Abstract

The thermal decomposition of famciclovir (FCV) was measured with thermogravimetry, differential scanning calorimetry, and thermogravimetric analysis coupled with Fourier transform infrared spectroscopy. The IR spectra, high-performance liquid chromatography, and liquid chromatography–mass spectrometry of FCV and the residues of its thermal decomposition at various temperatures were determined. The molecular bond orders were calculated using an ab initio method from the GAMESS program of quantum chemistry. The mechanism of thermal decomposition for FCV was discussed. The kinetic parameters for thermal decomposition such as activation energy E a and the pre-exponential factor A were obtained using the Ozawa method. The prospective lifetime of FCV was estimated using the Dakin equation. The results indicated that the thermal decomposition of FCV is a two-step process. The initial decomposition temperature in either nitrogen or air is about 205 °C. The decomposition of FCV does not go through 2-amino-purine stage, 2-amino-purine, and alkane chain segment both decompose simultaneously during the first stage. For decomposition in nitrogen, the E a and A for the initial thermal decomposition are 107.8 kJ mol−1 and 2.19 × 109 min−1, respectively. For decomposition in air, the corresponding E a and A are 96.4 kJ mol−1 and 1.45 × 108 min−1, respectively. The FCV has good thermal stability under routine temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Famciclovir (FCV), which chemical name is 2-[2-(2-amino-9H-purin-9-yl)ethyl]-1,3-propanediol diacetate [1], is a guanosine analogue antiviral drug used for the treatment of various herpesvirus infections, most commonly for chronic delta hepatitis [2] herpes zoster (VZV) [3], herpes simplex virus types 1 (HSV-1), and 2 (HSV-2) [4]. FCV is licensed oral formulation of the guanosine analogue penciclovir. FCV is absorbed well and converted efficiently to penciclovir, which is a potent inhibitor of viral DNA synthesis [5,6,7]. FCV is marketed under the trade name Famvir (Novartis). On August 24, 2007, the United States Food and Drug Administration approved the first generic version of FCV.

Thermoanalysis has been widely applied in the pharmaceutical field for several purposes including purity determination for drugs, composition analysis of drugs and raw materials, melting point testing, crystal formation and change tests, thermal stability of medicines, evaluation of the validity, thermal decomposition kinetics, identification of natural drugs, and process optimization for production of drugs [8,9,10,11,12].

The results of thermal stability studies and the mode of thermal decomposition of FCV have important theoretical significance for further understanding of the chemical properties of FCV. These considerations may also have practical consequences for the production, processing and storage of FCV. However, the researches on the thermal stability and the decomposition kinetics of FCV have not yet been reported. Now, the thermal decomposition processes for FCV in nitrogen and air atmospheres have been examined using thermogravimetric analysis (TG) and differential scanning calorimetry (DSC). The identity of volatile species that evolved during thermogravimetric decomposition was established using coupled with Fourier transform infrared spectroscopy (TG–FTIR). Residues of thermal decomposition at different stages were examined using IR spectra, high-performance liquid chromatography (HPLC), and liquid chromatography–mass spectrometry (LC–MS). Molecular bond orders for FCV were calculated using an ab initio method from the GAMESS program of quantum chemistry [13, 14]. The mode of thermal decomposition for FCV was discussed. The kinetics of thermal decomposition of FCV was studied using the Ozawa method [15,16,17]. The apparent activation energy E a and pre-exponential factor A for thermal decomposition reactions were obtained from thermogravimetric data under different heating rates. The prospective lifetime of FCV at different temperatures was estimated to provide reference for the correct and reasonable use of this drug.

Experimental

Reagents

FCV (99.5%) and 2-amino-purine (99.0%) were purchased from the Aladdin Chemistry Co. Ltd. (Shanghai, China). These compounds were used without further purification. Acetonitrile (ACN) (HPLC purity grade) and ammonium acetate (analytical purity grade) were purchased from Shanghai Zhanyun Chemical Co., Ltd. (Shanghai, China). Ultrapure water was produced by a Millipore Elix3 (Billerica, MA, USA) water purifying system.

