Abstract

This paper is a fundamental exploration of the dynamic area of nanocatalysis, offering a detailed analysis of recent advancements and practical applications. Tailored for researchers and professionals, this article begins with a historical overview, emphasizing nanocatalysis’ pivotal role in contemporary science and industry. It delves into foundational principles, covering nanoparticle synthesis, characterization, surface chemistry, and reactivity mechanisms at the nanoscale. Advanced sections explore the design of nanomaterials for catalysis, hybrid catalyst synthesis, and the integration of computational approaches. Mechanistic insights are presented through a detailed examination of reaction pathways and cutting-edge spectroscopic techniques. Practical applications span energy conversion, sustainable synthesis, and environmental remediation, with illustrative case studies. The article concludes by addressing current challenges, outlining future perspectives, and highlighting emerging trends, making it an essential guide for those navigating the multifaceted landscape of nanocatalysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanocatalysis stands at the forefront of scientific and industrial innovation, representing a dynamic and transformative field that operates at the intersection of nanoscience and catalysis. At its core, nanocatalysis involves catalytic processes that unfold on the nanoscale, where materials exhibit unique and often remarkable properties [1, 2]. Nanocatalysis, in its essence, encompasses the catalytic phenomena occurring within the nanometer scale range [3]. It is the study of catalytic reactions facilitated by nanoparticles, where the distinctive characteristics of materials at this scale dictate the reactivity and efficiency of the catalytic process [4]. Nanocatalysts, often composed of metals, metal oxides, or organic materials, present an extensive surface area and quantum size effects that set them apart from their bulk counterparts [5, 6].

The scope of nanocatalysis extends across a multitude of disciplines, including chemistry, physics, materials science, and engineering. Its applications span a wide spectrum, from the development of energy-efficient technologies to environmentally sustainable synthesis processes [7, 8]. As we delve into the intricacies of nanocatalysis, it becomes evident that this field is not merely a subdomain but a pivotal player influencing the landscape of modern science and industry [9].

Nanocatalysis, the study and application of nanoparticles as catalysts, has a rich history spanning several millennia (shown in Fig. 1) [10,11,12,13,14,15]. In the fourteenth century BC, ancient Egyptians and Mesopotamians used gold nanoparticles to produce red-colored glass, demonstrating an early use of nanotechnology in decorative arts. By the fourth century AD, Roman craftsmen had advanced this concept further, creating the Lycurgus Cup, a remarkable artifact that changes color depending on light direction, using gold and silver nanoparticles. The first documented use of nanoparticles in catalysis, however, came much later, in 1941, with palladium nanoparticles. The field saw significant development in 1987, when researchers noted that the catalytic properties of gold nanoparticles were strongly influenced by their size. This discovery prompted a deeper exploration into the role of nanoparticle size and structure in catalysis. By 2020, the first high-entropy alloy nanoparticle containing six platinum group metals was developed, providing a potent catalyst for complex or multi-step reactions. More recently, in 2022, scientists created a high-entropy alloy nanoparticle containing all eight noble metal group elements, demonstrating remarkable activity in hydrogen evolution reactions. These milestones reflect the evolving understanding of nanocatalysis and its growing importance in modern science and industry.

To comprehend the present and envision the future of nanocatalysis, we must first traverse its historical landscape. Nanocatalytic processes, though not explicitly recognized as such, have left traces in the annals of scientific discovery for centuries [16]. From the earliest observations of catalytic reactions to the groundbreaking advancements in the twentieth century, the evolution of nanocatalysis mirrors the broader development of nanoscience [17]. The twentieth century witnessed seminal contributions, with the advent of nanomaterial synthesis techniques and the exploration of quantum effects at the nanoscale. Notable milestones include the development of colloidal chemistry and the discovery of catalytic properties inherent in finely divided materials. These foundational steps covered the way for the emergence of nanocatalysis as a distinct and influential field in contemporary science [18, 19].

As we navigate the intricate landscape of nanocatalysis, it becomes evident that its importance extends far beyond the confines of laboratory research [20, 21]. Nanocatalysis plays a pivotal role in shaping the trajectory of modern science and industry. In the realm of catalysis, the nanoscale regime introduces a paradigm shift, enabling unprecedented control over reaction pathways and catalytic selectivity [22]. Industrially, nanocatalysis has become indispensable for processes ranging from fine chemical synthesis to environmental remediation. The utilization of nanocatalysts has revolutionized energy conversion and storage technologies, offering solutions to global challenges such as climate change and resource sustainability [23, 24]. The integration of nanocatalysis into various industrial sectors underscores its role as a driving force behind technological advancements with profound implications for a sustainable and innovative future [9, 25].

In the subsequent sections, we embark on a comprehensive exploration of the fundamentals of nanocatalysis, unraveling the intricacies of nanoparticle synthesis, characterization, surface chemistry, and reactivity mechanisms. As we traverse this intellectual terrain, the transformative potential of nanocatalysis unfolds, offering a nuanced understanding of a field that is both historically grounded and dynamically evolving.

Fundamentals of nanocatalysis

Nanoparticles: synthesis and characterization

At the heart of nanocatalysis lies the intricate world of nanoparticles, the building blocks that define the catalytic landscape on the nanoscale. In this section, we embark on a journey to understand the fundamentals of nanocatalysis by exploring the synthesis and characterization of nanoparticles. These minute entities, often measuring in the nanometer range, exhibit unique properties that make them indispensable in catalytic processes. The synthesis of nanoparticles is a cornerstone in nanocatalysis, as it determines the physical and chemical properties that govern catalytic behavior (shown in Fig. 2). Various methods, including chemical reduction, sol–gel processes, and green synthesis approaches, are employed to tailor the size, shape, and composition of nanoparticles [26]. Chemical methods, known for their simplicity and mild conditions, include chemical reduction and coreduction of mixed ions. Chemical reduction involves reducing metal ions in solution by providing extra energy, commonly through photo energy, electricity, or thermal energy. Coreduction, used for bimetallic nanoparticles, entails reducing metal ions of two or more metals using suitable reductants. Physical methods, requiring the evaporation of solid material into supersaturated vapor, include vapor synthesis, sputtering, laser reactors, flame reactors, plasma reactors, wire electrical explosion, expansion-cooling, carbothermal shock, and electrospray systems. Specifically, in the carbothermal shock (CTS) method, we can obtain nanoparticles with desired composition, size, and phase by carefully controlling CTS parameters such as substrate, temperature, shock duration, and heating/cooling rate. These methods provide various approaches for controlling particle size, composition, and phase, allowing for customization to meet specific manufacturing requirements and applications. Understanding these synthesis techniques provides a crucial foundation for manipulating catalytic performance [27,28,29].

Equally important is the characterization of nanoparticles, a multidimensional task that involves unraveling their structural, morphological, and compositional attributes. Techniques such as transmission electron microscopy (TEM), scanning electron microscopy (SEM), X-ray diffraction (XRD), and spectroscopic methods play pivotal roles in deciphering the intricate details of nanoparticles. A nuanced understanding of nanoparticle characteristics is essential for correlating structure with catalytic activity (Table 1) [30,31,32].

Surface chemistry and reactivity

In the nanocatalytic realm, the surface is not merely a boundary but a dynamic interface where catalytic reactions unfold. This subsection delves into the world of surface chemistry, exploring how the properties of the nanocatalyst’s surface dictate its reactivity and catalytic performance.

Understanding the intricacies of surface chemistry involves unraveling phenomena such as adsorption, desorption, and surface reactions that dictate the interaction between reactants and the catalyst surface. The high surface area-to-volume ratio of nanoparticles amplifies the significance of surface chemistry, influencing catalytic selectivity and overall efficiency [33, 34].

