Abstract

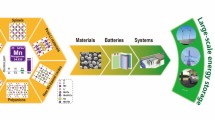

The ever-growing market of electrochemical energy storage impels the advances on cost-effective and environmentally friendly battery chemistries. Lithium-ion batteries (LIBs) are currently the most critical energy storage devices for a variety of applications, while sodium-ion batteries (SIBs) are expected to complement LIBs in large-scale applications. In respect to their constituent components, the cathode part is the most significant sector regarding weight fraction and cost. Therefore, the development of cathode materials based on Earth’s abundant elements (Fe and Mn) largely determines the prospects of the batteries. Herein, we offer a comprehensive review of the up-to-date advances on Fe- and Mn-based cathode materials for LIBs and SIBs, highlighting some promising candidates, such as Li- and Mn-rich layered oxides, LiNi0.5Mn1.5O4, LiFe1-xMnxPO4, NaxFeyMn1-yO2, Na4MnFe2(PO4)(P2O7), and Prussian blue analogs. Also, challenges and prospects are discussed to direct the possible development of cost-effective and high-performance cathode materials for future rechargeable batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The demand for electrical energy storage is increasing exponentially along with the advancement of technologies and our ambition for clean and sustainable development. As a state-of-the-art energy storage system, lithium-ion batteries (LIBs) continue to power consumer electronics and are increasingly used in defense, automotive, and aerospace applications owing to their high energy density (Larcher and Tarascon 2015; Thackeray et al. 2012). Such penetration also raises the concern of lithium shortage. In this context, sodium-ion batteries (SIBs) have entered the spotlight due to having similar electrochemistry and a higher global abundance of Na (Slater et al. 2013; Yabuuchi et al. 2014b). Though it is hard for them to compete with LIBs in compact applications due to reduced energy density, SIBs are deemed as the most promising complements to LIBs for large-scale electrical storage applications (Palomares et al. 2012).

A typical LIB is an enclosed device consisting of a cathode, an anode, a separator, and an electrolyte. In respect to the manufacturing cost of a LIB (Fig. 1a), the cathode part accounts for the most significant share, 36% of the total cost, due to the high content of material required and costly constitution (Kim et al. 2014). Most cathode materials are compounds containing extractable Li and multivalent transition metal (TM) ions. For example, LiCoO2 (LCO) is the first commercially successful cathode material and still the most commonly used one (Mizushima et al. 1980; Nitta et al. 2015), in which both Li and Co are non-abundant and expensive. However, the expense of the Co precursors is significantly higher than Li ones. Thus, switching from Li to Na is only expected to afford a 3.6 % cost reduction of cathode materials in the case of SIBs. Therefore, to improve the affordability and sustainability of the rechargeable batteries, it is essential to develop low-cost cathode materials incorporating earth abundant TM elements, preferably Fe and Mn (Fig. 1b, c), which primarily determine the scope and prospect of the rechargeable batteries (Larcher and Tarascon 2015).

a Constitutional costs for manufacturing a typical LIB and SIB. Values are from ref. (Kim et al. 2014). b Abundances of metal elementals involved in standard cathode materials. Values are taken from ref. (Nitta et al. 2015). c Sustainable (naturally recycled) elementals (shown in green) in the periodic table, in which main elements of current LIBs are circled in red. Reproduced from ref. (Larcher and Tarascon 2015)

Although both LIBs and SIBs should be directed to lower cost and higher performance, given the different application scenarios and development phases of LIBs and SIBs, the challenges existing in them still varies. In LIBs, Mn-based spinel LiMn2O4 (LMO) and Fe-based polyanionic LiFePO4 (LFP) are progressively replacing LCO in some areas. However, both of them are restricted by lower galvanometric and volumetric energy densities compared with LCO (Zheng et al. 2017). Consequently, LFP and LMO are not capable of weight or size-sensitive applications including advanced portable devices and electrical vehicles (EVs). Therefore, a critical criterion for the development of future Fe- and Mn-based cathodes for LIBs is to achieve comparable or even higher energy densities. The energy density of cathode material is determined collectively by its Li storage capacity and discharge potential. In this regard, some high-capacity and high-voltage materials such as Li- and Mn-rich oxides, LiNi0.5Mn1.5O4, and LiFe1-xMnxPO4 have attracted more attention. Meanwhile, candidates should also meet the requirements of rate capability, lifespan, and safety for practical applications.

Taking advantage of abundant Na sources, SIBs hold the promise to support large-scale energy storage applications, which is critical in harnessing intermittent renewable energies such as solar and wind power. An essential step to realizing large-scale SIB applications is the quest of suitable electrode materials that meet the long-term stability requirement and can deliver and accept large amounts of energy quickly. However, the radii of Na+ (0.102 nm) is much larger compared to that of Li+ (0.076 nm), posing considerable challenges of sluggish ion mobility and volumetric change of the hosts (Dai et al. 2017; Yabuuchi et al. 2014b). Direct analogs from LIB cathodes often result in continuous structural change and inferior kinetics (Berthelot et al. 2010; Tripathi et al. 2013). Therefore, many efforts have been made on crystal-structure engineering, nanostructuring, hybridization, etc. For example, the combinations of different polyanion groups such as Na4MnFe2(PO4)(P2O7) create new open crystal frameworks with feasible paths for Na+ diffusion (Kim et al. 2016a).

Herein, this review summarizes the research advances on Fe- and Mn-based cathode materials for LIBs and SIBs, respectively, which are categorized into oxides, polyanion compounds, and hexacyanometalates (for SIBs). With a grasp of the inherent properties and up-to-date achievements of these candidates, especially high-energy LIB cathode candidates and highly stable SIB cathodes, we further discuss the impendent challenges and prospects in this field and put forward some insights into the opportunity of Fe- and Mn-based cathode materials. We hope that this review can inform readers of the rationality and priority of Fe- and Mn-based cathode materials as candidates for future LIBs and SIBs, and call for further efforts to fulfill this goal.

Fe- and Mn-based oxides as LIB cathodes

The introduction of LCO cathode has empowered the commercialization of the first LIB. LCO also guides the investigation of a family of α-NaFeO2-type layered oxides LiMO2, where M can be a TM or a mixture of several (Chen et al. 2016). As shown in Fig. 2a, they have a rhombohedral structure with a space group of R-3m, in which the M-O octahedral slabs and Li-O octahedral layers follow O3 stacking along the c axis. Though LCO has a high theoretical capacity of 282 mAh g−1, the structure will undergo an irreversible phase transition when more than half of the Li ions are removed (Xia et al. 2007). Moreover, LCO also suffers from safety issues due to its thermal instability at the highly charged states (MacNeil et al. 2002). Therefore, motivation exists for Co to be replaced by abundant, inexpensive, and non-toxic transition metals.

a Crystal structure of layered LiMO2. Reproduced from ref. (Chen et al. 2016) with permission. b Cycling profile of layered LiMnO2. Reproduced from ref. (Armstrong and Bruce 1996) with permission. c Structural illustration and voltage profiles of orthorhombic LiMnO2. Reproduced from ref. (Croguennec et al. 1997b) and ref. (He et al. 2010) with permissions

LiMnO2

After the success of LCO, researchers have made significant efforts to investigate the Mn-based structural analog of LCO (Fuchs and Kemmler-Sack 1994; Rossouw et al. 1993). However, layered O3-type LiMnO2 is challenging to prepare due to its thermodynamic instability (Armstrong and Bruce 1996). Moreover, as the Mn ions in LiMnO2 all present as Mn3+, which is susceptible to Jahn–Teller distortion, rendering structural change and the disproportionation reaction to soluble Mn2+. Such issues also haunt the thermodynamically favorable orthorhombic LiMnO2 (Croguennec et al. 1997a; Davidson et al. 1995; He et al. 2010; Liu et al. 2007; Xiao et al. 2009). Therefore, to make cost-effective and environmentally friendly layered oxides, most of the research interest has been shifted to multi-metal constitution such as LiNixMn1-xO2 (Rossen et al. 1992) and LiNixMnyCo1-x-yO2 (Shaju et al. 2002; Tsutomu and Yoshinari 2001) (NMC). For example, the existence of low valance Ni (Ni2+) can reduce the proportion of Mn3+. The synergistic contributions of various metals guarantee improved electrochemical performance, leading to the successful commercialization of NMC.

Mn-substituted LiNixMn1-xO2 has been initially designed to address the issues in LiNiO2 (Chen et al. 2014; Ohzuku et al. 1993), which is hard to prepare due to the difficulties in controlling stoichiometry, Li/Ni ordering, and the oxidation state of Ni (Nitta et al. 1995; Rossen et al. 1992). In 2001, Ohzuku et al. prepared the isometric LiNi0.5Mn0.5O2 cathode which maintained a discharge capacity of 150 mAh g−1 after 30 cycles. However, the binary LiNi0.5Mn0.5O2 still suffers from problematic preparation and cation disordering that results in obstructive Li diffusion. In 2006, Kang et al. reported the use of an ion-exchange process to prepare high-quality LiNi0.5Mn0.5O2 with very low little intralayer disordering, which could maintain a capacity of ∼ 180 mAh g−1 even at a high rate of 6 °C (Kang et al. 2006). However, the extra cost from the method prevents it from practical application.

Meanwhile, researchers investigated the co-substitution of Co and Mn for better structural stability. In 2001, Ohzuku et al. reported the isometric LiNi1/3Mn1/3Co1/3O2 (NMC111) cathode, which demonstrated a rechargeable capacity of 150 mAh g−1 in 3.5–4.2 V or 200 mAh g−1 in 3.5–5.0 V (Tsutomu and Yoshinari 2001). The appreciable capacity and cycling stability of NMC soon attracted considerable interest from the science community as well as industry. It is widely recognized that high Ni content in the layered NMC as the active redox species contributes to a higher capacity but at the expense of safety and difficult preparation. High Mn content existing as inactive Mn4+ enhances the structural stability, and high Co content improves the rate performance and processing ability. As the NMC materials still consume Ni and Co largely, the next-generation cathodes should be Ni and Co poor or free materials.

