Abstract

As carbon nanotubes (CNTs) are widely used in various applications, exposure assessment also increases in importance with other various toxicity tests for CNTs. We conducted 24-h continuous nanoaerosol measurements to identify possible nanomaterial release in a single-walled carbon nanotube (SWCNT) manufacturing workplace. Four real-time aerosol instruments were used to determine the nanosized and microsized particle numbers, particle surface area, and carbonaceous species. Task-based exposure assessment was carried out for SWCNT synthesis using the arc plasma and thermal decomposition processes to remove amorphous carbon components as impurities. During the SWCNT synthesis, the black carbon (BC) concentration was 2–12 μg/m3. The maximum BC mass concentrations occurred when the synthesis chamber was opened for harvesting the SWCNTs. The number concentrations of particles with sizes 10–420 nm were 10,000–40,000 particles/cm3 during the tasks. The maximum number concentration existed when a vacuum pump was operated to remove exhaust air from the SWCNT synthesis chamber due to the penetration of highly concentrated oil mists through the window opened. We analyzed the particle mass size distribution and particle number size distribution for each peak episode. Using real-time aerosol detectors, we distinguished the SWCNT releases from background nanoaerosols such as oil mist and atmospheric photochemical smog particles. SWCNT aggregates with sizes of 1–10 μm were mainly released from the arc plasma synthesis. The harvesting process was the main release route of SWCNTs in the workplace.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At an industrial scale, nanomaterials can be produced and used in high volumes with relatively uniform composition and characteristics in a given occupational environment (Ramachandran et al. 2011). The commercial market for carbon nanotube (CNT) and carbon nanofiber (CNF) is expected to grow substantially over the next decade (Lux Research 2007) with global capacity in 2013 estimated to be 2,000 tons/year for multi-walled carbon nanotubes (MWCNTs) and 6 tons/year for single-walled carbon nanotubes (SWCNTs) (Nanotech 2013). Moreover, SWCNTs and MWCNTs are attractive for use in many industrial applications. However, many in vivo studies provide inconsistent evidence on the degree of pulmonary and extrapulmonary toxicities (Shvedova et al. 2008; Ma-Hock et al. 2009; Pauluhn 2010) of these SWCNTs and MWCNTs. In vitro studies with human lung cells (Muller et al. 2008; Sargent et al. 2009, 2011) showed that SWCNTs can cause genotoxicity and result in abnormal chromosome number by interfering with mitosis (cell division). The most significant exposures and risks will likely be in the occupational arena, and an estimated two million new workers will be exposed to engineered nanomaterials (ENMs) in occupational environments over the next 15 years (Ramachandran et al. 2011). An important measure to protect the health of workers against hazardous substances in the workplace is to minimize inhalation exposure.

Various exposure assessment studies for CNT workplaces have been carried out. Maynard et al. (2004) assessed the susceptibility of SWCNTs to be released during the agitation of unprocessed SWCNT material in a laboratory-based study and during the handling (e.g., powder from furnace, powder transfer, and cleaning) of unrefined material at four small-scale SWCNT manufacturing facilities. The concentration, size, shape, and number of airborne tubular MWCNTs released in a research facility have been measured via personal and area air sampling, and also by real-time aerosol monitoring (Han et al. 2008; Lee et al. 2010a). Scanning mobility particle sizer (SMPS), aerodynamic particle sizer (APS), and optical particle counter (OPC) have been used to measure number-based particle size distributions. Due to high aspect ratios, SWCNTs and MWCNTs respond to wide particle size range of both SMPS and APS or OPC (Maynard et al. 2004; Lee et al. 2010b). An aethalometer has been used to monitor the mass concentration of black carbon (BC) particles in a MWCNT manufacturing workplace (Han et al. 2008; Evans et al. 2010; Lee et al. 2010a), thereby allowing the characterization of the chemical composition of atmospheric aerosols (Park et al. 2002) and the tracing of combustion sources in diesel-fueled vehicles (Fruin et al. 2004). However, the lab scale workplace or a research laboratory in a university or institute is not well controlled for protecting nanomaterial emissions. In some well-controlled mass production workplaces, it is not easy to find evidence of MWCNT emission. On the other hand, low concentrations of nanomaterials are easily detected as being emitted from a spraying chamber into the MWCNT handling workplace in a cleanroom. The level of particles reaching the workplace was sufficiently low to make their detection difficult in a normal environment (Ji et al. 2013). The National Institute for Occupational Safety and Health (NIOSH) conducted emission and exposure assessment studies at 12 sites where ENMs were produced or used (Methner et al. 2010). The purpose of the studies was to determine whether airborne exposures to these ENMs occur and to assess the capabilities of various measurement techniques in quantifying exposures. However, most studies provided raw data from real-time detectors, which did not explain the mechanisms or evidence of CNT source generation.

