Abstract

High-quality polymeric composite films containing Congo red dye and PVA were prepared using the casting technique. The proposed Cr-doped PVA composites were examined using XRD, UV–visible optical, dielectric, and optical limiting effect techniques. The XRD patterns of CR-doped PVA composite films display diffraction peaks belonging to CR organic dye. There was a broadening and reduction of the initial peak intensity in polymer composite films at higher doping concentrations. The band edge of CR: PVA composites reduced with a massive shift from 4.63 to 1.86 eV, where Congo red controls the energy bandgap of the PVA polymer. Dielectric permittivity diminishes with increasing the frequency and achieves constant values at higher frequencies through the relation between the electric dipole and the electric field differences. Increasing the percentage ratio of the CR doping enhances the electrical conductivity and dielectric permittivities due to the large size of the CR molecules. The solid optical limiting of the CR-doped PVA composites is determined using different laser sources of 632.8 and 532 nm wavelengths. The excellent obtained results imply that CR: PVA composite films are very significant for applying large-scale CUT-OFF laser filters for medical optical and electronic device systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Optical filters are devices transmitting or blocking specific wavelengths of incident light. Synthetic glass or plastic materials dyed in bulk or coated interference films can control the transmitted or blocked light (Madsen and Zhao 1999). The optical properties of the filters were adequately designed to adjust the spectral response of the input electromagnetic signal to the filter (Zou et al. 2016). Filters can generally be divided into two categories: absorbent filters and dichroic (interference filters) (Epstein 1952). The vision of the filter is based on the absorption of specific wavelengths of the incident light and the transfer of the remaining residues (Wyszecki and Stiles 1982). The optical filters are divided into two categories: low pass filters (SP) and long-range (LP) (Macleod and Macleod 2010). As of late optical glass has been replaced with optical polymer since it is cheap, light, and easy to manufacture, for example, polyvinyl alcohol (PVA), polymethylmethacrylate (PMMA), and polycarbonate (PC) (Sultanova et al. 2009; El-Bashir et al. 2017).

Polyvinyl alcohol (PVA) is one of the most widely detectable polymers and recently has gained significant interest from polymeric researchers due to its exceptional properties. PVA polymer with a semi-crystallinity structure has distinctive features such as high mechanical strength, chemical stability, water solubility, and outstanding transparency because it contains significant hydroxyl group numbers (Konieczkowska et al. 2015). It also has a low conductivity limit and a lower refractive index. PVA has been applied in several technical applications due to its advantages of low cost, non-toxicity, biocompatibility, high durability, and chemical stability (Yang et al. 2002; Friedrich et al. 2005; Hebbar et al. 2016). PVA polymeric films have been considered exceptional candidates in various fields, such as pharmaceutical, medical, and electrochemical membranes and optoelectronic applications (MirelaTeodorescu and SimonaMorariu 2019; Sedlarik et al. 2006). The intensive study has been paid to the large volume of polymer growth with the PVA compound, which is considered a host polymeric matrix doped with diverse dyes (Zidan et al. 2016; Dittmer et al. 2000; Kawai and Hu 2009; Kokabi et al. 2007).

Congo red dye (CR) is an organic compound (azo dye) that is water-soluble and yields a red colloidal solution, where its solubility is more excellent in organic solvents. CR dye is more commonly used in histology, biochemistry, paper printing, and textile dyeing. CR-doped polymeric composites were examined as optical amplifiers, optical storage media, solid-state lasers, and optical waveguides (Yahia and Keshk 2017; Singh et al. 2003). The suggested procedures show that the aromatic rings of the dye molecules have hydrophobic interactions leading to the pi-pi stacking phenomenon. In literature, the PVA polymeric films doping with the dye materials have been reported to enhance the optical fields. The xanthene dye has improved the optical properties of polymers as dopants by Nadia Ali Abed1 and Asrar Abdulmunem Saeed (2019). Furthermore, CR: PVA composites have powerful optical limiting effects, as concluded by Geetha et al. (2002), Qi et al. (2007). Chung, W. H. has investigated PVA-doped CR polymeric films for electrons and gamma rays shielding (Chung 1994). Also, the optical nonlinearities of PVA polymers have been improved through doping with CR dyes for optic and photonic applications, as reported by Qi et al. (2004). The CR-doped PVA composite films can absorb wavelengths of less than 600 nm that are more effective than the elevated wavelengths (Chung 1994; Qi et al. 2004; Peng et al. 2014).

In this current research, PVA doping with different concentrations of Congo red dye composite films was prepared for optoelectronic applications using a simple casting method. X-ray diffraction (XRD), optical, dielectric studies, and optical limiting effects were used to support the advantages of CR-doped PVA composites for large-scale laser CUT- OFF filters. All the required parameters were calculated and discussed in detail to determine the properties for the applications in the optical laser’s limiters.

