Abstract

Carbon nanotubes (CNTs), including single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs), are considered to be the promising candidates for next-generation interconnects with excellent physical and chemical properties ranging from ultrahigh mechanical strength, to electrical properties, to thermal conductivity, to optical properties, etc. To further study the interfacial contact configurations of SWNT-based nanodevice with a 13.56-Å diameter, the corresponding simulations are carried out with the molecular dynamic method. The nanotube collapses dramatically into the surface with the complete collapse on the Au/Ag/graphite electrode surface and slight distortion on the Si/SiO2 substrate surface, respectively. The related dominant mechanism is studied and explained. Meanwhile, the interfacial contact configuration and behavior, depended on other factors, are also analyzed in this article.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Scaling down of the current Cu interconnect is inevitable for higher integration density and higher performance requirements according to the Moore’s law. Unfortunately, according to the International Technology Roadmap for Semiconductors (ITRS), the complementary metal oxide-semiconductor (CMOS) fabrication technology, especially in 14 nm and below by “top-down” nanolithography method, has been constrained by diffraction limit of light, which fails to meet the fabrication requirements of the next-generation nano-electronic device. And with the decrease of the size of Cu interconnect, electro-migration phenomenon becomes more and more obvious with increasing the current density, which could cause the damage and failure of nanocircuits with performance degradation (Ceyhan and Naeemi 2013; Subash et al. 2013). Although vigorous and unfettered, yet the carbon nanotubes (CNTs) including single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs), as the emerging materials fabricated by “bottom-up” method, are considered to be the promising candidates for next-generation interconnects with excellent physical and chemical properties ranging from ultrahigh mechanical strength, to electrical properties, to thermal conductivity, to optical properties, etc. (Iijima, 1991; Fuhrer et al. 2000; Close et al. 2008; Malapanis et al. 2013).

Recently, De Volder et al. summarized the present and future worldwide commercial interest of CNTs from the perspective of multiscaling: nano–micro–macro (De Volder et al. 2013). And, as for the frontier research of CNTs in various countries, extensive investigations, especially those on SWNT-based nano-electronic devices such as single-electron transistors and field-effect transistors, have been experimentally carried out to obtain attractive and unique applications in many fields (Do et al. 2015; Cui et al. 2015; Geier et al. 2015; Laird et al. 2015) based on the advanced and reliable synthesis research of CNTs and composites (Manikandan et al. 2010; Motaung et al. 2010; Thangavel et al. 2012). However, as the SWNT-based nanocircuits, the interfacial contact characteristics between SWNTs and the surface of substrate or electrode, which may bring some impacts on the subsequent electrical properties, are difficult to observe experimentally. But the molecular dynamic (MD) simulation provides a powerful tool to present dynamical evolution and final atomic configuration in a realistic manner (Krasheninnikov et al. 2002; Terrones et al. 2002; Jang et al. 2004; Cui et al. 2014; Ma et al. 2015). And as SWNT-based nanocircuits, the achievements about the covalent and noncovalent connection between SWNTs were reported to reveal the atomic configurations of different nanojunctions with the atomistic simulations (Krasheninnikov et al. 2002; Terrones et al. 2002; Jang et al. 2004). Unfortunately, to date, little is known regarding the atomistic simulations about interfacial contact configuration between SWNTs and the surface of substrate or electrode. Thus, on this account, we present the interfacial contact evolution behavior and configuration. In addition, the dominant mechanism and detailed structural characteristic are analyzed and discussed on the basis of a series of MD simulation results.

Computational methodology

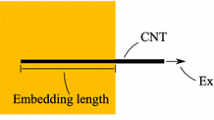

As the SWNT-based nanodevice, Si and Au materials, respectively, are usually selected as the substrate surface and metal electrode. Then, to reveal the interfacial interaction between SWNTs and surface, we present the atomistic schematic diagram of initial interface situation in Fig. 1, with a SWNT positioning on the surface of Si substrate and Au electrode. In addition, considering the actual height situation between substrate and electrode as SWNT-based nanodevice, the Au electrode surface is slightly higher than the substrate surface. For the unmodified SWNTs, involved in the MD simulations, the hybrid orbital of each carbon atom is sp 2 with the same C–C atomic bond length of 1.42 Å. And the Si substrate and Au electrode have the 3D cubic lattice type with the lattice parameter of 5.4307 Å × 5.4307 Å × 5.4307 Å and 4.0783 Å × 4.0783 Å × 4.0783 Å, respectively.