Nanocatalysis introduces a level of complexity where traditional catalytic mechanisms may be modified or entirely redefined. The quantum size effects and unique electronic properties of nanoparticles contribute to unconventional reactivity mechanisms. Exploring these mechanisms provides insights into how nanocatalysts influence reaction pathways and enhance catalytic performance [30, 35, 36].

Catalytic mechanisms at the nanoscale

Building upon the foundation laid in the previous subsection, this section takes a closer look at the catalytic mechanisms that govern nanocatalytic reactions. Operating at the nanoscale introduces intricacies that differ from bulk catalysis, and understanding these mechanisms is essential for harnessing the full potential of nanocatalysts.

The unique characteristics of nanocatalysts, such as size-dependent electronic properties and enhanced surface reactivity, influence catalytic processes. This subsection explores how these factors contribute to catalytic efficiency, selectivity, and the ability to catalyze specific reactions that may be challenging in bulk materials [7, 37, 38]. Nanocatalytic reactions often exhibit dynamic behaviors influenced by factors such as nanoparticle size, shape, and surface modifications. Investigating the dynamic nature of these reactions sheds light on the intricacies of nanocatalysis, guiding the design of catalysts for optimal performance [39,40,41,42].

In the subsequent sections, we delve deeper into the advances in nanocatalyst design, exploring the tailoring of nanomaterials for catalysis, the synthesis of hybrid and composite nanocatalysts, and the integration of computational approaches in catalyst design. As we unravel these intricacies, the multifaceted nature of nanocatalysis comes to the forefront, showcasing its transformative potential in contemporary scientific and industrial landscapes.

Advances in nanocatalyst design

Tailoring nanomaterials for catalysis

In this section, we explore the forefront of nanocatalyst design, delving into strategies aimed at optimizing properties for enhanced performance. The evolution of nanocatalysis has been propelled by the intentional design and tailoring of nanomaterials for specific catalytic applications [43].

Tailoring nanomaterials for catalysis involves a nuanced understanding of design principles. This includes the careful selection of materials, control over particle size and shape, and the incorporation of functionalities that promote catalytic activity. These design parameters are pivotal in crafting nanocatalysts with tailored properties to address specific reaction pathways [44].

Surface engineering plays a crucial role in nanocatalyst design, allowing for the manipulation of surface properties to influence catalytic performance. Strategies such as doping, functionalization, and the introduction of defects enable researchers to fine-tune the surface chemistry of nanocatalysts, thereby enhancing their reactivity and selectivity [45].

Advancements in nanocatalyst design also leverage synergistic effects arising from the combination of different materials. Hybrid nanocatalysts, formed by integrating two or more distinct materials, exhibit properties that surpass those of individual components. Understanding and harnessing these synergies open new avenues for tailoring nanocatalysts with unprecedented catalytic capabilities [46, 47].

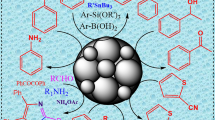

Hybrid and composite nanocatalysts

The synthesis of hybrid and composite nanocatalysts represents a paradigm shift in catalytic design, capitalizing on the strengths of diverse materials. This subsection explores the principles behind the creation of these multifunctional catalysts and their applications in catalytic processes.

Hybrid nanocatalysts combine different types of nanomaterials, such as metals, metal oxides, and organic components. The synergistic effects between these components result in enhanced catalytic performance. This subsection investigates the strategies for designing hybrid nanocatalysts and the underlying principles governing their catalytic activity [48,49,50].

Composite nanocatalysts involve the integration of nanoparticles into a supporting matrix, creating a unique catalytic entity. This matrix can be organic or inorganic, providing stability and facilitating recyclability. Understanding the interplay between the nanoparticle and matrix is crucial for optimizing the catalytic properties of composite nanocatalysts [51,52,53].

Computational approaches in catalyst design

In the era of computational advancements, the integration of computational approaches has revolutionized the design of nanocatalysts. This section explores how theoretical modeling and simulations contribute to the rational design and optimization of nanocatalysts.

Quantum mechanical studies offer insights into the electronic structure, energy levels, and bonding interactions within nanocatalysts. By employing computational methods such as density functional theory (DFT), researchers can predict catalytic activity, identify active sites, and optimize catalysts for specific reactions [54, 55]. Molecular dynamics simulations provide a dynamic perspective, allowing researchers to observe the behavior of nanocatalysts over time. These simulations help unravel the intricate details of catalytic mechanisms and guide the design of catalysts with improved stability and efficiency [56, 57]. The intersection of nanocatalysis and machine learning has ushered in a new era, where algorithms analyze vast datasets to identify patterns and correlations. Machine learning models aid in predicting catalytic properties, accelerating the screening of potential catalysts, and guiding experimental efforts [58].

In the subsequent sections, we delve into mechanistic insights, exploring the probing of reaction pathways, spectroscopic techniques, and quantum mechanical studies. As we navigate through these advances, the intricate tapestry of nanocatalysis continues to unfold, offering a glimpse into the cutting-edge innovations shaping the landscape of catalytic science.

Mechanistic insights

Probing reaction pathways

Understanding the intricate dance of atoms and molecules during a catalytic process requires a detailed exploration of reaction pathways [59]. In this section, we delve into the methodologies employed to probe the paths that reactions follow on the nanoscale.

Probing reaction pathways involves a diverse array of experimental techniques. In situ spectroscopy, chromatography, and mass spectrometry offer real-time insights into the evolution of reactants and intermediates. Isotope labeling provides a powerful tool for tracing the movement of atoms, unraveling the sequence of procedures in nanocatalytic reactions [60, 61].

Surface science techniques, such as scanning tunneling microscopy (STM) and X-ray photoelectron spectroscopy (XPS), play a pivotal role in elucidating surface reactions [62, 63]. These techniques provide high-resolution images and chemical information, enabling researchers to interpret the interactions between catalysts and reactants at the atomic level [64,65,66].

Time-resolved methods, including femtosecond laser spectroscopy and pump-probe experiments, allow researchers to capture the dynamics of nanocatalytic reactions with unprecedented temporal resolution. These methods unveil the rapid transitions between reaction intermediates, shedding light on transient species critical for mechanistic understanding [67, 68].

Spectroscopic techniques in nanocatalysis

Spectroscopic techniques serve as powerful tools for unraveling the structural and electronic characteristics of nanocatalysts [69,70,71]. In this subsection, we explore the diverse spectroscopic methods employed to gain insights into the nature of catalysts and the mechanisms governing their catalytic activity.

XAS provides information about the local structure and oxidation states of catalysts. By probing the absorption of X-rays, researchers can discern the coordination environment of catalytic sites, helping unravel the structural aspects crucial for catalytic activity [72,73,74,75]. NMR spectroscopy offers a unique perspective on nanocatalysis by providing information about molecular interactions in solution. It aids in understanding dynamic processes, such as substrate binding and product formation, offering a bridge between solution-phase and solid-state studies [76,77,78,79].

Infrared (IR) spectroscopy plays a crucial role in analyzing molecular vibrations and surface functional groups. Within nanocatalysis, this technique serves to pinpoint active catalytic sites, monitor alterations in surface chemistry, and unveil the characteristics of adsorbed species during chemical reactions [78]. Raman spectroscopy is offering insights into their structure, composition, and activity. It helps characterize nanoparticle structure, identify surface species, monitor surface chemistry dynamics, quantify catalytic activity, and conduct in situ/operando studies. This analytical tool aids in optimizing catalyst design for diverse applications [79].

Quantum mechanical studies

Quantum mechanics serves as a theoretical backbone for understanding the electronic structure and behavior of nanocatalysts. In this section, we explore how quantum mechanical studies contribute to mechanistic insights in nanocatalysis. DFT calculations provide a quantum-level understanding of the energetics and electronic structure of nanocatalysts. By simulating electronic interactions and predicting reaction pathways, DFT aids in identifying catalytically active sites and guiding experimental efforts. Ab initio methods go beyond DFT, offering high-accuracy calculations of molecular properties. These methods, such as coupled cluster theory, provide detailed electronic structure information, allowing for precise predictions of reaction energetics and mechanistic details. The combination of quantum mechanics and computational power enables researchers to model complex catalytic reactions. Computational catalysis explores reaction mechanisms, transition states, and kinetics, providing invaluable insights that guide experimentalists in designing novel nanocatalysts.