LiFeO2

In principle, the structure of LiMO2 is dependent on the size of the M cation (Shirane et al. 1995). When Co is substituted by similarly smaller M cations, such as V3+, Cr3+, Ni3+, the layered rock-salt structure can be easily preserved, whereas the same structure can hardly be inherited when accommodating Fe3+ with much larger size. In fact, the structural complexity of LiFeO2 is much higher than other LiMO2. Around ten phases of LiFeO2 have been reported under different preparation conditions (Catti and Montero-Campillo 2011). Those include disordered rock salt α phase and its derivate (Tabuchi et al. 1995), layered O3 phase (Shirane et al. 1995), corrugated layered phase (orthorhombic), goethite-type (orthorhombic) (Sakurai et al. 1997), β-NaFeO2-type (orthorhombic) (Armstrong et al. 2008), and hollandite-type (tetragonal) (Matsumura et al. 2002).

The electrochemical performance of LiFeO2 is strongly related to the crystal structure, which decides the Li+ pathway during the reaction. For example, bulk α-LiFeO2 obtained by solid state reaction is found to be electrochemically inactive as the iron ions block the Li pathway in the disordered structure (Li et al. 2011). However, the reactivity problem has been solved by tailoring the particles into nanoscale. As a result, α-LiFeO2 with particle size over 50 nm demonstrates a discharge capacity up to 150 mAh g−1 in the 50th cycle (Morales and Santos-Peña 2007). Another nano-α-LiFeO2 also achieves similar results (Liu et al. 2016b). Carbon modification can further enhance the reactivity, and nanocrystalline porous α-LiFeO2–C composite can deliver 230 mAh g−1 at 0.5 °C after 100 cycles (Rahman et al. 2011).

Though electrochemical activities have repeatedly been demonstrated for LiFeO2 with different phases, a critical issue is the abnormal redox reaction. Different from the reversible Li+ intercalation/deintercalation in LCO on the basis of Co3+/Co4+, LiFeO2 cannot work on the Fe3+/Fe4+ redox couple, as the Fe3+ 3d-orbital is strongly hybridized with the oxygen 2p orbital in the LiFeO2, the first delithation process will trigger the oxygen removal instead of the oxidation of Fe3+ (Yabuuchi et al. 2012a). Hirayama et al. studied the structure and electrode reactions of layered LiFeO2 (Hirayama et al. 2011). As shown in Fig. 3, large voltage hysteresis is identified in the first cycle of LiFeO2, and the following profiles are similar with initially reduced LiFeO2-x. X-ray diffraction (XRD) patterns also clearly revealed the degradation of the structure. To address the intrinsic redox issue, the possible route is to incorporate other materials to form solid solutions or nanocomposites. For example, LiFeO2-Li2MnO3 solid solution (Li1+x(FeyMn1−y)1−xO2) with optimized Fe content (0.2 < y < 0.4) is found to show high initial discharge capacity (240–300 mAh g−1) under 40 mA g−1 (Tabuchi et al. 2010).

a, b Charge/discharge curves of LiFeO2 (a) and oxygen-deficient LiFeO2-x (b). c XRD pattern of cycled O3-type LiFeO2. Reproduced from ref. (Hirayama et al. 2011) with permission

Li2MnO3-based oxides

With the low-cost constitution and very high deliverable capacities exceeding 250 mAh g−1, Li2MnO3-based layered oxides are considered as one of the most promising cathode candidates for next-generation LIBs (Thackeray et al. 2007; Yabuuchi et al. 2011). Bare Li2MnO3 possesses a layered structure that can be represented in conventional-layered LiMO2 notation as Li(Li1/3Mn2/3)O2, in which Li+ has substituted 1/3 of the Mn ions in the transition metal layers. Such composition change also results in a symmetry of monoclinic C2/m, and all the Mn are oxidized to the more stable valance of 4+. Commonly, the Li2MnO3 is incorporated with traditional layered LiMO2 to form a class of Li- and Mn-rich layered oxides (LMRs), which is deemed as either a single-phase solid solution (Jarvis et al. 2012; Koga et al. 2012; Shukla et al. 2015) expressed as Li(Li1/3-2x/3MxMn2/3-x/3)O2 or a structurally integrated xLi2MnO3·(1-x)LiMO2 composite (Amalraj et al. 2013; Gu et al. 2013; Thackeray et al. 2007; Yu et al. 2013). To our best knowledge, the crystal structure may vary in different samples, depending on the preparation method, constitution, etc. Apart from the disputes on the structure model, it is widely acknowledged that a range of technical challenges including large initial irreversible capacity, voltage and capacity decay, and poor rate capability must be solved before their application (Fig. 4).

a Crystal structure of monoclinic Li2MO3. Reproduced from ref. (Mohanty et al. 2013) with permission. b Charge voltage profile of a model LMR, 0.35LiMn2O3·0.65LiMn0.45Ni0.35Co0.20O2 with the illustration of structure evolution. Reproduced from ref. (Erickson et al. 2017) with permission. c Synchrotron XRD patterns over the first cycle showing the loss of in-plane superstructure peaks. Reproduced from ref. (Gent et al. 2017) with permission. d, e Our previous results and understandings of the activation process on the basis of Li1.87Mn0.94Ni0.19O3. Reproduced from ref. (Ye et al. 2015a) with permission

The electrochemical properties of LMRs are highly associated with a unique activation behavior. The typical first charge profile involves several steps (Erickson et al. 2017). Below 4.4 V is a Li extraction from the Li-layer, which requires oxidizable TM ions such as Ni2+ and Co3+. Next is the activation of initially inactive Li2MnO3, during which the removal of Li+ from the TM layers is accompanied with the oxidation of O2−, leading to the formation of oxygen vacancies and structural change (Armstrong et al. 2006). Synchrotron XRD patterns disclosed the loss of in-plane superstructure peaks, indicating the irreversible structural change, which answers the voltage hysteresis and large initial irreversible capacity (Gent et al. 2017). Wang’s group reported the critical role in the activation process. For a low Ni-doped LMR material, Li1.87Mn0.94Ni0.19O3, the Li2MnO3 activation process took dozens of cycles (Fig. 1d). By combining the electrochemical measurements with material characterisation including in-situ XRD and high-angle annular-dark-field scanning transmission electron microscopy (HAADF-STEM) observation, it was unveiled that the oxygen release reaction is completed in first five cycles while the Li and TM ions from TM layers migrate gradually to the Li layers, leading to a stepwise capacity increase (Ye et al. 2015a). The stepwise capacity increase can also be controlled by tuning the Ni or Co doping, which also profoundly influences the rate capability and cycling performance (Ye et al. 2014a, b, 2015b). Our studies shed light on the compositional design for high-performance LMRs.

As a promising cathode candidate that has been under the spotlight in past years, extensive work has been conducted to understand the local crystal structure, structural evolution, electrochemical behavior of LMRs, and to engineer the electrode materials for better performance. The history and progress have also been summarized elsewhere (Erickson et al. 2017; Hy et al. 2016; Manthiram et al. 2016; Zheng et al. 2017). In the pursuit of commercial application, the major obstacles including voltage and capacity decay over cycling, initial irreversible capacity, poor rate capability, and low volumetric energy density still need to be overcome.

LiMn2O4

Spinel LiMn2O4 is another classic cathode material for LIBs, of which Thackeray et al. have studied the lithium insertion/deinsertion properties since the 1980s (Thackeray et al. 1983, 1984). Different from the layered structure, Li ions in the spinel structure occupy 1/8 tetrahedral sites, and the MnO6 octahedrons form a three-dimensional (3D) framework, leaving vacant tetrahedral and octahedral interstitial sites for the highly efficient diffusion of Li+ (Fig. 5a). Even though the low concentration of Li ions in the spinel body (Li/Mn = 1:2) results in only half of the theoretical specific capacity (146 mAh g−1) of layered LiMO2, attributing to the low-cost, stable, and kinetic Mn-based 3D spinel framework, LiMn2O4 has progressively substituted LCO in some large-scale and high-power applications. Another pronounced feature from the spinel configuration is the flat working voltage plateau at 4.0 V. In contrast, layered structured cathodes display sloping potential profiles and significantly lower potentials based on the same Mn3+/Mn4+ redox couple. As an explanation, the 3D spinel framework experiences negligible structural distortion during the insertion/deinsertion of Li ions, thereby displaying an almost constant electrochemical potential due to the consistent site energy. However, the layered structures are greatly distorted, resulting in the gradual change in site energy and hence sloping potential profiles for the insertion of Li-ions. The Li ions in the spinel structure are located in the tetrahedrons, experiencing less repulsive forces from the local environment compared with the Li ions in the octahedrons of layered oxides, and the reduced site energy contributes to a higher potential (Liu et al. 2016a).

