Abstract

ZnO is a fundamental wide band gap semiconductor. Especially, doped elements change the optical properties of the ZnO thin film, drastically. Doped ZnO semiconductor is a promising materials for the transparent conductive oxide layer. Especially, Zr doped ZnO is a potential material for the high performance TCO. In this paper, ZnO semiconductors were doped with Zr element and microstructural, surface and optical properties of the Zr doped ZnO thin films were investigated. Zr doped ZnO thin films were deposited thermionic vacuum arc (TVA) technique. TVA is a rapid and high vacuum deposition method. A glass, polyethylene terephthalate and Si wafer (111) were used as a substrate material. Zr doped ZnO thin films deposited by TVA technique and their substrate effect investigated. As a results, deposited thin films has a high transparency. The crystal orientation of the films are in polycrystal formation. Especially, substrate crystal orientation strongly change the crystal formation of the films. Substrate crystal structure can change the optical band gap, microstructural properties and deposited layer formation. According to the atomic force microscopy and field emission scanning electron microscopy measurements, all deposited layer shows homogeneous, compact and low roughness. The band values of the deposited thin film were approximately found as to be 3.1–3.4 eV. According to the results, Zr elements created more optical defect and shifted to the band gap value towards to blue region.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

ZnO thin film is one of the most investigated and promising material of the II-VI semiconductor compounds. ZnO is composed in hexagonal wurtzite crystal structure. ZnO thin films are used to in the field of optoelectronics, nanotechnology, sensor, transparent conductive oxide (TCO), solar cell windows, field-effect transistor, heat mirror and etc [1,2,3,4,5].

To obtain tunable properties of the ZnO semiconductor should be doped with variously element. For the ZnO thin film deposition, variously methods have been used such as sol–gel [1], RF magnetron sputtering [2, 3], vapor liquid solid catalytic [4], pulsed deposition [5], spray pyrolysis [3], and so on. ZnO material can be doped with various elements such as Al, In, Cu, Fe, Sn [6, 7], Mg [8], B [9], Fe [10], Pb [11], etc. Nunes et al. stated that the properties of the ZnO thin films strongly depends on the presence of the oxygen vacancies and interstitial zinc [3]. The optical properties of the ZnO thin film can be changed with experimental conditions [12] as well. In general, ZnO shows the different properties which related with the morphology of nanostructures [13].

Zr doping element is promising materials for the ZnO semiconductor, because Zr doped ZnO is a potential TCO material [14,15,16,17,18,19,20,21,22,23,24,25]. TCO materials are key component for the various applications and a novel TCO material is searching instead of the indium tin oxide. It has not find a novel TCO material, yet. When ZnO semiconductor thin film was Zr doped, the carrier concentration of the ZnO thin film decreases and the transparency of the film increased [14,15,16,17,18,19,20,21,22,23,24,25]. The ionic number of the zirconium element (+ 4) is higher than the zinc element (+ 2) [17]. The band gap of the Zr doped ZnO semiconductor changes according to the Zr element ratio [14, 17]. Approximately at 10% Zr in ZnO semiconductor, band gap values are very close to 3.50 eV. For a small doping ratio or un-doped ZnO semiconductor, the band gap value is obtain as to be 3.2 eV. Also, Zr creates some defects related with the Zr ratio in semiconductor [19]. So, Zr element is a critical elements for the shift band gap value towards to the blue region. Approximately variation for band gap of 300 meV in band gap of Zr doped ZnO semiconductor can be measured.

In this paper, the microstructural, surface and optical properties of the Zr doped ZnO thin films were investigated. Thin films were deposited by Thermionic vacuum arc (TVA) technique. These properties are key properties of a semiconductor. X-ray diffractometer, atomic force microscopy, field emission scanning electron microscopy, UV–Vis spectrophotometer, Interferometer and Photoluminescence device were used to determine the microstructural, surface and optical properties of the Zr doped ZnO semiconductors. In this paper, the substrate effects were also investigated for the Zr doped ZnO thin film. As a substrate, standard microscope slide, polyethylene terephthalate and Si wafer (111) were used.