As we transition to the next section, we carry with us a profound understanding of the mechanisms governing nanocatalysis. The synthesis of experimental and theoretical approaches paints a comprehensive picture, allowing us to unravel the complexities of nanoscale catalytic processes and cover the way for their optimization and application (Table 2).

Catalytic characteristics of nanocatalyst

Catalytic properties of nanocatalysts represent a fascinating and rapidly evolving field in the dominion of nanotechnology and materials science. Nanocatalysts, as the name suggests, are catalysts with dimensions at the nanoscale, typically ranging from 1 to 100 nm (shown in Fig. 3). This reduced size imparts unique and enhanced catalytic properties compared to their bulk counterparts, making them highly sought after in various industrial applications. One of the defining features of nanocatalysts is their high surface area-to-volume ratio. This characteristic arises from the fact that as the size of the catalyst particles decreases, the surface area available for catalytic reactions increases exponentially. This increased surface area allows for more active sites where chemical reactions can occur, leading to higher catalytic efficiency and reaction rates [17, 82,83,84].

The size-dependent properties of nanocatalysts also result in quantum effects, which can significantly influence their catalytic behavior. Quantum confinement effects, where the movement of electrons is restricted to nanoscale dimensions, can alter the electronic structure of the catalyst and affect its interaction with reactant molecules [85]. This quantum behavior can lead to tunable catalytic properties, allowing for precise control over reaction pathways and selectivity [86, 87].

Furthermore, nanocatalysts often exhibit size-dependent chemical reactivity. Small nanoparticles may display different catalytic activities compared to larger particles of the same material. This size-dependent reactivity can be attributed to the increased prevalence of under-coordinated surface atoms and unique crystal facets on the nanocatalyst, providing distinctive sites for adsorption and reaction. The morphology and composition of nanocatalysts play a crucial role in determining their catalytic properties. Tailoring these factors enables the design of catalysts with specific functionalities, making them suitable for a wide range of applications [88]. For instance, the incorporation of various metals, metal oxides, or organic components in nanocatalysts allows for the creation of hybrid materials with enhanced catalytic performance and selectivity [89,90,91,92].

Nanocatalysts have demonstrated remarkable efficiency in various catalytic processes, including hydrogenation, oxidation, and dehydrogenation reactions. Their applications extend to environmental remediation, energy conversion, and the synthesis of fine chemicals. The use of nanocatalysts in environmental applications, such as wastewater treatment and air purification, has gained significant attention due to their ability to enhance reaction rates and reduce the amount of required catalyst material. Moreover, nanocatalysts have shown promise in the field of renewable energy. For example, they play a crucial role in catalyzing reactions in fuel cells and photocatalytic systems, contributing to advancements in clean energy technologies [93, 94]. The unique properties of nanocatalysts make them indispensable in the development of more efficient and sustainable energy conversion processes [95,96,97].

Despite their immense potential, challenges exist in the synthesis, stability, and scalability of nanocatalysts. Researchers continue to explore novel fabrication methods and support materials to address these challenges and unlock the full potential of nanocatalysts for practical applications.

In conclusion, the catalytic properties of nanocatalysts represent a dynamic and evolving area of research with profound implications for various industries. The combination of size-dependent effects, high surface area, and tunable reactivity makes nanocatalysts versatile tools for advancing catalysis and driving innovations in fields ranging from environmental science to energy production. As our understanding of nanomaterials and catalysis deepens, the applications of nanocatalysts are likely to expand, ushering in a new era of highly efficient and sustainable chemical processes.

Applications of nanocatalysis

Nanocatalysis, with its unique properties and versatile capabilities, has found applications across a spectrum of scientific and industrial domains. In this section, we explore the multifaceted contributions of nanocatalysis in diverse fields, showcasing its transformative impact on energy conversion and storage, green chemistry, sustainable synthesis, and environmental remediation [86, 98, 99].

Energy conversion and storage

Nanocatalysis has emerged as a cornerstone in advancing energy conversion and storage technologies, addressing critical challenges in the quest for sustainable energy solutions. This subsection unravels the pivotal role nanocatalysis plays in this dynamic arena [26, 100,101,102,103].

Nanocatalysts contribute significantly to the efficiency and performance of fuel cells. Catalysts tailored at the nanoscale enhance the kinetics of electrochemical reactions, promoting faster fuel cell operation and improved energy conversion efficiency. Platinum-based nanocatalysts, for instance, exhibit superior catalytic activity, making them vital components in proton-exchange membrane fuel cells [104, 105].

Menezes et al. synthesized structurally ordered non-noble intermetallic cobalt stannide (CoSn2) nanocrystals and explored their application in electrocatalytic overall water-splitting in alkaline media (Fig. 4). The CoSn2 nanocrystals exhibited low overpotentials for both the oxygen evolution reaction (OER) and hydrogen evolution reaction (HER) when supported on fluorine-doped tin oxide (FTO) and Ni foam (NF). Under strongly alkaline conditions, CoSn2 transformed into highly active amorphous CoOx(H) for OER, while CoO in CoSn2 served as active sites for HER. This cost-effective bifunctional electrocatalyst demonstrated promising performance in a two-electrode electrolyzer, achieving a low cell voltage of 1.55 V at 10 mAcm−2 with long-term stability [106].

Macaskie et al. investigated the potential of biosynthesized bimetallic Pt/Pd nanoparticles by E. coli as a catalyst for polymer electrolyte fuel cells (PEMFCs) (Fig. 5). Unlike conventional chemical synthesis methods, biosynthesis offers an eco-friendly alternative. The E. coli-Pt/Pd catalyst exhibited superior performance compared to single metal versions (E. coli-Pt and E. coli-Pd) when tested ex situ as an electrocatalyst. However, direct use in PEMFCs faced challenges due to bacterial resistance and nanoparticle localization. By synthesizing Pd nanoparticles on E. coli cells first, followed by Pt, a cell surface-localized metallic shell was achieved, enhancing conductivity. While the catalyst underperformed compared to commercial ones, this study lays the groundwork for further optimization and engineered biosynthesis of nanoparticles for PEMFC catalysts [107].

Nanocatalysts contribute to the development of advanced energy storage devices, including lithium-ion batteries and supercapacitors. The tailored design of nanomaterials enhances electrode performance, accelerates charge–discharge kinetics, and increases the overall energy storage capacity. Nanocatalytic approaches are crucial for addressing challenges associated with energy storage, paving the way for more sustainable and efficient energy systems [108].

Wu et al. address the challenges associated with silicon-based electrodes in lithium-ion batteries, particularly the issues related to volume expansion during lithiation. They review various approaches to mitigate these challenges, including the use of binders, modifying silicon structures, and employing silicon/carbon nanocomposites. While binders effectively maintain electrical conductivity, improving reversible capacity remains a challenge. Changing silicon structures, such as using silicon nanotubes and nanowires, shows promise in addressing pulverization issues. However, manufacturing these structures at scale poses challenges. The combination of silicon with novelty carbon structures, especially graphene and reduced graphene oxides, proves effective in stabilizing the SEI layer and mitigating volume expansion, as shown in Fig. 6. This approach also offers cost-effective synthesis methods. Future research aims to improve initial coulombic efficiency and capacity retention, ultimately advancing silicon-based anodes in lithium-ion batteries [109].

Green chemistry and sustainable synthesis

This subsection explores how nanocatalysts facilitate sustainable synthesis practices and contribute to the broader goals of green chemistry. The principles of green chemistry, emphasizing environmentally benign processes, align seamlessly with the capabilities of nanocatalysis [17, 110, 111].

