Abstract

Using data for 30 provincial panels in China from the period 1997–2014, this study analyzes the impact of multi-dimensional industrial structures and technological progress on carbon emissions in the STIRPAT framework. A spatial autocorrelation test demonstrated that there were significant positive global spatial correlations and local spatial agglomerations among the regions that were assessed. The dynamic spatial regression results show that industrial structure rationalization, industrial structural transformation and industrial structural upgrading significantly reduced carbon emissions. Industrial structural transformation provided the greatest contribution to carbon emissions. Technological progress was also conducive to reducing carbon emissions. Furthermore, efficiency improvements and technological innovation reduced carbon emissions, and efficiency improvements played a relatively greater role. There was an inverted U-shaped relationship between regional affluence and carbon emissions. The energy consumption structure, population and urbanization had significantly positive effects on carbon dioxide emissions, but the impact of foreign direct investments on carbon reduction was insignificant. Finally, some policy recommendations are given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In industrialization processes, extensive patterns of economic development have caused huge amounts of energy consumption and serious environmental problems. Because economic development has led to sharp increases in carbon emissions, China has surpassed the United States to become the largest carbon emitter in the world and is facing tremendous pressure to reduce carbon emissions. In 2009, the Chinese government announced that by 2020 the national carbon emissions per unit of gross domestic product will be reduced by 40–45% compared with that in 2005. In the “Paris Climate Agreement”, China committed that carbon emissions will reach their peak in China by the year 2030. Trends in gross domestic product, total energy consumption and carbon emissions in China from 1997 to 2014 are shown in Fig. 1. From Fig. 1, we find that the economic growth rate is less than that of carbon emissions. Energy shortages and environmental problems are increasingly severe, and energy conservation and carbon reduction have therefore become extremely urgent issues (Stigson et al. 2009). How to simultaneously achieve sustainable economic growth and carbon reduction goals is the most important issue we face (Fang et al. 2013). In fact, the Chinese government has realized the importance of energy conservation and carbon reduction for sustainable development and taken a number of measures to reduce emissions.

To effectively achieve carbon emission reduction targets, we need to analyze some key influencing carbon emissions factors, which are various. Studies have shown that economic development, technological progress, energy structure, international trade, urbanization and geographical features have an impact on carbon emissions (Kang et al. 2016; Xu and Lin 2015; Li et al. 2012; Wang et al. 2016; Kang et al. 2016; Ozbugday and Erbas 2015). The existing works focus on industrial structure and technological progress. However, the existing analyses of industrial structure or technological progress are not profound and are thus unable to reveal deep impacts on carbon emissions. In this paper, we report on a multifaceted analysis of industrial structure and technological progress to more deeply analyze their impacts on carbon emissions. Research has shown that the IPAT model is a suitable method for studying carbon emissions (Sadorsky 2013). Carbon emissions have a spatial spillover effect (Yang et al. 2014). Therefore, we incorporated the multi-dimensional industrial structure and technological progress into a dynamic spatial panel model under the STIRPAT framework. We analyzed the influence of industrial restructuring and the paths of technological progress on carbon emissions to provide a reference for carbon emission reductions.

2 Literature review

Due to global climate change, carbon emissions have been an issue of great concern to the public. Many studies have addressed the factors that influence carbon emissions. In general, the discussions have primarily adopted the perspectives of industrial structure adjustment and technological progress.

-

1.

Industrial structure adjustment

Grossman and Krueger (1995) found that economic development influences the environment through industrial structure. Carbon emissions are mainly attributed to fossil fuel combustion. Secondary industries are a major source of carbon emissions (Cole et al. 2008; Fisher-Vanden et al. 2006; Talukdar and Meisner 2001). The levels of energy consumption in different sectors are quite different. Changes in industrial structure affect carbon emissions. These especially include changes between industries and services as well as internal structural changes in industries (Xu et al. 2014). Some scholars have analyzed the impact of industrial structures on carbon emissions using index decomposition models (Ang 2005; Xu et al. 2015; Li and Wei 2015; Hoekstra and van den Bergh 2003) and input–output models (Xiang et al. 2013; Liu et al. 2015a, b; Chi et al. 2014). Alternatively, some scholars have used proxy variables to analyze the impacts of industrial structures on carbon emissions, including the added value proportions of secondary industries (Liu et al. 2015c) and services and industrial ratios (Zhou et al. 2013) and proportion of service to gross domestic product (Li and Lin 2016). The existing studies’ conclusions differ from each other to a great degree. Some researchers argue that industrial structural adjustments would result in increasing carbon emissions because of the dominant positions of high-carbon industries in the industrial revolution (Geng et al. 2013; Zhang and Da 2015). Others believe that carbon emissions reduction is attributable to adjustments in industrial structures to low-carbon industries and services (Tian et al. 2014). The conclusions differ partly because the regions, time periods, variables, selected data and empirical methods differ in the available literature.

-

2.

Technological progress

Technological progress affects carbon emissions by increasing economic output or reducing energy consumption. Technological progress is an effective way to reduce carbon emissions and promote economic development (Long et al. 2016; Hua and Wang 2015). The following methods are used to measure technological progress. The first method is to select proxy variables based on the perspective of research and development, for example, the number of patents, scientific personnel and R&D expenditures (Yang et al. 2014; Wang et al. 2011; Ang 2009; Liu et al. 2015c). In the second method, total factor productivity (TFP) is used as a proxy variable of generalized technological progress using data envelopment analysis (DEA) or stochastic frontier analysis (SFA) (Wu et al. 2016; Fei and Lin 2016; Yu et al. 2016; Weng et al. 2015; Guesmi et al. 2015). Comparing the above methods, we find that the use of R&D to measure technological progress is insufficiently general, whereas TFP can more comprehensively generalize technological progress. Research and development is merely a factor that influences technological progress rather than the technological progress itself. Most studies have shown that technological progress reduces carbon emissions through energy efficiency improvements (Wang et al. 2011; Ang 2009). However, some scholars have arrived at opposite conclusions. In their opinion, technological progress has resulted in an increase in total energy consumption and carbon emissions due to the rebound effect (Khazzoom 1980).

