Abstract

In this study, dibutyl sulfide (DS), phenyl sulfide (PS) and 2-methyl thiophene (2-MT) were selected as model compounds to investigate the effect of Fe3+ on sulfur release by pyrolysis connected with gas chromatography (Py-GC) and pyrolysis coupled with mass spectrometer (Py-MS) under Ar and 3% O2–Ar atmospheres. It is found that main forms of sulfur-containing gases are different during their pyrolysis under different atmospheres. Sulfur gases are mainly SO2 under 3% O2–Ar atmosphere. Under Ar atmosphere, PS is more difficult to decompose than 2-MT, while easier under 3% O2–Ar atmosphere. 0.5% Fe3+ only significantly promotes the sulfur release amount of PS under Ar atmosphere. However, 2% Fe3+ is more effective for DS and 2-MT to decompose under Ar atmosphere and it promotes all these sulfur gases release at lower temperatures under Ar atmosphere. And 2% Fe3+ is more beneficial for all these three compounds to decompose under 3%O2–Ar atmosphere than 0.5% Fe3+, especially for PS. Therefore, 2% Fe3+ can more efficiently promote sulfurs release of these sulfur compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the development of social economy, a series of environmental problems, such as acid rain and greenhouse effect, have appeared during the utilization of medium and high sulfur coals [1,2,3,4,5]. Coal pyrolysis has attracted more and more attention, because it can be used as a single pre-combustion pretreatment process to improve coal utilization efficiency and pollutant control [6,7,8,9,10]. To a certain extent, the directional migration of sulfurs in coal can be achieved through co-pyrolysis of coal and additives [11,12,13,14,15,16,17,18]. In addition, the purpose of more efficient utilization of medium and high sulfur coal resources can also be realized by their co-pyrolysis. However, it is difficult to determine the decomposition and transformation behavior of different sulfur forms in coal due to their complexity and their mutual transformation during pyrolysis [19,20,21,22].

The sulfur-containing model compounds are similar to the sulfur structures in coal. But, the release and transformation behavior of sulfur model compounds can be more easily analyzed and measured than that of sulfurs in coal during pyrolysis. Therefore, many scholars have selected some model compounds instead of coal to study the decomposition, release and transformation behavior of organic sulfurs, and have obtained some important conclusions. Guo et al. [23] studied the sulfur release and its transformation behavior of six sulfur-containing model compounds under Ar and CO2 atmospheres. The sulfur stability of the model compounds was different under CO2 atmosphere, and their decomposition temperatures are all lower than those under Ar atmosphere. Yan et al. [24] studied the pyrolysis behavior of sulfur-containing model compounds under inert atmosphere. They found that the migration of organic sulfurs in the pyrolysis process was accompanied by the transformation of SH radical, which was the intermediate of sulfur transition resulted from thermal initiation.

However, most studies [25,26,27,28,29] mainly focus on the individual pyrolysis of model compounds, and the effect of additives on the release of different types of organic sulfides remains unclear under different atmospheres. Therefore, three sulfur-containing model compounds (dibutyl sulfide, phenyl sulfide and 2-methyl thiophene) were selected to replace complicated organic sulfurs in coal and to obtain some theoretical basis for further monitoring the detailed sulfur release behavior of organic sulfurs of coal during pyrolysis. Py-MS combined with Py-GC was used to investigate the effect of Fe3+ on sulfur release behavior during these three compounds pyrolysis under Ar and 3% O2–Ar atmospheres as a relatively moderate atmosphere. Therefore, this study can provide some theoretical basis for comprehensive utilization of medium and high sulfur coal and effective control of sulfur-containing pollutants.

Experimental

Samples

Three model compounds, dibutyl sulfide (DS), phenyl sulfide (PS) and 2-methyl thiophene (2-MT), were loaded onto active carbon by the incipient wetness method, respectively, and acetone was used as the solvent. The specific steps are as follows, appropriate amount of sulfur-containing model compound (according to sulfur content of model compounds) was added into a beaker with 5 mL acetone solution for complete dissolution. Then, the solution was poured into another beaker where about 1 g activated carbon had been added. The mixed sample was stirred under ultrasonic for 20 min, dried at room temperature for about 48 h and collected for further experiment. The molecular mass of the model compound and the theoretical loading are shown in Table 1.