Catalytic selectivity

Nanocatalysis enables precise control over reaction pathways and enhances catalytic selectivity. This selectivity is pivotal in reducing waste generation and optimizing resource utilization, aligning with the principles of green chemistry. Nanocatalysts can be tailored to favor specific reaction pathways, minimizing the formation of undesired by-products [112].

Sudarsanam et al. have devised a highly efficient MoO3/MnOx nanocatalyst, finely tuned for shaping, enabling the selective production of 2-phenylquinoxaline drug motifs at ambient temperature, devoid of any external oxidant. Following calcination at 500 °C, termed MoO3/MnOx-5, the nanocatalyst exhibits abundant potent acid sites and an optimal Mn4+ /Mn3+ ratio, crucial for catalyzing the C–N cross-coupling reaction between 2-phenylethylamine and o-phenylenediamine, yielding 2-phenylquinoxaline in excess of 96% under mild conditions. The versatility of this catalytic approach at room temperature, sans an external oxidant, is underscored by achieving over 90% yields of functional 2-phenylquinoxalines via C–N cross-coupling across a range of o-phenylenediamines and 2-phenylethylamines. Moreover, the MoO3/MnOx-5 nanocatalyst exhibits remarkable reusability for up to five cycles without necessitating regeneration, coupled with effective scalability, endorsing the practicality of the MoO3/MnOx-5 based catalytic protocol for carbon–heteroatom coupling reactions at ambient temperature without an external oxidant. Computational studies shed light on the possible mechanisms behind the selective synthesis of 2-phenylquinoxaline over the MoO3/MnOx-5 nanocatalyst [113] (Scheme 1).

Shoukat et al. synthesized MnMoO4 nanomaterials via a solvothermal approach for the oxidation of toluene, an organic pollutant, into valuable chemical products, as shown in Scheme 2. The catalytic efficiency of these nanomaterials was evaluated for toluene oxidation through C–H activation using H2O2 as an oxidant at 80 °C. Optimization of reaction parameters yielded a maximum toluene conversion rate of 40.62% after 18 h with 0.06 g of catalyst. A maximum benzaldehyde selectivity of 78% was achieved under the same conditions. Additionally, 62.33% benzyl alcohol selectivity was obtained using 0.1 g of catalyst after 1 h. The catalyst showed good reusability with consistent toluene conversion rates for up to six cycles. FTIR spectra analysis indicated no significant change in the catalyst structure after recovery. These findings demonstrate the robustness and potential of MnMoO4 nanomaterials for toluene oxidation in a milder, greener, and chlorine-free environment [114].

Atom economy

The high surface area-to-volume ratio of nanocatalysts promotes efficient atom utilization in catalytic processes. This enhances atom economy, a fundamental aspect of green chemistry that strives to maximize the incorporation of reactant atoms into the final product. Nanocatalysis, with its ability to orchestrate reactions at the atomic level, contributes significantly to improving atom efficiency [110].

Maleki et al. presented a study on a cellulose-based nanocomposite enriched with Fe3O4 nanoparticles. This eco-friendly and cost-effective Fe3O4@cellulose nanocatalyst was employed in synthesizing benzodiazepine derivatives through a green and straightforward method. The protocol offered several advantages, including short reaction times, high yields, simplicity, easy work-up, and environmentally friendly conditions. Additionally, the nanocatalyst could be recycled multiple times with minimal loss of catalytic activity, although a slight reduction in activity was observed after initial reuse [115] (Scheme 3).

Shinde et al. employed coprecipitation to synthesize magnetically separable Fe3O4@MgO core–shell nanoparticles, serving as a heterogeneous catalyst for the one-pot synthesis of polyhydroquinoline derivatives, as shown in Scheme 4. Under solvent-free conditions and ultrasonication, various aldehydes were efficiently converted into their corresponding polyhydroquinoline derivatives with a maximum yield of 94%. This approach offers several advantages, including the use of a new catalyst, environmentally friendly methodology, straightforward technique, rapid reaction time, high product yield, and catalyst recyclability without degradation [116].

Sustainable catalyst design

Nanocatalysts themselves can be designed using sustainable and Earth-abundant materials. The use of non-toxic and eco-friendly catalyst components aligns with the principles of green chemistry, ensuring that catalytic processes have minimal environmental impact. Sustainable catalyst design extends the benefits of green chemistry to nanocatalytic applications [117].

Mosaddegh et al. synthesized nano-CaO through the calcination of ball-milled chicken eggshell waste. This novel, bioactive, heterogeneous catalyst exhibited high catalytic activity and reusability. It was employed in the green synthesis of pyrano[4,3-b] pyrans via the condensation of various aromatic aldehydes, malononitrile, and 4-hydroxy-6-methyl-2H-pyran-2-one at 120 °C under solvent-free conditions, as shown in Scheme 5. The reaction was completed within 5–45 min, yielding 93–98%. The nano-CaO catalyst was fully characterized using scanning electron microscopy, X-ray powder diffraction, infrared spectroscopy, X-ray fluorescence spectroscopy, and thermal gravimetric, surface area, and elemental analyses [118].

Environmental remediation

The remediation of environmental pollutants presents a pressing global challenge, and nanocatalysis has emerged as a powerful tool for addressing contamination in air, water, and soil. This subsection explores the applications of nanocatalysis in environmental remediation [2, 19, 21].

Water purification

Nanocatalysts play a crucial role in water purification processes, effectively removing pollutants and contaminants. Catalytic nanoparticles can facilitate the degradation of organic pollutants through advanced oxidation processes, providing a sustainable approach to ensuring clean and safe water resources [119].

Krishnan et al. explored the potential of two-dimensional (2D) materials for their large surface area and ability to support efficient photocatalytic processes (shown in Fig. 7). They synthesized binary Bi2WO6–TiO2 and ternary Bi2WO6–TiO2–Ti3C2 2D nanocomposites via electrostatic self-assembly. Structural and morphological characterization confirmed successful synthesis and 2D morphology. Optimized nanocomposites exhibited significantly enhanced degradation of methyl green compared to pristine materials, attributed to increased surface area, pollutant adsorption, and improved charge separation and transfer facilitated by a S-scheme mechanism and face-to-face interfacial contact. This study highlights the efficacy of 2D nanocomposites and the role of Ti3C2 as an electron acceptor in S-scheme photocatalysis [120, 121].

Air pollution control

Nanocatalytic materials contribute to air pollution control by facilitating the conversion of harmful gases into less harmful compounds. Catalytic converters employing nanocatalysts can effectively reduce emissions from industrial processes and vehicular exhaust, mitigating the impact of air pollutants on human health and the environment [122,123,124].

You et al. utilized a photocatalytic oxidation process (PCO) under visible light to degrade nitric oxide (NO) using a synthesized MgO@g-C3N4 Nano heterojunction photocatalyst, as shown in Fig. 8. The heterojunctions were prepared via one-step pyrolysis of MgO and commercial urea at 550 °C for 2 h. The photocatalytic efficiency of the MgO@g-C3N4 composites reached 75.4%, exhibiting 1.2-fold higher efficiency than pure g-C3N4 and 4.5-fold higher efficiency than commercial MgO. Characterization techniques such as XRD, FTIR, XPS, SEM, TEM, and DRS were employed to analyze the materials’ structural and optical properties. The bandgap of the materials decreased with increasing MgO content. Additionally, various tests including NO conversion, De NOx index, apparent quantum efficiency (AQE), trapping test, and electron spin resonance (ESR) were conducted to elucidate the photocatalytic mechanism. The MgO@g-C3N4 composites showed high reusability over five recycling tests [125].

Waste treatment

Nanocatalysis offers innovative solutions for waste treatment, converting hazardous waste into less harmful or even valuable products. From catalytic degradation of organic pollutants to the detoxification of industrial effluents, nanocatalytic processes contribute to sustainable waste management practices [126].

