Abstract

A facile and low-cost method for structuring carbon-encapsulated cobalt nanoparticles (Co@C) is presented. Three samples were solvothermally prepared in one step at 220 °C and one in two steps at 200 °C. Three different polyols such as propylene glycol, triethylene glycol, and tetraethylene glycol were used as carbon sources, solvents, and reducing agents. The samples were characterized by X-ray powder diffraction (XRD), transmission electron microscopy (TEM), and Raman spectroscopy. Concerning the crystal structure of the particles, a mixture of hcp/fcc Co phases was obtained in three of the samples, independently of the polyol used. The coexistence of cubic and hexagonal phases was revealed both from XRD and high-resolution TEM (HRTEM). The formation of the cubic fcc structure, despite the relatively low reaction temperature, is attributed to the role of the interface between carbon coating and metallic core. The presence of carbon coating was demonstrated by Raman spectrometry, exhibiting the characteristic D and G graphitic bands, and by HRTEM observations. All samples showed ferromagnetic behavior with saturation magnetization up to 158 emu/g and coercivity up to 206 Oe. From the magnetic particle hyperthermia measurements recorded at a frequency of 765 kHz, a maximum SLP value of 241 W/g was obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cobalt is a ferromagnetic transition metal that in its bulk state crystallizes in the hexagonal close packed (hcp) crystal structure (Yoon et al. 2015) or the face-centered cubic (fcc) phase (Nishikawa et al. 1993), which becomes stable above 450 °C (Sergiienko et al. 2007). Cobalt might also crystallize in a metastable phase (ε-Co), the synthesis of which has been only possible by means of solution-phase chemistry processes (De la Peña O’Shea et al. 2010).

Nanosized Co can be synthesized by a variety of wet chemistry methods. Wet chemistry nanostructuring offers a lot of advantages, such as reaction control, narrow size distribution, and size control. The main concept of the wet chemistry methods is the production of atoms in solution, which will aggregate into nanoparticles. It includes lots of methods, two of which are most frequently used, i.e., the thermal decomposition and the solvothermal method. With the first one, hcp (Rao et al. 2013) and fcc (Gajbhiye et al. 2008) cobalt or cobalt carbide (Harris et al. 2010; Huba and Carpenter 2012) nanoparticles have been produced. Similar results can be accrued with the solvothermal synthesis, a versatile approach in metal manufacturing, since temperature, ligand effects, reaction time, and reductant effects might change, leading to different nanoproducts (Lai et al. 2015). In the combined solvothermal and polyol process (Vamvakidis et al. 2013), where size and shape control is accomplishable, polyols such as tetraethylene glycol or triethylene glycol, with a relatively low molar mass and high boiling point, are used. Osorio-Cantillo and Perales-Perez (2009) synthesized single phase ε-Co, hcp Co, fcc Co, and a mixture of fcc/hcp Co nanoparticles by decomposing cobalt acetate in polyols under tunable conditions. Hcp cobalt nanoflowers, nanorods, or urchin-like nanoparticles have been synthesized solvothermally in polyols (Liu et al. 2009) using Ru as heterogeneous nucleation agent. Liu et al. (2015) managed to control solvothermally nanospheres’ and nanorods’ size and shape and Qiao et al. (2007) prepared magnetic hybrid copolymer–Co hierarchical hollow spheres, demonstrating that the solvothermal method can be quite controllable. Xu et al. (2007) synthesized solvothermally in two steps nearly monodispersed cobalt and nickel nanoparticles with spherical shapes by synthesizing nickel or cobalt oleylamine complexes in the first step.

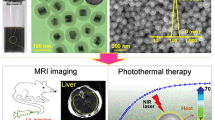

Due to their superior magnetic properties, Co nanoparticles could be a promising candidate for biomedical applications substituting the almost uniquely used biocompatible iron oxide nanoparticles. Since cobalt nanoproducts present high cytotoxicity, their passivation with an inert shell is a vital prerequisite. Carbon encapsulation of cobalt nanoparticles reduces cytotoxicity, allowing their use in in vivo applications (Abdulaeva et al. 2012; Seo et al. 2006). Carbon-encapsulated cobalt nanoparticles (Co@C) have been produced via chemical vapor deposition (CVD), under high pressure (13 bar) or temperature (900 °C) (El-Gendy et al. 2009), by applying catalytic CVD (Lukanov et al. 2011; Xu et al. 2008) or by etching in HF the silica support, where the nanoparticles were produced (Seo et al. 2006). However, the CVD method needs a high production cost. On the other hand, Zhu et al. (2011) synthesized Co@C nanoparticles by using mesoporous Co3O4 as precursor in a fixed-bed quartz flow reactor, were the Boudouard reaction (2CO➔C + CO2) (Snoeck and Froment 2002) gave the graphite shell. Despite the advantages that these nanoproducts have, such as narrow size distribution and high crystallinity both for the hcp metallic core and the graphitic shell, the synthesis was carried out in two steps, under high temperature (510 or 710 °C) and under gas flow, helium firstly and CO subsequently; a procedure that increases the cost. Ibrahim et al. (2013) synthesized high crystallized hcp Co@C nanorods in two steps: at the first step, cobalt nanorods were produced via the polyol process (Soumare et al. 2009); at the second, the thermal treatment of cobalt nanorods in solvents led to the encapsulation in a carbon shell.

