Abstract

Domestic refrigerator is one of the major energy-consuming appliances, and the enhancement of its energy efficiency plays a vital role in implementing the energy conservation policies and green building concepts in residential sector. The major strategies used to improve the performance of domestic refrigerators are the replacement of existing components, use of alternative refrigerants and the reduction in condensing pressure. Therefore, in this work, the conventional air-cooled condenser has been replaced with water-cooled condensers such as shell-and-coil and brazed-plate heat exchangers to maintain a low compression ratio and condensing pressure. The performance of a domestic refrigeration system retrofitted with water-cooled condensers has been studied using experimental methods. The result showed that the system with water-cooled condensers reduces the pull-down time and the per day energy consumption by 70% and 3.5%, respectively. Moreover, the proposed system can improve the COP and exergy efficiency by 6.4% and 4.9%, respectively. Compared to shell-and-coil heat exchanger, the system with brazed-plate heat exchanger can reduce irreversibility and TEWI by 3.9% and 3.7%, respectively. In this study, the system with brazed-plate heat exchanger showed better performance than the shell-and-coil heat exchanger for all operating conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The growth of developing countries leads to a rapid increase in energy consumption and a significant effect on environmental impacts like climate change, depletion of energy resources and deforestation [1]. The energy usage in domestic sector is about 35% of the global energy consumption, and it plays the most important role in energy-related issues in developing countries [2]. In the residential sector, cooling appliances like refrigerators and freezers consume more energy as they are connected with the grid for 24 h [3]. In China, 22.2% of additional electrical energy is consumed by the household with refrigerator when compared to the household without refrigerator [4]. In India, electricity consumed by refrigerators is estimated to be 13.2 TWh; however, this figure will increase to 65.5 TWh in 2030 [5].

There is a pressing need to decrease the carbon dioxide (CO2) emissions for decelerating the risk of global climate change and to achieve that the reduction in electricity demand and the increment in energy efficiency of the domestic sector play a vital role. The objective of any green building design is to reduce the energy consumption and lower the emission of greenhouse gases. The European Union emphasizes closer to zero energy consumption by 2020 for all the upcoming buildings [6]. The factors influencing the domestic electricity consumption decide the CO2 emission and energy consumption [4].

The studies on alternate refrigerants including HFCs, HCs, HFC/HC mixtures, HFC mixtures, R1234yf show that the energy consumption in refrigeration system is close to or slightly higher than the conventional systems [7, 8]. Therefore, the performance may be further improved by appropriate modifications in the components of the system. Among the various components in a refrigeration system, condenser plays a vital role in energy consumption. It has been reported that a reduction of 1 °C condenser temperature can reduce 2% of total energy consumption [9].

The condenser temperature decrement of approximately 8 °C and the corresponding decrement in power consumption of 10% are obtained by using a standard wire-and-tube condenser, equipped with phase-change materials [10]. The study on spiral wire-on-tube condenser in a refrigerator shows that the decrease in condensing temperature can reduce the per day energy consumption of the refrigerator by 2.37%. This is due to the combined effect of decrease in compressor ON time ratio and compressor power [11]. A mathematical model of hot-wall condensers in domestic refrigerators predicts that the heat transfer characteristics are influenced by various design parameters such as tube length and capacity. The outer heat transfer resistance of this type of condensers contributes to about 80% and 83–95% of the total heat transfer for single- and two-phase flows, respectively [12, 13].

Even though air-cooled condenser consumes more energy, its higher condensing temperature augments the pressure ratio and reduces the compressor life and COP. It is preferred in small systems due to its low cost and easy maintenance. Compared to air-cooled condensers, the superiority of water-cooled condensers is their ability to absorb more heat and consume less energy. The water-cooled condensers lower the condensing pressure and reduce the compression work, thus increasing compressor life and refrigeration capacity [14]. The simulation study conducted on air-conditioning system shows that the energy consumption of air-cooled condenser is 20% higher than the water-cooled condenser [15]. The water-cooled condensers also play an important role in minimizing refrigerant charge and reducing the environmental impact [16].

