Abstract

Copper oxide nano layers were prepared on glass and SiO2 amorphous substrates by chemical bath deposition (CBD) technique at different deposition times as 30, 60 and 90 min and then post annealed at 250°C for 1 h. Their crystallography, phase transitions, element analysis and nanostructures were investigated by X-ray diffraction (XRD), scanning electron microscope (SEM), energy-dispersive X- ray spectroscopy (EDAX) and atomic force microscopy (AFM) analysis. Optical reflectance was measured in the wavelength of 350–1100 nm by spectrophotometer instrument. We used Kramers–Kronig relations to investigate the relation between deposition time and optical parameters. The XRD spectra shows a mixed phases of CuO and Cu2O, but the monoclinic crystalline CuO phase is dominant. SEM images shows large particles with big fraction of voids between them for 30 min deposited film while, increasing deposition time caused to smaller particle size with round shapes. Deposited sample at 90 min has the higher absorbance because of low fraction of voids and configured complete sample. By increasing deposition time, the band gap energies decreases at first and then increases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Copper oxide-based materials have been broadly investigated owing to their potential applications in several fields. There are two common forms for copper oxide, cuprous oxide or cuprite (Cu2O) and cupric oxide or tenorite (CuO) (Rai 1988). Cupric oxide (CuO, tenorite) has a monoclinic structure with a narrow band gap in the range of 1.2–1.5 eV at room temperature with lattice parameter a = 4.6837 Å, b = 3.4226 Å, c = 5.1288 Å and β = 99.54° (Rakashani 1986), whereas cuprous oxide (Cu2O, cuprite) has a cubic (a = 4.253 Å) structure with a direct band gap of 2.0 eV (Han and Tao 2009; Hara et al. 1998). Both phases usually show p-type conductivity, but n-type conductivity was also reported (Ozer and Tephan 1993).

CuO and Cu2O thin layers have applications in photocatalyst (Parretta et al. 1996), electro chromic devices (Richardson et al. 2001), solar cells (Mittiga et al. 2006), field emissions (Zhu et al. 2005), smart windows, microwave dielectric materials (Golden et al. 1996), high Tc superconductors (Ristov et al. 1985), supercapacitors (Selvamani et al. 2020), gas sensing (Nair et al. 1999), batteries (Fu et al. 2007), and biosensors (Huang et al. 2015).

Copper oxide thin layers have been deposited using different techniques such as reactive sputtering (Dolai et al. 2017), electron beam evaporation (Baturay et al. 2019), ultrasonic spray pyrolysis, oxidation of copper sheet (Madkour” 2021), spin coating (Baturay et al. 2019), chemical bath deposition (Wang et al. 2004), thermal evaporation (Huang et al. 2004),electro deposition (Gou and Murphy 2003), microwave (Volanti et al. 2010), pulsed laser deposition (Chen et al. 2009) and molecular beam epitaxy (Kita et al. 1994).

Depending on the kind of application, all these deposition methods offer different advantages. Among these techniques, chemical bath deposition is one of the chemical techniques and essentially suitable for the solar cell production, because it is an inexpensive, simple, low-temperature technique for nanostructured growth and uniform thin films without high vacuum and have feasibility for large area deposition, mild reaction conditions and good control over deposition process (Mukherjee et al. 2020).

Ramya et al. (2015) have been used chemical bath deposition method for synthesizing CuO thin films on glass substrates by varying the solution PH. They have investigated the effect of the solution PH on structural, optical and electrical properties of films.

CBD used by Saadaldin et al. (2015) for deposition of copper oxide thin films on the glass substrates at room temperature for 20 s intervals. They have deliberated the effect of annealing on the properties of the deposited films. The film’s structure had significant improvement at different annealing temperature.

Cetinkaya et al. (2013) have been synthesed CuO interlayers in the CuO/p-Si schottky diodes by using CBD and sol–gel methods. The film that grown via CBD method was denser than the film grown by sol–gel method. They reported that crystallization with CBD method is better than sol–gel method. They have concluded that, CBD is useful and effective technique to modify the device parameters of the diode.

