to have taken off (no pun intended!) (q21); only five growers in the survey had made use of a drone.

Of the 90 growers who have accessed remotely sensed imagery, 56% used it to guide variable fertilizer management; around 13% used it to guide crop choice or seeding rate. Other interesting applications for the use of remotely sensed imagery include identification of areas for clay spreading (e.g. Cann 2000; Hall et al. 2010), planning for changing paddock boundaries and identification of areas on a newly purchased property which were unsuitable for cropping. A few respondents indicated their use of imagery to assist in zoning without specifying what form of variable management such zoning might help to inform.

In contrast to remotely sensed imagery, there was a low rate (only 12% of 186 respondents) of use of proximal canopy sensing (q 23), with 14 of the 25 users being located in the southern region; there were only two users of proximal sensing in the northern region. This low rate of use of proximal canopy sensing may reflect the lack of Australian-based interpretive algorithms for such technology and/or uncertainty amongst Australian farmers as to its benefit:cost. The recent review of Colaço and Bramley (2018) suggests that such circumspection is appropriate in the absence of means to integrate the information provided by proximal canopy sensors and ‘N-rich strips’ (Raun et al. 2005) with that from other sources, such as soil moisture sensors. Lawes et al. (2009) have noted the importance of knowledge of soil moisture to N fertilizer decision-making. Importantly, recent research (R. Lawes and N Huth, CSIRO, 2018—pers. comm.) has identified that, under water-limited rain-fed systems such as predominate in the Australian grain belt, canopy sensing in conjunction with access to a ‘zero-N strip’ is likely to be considerably more beneficial than an ‘N-rich strip’ because the key decision aid is knowledge of when a crop is likely to encounter N stress. Unsurprisingly therefore, the responses to q24 (n = 41) suggest that the issue of using proximal sensing to guide N fertilizer management is not well understood amongst Australian grain growers. Nonetheless, it is of interest that the Crop Circle sensor (Holland Scientific, Lincoln, NE, USA) has no commercial use amongst the Australian farmer respondents to this survey, with GreenSeeker (Trimble, Sunnyvale, CA, USA) the dominant technology used by survey respondents. The CropCircle ACS-470 is arguably the ‘preferred’ model amongst Australian researchers due to the ability to change wavelength filters.

All but one of the 23 users of proximal canopy sensing had yield maps. Users of proximal sensing were also overwhelmingly (70%) on large farms (P < 0.001).

Management zones

One hundred survey respondents answered q25 dealing with management zones and the information used to derive them, although the ‘Other’ responses indicated that, in fact, 94 respondents work with zones. Of the 27 ‘Other’ responses that were retained, 22 clearly indicated use of zones based on farmer knowledge of their soil and other observations of variation in the land and/or crop performance; another 4 used soil testing to derive zones. Clearly, what one respondent noted as ‘technology-free zone delineation’ is important amongst Australian grain growers with 28% using this approach. However, if these responses are merged with the use of “other soil survey” (i.e. not high resolution soil survey using a sensor), 76% of growers can be seen to use a non-sensor based method of soil survey as a basis for zone delineation, which greatly outweighs the use of a sensor-based (i.e. high resolution) approach to acquisition of soil information (15%). This is the most used input to zone delineation followed by yield maps (68%), remote sensing (31%) and a DEM (21%). Only four respondents use proximal crop sensing as an input to zone delineation.

Whilst one respondent reported identifying as many as 11 zones, most respondents use a smaller number with three zones being the norm (99 respondents; q26). However, approximately 50% of survey respondents (n = 109) would consider increasing the number of zones used (q27). Of the 71 responses which explained why growers would/would not change the number of zones used, common themes included: a desire to keep things simple and/or concerns at the perceived complexity of VRT equipment (n = 14); concerns as to the benefit:cost of change (n = 8); perceptions that present knowledge of soil variation did not justify it and/or that soils were too variable for the simple implementation of zonal management (n = 11); a lack of access to equipment (n = 5); and agronomic concerns (n = 5). In the latter connection, one grower noted that response curves were not well enough understood, with another noting that he/she had insufficient information as to how to treat each zone.

Variable rate

Of the 188 respondents to q28 and q29, 57% had the capacity to implement variable rate fertilization whilst 52% actually use variable rate application (VRA) for fertilizers.