Loading of Fe3+

The method of impregnation was used to load Fe3+ according to the mass fraction of metal in chloride. 5 g sulfur-containing model compound was added to 0.5% and 2% FeCl3 solution, respectively. Then, the solution was stirred for 6 h, remained still for 6 h, placed into an oven and dried at 60 °C for collection.

Determination of total sulfur in sulfur-containing model compounds

The automatic sulfur determination analyzer (XK-5000) was used to measure sulfur content of samples in this study. The sulfur content of activated carbon, dibutyl sulfide (DS), phenyl sulfide (PS) and 2-methyl thiophene (2-MT) is 0.45, 3.24, 3.42 and 1.91%, respectively. The sulfur contents of these model compounds are all much higher than that of the activated carbon itself.

Py-GC equipment

Pyrolysis experiments were carried out in a quartz tube fixed bed reactor (i.d. 35 mm, length 60 cm). About 1.0 g sample was pyrolyzed under pure Ar and 3% O2–Ar atmospheres at the temperature range from room temperature to 900 °C at a flow rate of 0.3 Lmin−1 with a heating rate of 10 °C min−1.H2S, COS and SO2 contents (concentration Φ/10 − 6) were determined by gas chromatography (SP-7800) with flame photometric detector (GC-FPD) (SP-7800) every 50 °C, off-line. The column and detector temperatures were 80 and 250 °C, respectively.

Py-MS equipment

About 1.5 g sample was placed into a quartz reactor and heated from room temperature to 900 °C with a heating rate of 10 °C min−1 in a continuous flow of pure Ar or 3% O2–Ar atmosphere at a flow rate of 0.2 Lmin−1. The gaseous products of H2S, COS and SO2 were measured by an on-line MS (Hiden QIC-20).

Calculating methods

The sulfur mass in the form of COS (mS,COS) was obtained according to the formula:

where the gas was supposed of ideal gas, R is the heating rate of 10 °Cmin−1, V is the gas flow rate of 0.3 L min−1, Ms is the atomic mass of sulfur (unit: g mol−1), Ws is sulfur mass in per gram of the active carbon or sulfur model compounds loaded into the active carbon (unit: g), and ACOS is integrated area of COS (unit: \(\frac{\rm {mL}}{\rm {mL}}\) oC). Thus, mS,COS has a unit of g g−1 (or no unit). mS,H2S and mS,SO2 can also be obtained similarly.

Results and discussion

Effects of Fe3+ on the release amount of sulfur-containing gases under different atmospheres

Figure 1 shows the release amount of H2S, COS and SO2 during pyrolysis of these model compounds under Ar atmosphere. As shown in Fig. 1 a, 0.5% Fe3+ can inhibit H2S and SO2 to release during DS pyrolysis, especially SO2 release, and 0.5% Fe3+ has no obvious effects on COS release of DS. But, 2.0% Fe3+ can significantly promote these three gases to release. Contrary to DS, 0.5% Fe3+ promotes the releasing of these three sulfur-containing gases of PS (Fig. 1b), especially for H2S release. For PS (Fig. 1b), the promoting effect of 2.0% Fe3+ is less than that of 0.5% Fe3+, while 2.0% Fe3+ prevents COS releasing. This may be due to the different structures of these two different model compounds and their different bonds breaking mechanism during pyrolysis. For 2-MT (Fig. 1 c), these two concentrations of Fe3+ all can promote these sulfur-containing gases to release during pyrolysis. But, the promoting effect of 2.0% Fe3+ is better than that of 0.5% Fe3+, especially for SO2 release. It is known that content order is PS (3.42%) > DS (3.24%) > 2-MT (1.91%), while the total releasing amount of sulfur gases is DS > 2-MT > PS, indicating 2-MT is much easier to decompose than PS under Ar atmosphere.