Shell-and-coil heat exchanger is commonly used in all engineering applications. The experimental investigation shows that the pressure drop and average heat transfer coefficient of shell-and-coil exchanger increase with the increase in mass flux and vapour quality of refrigerant [17]. Plate heat exchangers (PHEs) used as condenser can provide the most compact design in terms of surface area with low initial cost. The heat transfer coefficient of PHE is also three to five times greater than that of shell-and-coil heat exchanger [18]. The higher thermal efficiency of PHE allows a system to operate at closer approach temperatures than shell-and-tube exchangers, by which it would result in energy savings [19]. The compactness of brazed-PHE results in a low refrigerant charge, which has lower environmental impact and higher safety level without compromising the system performance [20].

The major challenge expected to implement the water-cooled condensers in domestic refrigeration system is the management of cooling water and maintaining its temperature near to the WBT of the atmosphere. To overcome this issue, a few attempts are already made to utilize the heat taken by the water-cooled condensers. In Hong Kong, energy consumed by residential air conditioner is reduced by the wider application of SEHRAC (Applying Storage-Enhanced Heat Recovery Room Air-Conditioner). The idea behind this application is to use the compressor discharge temperature to satisfy the daily household water heating demand, which in turn decreases 9.3% of the total energy consumption of the residential sector [21]. A 263-litre refrigerator consisting of a counter-current shell-and-tube water-cooled heat exchanger with a 122-litre storage tank has been studied to check the improvement in performance. Since the heated water is stagnant during a study period of 1 month, compressor energy consumption has been observed to be 8% higher than the conventional systems [22].

The performance of domestic refrigerator has been checked with various new refrigerants, modification of system components and operating methods. But, the existing refrigerator is compact one in all aspects; however, the total energy consumption in domestic sector is increasing day by day due to the increase in the usage of refrigerators throughout the world. Moreover, intensive research is going on to reduce the energy consumption and implement the green building concept in residential buildings. Therefore, a specific research is focused on domestic refrigeration system with water-cooled condenser for improving the energy efficiency. Even though water-cooled condensers are tested in the domestic refrigerators, appropriate strategy to improve the performance is not reported explicitly. Among the water-cooled condensers, brazed-PHE has many advantages over other heat exchangers [15]. Since a detailed study with the use of brazed-PHE in domestic refrigerator is not established well, the same has been taken for this investigation.

The previous studies show that the water-cooled condensers have better performance than the system with air-cooled condensers [16, 19], and they are given preference for refrigeration capacity above 20 TR [14]. However, this paper investigates and compares the performance of a 190-l domestic refrigerator that works on shell-and-coil heat exchanger and brazed-plate heat exchanger (BPHE) as water-cooled condensers, which is more compact and can maintain a condensing temperature lower than the conventional air-cooled condensers. The experimental results indicated that the use of BPHE in domestic refrigerator could improve the energy efficiency and reduce the environmental impacts caused by the refrigeration sector and also that it is compact in size and has better heat transfer coefficient compared to the shell-and-coil type of water-cooled condenser. The proposed concept has been validated through an experimental investigation.

Experimental set-up

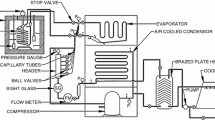

The schematic diagram of the experimental set-up is shown in Fig. 1. The experiments were conducted according to the guidelines of ISO 8187 [23]. The technical specification of experimental set-up is given in Table 1. Four compound pressure gauges with an accuracy of ± 0.02 bar with the range from 1 to 14 bar are used to measure the inlet and outlet pressures of the capillary tubes and the compressor. The RTD (PT100)-type temperature sensors with an accuracy of ± 0.1 °C over a wide temperature range from − 200 to 550 °C are provided in the compressor outlet, condenser outlet, evaporator inlet, compressor inlet, compressor dome and at various positions inside the freezer, food and crisper compartments of the system. The power consumption of the compressor is also measured by a single-phase, two-wire solid-state digital energy meter (current rating 5–30 A, LCD display, accuracy ± 0.1 W and sensitivity 0.01 W). The accuracy of measuring instruments has been fixed either by calibrating the same with standard methods or from the manufacturer specification.

Four ball valves are used to connect the calorimeter set-up and water-cooled condensers with conventional system. An evaporator is kept in a calorimeter to evaluate the actual COP. The calorimeter is insulated and filled with ethylene glycol solution. The tests were conducted in the calorimeter set-up for various heat loads. A dimmerstat is used to maintain the temperature inside the calorimeter. An electronic balance with accuracy ± 0.01 g has been used to ensure the charge quantity. A mini cooling tower is provided to cool the water left from the water-cooled BPHE. A pump and cooling fan are used to maintain the water circulation through water-cooled condensers.

