Abstract

Forestry residues are a plentiful, low environmental impact feedstock for biofuels and bioproducts. Douglas-fir is the most prevalent tree species in the timberlands of western North America, with approximately 5 million tons of sustainably harvestable forestry residues available each year. These forestry residues are an important potential biomass feedstock containing holocellulose, lignin, protein, ash, and phytochemicals commonly identified as “extractives”. The phytochemical extractive category make up 5–25 % of the dry weight for different tissues of Douglas-fir, but are rarely represented with molecular detail in feedstock models of residues for biofuel or other bioproduct. These extractives contain both primary and secondary metabolites and represent potential revenue sources as side products from processing, but also includes species that are astringent, toxic, endocrine disruptors and/or reactive in similar chemical processes. Within the “extractives” category are phytochemicals such as proanthocyanidins, phlobaphenes, waxes, flavonoids, terpenoids, phytosterols, lignans and many more. This review first identifies phytochemical molecules found in different Douglas-fir tissues, then quantities these by category and individual molecular species, to the extent allowed by the literature. We combine the literature into a quantitative, molecularly detailed, mass conserving model for a particular Douglas-fir forestry residue (“slash”). This model is used in a sulfite/bisulfite biofuel process simulation for understanding the molecular partitioning of extractives in different process streams. Model results are used to explore some implications for extractive species in the production of sugars and waste products from Douglas-fir forestry residue feedstock.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pseudotsuga menziesii (Mirb). Franco (common name, Douglas-fir) has been investigated as a feedstock for many natural products industries due to its abundance in western North American timberland. It has received attention recently for its potential to be a large component of a forestry residue-based biofuel industry (U.S.D.A. 2001). Douglas-fir biomass is a large portion of the 75 million tons a year of waste logging residue and forest thinnings that are available for sustainable harvesting in the USA (Perlack and Stokes 2011). Using waste biomass generated in forestry activities is attractive for biofuels because it has fewer potential land-use change and food competition issues than many other biofuel feedstocks (Fargione et al. 2008; Searchinger et al. 2008). Biofuel production from forest residues has yet to hit full-scale operations, but pilot scale studies are being conducted (Zhu et al. 2015). However, the biofuel community has yet to incorporate the molecular properties of the diverse “extractive” components of biomass—phytochemicals produced as part of the biological signaling, defense, and metabolism—into their most sophisticated feedstock models and process designs (Humbird et al. 2011). An improved phytochemical description of Douglas-fir could accelerate biofuel development. The purpose of this review is to provide a quantitative molecular description of Douglas-fir suitable for advancing the development of this field.

Research in the pulp and paper industry has shown that the fraction of the forestry biomass known as “extractives” account for many of the toxic emissions during processing, can participate in undesired side reactions, or inhibit chemical rates during processing (Leach and Thakore 1976; Hoge 1954; Foo et al. 1983). At the same time, some extractives may be valuable side products for a biofuel facility (Hall 1971). Extractives have been reported to be in the range of 5–25 % by oven dry (o.d.) mass for Douglas-fir, depending on tissue type (Kaar and Brink 1991; Kurth 1953). In the prominent tissues of Douglas-fir logging slash—heartwood, sapwood, and bark—the most abundant noncarbohydrate extractives can be categorized as proanthocyanidins, phlobaphenes, flavonoids, waxes, terpenoids, phytosterols, and lignans. The identity, but often not the quantity, of many specific extractive molecules in Douglas-fir have been cataloged (http://tree-chemicals.csl.gov.uk; Turley et al. 2006). Because extractives are particularly prevalent in bark tissue of Douglas-fir, quantitative and comprehensive reviews of extractive phytochemicals were undertaken decades ago for this tissue (Laver et al. 1977). While bark is the most extractive-rich component of logging slash, several percent of the mass in sapwood and heartwood can also be comprised of extractive molecules. We estimate that roughly a third of the non-carbohydrate extractive molecules in Douglas-fir forestry residues come from tissues types that have not been subjected to comprehensive, quantitative review.

In order for the biofuel field to identify possible side products, inhibitors, and toxic compounds, an up to date and comprehensive survey of the literature is needed that includes both the known extractives and their expected concentration in biomass. In this work, we review the characterization, possible economic value, and quantification of Douglas-fir extractives, as well as discuss implications of our quantitative feedstock model for biofuel processes based on sulfite/bisulfite pretreatment.

Extractives species in Douglas-fir and possible uses

The extractives considered here are non-carbohydrates isolated by steam distillation, ether extraction, alcohol extraction, water extraction, or other techniques that do not significantly deconstruct the cell wall. More aggressive extraction techniques can extract soluble carbohydrates such as pectin, but these are likely degraded structural components and are not further considered here. The identified non-carbohydrate extractives of P. menziesii (Mirb.) Franco have been assigned here to categories of proanthocyanidins and phlobaphenes, waxes, flavonoids, terpenoids, phytosterols, lignans, and other molecules.

There are two varieties of Douglas-fir, P. menziesii (Mirb.) Franco var. menziesii and var. glauca. Analysis of the foliage, leaves, and branches of the two varieties have shown that the concentrations of individual molecular species differ substantially, but the two generally have very similar molecular species present (Rudloff 1972). Considering this and how studies often do not identify the variety they analyzed, molecules identified in either variety are presented to give a more comprehensive picture of what may be found. The chemical structures of the identified extractives are presented in Tables 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 and 12.

Proanthocyanidins and phlobaphenes

This category contains various length proanthocyanidin polymers (condensed tannins), and related co-occurring phlobaphenes. The condensed tannins identified are mostly heterogeneous procyanidins. The extender units (main body) in the bark are almost exclusively epicatechin units while the terminal units are mixed epicatechin and catechin (Foo and Karchesy 1989c). The chain lengths vary and the inner bark has been reported to have condensed tannins with an average of 7 flavonoid units, with tetramers and pentamers of epicatechin and catechin specifically identified (Foo and Karchesy 1991). Bonds between individual flavonoids units are most commonly from the C-4 carbon of one to the C-8 of another (shown in the tetramers and pentamers of Table 1), but C-4 to C-6 linkages also occur (Foo and Karchesy 1989c). Another proanthocyanidin type, prodelphinidins, have also been identified in the needles but fewer studies have been conducted on them (Kaundun et al. 1998). The phlobaphenes co-occur with the condensed tannins in tissues such as the outer bark and heartwood. They are water-insoluble phenolic substance comprised of polymeric procyanidins, dihydroquercetin, carbohydrate (glucosyl) and methoxyl moieties (Foo and Karchesy 1989d). In addition, a very similar phlobaphene substance can be obtained by treating condensed tannins (sometimes called phlobatannins) with acid.

Tannins of Douglas-fir have been extensively studied for use in industries such as leather tanning, drilling muds, ore flotation, ceramics, and cement. However, competition with South American and European tannin production has limited its use in these areas. It is commonly believed that harvesting tannins in a multi-product process could be possible, but an industry based on extracting the tannins alone is not economical (Hall 1971). The phlobaphenes have been of less economic interest than the tannins and commonly are investigated indirectly through studies that target tannins, flavonoids, and lignans. Table 1 contains the proanthocyanidins specifically identified in literature.

