Computational relationships for estimating the performance of information and measurement systems and control systems are proposed. By means of these relationships it becomes possible to optimize the adjustment factors of a virtual device to enable measurement of the control efficiency criterion from its metrological characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The problem of increasing the efficiency with which modern power-intensive engineering systems are managed is a complicated one due to their slow response. This is connected with the fact that in engineering systems the equation for indirect measurement of the control efficiency criterion necessarily comprises a reference model of the control object in the form of a dynamic characteristic with respect to the control channel. For example, the current values of the control efficiency criterion of a boiler unit have the following form:

where i and j are the ordinal numbers of the elements of the file; T s , registration time, defined as the interval of time between two successive measurements (sampling time of sensors); Y 1(iT s ), Y 2(iT s ), and Y 3(iT s ), current values of the consumption, temperature, and pressure of the superheated vapor, respectively; X 1(iT s ) and X 2(iT s ), current values of consumption of fuel and water, respectively; h 12(iT s ) and h 21(iT s ), elements of file of weight factors with respect to the channel of influence of fuel consumption on the temperature of the superheated vapor and of the feed water on the consumption of the superheated vapor, respectively; int Y 3, enthalpy of superheated vapor at current value of the pressure of the superheated vapor; and N, length of realization of readings of virtual device.

The application of such control efficiency criteria requires the creation of special information and measurement systems, or virtual devices [1], as an integral component of the adaptive control system (1). All types of losses in the functioning of an engineering system may be determined from the readings of a virtual device and used both in diagnostics of the operating efficiency of an information and measurement system and in predicting the operating efficiency of an engineering system as a whole.

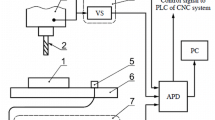

Diagnostics of Operating Efficiency of an Engineering System. In [2], it is shown that the technical state of a particular robust adaptive control system may be quantitatively estimated from the current deviation of the working point of the technical system from the optimal control criterion. Losses in information are characterized by losses of information in robust stabilization G R(t), from residual drift G Y1(t), from measurement inaccuracies G Y2(t), and from inaccuracies in identification G Y3(t). All types of information losses depend only on the sampling period of the sensors T s, the length of the realizations of the readings of the virtual device N, and the static measurement error of the virtual device M Z(iT s ) [1]. It is precisely these adjustment parameters of the computer software that support the functioning of an information and measurement system and control system with minimal losses of both information and resources ψ0(t) (Fig. 1).

In Fig. 1, it is shown how current values are formed in the case of a uniformly drifting control efficiency criterion: a loss of information due to residual drift of the characteristics of a control object G Y1(iT s ), the identification errors of the dynamical characteristics of the object G Y3(iT s ), and the total losses of information, given as the sum [2]

The ratio of the losses of information of an engineering system formed in robust stabilization of the parameters of the control system to the losses in the case of adaptive control,

should be adopted as the efficiency criterion of the operation of an engineering system.

The efficiency criterion (2) may be interpreted as the “efficiency of an information and measurement system,” calculated from the readings of a virtual device and, consequently, we will use it for diagnostics of the technical state of an information measurement system and to predict the operating efficiency of the engineering system as a whole. In addition, the criterion (2) may be used for optimization of the adjustment of the computer software of an information and measurement system.

Losses of information and errors in digital processing of measurement information are completely determined by the length of the realization of the readings of a virtual device N, the current position of the working point on the control criterion M{X(iT s ), Y(iT s ), iT s }, and adjustments of the modules of the components used for communication with the control object [2]. Losses of information on the ith step of a measurement may be characterized by the random variable

where T m is the measurement time, understood as the adjustment factor of the analog information input module, and S in(iT s ) and S p(i(T s – T m) the areas of the figures determined by the random components of the instrumental and procedural measurement errors.

Losses of information along the length of a realization of a measured parameter may be represented by the sum of the losses from N measurements performed by the virtual device [2]:

and the total losses of information on a single identification interval T id may be computed from the readings of the virtual device that measures the control criterion:

where S 1, S 2, and S 3 are the adjustment factors of the virtual device and Δε the losses on a single identification interval.