A complication related to ambient airborne particles, other nanoaerosol sources at workplaces, and the difficulties for the real-time instruments, has to distinguish between task- or process-related emissions from target nanomaterials and background nanoaerosols. While identifying the sources, it becomes necessary to distinguish between ENMs and incidental nanomaterials (Peters et al. 2008).

This work reports on the release characteristics of nanomaterials in a SWCNT workplace. For the time-dependent release characterization, particles’ number and surface area concentrations were monitored using an SMPS, an OPC, and a nanoparticle aerosol monitor (NAM). An aethalometer was used to assess the mass concentration of BC particles, and a particle collector was employed to gather particles to study their shapes and compositions. We propose a source estimation process for the discrimination of the nanomaterial sources by selecting the peak episode data measured by the real-time aerosol detectors. For each peak episode, we analyzed the change in particle mass distributions as well as the particle number distributions from SMPS and OPC data. The mass concentrations calculated by SMPS were obtained for the size range of 10–420 nm under an assumption of particle density of 1 g/cm3. For the OPC, the mass concentration was calculated to be between 0.25 and 10 μm. We attempted to identify the nanoparticle sources in order to determine whether the nanoparticles were emitted from process-related SWCNT or other incidental (or background) nanoparticles.

Materials and methods

Sampling site

The sampling site was a SWCNT manufacturing workplace where SWCNTs were produced by arc plasma synthesis. As shown in Fig. 1, measurements were made at two monitoring positions on May 30 and 31, 2013. Position 1 was set for measuring the SWCNT manufacturing process and position 2 for thermal purification of the manufactured SWCNT.

Real-time aerosol monitoring

We used various real-time aerosol detectors to assess the nanoaerosol release in the SWCNT manufacturing workplace. An SMPS (Nanoscan, model 3910, TSI) was used to determine the particle size distribution in the size range of 10–420 nm. It measures the particle size distribution for a total scan time of 60 s (45 s scan time, 15 s retrace). OPC (portable aerosol spectrometer, model 1.109, Grimm) was used to monitor the particle size distributions in the size range of 0.25–32 μm every 60 s. In addition, the surface area concentration of particles deposited in the alveolar regions of the lung was measured every 60 s using a NAM (model AeroTrak 9000, TSI) with PM1 cyclone. The mass concentration of BC aerosols was measured every 2 min using a portable aethalometer with PM1 cyclone (model AE42-7, Magee Scientific). Certain amount of SWCNTs may be lost due to use of PM1 cyclone. The air in the workplace was sampled at a flow rate of 0.75, 1.2, 2.5, and 2.0 L/min for the SMPS, OPC, NAM, and aethalometer, respectively. To monitor the concentrations of carbon monoxide (CO) and carbon dioxide (CO2) with temperature and relative humidity in the workplace, we used an IAQ monitor (model IQ-610Xtra, Graywolf). In Table 1, we present detailed specifications and information about the detectors used in this study. A portable particle sensor (Discmini, Matter Aerosol) and a BC sensor (aethalometer, Magee AE51) were used to check instant episodes and change between indoor and outdoor conditions. With increasing episodes of particle concentration, these portable detectors were very helpful in checking and confirming the location of the sources generating nanoparticles.

Sampling for TEM and SEM analyses

The morphology of SWCNTs was observed by transmission electron microscopy (TEM, model CM30, Philips with an accelerating voltage of 300 kV) and scanning electron microscopy (SEM, model NOVA 600, FEI with an accelerating voltage of 30 kV). Membrane filters (isopore membrane filter, pore size of 100 nm) were used for air sampling for the SEM analysis using a personal sampling pump (model GilAir Plus by 5 L/min, Gilian). For TEM image analysis, we used a nanoparticle collector (model NPC-10, HCT) which is an electrostatic precipitator with a high voltage of 9 kV. The particles sampled in air were collected on a copper TEM grid coated with a SiO film (Silicon monoxide-A, Ted Pella Inc.).