Experimental methods

The TG, DTG, and DSC curves for FCV decomposition were obtained using an SDT–Q600 simultaneous thermal analyzer (TA Instruments Inc., USA) and an alumina ceramic crucible containing 7 mg of sample in either nitrogen or air atmospheres (100 mL min−1). The software package provided by the manufacturer was used for estimating the decomposition kinetics and the prospective lifetime for FCV. Five different heating rates were used: 2.5, 5.0, 10.0, 15.0, and 20.0 °C min−1 from ambient to 800 °C.

The residues from thermal decomposition were obtained by FCV sample heated from room temperature to the selected temperature (nitrogen flow: 100 mL min−1, heating rate: 10 °C min−1), the beginning of mass loss, and middle of the first mass loss stage.

The TG–FTIR analysis was conducted using an SDT-Q600 Thermal Analyzer coupled with a Nicolet iS10 FTIR spectrophotometer (Thermo Fisher Scientific Inc. USA) equipped with a stainless steel transfer line and gas cell. Approximately 10 mg of sample was heated from room temperature to 800 °C at 20 °C min−1. These experiments were carried out in both dry nitrogen and dry air. The flow rate of gases into the TG–FTIR cell was 100 mL min−1. Both the gas cell for IR detection and the connection line transferring evolved gases from TG to FTIR were kept at 220 °C to prevent gas condensation. The IR spectra of the evolved gases were collected at 4 cm−1 resolution with co-adding of 32 scans per spectrum from 4000 to 500 cm−1.

The IR spectra of FCV and solid residues of thermal decomposition were collected by accumulating 32 scans at a resolution of 4 cm−1 from 4000 to 400 cm−1 using a KBr pellet technique.

Separation studies of standard samples and residues were performed using an HPLC system from Hitachi High-Technologies Corporation of Japan. The instrument consisted of an LC 2130 quaternary gradient pump with a LC 2140 UV–Vis detector. The data were acquired and processed using a HS 2000 chromatography workstation (Hangzhou Science & Techn. Co., China). Reversed phase C-18 columns (250 mm × 4.6 mm i.d. size) containing 5-μm stationery phase were purchased from Shanghai Awence Science & Technology Co., Ltd. The mobile phase consisted of 80% 50 mmol L−1 ammonium acetate solution and 20% ACN. The mobile phase was filtered through a 0.45-μm membrane and degassed via ultrasonication before use. The flow rate was kept constant at 0.6 mL min−1, and the temperature of column was maintained at 30 °C. The 2.5-mg samples (the standard samples or residues from thermal decomposition) were dissolved in 5 mL of mobile phase. The sample solution was filtered through 0.45-μm membrane before injection. The injection volume was 5 μL, and the detection wavelength was 254 nm.

An Agilent 1290 infinity LC system equipped with a G4220A binary pump, G4226A autosampler, and G1330B 1290 thermostat, coupled with a 6460 triple quadrupole mass spectrometer (Agilent Technologies, USA) with an electrospray ionization source, was used for LC–MS analysis. The autosampler was maintained at 4 °C, and the column compartment was set at 35 °C. Chromatographic separation was achieved using an Agilent ZORBAX XDB C-18 column (250 mm × 4.6 mm × 5 μm). The mobile phase consisted of 80% ultrapure water and 20% ACN. The mobile phase was filtered through a 0.45-μm membrane and degassed via ultrasonication before use. The flow rate was kept constant at 0.6 mL min−1, and the temperature of column was maintained at 30 °C. The mass spectrometer was operated in both negative and positive ion modes using ESI under the following general conditions: capillary voltage, 3.0 kV (+) or 3.5 kV (−); nozzle voltage, 0 (+) or 500 (−); fragment voltage, 135 V; nebulization pressure, 45 psi; temperature of drying gas, 325 °C; drying gas flow, 5 L min−1; sheath gas temperature, 350 °C; sheath gas flow, 11 L min−1. Data were acquired using the Mass Hunter software (Agilent Technologies) in the multiple reaction monitoring (MRM) mode by recording ion currents for the following transitions: 100–1000 m/z. About 2.5 mg of sample (residue from thermal decomposition) was dissolved in 5 mL of mobile phase. The sample solution was filtered through a 0.45-μm membrane before injection. The injection volume was 10 μL.