Experimental procedure

Before starting the experiment, the refrigeration system was completely flushed with nitrogen gas to remove the moisture content and other foreign materials inside the circuit. In order to reduce the experimental uncertainties, experiments were repeated for a minimum of three times and the average values were considered. All the experimental observations were taken at steady-state conditions. In large systems with water-cooled condensers, the RH level plays an important role in the performance of the condensers, since the water is cooled by atmospheric air in the cooling towers. In this study, such condition did not prevail; however, the inlet temperature of the cooling water was selected according to the wet bulb temperature. For the purpose of experimentation, a constant temperature water bath was used to maintain the inlet temperature of the cooling water as per the test requirements.

The optimization of charge quantity and capillary length was carried out as preliminary experimental study, and further pull-down test, per day energy consumption test and COP test were conducted. The pressure and temperature at various positions of the components were also recorded. The pump work was measured and incorporated in the calculation of all the performance parameters used in the study.

According to the methodology used in the literature [24], the influence of uncertainty in measuring instruments on the performance parameters was calculated. The maximum uncertainty in COP was observed as 2.4%. This justifies the reliability of the experimental study. Various operating conditions considered in the experimental study are shown in Table 2.

Exergy analysis

Exergy analysis is carried out to find the exergy efficiency and irreversibility of the domestic refrigerator. The assumptions and conditions used in this study for reducing the complexities are change in kinetic and potential energies is negligible, the variation in thermophysical properties is one-dimensional and the mass flow rate is constant.

The specific exergy in any state is given by the equation [25, 26]:

where h, T, so refer to the enthalpy (J/kg), temperature (K), entropy (J/kgK) and ambient, respectively. The total irreversibility of the system is

where I, comp, cond, capi and evap refer to irreversibility, compressor, condenser, capillary tube and evaporator, respectively. The exergy efficiency is given by the following equation [27, 28]:

where \(\psi_{\text{evap, out}}\) refers to evaporator outlet and \(\psi_{\text{evap, in}}\) refers to evaporator inlet and \( \varvec{W}\) refers to work done of the compressor. For this analysis, REFPROP 9.1 is used for obtaining thermophysical properties of the refrigerant [29]. The change in potential and kinetic energies is assumed as negligible.

Results and discussion

The performance of refrigeration system with water-cooled condensers such as shell-and-coil heat exchanger and BPHE has been investigated for various operating conditions. The results have been used to study the performance parameters such as per day energy consumption, compressor work, COP, exergy efficiency, total irreversibility of the system and total equivalent warming impact.

The energy consumption of the compressor in relation to time during the pull down is shown in Fig. 2. The figure shows that the cut-off for the system with shell-and-coil heat exchanger and BPHE is 48 min and 33 min, respectively. Among the water-cooled condensers, system with BPHE reduces 31.3% of the pull-down time, because it has high rate of cooling due to its high heat transfer coefficient. So the desired temperature is reached faster than the system with the shell-and-coil heat exchanger. Consequently, the per day energy consumption of the system with BPHE is reduced by 3.5% than that of shell-and-coil heat exchanger for 32 °C ambient temperature. When compared to the air-cooled condenser, water-cooled condensers reduce 70% of the pull-down time and 22% to 28% of the per day energy consumption (Fig. 3).

Figure 4 shows the compressor work as a function of the calorimeter temperature for the three types of condensers with similar operating conditions. It can be observed that the compressor work increases with increase in calorimeter temperature for all condensers. The compressor work of BPHE is 4% lower than that of the shell-and-coil heat exchanger. This is due to the low compression ratio and high mass flow rate of refrigerant. Accordingly, Fig. 5 represents that the system with BPHE can enhance the COP of the system from 3.6% to 6.4% than the system with shell-and-coil heat exchanger, which may be due to the low pressure ratio. Moreover, the system with water-cooled condensers reduces the compressor work by 17% and increases the COP from 42% to 53% than the domestic refrigerator with air-cooled condenser.