Results and discussion

SWCNT manufacturing workplace and workforce

The SWCNT manufacturing company investigated in this study is located in Korea. This company produces mainly SWCNTs by arc plasma synthesis. Figure 2 represents the manufacturing procedure for arc plasma synthesis of SWCNT. The process using arc plasma is the first method that was developed and used for CNT synthesis. SWCNTs can be grown during the arc discharge process using graphitic anode material with impregnated metal catalysts and pure graphite cathode. Table 2 shows details of the plasma arc discharge synthesis and the thermal purification process of SWCNTs. One batch process to produce SWCNTs was performed twice a day. The first task was the installation of the carbon rod as an electrode, and then helium gas was injected into the vacuum chamber. In the subsequent processes, a vacuum pump was operated to reduce the chamber pressure. Then, the arc plasma synthesis was carried out for ~1 h to manufacture SWCNTs from the carbon electrode. The process was repeated in the same batch by replacing the carbon electrode thrice (i.e., four electrodes were used). During the replacement of the old carbon electrodes, the vacuum chamber was opened and the conditions inside the chamber were visually checked by a worker. After the installation of a new carbon electrode, the vacuum pump was turned on to reduce the chamber pressure. After finishing one batch synthesis using four carbon electrodes, the SWCNTs were collected from the substrates and inner wall of the chamber.

The arc plasma synthesis can easily produce SWCNTs with a few structural defects. The manufactured SWCNTs tend to be short with random sizes and orientations; they often need to undergo extensive purification. Amorphous carbon particles as impurity were mixed with the manufactured SWCNTs. For the thermal purification process, SWCNTs were mixed and purified in a tube furnace. As explained in Table 2, this process was carried out for approximately 150 min from 14:40 p.m. on May 31, 2013. Purified SWCNTs were obtained and they were weighed and packed after the purification process.

In this SWCNT workplace, 1–2 employees could handle the collection and purification of SWCNTs during the whole day. Windows at the workplace were kept open during the synthesis for natural ventilation. This means that atmospheric aerosols with size range similar to that of the ENMs of interest may enter through the window.

Time-variant release characteristics in a SWCNT workplace

Change in particle concentrations over 2 days

The particle concentrations were measured in the SWCNT workplace for two consecutive days. First, we present the time-variant characteristics of aerosol in the workplace. Figure 3 compares the change in particle concentration with time for three real-time aerosol detectors, number concentration of an SMPS, surface area concentration of a NAM, and BC mass concentration of an aethalometer. As shown in Fig. 3a, the diurnal variation of particle number concentration over a day is different on different days. The number concentration of particles ranging from 10 to 420 nm in diameter ranged between 10,000 and 40,000 particles/cm3 in this SWCNT workplace on May 30, 2013. On the other hand, it was 10,000–25,000 particles/cm3 on May 31, 2013. The particle number concentration rapidly increased after 12:00 pm on May 30. We estimated that was due to the photochemical smog on the first sunny day, while the next day, there was no photochemical smog because of cloudy weather. Many researchers have reported that the high number concentrations of particles on sunny days in summer are due to photochemical smog (Woo et al. 2001; Watson et al. 2006); the photochemical smog results from the chemical reaction of nitrogen oxides with volatile organic compounds in the atmosphere under intense sunlight, which produces airborne particles and ground-level ozone. It is present in all modern cities, but it is more common in cities with sunny, warm, dry climates, and a large number of motor vehicles (Miller 2002).

Figure 3b shows the surface area concentrations of particles in the workplace over 2 days. Unlike the particle number concentration from SMPS, the concentration over the particle surface area shows very similar trends for 2 days. This indicates that nanoparticles generated from photochemical smog do not affect the total surface area concentrations of particles in the workplace air.

Figure 3c shows the BC concentrations throughout a day for 2 days. Diurnal variations of BC concentrations are very similar for the 2 days except for the episodes of rapidly increasing concentrations within short durations. The BC concentration was affected mainly by diesel emissions in the atmosphere in the trend of day time scale. BC concentration increased rapidly from 3 to 7 µg/m3 from 6:00 a.m. to 9:00 a.m. and then decreased over time. The cause of the high concentration of BC in the morning was the rush hour traffic (Shi et al. 1999). The BC concentration in this workplace was similar to the general atmospheric concentration of about 4.5–10.5 µg/m3 in Seoul (Park et al. 2002). Rapid increase occurred periodically during the work processes.

Figure 3d shows no relation between the BC mass concentration and the particle number concentration. It implies that variation of BC mass concentration is irrespective of photochemical smog.