The studies on the influence of industrial structure and technological progress on carbon emissions have gained fruitful achievements. However, shortcomings remain. (1) In the existing literature, the descriptions of industrial structures are not rich, and the studies of industrial structure adjustment are not comprehensive. In addition, regarding carbon emissions, industrial structure is measured mainly from the aspect of the sophistication of industrial structures but not industrial structure rationalization. In fact, industrial structure adjustments affect carbon emissions in a variety of ways. First, the rationalization of industrial structures can reduce carbon emissions. Proper factor allocations and resource flows among industries promote regional input–output efficiencies and thereby reduce carbon emissions (Chang 2015). Second, industries can reduce carbon emissions by being transformed into the service sector. Service industries produce less energy consumption and carbon emissions because they play a positive role in decreasing environmental pollution (Chi et al. 2014). Third, evolution towards low-carbon and high-tech industries can reduce carbon emissions. High-tech industries with knowledge-intensive characteristics reduce the proportion of highly polluting and energy-intensive industries. In high-tech industries, carbon emissions are reduced because of research, the development of environmental technologies and the use of cleaner production equipment (Tian et al. 2014). We therefore analyzed the impact of industrial structure on carbon emissions from three aspects: industrial structure rationalization, industrial structural transformation and industrial structural upgrading. (2) In existing studies, technological progress has been estimated using only a single indicator and without in-depth decomposition analyses. In fact, technological progress includes technology innovation and improvements in efficiency (Fare et al. 1994). These factors have different carbon emissions reduction mechanisms and effects. Efficiency improvements reduce carbon emissions by improving management efficiency, and technological innovations reduce carbon emissions by enhancing scientific and technological innovation capabilities (Du et al. 2014; Fan et al. 2015). Therefore, we further decomposed technological progress into efficiency improvements and technological innovations to analyze their impacts on carbon emissions. (3) From an empirical perspective, regression analyses are performed using ordinary dynamic panel models or Tobit models. The spatial evolutionary mechanisms of carbon emissions are not truly reflected due to neglecting the spatial spillover effect on carbon emissions and the spatial heterogeneities of industrial structures and technological progress among regions. We therefore used a dynamic spatial panel model that was significantly superior for analyzing the impacts of multi-dimensional industrial structures and technological progress on regional carbon emissions under environmental constraints. The model’s regression results became more accurate and reliable by taking into account the spatial spillover effects on carbon emissions.

Based on existing research, we used the dynamic spatial panel model to analyze the influences of industrial structural adjustments and technological progress on carbon emissions to find the critical path to realizing the goal—maintaining growth and reducing carbon emissions. The rest of the study is organized as follows. Section 3 describes the research models and data employed in our study. Section 4 analyzes the spatial autocorrelations and spatial heterogeneities of the carbon emissions. Section 5 provides an analysis and discussion of the results. Section 6 concludes the study and provides policy recommendations.

3 Model, variables and data

3.1 Variables and data

3.1.1 CO2 emissions

CO2 emissions can be calculated using the following formula:

where \(E_{k}\) represents the consumption of fuel k, \(e_{k}\) is the net heat value of fuel k, \(c_{k}\) is the carbon emission factor of fuel k, and \(o_{k}\) is the carbon oxidation rate of fuel k. According to the “China Energy Statistical Yearbook,” there are eight fuel categories: raw coal, coke, crude oil, gasoline, diesel oil, kerosene, fuel oil and natural gas (see Appendix Table 4). The net heat values were taken from the “China Energy Statistical Yearbook”, and the carbon emission factors and carbon oxidation rates are from the IPCC.

3.1.2 Industrial structure

Industrial structure adjustment is an important factor that affects carbon emissions. We analyze the impacts of changes in industrial structures on carbon emissions from three dimensions. Industrial structure rationalization (ISR) refers to the collaborative development capabilities of different industries and the efficiencies of resource allocation among industries. ISR results in higher input–output efficiencies and lower carbon emissions. The Theil index (1967) is often used as a measure of the income gaps (or inequalities) among individuals or regions. Following the study of Gan et al. (2011), in this paper, the Theil index is used to measure the level of industrial structure rationalization and is calculated by

where ISR is the rationalization level of the industrial structure; Y, L, and n, respectively, represent the gross domestic product, total employment and total number of industrial sectors; i is the type of industry; and Y i and L i are the added value and employment for industry i, respectively. If the labor force allocations among the industry sectors are rational, \({\text{ISR}} = 0\), which indicates that the economic system is in equilibrium and that the industrial structure is rational. If \({\text{ISR}} \ne 0\), the economic system deviates from the equilibrium state, and the industrial structure is irrational. The larger the value of ISR, the more irrational the industrial structure and the more likely the economic development will deviate from equilibrium.

Industrial structural transformation (IST): According to the Petty-Clark’s Law (1940), economic activities are divided into primary industries (including farming, animal husbandry, hunting, fisheries and forestry), secondary industries (including mining, manufacturing, supply, and construction) and tertiary industries (services). As an economy develops, the relative proportion of the national income to the labor force of the first industry gradually decreases, whereas the corresponding relative proportion of second industries increases. As the economy develops yet more, the relative proportion of the national income to the labor force of tertiary industries begins to rise. The difference in carbon emissions from secondary industry and services is significant. When industries are transformed into the services sector, carbon emissions are reduced. The experiences of developed countries and regions suggest that industries tend to restructure towards a service-oriented economy. The ratio of tertiary industrial output to secondary industrial output is used to reflect the level of industrial structural transformation.