Waxes

Triglycerides and ferulic acid esters are the most abundant components in the Douglas-fir waxes category. Saponification of the triglycerides releases monocarboxylic acids ranging in size from palmitic acid (C 19:0) to montanic acid (C 28:0), dicarboxylic acids ranging in length from hexadecanedioic acid to tetracosanedioic acid, and alcohols ranging from 1-hexadecanol (C 16:OH) to 1-tetracosanol (C 24:OH). Corresponding alcohols that form upon hydrolysis of the ferulic acid esters are primarily behenyl alcohol and lignoceryl alcohol (Laver and Fang 1989). Further information on thin-layer chromatography and gas–liquid chromatography on the waxes of the bark was reviewed by (Laver et al. 1977). Free fatty acids have also been reported, but typically the concentration is an order of magnitude less than their ester counterparts (Pan et al. 2013; Foster et al. 1980).

Research into the waxes from Douglas-fir in the past has been spurred by interest in using them as a commercial source of natural wax. Possible applications for the wax that have been investigated in the past include polishes, ski wax, ointments, lubricants, soaps, art and sculpture work, preservatives, and many others (Hall 1971). Wax is one of the most commonly investigated extractable products from Douglas-fir, along with tannins and dihydroquercetin.

Flavonoids

Douglas-fir is known to have a variety of flavonoids and flavono-compounds, including flavanols, flavonol glycosides, O-acylated flavonol glycosides, a biflavonoid, and a flavonolignan. Studies of Douglas-fir also led to the discovery of several of these flavonoid chemistries. [5′, 5′]-Bisdihydroquercetin was discovered in Douglas-fir and was the first true biflavonoid linked by their B-rings found (Foo et al. 1992). The first flavonolignan, pseudotsuganol, was also found in Douglas-fir (Foo and Karchesy 1989a). In addition, four new novel O-acylated flavonol glycosides (daglesiosides) were recently identified in the needles of Douglas-fir from Poland (Krauze-Baranowska et al. 2013). Table 3 shows identified flavonoid moieties.

The flavonoids in Douglas-fir were first studied to determine pulping inhibitors in Douglas-fir. Dihydroquercetin (Taxifolin) is a relatively abundant flavonoid and was specifically identified as a mild pulping inhibitor, but was a small consideration compared to the difficulties associated with the lignin of Douglas-fir (Hoge 1954). Dihydroquercetin and quercetin were subsequently studied for economic uses. These chemicals are used in the food industry, however they have a limited market. In 1970, it was speculated that the world market for quercetin probably did not exceed 40,000 pounds (Hall 1971).

Terpenoids

Various sizes of terpenoids have been identified in Douglas-fir including monoterpenoids, sesquiterpenoids, diterpenoids, and triterpenes. The most abundant and well-characterized terpenoids are the monoterpenoids and diterpenoids. These components are found throughout the tree in different resins and are a large component of tall oil collected in pulping operations (Foster et al. 1980). Tables 4, 5, 6 and 7 contain the identified terpenoids.

Monoterpenoids and sesquiterpenoids are large components in the “essential oils” from needles, twigs, and branches. These components are known for their volatility and are commonly investigated in the gases above forests. Diterpenoids have been studied in the tall oil for uses such as rosin production and adhesives in asphalt. Diterpenoids have also been identified as one of the most toxic constituents of non-bleached pulp effluent streams (Peng and Roberts 2000; Ali and Sreekrishnan 2001).

Phytosterols

Both phytosterols and phytosterol esters appear in Douglas-fir. Sitosterol and Campesterol are specifically known to appear in the free state in the n-hexane extract of bark (Laver et al. 1971), while sitosterol, campesterol, sitostanol, campestanol, cycloartenol, and 24-methylenecycloartanol have been identified upon saponification of Douglas-fir wood (Fischer et al. 1981; Foster et al. 1980). The fatty acid counterparts of the sterol esters have been identified as being in the range of C13:0 through C19:0 (Laver et al. 1977).

Phytosterols are bioactive compounds and have been examined for their effects in both mammals and fish. In the pharmaceutical field, they have been studied as an effective dietary supplement to reduce cholesterols and suggested mechanisms for this are reviewed by De Smet et al. (2012). They have also been studied in pulping effluents and identified as suspected endocrine disruptors. Fish species that have been shown to be affected by high phytosterol concentrations include species such as brown trout (Lehtinen et al. 1999) and mosquitofish (Denton et al. 1985).

Lignans

Lignans, flavonolignans, and lignan glucosides have been identified in the sapwood, bark, callus resins, and knotwood of Douglas-fir. Like the phytosterols, attention has been paid to them due to their biological activity. Douglas-fir has three lignans that are enterolignan precursors, secoisolariciresinol, lariciresinol, and pinoresinol. These are being studied for their antioxidant abilities and potential to reduce the risk of certain cancers and cardiovascular diseases (Heinonen et al. 2001).

Others

Various other molecules have been identified in Douglas-fir that do not fall into these previously mentioned classes and appear in needles, buds, cones, shoots, and other developing tissues. These include primary metabolites, molecules that are intermediates in different metabolic pathways (e.g. phenylpropanoid pathway), growth hormones, and other small molecules. This includes molecular classes such as auxins, cytokinins, and many others. Representative molecules of these types reported in the literature are included in Tables 10, 11 and 12.

Extraction methods and extractive concentrations in slash tissues

Knowledge of the identity and concentrations of the extractives present in Douglas-fir is essential to understanding their implications for biofuel processing and other commercial ventures. In this section we identify how extractives in Douglas-fir have been extracted, and what is known about concentrations of extractives in the tissues of most interest for biofuels (i.e. bark, sapwood, and heartwood). Special emphasis is given to chemical components that could conceivably be extracted as side products during processing, and that are likely to represent ≥0.1 % of the biomass feedstock. Comparing differences between the varieties of Douglas-fir is complicated by the fact that many studies do not specifying which variety was studied. However, when the geographical origin of a sample is specified, we mention it as a means to speculate about the variety studied.

Proanthocyanidins and phlobaphenes

Condensed tannins have been extracted with a variety of solvent including water (Hubbard 1949), methanol (Hergert 1960), water–ether (Graham and Kurth 1949), water–acetone (Dellus et al. 1997), and water–methanol (Pan et al. 2013) solutions. Chromatography (paper, thin layer, or HPLC), NMR, MS, and wet-chemical assays often are used to characterize the smaller chain components. Larger chains are often degraded into smaller units before characterization, with common methods of doing this including reaction with phloroglucinol (Foo and Karchesy 1989c) and thiolysis (Dellus et al. 1997). Colorimetric assays have also been used to characterize total amounts of proanthocyanidins and polyphenols in tissues. The butanol–HCl assay has also been a common characterization tool, in which the proanthocyanidins are colored by iron salts after which their concentration can be measured by their optical absorbance at 550 nm (Porter et al. 1986). The Folin–Ciocalteu’s phenol reagent assay is another colorometric assay that has also been used to identify the total amount of polyphenols in the sapwood and heartwood (Dellus et al. 1997; Folin and Ciocalteu 1927). Crude phlobaphenes have been identified in the methanol extract (Foo and Karchesy 1989d), benzene extract (Kurth 1950), and acetone–water solutions (Dellus et al. 1997).

