Abstract

In this research, Ta doped ZnO thin films have been deposited onto glass and Si substrates by Thermionic vacuum arc (TVA) thin film deposition system. TVA is an anodic plasma thin film deposition system and it is used to relatively high-quality thin films deposition. ZnO thin films have direct optical band gap of 3.37 eV. Tantalum is an efficient higher-valance element. Ta atom gives the more electrons compared to Zinc atom and their ionic radius are very close to each other, so substituted element does not bring into additional stress in crystal network. The deposited thin films were analyzed by field emission scanning electron microscopy, energy dispersive X-ray spectroscopy, atomic force microscopy, UV–Vis spectrophotometry and interferometer. To change the band gap properties of the ZnO thin film, Ta doping was used and band gap of Ta doped ZnO thin film was obtained 3.1 eV by Tauc’s method. The wt% ratios for Zn/Ta were calculated as 0.45 and 0.42 for the films deposited onto glass and Si substrates, respectively. Crystallite sizes of Ta doped ZnO thin film was decreased by changing substrate material. To the best of our knowledge, substituted Ta elements connected to the oxygen atom in crystal network and orthorhombic β′-Ta2O5 were detected in the all films structure. Their band gaps of the β′-Ta2O5 were measured as 2.70 eV and 2.60 eV for Ta-doped ZnO thin films deposited onto glass and Si substrates, respectively. Up to day, the band gap of the β′-Ta2O5 was calculated by density function theory. According to results, β′-Ta2O5 structure was found as embedded from in the ZnO crystal network.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Zinc oxide (ZnO) material has appealing tremendous attention in both researchers and industry groups owing to their transparency, large optical band gap (3.37 eV), the high exciton binding energy (60 meV) at room temperature as well as piezoelectricity properties (Mohammadigharehbagh et al. 2017). This material is a combination of II–VI group semiconductors that formed mainly as hexagonal wurtzite structure, and well known as the best n-type semiconductor. The mentioned characteristics cause to emerging various application fields such as acoustic (resonator and wave) devices, sensors, solar cells, panel displays, thin film transistors, light-emitting diodes (LEDs) and detectors (Mohammadigharehbagh et al. 2018a, b). Despite the application fields, by benefit of their non-toxicity, earth-abundant, high thermal stability, high oxidation resistance and low electron mobility using in harsh conditions and especially field emission devices also reported recently. Unfortunately, the main obstacles are poor conductivity, thermal treatment and stable p-type conductivity that restricted the spreading of area for application. Enhancing the conductivity of ZnO by different doping elements can lead to broadening utilizing of the material as the best candidate for the replacement of indium tin oxide (ITO). Indeed, the abundance and low-cost advantages of ZnO regarding indium result in attention as an alternative material by researchers (Mohammadigharehbagh et al. 2018c). According to the literature review, doping by Al, Ga and In (Mohammadigharehbagh et al. 2018a; Pat et al. 2017) enable of reduction in the resistivity value of the ZnO but undesirably appear lattice deformation as well as of weakened oxidation resistance of the main material. However, doping with N, P and Sb (Paradowska et al. 2019) elements already reasoned p-type ZnO that extent exploit it’s in optoelectronics such as LED and detectors. Furthermore, doping with Fe, Mn and Co (Sree et al. 2019) elements paved the way for using ZnO in spintronic applications in light of ferromagnetic features.