Apart from the relatively low energy density, the other most claimed issue is the limited cycle life of LiMn2O4 due to Mn ions’ dissolution, especially under elevated temperatures (Jang et al. 1996; Xia et al. 1997). Previously, the cause of the degradation was ascribed to the dissolution of Mn2+ ions, originating from the disproportionation of Mn3+ ions LiMn2O4 (2Mn3+ ⇆ Mn2+ + Mn4+) (Gummow et al. 1994; Jang et al. 1996; Xia et al. 1997). However, a recent combined analysis of electron paramagnetic resonance and inductively coupled plasma spectroscopy data disclosed that Mn3+ is the dominant dissolved Mn cation in LiPF6-based organic electrolytes, and the Mn3+ can stably exist in the electrolyte instead of suffering disproportionation (Banerjee et al. 2017). Even though the metal dissolution is not negligible and haunts all the metal oxides, the practical cycling performance depends on its microstructure and physico-chemical properties. In general, hierarchical microstructures are considered as optimal choices, which can shorten the ion diffusion pathway compared with bulk materials. Meanwhile, in contrast to nanosized particles, the primary micron particles can be densely packed for high volumetric energy density and show better structural integrity over repeated charge/discharge cycles (Zhou et al. 2017). For example, as shown in Fig. 5b–e, Lee et al. recently reported densely packed composites composed of carbon coated nanosized Li1.015Al0.06Mn1.925O4, maintained 84.5% of the initial capacity over 5000 cycles (Lee et al. 2017).

LiNi0.5Mn1.5O4

Substitution of Mn in LiMn2O4 by low-valance metal ions (Co3+ (Kawai et al. 1998), Cr3+ (Sigala et al. 1995), Ni2+ (Zhong et al. 1997), Fe3+ (Amine et al. 1997), Cu2+ (Ein-Eli et al. 1998), etc.) was initially designed to enhance the cycling stability by elevating the valance of Mn ions. Among the doped spinels, LiNi0.5Mn1.5O4 (LNMO) surprisingly displays one dominant plateau at around 4.7 V along with good electrochemical activity, thus presenting it as the most attractive spinel cathode for high-energy and high-power densities (Ohzuku et al. 1999). The massive substitution of Mn by 1/4 Ni adds complexity to the spinel structure, which is divided into two different symmetries: Fd-3m and P4332. The former one is isostructural to LiMn2O4 with Ni and Mn ions randomly distributed in the 16d octahedral sites, named the disordered phase. The later one has distinct 4a and 12d sites to accommodate Ni and Mn ions, known as an ordered phase (Kim et al. 2004; Liu et al. 2012a). It is accepted that oxygen stoichiometry plays a leading role to determine the phase. In an oxygen-stoichiometric LNMO, all the Mn ions are Mn4+ and inclined to occupy distinct sites with Ni2+. The existence of oxygen vacancies can bring about a fraction of the Mn3+ ions, leading to a Ni/Mn disordered phase (Kim et al. 2004; Wang et al. 2011b). Many reports have shown the disordered LNMO to have better electrochemical performance due to the more efficient Li+ diffusion and better conductivity of Mn3+ (Jin et al. 2012; Kim et al. 2004; Wang et al. 2011b; Xiao et al. 2012). However, it also plausible to achieve high rate performance on the basis of an ordered phase (Ma et al. 2010; Zhang et al. 2013b). Therefore, more experimental and computational studies are required to understand the correlation between electrochemical performance and structural properties better.

Previously, with the aid of high-resolution transmission electron microscope (HR-TEM) imaging and energy-dispersive X-ray spectroscopy (EDS) elemental scanning, we observed minor P4332 phase on the edge of Fd-3m body coupled with the different Mn/Ni ratio in the naturally cooled sample (Fig. 6c). As shown in Fig. 6d, both the samples delivered favorable rate and cycling performances. The role of the crystal phase may be eclipsed by other factors (Zhu et al. 2014a). The physical morphology of LNMO which profoundly influences its performance (Yang et al. 2013; Yi et al. 2016; Zhang et al. 2013a; Zhou et al. 2012; Zhu et al. 2014b). In another study, we designed two types of porous LNMO microspheres, and it was surprisingly found that pore diameter shows a profound influence toward the rate capability. The LNMO microspheres with larger pores achieved a discharge capacity of 101.7 mAh g−1 even at 50 °C (Zhu et al. 2014b). This would inspire the design of high-performance cathode materials via refined control of physical parameters.

a Comparison of the two structural configurations in LNMO. Reproduced from ref. (Liu et al. 2012a) with permission. b Typical charge/discharge curves of LNMO with the two phases. Reproduced from ref. (Wang et al. 2011b) with permission. c, d Structural characteristics and electrochemical properties on the basis of our prepared samples. e, f Outstanding capacity retention achieved by using lithium phosphorus oxynitride solid electrolyte. Reproduced from ref. (Li et al. 2015b) with permission

Perhaps the biggest barrier preventing LNMO from the practical application is the lack of long-cycling reliability. LNMO was initially introduced to prolong the cyclability of primary LiMn2O4 spinel. However, the exploitation of high-potential Ni2+/Ni4+ redox leads to adverse cycling performance, as it is largely below the highest occupied molecular orbital (HOMO) of current electrolytes. Some investigators suggested the Mn4+ in the ordered phase can stabilise the electrode for long cycles (Zhang et al. 2013b). However, this hypothesis was not supported by any experimental and computational evidences. On the contrary, Talyosef et al. identified the dissolution of manganese and nickel and reduction of Mn2+ and Ni2+ on the lithium counter electrode by electrolyte and electrode analyses (Talyosef et al. 2005). X-ray absorption and optical fluorescence spectroscopy and imaging analyses conducted by Jarry et al. also confirmed the formation of fluorescent Ni2+ and Mn2+/3+ complexes with β-diketonate ligands and Ni2+ and Mn3+ oxalates and carbonates, accompanying the oxidation of electrolyte (Jarry et al. 2015). The problematic Ni2+/Ni4+ redox is also reflected in the electrochemical process. Song et al. investigated a series of spinel cathodes with compositions of LiNi0.5-xMn1.5+xO4 (x = 0, 0.05, and 0.08) and found the removal of the Ni4+/Ni2+ redox reactions from the surface stabilizes the electrochemical performance at 55 °C. Doping with alien ions and surface coating are widely used strategies to improve the cyclability of cathode materials, which have also been extensively studied on LNMO. In general, elemental doping aims at improving the electronic conductivity of LNMO by altering the conduction band of the whole bulk, whereas the goal of the surface coating is to reduce the side reactions by creating artificial electrode/electrolyte interfaces. A wide variety of doping elementals (e.g., Na+, Mg2+, Cu2+, Zn2+, Al3+, Cr3+, Co3+, Ti4+, F−) and coating layers (e.g., carbon, Ag, ZnO, CuO, Al2O3, TiO2, ZrO2, Li3PO4, Al3PO4, LiFePO4) have been exerted on LNMO and proved effective for enhanced stability, which have been summarised elsewhere (Xu et al. 2017b; Yi et al. 2016; Yi et al. 2011). However, it should be noted that there is a lack of long cycling results (over 1000 cycles). As pristine LNMO can also stand for hundreds of cycles (Zhang et al. 2013b), the modifications will only be attractive if substantial improvements are achieved with an acceptable extra cost on materials and processing. This may rely on the introduction of new strategies or techniques. Apart from electrode engineering, the development of better electrolytes may provide a more effective solution. As shown in Fig. 6e, f, Li et al. reported the use of the lithium phosphorus oxynitride solid electrolyte, which enables exceptional capacity retention of 90% over 10,000 cycles (Li et al. 2015b). Such high capacity retention demonstrates the critical role of the solid electrolyte in supporting high-voltage batteries.

Fe- and Mn-based polyanion compounds as LIB cathodes

Represented by LiFePO4, polyanion cathode materials are typically 3D structured compounds constructed by corner- and/or edge-shared M-O and X-O (X = P, S, As, Mo, or W) polyhedrons. These frameworks afford much better structural stability toward lithium (de)insertion compared with layered oxides, and the covalently bonded oxygen atoms prevent the oxygen loss that haunts lithium metal oxides. Also, the strong X-O bond can pull some charge density out of M–O bonds, and as a result, the M-O bond exhibits increased ionicity, leading to higher redox potential as a result of the inductive effect (Gong and Yang 2011; Masquelier and Croguennec 2013).

Fe- and Mn-based phosphates

Olivine LiFePO4 (LFP) is the most successful polyanion cathode material, attributing to its low-cost and non-toxic constitution, appreciable capacity (ca. 170 mAh g−1) and excellent thermal and structural stability. The key drawbacks of LiFePO4 are inferior electric conductivity (ca. 10−9 S cm−1), the selective one-dimensional (1D) lithium pathway (Fig. 7a), and low gravimetric and volumetric energy densities. Intensive studies in the last 20 years have effectively addressed the kinetic issues by size tailoring, crystal facet controlling, bulk doping, and surface conducting modification. In light of the 1D lithium ion pathway along [010], constructing nanostructures, especially 2D nanosheets with exposed (010) facets and shortened diffusion length, is an effective solution (Zhao et al. 2014). Surface modification with conductive layers, mainly carbonaceous materials, is widely used to improve the conductivity. However, common procedures easily result in uneven and/or incompact coating layers due to the lack of affinity between the two substances. Constructing high-quality coating layers requires new feasible strategies. For example, Paolella et al. reported the use of LiPF6 treatment to make LFP nanocrystals hydrophilic, thereby enabling carbon coating uniformly (Paolella et al. 2014). Compared with surface modification, the improvement made by tuning fundamental crystal chemistry is more appealing, as it is a uniform melioration of the lattice electronic and/or ionic conductivity without the penalty of energy densities from inactive additives. For example, Chung et al. combined cation non-stoichiometry with solid-solution doping to dramatically improve the electronic conductivity of LFP to > 10−2 S cm−1, resulting in markedly improved rate capability (Chung et al. 2002). As shown in Fig. 7b, Kang et al. also reported enhanced fast charging capability by an off-stoichiometric LiFe0.9P0.95O4-δ (Kang and Ceder 2009). Recently, Naoi et al. achieved ultrafast charge/discharge of up to 480 °C by developing ultra-small core-shell nanocomposites (Naoi et al. 2016). The charge/discharge curves are dominated by the sloping pseudocapacitive behavior (Fig. 7c), and the rate capability is generated at the large expense of energy density.