Comparison of data measured by SMPS, NAM, OPC, and aethalometer for a day

Figure 4 shows the changes in the concentrations of particles measured by SMPS, NAM, OPC, and aethalometer from 07:00 a.m. to 19:00 p.m. on May 30 and 31. Unlike May 30, data from four real-time aerosol detectors changed via a similar pattern throughout the day on May 31. Photochemical smog in the atmosphere is a very important factor in the analysis of the nanomaterial release in a workplace. The SMPS data on May 30 show a different pattern except for several peak episodes due to photochemical smog. However, many rapidly increasing peak episodes measured by the four real-time detectors were found periodically during the SWCNT synthesis processes. The increasing episodes were observed by all four detectors or by some detectors.

Because the BC concentration measured by an aethalometer was based on mass, the number-based data of SMPS and OPC were converted to mass-based data. Figure 5 shows the change in particle mass concentrations measured by SMPS, OPC, and aethalometer during the working hours of 2 days. In comparison to Fig. 4, peak episodes of OPC data appeared more clearly. Generally, peak concentrations on May 30 were much higher than those on May 31.

The origins of the peak episodes need to be analyzed. In the following section, an analysis process is discussed using the information of the particle size distributions of the real-time aerosol detectors.

Task-based release characteristics and peak episode analysis from the change in particle size distributions (SMPS and OPC)

In this section, we suggest an analysis process using real-time aerosol detectors for the release characterization of an SWCNT workplace in a general indoor environment. We attempted to investigate the three batch processes of arc plasma syntheses and one thermal purification process. We selected peak episodes that showed the rapidly increasing concentration characteristics. Because of the loss of some data due to detectors’ error, all the process conditions could not be analyzed thoroughly. Nevertheless, we could clearly discriminate the peak episodes in the measured data. The source analysis for SWCNT was made by investigating the changes in the particle size distributions measured using the SMPS and OPC, and the change in BC mass concentration measured using the aethalometer. To compare with the mass basis of the aethalometer, we used the mass concentration data, which were calculated with SMPS and OPC software. Additional SEM and TEM images were also helpful in confirming SWCNT release.

Characteristics of particle size distribution during the day time

Prior to source analysis, we investigated the particle size distribution of background particles except SWCNTs. As shown in Fig. 3a, diurnal variations of the particle number concentration were different for 2 days. Figure 6a and b shows the particle size distributions and concentration contours with time measured by SMPS on May 30 and 31, respectively. When the photochemical smog occurred on May 30, nanoparticles were formed and grew to bigger particles with time as shown in Fig. 6a. The mode diameters of two peak episodes were about 20 and 100 nm. From the contour graph, the growth phenomena of nanoparticles appeared after 12:00 p.m. The background particle size distributions with time were very similar to those on May 31, as shown in Fig. 6b. The peak mode diameter was nearly unchanged at about 100 nm during the working hours. The nanoparticles formed from photochemical smog should be considered as background incidental particles. It is necessary to distinguish between the target nanomaterials from the process-related emissions and the background or incidental nanoparticles.

Release characteristics from arc plasma process

As described in Table 2, one batch of SWCNT synthesis using arc plasma needs the exchange of four carbon electrodes. It took about 1 h for each carbon electrode. Because the replacement of carbon electrode and SWCNT collection was made subsequently, episodes of increasing concentration appeared at almost the same timeline. As shown in Fig. 7, we selected eleven peak episodes for the SWCNT manufacturing process. The basis of SWCNT exposure was the characteristics of BC mass concentration increase measured by an aethalometer. For each peak episode, we used the calculated mass concentration data from the number-based data of SMPS and OPC. The selected eleven peak episodes show a trend of the increase in BC mass concentration measured by the aethalometer and particle mass concentration larger than 250 nm measured by the OPC. On the other hand, mass concentration of particles smaller than 420 nm measured by SMPS increased via six peak episodes. From just this information alone, we could not determine the SWCNT release from all of the peak episodes. However, we assumed that most SWCNTs were released as aggregates or powder formed from the carbon electrode exchange process. In particular, for the two peak episodes of P3 and P11, the BC concentration increased substantially and rapidly. Hence, these two processes were the main harvesting processes in the arc plasma synthesis. As shown in Figs. 3c and 4, the BC concentration increased rapidly after these main harvesting processes and the background concentration in the workplace also increased after these processes. This signifies that a large number of SWCNTs were released in the workplace during the main harvesting process.

