Abstract

This paper investigates the relationship between green technology innovation and energy intensity for 29 provinces in Mainland China from 1999 to 2010. Based on changes in energy intensity in the data, the provinces are divided into four groups: the conventional group, the gradational group, the contemporary group, and the low-carbon group. Industrial structure is included in the study because of its impact on energy intensity, thus avoiding the problem of omitted variable bias. The empirical results indicate that there is a negative, long-run, cointegrated relationship between energy intensity and green technology innovation. We also discover unidirectional causality from green technology innovation to energy intensity in the conventional and low-carbon groups, whereas green technology innovation directly affects energy intensity through a feedback system for the gradational and contemporary groups. To achieve the goal of energy intensity, policymakers should encourage green technology diffusion from the low-carbon group to the conventional group and improve the share of green technology innovation in the gradational and contemporary groups.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is now widely recognized that green technology innovation and diffusion are required to address the global climate change and energy crises (Acemoglu et al. 2012). However, there has yet to be a study exploring how green technology innovation influences energy intensity in China. There are several reasons for this, but perhaps the most significant is the lack of classification and measurement for green technology innovation. It is well known that quantitative research on green technological innovation cannot take place before the problem of green technology classification and measurement is solved. In 2006, Popp (2006) identified the technical characteristics of energy technology in the USA and confirmed that identifying these characteristics has two benefits: It can (1) help policymakers design appropriate policies to stimulate innovation and reduce costs and (2) facilitate analysis of reaction to those policies. At the end of 2011, the Organization for Economic Co-operation and Development (OECD) released patent search strategies for the identification of selected environment-related technologies (OECD 2011a). Based on previous studies, the technologies were divided into green technologies and dirty technologies according to their environmental effects (Hart 2004). Green technologies are mainly technologies relevant to climate change, whereas dirty technologies are mainly fossil fuel-based technologies. We explore the effects of green technology innovation on energy intensity using provincial-level data.

The contribution of this paper is to investigate the relationship between energy intensity and green technology using patent statistics. Technology innovation can be measured using R&D investment or patent statistics. Patents are strongly correlated with R&D expenditures and consequently can be considered a good proxy for knowledge capital (Aghion et al. 2014). Xu and Chiang (2005) argued that low- and middle-income countries acquire more technology spillover effects from patents than do high-income countries. As a developing country, China has made substantial investments to imitate technology from developed country. Furthermore, Vanessa and Maider (2005) argued that patents are an appropriate proxy measure of innovative activity at the regional level and can be used to measure ecological technology innovation (a kind of green technology innovation). China has three types of patents: inventions, utility models, and design applications. Invention patents have high-level originality and high-technology features, so this paper focuses on invention patents.

Another highlight of our study is that we consider regional differences in energy intensity and thus avoid the omitted variable bias problem. An early approach to understanding the relationship between technology innovation and energy intensity was to use a regional integrated assessment model. A second, related stream of the literature uses time series country-level data to test the impact of technology innovation on energy consumption. We find that the role of green technology in reducing emissions remains controversial when the literature is scrutinized. Some studies claim that green technology does not play a role in reducing CO2 emissions, and some have even found some specific green technology to have a negative effect (Hang and Tu 2007). We suggest there are two reasons for this. The first is a version of the omitted variable bias problem, involving industrial structure, as we discuss in detail later. Industrial structure, which has a direct impact on the amount of CO2 emissions, differs among China’s provinces and municipalities. Thus, when analyzing the relationship between green technology patents and CO2 emissions in China in this paper, we include industrial structure as a control variable. Second, even ignoring the omitted variable bias problem, there is an interregional difference problem (Zeng and Chen 2009). China displays striking differentiation in energy consumption between regions. We use these differences to divide China into four groups based on energy intensity. Since cluster analysis is superior to simple regional division in describing this differentiation, it is used in this paper to divide the 29 provinces in Mainland China into the conventional, gradational, low-carbon, and contemporary groups according to differences in energy intensity (Jin et al. 2011). This allows us to describe regional features of energy consumption, providing strong evidence of the relationship between energy intensity and green technology.