The MD simulations have been performed by DISCOVER module of MATERIALS STUDIO software, which was developed by Accelrys Software Inc. And as for the MD simulation, the key of calculation is the selection of interatomic force field, which determines the work load, accuracy of results, and the approximate extent between the calculation model and the real system. Thus, all the MD simulations are implemented by the powerful Condensed-phase Optimized Molecular Potentials for Atomistic Simulation Studies (COMPASS) force field. It is a parameterized, tested, and validated first ab initio force field, which enables an accurate and simultaneous prediction of structural, conformational, vibrational, and thermophysical properties of condensed matter physics (Cui et al. 2016a, b, 2013a, b; Sun 1994; Yan et al. 2009). The total energy E total includes potential energy E potential and kinetic energy E kinetic, which can be described as follows:

And the total potential energy E potential can be expressed by the following terms:

Here, the E bond, E angle, E torsion, E oop, and E UB, included the valence energy E valence, represent the bond stretching term, two-bond angle term, dihedral bond-torsion term, out-of-plane interaction term, and Urey-Bradlay term, respectively. The cross-term interacting energy E cross-term explains the effects such as bond changes or angle distortions determined by surrounding atoms. And the different energy term E bond-bond, E angle-angle, E bond-angle, E end-bond-torsion, E middle-bond-torsion, E angle-torsion, and E angle-angle-torsion, respectively, gives the stretch-stretch interaction between two adjacent bonds, bend-bend interaction between two valence angles, stretch-bend interaction between a two-bond angle and one of the bonds, stretch-torsion interaction between a dihedral angle and one of the end bonds, stretch-torsion interaction between a dihedral angle and the middle bond, bend-torsion interaction between a dihedral angle and one of the valence angles, and the bend-bend-torsion interaction between a dihedral angle and its two valence angles. In addition, the non-bond energy E non-bond, containing the Lennard-Jones (LJ) 9–6 potential function for the van der Waals interaction term E vdW, a Coulomb term for electrostatic interaction E Coulomb, and the hydrogen bond energy E H-bond, accounts for the interaction between non-bond atoms.

After selecting the interatomic force field, the cutoff distance of interaction was set to 9.5 Å. Considering the MD simulations aim at exploring the evolution and characteristics of interfacial contact configuration between SWNT and the surfaces of the substrate and electrode, the positions and motions of all Si and Au atoms were constrained in the x, y, and z directions. Meanwhile, combining the structural features and size effect of SWNT, the non-periodic boundary conditions were imposed on x, y, and z directions of simulation box. Then, the MD simulations were carried out under the constant NVT (N is the number of atoms, V represents the volume, T gives the temperature) ensemble, and the Andersen thermostat was chosen in the simulation. In addition, because the energy is changed through the so-called thermal process, the initial random velocities of all atoms were set according to Maxwell-Boltzmann distribution, which is statistics about a large number of atoms with greater fluctuation of simulation results. In order to make atoms to balance as soon as possible, the Velocity Verlet was selected as the integration method and the fixed time step of 2 fs was set in all cases. In the MD simulation, to obtain the stable and accurate atomic configurations and physical data, the total simulation time was set to 500 ps for the adequate interaction of all atoms, and the coordinates and velocities of all atoms were stored and output every 5000 steps.

Results and discussion

Depending on the helicity of CNTs, a CNT can be either metallic or semiconducting and a 147.57-Å-long metallic SWNT (10, 10) was selected with the diameter of 13.56 Å in MD simulations. And configuration size of Si substrate and Au electrode, shown in Fig. 1, was set to 76.802 Å × 57.601 Å × 9.696 Å and 43.257 Å × 57.676 Å × 6.285 Å in x, y, and z directions, respectively. Then, based on the initial interface situation of SWNT-based nanodevice in Fig. 1, the MD simulations were performed at the temperature of 500 K, which is slightly lower than the standard soldering temperature, showing the special interfacial contact configurations in Fig. 2.