The cooling water temperature plays an important role in the performance of the system in water-cooled condensers. Therefore, the variation in COP has been studied for various cooling water temperatures at constant evaporator temperature of 18 °C and is plotted in Fig. 6. The figure shows that the COP decreases with the increase in cooling water temperature. When the cooling water temperature is above 30 °C, the COP reduces below the normal. Therefore, it is not advisable to operate the condenser with the cooling water temperature above 30 °C. Among the two types of water-cooled condensers in the study, BPHE shows 4%–6% higher COP than the shell-and-coil heat exchanger. This is due to the high heat transfer properties of the BPHE.

The environmental impact of any system can be studied from the exergy efficiency. Therefore, the calculation has been done for the system with three different types of condensers, operating with similar working conditions at various calorimeter temperatures, and is shown in Fig. 7. It is observed that the system with BPHE can improve the exergy efficiency by 4.9% as compared to system with shell-and-coil heat exchanger. Figure 8 shows that the total irreversibility of system with BPHE is 1.5–3.9% less than the system with shell-and-coil heat exchanger. This is caused by the low exergy destruction, which is due to the low temperature difference maintained in the BPHE. Compared to the air-cooled condenser, the system with water-cooled condensers shows high exergy efficiency and lower total irreversibility in all the tested conditions.

Total equivalent warming impact (TEWI) is a prominent environmental index, and it is calculated using the summation of direct impact and indirect impact according to the following equation [17]. It was calculated for 15 years’ lifetime, − 18 °C freezer compartment temperature, 32 °C ambient temperature, 24 °C cooling water temperature and is compared in Table 3.

where m, l, Sl, r and E are refrigerant charges (kg), leakage rate (%), service life (years), CO2 generation emission (kg CO2/kWh) and energy consumption (kWh/year), respectively. Table 3 shows that the calculated TEWI of the system with BPHE is lower than that of the system with shell-and-coil heat exchanger by about of 3.7%. This is due to the higher energy efficiency. The water-cooled condensers show better performance than the air-cooled condenser.

Conclusions

The domestic refrigerator with BPHE, shell-and-coil heat exchanger and air-cooled condenser has been studied to check the possibility of energy conservation and exergy efficiency. Based on the experimental observations, the system with BPHE or shell-and-coil heat exchanger as water-cooled condensers can significantly reduce the compression ratio of a refrigeration system. The system with BPHE can reduces the per day energy consumption by 3.5% and increases the COP from 3.6% to 6.4% than the system with shell-and-coil heat exchanger. The exergy efficiency and TEWI of the system with BPHE are 4.9% higher and 3.7% lower, respectively, than that of the system with shell-and-coil heat exchanger. In this study, system with brazed-plate heat exchanger showed better performance than the shell-and-coil heat exchanger for all operating conditions. Thus, the energy shared by domestic refrigerator in the total energy consumption of the building can be minimized by the implementation of the proposed system.

References

IEA. World Energy Outlook 2010. International Energy Agency.Paris.IndiaStat.com. India Statistical Information Database. Delhi; 2010.

van Ruijven BJ, van Vuuren DP, de Vries BJM, Isaac M, van der Sluijs JP, Lucas PL, Balachandra P. Model projections for household energy use in India. Energy Policy. 2011;2011(39):7747–61.

Geppert J, Stamminger R. Analysis of effecting factors on domestic refrigerator’s energy consumption in use. Energy Convers Manag. 2013;76:794–800.

Jones RV, Fuertes A, Lomas KJ. The socio-economic, dwelling and appliance related factors affecting electricity consumption in domestic buildings. Renew Sustain Energy Rev. 2015;43:901–17.

McNeil, MA. Progress towards managing residential electricity demand: impacts of standards and labeling for refrigerators and air conditioners in India. In: 5th international conference on energy efficiency on domestic appliances and lighting EEDAL, Berlin, Germany; 2009.

Yu H, Pan SY, Tang BJ, Mi ZF, Zhang Y, Wei Y-M. Urban energy consumption and CO2 emissions in Beijing: current and future. Energ Effic. 2015;8:527–43.

Raja B, Santhappan SJ, Dhasan LM. Heat transfer correlation for a refrigerant mixture in a vertical helical coil evaporator. Therm Sci. 2009;13:197–206.