Xu et al. (2013) have been deposited the CuO films with different particle shapes by CBD technique. Also Xu et al. (2011) studied on nanostructured CuO thin films that have been prepared by CBD on glass substrate at 40–80°C for 1–5 h with PH value ranging from 8.5 to 10.

In the present work, copper oxide (CuxO) layers are deposited by CBD technique at different deposition time (30, 60, 90 min) and the same other deposition parameters, such as growth temperature, PH value and deposition runs. The structural and optical properties of produced thin layers were analytically investigated as a function of deposition time by different techniques like X-ray diffraction (XRD), scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDAX) and atomic force microscopy (AFM). Optical spectra are determined by spectrophotometry.

There are many different methods that have been used for calculating the optical constants of materials but there are a few reviews about nanostructured CuxO films based on Kramers–Kronig analysis for study of optical properties. Kramers–Kronig analysis is one of the most common techniques over the whole measurement range. The reflectance spectra of the deposited layers on solid surfaces, optical constants such as real and imaginary part of refractive index (n and k) can be determined (Dolai et al. 2017).

2 Experimental details

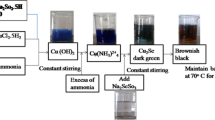

Standard 1cm × 1cm × 1 mm thick glass slides were used as substrates. All the substrates were cleaned by acetone, isopropanol and de-ionized (DI) water under ultra-sonic action bath. 25 mL of copper chloride (CuCl2) as sources of Cu2+ and NH3 as complex agent of the Cu2+ and 100 mL water distillated are mixed and prepared as same aqueous solution in several flasks. This reaction takes place during deposition:

The color of aqueous solution was black. Formed mixtures are thoroughly stirring for one minute in order to dissolve and solution to become homogeneous and aqueous solutions were appeared. The substrates were maintained vertically in these reaction flasks for 30, 60 and 90 min as deposition time. The deposited films were annealed in air at 250 °C for 1 h. Annealing is a vital way to control the phases of the deposited thin films. Both phases of CuxO could be created by varying the atmospheric condition (vacuum, air) and annealing temperature (Patwary et al. 2022).

Phase structure of the deposited CuxO layers are identified using an X-Ray Xpert MPD diffractometer (CuKα radiation, λ = 0.15406 nm) with step size of 0.03 and count time of 1s per steps. Nano structures are investigated by SEM (S-3400, Hitachi, Japan). Surface physical morphology is obtained by means of AFM (Dual Scope ™ DS, 95–200/50) instrument.

3 Result and discussion

3.1 Structural properties of CuxO nano layers

3.1.1 X-ray diffraction analysis

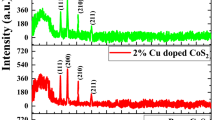

To study of the crystalline structure and phase identification of CuxO nano layers, the XRD was used with a source of CuKα with wavelength λ = 1.5406 A. The XRD patterns were measured between the range of 2ϴ = 20 to 70°.

Figure 1 shows the variation of XRD patterns at different deposition times.

The XRD spectra display good crystalline structure of CuO phase in the deposited samples. Some of the small peaks are related to both Cu2O and CuO phases. By increasing deposition time, chemical reaction of CuCl2 with H2O increases, thus the rate of CuO formation increases and leads to decrease in Cu2O and Cu phase in the XRD results. The observed CuO (111) reflection at 2ϴ = 35.49° has the highest intensity. As can be seen, the samples showed a high degree of crystallinities. Additionally, the Cu2O phase has a prominent peak at 2ϴ = 36.45° that observed at samples.

The XRD results show that the mixed phases of CuxO are appeared but the monoclinic crystalline CuO is dominant. CuO is more stable than Cu2O, and more easily prepared.

By increasing deposition time, the color of samples and their reaction solutions change from brown to black that can also be attributed to increasing the CuO phase.