Use of VRA was significantly lower (P < 0.05) in the northern region (35%) compared to the southern and western regions (58%). Furthermore, whereas 71% VRA users in the southern region vary fertilizer rate within-paddocks, within-paddock rate variation drops to 59% VRA users in the western region and to only 32% in the northern region, with this regional difference also significant (P < 0.05).

Of the 97 growers who use VRA, 82 employ a consultant and 66 have yield maps. Fifty-eight of these growers use VRA within-paddock and of these, 50 employ a consultant whilst all of them have yield maps, suggesting that these growers are amongst the more sophisticated adopters of PA. Overall, VRA is used on 63% of large farms and 69% of farms receiving < 350 mm rainfall; whilst 66% of farms with yield maps use VRA. Thus, consultant use (P < 0.05), farm size (P < 0.05), rainfall (P < 0.01) and having yield maps (P < 0.001) all had significant association with adoption of VRA, although neither consultant use nor having yield maps had an impact on whether VRA use was between- or within-paddock (P > 0.05). Nonetheless, of the 82 VRA users who employ an agronomic consultant, 61% vary fertilizer rates within-paddock. Only 15 growers without a consultant use VRA with only eight of these varying rates within-paddock. Within-paddock use of VRA was significantly more likely on low rainfall farms (P < 0.05); between-paddock VRA was more likely on higher rainfall farms.

Nitrogen is the dominant nutrient managed using VRA (68% VRA users) with 43% of VRA users varying phosphorus (P) rates, in spite of the interest in recent years in P replacement (e.g. Whelan and Taylor 2013) as a management strategy (q30). When the analysis is restricted to those using VRA within-paddock, 72% vary N rates and 43% vary P. Other uses of VRA amongst the 97 growers using this technology included lime (6), gypsum (2), sulphur (3) and seed (2). Almost 100% survey respondents continue to use solid fertilizers (q31) with liquids also used by 32%. Of the 59 survey respondents using liquid fertilizers, 25 (42%) did not use VRA, although there was no significant interaction between fertilizer type and use of VRA (P > 0.05), an interesting result given that VRA application of liquids may be more precisely controlled than for solid fertilizers.

Soil moisture

In spite of the recent interest in soil moisture sensors as a tool to assist in enhancing water use efficiency (WUE; e.g. Kirkegaard et al. 2014), only 44 out of 188 respondents to q32 (23%) have a soil moisture sensor, with 40 of these using an agronomic consultant (P < 0.01). Amongst those with soil moisture sensors, three have five sensors, whilst 16 have one; most owners of soil moisture sensors have two of them (q33). Farm size had no bearing on ownership of a soil moisture sensor (P > 0.05), whilst their use was significantly greater on higher rainfall farms (P < 0.05). Consistent with this, use of soil moisture sensors was significantly affected by region (P < 0.05); whilst 90% of growers in the western region do not have a soil moisture sensor, 25 and 31% of growers in the northern and southern regions use this technology. Growers with yield maps were significantly more likely to own a soil moisture sensor than those without (P < 0.01). Given this rate of use of soil moisture sensing, it is perhaps not surprising that only 37% of growers take any notice of soil moisture when making N fertilizer decisions (q34), with fertilizer rate the dominant consideration (46% respondents); timing of application (26%) and fertilizer type (8%) were also considered. Since 37% of growers take notice of soil moisture in making N fertilizer decisions, but only 23% have a soil moisture sensor, non-sensor sources of soil moisture information are used by at least 14% of growers. Anecdotal evidence suggests that many growers integrate knowledge of seasonal rainfall (to date) with knowledge of rainfall patterns and crop yields from previous seasons, along with public weather forecasting to make a judgement as to the need for fertilizer and its likely benefit:cost.

N fertilizer decision making

An array of information sources is used to guide decisions as to how much N fertilizer to apply (Table 3). The dominant inputs to N fertilizer decision-making are the growers own calculations and the advice of an agronomist, used by 77 and 66% respondents respectively. Interestingly, simply following district practice (10%) is the least used of the methods, and does not draw on a specific technology. Amongst the ‘Other’ responses to q39, pricing and cash flow were important; only one grower noted the value of an ‘N-rich strip’ (Raun et al. 2005) and another commented on conducting trials to assist with decision making. When analysis of the answers to this question are confined to growers who use an agronomic consultant, the response percentage for the various options changed very little, with the exception of the to-be-expected finding that the use of advice from consultants increased to 81%. Of interest, whether or not a consultant is employed was not associated with use of a DSS. Overall, the main conclusion to be drawn from q39 is that growers typically use more than one source of information in making their fertilizer decisions. Indeed, of the 184 respondents to q39, only 45 used a single source of information; 54 growers used two sources of information, 56 used three, 22 used four and five used five. Notably for Future Farm and other initiatives targeted at sensor-based solutions, whether these be research-focussed or commercially driven, only 3% of growers currently make use of sensor-based algorithms (Table 3). This is presumably a reflection of the lack of calibrated algorithms for the Australian grain regions and, more broadly, uncertainty over benefit:cost (Colaço and Bramley 2018).