Quantum chemical methods

ChemDraw software attached to ChemOffice (version: Ultra 11.0.1, Cambridgesoft, 2007) was used to predict the molecular structure of FCV. The GAMESS package is a general ab initio quantum chemistry package attached to ChemDraw and was used to calculate molecular energy, charge distribution, and bond order. The HF/6-31G level was used. The calculation accuracy and convergence threshold were the default values in all programs. All the calculations were completed using a personal computer.

Results and discussion

The thermal decomposition process for FCV

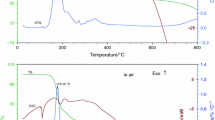

The thermal decomposition curves for FCV in nitrogen and air atmosphere obtained at a heating rate of 10 °C min−1 are shown in Fig. 1. It can be seen that the thermal decomposition of FCV occurs in two-step with decomposition beginning at about 205 °C. In nitrogen, the DTG peak temperature of the first stage is 314.1 °C, and the residual mass is 5.0% at 340 °C. The second stage is a slow mass loss process, and there is 1.3% remnant at 800 °C. In air, the DTG peak temperature of the first stage is 314.3 °C, and the residual mass is 6.6% at 335 °C. The mass loss rate of the second stage is quicker than in nitrogen, and the decomposition completes about 610 °C. The mass loss ratios of the first stage both are much larger than the theoretical value of losing the alkyl diester portion (58.3%, the residue is 2-amino-purine). It means that the first stage of the decomposition already contains the decomposition of 2-amino-purine, and these small amounts of residues mainly are carbide. The second stage of thermal decomposition in nitrogen atmosphere is a thermal carbonization process of organics, and the second stage in air atmosphere is an oxidative decomposition process of organics.

Before the decomposition of FCV, the DSC curves both have an obvious endothermic peak. This suggests that FCV melts before decomposition. In nitrogen, the DSC peak temperature is 98.6 °C, and the melting heat (peak area) is 94.7 J g−1. In air, the DSC peak temperature is 98.4 °C, and the melting heat of FCV is 95.4 J g−1. The DSC curves corresponding to each first mass loss stage both have an endothermic peak. This suggests that the first stages of thermal decomposition both are mainly thermal cracking processes.

By comparing the thermogravimetric curves at different heating rates, experimental results show that with the increase in heating rate, thermogravimetric curves and the peak temperature of DTG curve T max move slightly to higher temperature. The relationships between heating rate β and DTG peak temperature T max1 of FCV in nitrogen atmosphere and in air atmosphere are shown in Table 1.

The FTIR analysis of the gaseous species and the solid residues produced by the thermal degradation of FCV [18, 19]

The analysis of the gases produced during the decomposition process can provide valuable information about the pathway of decomposition. TG–FTIR is widely used to analyze the gaseous products during the thermal decomposition [9, 12, 20, 21]. The three-dimensional diagrams of infrared absorption of evolved gas products versus time and wave number during the thermal decomposition processes are shown in Fig. 2. The Gram–Schmidt (GS) curves of the TG–FTIR are shown in Fig. 3. TG–FTIR spectra of the gaseous products at different temperatures of the thermal decomposition of FCV are shown in Fig. 4. Contrast to Fig. 1, it can be seen that the GS plots both are similar to the DTG curves, and each GS peaks corresponding to DTG peaks. From Figs. 3 and 4, it can be seen that the IR spectra of a, b, and c points in two atmospheres are highly consistent, respectively. It means that the decomposition process of this region in two atmospheres is the same. The IR spectra of the a points, namely the initial stage of thermal decomposition, mainly contain C=O band (1796 cm−1) and C–O band (1220 cm−1) of carboxylic ester. It means that the initial stages of thermal decomposition both mainly are the thermal cracking of the acetic acid ester. The IR spectra of the b points, namely the first DTG peak of thermal decomposition, contain C=O band and C–O band of carboxylic ester, C=N bond (1605 cm−1) of imine, CH bands (2956, 1422, and 1372 cm−1) of alkane, and small amount of CO2 bands (2282, 2308, and 669 cm−1). It means that the whole FCV molecule including carboxylic ester, alkane chain, and purine ring all is decomposed during the first stage of thermal decomposition. The IR spectra of the c points, namely the end of the first stage, are similar with those of b points, just the proportions of bands are the smaller, and meanwhile the NH3 bonds (965 and 931 cm−1) can be seen. It means that part of amino translates into NH3 during this stage. The IR spectrum of the d point, namely the second stage, in nitrogen atmosphere, just contains very small amount of bonds of carboxylic ester and NH3. It means that the second stage in nitrogen atmosphere is the thermal cracking process of the residue. The IR spectrum of d point in air atmosphere contains very stronger CO2 bonds. It means that the second stage in air atmosphere is the oxidation decomposition of the residue.