Industrial structural upgrading (ISU): Considering all industries, the secondary industries accounted for the largest proportion of carbon emissions in China (Geng et al. 2013). According to the definition of high-tech industry from China’s high-tech industry statistical yearbook, high-tech industries include pharmaceutical manufacturing, aviation, spacecraft and equipment manufacturing, electronics and communications equipment manufacturing, computer and office equipment manufacturing, medical equipment and instrumentation manufacturing, and information chemical manufacturing. Regarding secondary industries, high-tech industries produce more added value while discharging relatively less carbon dioxide. When industries upgrade from low to high technology levels, carbon emissions are reduced. If the proportion of high-tech secondary industries increases, it indicates that the secondary industries are upgrading in a low-carbon and high-tech direction. The proportion of high-tech to secondary industries is used to measure the level of secondary industries’ structural upgrading.

3.1.3 Technological progress

In this paper, environmental total factor productivity (ETFP) is used to characterize the level of technological progress (Chung and Heshmati 2015). According to Tone (2001) and Fukuyama and Weber (2009), we define slack-based directional distance functions with constrained resources and establish a production possibility set comprising the desired and undesirable outputs. Furthermore, we adopt the Malmquist–Luenberger productivity index proposed by Chung et al. (1997) to calculate ETFP. On that basis, we decompose technological progress into efficiency improvements and technology innovations. Efficiency improvements, which are mainly brought about by management innovations and institutional reforms, involve the movement of decision units to the production frontier but not the movement of the production frontier. Technology innovation, which includes scientific and technological inventions and patents can capture the movement of the production frontier.

Supposing that each region is a production decision unit. According to Tone (2001) and Fukuyama and Weber (2009), the slacked-based measure directional distance function based on the resource environment is defined as

where the vector \((x^{{t,k^{\prime}}} ,y^{{t,k^{\prime}}} ,b^{{t,k^{\prime}}} )\) is the input, desired output and undesired output at time t in region k′, \((g^{x} ,g^{y} ,g^{b} )\) is the direction vector of the input compression, expansion of desired outputs and reduction of undesired outputs, which has a positive value. \((s_{n}^{x} ,s_{m}^{y} \,{\kern 1pt} ,s_{i}^{b} )\) represents the input and output slack variables.

Using the directional distance function, the environment Malmquist–Luenberger (ML) productivity can be constructed. According to Chung et al. (1997), from period t to period t + 1, the ML productivity index of ETFP can be obtained using a four directional distance function:

Furthermore, technical progress can be decomposed into a pure technical progress index (TI) and efficiency improvement index (EI):

We used the MATLAB 2010b to calculate ETFP and its decomposition. The relevant input and output indicators and data processing for the above formulas are now described. Labor input is the employment figures at the end of the year. Energy inputs are the annual energy consumptions in each region. We converted the consumption of coal, coke, crude oil, gasoline, diesel oil, kerosene, fuel oil and natural gas to “tons standard coal”. In this paper, capital stock represents capital investment. We estimated capital stock using the perpetual inventory method and set the depreciation rate to 10.96%. Desired output is the gross regional product (GRP), which was adjusted to constant 1997 prices according to each provincial GRP deflator. Undesired output is CO2 emissions.

3.1.4 Control variables

In addition to the above factors, energy consumption structure, foreign direct investment and urbanization level affect regional carbon emissions. (1) Energy consumption structure (ES). Energy consumption structure has a significant impact on carbon emissions because the carbon emissions of coal, coke, crude oil, gasoline, diesel oil, kerosene, fuel oil and natural gas are quite different. Compared with other energy sources, the carbon intensity of coal is greater. In primary energy structures, dirty coal accounts for a high proportion. Although the use of other energy increases continuously during recent years, the proportion of coal consumption in China’s primary energy structure is still very high. The change of the coal-dominated energy structure is the mean point to reduce carbon emissions (Lin et al. 2010). Therefore, in this paper, the proportion of coal consumption to total energy consumption is used to characterize the structure of energy consumption. (2) Foreign direct investment (FDI). Compared with domestic enterprises, foreign enterprises have more advanced technologies that can directly reduce carbon emissions. The ratio of the actual use of foreign investment to gross domestic product is used to measure foreign direct investment. (3) Urbanization level (UL). In the process of urbanization, huge energy consumption results in large amounts of carbon emissions. Urbanization level is the proportion of the non-agricultural population to the regional total population. (4) Affluence is represented by per capita gross domestic product of the regions. (5) Population size (P) is the total population of each region.

3.1.5 Data sources

In view of data availability and effectiveness, we selected relevant data for 30 provinces in China from 1997 to 2014. Tibet was eliminated due to a lack of data. The data were mainly taken from the “China Statistical Yearbook” (1998–2015), “China Energy Statistical Yearbook” (1998–2015), “China Statistical Yearbook on High Technology Industry” (1998–2015) and “China Population Statistics Yearbook” (1998–2015).

3.2 Model specification

The IPAT framework proposed by Ehrlich and Holdren (1971) is an important approach to analyzing the impacts of population, affluence and technology on the environment. Dietz and Rosa (1997) actually reformulated the IPAT equation as Stochastic Impacts by regression on population, affluence and technology (STIRPAT). They analyzed the impacts of population, affluence and technology on CO2 emissions for the first time and established the values and status of the IPAT model for the analysis of global climate change problems. Compared with the IPAT model, the STIRPAT model has a good additive property and can capture the complexities and interactions among variables. In recent years, the STIRPAT model has been widely used and extended in analyses of carbon emissions (Shahbaz et al. 2015; Alegría et al. 2016; Noorpoor and Kudahi 2015).