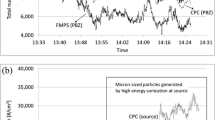

Figure 8 shows the changes in particle size distribution for eleven peak episodes. To analyze the source of the nanoscale particles, we used the number-based particle size distribution measured by an SMPS. For SWCNT powder or dust dispersed in the workplace, we investigated the mass-based particle size distribution, which was calculated from the raw data measured by an OPC. A high-concentration episode was observed in P4, P5, P6, P7, and P8 episodes. The geometric mean diameters were between 100 and 200 nm approximately, and the particle size distributions were caused by the oil mist of the vacuum pump (Chen et al. 2007; Han et al. 2008). The maximum number concentration of 40,000 particles/cm3 was measured when the vacuum pump was operated to create a vacuum in the SWCNT synthesis chamber. We also observed that highly concentrated oil mists penetrated through the opened windows.

Table 3 shows the mass concentration of each peak episode measured by the SMPS, OPC, and aethalometer, and the concentration ratio between the mass concentration before the release of particle source and that of maximum peak. The reasons for all peak episodes are described. Although these calculated mass concentrations with some assumptions are not exact, the quantitative value of the concentration ratio between peak and background before source generation is of significance.

Release characteristics from thermal purification process

The manufactured SWCNTs were mixed with the amorphous carbon particles as an impurity. For the thermal purification process, SWCNTs were mixed and purified in a tube furnace. As explained in Table 2, this process was carried out for approximately 150 min from 14:40 p.m. on May 31. The measurement point position was moved from position 1 to position 2 as shown in Fig. 1. Position 2 was located near the furnace in which the purification was carried out. Figure 9 shows the particle number concentration, the mass concentration, and the BC concentration measured by the SMPS, OPC, and aethalometer, respectively. Additionally, the CO concentration measured by an IAQ monitor presented in Fig. 9. In analyzing the data from the real-time aerosol detectors, we could not find evidence of SWCNT exposure from the purification process. The several peak episodes came from the arc plasma synthesis, which was carried out simultaneously with the purification process. When the SWCNT powders were injected into the tube furnace, the CO concentration increased rapidly from 2 to 6 ppm, and decreased slowly in the workplace to 3 ppm at the end of the purification process.

Characteristics from TEM and SEM image analyses

In order to analyze the shape of the nanoparticles sampled in a SWCNT workplace, we used SEM and TEM analyses. Air sampling was carried out at two positions near the arc plasma synthesis chamber and near the tube furnace system for the thermal purification process. As a result of image analysis, SWCNTs in the form of a bundle were found from the SEM and TEM images shown in Fig. 10. We found some partial evidence of diesel particulate matters in the atmosphere. Individual SWCNT or fragments were found from TEM images. However, discrimination of SWCNT source from the process or task was not easy because the nanoparticles moved in air through convective diffusion. We present the images as evidence of SWCNT release in the workplace.

Discussion for SWCNT detection using an aethalometer

As Dahm et al. (2012) reported, a mass metric based on elemental carbon as BC in our study may be the most reliable and realistically feasible metric to determine exposure to CNTs, until a thorough microscopy method is developed and validated. The concentration of BC measured by an aethalometer in this study was below the recommended exposure limit (REL) of 7 µg/m3 (proposed by NIOSH in 2010) without peak episodes in the harvesting processes. Recently, NIOSH proposed a REL of 1 μg/m3 elemental carbon as a respirable mass 8-h time-weighted average (TWA) concentration (NIOSH 2013). Under background atmospheric conditions, however, the PM2.5 BC concentration was about 4.5–10.5 µg/m3 in Seoul, Korea (Park et al. 2002). In this study, the peak concentration of BC was 2–12 µg/m3 during the synthesis of SWCNT and the background concentration was above 1 μg/m3 in 8-h TWA concentration. At the workplaces manufacturing SWCNT, it is not easy to distinguish the SWCNT emission from the background BC concentration. We thus possibly need another marker for the effective assessment of CNT release.