TG–FTIR spectra of the evolved gaseous products of FCV obtained at different temperatures (a, b, c, and d corresponding to Fig. 3)

The analysis of solid residues formed at various temperatures can also provide direct information on changes that occur in the chemical composition of organic samples during thermal degradation. The infrared spectra of FCV and residues that formed at the various temperature stages during the thermal decomposition processes in nitrogen atmosphere are shown in Fig. 5. From Fig. 5, it can be seen that the IR spectrum of residue obtained at the initial stage of thermal decomposition (260 °C) is almost same with that of FCV. It means that the residue mainly is FCV and implies that FCV directly decomposes to small molecules. The IR spectrum of residue formed at 305 °C (the residual mass about 44.0%) is somewhat different from the IR spectrum of FCV, but their spectral profiles are very similar. It means that the most of residue still is FCV and implies that the decomposition of FCV has not undergone through 2-amino-purine stage.

HPLC analysis on intermediate residues from the thermal decomposition of FCV

In order to know whether the thermal decomposition of FCV goes through 2-amino-purine stages, the intermediate residues from thermal decomposition were analyzed with HPLC and compared with the chromatograms of standard samples. The results are shown in Fig. 6. The standard samples of 2-amino-purine and FCV are dissolved in mobile phase and turn into a colorless solution, and their retention times are 4.65 and 15.08 min, respectively. The residue obtained at 260 °C is a light brown solid that can be almost completely dissolved in mobile phase and turn into a nearly colorless solution. Its HPLC chromatogram contains X, Y, and Z three peaks, in which the Z peak should be FCV. The X and Y peaks should be intermediates. The residue of FCV obtained at 306 °C is a light brown solid, most of it can be dissolved in mobile phase and turn into a nearly colorless solution, and there is small amount of insoluble precipitate. Its HPLC chromatogram also contains X, Y, and Z three peaks, but the X and Y peaks are larger and the Z peak is smaller. The HPLC chromatograms of two residues both do not contain the peak of 2-amino-purine; it is demonstrated once again that the thermal decomposition of FCV does not undergone through 2-amino-purine stage.

LC–MS analysis on intermediate residues from the thermal decomposition acetyl

In order to confirm the composition of the residue, the soluble fraction of the residues formed at 305 °C was analyzed using LC–MS method, and the results are shown in Figs. 7. The LC–MS analysis proves that the Z peak in the HPLC chromatogram is FCV. The molecular mass of X is 279, it means that X is the product of FCV losing an acetyl group, and its structure may be 4-(2-amino-9H-purin-9-yl)-2-(hydroxymethyl)butyl acetate. The molecular mass of Y is 363, it means that Y is the product of FCV adding an acetyl group, and its structure may be 2-[(acetyloxy)methyl]-4-{2-[(1-hydroxyethyl)amino]-9H-purin-9-yl}butyl acetate. The molecular structures of intermediates X and Y are shown in Scheme 1.

