We present the equation of diffusion running in the process of deformation of a body with regard for the corresponding hydrogen flow caused both by the external mechanical loads and the stresses induced by the hydrogenation of the metal weakened by a smooth (or cracklike) defect. Closed analytic solutions are obtained in the quasistationary case of weakly varying stresses. We also reveal the redistribution of hydrogen initiated by the presence of elliptic holes and cracklike defects with process zones.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The problem of hydrogen embrittlement becomes especially urgent in the presence of technological and operating defects in materials [1, 2]. On the other hand, the redistribution of the content of hydrogen [3, 4] stimulated by stress concentrators occurs in hydrogenated bodies due to the action of external loads. Therefore, it is necessary to develop new methods for the investigation of the influence of concentration of stresses on the redistribution of hydrogen and to take into account cracklike defects present in the materials in the evaluation of their hydrogen saturation and, in particular, the local concentrations of hydrogen. Moreover, it is also necessary to take into account the initiation of internal stresses by hydrogenation [5]. Note that this specific feature affects the general stress-strain state of the material and, hence, the distribution of hydrogen in the vicinities of stress concentrators.

Statement of the Problem

Consider an elastic body containing a smooth or cracklike defect with plastic or loose process zones at its vertices. It is necessary to determine the distribution of hydrogen in the vicinity of this defect and to estimate its relative concentration depending on the stress-strain state of the body and, in particular, on the corresponding hydrostatic stresses.

It is known [6,7,8,9,10,11,12,13] that hydrogen creates hydrostatic stresses in the metal. In turn, the external loads also induce hydrostatic stresses. Together with hydrogen-induced stresses, these stresses initiate the redistribution of hydrogen content near cracklike stress concentrators [12, 14]. The actual cracks in deformed materials are accompanied by the presence of process zones, which strongly affect the distribution of hydrogen around them. Therefore, in order to evaluate the concentration of hydrogen near cracklike defects in hydrogenated materials, it is necessary to consider hydrogen-induced hydrostatic stresses caused by the corresponding concentrators under the action of external mechanical forces and find the relative concentration of hydrogen near cracklike defects with regard for the combined action of hydrogen and external mechanical forces.

Basic Input Relations

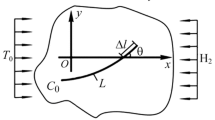

We refer a metallic body weakened by a smooth or cracklike stress concentrator to a chosen coordinate system q 1 Oq 2 . Assume that the body is hydrogenated to a certain concentration of hydrogen C 0 and stay in the state of plane deformation under the action of external mechanical loads. In [9,10,11,12, 14], the analysis of the influence of external loads and internal hydrogen stresses on the redistribution of the concentration of hydrogen in the metal is reduced to the investigation of the diffusion equation

and the hydrogen flow

Here, C is the concentration of hydrogen atoms in the metallic body, D is the diffusion coefficient, V H is the partial molar volume of hydrogen in the metal [15], R is the universal gas constant, T is absolute temperature, E is Young’s modulus, ν is Poisson’s ratio of the material, α c is the coefficient of hydrogen concentration expansion of the metal [8,9,10,11,12], which reflects the direct proportionality of the concentration of hydrogen to hydrogen-induced hydrostatic stresses [16],

are hydrostatic stresses caused by the external loads [17], and σ ii are the principal stresses.

In order to consider the influence of external loads on the redistribution of hydrogen in the metal, we analyze Eqs. (1) and (2) for ∂C/∂t = 0 . Specifying the boundary conditions, we consider that the concentration of hydrogen at the infinitely remote points of the body ( q 1, q 2 ) is constant

We also assume that the hydrogen flow is zero on the contours of defects L n , i.e., the normal component [18]

In view of these boundary conditions, we arrive at the transcendental equation for the redistributed hydrogen concentration C ( q 1, q 2 ):

Its solution is as follows [14]:

where

Here, Lambert W( x ) is the Lambert function [19], which can be found as a result of the solution of the equation

or, approximately, from the recurrence relation

Here,

In our calculations, we take w0 = 0.

Examples of Calculations of the Content of Hydrogen Near Stress Concentrators

By using the relations presented above, we consider an elliptic hole and a crack with process zones in the hydrogenated elastic metallic body.