The sol–gel, atomic layer deposition, magnetron sputtering, pulsed laser deposition, electrospraying, spray pyrolysis, molecular beam epitaxy and other methods have been carried out for the formation of ZnO as nanostructures or thin films (Tao et al. 2019; Pérez-González et al. 2019; Adachi et al. 2019). In this research, far from the mentioned methods, a thermionic vacuum arc technique for coating Ta doped ZnO thin film was used. The glass and Si wafer were selected as substrate materials. The coating technique has a very high deposition rate that shortened the duration of coating coincide with a run in high vacuum conditions, eco-friendly (lack of using buffer or carrier gas inside the chamber during coating) and very low row material. A literature survey revealed a few research-based on Ta doping on the ZnO structure that motivates to focus on doping the element and physical properties introduced by the element in the main ZnO structure despite amazing properties. Tantalum is a good candidate as a doping element for reaching an n-type semiconductor, it means, the element includes low-toxicity, chemical stability, high refractive index, cheap and low dangerous and hazardous advantageous beside of ionic radius value for substituting by Zn in this structure (Shiri et al. 2019). Ta has known as Ta+5 instead of Zn+2 that logically introduces more electrons as carrier concentration to the structure, that is improves carrier concentration and increment impurity value at this route. It was noticed the amount of electron introduced by Ta is higher than In3+, Al3+ and Ga3+elements which inferred using as Ta in a small value is fully enough for satisfying necessary carrier concentration along with a reduction in ion scattering in this structure. That means, enhancing the free carriers by entering a proper candidate such as Ta may be successfully reduce resistivity and gaining better optical characteristics for making a new application realm. The element has been frequently used in medical, electronics due to their high corrosion resistance, ductility, toughness, density, melting point and refractory materials. For instance, Ta thin films are extensively take a major role in microelectronics as a diffusion barrier between metals and Si substrates, as well as protect steel and glass-like materials when exposed to wear or corrosion (Bunting et al. 2016).

In this research, Ta doped ZnO thin films have deposited onto glass and Si substrates by thermionic vacuum arc (TVA) technique . The morphological, microstructure, electronic and optical properties of the thin film were performed using suitable devices. TVA is a physical vapor deposition technology. Deposited thin films were analyzed by field emission scanning electron microscopy, atomic force microscopy, Raman spectroscopy, interferometer and UV–Vis spectrophotometer. The surface and detailed optical properties of Ta doped ZnO thin films were determined. The β′-Ta2O5 crystal properties were determined from the photoluminescence measurement (PL) and Raman shift spectra. For the crystal properties β′-Ta2O5, PL and Raman shift spectra are deterministic method. Because, for the thin layer, X-ray diffraction pattern has very low intensity for interference fringes.

2 Materials and methods

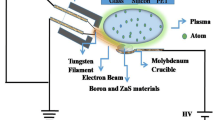

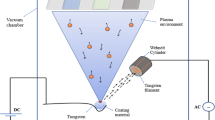

TVA method is a physical vapor deposition technology. Physical vapor deposition techniques work in vacuum conditions. TVAis also plasma source and generates the pure materials' or alloys' plasma. TVA system has two electrodes, these are anode and cathode. Anode is a tungsten boat and deposited materials (Ta slug and ZnO pellet) were placed inside of the boat. Cathode is an electron gun and it is constructed from tungsten filament and Wehnelt cylinder. In TVA, the filament is heated by AC high current. After the heating of the filament, emitted electrons are accelerated towards to anode boat by DC high voltage. For TVA plasma generation, ignition voltage must be determined. The ignition voltage value relates with vapor pressure and melting point of the materials. Firstly, the materials need energy for the evaporation in the interelectrodic space. Then, using by high DC voltage, TVA plasma generates in vacuum chamber (Mohammadigharehbagh et al. 2017, 2018a, b, c). In Table 1, TVA coating parameters are summarized.

3 Results and discussion

Ta doped ZnO thin films were deposited onto glass and Si substrates. The film thicknesses of the coated surface for glass and Si substrates are about 100 nm and 60 nm, respectively. Before the deposition, substrate materials were cleaned by ethanol and deionized water. Field emission scanning electron microcopy (FESEM) analysis were done by Hitachi Regulus 8230 scanning electron microscopy. 10.0 kV acceleration voltage and conductive coating were used to obtain a good image. Obtained surface images for deposited films onto glass and Si substrates are shown in Fig. 1a, b, respectively. Crystallites for the film deposited onto Si substrate are bigger than the film deposited onto glass substrate and also crystallites are seen clearly in Fig. 1a, b.