As shown in Fig. 2, for DS, PS and 2-MT, the main form of these sulfur gases is SO2 during pyrolysis in 3% O2–Ar atmosphere, and Fe3+ has no obvious effect on their H2S release. For DS, Fe3+ can obviously promote SO2 release, and SO2 release amount and the total sulfur release amount increase with the increasing of Fe3+ concentration. But, Fe3+ prevents COS release of DS. For PS (Fig. 2b), 0.5% Fe3+ has no obvious promoting effect on SO2 release, while 2% Fe3+ can significantly promote SO2 release. Similar to DS, Fe3+can also prevent COS release of PS. Similar to DS, Fe3+ can obviously promote SO2 release and the total sulfur release of 2-MT, and the promoting effect becomes stronger with the increasing of Fe3+ concentration. Compared with DS and PS, the promoting effect of Fe3+ on 2-MT is most significantly under 3% O2–Ar atmosphere. This is very consistence with our previous calculated results of 2-MT [30]. SO2 rather than COS is the main sulfur-containing gaseous product during 2-MT pyrolysis under oxidative atmosphere. For these three compounds, their total release amount of sulfur gases under 3% O2–Ar atmosphere rises much higher than that under Ar atmosphere, especially for PS. This suggests that 3% O2–Ar atmosphere is more beneficial for PS to decompose than Ar atmosphere.

Effects of Fe3+ on the release of sulfur-containing gases of model compounds under different atmospheres

Effects of Fe3+ on H2S release of model compounds under different atmospheres

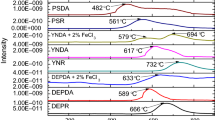

Figure 3 shows H2S release of DS, PS and 2-MT during pyrolysis under Ar atmosphere. Under Ar atmosphere, H2S release cannot be detected during pyrolysis of activated carbon and activated carbon with 0.5% and 2% Fe3+, so H2S release of these model compounds is unrelated to activated carbon during pyrolysis. For these three model compounds, only H2S release of DS was detected by MS during pyrolysis under Ar atmosphere. The first release peak at 410 °C should be attributed to the decomposition of DS itself, as HS radicals can directly combine with active hydrogen of DS and release in the form of H2S. And the second peak at 600 °C is related to the decomposition of secondary product of DS. The area of the first peak is significantly larger than that of the second peak, indicating that the initial decomposition rate of DS is greater than the generation rate of its secondary product. 0.5% Fe3+ can make the first H2S release peak of DS move toward higher temperature at 426 °C, and the second peak become a shoulder peak at 550 °C, suggesting that 0.5% Fe3+ prevents H2S release of DS under Ar atmosphere. This is very consistent with the lower H2S release amount of DS with 0.5% Fe3+ (Fig. 1a). However, 2% Fe3+can promote H2S of DS release at much lower temperature. This is also very consistent with higher H2S release amount of DS with 2% Fe3+ (Fig. 1a). But, H2S release of PS and 2-MT was not detected by MS as of its lower concentration.

As shown in Fig. 4, no significant H2S release was detected by MS during pyrolysis of all these samples, as the MS fragments of H2S are similar to those of O2.

Effects of Fe3+ on COS release of model compounds under different atmospheres

Figure 5 shows COS release of DS, PS and 2-MT during pyrolysis under Ar atmosphere. Under Ar atmosphere, no obvious COS was detected during pyrolysis of activated carbon and activated carbon with 0.5% and 2% Fe3+, while COS was detected during pyrolysis of these three model compounds. This also indicates that COS release of these model compounds is not related to the activated carbon. As shown in Fig. 5, 0.5% Fe3+can make the maximum COS release peaks of these three compounds move toward higher temperatures, while 2% Fe3+promotes COS release of PS and DS at lower temperatures. For example, for PS and PS with 0.5% Fe3+, their corresponding maximum peak temperatures are 576 °C and 582 °C, respectively. And the initial release temperature of COS and its maximum release peak temperature are significantly reduced during PS with 2.0% Fe3+. However, 2% Fe3+ has no obvious effects on COS release temperature of 2-MT. As the methyl of 2-MT is attributed to more H2S formed than COS under Ar atmosphere [30], and COS release temperature changes indistinctly.