Elliptic Hole. In the body with elliptic hole under the conditions of plane deformation subjected to the action of tensile forces with intensity p (Fig. 1 ), the hydrostatic stresses are given by the formula

z = x + iy, and \( \overline{\Phi (z)} \) is the function complex conjugate to Φ( z ). Thus, by formula (3), the concentration of hydrogen near the elliptic stress concentrator

The results of evaluation of hydrostatic stresses according formula (4) and the corresponding redistribution of hydrogen concentration on the continuation of the major semiaxis of the elliptic hole by relation (5) for

T = 300∘K , E = 2 ⋅ 105 MPa , v = 0.3 , α c = 5.01 ⋅ 10−6m3/mole, and V H = 1.96 ⋅ 10−6m3/mole are presented in Fig. 1 .

Hence, the character of changes in the relative concentrations of hydrogen for the elliptic hole is the same as for the hydrostatic stresses (Fig. 1 ). As the ratio b/a decreases, i.e., as the elliptic hole approaches the cracklike defect, the concentration of hydrogen in the vicinity of the tip of the major semiaxis of the ellipse increases. Hence, we obtain the numerical results for the Griffiths pointed cracklike defect [14] by the finite-element method.

Cracks with Process Zones. We assume that a pressure formed in the crack is constant. In order to find the hydrostatic stresses near the crack with weakened process zones, we take the complex potential [20]

where, according to [21], we can set

Integrating relation (6), we obtain

Taking into account the values of the logarithmic function

we get the complex potential

Since [21]

we can write

where σ0 are stresses with which the opposite faces of the process zones near the crack tip attract each other.

The results of calculations of hydrostatic stresses by using relations (4) and (7) and the redistribution of the relative concentration of hydrogen C/C 0 caused by these stresses on the continuation of the crack at different distances from its tip by using relations (5) and (7) are presented in Fig. 2. It is easy to see that the concentration of redistributed hydrogen is leveled for the triple length of the process zone in the metal.

The results of calculations of the relative concentration of hydrogen obtained by using the proposed approach agree with the experimental data [22, 23] (Fig. 3 ). The numerical data (Fig. 4) obtained for a model crack [21] with process zones also coincide with the corresponding experimental data on the distribution of hydrogen [24] (Fig. 5 ).

Distribution of hydrogen on the continuation of the crack [22].

Distribution of hydrogen in the process zone at a distance of 1.5 mm from the crack tip [24].

Conclusions

On the basis of the equation of diffusion running in the process of deformation of the body weakened by smooth or cracklike defects with regard for the corresponding hydrogen flow caused both by the external load and by the stresses caused by the hydrogenation of the metal, we deduce the analytic relations for the evaluation of the redistribution of hydrogen under the action of external forces. We computed the changes in the relative concentration of hydrogen in the vicinities of the elliptic hole and the crack with process zones. The obtained results are compared with the corresponding experimental data.

References

O. T. Tsyrul’nyk, E. I. Kryzhanivs’kyi, D. Yu. Petryna, O. S. Taraevs’kyi, and M. I. Hredil’, “Susceptibility of a welded joint of 17G1s steel in a gas main to hydrogen embrittlement,” Fiz.-Khim. Mekh. Mater., 40, No. 6, 111–114 (2004); English translation : Mater. Sci., 40, No. 6, 844–849 (2004).

E. I. Kryzhanivs’kyi, R. S. Hrabovs’kyi, and O. M. Mandryk, “Estimation of the serviceability of oil and gas pipelines after longterm operation according to the parameters of their defectiveness,” Fiz.-Khim. Mekh. Mater., 49, No. 1, 105–110 (2013); English translation : Mater. Sci., 49, No. 1, 117–123 (2013).

J. Capelle, J. Gilgert, I. Dmytrakh, and G. Pluvinage, “The effect of hydrogen concentration on fracture of pipeline steels in presence of a notch,” Eng. Fract. Mech., 78, 364–373 (2011).

G. Mulder, J. Hetland, and G. Lenaers, “Towards a sustainable hydrogen economy: hydrogen pathways and infrastructure,” Int. J. of Hydrogen Energy, 32, 1324–1331 (2007).

M. H. Stashchuk and M. I. Dorosh, “Evaluation of stresses caused by hydrogen concentrated in the metal,” Fiz.-Khim. Mekh. Mater., 51, No. 4, 60–68 (2015); English translation : Mater. Sci., 51, No. 4, 520–529 (2015).

V. N. Ageev, I. N. Bekman, O. P. Burmistrov, et al., Interaction of Hydrogen with Metals [in Russian], Nauka, Moscow (1987).

O. E. Andreikiv and O. V. Hembara, Fracture Mechanics and Durability of Metal Materials in Hydrogen-Containing Media [in Ukrainian], Naukova Dumka, Kiev (2008).