2 Experimental techniques

2.1 Synthesis of CR: PVA polymeric composite films

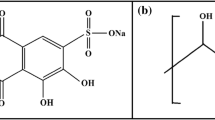

PVA and Congo red (CR; C.I. 22,120) were provided by LOBA Chemicals (India) and Sigma-Aldrich (St Louis, MO). The chemical structure of the Congo red dye is presented in Fig. 1. A solution casting method was developed to prepare CR-doped PVA composite films at various concentrations of Congo red. In 1 L of distilled water, nearly 22.5 g of PVA was dissolved for 24 h with a magnetic stirrer at a temperature of 50 °C. Different contents of CR dye, from 0.11 to 27.27 wt%, were doped with PVA polymeric films. All CR: PVA nanostructured samples were operated at room temperature using a magnetic stirrer at 700 rpm. The CR-doped PVA composites were solubilized in 30 ml distilled water (DI) and then dehydrated at 35 °C for five days. After that, the proposed CR: PVA composite films were removed and cut into suitable dimensions for further structural and optical investigations.

2.2 Devices and measurements

Shimadzu Lab XRD-6000 diffractometer with CuKα (= 1.5406 Å) radiation at 30 kV voltage, 30 mA of the current was used to measure the X-ray diffraction pattern. A double beam spectrophotometer of wavelength 190–2500 nm (JASCO, model V–570 UV–vis–NIR) at room temperature was applied for the optical characterizations of the examined CR: PVA composites. The CR-doped PVA composites' electrical conductivity and dielectric properties were performed using a programmable automatic LCR meter (Model FLUKE-PM6306). The impedance Z, capacitance C, and loss tangent (\(tan\delta\)) were determined at room temperature over a broad frequency area scale from 100 Hz to 1 MHz.

The optical limiting effects were investigated using two sources of laser beam: He–Ne with 632.8 nm and diode laser with 532 nm wavelengths, to get the normalized power of the CR: PVA composites. The 10 cm focal lens was mounted on an optical base, where the CR: PVA sample holder was detached at the lens focus. An optical measuring instrument was linked to the photodetector (Newport 1916-R) to estimate the input/output powers.

3 Results and discussion

3.1 Structural analysis of CR: PVA polymeric composite films

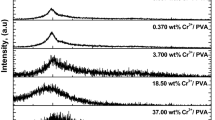

XRD histograms of CR: PVA composite films are exhibited in Fig. 2. The XRD diffraction patterns of pure CR dye exhibited firm diffraction peaks at 2Ɵ = 27.25°, 32.18°, 37.84°, 44.91°, and 45.33° that were matching to (101), (111), (117), (124), and (134) planes, respectively (Mansour et al. 2010; Yahia et al. 2012). The XRD pattern of pure PVA polymer reveals the semi-crystalline character with a peak at 2θ = 19.32° (Yahia et al. 2019; Yahia and Mohammed 2018), which results from the hydrogen bonding between PVA chains and leads to partial polymer chain ordering. Besides, intramolecular and intermolecular hydrogen bonds are generated between the PVA matrix and CR dye. These hydrogen bonds were obtained between the external site of CR dye (amino groups or sulfonate groups) or will be in the inner CR site (the azo group) with the OH group in the PVA chain (Papancea et al. 2010; Carrasco-Correa et al. 2011). The obtained diffraction peak for pure PVA nanostructure was well-matched with the PVA published XRD bands of sodium iodide-doped poly (vinyl alcohol) polymer by Balaji Bhargav et al. (2007).

No diffraction peaks in CR-doped PVA composite films have belonged to Congo red at lower dye contents, but the central peak of the PVA polymer has been broadened. This relates to CR dye being dispersed and well absorbed within the PVA structure. Suppose the solution casting method is employed to prepare CR: PVA composite membranes. In that case, the dopant can react with the polymer through weak bonds or distribute as an isolated phase by creating a weak bond through the functional PVA polymer group (hydroxyl group) (Sreeja et al. 2013). Thus, if the CR dye molecules were inserted into the PVA matrix, they can be restricted or distributed within free volumes, such as interstitial sites or voids between the PVA matrix chains. At the higher dye concentration, more crystalline peaks appeared that belonged to the CR dye, and the degree of crystallinity was reduced due to the increased PVA chain disorder (Hebbar et al. 2016). R.M. Hodge et al. identified a linear dependency between the PVA crystallinity level and the intensity of the diffraction peaks. The increase in the amorphous structure indicated a decrease in intensity (Hodge et al. 1996).

3.2 Optical analysis of CR: PVA polymeric composite films

Optical transmittance spectra for CR-doped PVA composite films are represented in Fig. 3a, b. High transmission of over 91% is noticed for pure PVA due to the lack of a free electron. In CR: PVA composite films containing 1.11 wt% of CR dye or less, there are two broad absorption bands at 290 nm and 410 nm, distinguishing CR dye molecules and referring to the interaction between dye molecules and PVA polymer (Yahia and Keshk 2017). As seen in Fig. 3, all prepared CR: PVA thin films have high transmittance after 566 nm wavelength. As the dye content increased in the studied Cr: PVA composites, transmittance values reduced in the wavelength range (190–585 nm) due to more excellent CR absorption. If the concentration of CR dye in the proposed composites is greater than 1.11 wt% in the region from 190 to 585 nm, the incident light is completely blocked, and the transmittance reaches zero (T = 0). These CR: PVA composites can be used as laser CUT-OFF filters (laser blocking filters) and multiple optoelectronic applications (Sheng et al. 2003; Ireland 1999; Costela et al. 2009). They are taking advantage of the attained linear optical results; F.A. Mustafa stated that the material transmission decreased as the doping concentrations increased in the region of short wavelengths (Mustafa 2013), which excellently agreed with the recorded data in this current study CR dye-doped PVA films.