In copper oxide, copper ion vacancies (or excess oxygen ions) are the main sources of acceptors, that causing to p-type conductivity (Siripala and Premasiri Kumar 1989). Table 1 shows XRD diffraction peaks for nano layers produced in this work.

3.1.2 Energy dispersive X-ray spectroscopy

The element analyses of produced layers were investigated by EDAX that is shown in Fig. 2. The copper and oxygen peaks were observed in the spectrum with the small peak of chloride and Si.

The Cu/O ratio decreases with increasing deposition time. The deposited layer at 90 min has a more oxygen-rich composition. Increasing in the deposition time can be leading to increasing oxygen content in the layer.

3.1.3 Scanning electron microscopy analysis

Figure 3 show scanning electron microscopy images of copper oxide thin layers produced by CBD method at different deposition times in this work. SEM images are completely in agreement with XRD diffraction and different nanostructure shapes are because of different chemical deposition times also because of both CuO and Cu2O phase in samples. As it can be seen from Fig. 3a, layer seems to consist of large particles along with big fraction of voids between them. By increasing deposition time to 60 min, the particle size was reduced and the shape was changed to more rounds. It is because of convenient time for chemical reactions in aqueous solution. Both nucleation and growth process happens. Grains are semi amorphous that is in exact agreement with XRD results (Fig. 1b).

The layer deposited at 90 min covered by tiny and a similarly particles. This sample is more compact than other samples. Nucleation, growth and coalescence process happens and fraction of voids very decreased (Fig. 3c).

3.1.4 Atomic force microscopy analysis

Figure 4 shows atomic force microscopy of copper oxide thin layers produced by CBD method at different deposition times. As it can be seen, deposition time has strong influence on the CuxO thin film morphologies.

In the 30 min deposition time, the non-uniform grains with a voids between them occurrence on the surface of thin film. In Fig. 4b, the morphology is changed and tiny compact grains are appeared on the surfaces of the film. The film has dense structure. By increasing the deposition time to 90 min, the film surface is full of grains along with lower void between them. The film has grainy structure with separate grains on the surface.

3.2 Optical properties

We were used to the Kramers–Kronig relations to calculate the phase angle \(\theta (E)\) that have explained in our earlier works (Kangarlou et al. 2015; Mohammadzadeh Bazarchi et al. 2020; Esmaili and Asgary 2021; Entezar Mehdi et al. 2018; Nasiri Sarvi et al. 2020; Kangarlou and Asgary 2022), extensively.

where E indicates the photon energy, E2 is the asymptotic limitation of the free-electron energy, and R(E) is the reflectance. Therefore, the ϴ(E) can be calculated. After that, the real and imaginary parts of the refractive index were obtained.

Figure 5a, b show the transmittance and reflectance curves of CuxO layers produced in this work. As it can be seen in Fig. 5a, b, the increase in deposition time affects the transmittance spectra. With increasing deposition time, transmittance decreased. This is maybe due to the formation of the voids on the layer. It can be seen that transmittance curves begin from minimum and basically end to a maximum. The effect of voids on the optical properties of the deposited thin films at different deposition time, were investigated by the Bruggman effective-media approximation (Cardoso et al. 2001) and its version developed by Ghodsi et al. (2007).

Rajesh Kumar et al. (2017) reported, increase in the optical transmittance of nanostructured Cu2O thin films at different substrate temperatures owing to improvement of structural homogeneity and film’s crystallanity.

Aswad et al. (2021) calculated optical constants for CuO thin films deposited by CBD method.

In their results, all optical constants decrease at the visible region with increasing wavelength and increase with increasing deposition time, except for transmittance. It increases with increasing wavelength and decrease with increasing deposition time.

When light interacts with a material, two important values are describing the optical properties. They are usually characterized as a complex numbers and involve of the index refraction (n) and extinction coefficient (k).

Figures 6a, b display the real part of refractive index (n) and the extinction coefficient for produced thin films, respectively. Extinction coefficient defines how fast light disappears in the medium and is correlated to absorption coefficient (α). By increasing deposition time, n values increased.