Summary

In this study, we reported on the characteristics of nanomaterials released in a SWCNT manufacturing workplace. At this workplace, SWCNTs were produced by arc plasma synthesis. For the task-based release characteristics, particles’ number and surface area concentrations were monitored using an SMPS, an OPC, and a NAM. An aethalometer assessed the mass concentration of BC particles. SEM and TEM images of the air sample in the workplace were obtained. We suggested the discrimination of the nanomaterial sources by comparing the peak episode data measured by the real-time aerosol detectors. For each peak episode, we analyzed the change in particle size distributions from SMPS and OPC. Using this analysis process, we tried to identify the nanomaterial sources to understand whether they were SWCNTs or other incidental (or background) nanoparticles. More systematic analysis method for peak episodes needs to be developed.

During the synthesis of SWCNT, the concentration of BC was 2–12 μg/m3. The particle mass concentrations at the workplaces ranged from 30 to 150 μg/m3. The maximum mass concentrations of particles and BC occurred when the synthesis chamber was opened for harvesting the SWCNTs. The particle number concentrations at the workplaces ranged from 10,000 to 40,000 particles/cm3 with a size range of 10–420 nm during the tasks. The maximum number concentration of 40,000 particles/cm3 was observed when the vacuum pump was operated to create a vacuum in the SWCNT synthesis chamber. Highly concentrated oil mists penetrated through the opened windows, as confirmed from the particle size distribution with peak concentration.

Using the real-time aerosol detectors, we separated the SWCNTs from background nanoparticles such as oil mist and atmospheric photochemical smog particles. SWCNT aggregates between 1 and 10 μm in size, measured using an OPC, were mainly released during the arc plasma synthesis. Note that BC measurement method may not work when the background concentration is high, or SWCNT release is low, or there are other BC sources nearby. Harvesting process was the main release route of SWCNT in the arc plasma synthesis workplace. A well-designed control system is needed that can block exposure from the synthesis chamber during collection process.

References

Chen MR, Tsai PJ, Chang CC, Shih TS, Lee WJ, Liao PC (2007) Particle size distributions of oil mists in workplace atmospheres and their exposure concentrations to workers in a fastener manufacturing industry. J Hazard Mater 146(1–2):393–398

Dahm MM, Evans DE, Schubauer-Berigan MK, Birch ME, Fernback JE (2012) Occupational exposure assessment in carbon nanotube and nanofiber primary and secondary manufacturers. Ann Occup Hyg 56:542–556

Evans DE, Ku BK, Birch ME, Dunn KH (2010) Aerosol monitoring during carbon nanofiber production: Mobile direct-reading sampling. Ann Occup Hyg 54(5):514–531

Fruin SA, Winer AM, Rodes CE (2004) Black carbon concentrations in California vehicles and estimation of in-vehicle diesel exhaust particulate matter exposures. Atmos Environ 38:4123–4133

Han JH, Lee EJ, Lee JH, So G, Lee YH, Bae GN, Lee SB, Ji JH, Cho MH, Yu IJ (2008) Monitoring multiwalled carbon nanotube exposure in CNT research facility. Inhal Toxicol 20:741–749

Ji JH, Woo D, Lee SB, Kim T, Kim D, Kim JH, Bae GN (2013) Detection and characterization of nanomaterials released in low concentrations during multi-walled carbon nanotube spraying process in a cleanroom. Inhal Toxicol 25(14):759–765

Lee JH, Lee SB, Bae GN, Jeon KS, Yoon JU, Ji JH, Sung JH, Lee BG, Lee JH, Yang JS, Kim HY, Yu IJ (2010a) Exposure assessment of CNT manufacturing workplaces. Inhal Toxicol 22(5):369–381

Lee SB, Lee JH, Bae GN (2010b) Size response of an SMPS-APS system to commercial multi-walled carbon nanotubes. J Nanoparticle Res 12:501–512

Lux Research (2007) The nanotech report, 5th edn. Lux Research, New York

Ma-Hock L, Treumann S, Strauss V, Brill S, Luizi F, Mertler M, Wiench K, Gamer AO, Ravenzwaay B, Landsiedel R (2009) Inhalation toxicity of multi-wall carbon nanotubes in rats exposed for 3 months. Toxicol Sci 112(2):468–481

Maynard AD, Baron PA, Foley M, Shvedova AA, Kisin ER, Castranova V (2004) Exposure to carbon nanotube material: aerosol release during the handling of unrefined single walled carbon nanotube material. J Toxicol Environ Health A 67(1):87–107

Methner M, Hodson L, Dames A, Geraci C (2010) Nanoparticle emission assessment technique (NEAT) for the identification and measurement of potential inhalation exposure to engineered nanomaterials part B: results from 12 field studies. J Occup Environ Hyg 7(3):163–176