2 Experimental

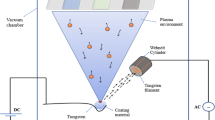

TVA is a plasma coating technology and it works under the high vacuum condition. Metal and non-metal materials can deposit easily. TVA is a fast deposition technology in plasma conditions. Many materials can be coated by using TVA technology. In this paper, ZnO material was doped with Zr metal via TVA technology. Doped semiconductors can be deposited rapidly and easily thanks to TVA. A TVA system have a two electrode, which named as anode and cathode. Anode was a Mo evaporation boat. ZnO and Zr metal were placed inside of the anode [26,27,28,29]. Cathode is an electron gun, which works with high AC current of 21.3 A. When AC current passing through overall the tungsten filament, thermoelectrons creates onto surface of the filament. After the electron production, these are focused onto materials via Wehnelt cylinder. Accelerated voltage is a DC voltage and its applied between the anode and cathode of the TVA electrodes. All electrodes were placed inside a vacuum chamber. Before thin film deposition, vacuum chamber was pumped to base pressure approximately 5 × 10−5 torr. For a thin film deposition, electron gun starts the electron emission. The emitted electrons accelerated by a high DC voltage towards to the anode materials (Zr and ZnO). The evaporation of the materials started by the emitting electrons. At reach the sufficiently vapor pressure, DC high voltage is applied and a bright arc discharge is seen in the interelectrodic region. After the plasma ignition, applied voltage drops to the lower value and simultaneously bombardment current reaches to the higher value. This is called as discharge current. In a plasma condition, the deposition rate is very high according to the other physical vapor deposition process and chemical vapor deposition process. Compared the quality of the films, the thin films deposited by TVA have some advantages. Especially wall and precursor impurity plays important role for the semiconductors quality [26,27,28,29]. The TVA process, doesn’t require any precursor and buffer gas. So, these impurity trace cannot detect in film composition. Especially, NH3 and water cannot find in the deposited film composition [26,27,28,29]. The deposition parameter values are given in Table 1.

All substrates were cleaned before the coating process. Distilled water and ethyl alcohol were used for the cleaning procedures in ultrasonic bath.

3 Experimental results

Zr doped ZnO thin films were deposited onto glass, PET and Si substrate using TVA technique. The thickness of the Zr doped ZnO thin films were approximately measured as 70 nm. The thicknesses of the films were measured in Cauchy model by a Filmetrics F20 thin film thickness measurement system. Microstructural properties were investigated by a X-ray diffractometer. Panalytical Empyrean X-ray diffractometer was used for the analyses in the 2-theta range from 20° to 80°. Obtained XRD patterns are seen in Fig. 1. A Pixel 3d detector was used in Bragg–Brentano geometry. Compared the XRD patterns, crystalline structures for the crystalline and semi crystalline substrate are different from the amorphous substrate crystalline structure. Considering the XRD patterns of the Zr doped ZnO thin films, Zr3O, ZrO2 and ZnO phases were detected for all samples. These films are in alloys form and they are contains mixed phases of the metal oxides [14, 18, 30]. In XRD patterns, any bi-metallic oxide reflection was not detected. This is a important findings and show the very good adherence with the published paper in literature [14, 18, 30]. But, Zhang et al. show the bi-metallic oxide phases [19]. The calculated crystallite sizes and XRD data are shown in Table 2. Crystallite sizes calculations were done by using Scherrer equation [28, 29]. Calculated crystallite sizes are bigger than value published in Tsay and Fan [14]. Also, Intensities of the obtained XRD pattern are bigger than the interested paper [14] and smaller than the literature [20]. All obtained data are in good agreement with JCPDS card. Used JCPDS card numbers are 93-153-5865 for Zr3O, 96-101-0913, 96-900-9052, 96-900-5835, 96-810-4265 for ZrO2 and 96-900-4182 for ZnO.

According to the XRD patterns, microstructural properties of the deposited films were different from the each others. Si wafer is in (111) direction. Polyethylene terephthalate (PET) substrate is in semi-crystalline form.

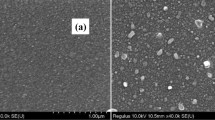

Surface analysis of the Zr doped ZnO thin films were done by Ambios Q-Scope AFM and FESEM analyses. Crystallites and granules can be clearly seen in AFM images as shown in Fig. 2a–c. The smallest granules were imaged in Fig. 2c. AFM images were taken non contact mode at room temperature. Scanning frequency of the AFM was adjusted to 6 Hz. FESEM images of the Zr doped ZnO thin films are illustrated in Fig. 2d–f.