Herein, a simple solvothermal method for Co@C nanostructuring in one step is reported. 1,2-propylene glycol (PG), triethylene glycol (TrEG), and tetraethylene glycol (TEG) that exhibit different physical and chemical properties have been used in order to investigate the influence of the polyols on the composition and the surface chemistry of the as-produced NPs. The polyol process was selected as high boiling polyalcohols serve as solvents, stabilizing and reducing agents, resulting in an effective control over the physicochemical characteristics of the NPs. Meanwhile, the transformation of the polyols happens through dehydrogenation oxidation reactions where partial graphitic carbon is formed as a carbonaceous by-product (Stefanescu et al. 2007; Dong et al. 2014) and a carbon shell is likely to form, decreasing the cytotoxicity of the nanoparticles (Abdulaeva et al. 2012; Seo et al. 2006). During the synthesis of the NPs, polyols can decompose through heating (Wingfield and Raffe 2002; Yaylayan et al. 1998), or participate in redox reductions with the metal ions existing in the solution (Caizer and Stefanescu 2002). The mechanism behind the reduction of metal precursors by the polyols remains poorly understood; however, it is proposed by recent studies that polyols form intermediate complexes with the metals, prior to the production of metallic nanoparticles (Carroll et al. 2011; Vamvakidis et al. 2014). Different metal precursors and/or polyols have an impact on the formation of the intermediate complexes, specifically on their stability, formation, and decomposition temperatures. According to literature, the carbon nanoproducts can be used as fluorescent agents (Xu et al. 2008; Lim et al. 2015; Lu et al. 2012). In the present work it is demonstrated that the Co@C nanoparticles can be used both in hyperthermia and as fluorescence agents for combinative biomedical applications.

Experimental

Reagents

Cobalt (II) acetate tetrahydrate (Mr = 249.08 g/mol) and triethylene glycol (> 99%, Mr = 150.18 g/mol, bp = 285 °C) were purchased from Merck, cobalt (II) nitrate hexahydrate (Mr = 291.03 g/mol) from Chem-Lab NV, tetraethylene glycol (> 99%, Mr. = 194.23 g/mol, bp = 314 °C) from Aldrich, and propylene glycol (> 99.5%, Mr = 76.1 g/mol, bp = 188 °C) from Fluka. All chemicals were used as received without further purification.

Synthesis

All the synthetic routes followed a similar protocol, where a precursor was solvothermally decomposed in the presence of sodium hydroxide (NaOH) and a polyol. NaOH was used because the alkaline condition provided by the ΟΗ− ions leads to an acceleration of the reaction (Osorio-Cantillo and Perales-Perez 2009). Two different precursors, cobalt (II) nitrate hexahydrate (Co(NO3)2·6H2O) or cobalt (II) acetate tetrahydrate (Co(ac)2·4H2O) and three different polyols, propylene glycol (PG), triethylene glycol (TrEG) or tetraethylene glycol (TEG) were used. In all cases, polyols acted as solvents, reducing agents and carbon sources. Considering samples nomenclature, for sample S2Co-TEG/PG, number 2 refers to the two steps of the procedure and TEG/PG to the polyols that were used in the first and the second step, respectively. In the first step, cobalt nitrate hexahydrate was used as a precursor. For samples S1Co-TEG, S1Co-PG, and S1Co-TrEG, number 1 refers to the one-step procedure and TEG, PG, or TrEG to the polyol in which the precursor (cobalt acetate tetrahydrate) was diluted. In a typical procedure (S1Co-PG), 300 mg Co(ac)2·4H2O was dissolved in 8 mL of PG with 48 mg NaOH, under vigorous stirring and slight heating for 20 min. The solution was hermetically closed in an autoclave pot and heated at 220 °C for 24 h, with a heating rate of 2.5 °C per minute. The dark brown-black solution was allowed to cool at room temperature and the sediment obtained by centrifugation (6000 rpm) was washed several times with ethanol to remove the by-products. The final solution was dried in vacuum and the powder was collected.

For the synthesis of S2Co-TEG/PG, firstly a Co complex was prepared. Three different solutions were tested, where 300 mg of Co(NO3)2·6H2O was diluted without NaOH in 8 mL TEG, PG, or TrEG, respectively, under vigorous stirring and slight heating. The solutions were heated in an autoclave pot at 200 °C for 24 h, with a heating rate of 2.5 °C/min. Only the solution that was prepared with TEG reacted, resulting to a Co-TEG complex. The obtained light purple powder after washing and drying (Co-TEG complex), approximately 150 mg, was dissolved in 8 mL PG with 32 mg NaOH. The solution was heated under the same conditions (heating rate 2.5 °C/min, final temperature 200 °C) for 24 h. Synthesis conditions are summarized in Table 1.

Generally, the reducing ability of a polyol depends on its molecular weight and increases with decreasing of the molecular weight (Biacchi and Schaak 2011). However, in our work, cobalt nitrate hexahydrate did not react with PG and TrEG, namely the polyols with less molecular weight; contrariwise it reacted with TEG, the polyol with the highest molecular weight among those that were used. According to Vamvakidis et al. (2015) the decrease of the reducing ability of PG is attributed to the exceedance of the boiling point of PG (188 °C).

Characterization

The crystalline structure of the particles was analyzed by means of X-Ray powder diffraction patterns (XRD) recorded at Bragg-Brentano geometry using a two-cycle Rigaku Ultima+ powder X-ray diffractometer with a Cu Ka radiation operating at 40 kV/30 mA. The 2θ angular range was 20–80°, the step size 0.05° and the step time 2 s. Phase composition was confirmed by Rietveld analysis of the X-Ray data (Hunter 1998).

To investigate the morphology, the microstructure, the size, and the arrangement of the nanoparticles, samples for transmission electron microscopy (TEM) were prepared by drop-casting the colloidal dispersions onto carbon-coated Cu grids after sonication for 1 h in hexane. TEM and HRTEM images were acquired in a Jeol 2011 UHR electron microscope with a 0.194 nm resolution, operated at 200 kV.

Raman spectra were recorded in the backscattering geometry using a LabRAM HR (HORIBA) micro-Raman spectrometer equipped with a Peltier-cooled charge-coupled detector. For the excitation, the 514.6 nm line of a diode pumped solid state laser was focused on the samples using a 100× objective at a power of 12 μW to avoid any laser heating induced effects. For the same reason, averaged Raman signal was obtained from a 4 × 4 μm2 area on the surface of the samples taking advantage of the DuoScan™ (HORIBA) system.

The fluorescence spectra were recorded by a Hitachi F7000 fluorescence spectrophotometer. The excitation wavelengths were ranged between 360 and 510 nm.

Magnetic measurements were accomplished using a vibrating sample magnetometer (VSM) at room temperature, at a field with values between −1.8 and 1.8 T. Concerning the minor loops, the measurements were carried out at a field with values between −0.03 and 0.03 T.