Dietz and Rosa investigated the environmental impact I from a population of size P, affluence A and technological progress T using the STIRPAT model. For region i, the environmental impact I is

where b, c, and d are the elasticities to environmental impacts from a population of size P, affluence A and technological progress T. a is a parameter, and e i is the error term. Taking the logarithm of Eq. (1), we obtain

where \(a_{0}\) and \(z_{i}\) are the logarithms of a and \(e_{i}\), respectively, and b, c, and d reflect the driving levels of the impacts on environment I due to a population of size P, affluence A and technological progress T. Because of the additive property, this model can be expanded by adding more variables to analyze the impact of these factors on the environment. In this paper, this model is used to analyze the impacts of industrial structure and technological progress on regional carbon emissions. Because there may be an inverted U-shaped relationship (EKC) between per capita income and carbon emissions (Jalil and Mahmud 2009), we introduce quadratic terms of per capita income into the model. Therefore, Eq. (2) can be extended to Eq. (3):

where i and t represent the region and year. CE represents carbon emissions. ISR is industrial structure rationalization. IST is industrial structural transformation. ISU is industrial structural upgrading. ML is technological progress (we substitute EI and TI for ML, wherein EI denotes efficiency improvement, and TI is technology innovation). P is the total population. GDP is per capita gross domestic product. ES is energy consumption structure. FDI represents the foreign investment level. UL is the level of urbanization. \(\alpha\) is a coefficient.

The regression analysis is performed in three steps. For the first step, without considering the spatial relationships among the variables, an ordinary dynamic panel model is used for the regression analysis. The regression equation is shown in Eq. (4), where \(\tau\) is the regression coefficient of the lagged carbon emission.

Anselin (1995) found that each region might be variously affected by its adjacent regions. Spatial econometrics can identify the spatial evolution of regulations and key influencing factors of CO2 emissions. In comparison with traditional econometric models, spatial econometric models reduce estimation error. Therefore, for the second step, a static spatial panel model will be used to analyze the impact of industrial structure and technological progress on regional carbon emissions. Static spatial panel models include spatial autoregressive models (SAR) and spatial error models (SEM). Equations (5) and (6) are the SAR and SEM models:

In Eqs. (5) and (6), \(\rho\) and \(\lambda\) represent regression coefficients of spatial items that reflect the spatial spillover effect of carbon emissions. \(\beta_{i}\) is a regional effect. \(v_{t}\) is the time effect, and \(\varepsilon_{it}\) is a random disturbance term. They represent random disturbances that have different dimensions. \(W = (W_{ij} )\) is a spatial weight matrix, which reflects the spatial relationships among the various regions. If regions i and j are adjacent, \(W_{ij} = 0\), and if regions i and j are not adjacent, \(W_{ij} = 1\).

In fact, carbon emission is a dynamic process, as it is not only affected by current factors but also lagged factors. Thus, in the third step, we use a dynamic spatial panel model to examine the impact of industrial restructuring and technological progress on carbon emissions. Compared with a static panel model space, a dynamic spatial panel model has significant advantages. Estimation results are more accurate and reliable because the model takes into account both spatial spillover effects and the dynamic effects of carbon emissions and offers the opportunity to control for independent variables lagged in time (Elhorst 2012). Therefore, we construct the following dynamic spatial panel model:

In Eq. (7), \(\ln {\text{CE}}_{i(t - 1)}\) is the lagged carbon emission in the province. \(\theta \;\) is the regression coefficient of lagged carbon emissions. It reflects the impact of relevant factors from the previous period to the current period.

4 Spatial autocorrelation and spatial heterogeneity of carbon emissions

4.1 Global spatial autocorrelation analysis

Economists and ecologists have realized that the spatial correlations among variables have an important influence on regional issues (Tian et al. 2012; Krugman and Venables 1995). A characteristic of carbon emissions is spatial correlation (Yang et al. 2014; Cheng et al. 2017). To further excavate important information and rules underlying spatial interactions, Moran’s index (Moran’s I) is used to test the spatial autocorrelations of carbon emissions (Dong and Liang 2014; Black et al. 2014; Zhang et al. 2016). Moran’s I is the preferred means to test whether the characteristics or properties of the adjacent regions (provincial carbon emissions in the paper) are dependent or not. Moran’s I includes the global autocorrelation Moran’s I and local autocorrelation Moran’s I. The former describes the spatial characteristics of global distributions for the entire study area, whereas the latter characterizes the spatial relationship of local distributions. The global Moran’s I is defined as

where N is the total number of provinces,\(Y_{i}\) and \(Y_{j}\) are the carbon emissions in provinces i and j, \(\bar{Y}\) is the average value of all the provincial carbon emissions, and \(W_{ij}\) is the spatial weight matrix. We use the standard statistic Z to test the significance level of Moran’s Index. The standardized value of the test statistic Z is

Moran’s I ranges from −1 to 1. When I > 0, a positive spatial correlation indicates that provinces that have similar carbon emissions cluster together. When I < 0, a negative spatial correlation means that provinces that have adverse carbon emissions cluster together. When I = 0, there are no spatial correlations among provinces.

We calculated global Moran’s Index using ARCGIS10.2.2. As we can see from Table 1, the results indicate the following spatial distribution characteristics of regional carbon emissions in China. (1) From 1997 to 2014, the Moran’s I of the regional carbon emissions exceeded 0 and passed the significance test at a 1% level. The spatial dependence of the carbon emissions was significant, and regions with similar carbon emissions had relatively stable spatial agglomerations. (2) Between the years 1997 and 2014, Moran’s I fluctuated but increased overall, reached a peak in 2008, and then decreased while continuing to fluctuate, which shows that the effects due to the spatial correlation of carbon emissions in China gradually decreased after previously increasing.

4.2 Local spatial autocorrelation analysis

To clarify the similar and contrasting clusters in the local regions, we used the local indicators of spatial association (LISA) proposed by Anselin (1995) to measure the degree of correlation between a region i and its adjacent regions. According to LISA, local spatial autocorrelations can be divided into four types: High–High, High–Low, Low–High and Low–Low. High–High indicates that a region with high carbon emissions is surrounded by regions with high carbon emissions. High–Low means that a region with high carbon emissions is surrounded by regions with low carbon emissions. Low–High attests that a region with low carbon emissions is surrounded by regions with high carbon emissions. Low–Low denotes that a region with low carbon emission is surrounded by regions with low carbon emissions.