Figure 4 depicts the absorbance spectra for CR dye-doped PVA composite films, where the absorption of pure PVA is less than CR: PVA composites. For composites containing (0.11 wt%, 0.85 wt%, and 1.1 wt%) CR dye, Congo red's characteristic absorption peaks were distinguished due to several electronic transitions within the Cr: PVA composite polymeric films. The first characteristic absorption peak was located at around 290 nm and can be attributed to the n-π* transition of the benzene ring in the CR molecule. The second peak, which was about 410 nm, was due to the transition of n-π* to the chromophore –N=N– along the axis of the CR molecule (Du and Liang 2000). As a result, the absorption intensity increases at higher concentrations (5.5 wt%, 11.11 wt%, and 27.27 wt%) of CR dye in the proposed composites. Also, the absorption peaks disappeared in the region between 190 and 585 nm due to an increase in the number of molecules (or complexes) absorbed, increasing the interaction between the CR dye molecules in the PVA matrix.

The variation in the PVA bandgap was estimated when using CR dye to study their interaction. The optical energy bandgaps (Eg) for CR: PVA composite films were acquired according to Mott and Devi's equation (Mott and Davis 1979).

where B is a constant, \(\upalpha (\upupsilon )\) is the absorption coefficient that is calculated from Beer’s law \(= 2.303\frac{{{\text{Abs}}}}{{\text{d}}}\), Abs and d are the absorbances and the thickness of the examined film, and r is an exponent that takes the values of 1/2 and 2, relying on the kind of electronic transitions for allowed indirect and direct transition. Figure 5a, b depicts the relation between \(\left( {\upalpha {\text{h}}\upupsilon } \right)^{1/2}\) and \(\left( {\upalpha {\text{h}}\upupsilon } \right)^{2}\) with photon energy \(\left( {{\text{h}}\upupsilon } \right)\) for the proposed CR-doped PVA materials. From the extrapolation of the straight-line portion to the x-axis at \(\left( {\upalpha {\text{h}}\upupsilon } \right)^{1/2}\) and \(\left( {\upalpha {\text{h}}\upupsilon } \right)^{2}\) = 0, the bandgap values (indirect and direct) are obtained and listed in Table 1. The diagrams show that both direct and indirect optical band gaps have the same behavior, decreasing due to increased CR dopants in a PVA matrix. The direct energy bandgap Eg(ind) for the neat PVA polymeric film was optically evaluated to be around 4.63 eV, while the indirect value Eg(dir) was about 5.24 eV. Respectively, the direct and indirect bands for 27.27 wt% PVA-doped CR composite film were calculated to be 1.77 and 1.87 eV, indicating bandgap engineering was affected by the added Congo red dye in the PVA matrix. The energy bandgap optically shifted from high incident photon for the pure PVA host to the low energy value as doping CR dye, where the reduction in the energy bands related to the high absorption behavior. In this present study, the calculated optical bandgaps were in excellent agreement with the reported data for TiO2-doped PVA nanocomposites via Sugumaran and Bellan ( 2014). Moreover, Mahendia et al. utilized the sol–gel method to prepare Ag: PVA nanostructured films, where the PVA optical bandgap was calculated to be 4.92 eV, and that value decreased to reach 3.93 eV (Mahendia et al. 2011), which was greatly compatible with the estimated bandgaps in this recent research.

CR dye generates multi-absorption bands in ultraviolet–visible optical zones for the PVA polymeric film. Captivated CR to PVA matrix generates a new trapped level as a point defect inside the high-occupied molecular orbital and the lowest unoccupied molecular orbital (HOMO-LOMO) gaps (Mahendia et al. 2011). The composition of the Congo red dye contains groups with high electronegativity (oxygen and nitrogen atoms) (Rozra et al. 2012). Consequently, the hydrogen bond was formed between CR dye (the amino and sulfonate groups) and the hydroxyl group in the PVA matrix. The inclusion of CR in the elevated content into the PVA matrix produces additional molecular dipoles. It, therefore, changes the performance of PVA from dielectric material into a semi-conductive material with a small bandgap (Hemalatha et al. 2014; Omed et al. 2015). This confirms the enhanced interaction among CR-doped PVA composites by raising the concentration of the dye. Similar findings are consistent with those reported in prior research (Yahia and Keshk 2017; AlAbdulaal et al. 2021). AlAbdulaal et al. investigated the structural and optical properties of Nd2O3: PVA polymeric composites that were prepared using the solution casting method. They concluded that the optical energy bandgaps of the PVA polymer decreased as increasing the dopant concentrations (AlAbdulaal et al. 2021).