a Crystal structure of spinel LiMn2O4. Reproduced from ref. (Chen et al. 2016) with permission. b High-rate discharge capability of LiFe0.9P0.95O4-δ. Reproduced from ref. (Kang and Ceder 2009) with permission. c Structural and electrochemical properties of a core-shell LFP nanocomposites. Reproduced from ref. (Naoi et al. 2016) with permission. d Morphology and discharge curves of LMO nanoparticles. Reproduced with permission (Hong et al. 2015). e Phase transformation diagram of LiMn0.6Fe0.4PO4 over the extraction/insertion of Li ions. Reproduced from ref. (Ravnsbæk et al. 2014) with permission. f Phase transformation strain as a function of the Mn content in LFMP, and a special case of LiMn0.2Fe0.8PO4 with no misfit strain. Reproduced from ref. (Ravnsbæk et al. 2016) with permission. g LiMn0.5Fe0.5PO4 nanocrystals with different Fe-Li antisite defects showing distinct rate performance. Reproduced from ref. (Hu et al. 2017) with permission

The gravimetric and volumetric energy densities are restricted from the essential redox reaction and atom density in the crystal structure. Even though the inductive effect from the PO43− elevates the Fe2+/Fe3+ redox to 3.4 V, much higher than that in LiFeO2, it is still considerably lower than 4 V-class LiCoO2 and LiMn2O4. In the pursuit of high energy density, there is motivation to replace Fe with other transition metals, mainly Mn, Co, Ni to attain higher potentials. Among them, Co and Ni are not abundant elements, and the very high potentials of LiCoPO4 and LiNiPO4 at 4.8 and 5.1 V inhibit the research due to severe side reactions with commonly used electrolytes. LiMnPO4 (LMP), on the other hand, is environmentally friendly and operates at a moderately high potential of 4.1 V, which enables a theoretical energy density of 697 W h kg−1, 20% higher than that of LFP. However, the pathway for switching from Fe to Mn is unsatisfactory due to the sluggish kinetics of LMP (Delacourt et al. 2004). The origin of the depressed kinetics is ascribed to the small polaronic conductivity of Jahn–Teller active Mn3+ (Martha et al. 2009b). It not only leads to extremely low electronic (< 10−10 S cm−1) and lithium ion conductivities (< 10−16 cm2 s−1), but also triggers the large lattice misfit between the delithiated and lithiated phases (6.5% volume misfit for LFP, 11.6% for LMP), resulting in inferior boundary mobility (Chen et al. 2011; Delacourt et al. 2005; Li et al. 2002; Meethong et al. 2008; Nie et al. 2010; Norberg and Kostecki 2012; Ong et al. 2011; Zhou et al. 2004). In search of better kinetics, many attempts have been reported on confining particle size and/or conductive modification (Barpanda et al. 2011; Guo et al. 2014a; Hong et al. 2015; Oh et al. 2010; Pivko et al. 2012; Qin et al. 2012; Wang et al. 2017; Yoo et al. 2011). As shown in Fig. 7d, Hong et al. prepared carbon-coated LMP nanorods, which showcased a high reversible capacity of 168 and 110 mAh g−1 at 0.05 and 10 °C, respectively, and capacity retention of 94.5% after 100 cycles at 0.5 °C (Hong et al. 2015).

Another effective approach to boost the kinetics of LMP is Fe-substitution. The as-formed LiFe1-xMnxPO4 solid solutions (LFMP) combines the dynamics of LFP and high energy density of LMP, and they are considered as the second-generation olivine cathode materials, which have received much attention from investigators (Kim et al. 2016b; Li et al. 2013; Martha et al. 2009a; Wang et al. 2011a; Yan et al. 2015; Yang et al. 2015c). Yamada et al. (Yamada et al. 2001) and Ravnsbæk et al. (Ravnsbæk et al. 2014) disclosed a different phase transformation mechanism of LiMn0.6Fe0.4PO4 over the extraction/insertion of Li ions, which possesses an extended solid-solution region, different from the two-phase mechanism of LFP (Fig. 7e). Ravnsbæk et al. further investigated the phase transformation strain as a function of the Mn content in LFMP, and disclosed a direct negative influence of volume misfit toward electrode kinetics. Figure 7f demonstrates that LiMn0.2Fe0.8PO4 with no misfit strain showed the best rate capability (Ravnsbæk et al. 2016). A range of in-situ electrochemical and material analyses conducted on Mn-rich LFMP (LiMn0.8Fe0.2PO4) revealed that the Mn redox reaction is the kinetic bottleneck of LFMP, which triggers the poor apparent Li+ diffusivity (Wi et al. 2017a, b). However, current studies on achieving the appreciable performance of LFMP still focused on nanostructuring and carbon modification, which raise the concern of low volumetric density and increased costs. For example, Kim et al. synthesized reduced graphene oxide (rGO)-modified LiMn0.75Fe0.25PO4 microspheres, which showed 161 and 90 mAh g−1 at 0.05 and 60 °C, respectively. The claimed “high” tap density (1.1 g cm−3), far lower than the practical standard of ca. 3 g cm−3. Pan et al. reported LiMn0.5Fe0.5PO4 nanocrystals with tuned Fe-Li antisite defects which also showed impressive rate capacities (Fig. 7g) (Hu et al. 2017). Therefore, the future successes of LMP and LFMP still await the achievements of reasonable kinetics without the compromise of volumetric energy density and processing cost.

Apart from the olivine-type structure, the lithium metal phosphates can also exist as NASICON, anti-NASICON, alluaudite, pyrophosphate, tavorite, and even amorphous phases with varied composition (Masquelier and Croguennec 2013). However, these phases largely eclipsed by LiMnxFe1-xPO4 regarding practical energy (capacity and potential) density and power density.

Fe- and Mn-based silicates

Encouraged by the success of phosphate, other polyanion compounds are successively explored to function as cathode materials for LIBs. Particularly, lithium silicates Li2MSiO4 are very attractive as they potentially afford a two-electron reaction with a theoretical capacity of 332 mAh g−1. The structures are composed of tetragonally packed oxygen ions (a distorted form of hcp), in which the cations (Li+, M2+ and Si4+) occupy half of the tetrahedral sites (Nytén et al. 2005). The various cationic arrangements and structural distortions create a rich polymorphism, including monoclinic and orthorhombic structures (Islam et al. 2011). Li2FeSiO4 was introduced as a LIB cathode by Nytén et al. in 2005 (Nytén et al. 2005). At that time, it was regarded as a one-electron reaction electrode, given the difficulties of Fe3+/Fe4+. It was then found that even Fe4+ can be stable in tetrahedral coordination, which is difficult for Mn4+ and Co4+ (Arroyo-de Dompablo et al. 2006).

The slow Li reaction kinetics are due to the frustrated ion migration in the complex lattices as well as the separated M redox centers, resulting in extremely low electronic conductivity (∼ 5 × 10−16 S cm−1 for Li2MnSiO4 and ∼ 6 × 10−14 S cm−1 for Li2FeSiO4 ) (Dominko 2008). Also, the Li conductivity is very low due to high diffusion activation energy, which is approximately 1.0 eV determined by theoretical calculations and experimental studies (Armstrong et al. 2011; Fisher et al. 2013; Kokalj et al. 2007), much higher concerning that of LFP (0.3 eV) (Sun et al. 2012). Although the accurate understanding of the ion transfer mechanism remains an ongoing task, researchers have made considerable efforts in advancing the synthesis of these promising cathode materials with satisfactory performance (Ding et al. 2016; He and Manthiram 2014; Li et al. 2016; Muraliganth et al. 2010; Pei et al. 2016; Ramar and Balaya 2016; Rangappa et al. 2012; Yang et al. 2015b; Zhang et al. 2015b). Similar to the cases of phosphates, the strategy is focused on tunning the size, shape, and electronic structure by varying the synthetic approach and experimental conditions, summarised by two recent reviews (Cheng et al. 2017; Ni et al. 2017). For example, Pan et al. reported the achievement of better performing Li2FeSiO4 nanocrystals by Ti(IV) doping (Yang et al. 2016). However, the realization of reversible two-electron reactions in silicates is still difficult, and the average potential is quite low (below 3 V) within a large window, which is therefore not suitable for the application.

Fe- and Mn-based borates

Lithium metal borates entered into researchers’ sight in 2001, because the polyanion group BO33− is the lightest one, ensuring a high theoretical capacity of ~ 220 mAh g−1 (Legagneur et al. 2001). However, the early practice only realized the reversible capacity of ~ 8 mAh g−1 at C/250, suggesting deficient electrochemical activity. Until 2010, Yamada et al. obtained an attractive capacity of 200 mAh g−1 by introducing Ketjen black and vapor grown carbon fibers to increase its electrical conductivity (Yamada et al. 2010). They also pointed out the moisture sensitivity of this material, of which the surface degradation happens after exposure to air. Considering the appreciable electrical conductivity of LiFeBO3 (reported to be 3.9 × 10−7 S cm−1) together with the negligible volume change of ~ 2%, the inferior performance may be due to the constricted Li+ mobility in the lattice. LiMBO3 is most commonly reported to crystallize in the monoclinic space group C2/c (LiMnBO3 also exists as a hexagonal form) (Bo et al. 2014; Kim et al. 2011; Tao et al. 2014). The structure is composed of chains of edge-sharing FeO5 trigonal bipyramids along [−101] direction, which are linked by BO3 groups to form a 3D network. Also, edge-sharing LiO4 tetrahedrons along [001] direction result in zigzag one-dimensional (1D) Li diffusion tunnels, but as disclosed by first-principles calculations, the easily formed Li-M antisite can block the 1D Li diffusion path (Kim et al. 2015c; Seo et al. 2011). The prospect of borates is largely compromised by problematic kinetics, sample preservation, and low operating potential, which cannot be simply alleviated by common modifications (Fig. 8e) (Chen et al. 2015; Dong et al. 2017).