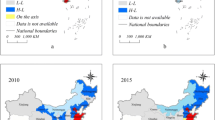

We used GeoDA to draw a LISA agglomeration map of regional carbon emissions in China for 1997 and 2014 (see Fig. 2). The results show that the spatial structure of the regional carbon emissions was stable from 1997 to 2014. The High–High agglomeration regions mainly included eight provinces. The carbon emissions in the High–High regions accounted for approximately 48% of the total carbon emissions. The Low–High agglomeration regions included Beijing and Tianjin. The carbon emissions in the Low–High regions were low because of the high level of social development as well as strict environmental requirements. The High–Low agglomeration region was Guangdong, whose total economic output ranks first in China. It has a large amount of energy consumption and carbon emissions. Hainan and Guangxi are Low–Low agglomeration regions that have poor economic development and low carbon emissions.

In short, carbon emissions in China have significant global spatial autocorrelations and spatial heterogeneity. This indicates that geographical factors have important impacts on carbon emissions. Therefore, when analyzing carbon emissions in China, geographic factors should be accounted for. It is feasible to perform the empirical analysis with a spatial econometric model.

5 Results

We selected panel data for 30 provinces in China from 1997 to 2014, excluding Tibet, whose data are seriously deficient. A total of 540 observations are considered in this paper. Table 2 lists the descriptive statistics of the variables. Traditional regression methods without spatial effects produce estimation errors due to spatial autocorrelations and the spatial heterogeneity of carbon emissions. We therefore used the dynamic spatial panel model to perform the empirical analysis. In addition, the ordinary dynamic panel model and static spatial panel model were used to perform the comparative analysis and robustness test.

There are two estimation methods for dynamic panel models: the difference generalized method of moments (DIF-GMM) and the system generalized method of moments (SYS-GMM). Compared to DIF-GMM, SYS-GMM greatly improves the effectiveness and consistency of estimates because it corrects biases by paying attention to the extra variations in small samples. Therefore, ordinary dynamic panel and dynamic spatial panel models use SYS-GMM to make estimates. In SYS-GMM, the lagged values of all the explanatory variables are used as instrumental variables (Elhorst 2012). Sargan test was used to identify the effectiveness of the instrumental variables in the SYS-GMM estimation. The Arellano–Bond test statistic AR (2) was used to test whether there were residual correlations. The SAR and SEM models were selected by comparing the corresponding Lagrange multipliers (LM) and their robustness. A SAR model should be selected if LM-LAG is more significant than LM-ERR and Robust-LM-LAG passes a significance test, whereas Robust-LM-ERR does not. Otherwise, an SEM model is selected. The regressions were conducted via Stata12.0. The estimation results are shown in Table 3. Models (1) and (2) are ordinary dynamic panel models. Models (3) and (4) are static spatial panel models. Models (5) and (6) are dynamic spatial panel models.

As seen from the AR (2) test results in Table 3, the ordinary dynamic panel models (1) and (2) were valid because the residual sequence was not a second-order serial correlation. For static spatial panel models (3) and (4), model SEM was used to make estimates because LM-ERR was more significant than the LM-LAG, and Robust-LM-ERR passed the significance test, whereas Robust-LM-LAG did not. As for dynamic spatial panel models (5) and (6), firstly, model SEM was used for estimation because LM-ERR was more significant than the LM-LAG, and Robust-LM-ERR passed the significance test, whereas Robust-LM-LAG did not. Secondly, the AR (2) test showed that the residual sequence was not a second-order serial correlation, and finally the Sargan test showed that instrumental variables were valid. Therefore, model SEM was used to estimate the static and dynamic spatial panel models. The ordinary dynamic panel and dynamic spatial panel models were estimated using SYS-GMM.

From the regression results in Table 3, we can see that the coefficients of the explanatory variable basically had the same sign, although their values and significance levels differed. This indicates that the results of the regression model were robust. The regression results of the ordinary dynamic panel and dynamic spatial panel models were significantly different. The coefficient of the lagged term in the dynamic spatial panel model was higher than that for the ordinary dynamic panel model. The coefficient of the spatial term in the dynamic spatial panel model was significant. The significance of industrial rationalization, industrial structural transformation, industrial upgrading and urbanization in the dynamic spatial panel model was superior to that in ordinary dynamic panel model. This indicates that the regional carbon emissions were influenced by the surrounding regions through the spatial spillover effect. The ordinary dynamic panel model ignores spatial spillover effects and increases estimation error. After adding the carbon emission spatial term, its coefficient was positive and passed the significance test at the 1% level. This fully verifies the spatial characteristics of the carbon emissions. The regression results of the static spatial panel and dynamic spatial panel models were quite different. The coefficient of the spatial term in the dynamic spatial panel model was far less than that of the static spatial panel model because carbon emission is a continuous dynamic process and technological level and human capital in the previous period influence production activities and carbon emissions in the current period. The static panel model spatially neglects dynamic effects and results in estimation errors. The coefficient of the lagged term was positive and passed the significance test at the 1% level. This fully verifies the dynamic characteristics of the carbon emissions. After a comprehensive consideration of the ordinary dynamic panel model, static spatial panel model and dynamic spatial panel model, we chose the dynamic spatial panel model as the final explanatory model.