Comparing the configurations in Fig. 2 and initial Fig. 1, the nanotube collapses dramatically into the surface of Si substrate and Au electrode. As the total collapse configuration of SWNT in the x-z plane of Fig. 2, the middle part on the Si surface has smaller collapse degree than the situations at two ends. According to the simulation result, a relatively small deformation occurs, with the diameter varying from 13.56 to ∼10.475 Å in the middle of SWNT on the Si substrate surface. More seriously, both ends of SWNT collapse with larger diameter deformation from 13.56 Å to ∼5.219 or 5.238 Å, forming similar nanosheet structures. As for the both ends of SWNT, if the distance is measured from the average center position of upper C atoms to that of lower C atoms, the size of 3.707 Å can be obtained in the x-z plane and y-z plane, which is similar to the 0.34-nm spacing between two adjacent C atomic layers of MWNTs with the π-π stacking, indicating that the both ends of SWNT collapse completely. Based on the size decrease of SWNT in the radial direction perpendicular to electrode surface, the size of SWNT, parallel to x-y plane, accordingly becomes larger with increasing the interfacial contact area on the material surface. In the x-y plane of Fig. 2, similar nanosheet structures have similar width with 19.764 Å in the left part and 19.603 Å in the right part. And the extent of SWNT collapse gradually weakens from the both ends to the central part with the smaller radial size of 15.709 Å in the y direction, maintaining good tubular structure as the central part of SWNT. In addition, because the Au electrode is slightly higher than the Si substrate in z direction, the central part of SWNT sinks to the Si surface to adapt to the surrounding nanostructural characteristic situation, under the premise of the stronger thermal motion of the all C atoms at the temperature of 500 K, which shortens the current SWNT length 4.058 Å. Overall, the SWNT presents the special interfacial contact configuration with its special atomic structure.

Next, enormous efforts have been taken to explore the reason why the special interfacial contact configuration and its special atomic structure will appear as the final atomic configuration of SWNT-based nanodevice when the same SWNT is positioned on the different material surface. To reveal the dominant mechanism, the same SWNT was respectively positioned on the surface of Au and Si materials as the initial atomic configurations in Fig. 3, to avoid the influence of uncertainties. And, in the separated simulation systems of SWNT-Au and SWNT-Si, the SWNTs on the surface of Au and Si materials with similar dimensions have the same (10, 10) armchair form, the diameter of 13.56 Å, and length of 61.49 Å. According to the above MD simulation parameters in Fig. 2, the separated systems of SWNT-Au and SWNT-Si were carried out at the temperature of 500 K, with a series of simulation results about the instantaneous atomic configurations in Fig. 3. In the y-z plane, combining the interfacial contact configurations in Fig. 3a and Fig. 3b, they still have similar atomic structures with that in Fig. 2. In the SWNT-Au system, the SWNTs have collapsed completely at the time of 10 ps, becoming the nanosheet composed of bilayer graphene. And no special differences are manifested with similar structures of SWNTs at the different time of 10, 50, 100, 200, and 500 ps. By carefully observing the position of SWNT in y and x direction, the SWNT moves slightly towards the −x and −y direction, which may be related to the random thermal motions of all C atoms. By contrast, the SWNT on the Si substrate has a slight deformation of collapse keeping good cylindrical structure, and the SWNT rotates slightly along the z axis in the x-y plane. About the different interfacial contact configuration, self-structure, and motion behavior, the systems of SWNT-Au and SWNT-Si were analyzed from an energetic standpoint.

As the initial and final atomic configurations of SWNT-Au and SWNT-Si systems in Fig. 3, the total energy, potential energy, and kinetic energy are obtained in Table 1. Although the initial energy and final energy are different in the separated SWNT-Au and SWNT-Si systems based on the different number of Au and Si atoms, the energy difference between the initial and final energy is associated with the change of SWNT configuration, eliminating the influence of different energy components of all constrained Au and Si atoms, respectively. Due to the same simulation temperature, the SWNT-Au and SWNT-Si systems have similar kinetic energy, with very slight differences caused by initial random atoms’ motions and not very accurate final temperature 500 K within the margin of error of approximately 1 K in the MD simulation process. So according to formula (1), the SWNT configurations affected by the total energy almost entirely depend on the potential energy. Then, Table 2 firstly provides the corresponding potential components of the SWNT-Au and SWNT-Si systems for the initial and final state, with similar energy differences between −672.626 and −722.677 kcal/mol in the stage of energy minimization for getting the optimized atomic configuration. In the MD simulations, the total potential energy is mainly composed of internal energy and non-bond energy, while the internal energy mainly consists of the valence energy E valence and the cross-term interacting energy E cross-term. In addition, because the value of the Coulomb energy E Coulomb and the hydrogen bond energy E H-bond is respectively zero in the MD simulations, the non-bond energy E non-bond completely equals to the van der Waals interaction energy E vdW according to Eq. (5). From the small differences of different energy terms in the different SWNT-Au and SWNT-Si systems in Table 2, the main factors that greatly change atomic configurations cannot be identified in the stage of energy minimization.