The rest of this paper is organized as follows: Sect. 2 introduces the related literature, and Sect. 3 explains the data for China’s four energy intensity groups. Section 4 analyzes and discusses the empirical results. Section 5 describes the policy implications derived from this study.

2 Theoretical background

Energy intensity has long been of interest to energy researchers. Scholars both within and outside of China have analyzed the relationship between technological progress and the environment by capturing the impact of new technology on energy use. The Chinese government has struggled to reduce energy intensity in order to alleviate the dual pressures of energy and the environment through green technology innovation. Green technologies comprise a vast range of radically different technologies that support wealth creation and energy efficiency through several means: pollution reduction and greater resource efficiency, climate change mitigation based on a cleaner energy supply, end-use and carbon capture and storage, the creation of products and processes appropriate for changing environments, and more sustainable production. Green technology includes both energy-saving and emission-reduction technologies. Therefore, green technology should reduce energy intensity in the following ways.

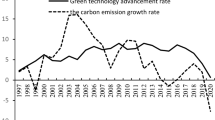

First, the use of green technologies can increase energy efficiency. The literature in these areas makes use of the well-known environmental Kuznets curve (EKC), which decomposes the effects of economic activity into scale, composition, and technique effects (Ma and Stern 2008). The scale effect is not central because energy intensity is defined as energy consumption per unit of output. The composition effect, which captures changes in the industrial structure, can be measured based on our data. The technique effect captures the impact of new management practices and technology on energy use. Smulders et al. (2011) give an explanation for the EKC inverted U relationship by policy-induced technology shifts and intrasectoral changes. Studies on the relationship between green technology and energy intensity in China are scarce, but there are some studies on the effect of technology changes on energy intensity in China. Fan et al. (2007) provide empirical evidence that the improvement in energy efficiency improved energy intensity in China from 1980 to 2003. Garbccio et al. (1999) employed the input–output method to explore the causes of the decrease in energy intensity in China based on data from 1978 to 1995 and concluded that technological progress was the main influence factor. Feng et al. (2008) used hierarchical regression and time series data to examine how industrial structure, technological progress, and energy prices influence energy intensity and found that technological progress significantly reduces energy intensity. However, one explanation for the relatively slow reduction in China’s energy intensity is that there are relatively fewer green technology innovations in China than in other countries. Yang (1993) found the slow pace (compared with Japan) of green technology innovation was the primary factor explaining why energy intensity had stayed at a high level in China. As a result, low-carbon urban planning and development guidelines were presented for the first time in 2007. It is exciting that China’s green technology patent growth rate is now at about 33 %, while its dirty technology patent growth rate has been at about 22 % since 1998.

Second, technological diffusion and spillover from other countries to China is a channel to reduce energy intensity; technological transfer plays a key role in helping developing countries to achieve reductions in greenhouse gas (GHG) emissions. The definition of technological spillovers includes product and process innovations, improvements in distribution channels, and better marketing and management. Wang (2010) examined the role of a clean development mechanism (CDM) in GHG emissions and found that international carbon trading plays a larger role than other channels. However, few studies on the economics of GHG stabilization have addressed the role of international knowledge flows in the process of technological improvement (Fisher-Vanden and Jefferson 2008).

Finally, green technology spillovers can influence energy use. Green technology spillovers can be both horizontal and vertical. First, domestic firms can benefit from the presence of cleaner technology in the same industry through demonstration effects. We should note that the diffusion and evolution of green technology are slow and uncertain, and there are many obstacles to widespread diffusion. Second, there may be spillovers from foreign firms operating in other industries, known as vertical spillovers. Elena and Marzio (2011) employed a sample of 38 innovating countries to study how green technologies flow across geographical and technological space and showed that spillovers between countries have a significant positive impact on further innovation. Lun (2010) explained the decrease in energy intensity in China based on inter-industry spillovers of energy-saving techniques. The results showed that backward and forward linkage spillovers were all distinct, which benefited industrial policy on structure adjustment aimed at high-energy-consumption industries.