Reports for condensed tannins in Douglas-fir bark have ranged between 7.5 and 18 % of the o.d. mass, with higher tannin concentrations observed at the top of the tree than the bottom (Kurth 1953). A recent report by Pan et al. (2013) of bark from a Washington state pulp mill found a value of 13.2 % air-dry mass of tannins by extraction with dichloromethane then a methanol–water solution. In addition to tannins, phlobaphenes have been reported to be 3.2 % of outer bark weight by Foo and Karchesy (1989d) by methanol extraction, however they were unable to find phlobaphenes in the inner bark (Foo and Karchesy 1989d).

The sapwood and heartwood proanthocyanidins and phlobaphenes are present at a much lower concentration than in the bark, and have not been as thoroughly characterized. Dellus et al. (1997) extracted polyphenols in heartwood and sapwood in Douglas-fir wood from France with an acetone–water solution. They found that procyanidins (a form of condensed tannins) were 0.1 % of the dry weight. Procyanidin identification in the heartwood was much more difficult however and they instead opted to create a pseudo component called “phenolic polymer”, which they identified at 0.51 % of the dry weight. It was believed that the procyanidins oxidized with lignans and other components at the sapwood/heartwood interface to form complex phlobaphenes. While oxidation to form phlobaphenes is likely to occur, both proanthocyanidins and phlobaphenes were probably in the phenolic polymer. Indeed, Graham and Kurth (1949) did specifically identify tannin materials in heartwood (Graham and Kurth 1949). Heartwood crude tannins were found to be 0.23 % of the wood weight in the water-soluble portion of ether extracts. With these two reports, it can be surmised that both species are likely present in the heartwood (an estimate would be 0.2 and 0.4 % of the o.d. weight, respectively).

Waxes

Early work on the waxes of Douglas fir was focused on extracting two types of waxes from bark, one that was soluble in hexane or petroleum type hydrocarbons, and another that is isolated using benzene or chlorinated hydrocarbons after the hexane extraction (Kurth 1950, 1953; Laver et al. 1977). Specific solvents used include diethyl ether (Foster et al. 1980) hexane (Kurth 1950), benzene, and dichloromethane (Pan et al. 2013). Ferulic acid esters are one of the main components of the waxes and have been shown to be in the hexane extract, but not the benzene soluble wax. Glycerol (indicating triglycerides, post saponification) was specifically found by Kurth (1950) in saponified benzene extracted wax. Foster et al. (1980) studied the sapwood and heartwood using diethyl ether as a solvent and which was used to identify triglycerides and small amounts of free fatty acids.

Early work by (Kurth 1953) reported that the n-hexane soluble fraction is about 5 % of the o.d. weight of bark, while the benzene wax is about 2.5 % (Kurth 1953). These two fractions contain large amounts of ferulic acid ester and triglycerides, but also contain other components such as phytosterol esters. Laver and Fang (1989) studied the ferulic acid esters in the hexane soluble fraction of Douglas-fir bark from western Oregon and reported them to be 1.4 % of the bark (dry-weight basis). In Foster et al. (1980) diethyl ether extract of sapwood and heartwood from Colorado they found that readily saponifiable triglycerides accounted for 0.319 % of the o.d. sapwood and that free fatty acids only accounted for 0.01 % of the sapwood or heartwood mass. With these studies it is reasonable to expect that waxes are around 6, 0.3, and 0.4 % of the o.d. weight of bark, sapwood, and heartwood respectively.

Flavonoids

Flavonoids have been extracted with various polar solvents including alcohols, alcohol–benzene, acetone, hot water (Pew 1948; Hergert 1960), alcohol–water (Dellus et al. 1997; Foo and Karchesy 1991, 1989b), and ethyl acetate (Foo and Karchesy 1989a). Methanol has been a very popular solvent due to its ability to dissolve both hydrophobic flavonoids such as quercetin (Abraham and Acree 2014) and more hydrophilic flavonoids such as dihydroquercetin (Auriol et al. 2009). Flavonoids commonly show up in the same extracts as tannins and also have been found in the benzene soluble wax extract (Kurth 1950). They also are found in the Folin–Ciocalteu’s phenol reagent assay for total polyphenols.

Dellus et al. (1997) study of the sapwood and heartwood from France identified total polyphenols (e.g. proanthocyanidins and flavonoids) as 0.7 and 2.4 % of the wood dry weight (not o.d. however). The bark of Douglas-fir is known for being rich in dihydroquercetin, with some reports indicating that dihydroquercetin was 4.5–7.5 % of the o.d. bark mass (Kurth 1953). Dihydroquercetin shows up substantially in the heartwood (1.5 % dry weight reported), however a glucoside of dihydroquercetin, dihydroquercetin-3′-O-glucoside has been reported to be more abundant than the aglycone in the sapwood (0.2 and 0.04 % respectively) (Dellus et al. 1997). With this information and that from the proanthocyanidins and phlobaphenes section, reasonable estimates for flavonoids in the bark, sapwood, and heartwood would be around 6, 0.5, and 2 % of the o.d. mass, respectively.

Terpenoids

Terpenoids have been isolated through both steam distillation and solvent extraction. Steam distillation has commonly been used to identify monoterpenoids and sesquiterpenoids (Buchbauer et al. 1994; Jirovetz et al. 2000; Tesevic et al. 2009; Rudloff 1972; Sakai et al. 1967). However, it is not as reliable a technique for identifying species inside the actual tissue as solvent extraction, since steam distillation may alter certain compounds in the bark (Laver et al. 1977). Solvent extraction of Douglas-fir terpenoids has been carried out with dichloromethane (Pan et al. 2013), diethyl ether (Wagner et al. 1989; Foster et al. 1980; Conner and Foster 1981), chloroform (Zou and Cates 1995), and light petroleum (Erdtman et al. 1968).