Decision support tools (DSS) such as Yield Prophet (Hochman et al. 2009), or proprietary systems such as NU Logic (CSBP Ltd, Kwinana, Western Australia) are used by 26% of growers. A possible reason for the relatively low ranking of DSS tools is the wide array available; 25 were listed for q40. Another might be that, having been used a few times, they are no-longer actively used given some adjustment of a growers ‘rule of thumb’ through temporary DSS use. Given that all of these provide guidance in some aspect of N fertilizer decision making (some also consider factors other than N), understanding how growers perceive their points of difference and/or suitability to their particular farming situation would be of interest. Indeed, what is clear from q39 and q40 is that if a grower uses a DSS at all, he/she is highly likely to use more than one of them. Thus, whereas 26% of growers use a DSS (q39), 206 DSS uses were reported by the 112 respondents to q40. All but two of the ‘Other’ responses to q40 did not infer use of a DSS, listed or otherwise, and it is therefore concluded that the 206 DSS uses is spread amongst 82 respondents; that is, on average, each DSS user in fact accesses 2.5 DSS. Whether this is a reflection of lack of trust in this technology (Leonard et al. 2017) is unclear, although even accounting for the geographical spread of the Australian grainbelt (Fig. 1), it would not be surprising to learn that farmers are confused by the simple fact that 25 different Australian DSS are available to grain growers making N decisions.

Of the 206 DSS uses, 75 (36%) involve tools based on the APSIM crop model (Keating et al. 2003) with Yield Prophet (Hochman et al. 2009) accounting for over half of these. Suggestions as to what would further assist with N decision making (q45) were dominated by pleas for improved weather forecasting/rainfall prediction, although remote and ‘in crop’ N sensing were mentioned, as were sensor based algorithms and N rich strips, the integration of yield mapping with protein sensing and tools for converting such maps into prescription maps for following seasons. A greater focus on N budgeting and an ‘N tracker’ were also suggested.

Future intentions regarding sensing

Of the growers who do not currently use a particular sensor type, a high proportion envisage using one in the future (q35). Thus, for example, of the 95 growers who are not currently using yield maps, 54% expect to start doing so within the next three years, with a further 27% expecting to adopt this technology in 3–10 years. However, time spent farming was seen to have a significant (P < 0.01) effect on the likelihood of adopting sensing technologies. Eighty seven percent of growers who have been farming for less than 10 years intend to use sensors as a part of their farm practice compared to 65% of growers who have been farming for more than 20 years; those who have farmed for between 10 and 20 years were intermediate between the other groups in their intention to use sensors. It is assumed here that those who have been farming for less than 10 years are the youngest group amongst the survey respondents.

Elevation models were the technology least likely to be adopted, again reflecting the relative lack of awareness that machine guidance technology readily enables production of a DEM and/or a low perceived value of DEMs by farmers. As illustrated by Table 4, the proportions of respondents not currently using a technology who could not readily conceive of using it in the future (i.e. no intention to adopt) were markedly affected by whether they currently had yield maps. Thus, as with other elements in this survey, this result strongly suggests that an important enabling step in promoting the use of agricultural sensing and integration of its use into decision-making, may be assisting growers to get value from yield monitoring and the yield maps produced as a result. Such an approach is consistent with, and would also facilitate, the stepwise adoption (Aldana et al. 2010; Robertson et al. 2012; Wilkinson 2011) of PA technologies other than yield maps. Overall, growers with yield maps were significantly more likely to adopt remotely sensed imagery in the future (P < 0.05); whilst the effect of having yield maps on intention to adopt high resolution soil survey was not significant (P > 0.05), of the 71 growers who intend to adopt high resolution soil survey, 73% have yield maps. Neither rainfall (‘wet’ vs ‘dry’), farm size, region, nor consultant use, had any significant effect on intentions to adopt either high-resolution soil survey or remote sensing (P > 0.05). In spite of large farms being significantly more likely (P < 0.01) to have a DEM, there was no significant effect of farm size on future intention to acquire a DEM (P > 0.05).