a, b Crystal structures of P21/n Li2FeSiO4 (a), which transforms into Pmn21 Li2FeSiO4 (b). c Typical charge/discharge curves of Li2FeSiO4. Reproduced from ref. (Armstrong et al. 2011) with permission. d Structural transformation routes of LiFeBO3 during delithiation and degradation. Reproduced from ref. (Bo et al. 2014) with permission. e Charge/discharge profiles of mesoporous LiFeBO3/C hollow spheres. Reproduced from ref. (Chen et al. 2015) with permission

Fe- and Mn-based oxides as SIB cathodes

Sodium metal oxides have been intensively studied as SIB cathodes, which mimic the lithium metal oxides, but the considerably different physico-chemical properties (e.g., ionic size, electron configuration) renders some disparities on the crystal chemistry. First, the vast Na+ can hardly be hosted in tetrahedral sites. Therefore, there are no isostructural spinel cathodes for SIBs. Second, layered sodium metal oxides (NaxMO2) have a richer polymorphism due to the varied Na-O coordination and oxygen stacking rules. Figure 9a shows the crystal structures of the most common polymorphs, O3 and P2, which are present in layered NaxMO2 (Yabuuchi et al. 2012a). The notions were introduced by Delmas et al. (Delmas et al. 1980), where the O or P stands for the octahedral (O) or a prismatic (P) sites accommodating Na+ ions. The number n (n = 1, 2, 3, etc.) represents the Na ion octahedral or prismatic layers contained in each unit cell, and a prime symbol (′) is added to indicate a monoclinic distortion. In the synthesis of layered oxides, the resultant structure is decided by many factors, especially the sintering temperature and composition (Lei et al. 2014). In general, sodium-rich oxides with x approaching 1 are inclined to crystallize into the O3 structure, whereas P2 phase forms in the broader range of Na-deficient composition.

Though sodium ions are low-cost charge carriers, many layered oxides still rely on redox centers that are scarce and/or may be toxic transition metal elements such as cobalt (Berthelot et al. 2010), nickel (Han et al. 2014), and chromium (Komaba et al. 2010). The advantage of SIBs is therefore largely compromised regarding cost and sustainability. In this context, Fe and Mn-based oxides are of more research interest.

NaFeO2

NaFeO2 has been reported to have two polymorphs: hexagonal α-NaFeO2 and orthorhombic β-NaFeO2 (Kikkawa et al. 1985). The former one is the prototype of layered oxides, opening the era of LIB chemistry. An early study only realized removal of 0.1 Na using chemical oxidizer (Kikkawa et al. 1985). By coupling with Li foil into a battery, Takeda et al. reported the electrochemical desodiation of α-NaFeO2 into monoclinic Na0.5FeO2, suggesting its possibility to function as a cathode for SIBs (Takeda et al. 1994). The first demonstration of α-NaFeO2 working as a SIB cathode was in 2006 by Okada et al., where α-NaFeO2 showed a flat plateau at 3.3 V with a capacity of 80 mAh g−1 (Okada et al. 2006). Differing from LiFeO2, reversible Fe3+/Fe4+ redox couple has been realized in the electrochemical cycling of α-NaFeO2. Later studies revealed the critical role of the cut-off voltage in the electrode performance of α-NaFeO2 in the sodium cells. When a cut-off voltage was raised over 3.5 V, the cathode experienced irreversible structural transition coupled with significant capacity decay (Yabuuchi et al. 2012b). The fade of the electrode after heavy removal of Na+ should also be related to increasing amount of highly active Fe4+. A recent study disclosed the chemical instability of Fe4+ in batteries which spontaneously oxidized the electrolyte to reduce back to Fe3+ at charged state (Lee et al. 2015). α-NaFeO2 was also found to show an additional advantage of good thermal stability. As reported by Zhao et al. (Zhao et al. 2013), the highly charged Na0.58FeO2 powder decomposed thermally at a temperature higher than 300 °C, and NaFeO2 showed better thermal stability in the electrolyte than LCO in LIBs. The development of NaFeO2 is restricted by the low reversible capacity of 80–100 mAh g−1 and the inferior cycling performance (Fig. 10).

a Initial charge/discharge curves of NaFeO2 on the dependence of different cut-off potentials. Reprinted from ref. (Okada et al. 2006) with permission. b Voltage profiles along cycling. c A diagram illustrating the electrochemical active Fe3+/Fe4+ redox couple. Reproduced from ref. (Lee et al. 2015) with permission

NaxMnO2

NaxMnO2 has a variety of polymorphs, which can be divided into two large groups: 2D layered structures consisting of slabs of edge-sharing MO6 octahedra at high x (e.g., Na2/3MnO2, NaMnO2) and 3D tunnel-like structures at low x (e.g., Na0.2MnO2, Na0.4MnO2, Na0.44MnO2) (Clément et al. 2015; Parant et al. 1971). For NaMnO2, monoclinic α-NaMnO2 (O′3 structure) and orthorhombic β-NaMnO2 (consisting of zig-zag layers) show high specific capacities. However, similar to the case of its lithium counterpart, NaxMnO2 is subjected to severe capacity decay when cycled in SIBs. As reported by Ceder et al. (Ma et al. 2011), α-NaMnO2 delivered a reversible capacity of 185 mAh g−1 at 0.1 °C within in the potential window of 2.0–3.8 V, but only maintained 132 mAh g−1 after 20 cycles. In comparison, NaMnO2 consisting of intergrown regions of α-NaMnO2 and β-NaMnO2 domains was found to show a high capacity of ~ 190 and 142 mAh g−1 at C/20 and 2 °C, respectively, maintaining 70% after 100 cycles at 2 °C (Billaud et al. 2014a) (Fig. 11).

a Stability domain of the different structural types observed for as-synthesized NaxMnO2 compounds. Reproduced from ref. (Clément et al. 2015) with permission. b Schematic representations of β-NaMnO2 and an intergrowth model between α- and β-NaMnO2. Reproduced from ref. (Billaud et al. 2014a) with permission. c, d Voltage profiles of α-NaMnO2 and the complex structure. Reproduced from ref. (Ma et al. 2011), (Billaud et al. 2014a) with permissions

With the Na/Mn ratio of around 2/3, the distortion of the ideal P2 structure is dependent on the synthesis conditions. Lowering the sintering temperature below 600 °C with a more oxidizing atmosphere stabilizes a higher average Mn oxidation state, producing α-Na0.7MnO2+z (0.05 ≤ z ≤ 0.25) with a slightly distorted P2 structure. Otherwise, β-Na0.7MnO2+y (y ≤ 0.05) formed at high temperature with an orthorhombically distorted P′2 structure coexisted with α-NaMnO2 (Parant et al. 1971). Paulsen et al. confirmed the substitution of low-valance metals (Co, Li, and Ni) favors the formation of the ideal P2 structure by elevating the oxidation state of Mn and also extends its stable temperature range (Paulsen and Dahn 1999). Later, by using a sol-gel method, Caballero et al. reported the synthesis of an undistorted P2-Na0.6MnO2 phase at a high temperature of 800 °C. They further tested the material in SIBs, which delivered ca. 140 mAh g−1, but only withstood for 8 cycles. Correspondingly, the active material became amorphous after cycling (Clément et al. 2015). The inferior cycling stability of NaxMnO2 is associated with the complex phase transitions caused by the intense Jahn–Teller effect of Mn3+, which reflect as multiple voltage steps during charge and discharge. Therefore, it is a viable strategy to partially substitute the Mn ions by low valency ions to minimize the Jahn–Teller active Mn3+. For example, Billaud et al. introduced a series of Mg-substituted Na2/3Mn1-xMgxO2 (x = 0.05, 0.1, 0.2) compounds that gave a smoother voltage profile and smaller cell polarisation, leading to enhanced capacity retention (Billaud et al. 2014b). Their further studies unveiled that those achievements are attributed to the more gradual structural changes upon charge and discharge (Clement et al. 2016; Sharma et al. 2015). Similar improvements have also been realized by doping with other cations (de la Llave et al. 2016; Kumakura et al. 2017; Kwon et al. 2017; Luo et al. 2017; Wu et al. 2015; Yabuuchi et al. 2014a). Interestingly, contrary to most efforts made by elevating the Mn valance to suppress the Mn3+, a recent study from Komaba’s group showed the high energy density and excellent cycling stability on distorted Mn3+-rich P′2-Na0.7MnO2 (o-NMO) (Fig. 12), which exhibited broader P′2 regions when compared with P2-Na0.7MnO2 (h-NMO) (Kumakura et al. 2016). These conflicting findings also call for the elucidation of the role of Jahn–Teller distortion and Na/Mn stoichiometry, which may direct the design of future electrodes.

a, b Charge-discharge curves of o-NMO (a) and h-NMO (b). c, d Operando XRD patterns of o-NMO (c) and h-NMO (d) over initial charge/discharge curves. Reproduced from ref. (Kumakura et al. 2016) with permission