Foster et al. (1980) studied the resin acids of Douglas-fir from Colorado and found them to be 0.2 and 0.27 % of the o.d. weight of the sapwood and heartwood respectively. Pan et al. (2013) studied the resin acids in bark of Douglas-fir and reported them to be 0.4780 % of the bark o.d. mass. Resin acids have been the focus of most of the literature due to their toxic nature, and other terpenes were of much less interest. There is a wealth of information on monoterpenoids and sesquiterpenoids in needles and young growth of Douglas-fir around the world, but their presence in the sapwood, heartwood, and bark has been studied much less. However, Erdtman et al. (1968) studied monoterpenoids, sesquiterpenoids, and diterpenoids (acidic and neutral moieties) in pocket resin of wood from Oregon. In the study, α-pinene and limonene were the most abundant monoterpenoids (both 6.7 % of the pocket resin), Longifolene was the only sesquiterpenoid identified (0.2 % of the pocket resin), levopimaric and palustric acid were the most abundant resin acids (23.8 % combined), and thunbergol was the most abundant neutral diterpenoid (11.4 %). Until more extensive studies of terpenoids in tissues relevant for logging slash are undertaken, the three mentioned studies can be used to provide an estimate of the amount of terpenoids that can be found in typical bark, sapwood, and heartwood. If resin acids are 0.27 % of the heartwood and are 54 % of the resin in the wood, than the other terpenoid compounds should correspondingly be about 0.2 % of the o.d. weight. Similar deductions with the heartwood and bark can lead to estimates of terpenoids in the bark, sapwood, and heartwood being around 0.9, 0.2, and 0.4 % of the o.d. mass (Erdtman et al. 1968; Foster et al. 1980; Pan et al. 2013).

Phytosterols

Phytosterols from Douglas-fir have been extracted with dichloromethane (Pan et al. 2013), diethyl ether (Foster et al. 1980), and n-hexane (Laver et al. 1971). Phytosterols are difficult to characterize precisely because they form esters with a variety of fatty acids. Studies commonly will saponify the phytosterols and then report on the non-ester species they find (Fischer et al. 1981; Foster et al. 1980).

Foster et al. (1980) reported that 35 % of a fraction of their diethyl ether extract was predominantly sterol esters (0.1925 % of the o.d. weight of sapwood). Sitosterol was 25 % of the phytosterols, stigmastanol 25 %, campestanol 15, and 5 % each of cycloartenol and 24-methylenecycloartanol. In a report by Fischer et al. (1981), they also reported similar yields of 1.2 kg per green tonne of wood with sitosterol at 51 % of the phytosterols, campesterol at 30 %, sitostanol (stigmastanol) at 14 %, and campestanol at 5 %. A reasonable expectation for sterols in different tissues is about 0.2–0.3 % of the o.d. weight.

Lignans

Lignans have been found in methanol–water extracts (Dellus et al. 1997), ethanol (Holmbom et al. 2008), and a method involving successive solvents of increasing polarity (Kebbi-Benkeder et al. 2014) They have been reported to be 0.022 % of the dry weight of sapwood (Dellus et al. 1997), 4.8 and 7.5 % by weight of the callus resin from Finnish Douglas-fir trees (Holmbom et al. 2008), and 9 % of the of the acetone extract of knotwood from French Douglas-fir trees (Kebbi-Benkeder et al. 2014). Of the extractives classes identified here, it is expected that this class of extractives will show up in the smallest proportions.

Estimating logging slash composition

Logging slash is comprised of branches, treetops, and other unmerchantable timber; however, the bulk of the available literature has studied extractives in the bark, sapwood, heartwood, and needles. Our estimates for Douglas-fir slash treat the slash as if it were a mixture of bark, sapwood, and heartwood (needles fall off at the field site, and stumps/roots are not collected for slash). The proportions of bark, sapwood, and heartwood to be used for the compositional slash estimate come from data on a Douglas-fir forestry residue labeled FS-03 in Leu et al. (2013). FS-03 has well characterized glucan and Klason lignin values for the overall slash as well as its bark and wood (sapwood and heartwood not distinguished). Assuming bark and wood make up the FS-03 slash, a system of two equations and two unknowns can be solved with the glucan and lignin to determine bark/wood proportions as has been done in previous reports (Zhang et al. 2012). This results in a model of approximately 76 % “wood” and 23 % bark by mass (N.B., there is a small typo or calculational error in Leu et al. (2013) that states this as 3 % bark). To link FS-03 to the detailed chemical analysis in the literature, “wood” must be further segregated into sapwood and heartwood. We use a mass balance to relate the overall wood carbohydrate data reported in Leu et al. (2013) to the individual Douglas-fir sapwood and heartwood carbohydrate data reported in (Kaar and Brink 1991). This gives an estimate of 57 % heartwood and 43 % sapwood in the FS-03 wood residues. Combining all this data, the final FS-03 residue compositional model we use is 23 % bark, 33 % sapwood, and 43 % heartwood overall. For later discussion, we will assume that the missing 1 % is extra dirt and ash or some other component that falls out of the process. For modeling analysis, we will scale chemical component values by 100/99 to achieve mass balance.

Combined estimates of molecular classes

Table 13 takes information from previous sections and accumulates estimated concentrations of extractives in common tissues in Douglas-fir, bark, sapwood, and heartwood. The slash model also presented in Table 13 is intended to provide estimates of the compositions in feedstocks of Douglas-fir tissues and logging slash, by category of extractive compound. Table 16 collates all the specific molecular details described above, by individual extractive compounds, in a self-consistent, mass conserving manner with Table 13.

Implications: molecular partitioning of extractives in biofuel process streams

The previous sections have shown that extractives are a diverse set of molecules with diverse molecular properties and make up approximately 8 % of the o.d. mass of the Douglas-fir slash feedstock. Understanding the concentration and distribution of extractive molecules is an essential step for thoroughly describing a biofuel process. To this end, we have assembled a simple ASPEN simulation that provides a rich molecular description of extractives throughout the process.

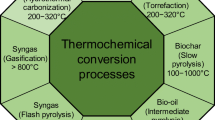

A simple process flow diagram for the simulation is presented in Fig. 1. The process output is a minimally processed (MP) sugar concentrate from Douglas-fir slash and represents the first stage of a two-stage biofuel strategy in which a saccharified and concentrated sugar product is created at one facility then transported to a separate location for large scale fermentation (Gao et al. 2013).

Process flow diagram of simulation used to create a minimally processed sugar concentrate from Douglas fir slash. Individual Aspen blocks have been grouped together in the boxes to identify the process step they are intended to simulate. R1&2 are reactors. H1&2 are heat exchanger. P1&2 are splitters, P3 is a mixer. E1 is an evaporator. The composition of the slash feedstock, spent sulfite liquor (SSL), evaporator waste, and minimally processed sugar stream are presented in Table 14

ASPEN simulations use a mass-conserving model for the slash feedstock composition (Table 14). The slash feedstock model includes representative molecules from Table 13, or a subclass of extractives (such as diterpenoids and monoterpenoids), where experimentally validated thermodynamics was available from the literature. Values for the carbohydrates, lignin, protein, and ash found in literature for bark, sapwood, and heartwood, were combined in the same proportions as the extractives to give an estimate for slash (Kaar and Brink 1991; Dziedzic and McDonald 2012; Leu et al. 2013; Robinson et al. 2003).

Figure 1 has four main sections that simulate a sugar production facility: sulfite pretreatment, collection of spent sulfite liquor (SSL) via pressing, enzymatic saccharification, and concentrating the sugar product with an evaporator. A Solid–Liquid Partitioning step is present as a dashed box in the simulation after pretreatment. This step ensures partially soluble solid extractive species are fully equilibrated with the aqueous stream prior to pressing, but it is not a physical operation at a process facility, and hence we denote it’s virtual nature with a dashed box. All process simulations used Aspen Plus V8.6. Thermodynamic property predictions used NRTL with UNIFAC unless direct comparisons to experimental data suggested the need for direct input of key thermodynamic data.