Mohanraj M, Jayaraj S, Muraleedharan C, Chandrasekar P. Experimental investigation of R290/R600a mixture as an alternative to R134a in a domestic refrigerator. Int J Therm Sci. 2009;48:1036–42.

Ayub ZH. Plate heat exchanger literature survey and new heat transfer and pressure drop correlations for refrigerant evaporators. Tex Heat Transf Eng. 2003;24:3–16.

Sonnenrein G, Elsner A, Baumhogger E, Morbach A, Fieback K, Vrabec J. Reducing the power consumption of household refrigerators through the integration of latent heat storage elements in wire-and tube condensers. Int J Refrig. 2015;51:154–60.

Zhang Z, Huang D, Zhao R, Leng Y. Effect of airflow field optimization around spiral wire-on-tube condenser on a frost-free refrigerator performance. Appl Therm Eng. 2017;114:785–92.

Gupta JK, Gopal MR. Modeling of hot-wall condensers for domestic refrigerators. Int J Refrig. 2008;31:979–88.

Bansal PK, Chin TC. Design and modelling of hot-wall condensers in domestic refrigerators. Appl Therm Eng. 2002;22:1601–17.

Hosoz M, Kilicarslan A. Performance evaluations of refrigeration systems with air-cooled, water-cooled and evaporative condensers. Int J Energy Res. 2004;28:683–96.

Li Y, Wua J, Shiochi S. Modelling and energy simulation of the variable refrigerant flow air conditioning system with water-cooled condenser under cooling conditions. Energy Build. 2009;41:949–57.

Raveendran PS, Sekhar SJ. Performance studies on a domestic refrigerators retrofitted with building-integrated water-cooled condenser. Energy Build. 2017;134:1–10.

Gupta A, Kumar R, Gupta A. Condensation of R-134a inside a helically coiled tube-in-shell heat exchanger. Exp Therm Fluid Sci. 2014;54:279–89.

ASHRAE Handbook. HVAC systems and equipment. Atlanta: ASHRAE. Inc; 2008.

Raveendran PS, Sekhar SJ. Experimental studies on domestic refrigeration system with brazed plate heat exchanger as condenser. J Mech Sci Technol. 2016;30:2865–71.

Longo GA. Refrigerant R134a condensation heat transfer and pressure drop inside a small brazed plate heat exchanger. Int J Refrig. 2008;31:780–9.

Jia J, Lee WL. Applying storage-enhanced heat recovery room air-conditioner (SEHRAC) for domestic water heating in residential buildings in Hong Kong. Energy Build. 2014;78:132–42.

de Marchi Neto IM, Padilha A, Scalon VL. Refrigerator COP with thermal storage. Appl Therm Eng. 2009;29:2358–64.

ISO, International Standard Organization, International Standard-8187, Household refrigerating appliances (refrigerators/freezers) characteristic and test methods, International Organization for Standardization, Switzerland; 1991.

Holman JP. Experimental methods for engineers. 7th ed. New York: McGraw Hill Publishers; 2000.

Raveendran PS, Sekhar SJ. Exergy analysis on domestic refrigeration system with brazed plate heat exchanger as condenser. J Therm Anal Calorim. 2017;127:2439–46.

Saravanakumar R, Selladurai V. Exergy analysis of a domestic refrigerator using eco-friendly R290/R600a refrigerant mixture as an alternative to R134a. J Therm Anal Calorim. 2014;115:933–40.

Anand S, Tyagi SK. Exergy analysis and experimental study of a vapour compression refrigeration cycle. J Therm Anal Calorim. 2012;110:961–71.

Prabakaran R, Lal DM. A novel exergy based charge optimisation for a mobile air conditioning system. J Therm Anal Calorim. 2018;132:1–12.

Lemmon EW, Huber ML, McLinden MO. Reference fluid thermodynamic and transport properties (REFPROP), Version 9.1.in NIST Standard Reference Database 23. Gaithersburg: National Institute of Standards and Technology; 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raveendran, P.S., Sekhar, S.J. Investigation on the energy and exergy efficiencies of a domestic refrigerator retrofitted with water-cooled condensers of shell-and-coil and brazed-plate heat exchangers. J Therm Anal Calorim 136, 381–388 (2019). https://doi.org/10.1007/s10973-018-7742-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7742-5