All images are taken by Zeiss Supra 40 VP field emission scanning electron microscopy device. Nano particles can be clearly seen in the FESEM images. According to obtained results from Fig. 1, the images grains and crystallites are different from the each other. Especially, grains onto glass substrate are closely related to the ZrO2 phases. ZrO2 crystallites show the colon structure. This results are obtained from the AFM image (Fig. 2a) as well. Moreover, some ZnO crystallites formation can be seen in Fig. 2d. In the same time, influence of the substrate crystal properties are illustrated in AFM and FESEM images.

The crystallite sizes were measured by the AFM. Mean crystallite sizes were found as to be 50 nm, 25 nm, and 10 nm for the Zr doped ZnO thin films deposited onto glass, PET, and Si substrate, respectively. The crystallite sizes were illustrated in Fig. 3. The roughness of the films were measured 20 nm, 5 nm, and 1.5 nm for the glass, PET, and Si substrate, respectively. These findings are related with the AFM and FESEM images.

Optical properties are important for the two-dimensions structures. Two dimensions structures should be a transparent in optical region. Transmittance, absorbance and refractive index graphs are illustrated in Fig. 4. Transmittance and absorbance graphs of the Zr doped ZnO were obtained from the UV–Vis spectrophotometer data in the range of 200–1100 nm. Refractive indices measurements of the deposited films were taken by Filmetrics F20 Thin Film Measurements System in the range of 400–1000 nm. Cauchy model was used for the refractive index and thickness measurement analysis. Optical analysis were done for the glass and PET substrates. The coated PET samples are transparent and coated glass substrate is semi-transparent. The transparency values of the coated films are approximately 40% and 80% for the glass and PET substrate, respectively. Refractive index (n) values are changed in the range of 1.55–2.00. For the deposited films on glass substrate, refractive indices value increased with the increasing wavelength (nm). The n value of the refractive indices for the deposited film on Si substrate was decreased by increasing photon wavelength (nm). For the Zr doped ZnO coated PET, n value is slightly decreasing in optical region.

The bang gap graphs of the Zr doped ZnO thin films are shown in Fig. 5a. Bang gap value was estimated the following equation;

where α is an absorbance coefficient, h is Planck constant, ν is frequency of the incident photon, B is a constant, \({E_g}\) is band gap, A is absorbance, measured from the UV–Vis spectrophotometer, and t is the thickness of the deposited films, measured by the Filmetrics F20 thin film measured system. Integer m is a constant, m = 1/2 for direct allowed transition, m = 2 for indirect allowed transition, m = 3 for direct forbidden transition and m = 3/2 indirect forbidden transition of a semiconductor. Band gap plots were obtained from the absorbance values, measured by UV–Vis spectrophotometer. The band gap values are approximately 3.3 eV and 3.45 eV for glass and PET substrate, respectively. Perkin Elmer LS 55 Photoluminescence spectrophotometer (PL) was used to measure the band gap of the deposited Zr doped ZnO thin film onto glass, PET and Si, respectively. Obtained PL spectra are illustrated in Fig. 5b. PL spectra were recorded in the range of 2.6–3.8 eV. PL device gives the band structures of the Zr doped ZnO thin films.

Moreover, PL device gives the defect in the electronic transition and optical properties. In obtained PL spectra, band structures are very board for the Zr doped ZnO thin film deposition onto PET substrate and its’ value is near to 3.4 eV. For a Zr doped ZnO thin film deposited on the glass substrate, the band gap value is smaller than the value of the deposited film onto PET substrate. It was measured about 3.1 eV. For the film deposited onto Si substrate, band gap value is approximately 3.2 eV. According to the PL spectra, Zr doped ZnO thin films deposited onto various substrate materials have different optical transition, but these transitions are near the band gap value. Except for the Zr doped ZnO thin film deposited onto PET substrate, other thin films’ band gap values were decreased.

The obtained band gap values are bigger than the related literature [17]. Herodotou et al. states the band edge shift according to Zr element ratio and they proved the results by optical analysis of the doped semiconductor. In higher Zr concentrations, the band gap values are bigger than the lower concentration Zr in ZnO semiconductor. So, obtained band gap values are very close to the literature values [14,15,16,17,18,19,20,21,22,23,24,25]. The differences in the band gap values were affect the absorbance edge of the deposited thin film semiconductor onto glass, PET and Si wafer.