The simulated pretreatment step is intended to be representative of sulfite/bisulfite processes. Yield data from two studies are combined and applied here for estimation purposes. Conversion of holocellulose to polymeric sugars, monomeric sugars, and furans come from a report on mild bisulfite pretreatment from Gao et al. (2013) while lignin reaction to form soluble or insoluble lignin comes from a SPORL pretreatment from Leu et al. (2013).

Chemical reactions involving extractive species in sulfite processing have been identified in various studies. Table 15 contains representative reactions that are included in the simulation. The six reactions presented in Table 15 were selected to demonstrate the possible effects of pretreatment chemistry on different classes of molecules. Neither kinetic data nor individual yields are available for the conditions we are simulating here, so we simply assume 50 % reactant conversion for the purpose of tracking the flow of extractive species reactants and products through the process.

The solid–liquid partitioning and pressing stages are carried out at 25 °C and create two streams, a 40 % solids stream and a liquid spent sulfite liquor (SSL) stream. Thermodynamic data used for the solid–liquid partitioning step came from (Auriol et al. 2009; Abraham and Acree 2014; Mota et al. 2008; Peng and Roberts 2000; Mahmood-Khan and Hall 2003). Water and enzymes are then added back into the solids stream for saccharification with yield and enzyme information used from the Gao et al. (2013) study. The evaporation stage is modeled with a flash drum at 50 °C and produces the MP sugar stream, which is 30 % water (mass basis). Since the purpose of the simulation was to evaluate the partitioning of extractives into the product and waste streams, we did not do next-level simulation such as cost or energy integration and optimization, or detailed unit designs, so scale-up factors on the 100 kg/h mass basis of these calculations are linear.

Extractives partition between the SSL and MP Sugar stream roughly in the ratio of 45:55 in our simulation and only a small amount of extractives leave in the evaporator waste. Polymeric materials and flavonoids end up in all streams except the evaporator waste. Waxes are likely to remain with the solid phase unless they are sulfonated during pretreatment to form soaps. The molecules of most concern for wastewater treatment, phytosterols and diterpenoids, will predominantly remain with the solid product, but do show up in the SSL and other liquid streams. The most volatile extractives, the monoterpenoids, will be found in the emissions from the evaporator steps. Other emissions in the waste stream from the evaporators include the acetic acid, furfural and a small amount of HMF.

Optimized biofuel processes will need to understand how extractives affect each processing steps. What follows is a discussion of extractives of interest for specific biofuel processing steps and considerations for an overall biofuel facility.

Pretreatment

Extractives can undergo a variety of reaction in pretreatment and there is a need to investigate which ones predominantly occur. Dihydroquercetin and condensed tannins have been specifically studied for their reactivity in sulfite processing (Hoge 1954; Foo et al. 1983) and it can be expected that other components such as waxes will also be reactive to some extent, depending on details of the pretreatment conditions (Ekman and Holmbom 2000). Treatment by sulfuric acid further polymerizes condensed tannins while treatment by sulfite breaks them up into smaller sulfonated units (Graham and Kurth 1949; Bae et al. 1994; Foo et al. 1983). With sulfite/bisulfite biofuel treatments using chemicals such as sulfuric acid, sulfite, and bisulfite (Gao et al. 2013; Zhu et al. 2015), it is unclear which preferentially happens. In addition, pretreatment products can have very different aqueous solubilities than the starting material (e.g. dihydroquercetin glucosides vs. quercetin), affecting the feasibility of extracting them for side products after pretreatment. Dihydroquercetin and its glucosides can be expected to be 0.5–5 % of the slash feedstock mass, with this same range expected for the polymeric polyphenol and waxes categories. Soluble tannins have more economic potential then the solid phlobaphenes, but which chemistries are observed and their kinetics still need to be studied.

Saccharification

Non-cellulosic components are often lumped into a lignin, or Klason lignin, category and this category is known to bind to cellulases and obstruct the saccharification step in biofuel production (Kumar et al. 2012). Extractives may be some of the key culprits. Depending on the amount of bark in the slash and processing, saccharification can expect from 10 to 100 g of proanthocyanidins and phlobaphenes/kg o.d. dry sugars, 10–100 g/kg (o.d. dry sugars) of flavonoids, 10–100 g/kg of waxes, 1–10 g/kg of diterpenoids and monoterpenoids, and 1–10 g/kg of phytosterols. The proanthocyanidins and flavonoids are of particular interest to saccharification since some are known for their astringent properties and have been seen to hinder cellulases (Petersen and Hill 1991). Many of these compounds have significant water solubility, and could be removed through washing or pressing. However, some biofuel pretreatment techniques produce lignosulfonates that act as possible surfactants to aid saccharification and would also be lost (Wang et al. 2013). Research comparing the effects of these two competing processes is needed to determine whether washing/pressing the biomass after pretreatment is advantageous or not.

Extractives sent to fermentation

Our simulation and other literature indicate that sulfite based degradation leaves many of the extractives in the solid phase throughout processing (Sithole et al. 2010). This corresponds to large proportions of extractives following the holocellulose through the biofuel process and into the fermentation feed in our simulation. Extractives that show up in significant quantities in the feed for fermentation include waxes, proanthocyanidins and phlobaphenes, hydrophobic flavonoids, diterpenoids, and phytosterols. Diterpenoids are of particular interest because of their known toxicity (Peng and Roberts 2000) as well as dihydroquercetin for its known antifungal properties (Kennedy 1955). Our simulation estimate that the concentrated sugar product could be 1–5 % by mass proanthocyanidins, phlobaphenes and flavonoids (combined), 1–5 % waxes, 0.1–0.5 % terpenoids, and 0.1–0.5 % phytosterols, depending on specific details of the slash feedstock. If these components are found to significantly affect fermentation processes, then removing the solids through decanting becomes an attractive processing step.

Waste treatment

Extractives have been found to be some of the most toxic components of mechanically and sulfite pretreated pulp waste streams and will also likely have a similar role for biofuel waste. This toxicity is due to compounds such as the diterpenoids whose parts per million aqueous solubility are toxic for fish (Peng and Roberts 2000) and phytosterols which are possible endocrine disruptors (Denton et al. 1985). In addition, our simulation indicates that aqueous waste streams are likely to carry significant amounts of extractive molecules such as procyanidins and soluble flavonoids. Of the gas emissions, the mono-terpenoids are the only ones that appear in these streams appreciable amounts (~10:1 abundance in evaporator waste compared to MP sugar stream). These extractive compounds are well known in the pulp and paper industry however and methods for handling them can be adapted from established techniques (Mahmood-Khan and Hall 2003; Nwaneshiudu and Schwartz 2015; Sithole et al. 2010).