Prediction of Losses in Reference Control. Losses of efficiency in reference control may be determined under the assumptions that the control criterion Y(t) drifts with constant rate of drift K d and that the static characteristic of the control object may be approximated by a parabolic model of the form

where X(t) is the current value of the control action and X 0(t) the assignment to the regulator of a control action. The losses are then proportional to the performance of reference control (Fig. 2) and may be quantitatively estimated by the integral quality criterion

where T c is the control time and Y(t) the readings of a reference measurement system.

In direct digital control, a quantitative estimation of the properties of the drift of the static characteristic of a control object is not performed (Fig. 2), hence the current reading of the reference measurement system may be written in the form

where M X is the coordinate of the working point, understood as an estimate of the mathematical expectation of the current values of the control action on the identification time interval T id. Suppose Δ X (iT m) = X(iT m) – M X , whence the current value of the rate of drift of the static characteristic may be estimated by the time derivative of expression (3). Assuming that the measurement time is equal to 1 s (dt ≈ Δt ≈ T m ≈ 1), we find that the current estimate of the rate of drift of the control criterion

Thus, the current value of the rate of drift of the control criterion may be estimated from the current value of the cross-correlation function K YX (iT m) and the square of the deviation of the control action Δ X 2(iT m) from the specified value:

This estimate is valid when averaging over a set of realizations. Recalling that the control parameter and the control efficiency criterion belong to the class of random stationary ergodic processes, averaging may be performed over the length of a single realization and the mean value of the rate of drift on the identification interval may be found:

If the variance of a sequence of readings of the reference measurement system is written in terms of the variance of the true value of the measured quantity D Y 2 = K d 2 D X 2, losses in the performance of direct digital control may be determined from readings of the reference measurement system Y(iT m) (Fig. 2) as

where K d is the rate of drift, defined as the adaptive adjustment factor of the reference control system (estimate of the rate of drift on the identification interval T id = T c).

If the instrumental component of the losses of information, which is proportional to the area of the figure included between the true value of the measured quantity on the time interval T m and if the reading of the reference measurement system at time iT m (Fig. 2) on the ith measurement step is denoted by Y in(iT m), an estimate of the variance of the losses of information may be computed as

where S 1 = K d T m/(N – 1) is adaptive adjustment of the reference measurement system, which depends on the adjustments of the analog information input module and M Yin(t) is an estimate of the mathematical expectation of the error of amplitude quantization on the time interval t = NT m.

The procedural component of the losses of information on the ith step of a measurement of the reference measurement system Y P(iT s ) is proportional to the area of the figure [2] enclosed between the true value of the measured quantity on the time interval (T s – T m) and the reading of the digital device at time iT s . An estimate of the variance of these losses of information may be calculated from the relationship

where S 2 = K d T s /(N – 1) is an adaptive adjustment of the analog information input module. The rate of information processing T s in a reference measurement system may usually be set equal to the time needed to measure the current value of the measured quantity T m [2]. The losses of information will depend only on the instrumental component of the losses of information in digital processing Y in(iT m) and, based on (4), the variance of the error of reference control will tend to zero.

Diagnostics of Losses of Robust Stabilization. Quantitative estimation of the losses in efficiency of monitoring control in robust stabilization is complicated by the removal of constraints on the stationarity of the drift of the characteristics, i.e., the control criterion Y(t) drifts with random rate αd(t). Let Z(iT s ) be the current value of a sequence of readings of the virtual device (1) at the ith moment. In averaging over an ensemble of realizations, the random component of the dynamic error of these readings will be equal to the current value of the variance of the readings D Z 2(iT s ) = M{Z(iT s ) – M Z 2}. As a result of parametric optimization of the information and measurement system from measurement of the control criterion, an optimal rate of information processing (sampling period of sensors) T s is found. The control criterion has a parabolic model of the form

where X(iT s ) are the current values of the control action; M X , assignment to the adaptive regulator of a control action on the identification time interval of the reference model, T id = NT s ; and αd(iT s ), current values of the non-steady-state random process characterizing the drift of the control criterion.