Gnana Prakash et al. investigated the photocatalytic properties of g-C3N4 and its nanocomposite with ZnO for crystal violet degradation under solar light, As shown in Fig. 9. g-C3N4 was synthesized from melamine pyrolysis, and the nanocomposite was prepared hydrothermally. Characterization revealed structural features, including inter-layer packing and interplanar stacking peaks. The nanocomposite showed enhanced efficiency (97%) due to improved charge separation at the ZnO/g-C3N4 heterojunction [127].

CO2 conversion

CO₂ conversion via nanocatalysts uses nanoscale materials to efficiently transform CO₂ into valuable chemicals like methane, methanol, and formic acid. These catalysts enhance reaction rates and selectivity due to their high surface area and unique properties, playing a key role in sustainable carbon capture and utilization efforts [128].

Polshettiwar et al. demonstrated that magnesium can convert CO₂ (from air or pure) into methane, methanol, and formic acid at room temperature and atmospheric pressure, using water as the hydrogen source without any external energy, as illustrated in Fig. 10. The reaction was very fast, with maximum yield in 15 min. Hydrogen production was predominant due to the favored reaction between water and magnesium. Despite converting to basic magnesium carbonate, magnesium can be regenerated using a solar-energy pumped laser process. The study highlighted magnesium’s ability to chemisorb and activate CO₂, facilitating its reduction through a cooperative action involving magnesium, basic magnesium carbonate, CO₂, and water [129].

Zhang et al. synthesized ZnO/ZnSe composites via a solvothermal method and analyzed their composition, morphology, microstructure, and CO₂ reduction activity. Bare ZnO and ZnSe produced methanol at rates of 763.9 and 503.88 μmol/gcat/h, respectively, while the 3% wt ZnO/ZnSe composite achieved a significantly higher rate of 1581.82 μmol/gcat/h. The enhanced performance was due to the ZnSe nanosheets improving light absorption and the ZnO/ZnSe heterojunction facilitating electron transfer for CO₂ reduction, as shown in Fig. 11 [130].

In the subsequent sections, we will explore the challenges and future perspectives of nanocatalysis, addressing current limitations, highlighting emerging trends, and outlining potential breakthroughs. As we reflect on the diverse applications discussed in this section, the transformative potential of nanocatalysis in shaping a sustainable and innovative future becomes increasingly evident.

Challenges and future perspectives

Nanocatalysis, despite its transformative potential, is not without challenges. This section critically examines the current limitations and obstacles faced by researchers in the field, while also glimpsing into the future to identify emerging trends and potential breakthroughs.

Nanocatalysis, while a promising field, grapples with several challenges that impede its seamless integration into various applications. Understanding these limitations is paramount for devising strategies to overcome them and unlock the full potential of nanocatalysts. One notable challenge lies in ensuring the durability and stability of nanocatalysts during prolonged catalytic processes. The harsh reaction conditions, coupled with potential agglomeration or leaching of nanoparticles, can compromise their structural integrity over time. Developing strategies to enhance the robustness of nanocatalysts is imperative for sustained and reliable catalytic performance. The scalable production of nanocatalysts for industrial applications presents a significant hurdle. Many synthesis methods that yield high-quality nanoparticles on a laboratory scale may prove challenging to translate into large-scale production while maintaining consistent properties. Bridging the gap between bench-scale synthesis and industrial scalability is a crucial aspect for the widespread adoption of nanocatalysis. Certain nanocatalysts rely on precious or scarce materials, contributing to elevated production costs. Addressing the cost-effectiveness and ensuring the availability of resources for nanocatalyst synthesis are essential, particularly when considering their applications in energy technologies and large-scale industrial processes. Ensuring the reproducibility of nanocatalytic results across different laboratories remains a challenge. Standardizing synthesis protocols and characterizations methods is crucial for establishing benchmarks and facilitating the comparison of results. Overcoming variability in nanocatalyst preparation and assessment is vital for building a reliable knowledge base.

In navigating the challenges, nanocatalysis continues to evolve, with emerging trends shaping its trajectory. These trends provide a glimpse into the future, showcasing the innovative directions that researchers are exploring to enhance the efficacy and applicability of nanocatalysts. A burgeoning trend in nanocatalysis involves the exploration of single-atom catalysis, where isolated metal atoms serve as catalytically active sites. This approach maximizes atom efficiency, reduces the reliance on precious metals, and offers enhanced control over catalytic reactions. Single-atom catalysis represents a paradigm shift in catalyst design with vast implications for sustainability and efficiency. Advances in computational methods are making it possible to design nanocatalysts with good precision. “Designer” nanocatalysts, tailored through computational approaches, allow researchers to predict and optimize catalytic properties with a level of control that was once elusive. This trend holds promise for accelerating the development of highly efficient and selective catalysts. Inspired by nature, researchers are exploring the design of nanocatalysts that mimic biological systems. Biomimetic nanocatalysts, taking cues from enzymes and biological processes, aim to achieve high catalytic activity with selectivity, offering environmentally friendly and sustainable alternatives for various applications.

Looking ahead, nanocatalysis holds the potential for groundbreaking developments that could reshape the landscape of catalytic science and technology. Exploring these future directions provides insight into the transformative possibilities that may unfold. The integration of nanocatalysis into unconventional realms, such as catalysis in extreme conditions or outer space, represents an intriguing avenue for exploration. Adapting nanocatalysts to operate under extreme temperatures, pressures, or radiation environments opens new frontiers for applications previously deemed inaccessible. The development of “smart” nanocatalysts with responsive and adaptive properties is a captivating prospect. Nanocatalysts that can modulate their activity based on external stimuli, such as pH, temperature, or the presence of specific molecules, hold promise for dynamic and controlled catalytic processes. Future breakthroughs in nanocatalysis are likely to stem from interdisciplinary collaborations that bridge the expertise of chemists, physicists, materials scientists, and engineers. Integrating diverse perspectives and knowledge domains will foster holistic approaches to address complex challenges and drive innovation in nanocatalytic research.

The development of nanocatalysts involves significant challenges, particularly in balancing catalytic activity with stability. High catalytic activity is crucial for efficient chemical reactions, driven by the large surface area and unique electronic properties of nanoparticles. These characteristics provide abundant active sites and enhance reactivity, making nanocatalysts more effective than their bulk counterparts. However, high activity often compromises stability, a vital factor for practical applications. Small nanoparticles, though highly reactive, tend to agglomerate and sinter at high temperatures, reducing their active surface area and catalytic efficiency. Conversely, larger nanoparticles or those supported on substrates are more stable but offer fewer active sites, resulting in lower catalytic activity. Surface modifications, like functionalization with ligands, can prevent aggregation and enhance stability but may block active sites, reducing activity. Similarly, core–shell structures that protect the active core can hinder reactant access, diminishing catalytic performance.

Material composition also influences this balance. Alloying can enhance stability through stronger metal–metal bonding but may alter the electronic structure, reducing catalytic activity compared to pure metals. Using metal oxides as supports can stabilize metal nanoparticles but modify the active sites, potentially lowering activity. To address these challenges, researchers are exploring several strategies. These include optimizing particle size to balance surface area and stability, designing core–shell structures that protect the core while allowing reactant access, and developing advanced supports that enhance stability without significantly blocking active sites. Other approaches involve creating catalysts capable of dynamic restructuring under reaction conditions and employing advanced surface engineering techniques to tailor surface properties.

In summary, the interplay between catalytic activity and stability in nanocatalysts is a complex challenge requiring innovative solutions. Future research aims to maximize both properties, ensuring practical and durable catalytic applications and advancing the capabilities of nanotechnology. Nanocatalysis navigates its current challenges and embraces emerging trends; the field stands on the precipice of transformative advancements. The journey ahead involves addressing limitations, fostering innovation, and capitalizing on interdisciplinary synergies to propel nanocatalysis into a future where it plays an even more integral role in shaping sustainable and efficient technological landscapes.