Growers were asked (q36) to nominate what kinds of sensors they would like if cost was not a consideration. Although specifically asked not to be constrained by their current knowledge of sensing and to assume that it would be possible to sense whatever they wished, many of the 149 respondents simply nominated the various technologies mentioned in the survey, which they were yet to adopt. For example, 17 people listed yield maps as their first or second choice; 19 did likewise for soil moisture sensing. In terms of ‘new’ sensors, plant nutrient sensing received 38 first or second choice nominations, whilst soil nutrient sensing received 18 nominations. Sensing of weeds (8), diseases (4) and soil biology were also mentioned as first or second choices. A possible reason for reticence/lack of novelty in these answers may be that 57% respondents believe that they need to develop substantial new skills and knowledge to use new sensors or PA technologies (q37). On the other hand, 43% did not see such a skills/knowledge need. Whether a consultant was employed had no bearing on the perceived need for new skills (P > 0.05), nor did current use of yield maps.

Recently, Colaço and Bramley (2018) have advocated a multi-sensor, multivariate approach to the use of crop sensors in N fertilizer decision-making, for example, coupling information from crop sensing with that from soil moisture sensing. Similarly, a recent analysis based on crop modelling and machine learning (R. Lawes and N. Huth, CSIRO, 2018—pers.comm.) noted a hierarchy of factors that benefit good N fertilizer management, identifying knowledge of soil moisture and ability to predict N stress, via use of a ‘zero-N strip’ as of greatest value. It is therefore of interest that adoption of multiple sensors is significantly affected by farm size (P < 0.01). Amongst farms where either no sensors, or just one sensor type is used, small farms predominate (80 and 76% respectively). On farms where either two (45% large, 55% small) or three (47% large, 53% small) sensors are used, farm size is clearly less important. However, 63, 56 and 67% of farms where, respectively, four, five or six sensor types are used are large (> 2500 ha). Paustian and Theuvsen (2017) report a somewhat similar effect of farm size on PA adoption in Germany, whilst Miller et al. (2017) found that, in Kansas (USA), farms which had either adopted no or several PA technologies were “steadfast” in their view of technology adoption, whereas intermediate adopters were more flexible. We infer from this that, whereas development of a multi-sensor approach to farm decision making might be most effectively undertaken in collaboration with growers from large farms, extension efforts aimed at encouraging new adoption of sensing technologies may be more productively targeted away from the largest farms and focussed on farms of medium size. Webster et al. (2016) drew a similar conclusion when working in the Australian sugar industry. Across all farm sizes, a greater focus on soil moisture sensing would also be beneficial (see above).

Of course, adoption of any new technology will ultimately be driven by its perceived relative advantage, compatibility, complexity, trialability and observability (Rogers 2003). Robertson et al. (2012) suggested that relative advantage (i.e. benefit cost) and complexity (i.e. ease of use) are arguably of greatest importance to the adoption of PA technologies. Leonard et al. (2017) identified trust in technology as critical to growers attitudes to ‘Big Data’. For growers not currently using sensors as a part of the N decision making process, there is an even spread of opinion as to what level of increased profitability would be required to encourage adoption (q38), with no significant effect of any perceived need for new skills on this required profit increase (P > 0.05). Using the target increases in profit detailed at q38 (< $10, $10–15, $15–20, $20–25, $25–30 and > $30/ha), current access to yield maps had a significant effect on the profit increase required to induce adoption of additional sensors (P < 0.05), with those who had yield maps willing to adopt additional sensors for lower profit gain than those without yield maps. Thus, amongst those with yield maps, the profit increase category attracting the greatest proportion of respondents (28%) was $10–15/ha, whereas amongst those without yield maps, the majority (24%) sought $20–25/ha to justify adopting a sensor; there were 111 respondents to q38. Whilst there was no significant regional effect on required profit increase (P > 0.05), over 40% of the growers seeking a > $30/ha profit increase from sensor adoption were from the northern region. To explore this further, the responses to q38 were grouped into either three (< $15, $15–25 and > $25/ha) or two profit increase classes (< $20 and > $20/ha). In spite of an apparent desire for greater profit increases amongst northern growers and willingness to accept lower increases amongst southern growers, the regional effect remained non-significant (P > 0.05) when either the two or three profit increase categories were used. However, we conclude that this issue needs more careful analysis with a larger sample set, because when the effect of current access to yield maps was examined with the reduced grouping of profit increases required for sensor adoption, the effect of current access to yield maps was no longer significant (P > 0.05) for the three class analysis. For the two class analysis, access to yield maps was significant (P < 0.05). Thus, 60% of growers without yield maps sought more than $20/ha in return for adopting a sensor, whereas 60% of growers with yield maps were willing to accept less than $20/ha to adopt an additional sensor.