Miller TG Jr (2002) Living in the environment: principles, connections, and solutions, 12th edn. The Thomson Corporation, Belmont, p 423

Muller J, Decordier I, Hoet PH, Lombaert N, Thomassen L, Huaux F, Lison D, Kirsch-Volders M (2008) Clastogenic and aneugenic effects of multi-wall carbon nanotubes in epithelial cells. Carcinogenesis 29(2):427–433

Nanotech (2013) Nanotubes hanging in there. Nanotech Magazine. Edn 13, 4–5 (www.futuremarketsinc.com)

NIOSH (2010) Draft current intelligence bulletin occupational exposure to carbon nanotubes and nanofibers. Cincinnati, OH: US Department of Health and Human Services, Centers for Disease Control, National Institute for Occupational Safety and Health. DHHS (NIOSH), NIOSH Docket Number: NIOSH 161-A

NIOSH (2013) Current intelligence bulletin 65 occupational exposure to carbon nanotubes and nanofibers. Cincinnati, OH: US Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. DHHS (NIOSH) Publication No. 2013–145

Park SS, Kim YJ, Fung K (2002) PM2.5 carbon measurements in two urban areas: Seoul and Kwangju, Korea. Atmos Environ 36(8):1287–1297

Pauluhn J (2010) Multi-walled carbon nanotubes (Baytubes): approach for derivation of occupational exposure limit. Regul Toxicol Pharmacol 57:78–89

Peters TM, Elzey S, Johnson R, Park H, Grassian VH, Maher T, O’Shaughnessy T (2008) Airborne monitoring to distinguish engineered nanomaterials from incidental particles for environmental health and safety. J Occup Environ Hyg 6(2):73–81

Ramachandran G, Ostraat M, Evans DE, Methner MM, O’Shaughnessy P, D’Arcy J, Geraci CL, Stevenson E, Maynard A, Rickabaugh K (2011) A strategy for assessing workplace exposures to nanomaterials. J Occup Environ Hyg 8(11):673–685

Sargent LM, Shvedova AA, Hubbs AF, Salisbury JL, Benkovic SA, Kashon ML, Lowry DT, Murray AR, Kisin ER, Friend S, McKinstry KT, Battelli L, Reynolds SH (2009) Induction of aneuploidy by single-walled carbon nanotubes. Environ Mol Mutagen 50(8):708–717

Sargent LM, Hubbs AF, Young SH, Kashon ML, Dinu CZ, Salisbury JL, Benkovic SA, Lowry DT, Murray AR, Kisin ER, Siegrist KJ, Battelli L, Mastovich J, Sturgeon JL, Bunker KL, Shvedova AA, Reynolds SH (2011) Single-walled carbon nanotube-induced mitotic disruption. Mutation Res/Genet Toxicol Environ Mutagen 745:28–37

Shi JP, Khan AA, Harrison RM (1999) Measurement of ultrafine particle concentration and size distribution in the urban atmosphere. Scie Total Environ 235:51–64

Shvedova AA, Kisin E, Murray AR, Johnson VJ, Gorelik O, Arepalli S, Hubbs AF, Mercer RR, Keohavong P, Sussman N, Jin J, Stone S, Chen B, Deye G, Maynard A, Castranova V, Baron PA, Kagan V (2008) Inhalation versus aspiration of single walled carbon nanotubes in C57BL/6 mice: inflammation, fibrosis, oxidative stress and mutagenesis. Am J Physiol Lung Cell Mol Physiol 295(4):L552–L565

Watson JG, Chow JC, Park K, Lowenthal DH (2006) Nanoparticle and ultrafine particle events at the Fresno Supersite. J Air Waste Manage Assoc 56:417–430

Woo KS, Chen DR, Pui DYH, McMurry PH (2001) Measurement of Atlanta aerosol size distributions: Observations of ultrafine particle events. Aerosol Sci Technol 34:75–87

Acknowledgments

We acknowledge the financial support of the Ministry of Trade, Industry & Energy (MOTIE), Republic of Korea, for the National Platform Technology Project (10034758), and of the Korea Institute of Science and Technology (KIST) for the Institutional Program (2E25290).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, J.H., Kim, J.B., Lee, G. et al. Nanomaterial release characteristics in a single-walled carbon nanotube manufacturing workplace. J Nanopart Res 17, 77 (2015). https://doi.org/10.1007/s11051-015-2884-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-2884-x