Magnetic particle hyperthermia was carried out at an AC magnetic field at f = 765 kHz, at different concentrations from 0.25 to 2 mg/mL, and field amplitudes of 0.025 and 0.03 T. Each microemulsion was placed in the center of a water-cooled induction coil connected to an AC field generator (SPG-10: Ultrahigh Frequency Induction Heating Machine, Shuangping Corporation).

Results and discussion

Structural characterization

The crystalline structure of the metallic core of all samples was determined by XRD. Figure 1 shows the XRD patterns, where all samples display a clear high crystalline structure. The samples that were synthesized in one step by diluting Co(ac)2·4H2O in a polyol (S1Co-TEG, S1Co-PG, and S1Co-TrEG) seem to have the same phase composition, while the sample that was synthesized in two steps (S2Co-TEG/PG) differentiates. Specifically, in S1Co-TEG, S1Co-PG, and S1Co-TrEG, both the Co cubic phase (JCPDS No. 15-0806), with three different peaks, as well as the Co hexagonal phase (JCPDS No. 05-0727), with four different peaks were identified. These peaks correspond to the (110), (200), and (220) fcc crystal planes of the cubic structure and to the (10–10), (0002), (10–11), and (11–20) hcp crystal planes of the hexagonal structure. The four peaks at 2θ = 41.9, 43.4, 47.1, and 75.3 correspond to a hexagonal structure of carbon (JCPDS No. 50-1083), indicating the presence of carbon in these samples. The crystalline phase of carbon was developed during the transformation of each polyol during syntheses as reported in relevant studies on Cr-doped TiO2 nanorods (Zhu et al. 2010) or doped Ni-ferrites (Ma et al. 2007). No oxidic species were found in samples S1Co-TEG, S1Co-PG, and S1Co-TrEG showing the metal purity of the samples. The hcp structure is more stable for bulk cobalt at room temperature, while fcc structure becomes stable above 450 °C (Ibrahim et al. 2013). Yet, the formation of cubic cobalt has been reported at lower temperatures (Gajbhiye et al. 2008), where the fcc structure may also stabilize due to the fine particle size (Sergiienko et al. 2007). In such a case, the surface energy of a particle prevails over the chemical free energy. Moreover, the tight core-shell interface Co-C may partially suppress the fcc phase to transform to the hcp phase and as a result the former remains metastable at room temperature (Sergiienko et al. 2007; Ma et al. 2003).

Beyond the interface effect between cobalt and carbon, significant role for the stabilization of the fcc structure may play the autogenous pressure developed in the reaction vessel. It is assumed that this pressure promotes the formation of the fcc structure, despite the low temperature, and during cooling, where the pressure falls down, the interface disinclines the transformation of the fcc to the hcp structure. In our samples, if the mass proportion of carbon was higher, maybe the transformation from fcc to hcp during cooling would be completely averted, a field of research that should be investigated in the future.

Concerning sample S2Co-TEG/PG, the peaks that correspond to the hcp phase seem less intense, as demonstrated from Rietveld analysis. On the other hand, the three peaks that correspond to the fcc phase dominate in the X-ray diffractogram (Fig. 1a). Α peak at 2θ = 34.2° indicates the presence of cobalt oxide, CoO, (JCPDS No. 42-1300), whereas a peak at 2θ = 31.6° corresponds to amorphous carbon (JCPDS No. 46-0943), which formed a shell around cobalt nanoparticles (Prajapat et al. 2016).

The mean size of the crystallites can be calculated by the Scherrer’s formula \( \left(D=\frac{0.9\lambda }{\beta cos\theta}\right) \), where λ is the X-ray wavelength, θ is the diffraction angle, and β is the full width at half maximum (FWHM). For the cubic structure, these values are 10.5, 16.5, 13.9, and 14.1 nm for S2Co-TEG/PG, S1Co-TEG, S1Co-PG, and S1Co-TrEG, respectively. Comparing them with the mean sizes of the particles determined by TEM as it is described below, it was concluded that the particles have a polycrystalline structure, as expected.

Rietveld analysis has confirmed that all samples consist mostly of fcc and hcp Co, while a small amount of C is also present (Table 2). In all cases, fcc Co was about the 2/3 of the total weight of the samples, ranging from 64 wt.% in the case of the S1Co-TrEG sample to 69 wt.% in the case of the S2Co-TEG/PG sample. The latter presents some deviation in the relative amount of the other phases detected. Hcp Co for the S2Co-TEG/PG sample is 10 wt.% while in all other samples is in the region between 24 and 25 wt.%; additionally C content is higher in that sample, 16 wt.% while in all other samples it was found between 9 and 11 wt.%; the rest 5% being CoO (see Table 2). It seems that with the exception of the S2Co-TEG/PG sample, the difference in phase composition of the samples under study is negligible. Co unit cell parameters also do not differ significantly, for example in the case of the S1Co-PG sample a = 0.354(4) nm for the Co

fcc phase, and a = 0.251(3) and c = 0.407(5) nm for the Co hcp phase. Rietveld analysis results are summarized in Table 2.

The presence of cobalt oxide in S2Co-TEG/PG was also confirmed by Raman spectroscopy, while the presence of metallic cobalt cannot be detected by this technique. As shown in Fig. 2, cobalt oxide is present in sample S2Co-TEG/PG in contrast to S1Co-PG. The Raman spectrum of cobalt oxide displays two intense bands. The first one at 524 cm−1, which is assigned to the F2g symmetric stretching mode of CoO, and the second one, which is highly polarized, at 691 cm−1 assigned to the A1g mode (Yang et al. 2010; Yeo and Bell 2011; Wang et al. 2009).

The stretching graphitic vibrations were also detected. The G-band, which is assigned to the vibration of sp2 hybridized carbon atoms of carbon layers (E2g mode), is observed in both S2Co-TEG/PG and S1Co-PG samples at ~ 1590 cm−1. On the other hand, the broader D-band, which is related to the presence of structural defects, can be clearly resolved at ~ 1350 cm−1 only in S1Co-PG (Xu et al. 2008; Wang et al. 2014). In the S2Co-TEG/PG sample, the stronger photoluminescence background covers the two graphitic bands. The intensities ratio of the D-band to G-band (ID/IG) is a measure of the graphitization degree. In S1Co-PG, a value of 0.85 was calculated, revealing the domination of the graphitic structure against the disordered carbon one.