Conclusion

This comprehensive review article delves into nanocatalysis, situated at the intersection of scientific innovation, catalytic chemistry, and technological progress. Exploring fundamental principles, advances, applications, challenges, and future prospects provides a nuanced understanding of this dynamic field. Nanocatalysis applications extend across sectors like energy, green chemistry, and environmental remediation, addressing global challenges and catalyzing positive change. From nanoparticle synthesis to advanced catalyst design, nanocatalysis blends theory and experimentation, fostering innovation. Addressing durability, scalability, cost-effectiveness, and reproducibility challenges is crucial for unlocking its full potential. Emerging trends, such as single-atom catalysis and biologically inspired approaches, hint at future developments. As computational methods advance, interdisciplinary collaborations flourish, positioning nanocatalysis for groundbreaking developments and applications beyond traditional boundaries. This field aligns with green chemistry, sustainability, and efficient resource utilization, contributing to a more sustainable and innovative future. In conclusion, this review article serves as a guide for researchers, navigating the multifaceted landscape of nanocatalysis from historical roots to emerging trends, shaping contemporary science and industry. The transformative potential of nanocatalysis remains a beacon for a future where catalysis at the nanoscale plays an increasingly integral and impactful role [80, 81].

References

Lakhani P, Modi CK (2023) Shaping enantiochemistry : recent advances in enantioselective reactions via heterogeneous chiral catalysis. Mol Catal 548:113429

Singh SB, Tandon PK (2015) Catalysis : a brief review on nano-catalyst. J Energy Chem Eng 2:106–115

Philippot K, Serp P (2013) Concepts in nanocatalysis. Nanomater Catal 1:1–54

Philippot K, Roucoux A (2021) New trends in the design of metal nanoparticles and derived nanomaterials for catalysis. Nanopart Catal 1:1–11

Sabatier P, Prize CN (2020) Introduction: nanoparticles in catalysis. Chem Rev 120:461

Verma A, Shukla M, Sinha I (2019) Introductory chapter: salient features of nanocatalysis. Nanocatalysts 86209

Chadha U et al (2022) Complex nanomaterials in catalysis for chemically significant applications : from synthesis and hydrocarbon processing to renewable energy applications. Adv Mater Sci Eng 2022:1

Abbasi R, Shineh G (2023) Structural parameters of nanoparticles affecting their toxicity for biomedical applications: a review. J Nanopart Res 25

Olveira S, Forster SP, Seeger S (2014) Nanocatalysis: academic discipline and industrial realities. J Nanotechnol 2014:324089

Faraday MX (1857) The Bakerian lecture. —Experimental relations of gold (and other metals) to light. Philos Trans R Soc London 147:145–181

Haruta M, Kobayashi T, Sano H, Yamada N (1987) Novel gold catalysts for the oxidation of carbon monoxide at a temperature far below 0 °C. Chem Lett 16:405–408

Tweney RD (2006) Discovering discovery: how faraday found the first metallic colloid. Perspect Sci 14:97–121

Astruc D (2020) Introduction: nanoparticles in catalysis. Chem Rev 120:461–463

Wu D et al (2020) Platinum-group-metal high-entropy-alloy nanoparticles. J Am Chem Soc 142:13833–13838

Wu D et al (2022) Noble-metal high-entropy-alloy nanoparticles: atomic-level insight into the electronic structure. J Am Chem Soc 144:3365–3369

Liu Q, Yang L, Chen S, Pollet BG, Li H (2020) Editorial : Recent development of nanocatalysts for hydrogen production. Front Chem 8:1–3

Babu S, Jagirdar BR (2011) Nanocatalysis and prospects of green chemistry. Chemsuschem 5:65

Khan Y et al (2022) Nanoparticles, and their applications in various fields of nanotechnology : a review. Catalysts 12:1386

Shaker LM, Al AA, Waleed A, Azzawi KAl (2024) Discover nano nanomaterials : paving the way for the hydrogen energy frontier. Discov Nano 19(1):3

Roy A et al (2021) Biological synthesis of nanocatalysts and their applications. Catalysts 11:1494

Corti HR et al (2021) Structure and dynamics of nanoconfined water and aqueous solutions. Eur Phys JE 44:136

Ghosh A, Nagabhushana KS, Rautaray D, Kumar R (2013) Role of nanocatalysis in chemical industry. Nanocatal Synth Appl 643:643–678

Kulkarni MB, Ayachit NH (2022) Recent advancements in nanobiosensors : current trends, challenges, applications, and future scope. Biosensors 12:892

Arya I, Poona A, Dikshit PK, Pandit S, Kumar J, Singh HN, Jha NK, Rudayni HA, Chaudhary AA, Kumar S (2021) Current trends and future prospects of nanotechnology in biofuel production. Catalysts 11:1308

Kadja GTM et al (2022) Recent advances on the nanoporous catalysts for the generation of renewable fuels silica to alumina ratio. J Mater Res Technol 17:3277–3336

Alshammari A, Kalevaru VN (2016) Metal nanoparticles as emerging green catalysts. Green Nanotechnol- Overview Further Prospects 63314

Nam NH, Luong NH (2019) Nanoparticles: synthesis and applications. Materials for Biomedical Engineering: Inorganic Micro and Nanostructures. Mater Biomed Eng 211–219

Saleh HM (2023) Synthesis and characterization of nanomaterials for application in cost-effective electrochemical devices. Sustainability 15:10891

Yao Y et al (2018) Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359:1489–1494

Mourdikoudis S, Pallares RM (2018) Characterization techniques for nanoparticles : comparison and complementarity upon studying. Nanoscale 10:12871

Joudeh N, Linke D (2022) Nanoparticle classification , physicochemical properties , characterization , and applications : a comprehensive review for biologists. J Nanobiotechnol 1–29

Lakhani P, Modi CK (2023) Asymmetric hydrogenation using a covalently immobilized Ru-BINOL-AP@MSNs catalyst. New J Chem 47:8767–8775

Lee SW et al (2021) Surface chemistry of hot electron and metal-oxide interfaces. Surf Sci Rep 76:100532

Martí G et al (2023) Surface‐functionalized nanoparticles as catalysts for artificial photosynthesis. Adv Energy Mater 13:202300282

Wittstock A et al (2009) Surface chemistry in nanoscale materials. Materials 2:2404

Roldan B, Behafarid F (2015) Nanocatalysis : size- and shape-dependent chemisorption and catalytic reactivity. Surf Sci Rep 70:135–187

Narayan N, Meiyazhagan A (2019) Metal nanoparticles as green catalysts. Materials 12(21):3602

Campisi S, Schiavoni M, Chan-thaw CE, Villa A (2016) Untangling the role of the capping agent in nanocatalysis : recent advances and perspectives. Catalysts 6:185

Hartman T, Geitenbeek RG, Wondergem CS, van der Stam W, Weckhuysen BM (2020) Operando nanoscale sensors in catalysis : all eyes on catalyst particles. ACS Nano 14:3725

Sudarsanam P, Peeters E, Makshina EV, Parvulescu VI, Sels BF (2019) Chem Soc Rev Advances in porous and nanoscale catalysts for viable biomass conversion. Chem Soc Rev 48:2366

Li X et al (2022) Functional CeOx nanoglues for robust atomically dispersed catalysts. Nature 611:284–288

Hu S, Li WX (2021) Sabatier principle of metal-support interaction for design of ultrastable metal nanocatalysts. Science 374:1360–1365

Poursadegh F (2023) Revolutionizing catalyst development – a comprehensive review of the past, present, and future of nanotechnologies in synthesis and development of new catalysts. IJMDES 2:5–11