One of the reasons that Future Farm and like endeavours might focus on sensing is the opportunity for automation in data collection that sensors afford. The rapid uptake of guidance and autosteer is indicative that automation per se is a concept that, in general, farmers are comfortable with. Similarly, VRA offers an automated solution to implementation of variable application of fertilizers and other inputs once the decision as to the rates to be applied has been made. However, the FARMSCAPE experience (Carberry et al. 2002) indicated that whereas Australian farmers like DSS to explore ‘what if’ questions, especially when explored in conjunction with their consultants, they do not want decision making to be taken away from them. Rather, effective DSS support the learning needs of farmers and their transactions with advisers and help build their ‘actionable knowledge' (Evans et al. 2017). It is important therefore, that as sensors become increasingly available to farmers, these are integrated into decision support as aids, rather than as a means of automating the decision making process and thereby lessening the role of the farmer in managing the farm business. Such an approach enables the farmer’s own attitude to risk, along with expectations of seasonal rainfall, to be factored into the decision, something which is arguably not readily achieved with fully automated systems.

Conclusions

These results suggest a very clear positive effect on adoption of sensing technologies, and intention to adopt, through present use of yield mapping with the profit increase required to justify adoption being lower amongst those with yield maps compared to those without maps. The survey indicates some support for crop sensing, albeit with low present rates of use of proximal sensors; the use of soil water sensors and DEM is presently very low.

Previous surveys support the view that agronomic research projects would be wise to interact closely with consultants in addition to leading growers. For the further development of PA, the present results make clear that expending at least some effort in enhancing the adoption and use of yield maps would be valuable as a lever to gaining ‘buy-in' to sensing and PA more broadly. Since growers clearly use many sources of information as input to decision making, any new fertilizer management DSS needs to establish a point of difference from existing tools. One way of doing so would be by making use of sensor input, supported by appropriate locally derived algorithms; desirably, it would also be able to work in concert with alternative decision tools such as those currently in use.

References

ABARES (2017). Agricultural commodity statistics 2017. Australian Bureau of Agricultural and Resource Economics and Sciences, Department of Agriculture and Water Resources, Canberra. http://data.daff.gov.au/data/warehouse/agcstd9abcc002/agcstd9abcc0022017_IugZg/ACS_2017_v1.1.0_lr.pdf. Accessed March 2018.

Adams, M. L., Cook, S. E., Caccetta, P. A., & Pringle, M.J. (1999). Machine learning methods in site-specific management research: An Australian case study. In Robert, P. C., Rust, R. H. & Larsen, W. E. (Eds.) Proceedings of the Fourth International Conference on Precision Agriculture (pp. 1321–1333). Madison, WI, USA: ASA-CSSA-SSSA.

Aldana, U., Foltz, J. D., Barham, B. L., & Useche, P. (2010). Sequential adoption of package technologies: The dynamics of stacked trait corn adoption. American Journal of Agricultural Economics, 93, 130–143.

Bramley, R. G. V., & Trengove, S. (2013). Precision Agriculture in Australia: present status and recent developments. Engenharia Agricola, 33, 575–588.

Cann, M. A. (2000). Clay spreading on water repellent sands in the southeast of South Australia—promoting sustainable agriculture. Journal of Hydrology, 231–232, 333–341.

Carberry, P. S., Hochman, Z., McCown, R. L., Dalgliesh, N. P., Foale, M. A., Hargreaves, J. N. G., et al. (2002). The Farmscape approach to decision support: Farmers’, advisers’, researchers’ monitoring, simulation, communication and performance evaluation. Agricultural Systems, 74, 141–177.

Colaço, A. F., & Bramley, R. G. V. (2018). Do crop sensors promote improved nitrogen management in grain crops? Field Crops Research, 218, 126–140.