From the regression results of dynamic spatial panel models (5) and (6), we found that industrial structure had a significant effect on carbon emissions. The regression coefficient of the industrial structure rationalization was significantly positive. Carbons emissions decreased with increasing industrial structural rationality. The regression coefficients for industrial structural transformation and industrial structural upgrading were both significantly negative. Carbon emissions decreased with increasing levels of industrial structural transformation and industrial structural upgrading. The absolute value of the coefficient of industrial structural transformation was the highest of the three coefficients. This shows that three types of industrial structure adjustments are conducive to reducing carbon emissions. The contribution of industrial structural transformation on carbon emissions reduction was greatest. Industrial structure reduces carbon emissions mainly because of the following three aspects. (1) Industrial structure rationalization. Regional productivity increases continuously because factors and resources flow from low productivity sectors to higher productivity sectors. Improvements in resource allocation efficiencies among industries cause improvements in regional input–output efficiencies and decreasing regional carbon emissions. (2) Industrial structural transformation. Tertiary industries, which are low-input and high-output industries, consume less energy and release less carbon dioxide. Therefore, vigorously developing modern service industries and gradually optimizing service sector structures can reduce the sector’s proportion to a certain degree. Industrial structural transformation has a positive effect on reducing environmental pollution. (3) Industrial structural upgrading. Upgrading primarily means the optimization of interior secondary industry structures. Developing high-tech industries can increase the proportion of technology-intensive and knowledge-intensive industries and promote technological progress. High-tech industries can also reduce the proportion of highly polluting, high-energy consumption industries and encourage investment in environmental technologies and clean production equipment. All of the above can control the generation and emission of carbon dioxide at the source.

The coefficient of technological progress was significantly negative. Carbon emissions decreased with increasing levels of technological progress. The coefficients of technology innovation and efficiency improvement were both significantly negative. In addition, the coefficient of efficiency improvement was less than the coefficient of technology innovation. This suggests that technological progress is conducive to carbon emission reduction in China. In the process of carbon emission reductions under technological progress, improving efficiencies and technological innovations have played important roles, among which improvements in efficiency have made greater contributions than have technology innovations. Improvements in efficiency causes decision-making units to move towards the technology frontier through continuous improvements in the abilities of technology applications and enterprise management levels. Efficiency improvements reduce carbon emissions and increase economic output by reducing energy consumption and production costs. Technological innovation causes the technology frontier to move and reduces carbon emissions by improving production techniques, energy-conserving techniques and carbon-reduction technologies.

The coefficient of per capita gross domestic product was significantly positive, whereas the coefficient of quadratic per capita gross domestic product was significantly negative. There is therefore an inverted U-shaped relationship between affluence and carbon emissions. Carbon emissions are low at lower per capita incomes. Carbon emissions increase and ecological environments deteriorate with increasing per capita income. When per capita income reaches a certain threshold, carbon emissions peak. Beyond the threshold, carbon emissions decrease and ecological environments improve with increasing per capita income. Energy consumption structure has a significantly positive impact on carbon emissions. This indicates that decreases in coal consumption ratios are beneficial to carbon emission reduction, which is mainly because carbon emissions per unit of output from coal are higher when compared with those of oil, electricity and natural gas. Energy consumption structural transformation, which was coal-dominated in the previous period, is therefore an important way to reduce carbon emissions. Population growth leads to increasing carbon emissions. Urbanization worsens the carbon emissions problem, showing that urbanization in China results in large amounts of carbon emissions because of an extensive growth mode based on high investments and emissions. Foreign direct investment has a negative impact on carbon emissions, but the impact is insignificant. This may be the reason why foreign direct investment businesses in China still focus on labor-intensive and resource-intensive industries such as low-tech processing, assembly, and manufacturing. Foreign direct investment does not play an important role in carbon emissions reduction because it does not bring obvious knowledge and technology spillovers.

6 Conclusions and implications

In this research, a dynamic spatial panel model was used to analyze the impacts of industrial restructuring and technological progress on carbon emissions from multiple perspectives. The conclusions confirm that carbon emissions have significant global spatial autocorrelations and heterogeneities. Shandong, Hebei, Liaoning, Henan, Shaanxi, Shanxi, Anhui, and Jiangsu are high carbon emission agglomeration regions. Carbon emissions in those regions account for approximately 48% of total carbon emissions. Industrial structure rationalization, industrial structural transformation and industrial structural upgrading reduce carbon emissions, and industrial structural transformation makes the greatest contribution to carbon emission reductions. Efficiency improvements and technological innovation can reduce carbon emissions, and efficiency improvements play a relatively greater role than technological innovations. There is an inverted U-shaped relationship between affluence and carbon emissions. Energy consumption structure, population and urbanization have significant positive influences on carbon emissions. Foreign direct investment has a negative impact on carbon emissions, but the impact is not significant. The following policy recommendations are based on the above conclusions.

-

1.

Carbon emissions should be reduced by industrial structural transformation. It is advised that effective policies be implemented to encourage the development of a modern service industry and to limit the excessive development of secondary industries with high energy consumptions. For example, services can be expanded through taxes and subsidies. Energy conservation and emission reductions for secondary industries should be promoted through carbon tariffs and emission quotas. The opening-up of the service industry should be expanded, and development environment of the service industry should be optimized. Producer services should be developed into specialized and more advanced value chains. Consumer services should be converted to fine processing and focus on superior quality. Policies should comprehensively promote the transformation of difficult regions that suffer resource depletion, industrial decline and serious ecological degradation. It is advisable to promote innovations and transformations in resource-based regions and to form a new pattern of multi-point support and diversified development.

-

2.

Carbon emissions should be reduced by upgrading industrial structures. Policies should change the patterns of industry in industrial areas to develop new industrialization paths. Policies should encourage the development of low-carbon, environmentally friendly and high-tech industries to achieve industrial upgrading and efficiency improvements. The excessive growth of energy-intensive and carbon-intensive sectors should be restricted, and backward production capacities should also be phased out in manufacturing industries. The development of high-tech industries, including information, electronics and equipment manufacturing, should be accelerated to increase their percentage. Steel, nonferrous metals, coal, electricity, oil, petrochemicals, chemicals, building materials and other carbon-intensive industries should also be adjusted.

-

3.

Carbon emissions should be reduced through industrial structure rationalization. Policies should make industry structures more reasonable and avoid low-level repetitive construction and disorderly competition while considering environmental capacity, natural resources, economic base, market demands, and location advantages in different regions. It is advised to perfect exit mechanisms for excess capacity industries and guide the rational distribution and ordered transference of industries. The rationalized development of industrial structures should be promoted by optimizing allocations of production factors and resource mobility among industries to reduce carbon emissions.