EDS detector in Hitachi Regulus 8230 device was used for the elemental analysis. Obtained results are illustrated in Table 2. Zn/Ta ration in wt% for the films deposited onto substrates were found nearly close to each other. For the glass substrate, oxygen ratio is higher than the film deposited onto Si substrate.

Atomic force microscopy is a powerful tool to determine the surface properties of a nanostructured surface. A lot of properties of a surface can easily determine by AFM tool. An Ambios QScope AFM was used for the determination of the surface morphology. AFM images were obtained at room temperature in 10 µm × 10 µm scale. NSC16 cantilever with 160 kHz was used for the surface characterization. Scanning frequency was adjusted to 5 Hz. Obtained AFM images for Ta doped ZnO thin film deposited onto glass and Si substrates are illustrated in Fig. 2a, b. Surface homogeneity and distribution function of crystallites are the key parameters. These parameters can easily measure by AFM tool. Roughness of the film surface were measured as 20 nm and 8 nm for the film deposited onto glass and Si substrates, respectively. Although, the lowest roughness obtained for the film deposited onto Si substrate, the roughness of the film deposited onto glass substrate is very low compared the literature value, too. Distribution function of the crystallites height should be similar to Gauss function. It is show that the films have homogeny crystallite distribution onto surface. The height distribution function plots are illustrated in Fig. 2c. Compared the results, height of the crystallites deposited onto glass substrate is slightly bigger than the crystallites for Si substrate. Mean crystallites heights are approximately same and they were measured as 80 nm and 60 nm, for glass or Si substrate, respectively. Skewness and Kurtosis values define the shape of the gauss function. Skewness values are 0.795 and 0.312 for the film deposited onto glass and Si substrates, respectively. Kurtosis values for the film deposited onto glass and Si substrates are 1.109 and 0.067, respectively.

Raman spectroscopy is a non-destructive chemical analysis that portrays the lattice vibration of the material. Raman shift relates to molecular interactions, crystallinity, phase, chemical structure, etc. Renishaw in Via Raman Microscope device was used for the analysis of the coated samples. The laser wavelength for Raman analysis is 532 nm. Obtained results for the films deposited onto glass and Si substrates are seen in Fig. 3a, b. The analyses were done in the range of 400–4000 cm−1. The ZnO material has categorized as \({C}_{6v}^{4}\) (P63mc) space group (Tripathi et al. 2011). It is well known the material belongs to a wurtzite structure that consists of eight different vibrational phonon modes in the Brillouin zone, it means:

in the above equation, the Γ point is an indication of the Brillouin zone. Also, the A1 and E1 modes comprised of transverse and longitudinal optical which abbreviated as TO and LO, respectively. The E2 mode is divided into the low and high-frequency phonon modes that assigned the vibrational modes of the Zn and O atoms in this structure. The B1 is a silent mode again include low and high frequencies modes, respectively. In our case, for analysis of the film deposited onto the glass substrate, two peaks at 553 and 1084 cm−1 were detected. The peaks emerged in 553 cm−1assigned as Zn interstitial which was reported by other researchers (Exarhos et al. 1995; Saw et al. 2007). Besides, the second peak is an indication of second-order longitudinal optical E1mode (Jothilakshmi et al. 2009). Furthermore, for the film deposited onto the Si substrate, the six main peaks were observed at 359, 538, 667, 801, 920 and 1109 cm−1. In this substrate, the peaks present at 359, 538 and 667 cm−1 are related to \({E}_{1}^{high}-{E}_{1}^{low}\), silent \({B}_{1}^{high}\)and two phonon processes of ZnO thin films (Yahia et al. 2008), respectively. The two phonon process peak already reported by Samanta et al. (2007) and co-workers as indication of the precipitation of a secondary and highly concentrated Mn-doped ZnO thin films, on the other hand, Cheng et al. (2004) similarly observed a Ce-rich layer in Ce-doped ZnO thin films, while Wang and co-workers (Wang et al. 2004) declared the peaks to fine ZnO powder to acoustic overtone by A1 symmetry. Moreover, the peaks at 801 and 920 cm−1are representations of the two optical phonon (2LO) mode of amorphous tantalum oxide and asymmetric stretching of Si and oxygen bonds, respectively (Gritsenko et al. 2018). The final peak at 1109 cm−1 is attributed to the symmetry acoustic combination of A1 and E2 modes of Raman bands (Ojha et al. 2014; Mohammadigharehbagh et al. 2020). Indeed, the Raman spectra have been executed for evaluation of the crystal disorders formation of thin films. In the all observed peaks on both substrates shifts to the higher wavenumber values were pronounced that giving rise to nano-crystalline behavior, stress because of Ta dopant and subsequently good adherence between the substrates and the produced films. According to the peaks that exist in Ta-doped ZnO thin films on both glass and Si substrates, the hexagonal wurtzite structure has been corroborated. The Raman spectra illustrated in Fig.3a, b. Figure 3a, b are similar to the spectra of the crystalline Ta2O5and high temperature annealed coating samples (Joseph et al. 2012).

Transmittance spectra of Ta doped ZnO thin films deposited onto glass substrate is seen in Fig. 4a. The reflectance of Ta doped ZnO thin films deposited onto glass and Si substrates are also illustrated in Fig. 4b. Measured spectra were recorded by Unico UV–Vis 4800 spectrophotometer. According to the Fig. 4a, transmittance of the film is very low, it is not transparent. Reflectance of the sample deposited onto glass substrate is bigger than the film deposited onto Si substrate. For the film deposited onto Si substrate, reflectance value are nearly same in UV–Vis region at very low value (∼ 2%). That is, Ta doped ZnO deposited onto Si substrate is a very good absorber for the UV–Vis region compared the film deposited onto glass substrate. The reflectance value for Ta doped ZnO thin film deposited onto glass substrate for 632 nm is approximately %10.

Refractive indices, n values of the samples were measured by Filmetrics F20 thin film thickness measurement device and refractive index via wavelength (nm) graph is seen in Fig. 5a. All samples show the normal distribution for refractive index. n values are decreasing with increasing wavelength (nm). Mean n value of the samples were determined as 1.95 at 600 nm for all samples deposited onto glass and Si substrates. 1.95 value is an intersection point for the n – λ (nm) graphs. For the film deposited onto glass substrate, n value decreasing by increasing wavelength.

The band gap value of Ta doped ZnO thin films for glass and Si substrates were calculated by optical method and photoluminescence tool. ZnO thin films is good candidate for the determination of the band gap of the material by using optical method. The optical model had use to amorphous semiconductors, but today’s application field too boarding and it is used to nearly all semiconductors materials (Viezbicke et al. 2015). In this method, the optical absorbance values of the samples was measured by UV–Vis spectrophotometer and then plotted the absorbance coefficient, (αhυ)1/m graph with respect to energy (hυ). α is calculated as following Eq. 2,

where A is absorbance value and t is the thickness of the film. The bad gap calculation relation for optic model is given below in Eq. 3 (Viezbicke et al. 2015);

where h is the Planck’s constant, hυ is the incident photon energy, m is the integer coefficient and its related with transition type of the semiconductor, B is a constant and Eg is the band gap of the semiconductor. A semiconductor has different type electron transition to conduction band from the valance band. m = 1/2, 3/2, 2, 3 corresponds to direct allowed transitions, direct forbidden transitions, indirect allowed transitions, indirect forbidden transitions, respectively. For the ZnO, m = 1/2 was determined from the optic model. Ta doped ZnO films show the similar behavior with un-doped ZnO semiconductor. To evaluate the band gap type, all m values graphics should be plotted and compared the each other to better fit. Finally, the correct transitions can be determined by the graphs. Figure 5b gives Ta doped ZnO thin films deposited onto glass substrate. Extrapolation of the (αhυ)1/m – hυ graph gave the 3.1 eV for Ta doped ZnO thin film deposited onto glass substrate. The obtained values are good agreement with the related literature.