Thermal decomposition mode of FCV

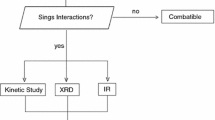

Theoretically, the thermal decomposition of organic molecules is due to the molecular kinetic energy increasing during heating. These include atomic oscillations that rupture the weaker chemical bonds. Lower the chemical bond order offers easier fracture. Thermodynamically, the decomposition process also depends on the stability of the decomposition products or intermediates generated. In order to understand the thermal decomposition mode of FCV, a theoretical discussion is made from the perspective of the molecular structure. A quantum chemical ab initio method is used to calculate molecular charge distribution and the bond orders for FCV (Scheme 2). According to the molecular bond order distributions of FCV, the position and sequence of the chemical bonds ruptured could be judged, and the thermal decomposition mode of FCV in the thermal decomposition process could be speculated. Because 2-amino-purine can have imino form and amino form structures [22,23,24], FCV should have imino form (labeled as FCV-1) and amino form (labeled as FCV-2) structures. From Scheme 2, it can be seen that the weakest bonds of FCV-1 are the C–O bonds (0.666 and 0.683) of acetate, and these bonds will rupture to form active intermediate I. Then, the weaker bonds, the C-N bond (0.729) of six-membered ring and the C-N bond (0.734) of five-membered ring, rupture subsequently to form active intermediate II. The active intermediate I and intermediate II immediately and directly decompose to small molecules and carbide. So, the FCV-1 all decompose at the first stage and the decomposition process of the FCV-1 does not go through 2-amino-purine stage. The weakest bonds of FCV-2 also are the C–O bonds (0.654 and 0.655) of acetate, but its weaker bond is the C-N bond (0.681) which links the purine ring and alkane chain segment, and all bond orders within purine ring are larger than this C-N bond. The rupture of this C-N bond will produce 2-amino-purine. In other words, the decomposition process of FCV-2 goes through 2-amino-purine stage. In fact, the results of the IR spectra, HPLC, and LC–MS all proved that the decomposition process of FCV does not go through 2-amino-purine stage, namely FCV exists with the imino form (FCV-1). The acetyl produced from thermal decomposition can combine with amino of FCV to form intermediate Y. The FCV just loses an acetyl to form intermediate X.

After comprehensive analysis of the above, speculated mode of thermal decomposition process for FCV is shown in Scheme 3.

Kinetics of thermal degradation of FCV in nitrogen and in air atmosphere

The thermal decomposition kinetics of FCV was studied using the ASTM E 1641 method [15]. This method is also known as the multiple heating rate method or the equal conversion rate method. This method does not use the model function of thermal decomposition. The activation energy E a and pre-exponential factor A are calculated independently based on the data that are determined from the same conversion rate of TA curves under different heating rate. Therefore, this method is also known as the model-free method.

The basic principle of this method is that the thermal decomposition reaction rate constant k relates to temperature T via the Arrhenius equation:

where k is reaction rate constant, t−1; A, is the pre-exponential factor, min−1; E a is the activation energy, J mol−1; R is the gas constant, 8.314 J K−1 mol−1; and T is the absolute temperature in Kelvin.

Ozawa [16], Flynn and Wall [17] deduced a thermodynamic approximate relationship between the heating rate β and the corresponding temperature T at a given conversion:

To specific convert ratio α 1 using heating rates β 1, β 2, and β 3, with corresponding temperature T 1, T 2, and T 3, Eq. (3) was obtained.

The Arrhenius activation energy is then determined from a plot of the logarithm of heating rate versus the reciprocal of the absolute temperature at a constant conversion level. The same linear relationship exists for the different conversions α 2, α 3, and α 4. Then, the pre-exponential factor A can be obtained from Eq. (4).

The experimental data were processed with Eqs. (3) and (4). The kinetic activation energy E a and pre-exponential factor A under different conversion rates of thermal decomposition process for the FCV could be obtained. The calculated kinetic parameters of thermal decomposition for the FCV are listed in Table 2, and the kinetic rate constants of thermal decomposition for FCV at the initial stages are expressed as Eqs. (5) and (6).