V. A. Gol’tsov, Zh. L. Glukhova, E. N. Lyubimenko, and T. A. Shchegoleva, “Hydrogen-induced concentration stresses: nature, experimental manifestations, value for engineering,” Nauk. Pratsi DonNTU. Metal., Issue 11 (159), 165–173 (2009).

M. H. Stashchuk, “Mutual influence of the stress-strain state and hydrogen concentration in the metal–hydrogen system,” Fiz.-Khim. Mekh. Mater., 47, No. 4, 71–77 (2011); English translation : Mater. Sci., 47, No. 4, 499–508 (2011).

M. H. Stashchuk and M. I. Dorosh, “Determination of the stress-strain state of a body depending on the hydrogen concentration,” in: V. V. Panasyuk (editor), Fracture Mechanics of Materials and Strength of Structures [in Ukrainian], Karpenko Physicomechanical Institute, Ukrainian National Academy of Sciences, Lviv (2009), pp. 689–694.

M. H. Stashchuk and M. I. Dorosh, “Evaluation of the concentration of hydrogen and hydrogen-induced stresses in a metal strip and in a hollow cylinder,” in: Proc. of the Internat. Sci.-Eng. Conf. “Theory and Practice of Rational Design, Production, and Operation of Machine-Building Structures” [in Ukrainian], KINPATRI, Lviv (2010), pp. 93–94.

M. H. Stashchuk and M. I. Dorosh, “Evaluation of hydrogen stresses in metal and redistribution of hydrogen around crack-like defects,” Int. J. Hydrogen Energy, 37, 14687–14696 (2012).

L. E. Kharchenko, O. E. Kunta, O. I. Zvirko, R. S. Savula, and Z. A. Duryahina, “Diagnostics of hydrogen macrodelamination in the wall of a bent pipe in the system of gas mains,” Fiz.-Khim. Mekh. Mater., 51, No. 4, 84–90 (2015); English translation : Mater. Sci., 51, No. 4, 530–537 (2015).

M. H. Stashchuk, “Influence of external loads on the redistribution of hydrogen in the metal near stress concentrator,” Fiz.-Khim. Mekh. Mater., 47, No. 6, 23–29 (2011); English translation : Mater. Sci., 47, No. 6, 737–745 (2011).

B. A. Kolachev, Hydrogen Embrittlement of Metals [in Russian], Metallurgiya, Moscow (1985).

T. Zhang, W. Y. Chu, K. W. Gao, and L. J. Qiao, “Study of correlation between hydrogen-induced stress and hydrogen embrittlement,” Mat. Sci. Eng. A, 347, 291–299 (2003).

N. I. Muskhelishvili, Some Basic Problems of the Mathematical Theory of Elasticity, Noordhoff, Groningen (1953).

L. K. Martinson and Yu. I. Malov, Differential Equations of Mathematical Physics [in Russian], Izd. Bauman MSTU, Moscow (2002).

S. R. Valluri, D. J. Jeffrey, and R. M. Corless, “Some applications of the Lambert W function to physics,” Canad. J. Phys., 78, 823–831 (2000).

M. H. Stashchuk, Problems of the Mechanics of Elastic Bodies with Cracklike Defects [in Russian], Naukova Dumka, Kiev (1993).

V. V. Panasyuk, Limiting Equilibrium of Brittle Bodies with Cracks [in Russian], Naukova Dumka, Kiev (1968).

Ya. L. Ivanyts’kyi, O. V. Hembara, O. D. Smiyan, and M. Kowalik, “Evaluation of the concentration of hydrogen in the process zone near the crack tip,” Fiz.-Khim. Mekh. Mater., 46, No. 6, 51–55 (2010); English translation : Mater. Sci., 46, No. 6, 769–774 (2010).

Ya. Ivanytskyi, S. Shtayura, Y. Molkov, and T. Lenkovskiy, “Hydrogen influence on the fracture of sheet carbon steel,” Int. J. Fracture, 176, No. 1, 17–23 (2012).

O. D. Smiyan, “Hydrogen in metals as a bosonic fluid,” Fiz. Khim. Tverd. Tila, 5, No. 4, 750–757 (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 52, No. 6, pp. 56–62, November–December, 2016.

Rights and permissions

About this article

Cite this article

Stashchuk, M.H. Determination of the Distribution of Hydrogen Near Cracklike Defects. Mater Sci 52, 803–810 (2017). https://doi.org/10.1007/s11003-017-0024-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-017-0024-8