Sun X, Han J, Guo R (2020) A mini review on yolk-shell structured nanocatalysts. Front Chem 8:1–8

Ratautas D, Dagys M (2019) Nanocatalysts containing direct electron transfer-capable oxidoreductases: recent advances and applications. Catalysts 10:9

Li H, Jian S, Baalousha M (2023) Applications of catalytic nanomaterials in energy and environment. Molecules 28:4000

Lakhani P, Modi CK (2024) Montmorillonite-silica-graphene oxide composite incorporating with chiral thiourea for the Strecker reaction. Mol Catal 559:114080

Forsythe RC, Cox CP, Wilsey MK, Mu AM (2021) Pulsed laser in liquids made nanomaterials for catalysis. Chem Rev 121:7568

Kustov LM (2021) Catalysis by hybrid nanomaterials. Molecules 26:352

Harun-ur-rashid M, Jahan I, Foyez T, Imran AB (2023) Bio-inspired nanomaterials for micro / nanodevices : a new era in biomedical applications. Micromachines 14:1786

Zikalala NE et al (2023) The role of inorganic and carbon nanomaterials in surface modification to attain antibiofouling polymeric membranes for water treatment - a review. Ind Eng Chem Res 62:9354

Kumar S et al (2022) Recent developments in nanocatalyzed green synthetic protocols of biologically potent diverse O-heterocycles—a review. Catalysts 12:657

Adetunji O et al (2021) Materials reports : energy integration of data-intensive, machine learning and robotic experimental approaches for accelerated discovery of catalysts in renewable energy-related reactions. Mater Reports Energy 1:100049

Han Y, Xu H, Li Q, Du A (2023) Carbon-based electrocatalysts design and mechanism study : a review. Front Chem 11:1–26

Lakhani P et al (2023) DFT stimulation and experimental insights of chiral Cu(ii)-salen scaffold within the pocket of MWW-zeolite and its catalytic study. Phys Chem Chem Phys 25:14374–14386

Chen BWJ, Xu L, Mavrikakis M (2020) Computational methods in heterogeneous catalysis. Chem Rev 121:1007

Nair AS (2020) Computational strategies to address the catalytic activity of nanoclusters. WIREs Comput Mol Sci 11:1–19

Shambhawi, Mohan O, Choksi TS, Lapkin AA (2024) The design and optimization of heterogeneous catalysts using computational methods. Catal Sci Technol 14:515

Taylor CJ et al (2023) A brief introduction to chemical reaction optimization. Chem Rev 123:3089

Kleiner M et al (2023) Ultra - sensitive isotope probing to quantify activity and substrate assimilation in microbiomes. Microbiome 11:1–23

Köhnke K, Wessel N, Esteban J (2022) Operando monitoring of mechanisms and deactivation of molecular catalysts. Green Chem 24:1951

Salmeron M, Eren B (2020) High-pressure scanning tunneling microscopy. Chem Rev 121:962

Krishna DNG, Philip J (2022) Applied surface science advances review on surface-characterization applications of X-ray photoelectron spectroscopy ( XPS ): recent developments and challenges. Appl Surf Sci Adv 12:100332

Somorjai GA, Li Y (2010) Impact of surface chemistry. Proc Natl Acad Sci USA 108:917

Baer DR et al (2013) Surface characterization of nanomaterials and nanoparticles : important needs and challenging opportunities. J Vac Sci Technol, A: Vac, Surf Films 31:1–34

Iii GEC, Debeer S (2022) Challenges and opportunities for applications of advanced X - ray spectroscopy in catalysis research. ACS Catal 12:5864

Hartman T, Wondergem CS, Kumar N, van den Berg A, Weckhuysen BM (2016) Surface- and tip-enhanced raman spectroscopy in catalysis. J Phys Chem Lett 7:1570

Jin L, Seifitokaldani A (2020) In situ spectroscopic methods for electrocatalytic CO2 reduction. Catalysts 10:481

Geißler D (2021) Analyzing the surface of functional nanomaterials — how to quantify the total and derivatizable number of functional groups and ligands. Microchim Acta 188:321

Tinnemans SJ et al (2006) Combining operando techniques in one spectroscopic-reaction cell : new opportunities for elucidating the active site and related reaction mechanism in catalysis. Catal Today 113:3–15

Chee SW, Lunkenbein T, Schl R, Rold B (2023) Operando electron microscopy of catalysts : the missing cornerstone in heterogeneous catalysis research. Chem Rev 123:13374

Timoshenko J, Cuenya BR (2020) In situ / operando electrocatalyst characterization by X - ray absorption spectroscopy. Chem Rev 121:882

Wang M, Árnadóttir L, Xu ZJ, Feng Z (2019) In situ X - ray absorption spectroscopy studies of nanoscale electrocatalysts. Nano-Micro Lett 11:1–18

Zhang H, Li X, Jiang Z (2019) Probe active sites of heterogeneous electrocatalysts by X-ray absorption spectroscopy: from single atom to complex multi-element composites. Curr Opin Electrochem 14:7

Nomura K (2019) Solution X-ray absorption spectroscopy ( XAS ) for analysis of catalytically active species in reactions with ethylene by homogeneous ( imido ) vanadium ( V ) complexes—Al cocatalyst systems. Catalysts 9:1016

Jurina T, Sokaˇ T, Benkovi M, Zeli B (2023) Application of spectroscopy techniques for monitoring ( bio ) catalytic processes in continuously operated microreactor systems. Catalysts 13:690

Borfecchia E et al (2017) Spectroscopic methods in catalysis and their application in well-defined nanocatalysts. Stud Surf Sci Catalysis 177:221–284

Zaera F (2021) In-situ and operando spectroscopies for the characterization of catalysts and of mechanisms of catalytic reactions q. J Catal 404:900–910

Lakhani P, Modi CK (2022) Spick-and-span protocol for designing of silica-supported enantioselective organocatalyst for the asymmetric aldol reaction. Mol Catal 525:112359

Groppo E, Rojas-buzo S, Bordiga S (2023) The role of in situ / operando IR spectroscopy in unraveling adsorbate-induced structural changes in heterogeneous catalysis. Chem Rev 123:12135

Loridant S (2021) Raman spectroscopy as a powerful tool to characterize ceria-based catalysts. Catal Today 373:98

Park H, Shin DJ, Yu J (2021) Categorization of quantum dots, clusters, nanoclusters, and nanodots. J Chem Educ 98:703

Prinsen P, Luque R (2019) Introduction to nanocatalysts. In: Nanoparticle Design and Characterization for Catalytic Applications in Sustainable Chemistry (RSC) 1–36

Jin R (2012) The impacts of nanotechnology on catalysis by precious metal nanoparticles. Nanotechnology Reviews 1:31–56

Liu P, Qin R, Fu G, Zheng N (2017) Surface coordination chemistry of metal nanomaterials. J Am Chem Soc 139:2122–2131

Chaturvedi S, Dave PN (2012) Applications of nano-catalyst in new era. J Saudi Chem Soc 16:307–325

Rao CNR, Kulkarni GU, Thomas PJ, Edwards PP (2002) Size-dependent chemistry: properties of nanocrystals. Chem Eur J 8:28

Parmar R et al (2024) Harnessing bimetallic oxide nanoparticles on ionic liquid functionalized silica for enhanced catalytic performance. J Organomet Chem 1008:123073

Alayoglu S, Somorjai GA (2014) Nanocatalysis II : in situ surface probes of nano-catalysts and correlative structure – reactivity studies. Catal Lett 145:249

Pieta P (2021) Nanoscale advances bimetallic nanocatalysts supported on graphitic carbon nitride for sustainable energy development : the shape-structure–activity relation. Nanoscale Adv 3:1342–1351

Chatterjee S, Bhattacharya SK (2018) Size-dependent catalytic activity and fate of palladium nanoparticles in Suzuki − Miyaura coupling reactions. ACS Omega 3:12905