The decomposition of FCV in two atmospheres is a two-step process. From the beginning of decomposition to about 95% mass loss is the first stage and over 95% mass loss is the second stage. The variation of the kinetic parameters in the first stage is obviously; it means that the thermal decomposition process of FCV at the first stage is a complex decomposition reaction. The activation energy E a of the first stage during the thermal decomposition reaction in nitrogen is slightly larger than that in air, and the pre-exponential factor A in nitrogen is also slightly larger than that in air. Thus, the rate constants of the decomposition reaction in two atmospheres are similar; the rate constants in nitrogen are slightly less than that in air.

Dakin [25] showed that the lifetime of the material (at a given conversion) has a linear relationship with the reciprocal of temperature:

Here, τ is the prospective lifetime and T is thermodynamics temperature. This equation had been also used to predict the lifetime of medicines [26]. Specifically, a = E a/2.303R, and b is a constant at a given conversion rate α and corresponds to the pre-exponential factor and the thermal reaction function mode. The temperature and time under the different heating rate at a given conversion rate α are obtained by experiment. A linear relationship is obtained from a plot of the logarithm of time (log t) versus the reciprocal of temperature 1/T, i.e., the Dakin equation. It can be used to speculate the lifetime of a drug at different temperatures. Using 5% mass loss as the lifetime of the drug, some calculated prospective lifetimes of FCV are shown in Table 3.

The data in Table 3 indicate that the FCV has good thermal stability, it can be preserved for long-time storage under normal temperature and these two atmospheres, and it has better thermal stability in nitrogen than in air atmosphere. It is not stable at high temperature, and the temperature should be controlled in the production and drying processes to ensure drug quality.

Conclusions

The thermal analysis for FCV shows that the thermal decomposition processes of FCV both are two-step processes in nitrogen or in air. There is a melting process before the decomposition. The IR spectra, HPLC, and LC–MS of FCV and its residues at different temperatures during the thermal decomposition processes were determined. The molecular bond orders for FCV and intermediates were calculated using an ab initio quantum chemistry method (GAMESS program), and the thermal decomposition mode of FCV was discussed. The decomposition of FCV does not go through 2-amino-purine stage, 2-amino-purine, and alkane chain segment both decompose simultaneously during the first stage, and the carbonized residue is decomposed in the second stage. The Ozawa method was used to calculate the kinetic parameters of the thermal decomposition reaction of FCV, the apparent activation energy (E a), and pre-exponential factor (A). The initial decomposition temperatures in nitrogen and in air both are 205 °C. For decomposition in nitrogen, the activation energy E a and the pre-exponential factor A for the initial stages are 107.8 kJ mol−1 and 2.19 × 109 min−1, respectively. For decomposition in air, the corresponding E a and A are 96.4 kJ mol−1 and 1.45 × 108 min−1, respectively. The calculation shows that the FCV has good thermal stability at normal temperature, and it can be preserved for long-time storage under normal temperature and air atmospheres. But it is unstable at high temperature, so the temperature should be controlled in the production and drying processes to ensure drug quality.

References

S. Budavari (Ed.). The Merck index, 13th edn. In: An encyclopedia of chemicals, drugs and biologicals. Rahway, NJ: Division of Merck and Co., Inc.; 2001, p. 3960.

Yurdaydin C, Bozkaya H, Gürel S, Tillmann HL, Aslan N, Heper AO, Erden E, Yalc K, Iliman N, Uzunalımoglu O, Manns MP, Bozday AM. Famciclovir treatment of chronic delta hepatitis. J Hepatol. 2002;37(2):266–71.

Simpson D, Lyseng-Williamson KA. Famciclovir—a review of its use in herpes zoster and genital and orolabial herpes. DRUGS. 2006;66(18):2397–416.

Cirelli R, Herne K, McCrary M, Lee P, Tyring SK. Famciclovir: review of clinical efficacy and safety. Antivir Res. 1996;29(2–3):141–51.

Bacon TH. Famciclovir, from the bench to the patient—a comprehensive review of preclinical data. Int J Antimicrob Agents. 1996;7(2):119–34.

Hodge RAV. Famciclovir and penciclovir: the mode of action of famciclovir including its conversion to penciclovir. Antivir Chem Chemother. 1993;4(2):67–84.