Cook, S. E., & Bramley, R. G. V. (1998). Precision agriculture—Opportunities, benefits and pitfalls of site-specific crop management in Australia. Australian Journal of Experimental Agriculture, 38, 753–763.

Cook, S. E., Corner, R. J., Riethmuller, G., Mussel, G., & Maitland, M. D. (1996). Precision agriculture and risk analysis: An Australian example. In Robert, P. C., Rust, R. H. & Larsen, W. E. (Eds.) Proceedings of the Third International Conference on Precision Agriculture (pp. 1123–1132). Madison, WI, USA: ASA-CSSA-SSSA.

Corsini, L., Wagner, K., Gocke, A., & Kurth, T. (2015). Crop farming 2030: The reinvention of the sector. Boston: The Boston Consulting Group. https://www.bcg.com/en-au/publications/2015/crop-farming-2030-reinvention-sector.aspx. Accessed March 2018.

Evans, K. J., Terhorst, A., & Ho Kang, B. (2017). From data to decisions: Helping crop producers build their actionable knowledge. Critical Reviews in Plant Sciences, 36, 71–88.

Hall, D. J. M., Jones, H. R., Crabtree, W. L., & Daniels, T. L. (2010). Claying and deep ripping can increase crop yields and profits on water repellent sands with marginal fertility in southern Western Australia. Australian Journal of Soil Research, 48, 178–187.

Hochman, Z., van Rees, H., Carberry, P. S., Hunt, J. R., McCown, R. L., Gartmann, A., et al. (2009). Re-inventing model-based decision support with Australian dryland farmers. 4. Yield Prophet® helps farmers monitor and manage crops in a variable climate. Crop and Pasture Science, 60, 1057–1070.

Keating, B. A., Carberry, P. S., Hammer, G. L., Probert, M. E., Robertson, M. J., Holzworth, D., et al. (2003). An overview of APSIM, a model designed for farming systems simulation. European Journal of Agronomy, 18, 267–288.

Keogh, M., & Henry, M. (2016). The implications of digital agriculture and big data for australian agriculture (p. 68). Research Report, Sydney, Australia: Australian Farm Institute.

Kirkegaard, J. A., Hunt, J. R., McBeath, T. M., Lilley, J. M., Moore, A., Verburg, K., et al. (2014). Improving water productivity in the Australian grains industry—a nationally coordinated approach. Crop and Pasture Science, 65, 583–601.

Lawes, R. A., Oliver, Y. M., & Robertson, M. J. (2009). Integrating the effects of climate and plant available soil water holding capacity on wheat yield. Field Crops Research, 113, 297–305.

Leonard, E., Rainbow, R., Trindall, J., Baker, I., Barry, S., Darragh, L., et al. (2017). Overview—Accelerating precision agriculture to decision agriculture: Enabling digital agriculture in Australia. Narrabri: Cotton Research and Development Corporation. http://farminstitute.org.au/LiteratureRetrieve.aspx?ID=161055. Accessed March 2018.

Llewellyn, R., & Ouzman, J. (2015). Adoption of precision agriculture-related practices: status, opportunities and the role of farm advisers. https://grdc.com.au/__data/assets/pdf_file/0024/208653/adoption-of-precision-agricultural-related-practices-status-opportunities-and-the-role-of-farm-advisers-2014.pdf.pdf. Accessed March 2018.

Llewellyn, R. S., Ronning, D., Ouzman, J., Walker, S., Mayfield, A., & Clarke, M. (2016). Impact of weeds on Australian grain production: The cost of weeds to Australian grain growers and the adoption of weed management and tillage practices. Report for GRDC. CSIRO, Australia. https://grdc.com.au/__data/assets/pdf_file/0027/75843/grdc_weeds_review_r8.pdf.pdf. Accessed March 2018.

Llewellyn, R., Whitbread, A., Jones, B., & Davoren, B. (2008). The role for EM mapping in precision agriculture in the Mallee. In Unkovich, M. (Ed.) Global issues, paddock action. Proceedings of the 14th Australian Agronomy Conference. Gosford, NSW: Australian Society of Agronomy/The Regional Institute Ltd. www.regional.org.au/au/asa/2008/concurrent/managing-site-season/5915_llewellynrl.htm#TopOfPage. Accessed June 2018.

Mark, T. B., Griffin, T. W., & Whitacre, B. E. (2016). The role of wireless broadband connectivity on ‘Big Data’ and the agricultural industry in the United States and Australia. International Food and Agribusiness Management Review, 19(A), 43–56.