The morphology and arrangement of the nanoparticles in sample S1Co-PG were obtained by TEM-HRTEM imaging. In Fig. 3, a TEM image of the sample shows almost spherical and large nanoparticles with an average diameter of 150–250 nm, assembled in clusters. Liu et al. (2009, 2015) have reported such a chain-like form of relatively large spheres (500 nm on average) created by heating cobalt acetate tetrahydrate and RuCl3 in propylene glycol or by heating the same precursor in propylene glycol with Ir and sodium stearate (30 nm on average). The strong alkaline conditions provided by the addition of NaOH in the final solution are also considered as critical, since the concentration of NaOH affects the size of nanospheres. It has been shown that the presence of hexadecylamine could lead to smaller particles, like the formation of nanoparticles with an average diameter of 50 nm, or the formation of nanoflowers, a result that depends on the concentration of the amine (Liu et al. 2009).

Furthermore, the local structure of different Co phase single crystals inside nanoparticles was identified by HRTEM observations (Fig. 4). In Fig. 4a, a cubic Co single crystal, viewed along the [011] projection direction, is depicted. A few \( \left(1\overline{1}1\right) \)-type stacking faults (SFs) were observed within the crystal (arrows). These temporarily transform the atomic stacking sequence from cubic …abcabc… to…abab…, forming thin hexagonal pockets delimited by partial dislocations, before another SF restores the cubic stacking. In the inset, a detail of the atomic structure is shown, where the d-spacing of the \( \left(1\overline{1}1\right) \) crystal planes (d = 2.05 Å) is clearly resolved. The fast Fourier transform (FFT) diffractogram corresponding to the area bordered by the white frame reveals the [011] zone axis of the cubic structure (inset). Conversely, Fig. 4b illustrates an image of a hexagonal Co single crystal, viewed along the [0001] zone axis. Its atomic structure is shown in the magnified framed area, where the d-spacing of the \( \left(10\overline{1}0\right) \) crystal planes (d = 2.17 Å) is resolved. Moreover, the corresponding FFT diffractogram of this area reveals the (0001) basal plane of the hexagonal structure, comprising the three {\( 10\overline{1}0 \)} equivalent crystal facets (inset). Hence, it is beyond doubt that the two polymorphic Co phases coexist in nanoparticles of the same sample.

Furthermore, hexagonal carbon (JCPDS No. 50-1083), in the form of randomly oriented nanocrystals with diameters in the range of 2–5 nm, was identified by HRTEM observations (Fig. 5). Since HRTEM images are 2-dimensional projections of 3-dimensional objects, the C nanocrystals were not identified only at the edge of the Co crystals but in all areas, which are

transparent to the electron beam. In Fig. 5, the C nanocrystals are denoted by black arrows and the d-spacing of the {\( 01\overline{1}1 \)} crystal planes of C (2.15 Å) is clearly resolved in all of them. Moiré fringes at the larger C nanocrystal (white arrow) arise due to overlapping with an underlying Co crystal, which suggests a core-shell configuration between the two structures.

Fluorescence properties

Fluorescence emission spectra of the Co@C nanoparticles were recorded and shown in Fig. 6. S1Co-PG dissolved in water was measured with increasing excitation wave length from 360 to 510 nm with a step of 30 nm. The maximum intensity for all measurements was observed at wave lengths ~ 115 nm higher than the excitation ones. The fluorescence of Co@C nanoparticles is directly connected to the presence of carbon and particularly to the defects of the carbon shell. The fluorescence of carbon dots is thought to be associated with passivated surface defects of the carbon particles (Wang et al., 2010a). Interestingly, not only the defects but also the size and the shape of the carbon dots play significant role in the emission spectra (Peng et al. 2012). As mentioned above, Raman spectroscopy evidenced the presence of defects in the graphitic structure. Consequently, the Co@C nanoparticles could be used as fluorescent probes, without any further procedure of coupling fluorescent molecules. The shell carbon that covers the metallic core of the nanoparticles during the solvothermal method is probably sufficient for measurable results. In previous reports (Dong et al. 2014), Zn3(PO4)2 core nanoparticles with a polyethylene glycol shell (PEGylated nanoparticles) were synthesized with unexpected fluorescence, which does not originate from the core, but from the carbon shell that is formed during heating with PEG or other polyols.

Magnetic characterization

In Fig. 7, the room temperature magnetization curves are presented. A ferromagnetic behavior with a narrow loop is clearly shown for each sample. Sample S1Co-PG appears with the highest saturation magnetization (158 emu/g) and the highest coercivity (206 Oe), while the weakest magnetic features were observed for sample S2Co-TEG/PG, with saturation magnetization of 128 emu/g and coercivity of 63 Oe. The % Mr/Ms ratio values range between 2.1% (S2Co-TEG/PG) and 10% (S1Co-PG). The magnetic characteristics of the samples are given in Table 3.

As compared to the value of bulk cobalt (hcp 162 emu/g, fcc 165 emu/g) (Nishikawa et al. 1993), the saturation magnetization values comprise approximately 94, 96, and 92% for S1Co-TEG, S1Co-PG, and S1Co-TrEG, respectively. This gives a proportion of carbon in the samples 6, 4, and 8 wt% for S1Co-TEG, S1Co-PG, and S1Co-TrEG, respectively, in good agreement with the Rietveld analysis results. For such large nanoparticles, the nanoparticle size effect (Qiao et al. 2007; Shafi et al. 2002) is negligible. The much lower saturation magnetization value of the sample S2Co-TEG/PG, 128 emu/g, is in agreement to the larger C content, 16 wt%, and probably to the presence of a cobalt oxide, revealed from Rietveld analysis.