Subsequently, with the MD simulations of interactions between atoms after the minimization, the initial and final energy data were extracted and the specific main internal energy and non-bond energy (vdW energy) components are listed in Tables 3 and 4, respectively. As the three main components of E bond, E angle, and E torsion affecting the internal energy, their energy differences do not have many changes between initial and final states. By contrast, the out-of-plane interaction energy E oop has the larger difference between the SWNT-Au system and SWNT-Si system, which is related to the deformation degree of SWNT. However, to sequentially explore the main mechanism for the extent of collapse deformation, the van der Waals interaction energy E vdW is given including the repulsive and dispersive parts in Table 4. The van der Waals repulsive energy E vdW_repulsive has especially obvious difference, with the 2196.760 and 124.905 kcal/mol in the different SWNT-Au and SWNT-Si systems, respectively, and so to the van der Waals dispersive energy E vdW_dispersive. Given the SWNT collapse deformation situation on the different Au and Si substrate surfaces, due to the π-π stacking of collapsed SWNT layers, the nanotube in SWNT-Au system will cost very larger energy to be transformed back into the initial atomic configuration, than the distorted SWNT on the Si surface. Taken together, the results as the collapse SWNT forming nanosheet on the Au surface and the smaller distortion on the Si surface mainly depend on the van der Waals force between C atoms and Au or Si atoms, thus having the relatively obvious differences of the out-of-plane interaction energy E oop in different SWNT-Au and SWNT-Si systems.

In the fabrication of semiconductor nanodevices, the other metallic electrode such as Ag material will also be selected with excellent electrical properties. So, the SWNT is positioned on the Ag surface and the collapse situation still exists at the temperature of 500 K, which is shown in Fig. 4a. Because the Au and Ag materials have similar lattice structures and metallic features, the van der Waals force including the repulsive and dispersive force becomes the dominant factor for SWNT collapse, which is different from the above distortion situation on the semiconductor Si material surface with weaker van der Waals force. Additionally, some substances are also usually selected as electrode materials, which are not the metal materials but possess the metallic properties. Graphite is such a favorable material with metallicity, which can be seen as the laminated graphene. With its excellent electrical properties, the graphite is often used as an electrode material. Then, if the graphite is selected as the electrode and the SWNT is positioned on its surface, the interfacial contact configuration is also simulated and shown in Fig. 4b. Similar collapse structures still appear, which is similar to the situation of SWNT on Au or Ag electrode surface and maybe related to the strong interactions between the C atoms of SWNT and the C atoms of graphite electrode, showing large van der Waals energy fluctuations between the initial and final state. Simultaneously, the formed nanosheet structure on the graphite surface rotates along z axis, which is similar to the rotation situation of SWNT on the Si substrate surface, and is different from the glide characteristics of SWNT on the Au or Ag surface. Considering that Si material is prone to form silicon oxide and most of circuits are made with SiO2 in nanodevices, the interfacial contact behavior and atomic configuration of SWNT on SiO2 surface were also simulated with the result in Fig. 4c. The collapse does not happen with only very small deformation, keeping the good cylindricity and slight slip behavior, which is similar to the situation of SWNT on Si substrate surface. The above research indicates that the collapse phenomenon will appear when the SWNT is positioned on the metallic material surface or graphite surface with metallicity, due to large van der Walls force interaction. And by contrast, slight deformation compared with the pristine cylinder structure can turn up when the SWNT is on the semiconductor Si or SiO2 surface, maintaining the good rigidity. Imagine, though, that whether other factors will affect the SWNT structure on Si or SiO2 surface, like the situation of SWNT on Au, Ag, or graphite surface. From the above MD simulation study, taking the metallicity of armchair SWNT (10, 10) into account, the semiconducting (17, 0) zigzag and (12, 8) chiral nanotubes were selected in the simulations about SWNT-Si system, in order to continue the in-depth study about atomic configuration of SWNT. And the related MD simulations were performed with the results in Fig. 5.