-

4.

Carbon emissions should be reduced through efficiency improvements. Enterprises should establish scientific management systems to improve information levels and operational efficiencies. Energy management systems and online carbon emission monitoring systems should be constructed to strengthen the management of energy conservation and emission reductions. Governments should encourage enterprises to carry out integrated and imitative innovations to constantly improve energy efficiencies and reduce carbon emissions.

-

5.

Carbon emissions should be reduced through technological innovation. Low-carbon technologies and the manufacturing capacities of environmentally friendly equipment should be improved through development, demonstration and promotion. Policies should encourage R&D technologies for clean, renewable energy and exploration technologies for natural gas, coal bed methane and shale gas. For energy structures, the proportion of renewable and newly emerging energy—winds, solar, hydro, nuclear, biomass, and geothermal—should be continuously improved, and the proportion of fossil fuel consumption should be reduced.

References

Alegría IMD, Basañez A, Basurto PDD et al (2016) Spain's fulfillment of its Kyoto commitments and its fundamental greenhouse gas (GHG) emission reduction drivers. Renew Sustain Energy Rev 59:858–867

Ang BW (2005) The LMDI approach to decomposition analysis: a practical guide. Energy Policy 33(7):867–871

Ang JB (2009) CO2 emissions, research and technology transfer in China. Ecol Econ 68(10):2658–2665

Anselin L (1995) Local indicators of spatial association-LISA. Geogr Anal 27:93–116

Black K, Creamer RE, Xenakis G et al (2014) Improving forest soil carbon models using spatial data and geostatistical approaches. Geoderma 232:487–499

Chang N (2015) Changing industrial structure to reduce carbon dioxide emissions: a Chinese application. J Clean Prod 103:40–48

Cheng Z, Li L, Liu J (2017) The emissions reduction effect and technical progress effect of environmental regulation policy tools. J Clean Prod 149:191–205

Chi Y, Guo Z, Zheng Y et al (2014) Scenarios analysis of the energies’ consumption and carbon emissions in China based on a dynamic CGE model. Sustainability 6(2):487–512

Chung Y, Heshmati A (2015) Measurement of environmentally sensitive productivity growth in Korean industries. J Clean Prod 104:380–391

Chung Y, Fare R, Grosskopf S (1997) Productivity and undesirable outputs: a directional function approach. J Environ Manag 51(3):229–240

Clark C (1940) Conditions of economic progress. Macmillan, London

Cole MA, Elliott RJR, Wu S (2008) Industrial activity and the environment in China: an industry-level analysis. China Econ Rev 19(3):393–408

Dietz T, Rosa EA (1997) Effects of population and affluence on CO2 emissions. Proc Natl Acad Sci USA 94(1):175–179

Dong L, Liang H (2014) Spatial analysis on china’s regional air pollutants and CO2 emissions: emission pattern and regional disparity. Atmos Environ 92:280–291

Du K, Lu H, Yu K (2014) Sources of the potential CO2 emission reduction in China: a nonparametric metafrontier approach. Appl Energy 115(4):491–501

Ehrlich PR, Holdren JP (1971) Impact of population growth. Science 171(3977):1212–1217

Elhorst JP (2012) Dynamic spatial panels: models, methods, and inferences. J Geogr Syst 14(1):5–28

Fan M, Shao S, Yang L (2015) Combining global Malmquist–Luenberger index and generalized method of moments to investigate industrial total factor CO2 emission performance: a case of Shanghai (China). Energy Policy 79:189–201

Fang G, Tian L, Fu M et al (2013) The impacts of carbon tax on energy intensity and economic growth—a dynamic evolution analysis on the case of China. Appl Energy 110(5):17–28

Fare R, Grosskopf S, Norris M et al (1994) Productivity growth, technical progress, and efficiency change in industrialized countries. Am Econ Rev 84(1):66–83

Fei R, Lin B (2016) Energy efficiency and production technology heterogeneity in China’s agricultural sector: a meta-frontier approach. Technol Forecast Soc Chang 109:25–34

Fisher-Vanden K, Jefferson GH, Ma J et al (2006) Technology development and energy productivity in China. Energy Econ 28(5–6):690–705

Fukuyama H, Weber WL (2009) A directional slacks-based measure of technical inefficiency. Socio Econ Plan Sci 43(4):274–287

Gan C, Zheng R, Yu D (2011) An empirical study on the effects of industrial structure on economic growth and fluctuations in china. Econ Res J 21(1):85–100

Geng Y, Zhao H, Liu Z et al (2013) Exploring driving factors of energy-related CO2 emissions in Chinese provinces: a case of Liaoning. Energy Policy 60(6):820–826

Grossman GM, Krueger AB (1995) Economic growth and the environment. Q J Econ 110(2):353–377

Guesmi B, Serra T, Featherstone A (2015) Technical efficiency of Kansas arable crop farms: a local maximum likelihood approach. Agric Econ 46(6):703–713

Hoekstra R, van den Bergh Jeroen J C J M (2003) Comparing structural decomposition analysis and index. Energy Econ 25(1):39–64

Hua L, Wang W (2015) The impact of network structure on innovation efficiency: an agent-based study in the context of innovation networks. Complexity 21(2):111–122

Jalil A, Mahmud SF (2009) Environment Kuznets curve for CO2 emissions: a cointegration analysis for China. Energy Policy 37(12):5167–5172

Kang YQ, Zhao T, Wu P (2016) Impacts of energy-related CO2 emissions in China: a spatial panel data technique. Nat Hazards 81(1):405–421

Khazzoom JD (1980) Economic implications of mandated efficiency in standards for household appliances. Energy J 1(4):21–40

Krugman PR, Venables AJ (1995) Globalisation and the inequality of nations. Q J Econ 110(4):857–880