Tunnel Na0.44MnO2 with an orthorhombic structure is another widely studied cathode material for SIBs. As shown in Fig. 13a (He et al. 2016), an open 3D framework is constructed by sheets of edge-sharing MnO6 and columns of MnO5 square-pyramids. Three types of Na ion sites exist in the structure, but only Na ions in the large S-shaped tunnels (Na1, Na2) are movable, constituting two kinds of tunnels along [001] for Na diffusion. Full occupation of the Na1 and Na2 sites leads to a formula of Na0.66MnO2. Correspondingly, it has a theoretical capacity of 121 mAh g−1. An early study of the properties of sodium storage based on Na0.44MnO2 prepared by solid-state reaction showed a reversible capacity of only 80 mAh g−1 at 0.1 °C and lost 50% of the capacity over 50 cycles with a noticeable cell polarisation increase (Sauvage et al. 2007). The optimization of preparation method and morphology control contribute to much improved electrochemical performance. For example, single crystalline Na0.44MnO2 nanowires prepared by Cao et al. delivered a capacity of 84.2 mAh g−1, corresponding to 77% capacity retention after 1000 cycles at 0.5 °C (Cao et al. 2011). Dai et al. reported Na0.44MnO2 produced by polyvinylpyrrolidone (PVP)-combustion delivered 99 mAh g−1 at a discharging rate of 20 °C and maintained 82.9% of its initial capacity even after 700 cycles at 10 °C (Dai et al. 2015). He et al. prepared Na0.44MnO2 nanoplates by a template-assisted sol-gel method, which discharged 96 mAh g−1 at 10 °C and maintains 97.8% capacity after 100 cycles at 0.5 °C (Fig. 13b–d) (He et al. 2016). It is rational to believe that the 3D tunnel is capable of fast and durable sodium extraction and insertion even for thousands of cycles (Liu et al. 2017a). However, its practical application awaits a feasible method to compensate the initial Na deficiency providing that the low energy density is accepted. There are some other emerging sodium manganese oxides, such as the “post-spinel” NaMn2O4 (tunnel-structure) (Liu et al. 2014), layered NaMn3O5 (Guo et al. 2014b), and Na2Mn3O7 (Adamczyk and Pralong 2017; Zhang et al. 2017).

a Schematic representation of the tunnel Na0.44MnO2. b Voltage profiles of the monocrystal Na0.44MnO2 nanoplates. c Cyclic voltammograms (CVs) of the Na0.44MnO2 electrode between 2.0 and 4.0 V at a scanning rate of 0.1 mV s−1. d Corresponding in-situ XRD patterns over the voltage scanning. Reproduced from ref. (He et al. 2016) with permission

NaxFeyMn1-yO2

Considering the distinct features of the two single metal oxides, it is promising to develop Fe and Mn-mixed Nax(FeyMn1-y)O2 which is expected to combine the high potential of NaFeO2 and high capacity of NaMnO2 to target high-energy and cost-effective electrodes. Komaba’s group made a critical step by reporting the unprecedented high-performance of P2-Na2/3Fe1/2Mn1/2O2, which delivered a capacity of 190 mAh g−1 at 0.05 °C (13 mA g−1). Attributing to the contribution of the reversible high-energy Fe3+/Fe4+ redox at above 3.2 V, the energy density of this cathode reached over 500 Wh kg−1. However, only a 30 cycling profile was presented (~ 79% capacity retention) together with poor rate capability. Also, they also presented the O3-Na2/3Fe1/2Mn1/2O2, only receiving an initial capacity of 125 mAh g−1 with more serious polarisation (Yabuuchi et al. 2012a). After that, Thorne et al. investigated a serious of NaxFexMn1-xO2 (0.5 ≤ x ≤ 1.0), confirming that the existence of Fe reduced the voltage hysteresis and increased capacity retention over cycling. By restricting the potential window below 4.0 V, more than 90% capacity retention was achieved after 20 cycles (Thorne et al. 2013). They further studied the sodium (de)intercalation behavior of P2-NaxMn1/2Fe1/2O2 by using operando in situ X-ray powder diffraction, which revealed a larger solid-solution region (0.35 < x < 0.82), and an orthorhombic P′2-type structure formed when charged over 4.0 V (Mortemard de Boisse et al. 2014). Recently, Rojo’s group carried out a series of studies on Fe-rich Na2/3Fe2/3Mn1/3O2. First, they decoupled the influence from Na/Mn stoichiometry and the structure by preparing P2 and O3 structured oxides on the basis of the same formula of Na2/3Fe2/3Mn1/3O2. As a result, the O3 structure demonstrated similar electrochemical performance (Gonzalo et al. 2014) or even slightly higher reversible capacity (Han et al. 2015) compared with its P2 counterpart. They further made a direct comparison of phase transitions for two electrodes during charge/discharge by in-situ synchrotron X-ray diffraction, and they showed distinct and rate-dependent structural evolution. Phase change in the P2 phase was limited at 0.4 °C, but amplified at 1 °C. Whereas the O3 electrode behaved inversely. Interestingly, the O3 structure converted partially into a P2-like phase after cycling (Sharma et al. 2016). These results offer new understandings about the Na/Mn stoichiometry-crystal structure-electrochemistry relations.

As the Fe- and Mn-based oxides suffer from the significant capacity drop as well as unsatisfactory rate capability, continuous efforts have been made to mitigate the issues. Low-valance metal substitution is still deemed as an effective strategy. Kim et al. reported the heavily Ni-substituted NaNi1/3Fe1/3Mn1/3O2 as a stable cathode in a SIB full cell with hard carbon, which maintained 100 mAh g−1 after 150 cycles at a 0.5 °C rate (75 mA g−1) (Kim et al. 2012a). After that, a range of Ni- (Hasa et al. 2014; Talaie et al. 2015), Co- (Liu et al. 2015a), and Cu-substituted (Li et al. 2015c) oxides have been investigated. These ions not only suppress the ratio of Mn3+ but also partially replaced the redox reactions. The deleterious high voltage transition is mitigated by substitution of Fe3+ by Mn4+/Ni2+, permitting better cycling performance. (Fig. 14).

Phase evolution in Na0.67Mn0.5Fe0.5O2 and Ni-substituted Na0.67Mn0.65Ni0.15Fe0.2O2 over the first cycle, and schematic illustration of Mn/Fe migration into tetrahedral sites in the Na space at high potential. Reproduced from ref. (Talaie et al. 2015) with permission

Fe- and Mn-based polyanion compounds as SIB cathodes

As discussed above, polyanion compounds feature robust crystal framework with the oxygen atoms covalently bonded by counterions (S, P, Si, etc.), affording favorable structural stability toward lithium (de)insertion. Such merit is more demanded in SIB chemistry, as the movement of the larger Na ions puts forward higher requirement for structural stability. Given the poor cycling stability haunting most of the layered oxides, much interest has shifted to develop polyanion compounds as long-life cathodes for SIBs.

Fe-and Mn-based phosphates

Olivine LFP is the most successful polyanion cathode for LIBs. Unfortunately, its sodium counterpart NaFePO4 (NFP) simply cannot duplicate its success, as the thermodynamically stable phase of NFP is a maricite structure (Bridson et al. 1998), in which Na+ and Fe2+ ions occupy the opposite sites of those in olivine LiFePO4. Due to the absence of Na+ channels in such atomic configurations (Fig. 11), the maricite structure is therefore electrochemically inactive (Moreau et al. 2010; Zaghib et al. 2011). Metastable olivine NFP is usually synthesized through electrochemical displacement from olivine LFP (Ali et al. 2016; Fang et al. 2015; Moreau et al. 2010; Oh et al. 2012; Zaghib et al. 2011; Zhu et al. 2013). Though the prepared NFP electrodes preserve the microstructures and conductive modifications from the LFPs, their performances are much lower than the original LFP in LIBs, receiving capacities of only around 120 mAh g−1 together with deteriorated rate capability. Atomistic simulations conducted in Nazar’s group showed the low formation of Na/M antisite defects in the Na-olivine and significant volume change of 15% during the removal of Na+, which possibly answered the poor performances (Tripathi et al. 2013). Moreover, their costs are even significantly higher than LFP, which are against the purpose of developing SIBs. Therefore, research interest has been shifted to explore other crystal chemistries of NFP. Amorphous α-FePO4, which is electrochemically active for (de)lithiation, is reinvestigated as a cathode material for SIBs (Fang et al. 2014; Liu et al. 2015b; Liu et al. 2012b). With the nanosized particle and high content of conductive carbon, they can deliver a capacity of up to 160 mAh g−1. The concern of the initial desodiated state was further addressed by Li et al. by the direct preparation of amorphous NFP nanospheres, which showed a capacity of 152 mAh g−1 and retained 144.3 mAh g−1 after 300 cycles (Li et al. 2015a). Recently, Kang et al. reported an alternative route toward amorphous NaFePO4, which was converted from nanosized maricite after long charging, after that, a reversible capacity of 142 mAh g−1 in a potential window of 1.5–4.5 V was achieved (Kim et al. 2015b).

Also, Fe-based phosphates crystalized in other structures have also been investigated as SIB cathodes. Trad et al. reported the electrochemical performance of a “layered” Na3Fe3(PO4)4, where only ~ 80 mAh g−1 was discharged at 0.02 °C (Trad et al. 2010b). Huang et al. prepared alluaudite Na2Fe3(PO4)3/CNT composites, delivering a discharge capacity of up to 143 mAh g−1 after 50 cycles (Huang et al. 2015b). Very recently, Liu et al. tested the NASICON-type Na3Fe2(PO4)3, which showed a low capacity of 61 mAh g−1 and low plateau at 2.5 V, but the capacity retention was excellent, maintaining 93% capacity after 500 cycles at 1 °C (Liu et al. 2017b). Those phases including the amorphous NFP are not competitive compared with olivine LFP in LIB system regarding energy density, power densities, and cycling stability. Considering the abundant polymorphism in the Na-Fe-P-O system, the future success of sodium iron phosphate may rely on the exploration of new structures.