Figure 7a illustrations the real part of dielectric constant (ε1). The real part of dielectric constant of deposited films increases with increasing growth time. Two structural peaks are seen at 1.9 and 2.35 eV energies for all layers. The real parts of dielectric constants for 60 and 90 min samples have almost the same trend.

Figure 7b shows the imaginary parts of dielectric constants for deposited thin films. In contract with extinction coefficient curves, the 90 min sample has the highest imaginary part of dielectric constant because of lower fraction of voids and higher fraction of grains.

The absorption spectrum of CuO thin films deposited in different growth time is shown in Fig. 8. The experimental absorption coefficient is calculated by following equation:

where c and k(E) are the velocity of light and the imaginary part of refractive index, respectively.

There is a clear difference between the absorption curves of the thin films especially for 90 min deposited sample. The absorption properties were greatly related to the film’s surface morphology (Akimov et al. 2009). By increasing growth time, the voids form on the surface layer decreased that tends to lower transmittance and higher absorbance, so absorption coefficient increases.

Figure 9 shows calculations of the optical band gap energy (Eg) for deposited layers, which has been obtained by Gou and Murphy (2003):

where hν is photon energy.

As it can be seen, maximum and minimum band gaps are related to 60 and 90 min, respectively. Optical band gap does not linearly increase with increasing deposition time. By increasing deposition time, the band gap energies decrease at first and then increase, which means valance band shifts near the Fermi level and more conducting films, produces. Values of band gap energies are shown in Table 2.

Saadaldin et al. (2015) were prepared copper oxide thin films by CBD technique on glass substrates. Their optical studies showed that the prohibited rang is changed between (1.3–2.4) ev according to annealing temperature.

Sultana et al. reported the direct band gap values of CuO films which are achieved to be 1.87, 1.56, 2 and 2.46 eV for the samples grown at different deposition time (5, 10,15 and 25 min, respectively) (Sultana et al. 2016).

According to Alsultany et al. study, the band gap energy values increased from 2.10 to 2.28 eV for Cu2O thin film at different growth temperature (Sadiq et al. 2022).

The difference in optical band gap values generally related to the difference in deposition methods and process parameters maintained during the film’s growth time. Also, chemical and the physical properties of oxide films are significantly related to the structures and morphology of the deposited samples (Wang et al. 2011).

4 Conclusions

In this study, we report on the preparation of nanostructured CuxO thin films by chemical bath deposition which is a low cost method. Copper oxide thin layers were characterized by compositional, structural, morphological and optical analyses are measured. The XRD measurement shows the crystalline structure for the samples with CuO dominant phase for copper oxide. EDAX result displays that the Cu/O ratio is decreased by increasing deposition time. Nano structures of copper oxide layers were investigated by SEM analysis. SEM images shows high fraction of voids between the particles for 30 min deposited film while, increasing deposition time caused to smaller particle size with round shapes. The optical properties of the produced layers were calculated based on Kramers–Kronig relations on reflectance curves in visible light wavelength range. Because of lower fraction of voids on the layers with increasing deposition time, transmittance decreased. The real part of dielectric constant has increased for the deposited layers at higher deposition time. Also, increasing deposition time leads to increasing absorption coefficient, which indicates a decrease in the volume fraction of holes in these layers. By increasing deposition time, the band gap energies decreases at first and then increases. The obtained results have significance for optoelectronic applications. Both of the CuxO (CuO and Cu2O) thin films show promising qualities and deserve equal investigation to understand which could be the future of solar cells. A future study could include finding which n-type semiconductors work best in conjunction with copper oxides in order to create the lowest possible band gap within the proper range for solar cell use.

Data availability

We use no code for this manuscript. The datasets analyzed during the current study are reported in the manuscript main body.