In summary, the research on technological innovation to reduce energy intensity has many problems, including the lack of rational classification based on the environmental effects of technology. The relationship between energy intensity and green technological innovation has not yet been examined. Furthermore, industrial structure has not been included as an important control variable when measuring this causal relation.

3 Green technology and energy intensity in China’s different groups

The limitation of bivariate tests for determining the relationship between energy intensity and technological change calls for a multivariable model. The multivariate framework includes energy intensity (EI), industrial structure (IS), and green technology innovation (GT). The panel data for 29 provinces and municipalities in Mainland China covering the period from 1999 to the end of 2010 were obtained or derived from the China Statistical Yearbook and the China Energy Statistical Yearbook. The energy intensity information for Tibet is not available for most years, and Shanghai, Chongqing, Liaoning, Jiangxi, Anhui, Jilin, Guizhou, Gansu, Qinghai, Inner Mongolia, the Xinjiang Uygur Autonomous Region is derived from the energy consumption for each unit of national output. All the variables are expressed in natural logarithms such that the elasticity can be interpreted. The data analysis involves two tasks as follows: First, the long-run relationship between green technology and energy consumption intensity is explored in a multivariate framework, and second, the signs and magnitudes of the respective coefficients of the different groups are determined.

3.1 Group divisions

China’s National Bureau of Statistics divides 29 Chinese provinces and municipalities (excluding Hong Kong, Macao, Taiwan, and Tibet) into the eastern, central, and western regions (Zeng and Chen 2009). There is large variance in the energy intensity within each region. China’s energy intensity plan has been implemented taking into account the actual situation of each province, so that each province has its own energy-saving plan. Based on an analysis of the changes in energy intensity, Jin et al. (2011) summarized four modes of energy consumption compared to gross domestic product (GDP) in various regions of China: the conventional mode, gradational mode, contemporary mode, and low-carbon mode (Jin et al. 2011). Since cluster analysis is superior to simple regional division in describing this differentiation, we divide the 29 provinces and municipalities in Mainland China into the conventional, gradational, low-carbon, and contemporary groups according to the differences in energy intensity. We analyze the energy intensity characteristics of each group to describe the regional features of energy intensity, providing strong evidence of the relationship between energy intensity and green technology.

3.2 Energy intensity in China’s different groups

EI represents the energy use per unit of GDP. Data on energy consumption are available in the China Energy Statistical Yearbook, and related GDP data can be obtained from the National Bureau of Statistics. Since all the provincial data reported in Chinese Statistical Yearbooks are calculated at current prices, we adjusted all data for provincial GDP per capita by considering the official price index. When we calculate energy intensity, the related GDP is translated to the 1990 price index.

Figure 1 shows that energy intensity has decreased significantly in the past 12 years, and the low-carbon and gradational groups present dramatic decline curves. Average energy intensity is taken as the standard, and the energy intensity in 1999 is the initial basis for comparison. Energy intensity is typically considered high when it is higher than the average level of 1.70 t of standard coal per 10,000 yuan; otherwise, it is viewed as low. According to the different rates of energy intensity, as mentioned earlier, the provinces can be divided into four groups: The low-carbon group begins with lower energy intensity and ends with a high decrease rate, as in Beijing and Tianjin. The gradational group begins with higher energy intensity and ends with a high decrease rate by reducing energy intensity as much as possible, as in Inner Mongolia and Shanxi, which are classified into the gradational group because they differ from the other western provinces in terms of energy intensity mode. The conventional group begins with higher energy intensity and ends with a low decrease rate, as in Ningxia and Heilongjiang. The contemporary group begins with lower energy intensity and ends with a low decrease rate, as in Hainan and Yunnan.

3.3 Measurement of green technology innovation based on patent statistics

We use patent statistics to measure green technology innovation. Although patent statistics have many disadvantages for measuring innovation output (Hang and Tu 2007), they are a rather good proxy for innovation activities because there is a strong relationship between the number of patents and R&D expenditure. Green technology patents are a subgroup of patents. The extraction of green technology patents and statistics consists of three steps.