To determine the extinction coefficient, the following equation can be applied through the absorption coefficient as follows (Saini et al. 2013; Farag and Yahia 2010):

Figure 6 represents the extinction coefficient (k) as a function of the wavelength of CR: PVA composites of different concentrations of the CR dye. Increasing the concentrations of the CR dye in the PVA matrix leads to an increase in the absorption coefficient. CR: doped PVA films showed multi-absorption bands at the lower wavelength due to the CR presence in the PVA matrix. Optically, O. G. Abdullah concluded that the PVA polymeric film's extinction coefficient increased as the doping concentrations increased (Abdullah 2011), which incredibly matched the current results. With increasing the dye-doping ratio, the absorption and denser of the films increased and hence the lower light velocity propagation. Then, the CR: PVA material becomes opaquer to the incident lights; thus, the speed of light decreases, and the absorption coefficient increases (Almusawe et al. 2018). This result indicates that the CR dopant will modify the structure of the PVA host polymer (Gordon and Gregory 2012).

3.3 Dielectric behavior and AC electrical conductivity of CR/PVA polymeric composite films

Research of the dielectric properties of polymeric materials is essential in estimating appropriate applications of polymeric materials (Ramana et al. 2013). The dielectric constant ε* can be given using the following equation:

where \(\upvarepsilon ^{\prime }\) is the dielectric constant and \(\upvarepsilon ^{\prime \prime }\) is the dielectric loss. Dielectric constant \({(}\upvarepsilon ^{\prime } )\) can be evaluated from the following formula (Sankarappa et al. 2008):

where C is the capacitance, and \(\varepsilon_{o}\) is the vacuum permittivity. The dielectric loss \({(}\upvarepsilon ^{\prime \prime } )\) can be estimated from the values of \(\varepsilon^{^{\prime}}\) and loss tangent (tanδ), as follows (Wu et al. 2008):

All measured dielectric parameters were examined at room temperature in the 100 Hz–1 MHz frequency range. Figures 7 and 8 represent the dielectric constant (\(\varepsilon^{\prime }\)) and dielectric loss \((\varepsilon^{\prime \prime } )\) spectra for the investigated CR: doped PVA polymeric films. For all composite films, \(\varepsilon^{\prime}\) and \(\varepsilon^{\prime \prime }\) values decline as the frequency increases to nearly 3 kHz owing to the interfacial effects at the electrode–electrolytes interfaces (Ramesh et al. 2002). In a polar matter, the initial values of \(\varepsilon^{\prime }\) and \(\varepsilon^{\prime \prime }\) are regarded to be high, but the dielectric value begins to decline by increasing the frequency. This is because the dipole is unable to change in frequency. The periodic reversal of the electrical field occurs rapidly at higher applied frequencies so that there is no over the propagation of ions towards the relevant field. \(\varepsilon^{\prime }\) and \(\varepsilon^{\prime \prime }\) values were increased with the increase wt% of CR dye, but the increase in \(\varepsilon^{\prime \prime }\) is very low.

The total AC electrical conductivity \(\sigma_{Total.AC} \left( \omega \right),\) the AC electrical conductivity \(\sigma_{AC} \left( \omega \right){\text{A}}\) nd DC electrical conductivity \(\sigma_{DC} \left( {\omega = 0} \right)\) can be calculated by using the following Jonscher’s equations (Jonscher 1996; AlAbdulaal and Yahia 2021; Jilani et al. 2018):

where Z is the measured impedance, t is the thickness of the film, ω is the angular applied frequency, and A is the cross-section area. The frequency-dependent of AC conductivity for CR-doped PVA composites obtained at room temperature is presented in Fig. 9. It is noted that the values of \(\sigma_{AC}\) increase by increasing the applied frequency and the level of CR doping in the polymeric composite films. Increased values of \(\sigma_{AC}\) The increased applied frequency has been caused by an increase in the oscillation field and the enhanced used frequency, which will raise the polarization of the composites (Jonscher 1996; AlAbdulaal and Yahia 2021; Jilani et al. 2018).

The frequency dependence of \(\sigma_{AC}\) can be analyzed by Jonscher’s power law to determine the conduction mechanism as follows (Jonscher 1996; AlAbdulaal and Yahia 2021; Jilani et al. 2018):

where A is a constant, and (s) is exponential power, in which the s value is the slope of the straight-line segment of the relationship among log \(\sigma_{AC}\) Fig. 10 shows that (s) dependence on wt% of CR-content for all studied composites. And logω. Pure PVA polymer has a value close to unity (one), whereas, on the other hand, the (s) values are slightly reduced by increasing the CR concentrations in the PVA matrix. The (s) behavior assumes the most favorable conduction mechanism is the correlated barrier hopping (CBH) model (Jonscher 1996; Ragab 2011). In conclusion, the optical conductivity of the undoped PVA polymer increased where the CR doping ratios increased, which are outstanding and consistent with the published optical data of NaI-doped PVA nanostructured films by Mustafa (2013).