Let Δ X (iT s ) = X(iT s ) – M X , then, if the measurement time is set equal to 1 sec, dt ≈ Δt ≈ T m ≈ 1, the current value of the rate of drift of the control criterion may be estimated by the derivative of (5), and the current value of the rate of drift of the control criterion will be given by

From (6) it follows that αd(iT s ) may be estimated from the current value of the cross-correlation function of the readings of the virtual device and the current value of the square of the deviation of the control action:

This estimate is valid in averaging over a set of realizations. Recalling that the control parameter and the control criterion measured by means of the virtual device belong to the class of random stationary ergodic processes, averaging may be performed over the length of a single realization and the average value of the rate of drift over an identification interval of the length of N measurements obtained [1]:

If an estimate of the variance of a sequence of readings of the virtual device is written in terms of the variance of the true value of the measured quantity and an estimate of the variance of the adaptive noise D Z 2 = K d 2(D X 2 – D p 2), the losses in the performance of robust stabilization may be defined in terms of a reading of the virtual device Z(iT s ) as

where T s is the registration time (understood as the rate of processing of information in the virtual device) and Z(iT s ) the current value of the readings of the virtual device.

Based on (4), the instrumental component of the losses of information is equal to zero. Studies that have been carried out [3] show that this type of loss is due to amplitude quantization and in modern controllers is less than 10−4. Thus, files of the length of 100 elements with total error in the representation of information less than 0.1%, which is sufficient for commercial identification algorithms, may be created. An estimate of the basic metrological characteristic of the performance of robust stabilization will have the form

where M Z is an estimate of the mathematical expectation of the readings on the control interval and S 2 = T s K d the adjustment factor of the virtual device.

Diagnostics of Losses of Adaptive Control. In the course of adaptive control, the current losses in efficiency consist of three components [2]:

where G Y1(iT s ) are the current values of the losses due to residual drift of the characteristics of the control object; G Y2(iT s ), current values of the losses due to the measurement noise; and G Y3(iT s ), the current value of the identification error of the characteristics of the object.

The current values of the losses due to measurement noise G Y2(iT s ) are completely determined by the metrological characteristics of the virtual device and, therefore, may be defined in terms of an estimate of the variance of the readings of the virtual device [1]:

where Z X (iT s ) is the current reading of the virtual device for registering a control action; Z Y (iT s ) the current reading of the virtual device for registering the control criterion; M ZX , estimate of the mathematical expectation of the control action on the time interval NT s ; and M ZY , mathematical expectation of an estimate of the control criterion on the time interval NT s .

Losses of information due to inaccuracy of measurements should be estimated from the file of centered current values of the control efficiency criterion:

where S 2 = NT dp T s is the adaptive adjustment of the virtual device, which depends on the adjustments of the analog information input module and the estimate of the rate of drift of the control criterion. The rate of drift of the control criterion is estimated from the current values of the cross-correlation function K YX (iT s ) and the square of the discrepancy of the control action Δ X 2(iT s ) [1]:

Thus, losses of information caused by measurement errors depend only on the sampling period of the sensors T s , the length of realizations of the readings of the virtual device N, and the current values of the square of the discrepancy of the control action Δ X 2(iT s ), which indirectly characterize the rate of drift of the control criterion K d on an identification segment of length NT s (Fig. 2).

Current losses of information caused by residual drift G Y1(iT s ) are determined by the current values of the readings of the virtual device for measurement of the control criterion Z Y (iT s ) and may be written in terms of a reading of the device for measurement of the control action Z X (iT s ) as follows:

Then the current value of a deviation of the working point from the extremum of the control criterion is given as

Unlike robust stabilization, an estimate of the rate of drift K d depends not only on the current values of the cross-correlation function K YX (iT s ) and the square of the deviation of the control action Δ X 2(iT s ), but also on the error of the identification method (Fig. 3):

where Δε is the error of the current identification on a single interval.

The losses of efficiency of the engineering system caused exclusively by residual drift may be estimated from the file of current values of the control criterion. The total losses of the residual drift in optimal control consist of M identification periods and may be calculated from the relationship

where M is the number of identification intervals over which the estimate of the losses is performed.

The third component of the losses G Y3(iT s ) is related to the operating features of the current identification algorithms with respect to the current values of the cross-correlation function K YX (iT s ) and the square of the discrepancy of the control action Δ2 X (iT s ) [1].

The procedure (7) is one of the most common procedures in model-free robust systems and is used not only for identification of the position of the working point, but also for the identification of the properties of the control object. The current values of the control criterion vary according to the law (cf. Fig. 3)

where M ZX is an estimate of the mathematical expectation of the control action on the identification period.