First, we must determine the statistical method and statistical channel of green technology patents. There are two ways to gather green technology patents. The first is to gather green patents according to the OECD (2011a) indicator of environmental technologies. This is especially useful for green technological activities, since the OECD (2011b) provides a definition of green technologies based on patent classification. The second way is to gather green patents from the State Intellectual Property Office of the People’s Republic of China (SIPO). Based on the international patent classification, the SIPO distinguishes eight environmental areas: (a) biofuels (b) other heat production or use not generated from burning, (c) railway vehicles, (d) energy supply lines, (e) general building, (f) mechanical energy recovery, (g) wind energy and (h) fuel cells (SIPO 2013). Because China is a developing country, its green technology innovation is based on “catch-up innovations,” which involve adapting existing green products, processes, organizational processes, and marketing to the local context. Green patents applied for through SIPO reflect not only the independent research and development in each province but also the results of green technology diffusion and spillover. Therefore, we collect green technology data using the second approach.

Second, the green technology patent data from 29 provinces and municipalities from 1999 to 2010 are collected. First, the above approaches are used to acquire the data on green technology patents and organize them by application year. Next, patents are assigned to a province. Patents can be assigned to provinces based on either the applicant’s home province or the inventor’s home province. We collected both the inventor’s information and the applicant’s information in Hebei Province to examine our assumption that there are no significant differences between the inventor’s and applicant’s address data. The examination confirmed this result. Hence, patents are assigned according to the applicant’s address, which is compulsory for patent applications. From 1999 to 2010, the number of green technology patents increased significantly: by 20 times in only 11 years. There were only a few green inventions registered in 1999. Between 1999 and 2001, the number increased slightly. A sharp increase in the number of green patents occurred in 2002. The growth in the number of green patents has remained at a higher level since 2003. There are 10 provinces at a level higher than the national average in terms of patent number, and 19 provinces lower than the average. The province with the highest number of patents is Jiangsu, followed by Zhejiang, Guangdong, Tianjin, and Shanghai. The lowest is Hainan, followed by Jilin, Liaoning, Yunnan, and Ningxia.

Third, we count the green technology patents for each of the groups. As shown in Fig. 2, green technology patents in the low-carbon group show a higher growth rate than those in the conventional and gradational groups, especially since 2008. It is impressive that the gradational group has brought about the reduction in energy intensity with few green inventions. It remains unknown whether green technology patents can help reduce CO2 emissions for the gradational group.

3.4 Industrial structure in China

Looking at industrial structure, the proportion of secondary industry has a large influence on energy consumption. The industrial structure is defined by the percentage of tertiary industry value added to the GDP. The energy intensity of tertiary industry is lower than that of secondary industry (Ma and Stern 2008). Thus, improving the proportion of tertiary industry value added to the GDP may reduce energy intensity effectively.

Figure 3 illustrates the phasic variation of China’s industrial structure from 1999 to 2010. Although the proportion of tertiary industry increased slowly, the proportion in the low-carbon group is obviously higher than that in other groups, which could be because China is in the middle of industrialization: The leading position of secondary industry is still stable, so the proportion of tertiary industry has not increased as much as expected.

4 Econometric approach and empirical results

4.1 Econometric approach

The panel data model has several advantages that make it suitable for researching dynamic adjustment processes. First, it can increase estimation effectiveness. Second, panel data can identify and measure other influential variables that cannot be identified using time series or cross-sectional data models, and can reduce the omission of important explanatory variables. Third, panel data provide more information, more variability, less nonlinearity, and higher efficiency than times series or cross-sectional models. Data used in this research cover 29 provinces over 12 years: a relatively short time frame. To avoid the weakness of a short time frame and reduce the impact of variables not mentioned, a cross section-specific model is employed. Same-order integration is the premise of cointegration and the Granger causality relationship. We set up the regression equation as follows:

where \(t = 1, \ldots ,T\) refers to the periods; \(i = 1, \ldots ,N\) indicates members of the balanced panel; \(j = 1,2 \ldots ,4\) refers to the groups; \(\alpha_{i}^{j}\) is the province-specific effects belonging to group j; \(\beta_{1}^{j}\) and \(\beta_{2}^{j}\) are the parameters to be estimated; \(\varepsilon_{it}^{{}}\) is the estimated residual; and LGT, LEI, and LIS are the logarithms of the variables GT, EI, and IS, respectively.