3.4 Optical limiting study of CR- doped PVA polymeric composite films

The optical limiting effect of CR: PVA composite films is studied using two different laser beams (He–Ne laser of 632.2 nm and green laser diode of 532 nm). The conventional Z-scan experimental technique was used in which the sample is constant. Figure 11 reveals the relationship between the normalized power curves (Normalized power = output power/input power) against the weight percent of CR-content. Pure PVA has a small optical limiting effect on the power intensity of the two laser sources. The normalized power is decreased by increasing the weight of CR dye in the film composites, attaining about (11 and 13) % of its initial value for 11.11 wt% CR/PVA composite film for the two laser beams. Concentration is known to play an essential role in the optical limiting effect. The added CR content reinforces it due to the increase in the number of molecules per unit volume that contributes to the interaction of the added CR material during nonlinear absorption processes. Thus, the optical limit for low CR samples is much weaker than that recognized for elevated concentration samples (Mghames et al. 2018; Badran et al. 2015, 2016).

From Fig. 11, the samples have a higher optical limiting effect for the laser beam of 532 nm than 632.8 nm. Because of the distinctive red-Congo two broad bands that appear in CR: PVA films at 290 nm and 410 nm, composites that contain less than 1.1 wt% of CR content are presented in Fig. 3. After 1.11 wt%, CR/PVA composite films exhibited UV–Vis blocking, enabling these composites as laser blocking filters (laser cut-off filters). Therefore, these composite films, which contain 11.11 wt% and 27.27 wt% CR, can be used extensively in optoelectronic applications and are appropriate for various types of laser wavelengths in the range 190–566 nm, like gas, chemical, dye, metal vapor, semiconductor, and solid-state lasers (Yahia and Keshk 2017).

Many research groups have used various materials as fillers with PVA to enhance the optical limiting and use them as laser blocking filters (laser CUT-OFF filters). Therefore, the normalized power of present composites was compared with that of other PVA composites with different dye content, as seen in Table 2. From this Table, one can notice that CR/PVA composite films improve the optical limiting effects characteristics compared to most composites doping with other colors.

4 Conclusion

Congo Red/PVA composite films were prepared using a simple solution casting technique. XRD was used to reveal the changes in the sample structures. Due to the intermolecular hydrogen bond between the hydroxyl group in PVA chains and amino and sulfonate groups in the CR dye, the transmission values of CR/PVA composites increase with reducing CR content. Also, the composites of a higher concentration of CR (11.11 and 27.27 wt.%) are suitable for a wide-scale cut-off filter varying from 190 to 566 nm. ε' and ε" values were reduced as the frequency increased, as shown by the dielectric analysis. Congo red dye in the PVA matrix changed in a good way the electrical conductivity and the dielectric properties of the high insulator PVA matrix. The correlated barrier hopping (CBH) model is the primary model. Laser beams at 632.8 nm and 532 nm wavelengths were used to stand up the optical limiting behavior of CR/PVA composites. The best optical behavior is determined at the higher dye content. CR/PVA composite films can be used in large-scale CUT-OFF laser filters for medical optical devices and other electronic systems.

Data availability

The datasets obtained and analyzed in this current research are available with the corresponding author “Dr. Ibrahim Yahia.”

References

Abdullah, O.G.: Evolution of the optical properties of PVA films filled with Sodium Iodide. Tikrit J. Pure Sci. 16(4), 195–200 (2011)

AlAbdulaal, T.H., Yahia, I.S.: Optical linearity and nonlinearity, structural morphology of TiO2-doped PMMA/FTO polymeric nanocomposite films: laser power attenuation. Optik 227, 166036 (2021)

AlAbdulaal, T.H., Ali, H.E., Ganesh, V., Aboraia, A.M., Khairy, Y., Hegazy, H.H., Yahia, I.S.: Investigating the structural morphology, linear/nonlinear optical characteristics of Nd2O3 doped PVA polymeric composite films: Kramers-Kroning approach. Phys. Scr. 96(12), 125831 (2021)

Abed, N.A., Saeed, A.A.: Optical properties of xanthene dye doped polymer blend. J. Phys. Conf. Ser. 1294(2), 0220271294 (2019)

Almusawe, A.J., Hassen, T.F., Rahma, M.A., Abdalrasheed, N.F.: Iraqi J. Sci. 59, 299–306 (2018)

Badran, H.A., Hassan, Q.M.A., Imran, A.: Large third-order optical nonlinearity and optical limiting properties of a 3, 4-diaminopyridine. J. Mater. Sci.: Mater. Electron. 26(8), 5958–5963 (2015)

Badran, H.A., Imran, A., Hassan, Q.M.A.: Thermal diffusivity of 2, 3-Pyridinediamine determination by thermal blooming. Optik 127(5), 2659–2665 (2016)