In Fig. 5, visibly, the two nanotubes still retain good cylindricity and rigidity, which is similar to the situation of metallic (10, 10) armchair SWNT on the Si substrate surface. As may be gathered from this, the properties of SWNT cannot greatly change the effect of van der Waals between C and Si atoms. Consequently, it is very fortunate because slightly distorted SWNT will continue to keep the good electrical and thermal properties on the Si or SiO2 substrate surface. In addition, the different behaviors of SWNT will appear with move in the x-y plane or/and rotation along z axis on different material surface, which may depend on the thermal dynamic performance of C atoms of SWNT and the properties of material surface. And the thermal dynamic property of atoms is related to the temperature. So, taking the SWNT on the Si substrate surface as example, the corresponding SWNT behavior is given at the different temperature in Fig. 6. As a whole, with the temperature rising, the SWNT structure has stable rigidity with slight deformation. However, at higher temperature, the C atoms own stronger thermal dynamic property, and the SWNT strongly moves with larger off-center placement of Si substrate in x-y plane. But the directional movement of SWNT is random, which may depend on the random thermal motion of C atoms and the following interaction force between C and Si atoms. At the same time, combining the atomic configuration in Fig. 2, the SWNT movement behavior will be limited due to the effect of interfacial contact configuration between the SWNT and electrode, which therefore does not affect the circuit performance.

Conclusions

In summary, from the atomistic simulations, the investigation of the interfacial contact configurations of SWNT-based nanodevice is carried out with the molecular dynamic method. The nanotube collapses dramatically into the surface of Si substrate and Au electrode with different deformation degree, and the complete collapse and slight distortion are studied in the separated SWNT-Au and SWNT-Si system, respectively. Analyzing this from an energetic standpoint, the different deformation degree is determined by different van der Waals energy, which includes the repulsive and dispersive components. And if the Au electrode is replaced by the Ag or graphite material, the collapse phenomenon still exists under strong van der Waals force. The nanotube only has slight deformation when SWNT is positioned on the Si or SiO2 substrate surface. Additionally, the SWNT may have even movement and rotation in 2D plane, depending on the random thermal motion of C atoms and the following interaction between C atoms and other atoms, which is greatly related with the temperature. And learning from the random behavior of SWNT affected by the temperature, it may become a driving method of carbon nanotubes. Reassuringly, the SWNT movement behavior will be limited due to the effect of interfacial contact configuration between the SWNT and electrode, which therefore does not affect the circuit performance of SWNT-based nanodevice.

References

Ceyhan A, Naeemi A (2013) Cu interconnect limitations and opportunities for SWNT interconnects at the end of the roadmap. IEEE Trans Electron Devices 60:374–382

Close GF, Yasuda S, Paul B, Fujita S, Wong HSP (2008) A 1 GHz integrated circuit with carbon nanotube interconnects and silicon transistors. Nano Lett 8:706–709

Cui J, Yang L, Wang Y (2013a) Nanowelding configuration between carbon nanotubes in axial direction. Appl Surf Sci 264:713–717

Cui J, Yang L, Wang Y (2013b) Molecular dynamics study of the positioned single-walled carbon nanotubes with T-, X-, Y-junction during nanoscale soldering. Appl Surf Sci 284:392–396

Cui J, Yang L, Zhou L, Wang Y (2014) Nanoscale soldering of axially positioned single-walled carbon nanotubes: a molecular dynamics simulation study. ACS Appl Mater Interfaces 6:2044–2050

Cui J, Yang L, Wang Y, Mei X, Wang Y, Hou C (2015) Nanospot soldering polystyrene nanoparticles with an optical fiber probe laser irradiating a metallic AFM probe based on the near-field enhancement effect. ACS Appl Mater Interfaces 7:2294–2300

Cui J, Theogene B, Wang X, Mei X, Wang W, Wang K (2016a) Molecular dynamics study of nanojoining between axially positioned Ag nanowires. Appl Surf Sci 378:57–62

Cui J, Wang X, Theogene B, Mei X, Wang W, He X (2016b) Nanojoining of crossed Ag nanowires: a molecular dynamics study. J Nanopart Res 18:175