References

Akimov, Y.A., Ostrikov, K., Li, E.P.: Surface plasmon enhancement of optical absorption in thin-film silicon solar cells. Plasmonics 4, 107–113 (2009)

Aswad, T.A., Abbas, T.A., Ali, G.G.: Effect of deposition time on optical properties of CuO thin film prepared by chemical bath deposition method. Dig. J. Nanomater. Biostruct. 16(3), 831–838 (2021)

Baturay, S., Tombak, A., Batibay, D., Ocak, Y.S.: n-Type conductivity of CuO thin films by metal doping. Appl. Surf. Sci. 477, 91–95 (2019). https://doi.org/10.1016/j.apsusc.2017.12.004

Cardoso, J., GomezDaza, O., Ixtlilco, L., Nair, M.T.S., Nair, P.K.: Conductive copper sulfide thin films on polyimide foils. Semicond. Sci. Technol. 16, 123 (2001)

Cetinkaya, S., Cetinkara, A. H. , Bayansal, F., Kahraman, S.: Growth and characterization of CuO nanostructures on Si for the fabrication of CuO/p-Si Schottky diodes. Sci. World J. Volume, 2013, Article ID126982.https://doi.org/10.1155/2013/126982

Chen, A., Long, H., Li, X., Li, Y., Yang, G., Lu, P.: Controlled growth and characteristics of single-phase Cu2O and CuO films by pulsed laser deposition. Vacuum 83, 927–930 (2009)

Dolai, S., Dey, R., Das, S., Hussain, S., Bhar, R., Pal, A.K.: Cupric oxide (CuO) thin films prepared by reactive D.C. magnetron sputtering technique for photovoltaic application. J. Alloy. Compd. 724, 456–464 (2017). https://doi.org/10.1016/j.jallcom.2017.07.061

Entezar Mehdi, H., Esmaili, P., Nasiri Sarvi, M., Asgary, S.: Effect of sputtering pressure on structural and optical properties of silver oxide thin films; Kramers-Kronig method. J. Opt. Quantum Electron. 50, 344 (2018)

Esmaili, P., Asgary, S.: Thin films; structural and optical characterization. Russ. J. Inorg. Chem. 66, 621–628 (2021)

Fu, L.J., Gao, J., Zhang, T., Cao, Q., Yang, L.C., Wu, Y.P., Holze, R.: Effect of Cu2O coating on graphite as anode material of lithium ion battery in PC-based electrolyte. J. Power Sources 171, 904–907 (2007)

Ghodsi, F.E., Tepehan, F.Z., Tepehan, G.G.: Influence of pH on the optical and structural properties of spin coated CeO2–TiO2 thin films prepared by sol–gel process. Surf. Sci. 601, 4497 (2007)

Golden, T.D., Shumsky, M.G., Zhou, Y., VanderWerf, R.A., Van Leeuwen, R.A., Switzer, J.A.: Electrochemical deposition of copper (I) oxide films. Chem. Mater. 8(10), 2499 (1996). https://doi.org/10.1021/cm9602095

Gou, L., Murphy, C.J.: Solution-phase synthesis of Cu2O nanocubes. Nano Lett. 3, 231–234 (2003). https://doi.org/10.1021/nl0258776

Han, K., Tao, M.: Electrochemically deposited p–n homojunction cuprous oxide solar cells. Solar Energy Mat. Solar Cells 93(1), 153–157 (2009). https://doi.org/10.1016/j.solmat.2008.09.023

Hara, M., Kondo, T., Komoda, M., Ikeda, S., Shinohara, K., Tanaka, A., Kondo, J.N., Domen, K.: Cu2O as a photocatalyst for overall water splitting under visible light irradiation. Chem. Commun. (1998). https://doi.org/10.1039/a707440i

Huang, L.S., Yang, S.G., Li, T., Yu, B.X., Du, Y.W., Lu, Y.N., Shi, S.Z.: J. Cryst. Growth 260, 130–135 (2004). https://doi.org/10.1016/j.jcrysgro.2003.08.012

Huang, Q., Lin, X., Lin, C., Zhang, Y., Hu, S., Wei, C.: A high performance electrochemical biosensor based on Cu2O carbon dots for selective and sensitive determination of dopamine in human serum. RSC Adv. 5, 54102–54108 (2015). https://doi.org/10.1039/C5RA05433H