Photoluminescence (PL) spectra of Ta doped ZnO thin films deposited onto glass and Si substrates are given in Fig. 6. Tantalum is an efficient element for the higher valence element and substitution of Ta+ x to Zn2+ sites in ZnO crystal network. After the substitution, TaOx formation should be detected in the crystal network. Most general oxide thallium phases are TaO2 and Ta2O5. Ta2O5 is an insulator with 4.3 eV band gap. According to theoretical investigations and papers, different phase of Ta2O5 has the lowest bans gap. From Fig. 6, PL transitions at 2.70 eV and 2.60 eV of Ta doped ZnO thin films deposited onto glass and Si substrates, respectively. To the best of our knowledge, these band gap transitions are related with orthorhombic β′-Ta2O5 (Hollerweger 2015). The crystal structures of Ta2O5 are formed in orthorhombic, tetragonal, hexagonal metastable form. The band gap of the β′-Ta2O5 was calculated by density function theory and results are appropriate our findings. According to results, β′-Ta2O5 structure embedded in the ZnO crystal network. Ta ions substituted Zn+2 ions in crystallite network of Ta doped ZnO semiconductors. So, it is investigated the surface and optical properties of the β′-Ta2O5 embedded ZnO thin film.

4 Conclusions

Ta doped ZnO thin films have been deposited onto glass and Si substrates by thermionic vacuum arc (TVA) technology. Ta doped ZnO is not research very well compared the other research paper about doped ZnO. Generally, optical properties of the doped ZnO are interested in research for the semiconductor applications. Un-doped ZnO has indirect band gap of 3.37 eV. Surface morphology of the deposited thin films were analyzed by field emission scanning electron microscopy. Crystallites sizes for the thin film deposited onto Si substrate are bigger than the film deposited onto glass substrate. The weight% of Zn/Ta for the deposited films were obtained 0.45 and 0.42, respectively. Average crystallite height for the film deposited onto glass and Si substrates is approximately 80 nm and 60 nm, respectively. Roughness of the film surface were measured as 20 nm and 8 nm for the film deposited onto glass and Si substrates, respectively. The peaks present at 359, 538 and 667 cm−1 are related to \({E}_{1}^{high}-{E}_{1}^{low}\), silent \({B}_{1}^{high}\) and two phonon processes of ZnO thin films. The deposited film are opac in UV–Vis spectral region. Refractive indices value of the samples were determined as 1.95 at 600 nm. According to the optical plot and calculations, Ta doped ZnO thin film has 3.1 eV and direct allowed transition semiconductor. Ta ions substituted Zn+2 ions in crystallite network of Ta doped ZnO semiconductors. Finally, TVA is a simple technology to obtain the doping semiconductor material.

References

Adachi, Y., Saito, N., Sakaguchi, I., Suzuki, T.T.: Polarity dependent gas sensing properties of ZnO thin films. Thin Solid Films. 685, 238–244 (2019). https://doi.org/10.1016/j.tsf.2019.06.023

Bunting, A., Cheung, R.: Evaluation of residual stress in sputtered tantalum thin-film. Appl. Surf. Sci. 371, 571–575 (2016). https://doi.org/10.1016/j.apsusc.2016.02.236

Cheng, B., Xiao, Y., Wu, G., Zhang, L.: The vibrational properties of one-dimensional ZnO: Ce nanostructures. Appl. Phys. Lett. 84(3), 416–418 (2004). https://doi.org/10.1063/1.1639131