De Volder MFL, Tawfick SH, Baughman RH, John Hart A (2013) Carbon nanotubes: present and future commercial applications. Science 339:535–539

Do JW, Chang NN, Estrada D, Lian F, Cha H, Duan XJ, Haasch RT, Pop E, Girolami GS, Lyding JW (2015) Solution-mediated selective nanosoldering of carbon nanotube junctions for improved device performance. ACS Nano 9:4806–4813

Fuhrer MS, Nygård J, Shih L, Forero M, Yoon YG, Mazzoni MSC, Choi HJ, Ihm J, Louie SG, Zettl A, McEuen PL (2000) Crossed nanotube junctions. Science 288:494–497

Geier ML, McMorrow JJ, Xu W, Zhu J, Kim CH, Marks TJ, Hersam MC (2015) Solution-processed carbon nanotube thin-film complementary static random access memory. Nat Nanotechnol 10:944–948

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Jang I, Sinnott SB, Danailov D, Keblinski P (2004) Molecular dynamics simulation study of carbon nanotube welding under electron beam irradiation. Nano Lett 4:109–114

Krasheninnikov AV, Nordlund K, Keinonen J, Banhart F (2002) Ion-irradiation-induced welding of carbon nanotubes. Phys Rev B 66:245403

Laird EA, Kuemmeth F, Steele GA, Grove-Rasmussen K, Nygård J, Flensberg K, Kouwenhoven LP (2015) Quantum transport in carbon nanotubes. Rev Mod Phys 87:703–764

Ma M, Grey F, Shen L, Urbakh M, Wu S, Liu JZ, Liu Y, Zheng Q (2015) Water transport inside carbon nanotubes mediated by phonon-induced oscillating friction. Nat Nanotechnol 10:692–695

Malapanis A, Perebeinos V, Sinha DP, Comfort E, Lee JU (2013) Quantum efficiency and capture cross section of first and second excitonic transitions of single-walled carbon nanotubes measured through photoconductivity. Nano Lett 13:3531–3538

Manikandan E, Moodley MK, Ray SS, Panigrahi BK, Krishnan R, Padhy N, Nair KGM, Tyagi AK (2010) Zinc oxide epitaxial thin film deposited over carbon on various substrate by pulsed laser deposition technique. J Nanosci Nanotech 10:5602–5611

Motaung DE, Moodley MK, Manikandan E, Coville NJ (2010) In situ optical emission study on the role of C2 in the synthesis of single-walled carbon nanotubes. J Appl Phys 107:044308

Subash S, Kolar J, Chowdhury MH (2013) A new spatially rearranged bundle of mixed carbon nanotubes as VLSI interconnection. IEEE Trans Nanotechnol 12:3–12

Sun H (1994) Force field for computation of conformational energies, structures, and vibrational frequencies of aromatic polyesters. J Comput Chem 15:752–768

Terrones M, Banhart F, Grobert N, Charlier JC, Terrones H, Ajayan PM (2002) Molecular junctions by joining single-walled carbon nanotubes. Phys Rev Lett 89:075505

Thangavel S, Manikandan E, Venugopal G (2012) Synthesis and properties of tungsten oxide and reduced graphene oxide nanocomposites. Mater Exp 2:327–334

Yan K, Xue Q, Xia D, Chen H, Xie J, Dong M (2009) The core/shell composite nanowires produced by self-scrolling carbon nanotubes onto copper nanowires. ACS Nano 3:2235–2240

Acknowledgements

This project was supported by the National Natural Science Foundation of China (51505371, 11372264), Hong Kong Scholars Program (XJ2015038), China Postdoctoral Science Foundation (2014M562397, 2015T81018), a research grant from the Research Grants Council of the Hong Kong Special Administrative Region, China (CityU 114013), Program for Changjiang Scholars and Innovative Research Team in University (IRT_15R54), State Key Laboratory of Robotics and System (HIT) (SKLRS-2016-KF-13), and State Key Laboratory of Surface Physics and Department of Physics, Fudan University (KF2016_11).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Cui, J., Zhang, J., He, X. et al. Investigating interfacial contact configuration and behavior of single-walled carbon nanotube-based nanodevice with atomistic simulations. J Nanopart Res 19, 110 (2017). https://doi.org/10.1007/s11051-017-3811-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-017-3811-0