The coercivity in nanoparticles increases with decreasing diameter up to a critical diameter (Dc), which is the limit between the multi domain and single domain region. Below Dc coercivity decreases, zeroing at a characteristic diameter (Dsp), the superparamagnetic limit (Leslie-Pelecky and Rieke 1996). The critical diameter of the single domain region for cobalt is 80 nm and the superparamagnetic limit is 10 nm (Krishnan et al. 2006). In our work, the mean diameter of nanoparticles (S1Co-PG) range between 150 and 250 nm classifying them at the multi domain region. In the literature, even larger hcp cobalt particles present lower coercivity (51.6 Oe) (Wang et al., 2010b). The coexistence of the anisotropic and hard magnetic hexagonal phase (hcp) and the soft magnetic cubic (fcc) one (Rao et al. 2013; Song et al. 2006) seems to influence coercivity. Yang et al. (2012) demonstrated that by transforming nanoparticles from the fcc polycrystalline phase to the hcp single-crystalline phase without changing their mean size, the coercivity at 5 K significantly increases. In our case, the harder hcp phase probably caused an increase of coercivity.

Carbon-encapsulated cobalt nanoparticles were studied for their magnetic hyperthermia response. Initially, low magnetic field magnetization measurements were carried out, to study the low field hysteresis curves. A crucial characteristic is the area of these minor loop hysteresis curves. Figure 8 shows the magnetization of the samples under a maximum magnetic field of 0.03 T, which is the amplitude of the external alternating field that is applied in our magnetic hyperthermia device. From these measurements, it was concluded that sample S1Co-PG might have the higher value of specific loss power (SLP). By integrating the values of hysteresis curve area and multiplying by the frequency of the alternating field used in direct hyperthermia measurements (765 kHz), an SLP value of 20 W/g was calculated for the sample S2Co-TEG/PG. The SLP values of 93, 176, and 38 W/g were calculated for samples, S1Co-TEG, S1Co-PG, and S1Co-TrEG, respectively.

Magnetic hyperthermia measurements were performed for samples S1Co-TEG, S1Co-PG, S1Co-TrEG, with two different amplitudes of external magnetic field (0.03 or 0.025 T) and for three different microemulsion concentrations (2.1 and 0.5 mg/mL). The frequency of the alternating field was 765 kHz. For the calculation of the SLP values, the effect of the solvent (ethanol) was deducted. The specific loss power (SLP) quantifies the heating efficiency and is given by the formula:

where c is the specific heat of the solvent, m f is the ferrofluid mass, m mag is the mass of the magnetic phase, and dT/dt is the slope of the straight line in the temperature versus time curve obtained during the hyperthermia measurements.

In general, the heat losses occurring under an alternating magnetic field arise due to different processes, which include hysteresis for larger nanoparticles and Néel and/or Brown relaxation for smaller ones. Néel relaxation depends on the magnetic characteristics of the nanoparticles and is caused by the fluctuation of the magnetic moment direction across an anisotropy barrier, while Brown relaxation does not depend on magnetic characteristics and is caused by the rotation of the particle as a whole (Hergt et al. 2006). These two mechanisms can coexist in superparamagnetic particles (Rosensweig 2002; Zeisberger et al. 2007). As mentioned above, our samples consist of multi domain nanoparticles with a mean diameter of 150–250 nm. For such large nanoparticles, hysteresis plays the most significant role for heating (Bakoglidis et al. 2012), since the domain walls exist and their pinning creates power losses. For large particles (> 100 nm), which exhibit ferromagnetic behavior, hysteresis losses per cycle depend on the field according to a third-order power law, usually indicated as the Rayleigh law (Hergt and Dutz 2007; Hiergeist et al. 1999). On the other hand, the dissipated magnetic energy is proportional to H2 for superparamagnetic nanoparticles (Hiergeist et al. 1999).

Figure 9 shows the SLP values of samples S1Co-TEG, S1Co-PG, and S1Co-TrEG for two different field amplitude values at a frequency of 765 kHz. Obviously, sample S1Co-PG demonstrates the highest SLP value for all concentration and field amplitude values (Table 4). This is attributed to the larger coercivity value of this sample. This is expressed in the minor loop as a larger hysteresis area (Fig. 8c), i.e., larger thermal losses, revealing stronger dipolar interactions (Nadeem et al. 2011). As a matter of fact, SEM photos showed a degree of aggregation of the nanoparticles in this sample.

Comparing the directly measured values with the values calculated from the hysteresis area multiplied by the frequency of the magnetic field of the minor loop (Fig. 9), it is found that the calculated values are 70–90% of the directly measured SLP values for S1Co-PG, indicating that hysteresis losses is the dominant magnetic-origin heating dissipation, as expected for such large nanoparticles. The deviation between the directly and the magnetically measured SLP values could be attributed to the presence of Néel relaxation mechanism due to some smaller superparamagnetic nanoparticles. In Fig. 10, a more detailed graph concerning only sample S1Co-PG is presented. As shown, at 30 mT, SLP increases with decreasing concentration to 0.5 mg/mL, where the maximum value is observed, 241 W/g, while for 0.25 mg/mL, SLP decreases. On the contrary, SLP at 25 mT remains almost stable, while the maximum value, 161 W/g, is observed for concentration of 0.25 mg/mL. The increase of SLP with the increase of the field is quite expected, considering that the provided energy increases.

To summarize, concerning the magnetic properties, a clear ferromagnetic behavior is shown for all samples. Interestingly, sample S1Co-PG presents the highest saturation magnetization (158 emu/g) and the highest coercivity (206 Oe) value. Thereafter, magnetic hyperthermia measurements gave promising results for future applications with a maximum SLP value of 241 emu/g at a field of 30 mT and at a frequency of 765 kHz. This is significantly higher than the value obtained from Co@C nanoparticles synthesized by Lukanov et al. (2011), 28.7 and 215.4 W/g at 0.038 and 0.088 T, respectively, at a frequency of 120 kHz and that obtained from El-Gendy et al. (2009), 162 W/g at 0.1 T at a frequency of 120 kHz.