We employ a two-step process to test for Granger causality in the long-run relationship. The first step involves estimation of the residuals from the long-run model, and the second step involves fitting the estimated residuals into a dynamic error correction model. The dynamic error correction model used is specified as follows:

where \([\alpha_{i}^{{}} ,\theta_{i} ,\lambda ]\) are adjustment coefficients; \(\Delta\) is a difference operator; ECM is the lagged error correction term derived from the long-run cointegrating relationship; \(k\) is the number of lags determined by the Schwarz information criterion (SIC); and \(\varepsilon\) is the serially uncorrected error term. Using the specification in Eq. (2a, 2b) allows us to test for both short-run and long-run causality.

Masih and Masih (1997) interpreted weak Granger causality as short-run causality in the sense that the dependent variable responds only to short-term shocks to the stochastic environment. The long-run causality can be tested by looking at the significance of the coefficient of the error correction term from Eq. (2a) and Eq. (2b). We can identify the sources of causation by testing for the significance of the coefficients for the lagged dependent variables from Eq. (2a) and Eq. (2b). To obtain the short-run causality, we first test \(H1:\theta_{12} = \theta_{11}\) for all \(i\) in Eq. (2a), or \(H2:\theta_{21} = \theta_{23}\) for all \(i\) in Eq. (2b).

The coefficients \(\lambda_{i}\) of the error correction term (ECT) represent how fast deviations from the long-run equilibrium are eliminated following changes in each variable. The sources of causation are determined by testing the joint hypothesis of \(H1:\lambda_{1} = \theta_{12} = \theta_{11}\) in Eq. (2a) and \(H2:\lambda {}_{2} = \theta_{21} = \theta_{23}\) in Eq. (2b). Granger causality of the dependent variables is tested using a simple t test of \(\lambda_{i}\) (Asafu-Adjaye 2000).

4.2 Empirical results

4.2.1 Panel unit root results

Table 1 shows the results of the panel unit root tests at the national level from LLC, IPS, Fisher ADF, Fisher PP, Breitung, and Hadri tests for the level and first differenced series of LEI, LGT, and LIS. For the three variables in level form, the null hypothesis of the unit root cannot be rejected for the IPS, Fisher ADF, Fisher PP, and Breitung tests, but the Hadri and LLC tests reject the null hypothesis with 1 % significance. By taking the first difference, the null hypothesis is rejected for all five tests at the 1 % level. When the panel unit root test is applied to the first difference of the variables in other groups, we can reject the null hypothesis of the unit root for each of the variables at the 1 % level. Overall, all the panel unit test techniques reject the null hypothesis for the differenced series and thus show that LEI, LGT, and LIS have integration of order one.

4.2.2 Panel cointegration test

Table 2 shows the results of the panel cointegration from the seven statistics of Pedroni (1999). The null hypothesis is accepted at the 5 % significance level according to Panel V, and the resulting value of the test statistic is rejected at the 1 % significance level with the other methods. There are cointegration relationships among green technology, industry structure, and energy intensity at the national level after allowing for a province-specific effect. Next, we test each of the low-carbon, contemporary, conventional, and gradational groups with the same method, and the results show a cointegration relationship among the four groups. The next step is to estimate this relationship.