Rodrigues TS, Silva AGM (2019) Controlled synthesis for the optimization and understanding of activities. J Mater Chem A 7:5857–5874

Bhanderi D, Lakhani P, Sharma A, Soni SS, Modi CK (2023) Efficient visible light active photocatalyst: magnesium oxide- doped graphitic carbon nitride for the knoevenagel condensation reaction. ACS Appl Eng Mater 1:2752

Bhanderi D, Lakhani P, Modi CK (2024) Graphitic carbon nitride (g-C3N4) as an emerging photocatalyst for sustainable environmental applications: a comprehensive review. RSC Sustain 2:265

Zhang K et al (2019) Recent advances in the nanocatalyst-assisted NaBH 4 reduction of nitroaromatics in water. ACS Omega 4:483

Ahmad H (2022) Materials advances supported nanocatalysts : recent developments in heterogeneous catalysis. Mater Adv 3:859–887

Nor W, Wan R, Al-amiery A (2024) Green technologies and sustainability catalysts driving efficiency and innovation in thermal reactions : a comprehensive review. Green Technol Sustain 2:100078

Roy A et al (2021) Biological synthesis of nanocatalysts and their applications. Catalysts 11:1494

Sharma N, Ojha H, Bharadwaj A, Pathak DP, Sharma RK (2015) Preparation and catalytic applications of nanomaterials: a review. RSC Adv 5:53381–53403

Singh SK, Xu Q (2013) Nanocatalysts for hydrogen generation from hydrazine. Catal Sci Technol 3:1889–1900

Yin Z, Lin L, Ma D (2014) Construction of Pd-based nanocatalysts for fuel cells: opportunities and challenges. Catal Sci Technol 4:4116–4128

Van Nguyen T et al (2021) WS2–WC–WO3 nano-hollow spheres as an efficient and durable catalyst for hydrogen evolution reaction. Nano Converg 8:28

Bhanja P, Bhaumik A (2016) Porous nanomaterials as green catalyst for the conversion of biomass to bioenergy. Fuel 185:432–441

da Silva EP et al. (2022) Nanocatalysts for fuel cells. Nanotechnol Automot Ind 579–604

Zhong CJ et al (2008) Fuel cell technology: nano-engineered multimetallic catalysts. Energy Environ Sci 1:454–466

Menezes PW et al (2018) Structurally ordered intermetallic cobalt stannide nanocrystals for high-performance electrocatalytic overall water-splitting. Angew Chemie - Int Ed 57:15237–15242

Stephen AJ, Rees NV, Mikheenko I, Macaskie LE (2019) Platinum and palladium bio-synthesized nanoparticles as sustainable fuel cell catalysts. Front Energy Res 7:1–13

Das H, Pathak B, Khanam S, Kalita PK, Datta P (2022) Nanomaterials for next generation energy storage applications. MRS Commun 12:285–294

Casimir A et al (2016) Silicon-based anodes for lithium-ion batteries: effectiveness of materials synthesis and electrode preparation. Nano Energy 27:359–376

Kumar S et al (2022) Recent developments in nanocatalyzed green synthetic protocols of biologically potent diverse O-heterocycles—a review. Catalysts 12:657

Lakhani P, Kane S, Srivastava H, Goutam UK, Modi CK (2023) Sustainable approach for the synthesis of chiral β-aminoketones using an encapsulated chiral Zn(ii)-salen complex. RSC Sustain 00:1–10

An K, Somorjai GA (2015) Nanocatalysis I: Synthesis of metal and bimetallic nanoparticles and porous oxides and their catalytic reaction studies. Catal Letters 145:233–248

Singh N et al (2023) Shape-controlled MoO3/MnOx nanocatalyst for the selective synthesis of 2-phenylquinoxaline drug motifs. ACS Appl Nano Mater 6:23442–23453

Shoukat H et al (2021) Catalytic oxidation of toluene into benzaldehyde and benzyl alcohol using molybdenum-incorporated manganese oxide nanomaterials. ACS Omega 6:19606–19615

Maleki A, Kamalzare M (2014) Fe3O4@cellulose composite nanocatalyst: preparation, characterization and application in the synthesis of benzodiazepines. Catal Commun 53:67

Shinde G, Thakur J (2023) Core-shell structured Fe3O4@MgO: magnetically recyclable nanocatalyst for one-pot synthesis of polyhydroquinoline derivatives under solvent-free conditions. J Chem Sci 135:14

Mitchell S, Qin R, Zheng N, Pérez-Ramírez J (2021) Nanoscale engineering of catalytic materials for sustainable technologies. Nat Nanotechnol 16:129–139

Mosaddegh E, Hassankhani A (2014) Preparation and characterization of nano-CaO based on eggshell waste: novel and green catalytic approach to highly efficient synthesis of pyrano [4, 3-b]pyrans. Cuihua Xuebao/Chinese J Catal 35:351–356

Nasrollahzadeh M, Sajjadi M, Iravani S, Varma RS (2021) Green-synthesized nanocatalysts and nanomaterials for water treatment: current challenges and future perspectives. J Hazard Mater 401:123401

Kumar A, Singla Y, Sharma M, Bhardwaj A, Krishnan V (2022) Two dimensional S-scheme Bi2WO6–TiO2–Ti3C2 nanocomposites for efficient degradation of organic pollutants under natural sunlight. Chemosphere 308:136212

Nicola R et al (2020) Silica-coated magnetic nanocomposites for Pb2+ removal from aqueous solution. Appl Sci 10:2726

Ningthoujam R et al (2022) Nanocatalyst in remediating environmental pollutants. Chem Phys Impact 4:100064

Cao JJ, Huang Y, Zhang Q (2021) Ambient air purification by nanotechnologies: from theory to application. Catalysts 11:1276

Bhoyar T et al (2023) Defective nano-silica loaded polymeric carbon nitride for visible light driven CO 2 reduction and dye degradation. Catal Commun 179:106692

Pham M-T, Tran DPH, Bui X-T, You S-J (2022) Rapid fabrication of MgO@ g-C3N4 heterojunction for photocatalytic nitric oxide degradation under visible light. Beilstein Arch 2022:30

Bandaru S et al (2023) Efficient wastewater treatment through nano-catalyst: the role of H2O2 and application in wide pH window. Environ Adv 13:100428

Manimozhi R, Mathankumar M, Prakash APG (2021) Synthesis of g-C3N4 / ZnO heterostructure photocatalyst for enhanced visible degradation of organic dye. Optik (Stuttg) 229:165548

Whang HS, Lim J, Choi MS, Lee J, Lee H (2019) Heterogeneous catalysts for catalytic CO2 conversion into value-added chemicals. BMC Chem Eng 1:1–19

Rawool SA et al (2021) Direct CO2capture and conversion to fuels on magnesium nanoparticles under ambient conditions simply using water. Chem Sci 12:5774–5786

Zhang S, Yin X, Zheng Y (2018) Enhanced photocatalytic reduction of CO2 to methanol by ZnO nanoparticles deposited on ZnSe nanosheet. Chem Phys Lett 693:170–175

Acknowledgements

One of the contributing authors (CKM) deeply appreciates and wishes to convey profound gratitude to the esteemed co-authors of this review article. Their steadfast passion, unwavering commitment, and tireless endeavors played a pivotal role in shaping this exhaustive review article into the final form.

Author information

Authors and Affiliations

Contributions

PL contributed to Literature Review and Writing - Original Draft Preparation (equal). DB contributed to Data Collection, Figure and Table Creation (equal). CKM contributed to Writing - Review and Editing, Critical Input and Revision and Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lakhani, P., Bhanderi, D. & Modi, C.K. Nanocatalysis: recent progress, mechanistic insights, and diverse applications. J Nanopart Res 26, 148 (2024). https://doi.org/10.1007/s11051-024-06053-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-024-06053-9