Conclusions

Co@C nanostructuring could be simple and economical by using a one-step solvothermal procedure with promising results. The carbon shell plays a crucial role in the formation of the fcc phase, since the interface between the shell and the metallic core partially prevents the transformation of the fcc phase to the hcp one. Thanks to the carbon shell, the Co@C nanoparticles present lower cytotoxicity and consequently they can be potentially used in biomedical applications. Since the carbon shell, due to its defects, emits visible radiation after ultraviolet or visible excitation, Co@C nanoparticles can be used simultaneously as fluorescent and heating agents in magnetic particle hyperthermia.

In order to optimize the heating efficiency of the Co@C particles, it is fundamental to synthesize finer ones of single fcc phase. The reduction of the particles’ size may allow them to be classified in the superparamagnetic region, where Néel and Brown relaxation play the most significant role in power losses (Zeisberger et al. 2007), leading to higher SLP values. Our future plan is to complement the described synthesis towards superparamagnetic core-shell Co@C nanoparticles, which would reach much larger SLP values (Zeisberger et al. 2007).

References

Abdulaeva Z, Omurzak E, Iwamoto C, Ganapathy HS, Sulaimankulova S, Liliang C, Mashimo T (2012) Onion-like carbon-encapsulated Co, Ni, and Fe magnetic nanoparticles with low cytotoxicity synthesized by a pulsed plasma in a liquid. Carbon 50(5):1776–1785. https://doi.org/10.1016/j.carbon.2011.12.025

Bakoglidis KD, Simeonidis K, Sakellari D, Stefanou G, Angelakeris M (2012) Size-dependent mechanisms in AC magnetic hyperthermia response of iron-oxide nanoparticles. IEEE T Magn 48(4):1320–1323. https://doi.org/10.1109/TMAG.2011.2173474

Biacchi AJ, Schaak RE (2011) The solvent matters: kinetic versus thermodynamic shape control in the polyol synthesis of rhodium nanoparticles. ACS Nano 5(10):8089–8099. https://doi.org/10.1021/nn2026758

Caizer C, Stefanescu M (2002) Magnetic characterization of nanocrystalline Ni – Zn ferrite powder prepared by the glyoxylate precursor. J Phys D Appl Phys 35(23):3035–3040. https://doi.org/10.1088/0022-3727/35/23/301

Carroll KJ, Reveles JU, Shultz MD, Khanna SN, Carpenter EE (2011) Preparation of elemental Cu and Ni nanoparticles by the polyol method : an experimental and theoretical approach. J Phys Chem C 115(6):2656–2664. https://doi.org/10.1021/jp1104196

De la Peña O’Shea VA, De PR, Moreira I, Roldán A, Illas F (2010) Electronic and magnetic structure of bulk cobalt: the Α, Β, and ε-phases from density functional theory calculations. J Chem Phys 133(2):24701. https://doi.org/10.1063/1.3458691

Dong H, Roming M, Feldmann C (2014) Unexpected fluorescence of polyols and pegylated nanoparticles derived from carbon dot formation. Part Part Syst Charact 32(4):467–475. https://doi.org/10.1002/ppsc.201400173

El-Gendy AA, Ibrahim EMM, Khavrus VO, Krupskaya Y, Hampel S, Leonhardt A, Büchner B, Klingeler R (2009) The synthesis of carbon coated Fe, Co and Ni nanoparticles and an examination of their magnetic properties. Carbon 47(12):2821–2828. https://doi.org/10.1016/j.carbon.2009.06.025

Gajbhiye NS, Sharma S, Nigam AK, Ningthoujam RS (2008) Tuning of single to multi-domain behavior for monodispersed ferromagnetic cobalt nanoparticles. Chem Phys Lett 466(4–6):181–185. https://doi.org/10.1016/j.cplett.2008.10.065

Harris VG, Chen Y, Yang A, Yoon S, Chen Z, Geiler AL, Gao J, Chinnasamy CN, Lewis LH, Vittoria C, Carpenter EE, Carroll KJ, Goswami R, Willard MA, Kurihara L, Gjoka M, Kalogirou O (2010) High coercivity cobalt carbide nanoparticles processed via polyol reaction: a new permanent magnet material. J Phys D Appl Phys 43(16):165003. https://doi.org/10.1088/0022-3727/43/16/165003

Hergt R, Dutz S (2007) Magnetic particle hyperthermia-biophysical limitations of a visionary tumour therapy. J Magn Magc Mater 311(1):187–192. https://doi.org/10.1016/j.jmmm.2006.10.1156

Hergt R, Dutz S, Müller R, Zeisberger M (2006) Magnetic particle hyperthermia: nanoparticle magnetism and materials development for cancer therapy. J Phys- Condens Mat 18(38):S2919–S2934. https://doi.org/10.1088/0953-8984/18/38/S26

Hiergeist P, Andrä W, Buske N, Hergt R, Hilger I, Richter U, Kaiser W (1999) Application of magnetite ferrofluids for hyperthermia. J Magn Magn Mater 201(1–3):420–422. https://doi.org/10.1016/S0304-8853(99)00145-6

Huba ZH, Carpenter EE (2012) Size and phase control of cobalt-carbide nanoparticles using OH - and Cl - anions in a polyol process. J Appl Phys 111(7):07B529. https://doi.org/10.1063/1.3677816

Hunter B (1998) Rietica - A visual rietveld program. Int Un Cryst Comm Newsletter 20:21

Ibrahim M, Marcelot-Garcia C, Atmane KA, Berrichi E, Lacroix LM, Zwick A, Warot-Fonrose B et al (2013) Carbon coating, carburization, and high-temperature stability improvement of cobalt nanorods. J Phys Chem C 117(30):15808–15816. https://doi.org/10.1021/jp3125457

Krishnan KM, Pakhomov AB, Bao Y, Blomqvist P, Chun Y, Gonzales M, Griffin K, Ji X, Roberts BK (2006) Nanomagnetism and spin electronics: materials, microstructure and novel properties. J Mater Sci 41(3):793–815. https://doi.org/10.1007/s10853-006-6564-1

Lai J, Niu W, Luque R, Xu G (2015) Solvothermal synthesis of metal nanocrystals and their applications. Nano Today 10(2):240–267. https://doi.org/10.1016/j.nantod.2015.03.001