Suppose that Δ ZX (iT s ) ≈ Z X (iT s ) – M ZX , whence the current value of the rate of drift of the control criterion may be estimated by the time derivative

Assuming that the measurement time dt ≈ Δt ≈ T m ≈ 1 sec, we find that

Consequently, the current value of the rate of drift of the control criterion on the identification interval

Since j = Ni, an estimate of the variance of the readings of the virtual device on a single identification interval will have the form

For the case where the rate of drift and the identification error are not correlated, we transform the latter expression into the form

From this it follows that an estimate of the error variance on a single identification interval

Since an estimate of the rate of drift on a single identification interval is determined by (7), an estimate of the variance of the identification error, understood as a real-time function, may be expressed in terms of the metrological characteristics of the virtual device as

Conclusion. An analysis of existing methods of diagnostics and prediction of the operating efficiency of information and measurement systems and engineering systems shows that for radar and telecommunication computer systems in which the rate of processed measurement information is greater than 1 MHz, losses of information in the measurement channel do not affect the relative measurement error [4]:

where l is the ordinal number of a processed realization; K, transmission capacity of the medium; S, noise level; α, rate of variation of measurement information; T s , relative duration of a digitized realization; and N, number of realizations. In such systems the basic problem is to combat noise that has been artificially superimposed on the useful signal.

For computer systems in which the rate of processed measurement information is less than1 MHz (noise and ultrasonic diagnostics), it is recommended that losses of information in the measurement channel should not be ignored, since the magnitude of the relative processing error of measurement information becomes a significant quantity:

where β is the ratio of the rate of variation of the noise to the rate of variation of the useful signal.

For an eight-digit analog information input module, this is a constant ≈ 4·10−4% [1]. The value is low for a single element of a file, but when processing several files it grows N l-fold. For example, when estimating the autocorrelation function using a file of the length of 100 measurements, the relative information processing error is not less than 4%.

In commercial computer systems, measurement information has low-frequency properties (rate of processed measurement information less than 1Hz). With the use of the proposed models (8)–(14) it becomes possible to estimate the current operating efficiency of an information and measurement system and of a control system from the sampling period of the sensors, the identification period of the model of the control object, and the readings of the information and measurement system.

Under actual conditions there are strict constraints on the length of the files that are used for identification of the properties of a control object whose function it is to implement a compromise between the length of the information storage process and the rate of drift of the characteristic. From Fig. 1 it follows that the current variation in the rate of drift αd(t), understood as the current value of the slope of the line representing the losses of the residual drift G Y1(t), lead to variations in the current values of the total losses G Y (t), and this, in turn, leads to drift of the optimal adjustments of the operation of information and measurement systems, and a need for periodic adaptation of the systems arises.

In view of the foregoing discussion, diagnostics of the efficiency of information and measurement systems must be performed on each identification interval T id = NT s . The losses of information that occur on each identification interval may be calculated from the readings of a diagnosed information and measurement system in the following way:

The total losses of information on M identification intervals will then be

where M is the number of identification intervals; Δε(jT id), the identification error on a single interval; and S 3, the adjustment coefficient of the virtual device.

In addition, the identification error Δε(jT id) depends on both the concrete conditions of digital processing of measurement information in the information measurement subsystem of a computer-based industrial process control system and on the identification method. The magnitude of the identification error Δε(jT id), assuming stationarity and ergodicity of the control action on the interval j = NT s , may be calculated from the readings of the virtual device thus:

References

V. P. Shevchuk, Modeling the Metrological Characteristics of Smart Measurement Devices and Systems, FIZMATLIT, Moscow (2011).

V. P. Shevchuk, “Information content and efficiency of smart measurement technology,” Metrologiya, No. 1, 12–21 (2012).

I. A. Boldyrev et al., Patent 94333 RF, “Test bench for diagnostics of the software and measurement channels of multifunctional control and management systems,” Izobret. Polezn. Modeli, No. 14 (2010).

A. V. Barkov, N. A. Barkova, and A. Yu. Azovtsev, Monitoring and Diagnostics of Rotary Machines Using Vibrations, Izd. SPbGMTU, St. Petersburg (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metrologiya, No. 7, pp. 24–38, July, 2014.

Rights and permissions

About this article

Cite this article

Shevchuk, V.P. Diagnostics and Prediction of the Operating Efficiency of Information and Measurement Systems and Control Systems. Meas Tech 57, 1004–1012 (2014). https://doi.org/10.1007/s11018-014-0573-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-014-0573-2