4 Conclusion

In this study, the substrate effect was investigated for the Zr doped ZnO semiconductor. Zr doped ZnO layers were deposited onto glass, PET and Si wafer. In XRD patterns, ZrO2 and ZnO peaks were detected. Any bi-metallic oxide XRD reflection was not detected. According to the field emission scanning electron microscopy results, oxide Zr nano crystals can easily detected. Especially, nano crystals in the FESEM images for deposited glass substrate are bigger than the crystal deposit on the other substrate. Mean crystallite sizes were found as to be 50 nm, 25 nm, and 10 nm for the Zr doped ZnO thin films deposited onto glass, PET, and Si substrate, respectively. The roughness’s of the films were measured 20 nm, 5 nm, and 1.5 nm for the glass, PET, and Si substrate, respectively. This findings are supported the atomic force microscopy results Zr doped ZnO is a promising TCO semiconductor. It’s band gap can change depends on Zr doping ratio. According to the literature, Zr ratio for higher concentration about 10%, the band gap values nearly equal to 3.5 eV. In obtained thin films, the band gap values are close to 3.3 and 3.5 eV and values were changed by substrate. The transparency of the deposited films onto glass sample is very high.

References

S. Ilican, Y. Caglar, M. Caglar, Preparation and characterization of ZnO thin films deposited by sol-gel spin coating method. J. Optoelectron. Adv. Mater. 10(10), 2578–2583 (2008)

E.M. Fortunato, P.M. Barquinha, A.C.M.B.G. Pimentel, A.M. Goncalves, A.J. Marques, L.M. Pereira, R.F. Martins, Fully transparent ZnO thin-film transistor produced at room temperature. Adv. Mater. 17(5), 590–594 (2005)

P. Nunes, E. Fortunato, R. Martins, Influence of the post-treatment on the properties of ZnO thin films. Thin Solid Films 383(1–2), 277–280 (2001)

M. Willander, Q.X. Zhao, Q.H. Hu, P. Klason, V. Kuzmin, S.M. Al-Hilli, O. Nur,.Y.E. Lozovik, Fundamentals and properties of zinc oxide nanostructures: optical and sensing applications. Superlatt. Microstruct. 43(4), 352–361 (2008)

F.K. Shan, B.I. Kim, G.X. Liu, Z.F. Liu, J.Y. Sohn, W.J. Lee, B.C. Shin, Y.S. Yu, Blueshift of near band edge emission in Mg doped ZnO thin films and aging. J. Appl. Phys. 95(9), 4772–4776 (2004)

M. Miki-Yoshida, J. Morales, J. Solis, Influence of Al, In, Cu, Fe and Sn dopants on the response of thin film ZnO gas sensor to ethanol vapour. Thin Solid Films 373(1–2), 137–140 (2000)

H. Gong, J.Q. Hu, J.H. Wang, C.H. Ong, F.R. Zhu, Nano-crystalline Cu-doped ZnO thin film gas sensor for CO. Sens. Actuators B 115(1), 247–251 (2006)

V. Etacheri, R. Roshan, V. Kumar, Mg-doped ZnO nanoparticles for efficient sunlight-driven photocatalysis. ACS Appl. Mater. Interfaces 4(5), 2717–2725 (2012)

S. Pat, R. Mohammadigharehbagh, C. Musaoglu, S. Özen, S. Korkmaz, Investigation of the surface, morphological and optical properties of boron-doped ZnO thin films deposited by thermionic vacuum arc technique. Mater. Res. Express (2018). https://doi.org/10.1088/2053-1591/aacc9a

T. Srinivasulu, K. Saritha, K.R. Reddy, Synthesis and characterization of Fe-doped ZnO thin films deposited by chemical spray pyrolysis. Mod. Electron. Mater. 3(2), 76–85 (2017)

M. Sathya, K. Pushpanathan, Synthesis and optical properties of Pb doped ZnO nanoparticles. Appl. Surf. Sci. 449, 346–357 (2018)

A. Janotti, C.G. Van de Walle, Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 72(12), 126501 (2009)

P. Uikey, K. Vishwakarma, Review of zinc oxide (ZnO) nanoparticles applications and properties. Int. J. Emerg. Technol. Comput. Sci. Electron. 21(2), 239–242 (2016)

C.Y. Tsay, K.S. Fan, Optimization of Zr-doped ZnO thin films prepared by sol-gel method. Mater. Trans. 49(8), 1900–1904 (2008)

M. Lv, X. Xiu, Z. Pang, Y. Dai, L. Ye, C. Cheng, S. Han, Structural, electrical and optical properties of zirconium-doped zinc oxide films prepared by radio frequency magnetron sputtering. Thin Solid Films 516(8), 2017–2021 (2008)