Leslie-Pelecky DL, Rieke RD (1996) Magnetic properties of nanostructured materials. Chem Mater 8(8):1770–1783. https://doi.org/10.1021/cm960077f

Lim SY, Shen W, Gao Z (2015) Carbon quantum dots and their applications. Chem Soc Rev 44(1):362–381. https://doi.org/10.1039/c4cs00269e

Liu Q, Cao X, Wang T, Wang C, Zhang Q, Ma L (2015) Synthesis of shape-controllable cobalt nanoparticles and their shape-dependent performance in glycerol hydrogenolysis. RSC Adv 5(7):4861–4871. https://doi.org/10.1039/C4RA13395A

Liu Q, Guo X, Li Y, Shen W (2009) Hierarchical growth of co nanoflowers composed of nanorods in polyol. J Phys Chem C 113(9):3436–3441. https://doi.org/10.1021/jp8081744

Lu W, Qin X, Liu S, Chang G, Zhang Y, Luo Y, Asiri AM, Al-Youbi AO, Sun X (2012) Economical, green synthesis of fluorescent carbon nanoparticles and their use as probes for sensitive and selective detection of mercury (II). Anal Chem 84(12):5351–5357. https://doi.org/10.1021/ac3007939

Lukanov P, Anuganti VK, Krupskaya Y, Galibert AM, Soula B, Tilmaciu C, Velders AH, Klingeler R, Büchner B, Flahaut E (2011) CCVD synthesis of carbon-encapsulated cobalt nanoparticles for biomedical applications. Adv Funct Mater 21(18):3583–3588. https://doi.org/10.1002/adfm.201100364

Ma LJ, Chen LS, Chen SY (2007) Study of the CO2 decomposition over doped Ni-ferrites. J Phys Chem Solids 68(7):1330–1335. https://doi.org/10.1016/j.jpcs.2007.02.022

Ma X, Cai Y, Li X, Wen S (2003) Growth and microstructure of co-filled carbon nanotubes. Mater Sci Eng A 357(1–2):308–313. https://doi.org/10.1016/S0921-5093(03)00250-8

Nadeem K, Krenn H, Traussnig T, Würschum R, Szabó DV, Letofsky-Papst I (2011) Effect of dipolar and exchange interactions on magnetic blocking of maghemite nanoparticles. J Magn Magn Mater 323(15):1998–2004. https://doi.org/10.1016/j.jmmm.2011.02.041

Nishikawa M, Kita E, Erata T, Tasaki A (1993) Enhanced magnetization in Co/MgO multilayer thin films. J Magn Magn Mater 126(1–3):303–306. https://doi.org/10.1016/0304-8853(93)90609-6

Osorio-Cantillo C, Perales-Perez O (2009) Synthesis and characterization of metastable nanocrystalline cobalt. J Appl Phys 105(7):35–38. https://doi.org/10.1063/1.3072091

Peng J, Gao W, Gupta BK, Liu Z, Romero-Aburto R, Ge L, Song L, Alemany LB, Zhan X, Gao G, Vithayathil SA, Kaipparettu BA, Marti AA, Hayashi T, Zhu JJ, Ajayan PM (2012) Graphene quantum dots derived from carbon fibers. Nano Lett 12(2):844–849. https://doi.org/10.1021/nl2038979

Prajapat CL, Sharma P, Gonal MR, Vatsa RK, Singh MR, Ravikumar G (2016) Synthesis and magnetic study of carbon coated iron oxide nanoparticles by laser ablation in solution. AIP Conf Proc 1731:130011. https://doi.org/10.1063/1.4948117

Qiao R, Zhang L, Qiu R, Kim JC, Kang YS (2007) Preparation of magnetic hybrid copolymer – cobalt hierarchical hollow spheres by localized Ostwald ripening. Chem Mater 19(26):6485–6491. https://doi.org/10.1021/cm701904x

Rao KS, Balaji T, Lingappaa Y, Prakash TL (2013) Synthesis and characterisation of ferromagnetic hexagonal cobalt nanoparticles. J Exp Nanosci 8(2):162–170. https://doi.org/10.1080/17458080.2011.563323

Rosensweig RE (2002) Heating magnetic fluid with alternating magnetic field. J Magn Magn Mater 252:370–374. https://doi.org/10.1016/S0304-8853(02)00706-0

Seo WS, Lee JH, Sun X, Suzuki Y, Mann D, Liu Z, Terashima M, Yang PC, McConnell MV, Nishimura DG, Dai H (2006) FeCo/graphitic-Shell nanocrystals as advanced magnetic-resonance-imaging and near-infrared agents. Nat Mater 5(12):971–976. https://doi.org/10.1038/nmat1775

Sergiienko R, Shibata E, Zentaro A, Shindo D, Nakamura T, Qin G (2007) Formation and characterization of graphite-encapsulated cobalt nanoparticles synthesized by electric discharge in an ultrasonic cavitation field of liquid ethanol. Acta Mater 55(11):3671–3680. https://doi.org/10.1016/j.actamat.2007.02.017

Shafi KVPM, Ulman A, Dyal A, Yan X, Yang N-L (2002) Magnetic enhancement of γ-Fe2O3 nanoparticles by sonochemical coating. Chem Mater 14(4):1778–1787. https://doi.org/10.1021/cm011535

Snoeck JW, Froment GF (2002) Steam/CO2 reforming of methane. Carbon filament formation by the Boudouard reaction and gasification by CO2, by H2, and by steam: kinetic study. Ind Eng Chem Res 41(17):4252–4265. https://doi.org/10.1016/S0140-6701(03)81702-2

Song Y, Modrow H, Henry LL, Saw CK, Doomes EE, Palshin V, Hormes J, Kumar CSSR (2006) Microfluidic synthesis of cobalt nanoparticles. Chem Mater 18(12):2817–2827. https://doi.org/10.1021/cm052811d