Exarhos, G.J., Sharma, S.K.: Influence of processing variables on the structure and properties of ZnO films. Thin Solid Films. 270(1–2), 27–32 (1995). https://doi.org/10.1016/0040-6090(95)06855-4

Gritsenko, V.A., Volodin, V.A., Perevalov, T.V., Kruchinin, V.N., Gerasimova, A.K., Aliev, V.S., Prosvirin, I.P.: Nanoscale potential fluctuations in nonstoichiometrics tantalum oxide. Nanotechnology. 29(42), 425202 (2018). https://doi.org/10.1088/1361-6528/aad430

Hollerweger, R., Holec, D., Paulitsch, J., Bartosik, M., Daniel, R., Rachbauer, R., Mayrhofer, P.H.: Complementary ab initio and X-ray nanodiffraction studies of Ta2O5. Acta Materialia, 83, 276–284 (2015). https://doi.org/10.1016/j.actamat.2014.10.006

Joseph, C., Bourson, P., Fontana, M.D.: Amorphous to crystalline transformation in Ta2O5 studied by Raman spectroscopy. J. Raman Spectrosc. 43(8), 1146–1150 (2012). https://doi.org/10.1002/jrs.3142

Jothilakshmi, R., Ramakrishnan, V., Thangavel, R., Kumar, J., Sarua, A., Kuball, M.: Micro-Raman scattering spectroscopy study of Li‐doped and undoped ZnO needle crystals. J. Raman Spectrosc. Int. J. Original Work all Aspects Raman Spectrosc. Including Higher Order Process. Brillouin Rayleigh Scatt. 40(5), 556–561 (2009). https://doi.org/10.1002/jrs.2164

Mohammadigharehbagh, R., Özen, S., Yudar, H.H., Pat, S., Korkmaz, Ş: The electrical, elemental, optical, and surface properties of Si-doped ZnO thin films prepared by thermionic vacuum arc. Mater. Res. Express 4(9), 096404 (2017). https://doi.org/10.1088/2053-1591/aa7a6b

Mohammadigharehbagh, R., et al.: Investigation of the optical properties of the indium-doped ZnO thin films deposited by a thermionic vacuum arc. Optik 157, 667–674 (2018a)

Mohammadigharehbagh, R., Pat, S., Musaoglu, C., Korkmaz, Ş, Özen, S.: The investigation of the Cr doped ZnO thin films deposited by thermionic vacuum arc technique. Mater. Res. Express 5(2), 026403 (2018b). https://doi.org/10.1088/2053-1591/aaab90

Mohammadigharehbagh, R., Pat, S., Özen, S., Yudar, H.H., Korkmaz, Ş: Investigation of the optical properties of the indium-doped ZnO thin films deposited by a thermionic vacuum arc. Optik. 157, 667–674 (2018c). https://doi.org/10.1016/j.ijleo.2017.11.102

Mohammadigharehbagh, R., Pat, S., Akkurt, N., Olkun, A., Ozgur, M., Demirkol, U., Korkmaz, S.: Surface, optical and electrochemical performance of indium-doped ZnO/WO 3 nano-composite thin films. SN Appl. Sci. 2(11), 1–11 (2020). https://doi.org/10.1007/s42452-020-03580-7

Ojha, A.K., Srivastava, M., Kumar, S., Hassanein, R., Singh, J., Singh, M.K., Materny, A.: Influence of crystal size on the electron–phonon coupling in ZnO nanocrystals investigated by Raman spectroscopy. Vib. Spectrosc. 72, 90–96 (2014). https://doi.org/10.1016/j.vibspec.2014.02.013

Paradowska, K.M., Przeździecka, E., Płaczek-Popko, E., Zielony, E., Stachowicz, M., Kozanecki, A.: Effect of annealing on photoluminescence and Raman scattering of Sb-doped ZnO epitaxial layers grown on a-Al2O3. J. Alloy. Compd. 774, 1160–1167 (2019). https://doi.org/10.1016/j.jallcom.2018.09.379