Like NFP, NaMnPO4 (NMP) also crystalized favorably in the maricite phase. However, the olivine phase of NMP is still more stable than olivine NFP. Lee et al. (Lee et al. 2011) and Boyadzhieva et al. (Boyadzhieva et al. 2015) have developed ion-exchange reactions to prepare olivine NMP from NH4MnPO4·H2O and KMnPO4·H2O, respectively. The olivine-to-maricite conversion temperatures are respectively 450, 500, and 550 °C for NFP, NaFe0.5Mn0.5PO4, and NMP. To our knowledge, there are no reports on the electrochemical properties of pure NMP up to now, indicating deteriorating reactive activity. Lee et al. showed discharge profile of NaFe0.5Mn0.5PO4 over 3 cycles at C/40, in which a discharge capacity around 90 mAh g−1 is obtained (Lee et al. 2011). Besides, Fe- and Mn-mixed alluaudite-type phosphates have been investigated as SIB cathodes (Huang et al. 2015a; Trad et al. 2010a), where the existence of Mn further lowers the limited specific capacity (Fig. 15).

a–e Crystal structures of olivine NFP, maricite NFP, NASICON-type Na3Fe2(PO4)3, layered Na3Fe3(PO4)4, alluaudite-type Na2Fe3(PO4)3. Reproduced from ref. (Naoaki and Shinichi 2014) with permission. Their typical charge/discharge curves are shown on the right side. Reproduced from ref. (Ali et al. 2016), (Kim et al. 2015b), (Trad et al. 2010b), (Huang et al. 2015b), and (Liu et al. 2017b) with permissions

Fe- and Mn-based pyrophosphates

Though pyrophosphates have been eclipsed by LFP in the LIB system due to the large gap of capacities, the pyrophosphates show intrinsically better kinetics when compared to other polyanion materials, including LFP (Furuta et al. 2012; Nishimura et al. 2010). Their sodium analogs, therefore, attract much interest. Barpanda et al. first reported the preparation and electrochemical properties of Na2FeP2O7. Na2FeP2O7 was preferably crystalized into a triclinic structure (P-1), consisting of interconnected FeO6 octahedral and PO4 tetrahedral building blocks. Attributing to the large channels within the 3D structure, the unmodified sample showed a reversible capacity of 82 mAh g−1 with an impressive rate capability (Barpanda et al. 2012). The ex-situ XRD test conducted by Kim et al. revealed that Na2FeP2O7 experienced a single-phase reaction at ~ 2.5 V and consecutive two-phase reactions in the higher potential range of 3.0–3.25 V (Kim et al. 2013b). Both Na2FeP2O7 and charged NaFeP2O7 phases exhibited impressive thermal stability up to 500 °C, adding its feasibility to practical applications (Barpanda et al. 2013a; Kim et al. 2013b). The electrochemical performance has been further enhanced by some recent efforts made on the optimization of morphology and conductive modification, such as Na2FeP2O7 decorated by carbon nanotubes, reduced graphene oxide-supported Na3.12Fe2.44(P2O7)2/C (Song et al. 2017b), and Na2FeP2O7 nanoparticles embedded in carbon (Song et al. 2017a).

Along with the success of Na2FeP2O7, its Mn analog Na2MnP2O7 has also been investigated. Unlike most Mn-based cathode materials suffering from sluggish kinetics, Park et al. found the unexpected high activity of micron-sized Na2MnP2O7, which exhibited a reversible capacity of 90 mAh g−1 with an elevated plateau at ∼ 3.8 V. First-principles calculations revealed that the impressive kinetics were attributed mainly to the corner-sharing crystal structure in triclinic Na2MnP2O7, permitting locally flexible accommodation of Jahn–Teller distortions of Mn3+ (Park et al. 2013). After that, Barpanda et al. reported the new polymorph of β-Na2MnP2O7 (triclinic P1), which was also electrochemically active and thermodynamically feasible (Barpanda et al. 2013b). Their further atomistic simulations disclosed low barriers for long-range Na+ diffusion in all directions in Na2(Fe, Mn)P2O7, theoretically proving the 3D Na+ pathway (Clark et al. 2014) (Fig. 16).

a–c Triclinic structure (P-1) of Na2FeP2O7 and corresponding electrochemical properties. Reproduced from ref. (Barpanda et al. 2012) with permission. d Voltage profiles of P-1 Na2MnP2O7. Reproduced from ref. (Park et al. 2013) with permission. e, f Crystal structure of β-Na2MnP2O7 (triclinic P1) and its voltage profiles. Reproduced from ref. (Barpanda et al. 2013b) with permission

Fe- and Mn-based sulfates and oxalates

The stronger inductive effect of the SO42- group can elevate the redox potential when compared with common PO43. In 2014, Barpanda et al. reported the use of a new Na2Fe2(SO4)3 with the alluaudite-type as a cathode material for SIB. The sulfate showed the highest-ever Fe3+/Fe2+ redox potential at 3.8 V and delivered a reversible capacity of 100 mAh g−1 coupled with good kinetics (Barpanda et al. 2014b). Further experimental and computational studies revealed the alluaudite sulfate witnesses a reversible single-phase reaction with a small volume change (ca. 3.5%) after the initial charge (Oyama et al. 2016). The sulfate also possessed four and two orders of magnitude higher intrinsic ionic and electronic conductivity than LFP, underpinning the high kinetics (Lu and Yamada 2016). With the intrinsic merits, the cathode can undergoes 40 °C charge/discharge by constructing the additional conductive network (Meng et al. 2016; Yu et al. 2016).

Apart from alluaudite-type sulfates, Kröhnkite-type Na2Fe(SO4)2·2H2O was also explored as a 3.25 V insertion compound for SIBs, showing a reversible capacity of around 70 mAh g−1 (Barpanda et al. 2014a). Besides, eldfellite NaFe(SO4)2 was validated to be electrochemically active by Singh et al., with a discharge capacity of ~ 80 mAh g−1 at 0.1 °C with a plateau of 3.0 V (Singh et al. 2015). Density functional theory calculations suggested the low kinetics of eldfellite is due to high activation energies over 1 eV for the Na+ ion hop (Banerjee et al. 2016).

Mn-based sulfates progressed much slower. Barpanda et al. continued to explore the sulfate-based cathode family by reporting the isostructural alluaudite-type Na2+2xMn2−x(SO4)3, but no electrochemical data was presented, as they claimed that the predicted high-potential (ca. 4.4 V) requires the advent of suitable electrolytes (Dwibedi et al. 2015). After that, Yamada’s group reported a series of Mn-substituted alluaudite solid solutions Na2.5(Fe1−yMny)1.75(SO4)3 (y = 0, 0.25, 0.5, 0.75, and 1.0). However, there were no Mn2+/Mn3+ redox reactions that had taken place. The material simply showed continuous capacity decrease along with the increasing Mn content (Wei et al. 2016).

Oxalates have also been investigated as Na+ host materials. According to the electronegativity order of SO42– > C2O42– > PO43–, metal oxalates can display competitive redox potentials. In 2014, Yamada’s group prepared K4Na2[Fe(C2O4)2]3·2 H2O and studied its Na storage capability (Wang et al. 2015b). The material initially discharged 54.5 mAh g−1 at C/50 with an average potential of 2.7 V in the subsequent 9 cycles. Yao et al. investigated the electrochemical properties of Na2Fe2(C2O4)3·2H2O(Yao et al. 2017b) and Na2Fe(C2O4)F2 (Yao et al. 2017a) as SIB cathodes. The former one was suggested to be electrochemically inactive in LIBs, but they found a reversible capacity of ca. 100 mAh g−1 (10 mA g−1 current) with three redox plateaus at 2.9, 3.3, and 3.6 V (Yao et al. 2017b). The fluoro-oxalate showed a reversible capacity of 70 mAh g−1 at 10 mA g−1 for 50 cycles (Yao et al. 2017a). Although electrochemical activities have been demonstrated in these polyanion compounds, especially the alluaudite-type sulfates, it is worth noting that some critical issues should be addressed before their practical application, including the air (water, oxygen) sensitivity and thermal instability (decomposition) (Fig. 17).

Crystal structures of alluaudite-type Na2Fe2(SO4)3 (a), eldfellite NaFe(SO4)2 (b), Na2Fe2(C2O4)3·2H2O (c), and Na2Fe(C2O4)F2 with their voltage profiles are shown on the right side. Reproduced from ref. (Barpanda et al. 2014b), (Singh et al. 2015), (Yao et al. 2017b), and (Yao et al. 2017a) with permissions

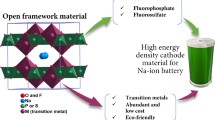

Fe- and Mn-based mixed anion compounds (fluorophosphates and mixed polyanions)

The combination of different anion groups (F−, PO43−, P2O74−, CO32−, etc.) offers new opportunities toward desirable electrode materials. The induction of highly electronegative F− ions enables higher redox potentials due to the stronger inductive effect. Na2FePO4F is a representative Fe-based fluorophosphate, which was first introduced by Nazar’s group in 2007 (Ellis et al. 2007). As shown in Fig. 18a, the structure is assigned to the orthorhombic Pbcn space group, in which the bioctahedral Fe2O7F2 chains are connected by PO4 tetrahedra to constitute 2D [FePO4F] layers. In this way, Na ions can transport between the layers. The structure also favors a small volume change (3.7%) after extraction of one Na+ ion, corresponding to a theoretical capacity of around 124 mAh g−1 as a cathode for SIBs. The atomistic simulations also suggested low activation energy for the Na+ diffusion between the layers (Tripathi et al. 2013). However, the strong iconicity of fluorine reduced the inherent electrical conductivity. Unlike the pyrophosphates, iron fluorophosphates are unlikely to perform well in micron particles. With the aid of carbon coating and nanosizing (Kawabe et al. 2011; Ko et al. 2017; Law et al. 2015), the electrochemical performance experienced some improvements.

a–d Crystal structures of Na2FePO4F (a), Na2MnPO4F (b), Na4Fe3(PO4)2(P2O7) (c), and Na3MnPO4CO3 (d). Reproduced from ref. (Naoaki and Shinichi 2014) with permission. Their representative voltage profiles are shown on the right side. Reproduced from ref. (Law et al. 2015), (Lin et al. 2014), (Wu et al. 2016), and (Huang et al. 2014) with permissions. e High-performance Na4Mn3(PO4)2(P2O7), which was ascribed to the cooperative Jahn-Teller effect of Mn3+. Reproduced from ref. (Kim et al. 2015a) with permission