Soumare Y, Garcia C, Maurer T, Chaboussant G, Ott F, Fiévet F, Piquemal J-Y, Viau G (2009) Kinetically controlled synthesis of hexagonally close-packed cobalt nanorods with high magnetic Coercivity. Adv Funct Mater 19(12):1971–1977. https://doi.org/10.1002/adfm.200800822

Stefanescu M, Stoia M, Popa A, Simon M, Ionescu C (2007) The interactions between TEOS and some polyols thermal analysis and FTIR. J Therm Anal Calorim 88(2):19–26. https://doi.org/10.1007/s10973-006-8002-7

Vamvakidis K, Katsikini M, Sakellari D, Paloura EC, Kalogirou O, Dendrinou-Samara C (2014) Reducing the inversion degree of MnFe2O4 nanoparticles through synthesis to enhance magnetization: evaluation of their 1H NMR relaxation and heating efficiency. Dalton T 43(33):12754–12765. https://doi.org/10.1039/c4dt00162a

Vamvakidis K, Katsikini M, Vourlias G, Angelakeris M, Paloura EC, Dendrinou-Samara C (2015) Composition and hydrophilicity control of Mn-doped ferrite (MnxFe3-xO4) nanoparticles induced by polyol differentiation. Dalton T 44(12):5396–5406. https://doi.org/10.1039/c5dt00212e

Vamvakidis K, Sakellari D, Angelakeris M, Dendrinou-Samara C (2013) Size and compositionally controlled manganese ferrite nanoparticles with enhanced magnetization. J Nanopart Res 15(6):1743. https://doi.org/10.1007/s11051-013-1743-x

Wang C, Han X, Zhang X, Hu S, Zhang T, Wang J, Du Y, Wang XXP (2010a) Controlled synthesis and morphology-dependent electromagnetic properties of hierarchical cobalt assemblies. J Phys Chem C 114(35):14826–14830. https://doi.org/10.1021/jp1050386

Wang G, Shen X, Horvat J, Wang B, Liu H, Wexler D, Yao J (2009) Hydrothermal synthesis and optical, magnetic and supercapacitance properties of nanoporous cobalt oxide nanorods. J Phys Chem C 113(11):4357–4361. https://doi.org/10.1021/jp8106149

Wang J, Gao D, Wang G, Miao S, Wu H, Li J, Bao X (2014) Cobalt nanoparticles encapsulated in nitrogen-doped carbon as a bifunctional catalyst for water electrolysis. J Mater Chem A 2(47):20067–20074. https://doi.org/10.1039/C4TA04337E

Wang X, Cao L, Yang S-T, Lu F, Meziani MJ, Tian L, Sun KW, Bloodgood MA, Sun Y-P (2010b) Bandgap-like strong fluorescence in functionalized carbon nanoparticles. Angew Chem Int Edit 49(31):5310–5314. https://doi.org/10.1002/anie.201000982

Wingfield WE, Raffe MR (2002) The veterinary ICU book. Teton NewMedia, USA

Xu R, Xie T, Zhao Y, Li Y (2007) Quasi-homogeneous catalytic hydrogenation over monodisperse nickel and cobalt nanoparticles. Nanotechnology 18(5):55602. https://doi.org/10.1088/0957-4484/18/5/055602

Xu Y, Mahmood M, Li Z, Dervishi E, Trigwell S, Zharov VP, Ali N, Saini V, Biris AR, Lupu D, Boldor D, Biris AS (2008) Cobalt nanoparticles coated with graphitic shells as localized radio frequency absorbers for cancer therapy. Nanotechnology 19(43):435102. https://doi.org/10.1088/0957-4484/19/43/435102

Yang J, Liu H, Martens WN, Frost RL (2010) Synthesis and characterization of cobalt hydroxide, cobalt oxyhydroxide and cobalt oxide nanodiscs. J Phys Chem C 114(1):111–119. https://doi.org/10.1021/jp908548f

Yang Z, Cavalier M, Walls M, Bonville P, Lisiecki I, Pileni M-P (2012) A phase-solution annealing strategy to control the cobalt nanocrystal anisotropy: structural and magnetic investigations. J Phys Chem C 116(29):15723–15730. https://doi.org/10.1021/jp303182n

Yaylayan VA, Harty-Majors S, Ismail AA (1998) Investigation of the mechanism of dissociation of glycolaldehyde dimer (2,5-dihydroxy-1,4-dioxane) by FTIR spectroscopy. Carbohydr Res 309(1):31–38. https://doi.org/10.1016/S0008-6215(98)00129-3

Yeo BS, Bell AT (2011) Enhanced activity of gold-supported cobalt oxide for the electrochemical evolution of oxygen. J Am Chem Soc 133(14):5587–5593. https://doi.org/10.1021/ja200559j

Yoon H, Xu A, Sterbinsky GE, Arena DA, Wang Z, Stephens PW, Meng YS, Carroll KC (2015) In situ non-aqueous nucleation and growth of next generation rare-earth-free permanent magnets. Phys Chem Chem Phys 17(2):1070–1076. https://doi.org/10.1039/C4CP04451G

Zeisberger M, Dutz S, Müller R, Hergt R, Matoussevitch N, Bönnemann H (2007) Metallic cobalt nanoparticles for heating applications. J Magn Magn Mater 311(1):224–227. https://doi.org/10.1016/j.jmmm.2006.11.178

Zhu H, Tao J, Dong X (2010) Preparation and photoelectrochemical activity of Cr-doped TiO2 nanorods with nanocavities. J Phys Chem C 114(7):2873–2879. https://doi.org/10.1021/jp9085987

Zhu W, Ren J, Gu X, Azmat MU, Lu G, Wang Y (2011) Synthesis of hermetically-sealed graphite-encapsulated metallic cobalt (alloy) Core/shell nanostructures. Carbon 49(4):1462–1472. https://doi.org/10.1016/j.carbon.2010.12.016

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kotoulas, A., Dendrinou-Samara, C., Sarafidis, C. et al. Carbon-encapsulated cobalt nanoparticles: synthesis, properties, and magnetic particle hyperthermia efficiency. J Nanopart Res 19, 399 (2017). https://doi.org/10.1007/s11051-017-4099-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-017-4099-9