Pat, S., Mohammadigharehbagh, R., Özen, S., Şenay, V., Yudar, H.H., Korkmaz, Ş: The Al doping effect on the surface, optical, electrical and nanomechanical properties of the ZnO and AZO thin films prepared by RF sputtering technique. Vacuum. 141, 210–215 (2017). https://doi.org/10.1016/j.vacuum.2017.04.025

Pérez-González, M., Tomás, S.A., Santoyo-Salazar, J., Gallardo-Hernández, S., Tellez-Cruz, M.M., Solorza-Feria, O.: Sol-gel synthesis of Ag-loaded TiO2-ZnO thin films with enhanced photocatalytic activity. J. Alloy. Compd. 779, 908–917 (2019). https://doi.org/10.1016/j.jallcom.2018.11.302

Samanta, K., Dussan, S., Katiyar, R.S., Bhattacharya, P.: Structural and optical properties of nanocrystalline Zn 1 – x Mn x O. Appl. Phys. Lett. 90(26), 261903 (2007). https://doi.org/10.1063/1.2751593

Saw, K.G., Ibrahim, K., Lim, Y.T., Chai, M.K.: Self-compensation in ZnO thin films: An insight from X-ray photoelectron spectroscopy, Raman spectroscopy and time-of-flight secondary ion mass spectroscopy analyses. Thin Solid Films. 515(5), 2879–2884 (2007). https://doi.org/10.1016/j.tsf.2006.08.047

Shiri, S., Odeshi, A., Chen, N., Feng, R., Sutarto, R., Yang, Q.: FCC tantalum thin films deposited by magnetron sputtering. Surf. Coat. Technol. 358, 942–946 (2019). https://doi.org/10.1016/j.surfcoat.2018.12.015

Sree, D.N., Deborrah, S.P.M., Gopinathan, C., Inbanathan, S.S.R.: Enhanced UV light induced photocatalytic degradation of Methyl Orange by Fe doped spray pyrolysis deposited ZnO thin films. Appl. Surf. Sci. 494, 116–123 (2019). https://doi.org/10.1016/j.apsusc.2019.07.091

Tao, K., Yi, H., Tang, L., Wu, J., Wang, P., Wang, N., Chang, H.: Piezoelectric ZnO thin films for 2DOF MEMS vibrational energy harvesting. Surf. Coat. Technol. 359, 289–295 (2019). https://doi.org/10.1016/j.surfcoat.2018.11.102

Tripathi, N., Vijayarangamuthu, K., Rath, S.: A Raman spectroscopic study of structural evolution of electrochemically deposited ZnO films with deposition time. Mater. Chem. Phys. 126(3), 568–572 (2011). https://doi.org/10.1016/j.matchemphys.2011.01.026

Viezbicke, B.D., Patel, S., Davis, B.E., Birnie, I.I.I.: Evaluation of the Tauc method for optical absorption edge determination: ZnO thin films as a model system. Physica Status Solidi (b) 252(8), 1700–1710 (2015). https://doi.org/10.1002/pssb.201552007

Wang, R.P., Xu, G., Jin, P.: Size dependence of electron-phonon coupling in ZnO nanowires. Phys. Rev. B. 69(11), 113303 (2004). https://doi.org/10.1103/PhysRevB.69.113303

Yahia, S.B., Znaidi, L., Kanaev, A., Petitet, J.P.: Raman study of oriented ZnO thin films deposited by sol–gel method. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 71(4), 1234–1238 (2008). https://doi.org/10.1016/j.saa.2008.03.032

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pat, S., Mohammadigharehbagh, R., Akkurt, N. et al. Studies on the surface and optical properties of Ta-doped ZnO thin films deposited by thermionic vacuum arc. Opt Quant Electron 53, 661 (2021). https://doi.org/10.1007/s11082-021-03248-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-021-03248-5