Figure 6 shows the effect of Fe3+ on the release of COS during pyrolysis of DS, PS and 2-MT under 3% O2–Ar atmosphere. Under 3% O2–Ar atmosphere, COS was not detected during pyrolysis of activated carbon with 0.5% and 2% Fe3+. An increasing trend of COS was detected during pyrolysis of activated carbon, but the temperature of COS release is significantly different from these three model compounds loaded into activated carbon. Thus, the COS release of these model compounds is also independent on activated carbon under 3% O2–Ar atmosphere. For raw DS, PS and 2-MT, one obvious COS release peak was detected during their pyrolysis, and their corresponding maximum peak temperatures are 480 °C, 590 °C and 438 °C, respectively. Different with Ar atmosphere, 0.5% Fe3+ can promote COS of these three model compounds to release at lower temperatures under 3% O2–Ar atmosphere. And 2% Fe+3 also make COS maximum peak temperatures of these three compounds all lower than that of 0.5% Fe3+. For PS, PS with 0.5% Fe+3 and PS with 2% Fe+3, their corresponding maximum peak temperatures were 590 °C, 530 °C and 480 °C, respectively.

Effect of Fe3+ on SO2 release of model compounds under different atmospheres

As shown in Fig. 7, under Ar atmosphere, there is also no SO2 release detected during pyrolysis of activated carbon and activated carbon with 0.5% and 2% Fe3+. Similar to H2S release of raw DS, there are two SO2 release peaks detected during pyrolysis, corresponding to their maximum peak temperatures at 405 and 608 °C, respectively. But, for DS with 0.5 and 2% Fe3+, only one wide SO2 release peak was detected, corresponding to their maximum peak temperatures at 445 and 410 °C, respectively. Compared with raw DS, Fe3+ makes the maximum peak temperature of SO2 move to the higher temperature under Ar atmosphere. For PS, PS with 0.5% Fe3+ and PS with 2% Fe3+, there is only one release peak of SO2 appeared, and their corresponding maximum peak temperatures are 580 °C, 600 °C and 510 °C, respectively. Different from DS, Fe3+ can promote SO2 of PS to release at lower temperatures under Ar atmosphere. Fe3+can also promote SO2 of 2-MT to release under Ar atmosphere, as no SO2 release was detected for raw 2-MT. For PS and 2-MT, the higher Fe3+concentration is, the lower the maximum peak temperature of SO2 is. Under Ar atmosphere, the SO2 release temperature of 2-MTs is lower than that of PSs. This can further prove 2-MT is easier to decompose than PS under Ar atmosphere.

Figure 8 shows the effect of Fe3+ on SO2 release during pyrolysis of DS, PS and 2-MT under 3% O2–Ar atmosphere. As seen in Fig. 8, a small SO2 peak was detected during pyrolysis of activated carbon with 0.5% and 2% Fe3+ under 3% O2–Ar atmosphere. But, the peak intensity is significantly lower than those of these three model compounds. Thus, SO2 release of these model compounds can be also considered to be independent on activated carbon during pyrolysis. Except for raw 2-MT, SO2 release of other samples was detected during pyrolysis. For raw DS, only a broad SO2 release peak was detected during pyrolysis, and its corresponding maximum peak temperature is 690 °C. Fe3+ is helpful for SO2 to release at low temperatures during DS pyrolysis under 3% O2–Ar atmosphere. But, its maximum peak temperatures of SO2 release are less affected by Fe3+ concentration. However, 2% Fe3+ can make more SO2 release of DS into gas phase at lower temperature, corresponding to its high intensity of SO2 shown in Fig. 8. This is very consistent with more SO2 release amount of DS with 2% Fe3+ detected by Py-GC (Fig. 2). For PS, PS with 0.5% Fe3+ and PS with 2% Fe3+, only a SO2 release peak was detected during pyrolysis, and their corresponding maximum peak temperatures are 672, 607 and 564 °C, respectively. With the increasing of Fe3+ concentration, the maximum peak temperature of SO2 also moves toward lower temperatures, and the movement trend is more obvious. No SO2 was detected during raw 2-MT pyrolysis under 3% O2–Ar atmosphere, while a distinct release peak appears for 2-MT with 0.5% Fe3+ and with 2% Fe3+. Similar to DS and PS, Fe3+ is beneficial for more SO2 to release at lower temperatures during 2-MT pyrolysis with the increasing of Fe3+ concentration under 3% O2–Ar atmosphere. Interestingly, unlike Ar atmosphere, the SO2 release temperature of PS with Fe3+ is lower than that of 2-MT with Fe3+, suggesting that the effect of Fe3+ on the decomposition of PS is more efficiently under 3% O2–Ar atmosphere. This is very consistent to the highest SO2 release and total sulfur release amount of PS in Fig. 2.