Bhargav, P.B., Mohan, V.M., Sharma, A.K., Rao, V.N.: Structural and electrical studies of sodium iodide doped poly (vinyl alcohol) polymer electrolyte films for their application in electrochemical cells. Ionics 13(3), 173–178 (2007)

Carrasco-Correa, E.J., Beneito-Cambra, M., Herrero-Martínez, J.M., Ramis-Ramos, G.: Evaluation of molecular mass and tacticity of polyvinyl alcohol by non-equilibrium capillary electrophoresis of equilibrium mixtures of a polymer and a dye. J. Chromatogr. A 1218(16), 2334–2341 (2011)

Chung, W.H.: Congo red/polyvinyl alcohol film dosimeter for gamma rays and electrons. Nucl. Technol. 105(3), 457–458 (1994)

Costela, A., García-Moreno, I., Sastre, R.: Medical applications of dye lasers. In: Duarte, F.J. (ed.) Tunable Laser Applications, 2nd edn. CRC, New York (2009)

Dittmer, J.J., Marseglia, E.A., Friend, R.H.: Electron trapping in dye/polymer blend photovoltaic cells. Adv. Mat. 12(17), 1270–1274 (2000)

Du, X., Liang, Y.: Spectroscopic study of the self-assembly behavior of a vertical soap film stabilized with cetyltrimethylammonium bromide and Thiazole Yellow. Phys. Chem. Chem. Phys. 2(7), 1515–1518 (2000)

El-Bashir, S.M., Yahia, I.S., Binhussain, M.A., AlSalhi, M.S.: Designing of PVA/Rose Bengal long-pass optical window applications. Results Phys. 7, 1238–1244 (2017)

Epstein, L.I.: The design of optical filters. JOSA 42(11), 806–810 (1952)

Farag, A.A.M., Yahia, I.S.: Structural, absorption, and optical dispersion characteristics of rhodamine B thin films prepared by drop-casting technique. Opt. Commun. 283(21), 4310–4317 (2010)

Friedrich, K., Fakirov, S., Zhang, Z. (eds.): Polymer Composites: From Nano-to Macro-Scale. Springer (2005)

Geetha, S.K., Kumari, S.S.P., Muneera, C.I.: Optical limiting behavior of congo-red and crystal-violet dyes in solid matrices for nanosecond pulses. J. Mater. Sci. Lett. 21, 1339–1342 (2002)

Gordon, P.F., Gregory, P.: Organic Chemistry in Color. Springer (2012)

Hassan, Q.M.A.: Nonlinear optical and optical limiting properties of chicago sky blue 6B doped PVA film at 633 nm and 532 nm studied using a continuous wave laser. Mod. Phys. Lett. B 22(16), 1589–1597 (2008)

Hebbar, V., Bhajantri, R.F., Naik, J., Rathod, S.G.: Thiazole yellow G dyed PVA films for optoelectronics: microstructural, thermal, and photophysical studies. Mater. Res. Exp. 3(7), 075301 (2016)

Hemalatha, K.S., Rukmani, K., Suriyamurthy, N., Nagabhushana, B.M.: Synthesis, characterization and optical properties of hybrid PVA–ZnO nanocomposite: a composition-dependent study. Mater. Res. Bull. 51, 438–446 (2014)

Hodge, R.M., Edward, G.H., Simon, G.P.: Water absorption and states of water in semicrystalline poly (vinyl alcohol) films. Polymer 37(8), 1371–1376 (1996)

Ireland, C.L.M.: Handbook of laser wavelengths. Opt. Laser Technol. 30, 564–565 (1999)

Jilani, W., Bouzidi, A., Yahia, I.S., Guermazi, H., Zahran, H.Y., Saker, G.: Effect of organic dyes on structural properties, linear optics, and impedance spectroscopy of methyl orange (CI acid orange 52) doped polyvinyl alcohol composite thin films. J. Mater. Sci.: Mater. Electron. 29(19), 16446–16453 (2018)

Jonscher, A.K.: Universal Relaxation Law: A Sequel to Dielectric Relaxation in Solids. Chelsea Dielectrics Press (1996)

Kawai, F., Hu, X.: Biochemistry of microbial polyvinyl alcohol degradation. Appl. Microbio. Biotech. 84(2), 227–237 (2009)

Kokabi, M., Sirousazar, M., Hassan, Z.M.: PVA–clay nanocomposite hydrogels for wound dressing. Euro. Polym. J. 43, 773–781 (2007)

Konieczkowska, J., Wojtowicz, M., Sobolewska, A., Noga, J., Jarczyk-Jedryka, A., Kozanecka-Szmigiel, A., Schab-Balcerzak, E.: Thermal, optical and photoinduced properties of a series of homo and co-polyimides with two kinds of covalently bonded azo-dyes and their supramolecular counterparts. Opt. Mater. 48, 139–149 (2015)

Macleod, H.A., Macleod, H.A.: Thin-Film Optical Filters. CRC Press (2010)