4.2.3 Panel cointegration estimation

Given the evidence of panel cointegration, the long-run relationships can be further estimated. There are several methods for panel cointegration estimation, such as the bias-corrected OLS (BCOLS) estimator, the fully modified OLS (FMOLS) estimator proposed by Phillips and Moon (1999) and Pedroni (1999), and the dynamic OLS (DOLS) estimator proposed by Kao and Chiang (2000). Because DOLS exhibits the least bias in small samples, we mainly use the DOLS estimators.

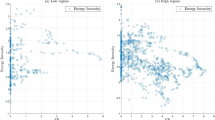

Table 3 reports the estimated long-run elasticities, which are significant at the 1 % level. The elasticity coefficients between energy intensity and green technology are −0.0005, −0.0006, −0.0020, and −0.0213 for the low-carbon, contemporary, conventional, and gradational groups, respectively, which shows there is a difference among groups.

The panel long-run green technology elasticity is −0.0016 at the national level, statistically significant at the 1 % level, and the effect is negative. This implies that a 1 % increase in green technology will reduce energy intensity by 0.0016 %. Moreover, the panel long-run industrial structure elasticity at the national level is −0.0244, which is statistically significant at the 1 % level. This implies that a 1 % increase in tertiary industry will reduce energy consumption by around 0.0244 %.

In line with expectations, for the gradational group, long-run green technology elasticity is −0.0213, which is the highest green technology elasticity coefficient among the four groups. For the low-carbon group, the elasticity of green technology is significantly lower than in the other groups because of the group’s high industrialization level, so there is little room for green technologies to reduce energy intensity. If the data are not classified, the elasticity is −0.0016, and the weak relationship between the two variables cannot be detected. Table 3 also indicates that the elasticities of industrial structure are negative, which means that the increase in tertiary industry does reduce energy intensity. Furthermore, the conventional group with low industrialization may see a quick decline in energy intensity when the developmental level of tertiary industry is improved.

4.2.4 Granger causality results

Once the variables are found to be cointegrated, the next step in the Engle–Granger methodology is to model the short-run variations of the variables. This is done by estimating the coefficient of ECT. Table 4 reports the results of the short- and long-run Granger causality tests. With respect to Eq. (2a), industrial structure has a positive and statistically significant impact on green technology innovation in the short run. An examination of the coefficients of the industrial structure indicates the gradational group has a greater impact on green technology innovation, whereas the low-carbon group has a lesser impact. Moreover, the error correction term is statistically significant at the 10 % level, also denoting a relatively slow speed of adjustment to long-run equilibrium in the low-carbon group. Energy intensity has different impacts on green technology innovation in the short run. We can see that the fluctuation of energy intensity has a statistically significant impact on green technology innovation in the contemporary and low-carbon groups. Conversely, for the conventional and gradational groups, energy intensity has insignificant impacts on green technology innovation. In light of the short- and long-run results, energy intensity may be considered exogenous to the other variables in the model, except in the low-carbon and contemporary groups.

In terms of Eq. (2b), it appears that green technology innovation and industrial structure do have statistically significant impacts on energy intensity in the short run. In general, an increase in green technology innovation will reduce energy intensity, but the effect is greatest in the low-carbon group. For the gradational group, an increase in green technology does not lead to energy intensity decreasing faster than it does in the contemporary and conventional groups. The estimation results of the error correction models in Eq. (2b) indicate that the lagged error correction terms have negative signs, as expected. This implies that the change in the level of green technology innovation does respond rapidly to any deviation in the long-run equilibrium. However, the return to equilibrium occurs at different rates: It is faster for the low-carbon and gradational groups and very slow for the other two groups.

To summarize, it is clear from the causality test results that the coefficients of \(\Delta {\text{EI}}\) are not significant individually in Eq. (2a). This indicates that there is no short-run causality from energy intensity to green technology innovation for our sample during the study period. We believe the cause of the reduction on energy intensity might be industrial structure adjustment rather than green technology innovation.