Conclusion

Studies on the composition of Douglas-fir have been conducted for over a century and provide a wealth of information on the phytochemical within this feedstock. There is considerable literature available for Douglas-fir extractives in general, but there are still large gaps in our knowledge such as the differences between extractives in var. menziesii or var. glauca in tissues relevant for biofuels. Also, thermodynamics parameters for many extractive molecules have yet to be determined. Optimized biofuel processes will need to understand how extractives affect each processing step. Extractives are both possible revenue sources and inhibitors at different point in chemical processing. The accumulated knowledge presented here provides a starting point for incorporating next-level details of extractive chemistry, biochemistry, and process-science in our understanding of biofuel production.

References

Abraham MH, Acree WE (2014) On the solubility of quercetin. J Mol Liq 197:157–159

Ali M, Sreekrishnan TR (2001) Aquatic toxicity from pulp and paper mill effluents: a review. Adv Environ Res 5(2):175–196

Auriol D, Nalin R, Robe P, Lefevre F (2009) Water soluble and activable phenolics derivatives with dermocosmetic and therapeutic applications and process for preparing said derivatives. US Patent 20090233876:17

Back EL (2000) The location and morphology of resin components in the wood. In: Pitch control, wood resin and deresination, TAPPI Press, Atlanta, G.A, p 135

Bae YS, Malan JCS, Karchesy JJ (1994) Sulfonation of procyanidin polymers—evidence of intramolecular rearrangement and aromatic ring substitution. Holzforschung 48(2):119–123

Buchbauer G, Jirovetz L, Wasicky M, Nikiforov A (1994) Comparative investigation of Douglas-fir headspace samples, essentail oils, and extracts (needles and twigs) using GC-FID and GC-FTIR-MS. J Agric Food Chem 42(12):2852–2854

Conner AH, Foster DO (1981) Triterpenes from Douglas fir sapwood. Phytochemistry 20(11):2543–2546

De Smet E, Mensink RP, Plat J (2012) Effects of plant sterols and stanols on intestinal cholesterol metabolism: suggested mechanisms from past to present. Mol Nutr Food Res 56(7):1058–1072

Dellus V, Mila I, Scalbert A, Menard C, Michon V, duPenhoat C (1997) Douglas-fir polyphenols and heartwood formation. Phytochemistry 45(8):1573–1578

Denton TE, Howell WM, Allison JJ, McCollum J, Marks B (1985) Masculinization of female mosquitofish by exposure to plant sterols and mycobacterium smegmatis. Bull Environ Contam Toxicol 35(5):627–632

Dziedzic JA, McDonald AG (2012) A comparative survey of proteins from recalcitrant tissues of a non-model gymnosperm, Douglas-fir. Electrophoresis 33(7):1102–1112

Ekman R, Holmbom B (2000) The chemistry of wood resin. In: Back EL, Allen LH (eds) Pitch control, wood resin and deresination. TAPPI Press, Atlanta, pp 37–76

Erdtman H, Kimland B, Norin T, Daniels PJL (1968) The constituents of the “pocket resin” from Douglas fir Pseudotsuga menziesii (Mirb.) Franco. Acta Chem Scand 22(3):938–942

Fargione J, Hill J, Tilman D, Polasky S, Hawthorne P (2008) Land clearing and the biofuel carbon debt. Science 319(5867):1235–1238

Fischer F, Koch H, Borchers B, Hontsch R, Pruzina KD (1981) Preparation and use of phytosterols from wood. Pharmazie 36(7):456–462

Folin O, Ciocalteu V (1927) On tyrosine and tryptophane determinations in proteins. J Biol Chem 73(2):627–650

Foo LY, Karchesy J (1989a) On tyrosine and tryptophane determinations in proteins. J Chem Soc Chem Commun 4:217–219

Foo LY, Karchesy JJ (1989b) Polyphenolic glycosides from Douglas-fir inner bark. Phytochemistry 28(4):1237–1240

Foo LY, Karchesy JJ (1989c) Procyanidin polymers of Douglas-fir bark—structure from degradation with phloroglucinol. Phytochemistry 28(11):3185–3190

Foo LY, Karchesy JJ (1989d) Chemical nature of phlobaphenes. In: Hemingway RW (ed) Chemistry and significance of condensed tannins. Plenum Press, New York, pp 109–118

Foo LY, Karchesy JJ (1991) Procyanidin tetramers and pentamers from Douglas-fir bark. Phytochemistry 30(2):667–670

Foo LY, McGraw GW, Hemingway RW (1983) Condensed tannins: preferential substitution at the interflavanoid bond by sulphite ion. J Chem Soc, Chem Commun 12:672–673

Foo LY, Helm R, Karchesy J (1992) 5′,5′–bisdihydroquercetin—a B-ring linked biflavonoid from Pseudotsuga Menziesii. Phytochemistry 31(4):1444–1445

Foster DO, Zinkel DF, Conner AH (1980) Tall oil percursors of Douglas fir. TAPPI 63(12):103–105

Gao J, Anderson D, Levie B (2013) Saccharification of recalcitrant biomass and integration options for lignocellulosic sugars from catchlight energy’s sugar process (CLE Sugar). Biotechnol Biofuels 6:10

Graham HM, Kurth EF (1949) Constituents of extractives from Douglas fir. Ind Eng Chem 41(2):409–414

Hall A (1971) Utilization of Douglas-fir bark. Northwest Forest and Range Experiment Station, Forest Service, US Department of Agriculture, Portland

Heinonen S, Nurmi T, Liukkonen K, Poutanen K, Wahala K, Deyama T, Nishibe S, Adlercreutz H (2001) In vitro metabolism of plant lignans: new precursors of mammalian lignans enterolactone and enterodiol. J Agr Food Chem 49(7):3178–3186

Hergert HL (1960) Chemical composition of tannins and polyphenols from conifer wood and bark. Forest Prod J 10(11):610–617

Hergert HL, Goldschmid O (1958) Biogenesis of heartwood and bark constituents. I. A new taxifolin glucoside. J Org Chem 23(5):700–704

Hoge WH (1954) the resistance of Douglas-fir to sulphite pulping. TAPPI 37(9):369–376

Holmbom T, Reunanen M, Fardim P (2008) Composition of callus resin of norway spruce, scots pine, European larch and Douglas fir. Holzforschung 62(4):417–422

Hubbard JK (1949) The distribution and properties of the tannin in Douglas fir bark (Pseudotsuga taxifolia, Britt.). Dissertation, Oregon State College

Humbird D, Davis R, Tao L, Kinchin C, Hsu D, Aden A, Schoen J, Lukas J, Olthof B, Worley M, Sexton D, Dudgeon D (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol. National Renewable Energy Laboratory, Golden, Colorado

Jirovetz L, Puschmann C, Stojanova A, Metodiev S, Buchbauer G (2000) Analysis of the essential oil volatiles of Douglas fir (Pseudotsuga menziesii) from Bulgaria. Flavour Fragr J 15(6):434–437

Kaar WE, Brink DL (1991) Summative analysis of 9 common North American woods. J Wood Chem Technol 11(4):479–494