Madsen, C.K., Zhao, J.H.: Optical Measurements and Filter Analysis: Optical Filter Design and Analysis: A Signal Processing Approach, pp. 355–395. Wiley (1999)

Mahendia, S., Tomar, A.K., Kumar, S.: Nano-Ag doping induced changes in optical and electrical behaviour of PVA films. Mater. Sci. Eng. B 176(7), 530–534 (2011)

Mansour, S.A., Yahia, I.S., Yakuphanoglu, F.: The electrical conductivity and dielectric properties of CI Basic Violet 10. Dyes Pigm. 87(2), 144–148 (2010)

Mghames, A.L., Badran, H.A., Hussain, H.F.: Optical limiting studies and saturated output of continuous-wave laser in Fluorescein solution. Int. J. Eng. Appl. Sci. 5, 2394–3661 (2018)

Mott, N.F., Davis, E.A.: Electronic Process in Non-crystalline Materials, 2nd edn., p. 604. Clarendom Press (1979)

Mustafa, F.A.: Optical properties of NaI doped polyvinyl alcohol films. Phys. Sci. Res. Int. 1(1), 1–9 (2013)

Omed, G., Aziz, S.B., Omer, K.M., Salih, Y.M., In-situ Synthesis of PVA/HgS Nanocomposite Films and Tuning Optical Properties, Mater. Sci. Mater. Electron., 26, 5303–5309 (2015)

Papancea, A., Valente, A.J., Patachia, S.: Diffusion and sorption studies of dyes through PVA cryogel membranes. J. Appl. Polym. Sci. 115(3), 1445–1453 (2010)

Peng, M., Xiao, G., Tang, X., Zhou, Y.: Hydrogen-bonding assembly of rigid-rod poly (p-sulfophenylene terephthalamide) and flexible-chain poly (vinyl alcohol) for transparent, strong, and tough molecular composites. Macromolecules 47(23), 8411–8419 (2014)

Qi, S., Zhang, C., Yang, X., Chen, K., Zhang, L., Yang, G., Tian, J.: Absorption characteristic and limiting effect of Congo red doped PVA film. Opt. Mater. 29(11), 1348–1351 (2007)

Qi, S., Zhang, C., Yang, X., Chen, K., Zhang, L.: Nonlinear optical properties of Congo red in aqueous solution and PVA film. In: Optical Materials in Defence Systems Technology. International Society for Optics and Photonics., Vol. 5621, pp. 125–132 (2004)

Ragab, H.M.: Spectroscopic investigations and electrical properties of PVA/PVP blend filled with different concentrations of nickel chloride. Physica B 406(20), 3759–3767 (2011)

Ramana, C.V., Kumar, A.K., Kumar, A.S., Kumar, M.A., Moodley, M.K.: Dielectric and excess dielectric constants in non-polar+ polar binary liquid mixtures of toluene with alcohols at 303, 313, and 323 K. Thermochim. Acta 566, 130–136 (2013)

Ramesh, S., Yahaya, A.H., Arof, A.K.: Dielectric behaviour of PVC-based polymer electrolytes. Solid State Ionics 152, 291–294 (2002)

Rozra, J., Saini, I., Sharma, A., Chandak, N., Aggarwal, S., Dhiman, R., Sharma, P.K.: Cu nanoparticles induced structural, optical, and electrical modification in PVA. Mater. Chem. Phys. 134(2–3), 1121–1126 (2012)

Saini, I., Rozra, J., Chandak, N., Aggarwal, S., Sharma, P.K., Sharma, A.: Tailoring of electrical, optical, and structural properties of PVA by addition of Ag nanoparticles. Mater. Chem. Phys. 139(2–3), 802–810 (2013)

Sankarappa, T., Kumar, M.P., Devidas, G.B., Nagaraja, N., Ramakrishnareddy, R.: AC conductivity and dielectric studies in V2O5–TeO2 and V2O5–CoO–TeO2 glasses. J. Mol. Struct. 889(1–3), 308–315 (2008)

Sedlarik, V., Saha, N., Kuritka, I., Saha, P.: Characterization of Polymeric Biocomposite Based on Poly(vinyl alcohol) and Poly(vinyl pyrrolidone). Polym. Compos. 27, 147 (2006)

Sheng, C.K., Yunus, W.M.M., Yunus, W.M.Z.W.: Measurement of thermal diffusivity, optical transmission, and optical absorption peaks of laser dyes R6G doped in poly (methylmethacrylate) using photoacoustic technique and fiber optics spectrophotometer. A scientific journal published by Universiti Putra Malaysia Press, 80 (2003)

Singh, S., Kanetkar, V.R., Sridhar, G., Muthuswamy, V., Raja, K.: Solid-state polymeric dye lasers. J. Lumin. 101(4), 285–291 (2003)

Sreeja, S., Sreedhanya, S., Smijesh, N., Philip, R., Muneera, C.I.: Organic dye impregnated poly (vinyl alcohol) nanocomposite as an efficient optical limiter: structure, morphology, and photophysical properties. J. Mater. Chem. C 1(24), 3851–3861 (2013)