Kangarlou, H., Asgary, S.: Investigation of structural and optical properties of deposited mercury sulfide thin layers as function of growth time. Phil. Mag. 102, 1739–1754 (2022)

Kangarlou, H., MotallebiAghgonbad, M., Abdollahi, A.: Investigations about the effect of annealing temperatures in the presence of oxygen flow on optical and electronic properties of titanium nano-layers by using Kramers-Kronig and DFT methods. Mater. Sci. Semiconductor Process. 30, 1–8 (2015)

Kita, R., Kawaguchi, K., Hase, T., Koga, T., Itti, R., Morishita, T.: J. Mater. Res. 9, 1280 (1994). https://doi.org/10.1557/JMR.1994.1280

Lu, C., Qi, L., Yang, J., Wang, X., Zhang, D., Xie, J., Ma, J.: One-pot synthesis of octahedral Cu2O nanocages via a catalytic solution route. Adv. Mater. 17, 2562–2567 (2005)

Madkour, M.: CuxO thin films via ultrasonic spray pyrolysis as efficient solar photocatalysts: Single source polymeric coordinated precursor. Colloid Interface Sci. Commun. 44, 100497 (2021). https://doi.org/10.1016/j.colcom.2021.100497

Mittiga, A., Salza, E., Sarto, F., Tucci, M., Vasanthi, R.: Heterojunction solar cell with 2% efficiency based on Cu2OCu2O substrate. Appl. Phys. Lett. 88, 163502 (2006). https://doi.org/10.1063/1.2194315

Mohammadzadeh Bazarchi, S., Esmaili, P., Asgary, S.: Characterization of silver doped In2S3 films. Eur. Phys. J. Appl. Phys. 92, 30301 (2020)

Mukherjee, A., Das, M.R., Banerjee, A., et al.: Influence of nickel incorporation in CdS: structural and electrical studies. Thin Solid Films 704, 138005 (2020)

Nair, M.T.S., Guerrero, L., Arenas, O.L., Nair, P.K.: Chemically deposited copper oxide thin films: structural, optical and electrical characteristics. Appl. Surf. Sci. 150(1–4), 143–151 (1999). https://doi.org/10.1016/S0169-4332(99)00239-1

NasiriSarvi, M., Esmaili, P., Asgary, S.: Effect of annealing on structural and optical properties of indium sulfide thin layers produced by chemical bath deposition method. Indian J. Phys. 94, 1545 (2020)

Ozer, N., Tephan, F.: Structure and optical properties of electrochromic copper oxide films prepared by reactive and conventional evaporation techniques. Sol. Energy Mater. Sol. Cells 30(1), 13 (1993). https://doi.org/10.1016/0927-0248(93)90027-z

Parretta, A., Jayaraj, M.K., Di Nocera, A., Loreti, S., Quercia, L., Agati, A.: Electrical and optical properties of copper oxide films prepared by reactive RF magnetron sputtering. Phys. Stat. Sol. (a) 155(2), 399–404 (1996). https://doi.org/10.1002/pssa.2211550213

Patwary, M.A.M., Hossain, M.A., Ghos, B.C., Chakrabarty, J., Haque, S.R., Rupa, S.A., Uddin, J., Tanaka, T.: Copper oxide nanostructured thin films processed by SILAR for optoelectronic applications. RSC Adv. 12, 32853 (2022)

Rai, B.P.: Cu2O solar cells: a review. Solar Cells 25(3), 265–272 (1988). https://doi.org/10.1016/0379-6787(88)90065-8

RajeshKumar, B., Hymavathi, B., SubbaRao, T.: Structural and optical properties of nanostructured Cu2O thin films for optoelectronic devices. Mater. Today: Proc. 4(2), 3903–3910 (2017). https://doi.org/10.1016/j.matpr.2017.02.289

Rakashani, A.E.: Preparation, characteristics and photovoltaic properties of cuprous oxide—a review. Solid State Electron. 29(1), 7–17 (1986). https://doi.org/10.1016/0038-1101(86)90191-7

Ramya, K. Neyvasagam, R. Chandramohan, S. Valanarasu A. Milton Franklin Benial, J. Mater. Sci. Mater Electron., 26 (2015) 8489.