Biswas S, Jennens L, Field HJ. The helicase primase inhibitor, BAY 57-1293 shows potent therapeutic antiviral activity superior to famciclovir in BALB/c mice infected with herpes simplex virus type 1. Antivir Res. 2007;75(1):30–5.

Zhang J, Sheng RL, Mai WP. Studies on the thermal decomposition process and kinetics of purine drugs. Acta Pharm Sin. 2002;3(7–8):644–8 (in Chinese).

Wang XJ, You JZ. Study on the thermal decomposition of capecitabine. J Therm Anal Calorim. 2016;123:2485–97.

Rompay JV. Purity determination and evaluation of new drug substances. J Pharm Biomed Anal. 1986;4:725–32.

Giron D, Goldbronn C. Use of DSC and TG for identification and quantification of the dosage form. J Therm Anal. 1997;48:473–83.

Silva ACM, Ga´lico DA, Guerra RB, Perpe´tuo GL, Legendre AO, Rinaldo D, Bannach G. Thermal stability and thermal decomposition of the antihypertensive drug amlodipine besylate. J Therm Anal Calorim. 2015;120:889–92.

Schmidt MW, Baldridge KK, Boatz JA, Elbert ST, Gordon MS, Jensen JJ, Koseki S, Matsunaga N, Nguyen KA, Su S, Windus TL, Dupuis M, Montgomery JA. General atomic and molecular electronic structure system. J Comput Chem. 1993;14:1347–63.

Alexeev Y, Mazanetz MP, Ichihara O, Fedorov DG. GAMESS as a free quantum-mechanical platform for drug research. Curr Top Med Chem. 2012;12(18):2013–33.

American Society for Testing and Materials. ASTM E1641-99. (1999). http://www.astm.org/DATABASE.CART/HISTORICAL/E1641-99.htm.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Flynn JH, Wall LA. A quick direct method for the determination of activation energy from thermogravimetric data. J Polym Sci B. 1966;4:323–8.

Xie JX, Chang JB, Wang XM. Applications of infrared spectroscopy in organic chemistry and medicinal chemistry. Beijing: Science Press; 2001.

NIST Chemistry Web book Standard Reference Database, 2011, 69 release. http://webbook.nist.gov/chemistry.

Fulias A, Vlase G, Grigorie C, Ledeti I, Albu P, Bilanin M, Vlase T. Thermal behaviour studies of procaine and benzocaine. Part 1. Kinetic analysis of the active substances under non-isothermal conditions. J Therm Anal Calorim. 2013;113:265–71.

Amorim PHO, Ferreira APG, Machado LCM, Cervini P, Cavalheiro ETG. Investigation on the thermal behavior of b-blockers antihypertensives atenolol and nadolol using TG/DTG, DTA, DSC, and TG-FTIR. J Therm Anal Calorim. 2015;120:1035–42.

Sheina GG, Stepanian SG, Radchenko ED, Blagoi YP. IR spectra of guanine and hypoxanthine isolated molecules. J Mol Struct. 1987;158:275–92.

Ganbold EO, Kang D, Joo SW. Raman spectroscopic study of 6-amino-7-deazapurine. Vib Spectrosc. 2015;80:6–10.

Ha T-K, Keller MJ, Gunde R, Gunthard HH. Quantum chemical study of structure, energy, rotational constants, electric dipole moments and electric field gradients of all isomeric adenines. J Mol Struct Theochem. 1996;364(2–3):161–81.

Dakin TW. Electrical insulation deterioration treated as a chemical rate phenomena. AIEE Trans Part I (Commun Electron). 1948;67:113–22.

Zhang LJ, Pang JX, Bai JH. Thermogravimetry study of the lifetime of azithromycin. J Hebei Norm Univ (Nat Sci Ed). 2001;25(4):488–9 (in Chinese).

Acknowledgements

This study was financially supported by Zhejiang International Studies University (No. 07029005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Cj., You, Jz. & Wang, Xj. Study on the thermal decomposition of famciclovir. J Therm Anal Calorim 131, 1361–1371 (2018). https://doi.org/10.1007/s10973-017-6639-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6639-z