Conclusions

The effect of Fe3+ on the release of sulfur-containing gases was investigated during pyrolysis of model compounds under different atmospheres. The following conclusions can be drawn:

The main forms of the sulfur-containing gases are different during pyrolysis in different atmospheres. Under the Ar atmosphere, H2S release amount is comparatively higher than COS and SO2, while the main form is SO2 under 3% O2–Ar atmosphere. Under Ar atmosphere, 2-MT is easier to decompose than PS. However, PS is easier to decompose and form SO2 than 2-MT under 3% O2–Ar atmosphere. 0.5% Fe3+ makes H2S release of DS and COS release of DS, PS and 2-MT all move to higher temperatures, while 2% Fe3+ promotes all these gases release at lower temperatures under Ar atmosphere. Under 3% O2–Ar atmosphere, Fe3+ beneficially promotes COS and SO2release of these compounds at lower temperature with the increasing of Fe3+ concentration, especially for SO2 release of PS. Thus, 2% Fe3+ can efficiently promote sulfur release under these two atmospheres. These results obtained by Py-MS are very consistent with those obtained by Py-GC. Therefore, these results can provide some theoretical basis for coal desulfurization mechanism during coal pyrolysis.

References

Liu Z, Wang G, Li P, Li C. Investigation on combustion of high-sulfur coal catalyzed with industrial waste slags. J Energy Inst. 2019;92(3):621–9.

Peng B, Wu D. Study on bromine release from bituminous coal during combustion. Fuel. 2015;157:82–6.

Wang G, Zhang J, Shao J, Liu Z, Zhang G, Xu T, Guo J, Wang H, Xu R, Lin H. Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag. 2016;124:414–26.

Yu X, Luo Z, Gan D. Desulfurization of high sulfur fine coal using a novel combined beneficiation process. Fuel. 2019;254:115603.

Hou J, Ma Y, Li S, Shi J, He L, Li J. Transformation of sulfur and nitrogen during Shenmu coal pyrolysis. Fuel. 2018;231:134–44.

Dong L, Han S, Yu W, Lei Z, Kang S, Zhang K, Yan J, Li Z, Shui H, Wang Z, Ren S, Pan C. Effect of volatile reactions on the yield and quality of tar from pyrolysis of Shenhua bituminous coal. J Anal Appl Pyrolysis. 2019;140:321–30.

Li X, Li J, Wu G, Bai Z, Li W. Clean and efficient utilization of sodium-rich Zhundong coals in China: behaviors of sodium species during thermal conversion processes. Fuel. 2018;218:162–73.

Liu T, Cao J, Zhao X, Wang J, Ren X, Fan X, Zhao Y, Wei X. In situ upgrading of Shengli lignite pyrolysis vapors over metal-loaded HZSM-5 catalyst. Fuel Process Technol. 2017;160:19–26.

Wang M, Jia T, Wang J, Hu Y, Liu F, Wang H, Chang L. Changes of sulfur forms in coal after tetrachloroethylene extraction and theirs transformations during pyrolysis. Fuel. 2016;186:726–33.

Kong L, Li G, Jin L, Hu H. Pyrolysis behaviors of two coal-related model compounds on a fixed-bed reactor. Fuel Process Technol. 2015;129:113–9.

Gao J, Zhang Y, Meng D, Jiao T, Qin X, Bai G, Liang P. Effect of ash and dolomite on the migration of sulfur from coal pyrolysis volatiles. J Anal Appl Pyrolysis. 2019;140:349–54.

Wang B, Zhao S, Huang Y, Zhang J. Effect of some natural minerals on transformation behavior of sulfur during pyrolysis of coal and biomass. J Anal Appl Pyrolysis. 2014;105:284–94.

Guan R, Li W, Li B. Effects of Ca-based additives on desulfurization during coal pyrolysis. Fuel. 2003;82(15–17):1961–6.