Kaundun SS, Lebreton P, Bailly A (1998) Needle flavonoid variation in coastal Douglas-fir (Pseudotsuga menziesii var. menziesii) populations. Can J Bot 76(12):2076–2083

Kebbi-Benkeder Z, Colin F, Dumarcay S, Gerardin P (2014) Quantification and characterization of knotwood extractives of 12 european softwood and hardwood species. Ann For Sci 72(2):277–284

Kennedy RW (1955) Fungicidal toxicity of certain extraneous components of Douglas fir heartwood. Dissertation, University of British Columbia

Kong LS, Abrams SR, Owen SJ, Van Niejenhuis A, Von Aderkas P (2009) Dynamic changes in concentrations of auxin, cytokinin, aba and selected metabolites in multiple genotypes of Douglas-fir (pseudotsuga menziesii) during a growing season. Tree Physiol 29(2):183–190

Kong LS, von Aderkas P, Owen SJ, Jaquish B, Woods J, Abrams SR (2012) Effects of stem girdling on cone yield and endogenous phytohormones and metabolites in developing long shoots of Douglas-fir (pseudotsuga menziesii). New Forest 43(4):491–503

Krauze-Baranowska M, Sowinski P, Kawiak A, Sparzak B (2013) Flavonoids from Pseudotsuga menziesii. Z Naturforsch C 68(3–4):87–96

Kumar L, Arantes V, Chandra R, Saddler J (2012) The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility. Bioresour Technol 103(1):201–208

Kurth EF (1950) The composition of the wax in Douglas-fir bark. J Am Chem Soc 72(4):1685–1686

Kurth EF (1953) Chemicals from Douglas-fir bark. TAPPI 36(7):119A–122A

Laver ML, Fang HHL (1989) Ferulic acid esters from bark of Pseudotsuga menziesii. J Agric Food Chem 37(1):114–116

Laver ML, Fang HH-L, Aft H (1971) The n-hexane-soluble components of pseudotsuga menziesii bark. Phytochemistry 10:3292–3294

Laver ML, Loveland PM, Chen CH, Fang HHL, Zerrudo JV, Liu YCL (1977) Chemical constituents of Douglas-fir bark: a review of more recent literature. Wood Sci 10(2):85–92

Leach JM, Thakore AN (1976) Toxic constituents in mechanical pulping effluents. TAPPI 59(2):129–132

Lehtinen KJ, Mattsson K, Tana J, Engstrom C, Lerche O, Hemming J (1999) Effects of wood-related sterols on the reproduction, egg survival, and offspring of Brown Trout (Salmo trutta lacustris l.). Ecotox Environ Safe 42(1):40–49

Leu SY, Zhu JY, Gleisner R, Sessions J, Marrs G (2013) Robust enzymatic saccharification of a Douglas-fir forest harvest residue by SPORL. Biomass Bioenergy 59:393–401

Mahmood-Khan Z, Hall ER (2003) Occurrence and removal of plant sterols in pulp and paper mill effluents. J Environ Eng Sci 2(1):17–26

Mota FL, Queimada AJ, Pinho SP, Macedo EA (2008) Aqueous solubility of some natural phenolic compounds. Ind Eng Chem Res 47(15):5182–5189

Nwaneshiudu IC, Schwartz DT (2015) Rational design of polymer-based absorbents: application to the fermentation inhibitor furfural. Biotechnol Biofuels 8:72

Pan SB, Pu YQ, Foston M, Ragauskas AJ (2013) Compositional characterization and pyrolysis of loblolly pine and Douglas-fir bark. Bioenergy Res 6(1):24–34

Peng GM, Roberts JC (2000) Solubility and toxicity of resin acids. Water Res 34(10):2779–2785

Perlack R, Stokes B (2011) US billion-ton update: biomass supply for a bioenergy and bioproducts industry. Oakridge National Laboratory, Oak Ridge

Petersen JC, Hill NS (1991) Enzyme inhibition by Sericea Lespedeza Tannins and the use of supplements to restore activity. Crop Sci 31:827–832

Pew JC (1948) A flavonone from Douglas-fir heartwood. J Am Chem Soc 70(9):3031–3034

Porter LJ, Hrstich LN, Chan BG (1986) The conversion of procyanidins and prodelphinidins to cyanidin and delphinidin. Phytochemistry 25(1):223–230

Redemann (1971) Extracting 4-p-tolylvaleric acid from Douglas fir. US Patent 3,631,098, 28 Dec 1971

Robinson J, Keating JD, Mansfield SD, Saddler JN (2003) The fermentability of concentrated softwood-derived hemicellulose fractions with and without supplemental cellulose hydrolysates. Enzym Microb Tech 33(6):757–765

Rudloff E (1972) Chemosystematic studies in the genus Pseudotsuga. I. Leaf oil analysis of the coastal and rocky mountain varieties of the Douglas fir. Can J Bot 50(5):1025–1040

Sakai T, Maarse H, Kepner RE, Jennings WG, Longhurs WM (1967) Volatile components of Douglas fir needles. J Agric Food Chem 15(6):1070–1072

Searchinger T, Heimlich R, Houghton RA, Dong FX, Elobeid A, Fabiosa J, Tokgoz S, Hayes D, Yu T-H (2008) Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 319(5867):1238–1240

Sithole B, Shirin S, Zhang X, Lapierre L, Pimentel J, Paice M (2010) Deresination options in sulphite pulping. Bioresources 5(1):187–205

Stromvall AM, Petersson G (1992) Terpenes emitted to air from TMP and sulphite pulp mills. Holzforschung 46(2):99–102

Tesevic V, Milosavljevic S, Vajs V, Dordevic I, Sokovic M, Lavadinovic V, Novakovic M (2009) Chemical composition and antifungal activity of the essential oil of Douglas fir (Pseudosuga menziesii Mirb. Franco) from Serbia. J Serb Chem Soc 74(10):1035–1040

Turley DB, Chaudhry Q, Watkins RW, Clark JH, Deswarte FEI (2006) Chemical products from temperate forest tree species—developing strategies for exploitation. Ind Crop Prod 24(3):238–243

U.S.D.A. (2001) US forest facts and historical trends

Wagner MR, Clancy KM, Tinus RW (1989) Maturational variation in needle essential oils from Pseudotsuga menziesii, abies-concolor, and Picea engelmanii. Phytochemistry 28(3):765–770

Wang ZJ, Lan TQ, Zhu JY (2013) Lignosulfonate and elevated pH can enhance enzymatic saccharification of lignocelluloses. Biotechnol Biofuels 6:9

Zhang C, Zhu JY, Gleisner R, Sessions J (2012) Fractionation of forest residues of Douglas-fir for fermentable sugar production by sporl pretreatment. Bioenergy Res 5(4):978–988

Zhu JY, Chandra MS, Gu F, Gleisner R, Reiner R, Sessions J, Marrs G, Gao J, Anderson D (2015) Using sulfite chemistry for robust bioconversion of Douglas-fir forest residue to bioethanol at high titer and lignosulfonate: a pilot-scale evaluation. Bioresour Technol 179:390–397

Zou JP, Cates RG (1995) Foliage constituents of Douglas-fir (Pseudotsuga menziesii (mirb) franco (pinaceae)—their seasonal-variation and potential roles in Douglas-fir resistance and silviculture management. J Chem Ecol 21(4):387–402

Acknowledgments

The authors thank the financial support of the Agriculture and Food Research Initiative Competitive Grant (No. 2011-68005-30416), USDA National Institute of Food and Agriculture (NIFA) through the Northwest Advanced Renewables Alliance (NARA). The authors also want to thank Ikechukwu C. Nwaneshiudu for his help and direction when starting work on the ASPEN simulations.