McBeath, T. M., Gupta, V. V. S. R., Llewellyn, R. S., Davoren, C. W., & Whitbread, A. M. (2015). Break-crop effects on wheat production across soils and seasons in a semi-arid environment. Crop and Pasture Science, 66, 566–579.

Miller, N. J., Griffin, T. W., Bergold, J., Ciampitti, I. A., & Sharda, A. (2017). Farmers’ adoption path of precision agriculture technology. In Taylor, J. A., Cammarano, D., Prashar, A. & Hamilton, A. (Eds.) Proceedings of the 11th European Conference on Precision Agriculture. Advances in Animal Biosciences: Precision Agriculture (ECPA) 2017 (Vol. 8, No. 2, pp. 708–712).

Paustian, M., & Theuvsen, L. (2017). Adoption of precision agriculture technologies by German crop farmers. Precision Agriculture, 18, 701–716.

Raun, W. R., Solie, J. B., Stone, M. L., Martin, K. L., Freeman, K. W., Mullen, R. W., et al. (2005). Optical sensor-based algorithm for crop nitrogen fertilization. Communications in Soil Science and Plant Analysis, 36, 2759–2781.

Robertson, M. J., Llewellyn, R. S., Mandel, R., Lawes, R., Bramley, R. G. V., Swift, L., et al. (2012). Adoption of variable rate technology in the Australian grains industry: status, issues and prospects. Precision Agriculture, 13, 181–199.

Rogers, E. M. (2003). Diffusion of innovations (5th ed.). New York, USA: Free Press.

SAS Institute Inc. (2013). JMP 11 basic analysis. Cary, NC, USA: SAS Institute Inc.

Schimmelpfennig, D., & Ebel, R. (2011). On the doorstep of the information age: Recent adoption of precision agriculture. Washington, DC: EIB-80, U.S. Department of Agriculture, Economic Research Service.

Sonka, S. (2014). Big data and the Ag sector: More than lots of numbers. International Food and Agribusiness Management Review, 17, 1–20.

Taylor, J. A., McBratney, A. B., & Whelan, B. M. (2007). Establishing management classes for broadacre agricultural production. Agronomy Journal, 99, 1366–1376.

Webster, T., Panitz, J., Jensen, T., & Bramley, R. (2016). Industry perspectives on precision agriculture. Proceedings of the Australian Society of Sugar Cane Technologists, 38, 29–39.

Whelan, B., & Taylor, J. (2013). Precision agriculture for grain production systems. Collingwood, VIC: CSIRO Publishing.

Whitbread, A., Llewellyn, R., Gobbett, D. L., & Davoren, B. (2008). EM38 and crop-soil simulation modelling can identify differences in potential crop performance on typical soil zones in the Mallee. In Unkovich, M. (Ed.) Global issues, paddock action. Proceedings of the 14th Australian Agronomy Conference. Gosford, NSW: Australian Society of Agronomy/The Regional Institute Ltd. www.regional.org.au/au/asa/2008/poster/agronomy-landscape/5823_whitbread.htm. Accessed June 2018.

Wilkinson, R. (2011). The many meanings of adoption. In D. Pannell, & F. Vanclay (Eds.), Changing land management: Adoption of new practices by rural landholders (pp. 39–49). Collingwood, VIC: CSIRO Publishing.

Wong, M. T. F., Asseng, S., Robertson, M. J., & Oliver, Y. (2008). Mapping subsoil acidity and shallow soil across a field with information from yield maps, geophysical sensing and the grower. Precision Agriculture, 9, 3–15.

Acknowledgments

This work was funded jointly by CSIRO and the Grains Research and Development Corporation (GRDC) and conducted as a part of the Future Farm initiative via GRDC Project No. CSP00201. The assistance of Dr. Rick Llewellyn (CSIRO), Tom McCue (formerly GRDC) and Prof. Craig Baillie (University of Southern Queensland) in the development of the survey is much appreciated, as are the comments of Dr Llewellyn and Prof. Brett Whelan (University of Sydney) on an earlier draft of this paper. Mention of trade names in this paper does not infer endorsement from CSIRO or the other parties to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bramley, R.G.V., Ouzman, J. Farmer attitudes to the use of sensors and automation in fertilizer decision-making: nitrogen fertilization in the Australian grains sector. Precision Agric 20, 157–175 (2019). https://doi.org/10.1007/s11119-018-9589-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-018-9589-y