Li K, Lin B (2016) China’s strategy for carbon intensity mitigation pledge for 2020: evidence from a threshold cointegration model combined with Monte-Carlo simulation methods. J Clean Prod 118:37–47

Li H, Wei YM (2015) Is it possible for China to reduce its total CO2 emissions? Energy 83:438–446

Li H, Mu H, Zhang M et al (2012) Analysis of regional difference on impact factors of China’s energy—related CO2 emissions. Energy 39(1):319–326

Lin B, Yao X, Liu X (2010) China’s energy strategy adjustment under energy conservation and carbon emission constraints. Soc Sci China 31(2):91–110

Liu H, Liu W, Fan X, Liu Z (2015a) Carbon emissions embodied in value added chains in China. J Clean Prod 103:362–370

Liu H, Liu W, Fan X, Zou W (2015b) Carbon emissions embodied in demand–supply chains in China. Energy Econ 50:294–305

Liu Y, Zhou Y, Wu W (2015c) Assessing the impact of population, income and technology on energy consumption and industrial pollutant emissions in China. Appl Energy 155:904–917

Long R, Shao T, Chen H (2016) Spatial econometric analysis of China’s province-level industrial carbon productivity and its influencing factors. Appl Energy 166:210–219

Noorpoor AR, Kudahi SN (2015) CO2 emissions from Iran’s power sector and analysis of the influencing factors using the stochastic impacts by regression on population, affluence and technology (STIRPAT) model. Carbon Manag 6(3–4):101–116

Ozbugday FC, Erbas BC (2015) How effective are energy efficiency and renewable emerging curbing CO2 emissions in the long run? A heterogeneous panel data analysis. Energy 82:734–745

Sadorsky P (2013) The effect of urbanization on CO2 emissions in emerging economies. Energy Econ 41(1):147–153

Shahbaz M, Loganathan N, Muzaffar AT et al (2015) How urbanization affects CO2 emissions in Malaysia? The application of STIRPAT model. Renew Sustain Energy Rev 57:83–93

Stigson P, Dotzauer E, Yan J (2009) Improving policy making through government–industry policy learning: the case of a novel Swedish policy framework. Appl Energy 86(4):399–406

Talukdar D, Meisner CM (2001) Does the private sector help or hurt the environment? Evidence from carbon dioxide pollution in developing countries. World Dev 29(5):827–840

Theil H (1967) Economics and information theory. North Holland Publishing Company, Amsterdam

Tian X, Chang M, Tanikawa H et al (2012) Regional disparity in carbon dioxide emissions. J Ind Ecol 16(16):612–622

Tian X, Chang M, Shi F et al (2014) How does industrial structure change impact carbon dioxide emissions? A comparative analysis focusing on nine provincial regions in China. Environ Sci Policy 37(3):243–254

Tone K (2001) A slacks-based measure of efficiency in data envelopment analysis. Eur J Oper Res 130(3):498–509

Wang Z, Yang Z, Zhang Y et al (2011) Energy technology patents–CO2 emissions nexus: an empirical analysis from China. Energy Policy 42(2):248–260

Wang Q, Wu SD, Zeng YE et al (2016) Exploring the relationship between urbanization, energy consumption, and CO2 emissions in different provinces of China. Renew Sustain Energy Rev 54:1563–1579

Weng Y, Yan G, Li Y et al (2015) Integrated substance and energy flow analysis towards CO2 emission evaluation of gasoline & diesel production in Chinese fuel-refinery. J Clean Prod 112:4107–4113

Wu J, Yin P, Sun J et al (2016) Evaluating the environmental efficiency of a two-stage system with undesired outputs by a DEA approach: an interest preference perspective. Eur J Oper Res 254(3):1047–1062

Xiang N, Xu F, Sha J (2013) Simulation analysis of China’s energy and industrial structure adjustment potential to achieve a low-carbon economy by 2020. Sustainability 5(12):5081–5099

Xu B, Lin B (2015) Regional differences of pollution emissions in China: contributing factors and mitigation strategies. J Clean Prod 112(4):1454–1463

Xu SC, He ZX, Long RY (2014) Factors that influence carbon emissions due to energy consumption in China: decomposition analysis using LMDI. Appl Energy 127(6):182–193

Xu SC, He ZX, Long RY et al (2015) Factors that influence carbon emissions due to energy consumption based on different stages and sectors in China. J Clean Prod 115:139–148

Yang Y, Cai W, Wang C (2014) Industrial CO2 intensity, indigenous innovation and R&D spillovers in China’s provinces. Appl Energy 131:117–127

Yu C, Shi L, Wang Y et al (2016) The eco-efficiency of pulp and paper industry in China: an assessment based on slacks-based measure and Malmquist–Luenberger index. J Clean Prod 127:511–521

Zhang YJ, Da YB (2015) The decomposition of energy-related carbon emission and its decoupling with economic growth in China. Renew Sustain Energy Rev 41:1255–1266

Zhang YJ, Hao JF, Song J (2016) The CO2 emission efficiency, reduction potential and spatial clustering in china’s industry: evidence from the regional level. Appl Energy 174:213–223

Zhou X, Zhang J, Li J (2013) Industrial structural transformation and carbon dioxide emissions in China. Energy Policy 57(3):43–51

Acknowledgements

The author is very grateful to the anonymous reviewers for their insightful and constructive suggestions. The work was supported by the Major National Social Science Foundation of China (12&ZD207), the National Natural Science Foundation of China (71172044, 71273047).

Author information

Authors and Affiliations

Corresponding author

Appendix

Rights and permissions

About this article

Cite this article

Li, W., Wang, W., Wang, Y. et al. Industrial structure, technological progress and CO2 emissions in China: Analysis based on the STIRPAT framework. Nat Hazards 88, 1545–1564 (2017). https://doi.org/10.1007/s11069-017-2932-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-017-2932-1