Richardson, T.J., Slack, J.L., Rubin, M.D.: Electrochromism in copper oxide thin films. Electrochim. Acta 46(13), 2281–2284 (2001). https://doi.org/10.1016/S0013-4686(01)00397-8

Ristov, M., Sinadinovski, G.I., Grozdanov, I.: Chemical deposition of Cu2O thin films. Thin Solid Layers 123(1), 63–68 (1985). https://doi.org/10.1016/0040-6090(85)90041-0

Saadaldin, N., Alsloum, M.N., Hussain, N.: Energy Procedia 74, 1459–1465 (2015)

Sadiq, Z.M., Hassan, M.A., Hassoon, K.I.: Rod-like nano-structures of copper oxide prepared by chemical bath deposition. Eng. Technol. J. 40(04), 573–581 (2022)

Selvamani, P.S., Vijaya, J.J., Kennedy, L.J., Saravanakumar, B., Bououdina, M.: High-performance supercapacitor based on Cu2O/MoS2/rGO nanocomposite. Mater. Lett. 275, 128095 (2020). https://doi.org/10.1016/j.matlet.2020.128095

Siripala, W., PremasiriKumar, K.: A photo electro- chemical investigation of the n- and p-type semiconducting behaviour of copper (I) oxide films. Semicond. Sci. Technol. 4(6), 465 (1989). https://doi.org/10.1088/0268-1242/4/6/007

Sultana, J., Paul, S., Karmakar, A., Yi, R., Dalapati, G.K., Chattopadhyay, S.: Chemical bath deposited (CBD) CuO thin films on n-silicon substrate for electronic and optical applications: Impact of growth time. Appl. Surf. Sci. 418, 1–8 (2016)

Volanti, D.P., Orlandi, M., Andres, J., Longo, E.: Cryst Eng. Comm. 12, 1696–1699 (2010)

Wang, Z., Chen, X., Liu, J., Mo, M., Yang, L., Qian, Y.: Room temperature synthesis of Cu2O nanocubes and nanoboxes. Solid State Comm. 130(9), 585–589 (2004). https://doi.org/10.1016/j.ssc.2004.03.028

Wang, S.B., Hsiao, C.H., Chang, S.J., Lam, K.T., Wen, K.H., Hung, S.C., Huang, B.R.: A CuO nanowire infrared photodetector. Sens. Actuators A 171, 207–211 (2011)

Xu, L., Xu, H.Y., Wu, S.B., Wang, X.D., Cao, T., Zhu, S.F., Li, Y.: Preparation of CuO Thin Film with Corncob-Like Morphology via Chemical Solution Processing. Asian J. Chem. 23(5), 2295–2298 (2011)

Xu, H.Y., Chen, C., Xu, L., Dong, J.K.: Direct growth and control of Cu2O film via one-step chemical bath deposition. Thin Solid Films 527, 76–80 (2013)

Zhu, Y.W., Yu, T., Cheong, F.C., Xu, X.J., Lim, C.T., Tan, V.B.C.: Large-scale synthesis and field emission properties of vertically oriented CuO nanowire films. Nanotechnology 16, 88–92 (2005)

Acknowledgements

The authors thanks from university laboratory.

Funding

There is no founding.

Author information

Authors and Affiliations

Contributions

All authors reviewed the manuscript. All authors contributed equally to this article.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Ethical approval

No human or animal tissue tests have been used in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kangarlou, H., Asgary, S. & Esmaili, P. Structural and optoelectronic properties of CuxO nano layers based on Kramers–Kronig relations. Opt Quant Electron 55, 1046 (2023). https://doi.org/10.1007/s11082-023-05289-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-023-05289-4