Different from the 2D-layered Na2FePO4F, Na2MnPO4F adopts a 3D tunnel structure (space group: P21/n) (Fig. 19b) (Yakubovich et al. 1997). By investigating the Mn-substituted Na2Fe1−xMnxPO4F, the presence of 0.25 Mn is enough to trigger the 2D-3D phase transition. The Mn substitution resulted in a substantial decay of the electrochemical performances (Wu et al. 2011). In the quest of active Mn2+/Mn3+, Yong’s group prepared a series of Na2Fe1−xMnxPO4F/C (x = 0, 0.1, 0.3, 0.7, 1) nanostructured composites. When operating at a high temperature of 60 °C, all these electrodes showed electrochemical activity. Na2FePO4F can even perform 1.46 electron reaction with a capacity of 182 mAh g−1. The partial substitution of Fe by Mn enables higher redox potentials with limited loss of capacity. However, entirely substituted Na2MnPO4F was much less active (Wu et al. 2011). After that, they optimized electrode materials by utilizing spray-drying precursor, the resultant Na2MnPO4F/C delivered 140 mAh g−1 at 6.2 mA g−1, when operating at 30 °C. However, the capacity retention was only around 50% after 50 cycles (Lin et al. 2014). The very low Na+ diffusion coefficient of 10−17 cm2 s−1 given by the GITT test suggests the formidable challenge in the use of this material.

a Crystal structure of PBAs with a face-centered cubic phase. b Charge and discharge curves of Na2MnMn(CN)6. c, d The schematic illustrations of the step-wise structural evolution over the extraction/insertion of Na+ ions. Reproduced from ref. (Lee et al. 2014) with permission. e, f Voltage profile and cycling performance of a Prussian blue@C composite. Reproduced from ref. (Jiang et al. 2016) with permission

Kim et al. first introduced the Fe-based mixed phosphate compound Na4Fe3(PO4)2(P2O7) to SIBs. As shown in Fig. 18c, the structure belongs to the orthorhombic Pbcn space group, which is constructed by [Fe3P2O13] layers and P2O7 pillars. First-principles calculations identified feasible 3D Na+ paths. The theoretical capacity based on one-electron reaction is 129 mAh g−1. Their result showed that 88% of the theoretical value can be achieved at an extreme rate of C/40 (Kim et al. 2012b). Furthermore, they employed ex-situ XRD to disclose a single-phase reaction mechanism coupled with a small volumetric change of less than 4% during the (de)sodiation of the NaxFe3(PO4)2(P2O7) (Kim et al. 2013a). Wood et al. simulated molecular dynamics for Na4M3(PO4)2P2O7 (M = Fe, Mn, Co, Ni), with the results showed a small activation barrier of 0.20–0.24 eV for 3D Na+ migration and diffusion coefficients of 10–10–10–11 cm2 s–1 at 325 K (Wood et al. 2015). Impressive electrochemical performance was realized by Na4Fe3(PO4)2(P2O7)/C nanocomposites synthesized by a sol-gel method, which showed capacities of 105 and 78 at 0.2 and 10 °C, respectively (Wu et al. 2016). Unexpectedly, Na4Mn3(PO4)2(P2O7) (Kim et al. 2015a) and Na4MnxFe3–x(PO4)2(P2O7) (x = 1, 2) (Kim et al. 2016a) reported by Kim et al. showed better performance. Na4Mn3(PO4)2(P2O7) had a redox potential of 3.8 V and a reversible capacity of 109 mAh g−1 at C/20, and maintained 55 mAh g−1 at 20 °C (Fig. 18e). The Na4MnFe2(PO4)(P2O7) showed capacity retention of 83% after 3000 cycles at 1 °C.

Carbonophosphates are an emerging class of mixed polyanion compounds in SIB system. The idea of engaging carbonophosphates was proposed by Ceder’s group using ab initio computations (Hautier et al. 2011). They successfully synthesized a series of carbonophosphates Na3M(PO4)(CO3) (M = Mg, Mn, Fe, Co, Ni, Cu, Sr) with a sidorenkite phase (space group: P21/m, Fig. 18d). Chemical desodiation performed on the Na3Fe(CO3)(PO4) suggested the possibility of serving as a SIB cathode (Chen et al. 2012). Then they reported the first use of Na3MnPO4CO3 as a cathode material for SIBs (Chen et al. 2013). The electrode displayed a high discharge capacity of 125 mAh g−1, indicating a two-electron intercalation reaction, which was further evidenced by 23Na NMR spectroscopy. In-situ XRD suggested a single-phase reaction upon electrochemical cycling. Until now, there are only limited reports on this type of material, and the rate capability still seems unsatisfactory after nanosizing and carbon modification (Hassanzadeh et al. 2016a, b; Huang et al. 2014). Additionally, carbonophosphates show appreciable thermal stability that can withstand a temperature of 500 °C.

Fe- and Mn-based hexacyanometalates

Metal hexacyanometalates, also known as Prussian blue analogs (PBAs), have a general formula of AxP[R(CN)6]1-y□y·nH2O (A: removable cations, P: N-coordinated metal ion; R: C-coordinated metal ion; □: [R(CN)6] vacancy; 0 ≤ x ≤ 2; 0 ≤ y < 1). They are crystallized into a cubic structure with the space group of Fm-3m. The cyanide ligands link the coordinated metal ions together to form elementary cubes that can host various cations due to the large channels and interstitial sites, and each unit cell contains eight elementary cubes (Lee et al. 2014). Goodenough’s group first investigated the use of metal hexacyanometalates as cathodes for non-aqueous SIBs. Among a range of hexacyanometalates, KFe2(CN)6 exhibited a reversible capacity near 100 mAh g−1 at 0.05 °C. However, they showed quite a low efficiency, which was ascribed to the crystal water contained in MHCs (Lu et al. 2012). Moving forward, they reported a high-performance Na1.72MnFe(CN)6, where the Na displacement at higher Na concentrations reduces the crystal symmetry to a rhombohedral phase. The initial rhombohedral structure demonstrated a capacity of 134 mAh g−1 at 0.05 °C, and retained 45 mAh g−1 at 40 °C (Wang et al. 2013). In search of high-capacity PBAs, Cui et al. prepared Na-rich monoclinic Na2MnMn(CN)6, which can even host additional Na+, resulting in a high discharge capacity of 209 mAh g−1 at C/5 (40 mA g−1). The three-step Na+ insertion corresponds to three plateaus with an average potential of 2.65 V (Lee et al. 2014). As the water residue and [R(CN)6] vacancies are considered to be detrimental to the coulombic efficiency, cyclic stability, and kinetics, many efforts have been to prepare high-quality PBAs for enhanced overall performance. Guo et al. developed a slow crystal growth process from Na4Fe(CN)6, with the resultant Prussian blue containing less zeolite water and [Fe(CN)6] vacancies, and showing a capacity of 170 mAh g−1 with no capacity loss for 150 cycles (You et al. 2014). Goodenough’s (Song et al. 2015) and Ma’s (Yang et al. 2015a) groups respectively reported the removal of Interstitial water by different methods, leading to much improved electrochemical performance. Recently, a Prussian blue@C composite was reported for excellent rate and cycling performance (Jiang et al. 2016), which maintained 77.5 mAh g−1 at 90 °C, and received 90% capacity retention after 2000 cycles at 20 °C, indicating a promising future for this type of material. It is worth mentioning that metal hexacyanometalates are subject to thermal decomposition at temperatures over 300 °C (Zhang et al. 2012). Therefore, the practical difficulties regarding sulfates also exist here.

Summary and outlook

Considering the technology advances achieved on energy conversion and storage and the pressing concerns of carbon emission and environmental pollution, the transitions to clean, green, and sustainable development are practically logical and urgent. LIBs, as the state-of-the-art energy storage system, are starting to support green vehicles and residential energy storage. To meet the enlarging market, batteries themselves should adopt green and low-cost chemistries. As the costliest sector of a LIB, cathode materials involve removable Li ions as charge carriers, and transition metal ions serving as redox centers, which account for most of the cost. Given their elemental abundance, Mn- and Fe-based cathode materials are therefore preferable choices, and their sodium analogs are also attracting much attention, as they might enable the future of Li-free SIBs, which would be ideal choices for large-scale applications.

This review involves the discussion of most of the Fe- and Mn-based cathode materials for LIBs and SIBs, including oxides, polyanion compounds, and hexacyanometalates (for SIBs). We especially emphasize their merits, drawbacks, and up-to-date advances. To gain a direct view of the recently achieved electrochemical properties of those materials, we list their average operating potentials, discharge capacities (at low and high rates), and cycling performances in Table 1 (LIBs) and Table 2 (SIBs). The energy densities of those Fe- and Mn-based cathode materials are plotted in Fig. 20. From the straightforward comparison, it is easy to understand the different development phases and goals of cathode materials for LIBs and SIBs. To meet the requirement of practical applications, significant challenges in this field remain in:

-

1)

The extensively investigated strategies of constructing conductive composites and tailoring particle size easily cause insufficient gravimetric and volumetric energy densities as well as additional materials and processing costs.

-

2)

Due to the large size of the Na ion, conventional host structures do not favor efficient and repeatable Na ion (de)intercalation. A critical step to realizing large-scale SIB applications is to search stable and kinetic SIB cathode materials.

-

3)

Instead of emphasizing the electrode performance of a cathode material in a half cell, the practical performance should be demonstrated in full battery level, which requires innovation in the design and optimization of both the cathode and the anode materials.