5 Conclusion and policy implications

5.1 Conclusions

This paper attempts to determine the relationship between green technology innovation and energy intensity in different regions of China. The 29 provinces are divided into four groups according to their changes in energy intensity. Our empirical results confirm a significant and negative relationship between green technology and energy intensity, and our study shows that the relationship is stronger for the gradational and conventional groups. Green technologies do not necessarily reflect inventions in the region based on its own R&D, but rather the adoption of a technology new to the region. Like dirty technology transfer, green technology transfer has both a direct effect on energy consumption decisions and an indirect effect via changes in goods prices; this will improve the effectiveness of green technology innovation. Gathering information of green technology transfer is quite difficult, as the green technology patents information does not include green technology transfer, which may lead us to underestimate the role of green technology innovation. In spite of this, we draw some conclusions based on the facts in China.

The result suggests that green innovation’s beneficial effect on energy intensity is not uniform across the groups, and that the differences across groups should be of interest for policymakers. For the short-run relationship, there is negative unidirectional causality from green technology innovation to energy intensity in all but the gradational and contemporary groups. It is important to stimulate new green investment to facilitate green technology diffusion. The reasons that green technology has relatively small long-term effects on reducing energy intensity in the low-carbon group are as follows: Economic development and green technology in the low-carbon group have developed rapidly, and there is little room to reduce energy consumption. The low-carbon group applies for an annual average of 136 green technology patents, which is enough to maintain the energy consumption level. In 2010, the low-carbon group entered into a low-carbon development pattern with average energy intensity reduced to 0.6 tons standard coal/10,000 yuan. However, the conventional group applies for an annual average of 19.4 green technology patents, which is far lower than the national average level. It is expected that green technology innovation will play an important role in energy intensity reduction in the future. For the gradational group, energy intensity reduction in the short run can be achieved through more efficient industrial structure adjustment.

In contrast to most previous studies, we need to consider interregional differences in energy intensity when energy consumption policies are made. A comparison of our econometric models and empirical results with the recent publication by Feng et al. (2012) suggests that the conclusions in this paper seem to be more consistent with this requirement. The low-carbon group is recommended to reduce dependence on fossil fuel energy because it has enough green patents. The contemporary group should pursue a continual energy consumption decrease. A green technology innovation incentive policy should be enacted for the conventional and gradational groups. In sum, a one-size-fits-all policy will not work well, as it may fail to implement the correct policies for the different groups.

5.2 Policy recommendations

In order to make effective energy and technical policies, policymakers need to understand the relationship between energy intensity and green technology. This study put forward the following suggestions:

First, each province should set and pursue a positive energy intensity goal to facilitate the accomplishment of an optimal national-level strategy. For the conventional and gradational groups, green technology innovation is the key to reducing energy intensity. The Chinese government should enact technology-pushing policies to save energy. China’s current investment in green technology R&D is insufficient, although the number of green technology patents has increased greatly. The Chinese government should emphasize increasing R&D investment in green technologies, especially in the conventional group.

Second, the Chinese government should encourage green technology diffusion from the low-carbon group to the conventional group. During the Eleventh Five-Year Plan, many compulsory measures were taken to achieve the goal of energy intensity, including power rationing. These measures may reduce energy intensity in the short term, but they cannot fundamentally reduce energy intensity. Therefore, energy intensity targets should be drafted to improve the green technology level.

References

Acemoglu D, Aghion P, Bursztyn L, Hemous D (2012) The environment and directed technical change. Am Econ Rev 102(1):131–166

Aghion P, Dechezlepretre A, Hemous D et al (2014) Carbon taxes, path dependency and directed technical change: Evidence from the auto industry. J Political Econ (forthcoming)

Asafu-Adjaye J (2000) The relationship between energy consumption, energy prices and economic growth: time series evidence from Asian developing countries. Energy Econ 22:615–625

Elena V, Marzio G (2011) At home and abroad: an empirical analysis of innovation and diffusion in energy technologies. J Environ Econ Manag 61:119–134

Fan Y, Liu LC, Wu G, Wei YM (2007) Changes in carbon intensity in China: empirical findings from 1980–2003. Ecol Econ 62:683–691

Feng T, Sun L, He Z (2008) An empirical study of technology progress moderating effect on energy intensity in China. Stud Sci Sci 23(1):1–6