Sreeja, S., Frobel, P.L., Mayadevi, S., Suresh, S.R., & Muneera, C.I.: Low-threshold Optical limiting and Nonlinear refraction in Nanocomposite films of Light Green dye-polymer system. In: IOP Conference Series: Materials Science and Engineering. IOP Publishing, Vol. 73, No. 1, p. 012116 (2015)

Sugumaran, S., Bellan, C.S.: Transparent nanocomposite PVA–TiO2 and PMMA–TiO2 thin films: Optical and dielectric properties. Optik 125(18), 5128–5133 (2014)

Sultanova, N., Kasarova, S., Nikolov, I.: Dispersion properties of optical polymers. Acta Physica Polonica-Ser. A Gen. Phys. 116(4), 585 (2009)

Teodorescu, M., Bercea, M., Morariu, S.: Biomaterials of PVA and PVP in medical and pharmaceutical applications: perspectives and challenges. Biotech. Adv. J 37, 109–131 (2019)

Wu, J., Lan, Z., Hao, S., Li, P., Lin, J., Huang, M., Huang, Y.: Progress on the electrolytes for dye-sensitized solar cells. Pure Appl. Chem. 80(11), 2241–2258 (2008)

Wyszecki, G., Stiles, W.S.: Color Science, vol. 8. Wiley, New York (1982)

Yahia, I.S., Keshk, S.M.: Preparation and characterization of PVA/Congo red polymeric composite films for wide-scale laser filters. Opt. Laser Technol. 90, 197–200 (2017)

Yahia, I.S., Mohammed, M.I.: Facile synthesis of graphene oxide/PVA nanocomposites for laser optical limiting: Bandgap analysis and dielectric constants. J. Mater. Sci.: Mater. Electron. 29(10), 8555–8563 (2018)

Yahia, I.S., Abd El-sadek, M.S., Yakuphanoglu, F.: Methyl orange (CI acid orange 52) as a new organic semiconductor: Conduction mechanism and dielectric relaxation. Dyes Pigm. 93(1–3), 1434–1440 (2012)

Yahia, I.S., Mohammed, M.I., Nawar, A.M.: Multifunction applications of TiO2/poly (vinyl alcohol) nanocomposites for laser attenuation applications. Physica B 556, 48–60 (2019)

Yang, J.C., Jablonsky, M.J., Mays, J.W.:NMR and FT-IR studies of sulfonated styrene-based homopolymers and copolymers, Polym. 43, 5125–5132 (2002)

Zidan, M., El-Ghamaz, N.A., Abdelghany, A.M., Lotfy, A.: Structural and electrical properties of PVA/PVP blend doped with methylene blue dye. Int. J. Electrochem. Sci. 11, 9041–9056 (2016)

Zou, X.H., Zhang, S.J., Wang, H., Zhang, Y.L.: A self-reference and high-resolution method for measuring the magnitude frequency response of optical filters. In: 2016 25th Wireless and Optical Communication Conference (WOCC). IEEE, pp. 1–3 (2016)

Acknowledgements

The authors would like to acknowledge the financial support from the Ministry of Education, Kingdom of Saudi Arabia, for this research through a Grant (PCSED-020-18) under the Promising Centre for Sensors and Electronic Devices (PCSED) at Najran University, Kingdom of Saudi Arabia. Also, The authors express their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through the research groups program under Grant Number R.G.P.2/216/41.

Funding

Ministry of Education, Kingdom of Saudi Arabia, through a Grant (PCSED-020-18) under PCSED at Najran University. Deanship of Scientific Research at King Khalid University under Grant Number R.G.P.2/216/41.

Author information

Authors and Affiliations

Contributions

TA: Formal analysis-Equal, Investigation-Equal, Methodology-Equal, Visualization-Equal, Writing-original draft-Equal, Writing-review & editing-Equal. MAA: Data curation, Formal analysis-Equal, Investigation-Equal, Visualization-Equal, Writing-original draft-Equal. MIM: Investigation-Equal, Methodology-Equal, Visualization-Equal, Writing-original draft-Equal. HZ: Methodology-Equal, Validation-Equal. FAH: Methodology-Equal, Visualization-Equal, Writing-original draft-Equal. MSA-A: Investigation-Equal, Software-Equal. IY: Funding acquisition, Project administration, Resources, Validation-Equal, Writing-review & edition. MAI: Methodology-Equal, Software-Equal.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this manuscript.

Ethical approval

Dr. Ibrahim Yahia has approved the ethics of this study.

Consent to participate

The authors participate in completing this paper from the beginning until sending it to the journal.

Consent to publish

All authors agree to publish this work in the Optical and Quantum Electronics journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

AlAbdulaal, T., Assiri, M.A., Mohammed, M.I. et al. Photophysical and electronic properties of Congo red dye embedded in polyvinyl alcohol as an efficient laser optical limiter: enhancement of the electrical conductivity and dielectric properties. Opt Quant Electron 54, 778 (2022). https://doi.org/10.1007/s11082-022-04101-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-022-04101-z