Jia X, Wang Q, Cen K, Cheng L. Sulfur transformation during the pyrolysis of coal mixed with coal ash in a fixed bed reactor. Fuel. 2016;177:260–7.

Zhang Y, Liang P, Jiao T, Wu J, Zhang H. Effect of foreign minerals on sulfur transformation in the step conversion of coal pyrolysis and combustion. J Anal Appl Pyrolysis. 2017;127:240–5.

Liang P, Jiang W, Zhang Y, Wang X, Zhu J. Effect of circulating ash on sulfur conversion characteristics in the coal polygeneration process. Fuel Process Technol. 2016;150:16–22.

Liu Q, Hu H, Zhou Q, Zhu S, Chen G. Effect of mineral on sulfur behavior during pressurized coal pyrolysis. Fuel Process Technol. 2004;85(08–10):863–71.

Liu Q, Hu H, Zhu S, Zhou Q, Li W, Wei X, Xie K. Desulfurization of coal by pyrolysis and hydropyrolysis with addition of KOH/NaOH. Energy Fuels. 2005;19(4):1673–8.

Zhang D, Yani S. Sulphur transformation during pyrolysis of an Australian lignite. Proc Combust Inst. 2011;33(2):1747–53.

Li D, Zhang C, Xia J, Tan P, Yang L, Chen G. Evolution of organic sulfur in the thermal upgrading process of Shengli lignite. Energy Fuels. 2013;27(6):3446–53.

Guo Z, Fu Z, Wang S. Sulfur distribution in coke and sulfur removal during pyrolysis. Fuel Process Technol. 2007;88(10):935–41.

Fallah RN, Azizian S, Reggers G, Carleer R, Schreurs S, Ahenach J, Meynen V, Yperman J. Effect of aromatics on the adsorption of thiophenic sulfur compounds from model diesel fuel by activated carbon cloth. Fuel Process Technol. 2014;119:278–85.

Guo H, Wang X, Liu F, Wang M, Zhang H, Hu R, Hu Y. Sulfur release and its transformation behavior of sulfur-containing model compounds during pyrolysis under CO2 atmosphere. Fuel. 2017;206:716–23.

Yan J, Yang J, Liu Z. SH Radical: the key intermediate in sulfur transformation during thermal processing of coal. Environ Sci Technol. 2005;39(13):5043–51.

Calkins WH. Investigation of organic sulfur-containing structures in coal by flash pyrolysis experiments. Energy Fuels. 1987;1:59–64.

Xu L, Yang J, Li Y, Liu Z. Behavior of organic sulfur model compounds in pyrolysis under coal-like environment. Fuel Process Technol. 2004;85(8–10):1013–24.

Mullens S, Yperman J, Reggers G, Carleer R, Buchanan AC III, Britt PF, Rutkowski P, Gryglewicz G. A study of the reductive pyrolysis behaviour of sulphur model compounds. J Anal Appl Pyrolysis. 2003;70:469–91.

Liu F, Xie L, Guo H, Mei X, Hu R, Hu H. Sulfur release and transformation behaviors of sulfur-containing model compounds during pyrolysis under oxidative atmosphere. Fuel. 2014;115:596–9.

Tao X, Tang L, Xie M, He H, Xu N, Feng L, Yang Y, Luo L. Dielectric properties analysis of sulfur-containing models in coal and energy evaluation of their sulfur-containing bond dissociation in microwave field. Fuel. 2016;181:1027–33.

Fuli Z, Huiqing G, Ying L, Fenrong L, Ruisheng H. Theoretical study on desulfurization mechanisms of a coal-based model compound 2-methylthiophene during pyrolysis under inert and oxidative atmospheres. Fuel. 2019;257:116028.

Acknowledgements

This study was financially supported by the Project of Natural Science Foundation of China (No.21865018) and the Project of Natural Science Foundation of Inner Mongolia (No. 2018MS02005 and No. 2019MS02001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Guo, H., Xue, Y. et al. Effects of Fe3+ on sulfur release during pyrolysis of sulfur-containing model compounds under different atmospheres. J Therm Anal Calorim 147, 1597–1605 (2022). https://doi.org/10.1007/s10973-020-10437-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10437-z