Feng D, Long R, Zhou D et al (2012) The relationship between industrial structure, technical progress, and opening degree with unit GDP energy consumption approach. Chin J Manag 9(4):603–610

Fisher-Vanden K, Jefferson GH (2008) Technology diversity and development: evidence from China’s industrial enterprises. J Comp Econ 36(4):658–672

Garbccio RF et al (1999) Why has the energy output ratio fallen in China? J Energy 20(3):73–82

Hang and Tu (2007) The impacts of energy prices on energy intensity: evidence from China. Energy Policy 35:2978–2988

Hart R (2004) Growth, environment and innovation—a model with production vintages and environmentally oriented research. J Environ Econ Manag 48:1078–1098

Jin L et al (2011) Energy consumption per GDP in various regions of China and its mode. Energy Procedia 5:2335–2339

Kao C, Chiang MH (2000) On the estimation and inference of a cointegrated regression in panel data. In: Baltagi BH (ed) Nonstationary panels, panel cointegration, and dynamic panels. Elsevier, Amsterdam

Lun R (2010) Mechanism analysis and empirical study on inter-industry spillovers of energy saving techniques. Stud Sci Sci 28:865–871 (In Chinese)

Ma C, Stern DI (2008) China’s changing energy intensity trend: a decomposition analysis. Energy Econ 30(3):1037–1053

Masih AMM, Masih R (1997) On the temporal causal relationship between energy consumption, real income and prices: some new evidence from Asian-energy dependent NICs based on a multivariate cointegration/vector error-correction approach. J Policy Model 19(4):417–440

OECD (2011a) Patent search strategies for the identification of selected environment-related technologies. http://www.oecd.org/environment/innovation. Accessed 25 March 2012

OECD (2011b) Invention and transfer of environmental technologies. OECD Studies on Environmental Innovation, OECD Publishing, Paris

Pedroni P (1999) Critical values for cointegration tests in heterogeneous panels with multiple regressors. Oxford Bull Econ Stat 61(4):653–670

Phillips PCB, Moon HR (1999) Linear regression limit theory for nonstationary panel data. Econometrica 67:1057–1111

Popp D (2006) International innovation and diffusion of air pollution control technologies: the effects of NOX and SO2 regulation in the US, Japan, and Germany. J Environ Econ Manag 51(1):46–71

SIPO (2013) State Intellectual Property Office of the People’s Republic of China website. http://www.sipo.gov.cn/. Accessed 25 May 2013

Smulders S, Bretschger L, Egli H (2011) Economic growth and the diffusion of clean technologies: explaining environmental Kuznets curves. Environ Resource Econ 49:79–99

Vanessa O, Maider SJ (2005) The dynamics of environmental innovations: three stylised trajectories of clean technology. Econ Innov New Technol 14(3):189–212

Wang B (2010) Can CDM bring technology transfer to China?-An empirical study of technology transfer in China’s CDM projects. Energy Policy 38(5):2572–2585

Xu B, Chiang E (2005) Trade, patents and international technology diffusion. J Int Trade Econ Dev Taylor & Francis J 14(1):115–135

Yang F (1993) Enterprise green technology innovation process and pattern. Zhejiang University, Hangzhou (In Chinese)

Zeng S, Chen Q (2009) The comparative study of the influence of economic growth on environmental quality in eastern China and the central China and the western China. Stat Decision 278:113–115 (In Chinese)

Acknowledgments

This paper was supported by the National Nature Science Foundation of China (Grant No. 70973011), the China Postdoctoral Foundation (Grant No. 2014M560882), and the social science research project of Hebei Province (Grant No. HB14YJ018). This work could not have been completed without the support of the Engineering Construction Management Key Research Institute of Humanities and Social Science of the Hebei Education Department.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Han, B. & Liu, W. Green technology innovation and energy intensity in China. Nat Hazards 84 (Suppl 1), 317–332 (2016). https://doi.org/10.1007/s11069-016-2158-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-016-2158-7