Author information

Authors and Affiliations

Corresponding author

Appendix: Sapwood, heartwood, and bark detailed models

Appendix: Sapwood, heartwood, and bark detailed models

Molecularly specific compositional models for softwood, hardwood, bark, and slash were assembled and used to come up with the specific compositional estimates in Table 13. This was done by using a combination of literature data, heuristics, and mass balances to estimate the concentrations of individual molecules for extractive classes that available literature can justify to be at least 0.1 % of the forestry biomass (o.d. basis). This excludes classes such as triterpenes, lignans, and sesquiterpenes (Dellus et al. 1997; Conner and Foster 1981; Erdtman et al. 1968). These models are presented in Table 16.

The concentrations of the most commonly studied sugars are included for the different tissue types (i.e., glucan, mannan, xylan, galactan, and arabinan). Analyses of other units of hemicellulose such as, 4-O-methyl-glucuronic acid, glucuronic acid, galacturonic acid, and rhamnose have been carried out for the heartwood and sapwood (Kaar and Brink 1991) and values for these components are included; these compounds are not regularly reported in studies of the bark. Lignin values reported here come from studies that measured acid soluble and insoluble lignin (Kaar and Brink 1991; Robinson et al. 2003). Protein values have been reported for the sapwood, heartwood, and cambium (Kaar and Brink 1991; Dziedzic and McDonald 2012). The value for protein in the cambium has been used here to estimate the protein composition of the entire region we label “bark”. We used reported ash values for sapwood, heartwood and bark (Kaar and Brink 1991; Leu et al. 2013).

In many instances data for the composition of specific extractive compounds were not directly quantified in the literature for sapwood, heartwood, and/or bark. When this was the case, estimates were made based on a synthesis of the best available data. In the cases of flavonoids and phytosterols in the full model, we found data for the total amount of that extractive category in a tissue, and then estimated the individual molecular composition using mass-conserving heuristics and other molecular characterizations we found in diverse literature reports. With the diterpenes and monoterpenes, we use reported values for components that have been quantified in the sapwood and heartwood (Foster et al. 1980) and estimated other components from their known relative abundance compared to the quantified compounds.

Dellus et al. (1997) reported the total polyphenol extractives (polymeric polyphenols and flavonoids) in sapwood and heartwood as 0.7 and 2.4 % of the dry mass respectively. The authors were also able to individually identify the species responsible for 52 and 86 % of the polyphenols in each tissue type, respectively. We took the individual species identified, and had them represent the whole polyphenol category (excluding phlobaphenes though) by scaling their values up proportionally to meet the total measured polyphenol values. To account for the complex polymeric polyphenols in a manageable way in this model, we separated the polymeric polyphenols into water soluble “condensed tannins” and water insoluble “phlobaphenes”. Specific types of condensed tannins or phlobaphenes are lumped into one these categories rather than using the diverse nomenclature associated with these compounds. For example, the procyanidin measurement of the sapwood from Dellus et al. (1997) are assigned to the condensed tannin category in the full compositional model Table 16 here, and the phlobatannins from Graham and Kurth (1949) were used for condensed tannins in the heartwood (~0.2 %). The polymers of dihydroquercetin, procyanidins, and other polyphenols Dellus et al. (1997) reported in the heartwood are assumed here to be comprised of condensed tannin and phlobaphene. The phlobaphene value in the heartwood was found by taking Dellus et al. (1997)’s adjusted values for “complex polymers” and subtracting Graham and Kurth (1949)’s value for phlobatannin (condensed tannin). In the bark, condensed tannins have been reported to be in the range of 7.5–18 % (Kurth 1953) and an intermediate value of 13 % is assumed here to be similar to a recent report on bark characterization (Pan et al. 2013). Studies have been undertaken to identify more polyphenol species in the bark (Hergert 1960), but because of limited quantitative data, the only bark flavonoid value in our model is for dihydroquercetin/dihydroquercetin-glucoside [a value of 6 % assumed here (Kurth 1953)].

Fats and Waxes values come from reports interested in the wax or tall oil and mass balances when total quantities of a category were known. Ferulic acid esters have been reported to be 1.4 % of the dry weight of the bark (Laver and Fang 1989), but reported data was not found for sapwood and heartwood. Ferulic acid esters and triglycerides show up in the hexane soluble wax of the bark (5–7.5 % by dry mass (Kurth 1953), an intermediate value of 6 % assumed here) so the portion of hexane soluble wax not attributed to ferulic acid esters was used for the Triglycerides/Free Fatty Acid section of our bark model (Kurth 1953). Foster et al. (1980) reported triglycerides in the sapwood were 58 % of the neutral section of the diethyl ether extract (corresponding to 0.319 % dry weight), and this same proportion of triglycerides in the neutrals was assumed for the heartwood (0.4 %; Foster et al. 1980). The free fatty acids also reported by Foster et al. (1980) for sapwood and heartwood were added to the triglycerides for the Triglycerides/Free Fatty acid portion of the full compositional model. For further information on the constituents of fats and waxes, see (Pan et al. 2013; Laver et al. 1977; Foster et al. 1980).

Foster et al. (1980) identified values for acidic diterpenes (resin acids) in the sapwood and heartwood and Pan et al. (2013) in the bark with their values used in our model. The resin acid data was paired with a study by Erdtman et al. (1968) which reported the chemical composition of a wood resin sample to estimate the non-acidic diterpenes and monoterpenes. Values for the total phytosterols (including phytosterol esters) in the heartwood and sapwood come from Foster et al. (1980), i.e. 35 % of their “neutrals” class in the sapwood and heartwood are used as phytosterols. We assume that 50 % of these phytosterols are sterol esters before saponification. This is combined with a report from Fischer et al. (1981) which identified the individual species of sterols present after saponification. The sapwood phytosterols values are also used as estimates for those in the bark since resin components are known to be similar in the sapwood and bark (Back 2000).

To complete the mass balance, the unaccounted remainders of the compositional models are treated as soluble carbohydrates such as pectin and called “Extractable holocellulose” in Table 16.

Rights and permissions

About this article

Cite this article

Oleson, K.R., Schwartz, D.T. Extractives in Douglas-fir forestry residue and considerations for biofuel production. Phytochem Rev 15, 985–1008 (2016). https://doi.org/10.1007/s11101-015-9444-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11101-015-9444-y