S.K. Yadav, S. Vyas, R. Chandra, G.P. Chaudhary, S.K. Nath, Study of electrical and optical properties of Zr-doped ZnO thin films prepared by dc reactive magnetron sputtering. Adv. Mater. Res. 67, 161–166 (2009)

S. Herodotou, R.E. Treharne, K. Durose, G.J. Tatlock, R.J. Potter, The effects of Zr doping on the optical, electrical and microstructural properties of thin ZnO films deposited by atomic layer deposition. Materials 8(10), 7230–7240 (2015)

M.C. Lin, Y.J. Chang, M.J. Chen, C.J. Chu, Characteristics of Zr-doped ZnO thin films grown by atomic layer deposition. J. Electrochem. Soc. 158(6), D395–D398 (2011)

J. Zhang, D. Gao, G. Yang, J. Zhang, Z. Shi, Z. Zhang, Z. Zhu, D. Xue, Synthesis and magnetic properties of Zr doped ZnO Nanoparticles. Nanoscale Res. Lett. 6(1), 587 (2011)

G. Murtaza, R. Ahmad, M.S. Rashid, M. Hassan, A. Hussnain, M.A. Khan, M.E. Haq, M.A. Shafique, S. Riaz, Structural and magnetic studies on Zr doped ZnO diluted magnetic semiconductor. Curr. Appl. Phys. 14(2), 176–181 (2014)

J. Wang, C.Y. Zhang, Z.G. Wu, P.X. Yan, Effect of annealing on structural and optical properties of Zr doped ZnO film grown by RF magnetic sputtering. Mater. Sci. Forum 686, 696–705 (2011)

A. Maldonado, D.R. Acosta, M.D.L.L. Olvera, R. Castanedo, G. Torres, J.C. Ortega, R. Asomoza, Physical characterization of zirconium doped zinc oxide thin firms deposited by spray pyrolysis. MRS Online Proc. Libr. Arch. (1998). https://doi.org/10.1557/PROC-520-57

H. Kim, J.S. Horwitz, W.H. Kim, S.B. Qadri, Z.H. Kafafi, Anode material based on Zr-doped ZnO thin films for organic light-emitting diodes. Appl. Phys. Lett. 83(18), 3809–3811 (2003)

V. Gokulakrishnan, K. Jeganathan, K. Ramamurthi, Growth and structural properties of ZnO and Zr doped ZnO nanostructures by low cost spray pyrolysis technique. Asian J. Chem. 25, S209–S210 (2013)

I. Khan, S. Khan, R. Nongjai, H. Ahmed, W. Khan, Structural and optical properties of gel-combustion synthesized Zr doped ZnO nanoparticles. Opt. Mater. 35(6), 1189–1193 (2013)

V. Şenay, S. Özen, S. Pat, Ş Korkmaz, Some physical properties of a Si-doped nano-crystalline GaAs thin film grown by thermionic vacuum arc. Vacuum 119, 228–232 (2015)

S. Pat, S. Temel, N. Ekem, Ş Korkmaz, M. Özkan, M.Z. Balbağ, Diamond-like carbon coated on polyethylene terephthalate by thermionic vacuum arc. J. Plast. Film Sheeting 27(1–2), 127–137 (2011)

S. Özen, V. Şenay, S. Pat, Ş Korkmaz, AlGaAs film growth using thermionic vacuum arc (TVA) and determination of its physical properties. Eur. Phys. J. Plus 130(6), 108 (2015)

S. Özen, S. Pat, V. Şenay, Ş Korkmaz, B. Geçici, Some physical properties of the SiGe thin film coatings by thermionic vacuum arc (TVA). J. Nanoelectron. Optoelectron. 10(1), 56–60 (2015)

N. Clament Sagaya Selvam, J.J. Vijaya, L.J. Kennedy, Effects of morphology and Zr doping on structural, optical, and photocatalytic properties of ZnO nanostructures. Ind. Eng. Chem. Res. 51(50), 16333–16345 (2012)

Acknowledgements

This research activity was supported by the Eskişehir Osmangazi University scientific research council, Grant Number is 201719041.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demirkol, U., Pat, S., Mohammadigharehbagh, R. et al. Investigation of the substrate effect for Zr doped ZnO thin film deposition by thermionic vacuum arc technique. J Mater Sci: Mater Electron 29, 18098–18104 (2018). https://doi.org/10.1007/s10854-018-9920-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9920-4