Abstract

Tenofovir disoproxil fumarate (TDF) is an antiretroviral belonging to the class of nucleotide analog reverse transcriptase inhibitors, approved for the use against HIV/Aids and hepatitis B. The objective of this study was to evaluate the thermal compatibility and non-isothermal kinetic degradation of TDF with pharmaceutical adjuvants used in its tablet dosage form. TDF in binary mixtures with these excipients (BM) was prepared at 1:1 (mass%). Starting with thermoanalytical techniques (differential scanning calorimetry and thermogravimetric analysis/DTG) were select some BM with signs of interaction and complementary techniques of X-ray diffraction (XRD), infrared spectroscopy (IR) and kinetic degradation were used to elucidate the drug–excipient interactions. The purity of TDF was 98.28%, with the fusion peak at 117.53 °C followed by the main degradation event at 146.49 °C. The BM with lactose and magnesium stearate (MgS) were selected as promoted interaction with the drug based on the anticipation of the fusion peak of TDF, with a probable occurrence of a Maillard reaction between TDF and lactose. According to FTIR, these interactions were confirmed by an intermolecular hydrogen binding; however, the XRD analyses only indicate some loss of drug crystallinity in the BM profiles after the heating process. Kinetic degradation showed a kinetic reaction of first order, a variation of activation energy negligible for the BM TDF + MgS (5%) and a greater variation in its value for the formulation (15%) in relation to the isolated TDF, thus indicating a higher negative interference of the whole excipients to guarantee the thermal stability of TDF. This study provided detailed information on the interaction between TDF and the excipients composing the dosage form as a first study of thermal compatibility involving this drug that aims to guide in the delineation of other formulations containing this drug.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tenofovir disoproxil fumarate (TDF) is an antiretroviral (ARV) belonging to the class of nucleotide analog reverse transcriptase inhibitors (NRTIs). TDF was also approved worldwide for the treatment of chronic hepatitis B in adults and in combination with other ARV agents in the treatment of the HIV-1 infection [1, 2]. Chemically, it refers to an acyclic nucleoside phosphonate diester analog that, in the organism, requires initial hydrolysis of the diester for conversion to the active substance, tenofovir, besides subsequent phosphorylations by cellular enzymes to form tenofovir diphosphate, the active metabolite. Inserted in the class of NRTIs, TDF acts by hindering the addition of new nucleosides to the DNA chain and, once incorporated into the DNA in formation, produces inhibition of the action of reverse transcriptase with consequent inhibition of viral response [3].

TDF is commonly found available in the form of a tablet, namely Viread® (150, 200, 250, and 300 mg) [4, 5], besides being present in diverse ARV associations, which are: Truvada® (300 mg TDF + 200 mg of emtricitabine), Atripla® (200 mg emtricitabine + 245 mg 600 TDF + 600 mg efavirenz), Complera® (200 mg emtricitabine + 25 mg Rilpivirina + 300 mg TDF), Stribild® (200 mg emtricitabine + 150 mg evitegravir + 150 mg cobicistat + 300 mg TDF) [5]. Among ARV therapies, the association of TDF with lamivudine (TDF/3TC) is one of the initial choices for the treatment of HIV because it presents a favorable profile of toxicity in relation to lipoatrophy and hematological toxicity when compared to zidovudine (AZT), besides only one daily administration is needed [6].

For the development of these and other pharmaceutical forms in the solid state, the compatibility study of this drug with excipients becomes fundamentally important during the pre-formulation phase, in view of the possibility of visualizing the possible physical and chemical interactions existing between these components. These interactions can alter physical chemical parameters of the drug (solubility, dissolution rate, and bioavailability), and even compromise its therapeutical effect and safety. Therefore, the investigation of incompatibility between components of the medicine is critical in the development of a stable pharmaceutical dosage form [7].

For 30 years, thermal analysis has been extensively used in the analysis of substances with pharmaceutical interest, identifying and/or solving problems in the field of pharmaceutical technology because it reveals valuable information regarding the physical properties of the materials [8]. Thus, through this technique, it is possible to verify modifications in the melting range, in thermal decay, and in the energy involved in these processes, thus making it possible to suggest pharmaceutical incompatibility.

Since the literature does not present any thermoanalytic compatibility study involving TDF with the excipients of its commercial pharmaceutical dosage form, the importance of this work is noteworthy, which makes it a priority to explain the thermal behavior of TDF with pharmaceutical adjuvants using thermal analysis. X-ray diffraction and spectroscopy techniques will be used as a complement to confirm the detected interactions. Additionally, the drug–excipient mixture will be evaluated as to its thermal stability by means of non-isothermal kinetic degradation in the solid state.

Materials and methods

Material

TDF was donated and certified by Cristália Produtos Químicos Farmacêuticos Ltd., batch No. 07470/2011 and synthesized by Cdymax India Pharma PVT. LTD., batch No. CD110081. The Viread® commercial coated tablet (300 mg) was obtained commercially, batch No. 11100192. The excipients used were Croscarmellose Sodium, batch No. 80275 (Blanver Farmoquímica Ltd.®); Lactose monohydrate, batch No. L0913A4033 (MEGGLE); Magnesium stearate (MgS), batch No. 2009121200 (Ind. Química Anastácio S/A®); Microcrystalline cellulose (MCC) (Blanver and Microcel), batch No. 1743105 and Starch (Starch 1500), batch No. IN516910 (Colorcon).

Methods

The thermal characterization was carried out by using the data obtained by differential scanning calorimetry (DSC) and thermogravimetry/differential thermal analysis (TG/DTA) for the evaluation of the thermal stability of TDF.

TDF compatibility study with excipients using thermal analysis

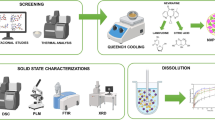

The flowchart (Fig. 1) presents the procedure used for verification of the thermal stability of TDF with the excipients [8]. TG and DSC curves of TDF, binary mixtures (BM) TDF + excipient (1:1, w/w), and the commercialized pharmaceutical dosage form were compared.

The possible interactions detected by thermal analysis in these samples were further investigated by X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR) and by non-isothermal kinetics degradation.

Differential scanning calorimetry (DSC)

DSC curves of TDF and excipients isolated, the BMs, and the Viread® were obtained using a Shimadzu differential scanning calorimeter® DSC-60, connected to Shimadzu software® TA-60WS, under a dynamic nitrogen atmosphere with a flow of 50 mL min−1 and a heating rate of 10 °C min−1, using a temperature range of 25–200 °C. The samples were placed in an enclosed aluminum sample holder with a mass of 2 mg (±0,3). Determinations were performed in triplicate. Before these assays, the temperature scale and response enthalpy were verified by calibrating the instrument with indium (99.98%, mp 156.65 °C, Aldrich®, Milwaukee, USA).

Thermogravimetry (TG/DTA)

The same samples were evaluated by TG/DTG using a Shimadzu® thermobalance, model TGA Q60, in a dynamic nitrogen atmosphere with a flow of 50 mL min−1, where the drug mass and the BM were about 6 mg and 12 mg (±0,3), respectively. The samples were packed in a platinum crucible and were scanned at a temperature range of 25–600 °C, at a heating rate of 10 °C min−1. Before the assays, the instrument calibration was verified using a zinc sample (99.98%, Aldrich®, Milwaukee, the USA).

X-ray diffraction (XRD)

XRD of TDF and excipients isolated, as well as the BMs prepared at the same ratio (1:1, w/w), were obtained by means of a Siemens® diffractometer (X-ray diffractometer, D-5000), equipped with a copper anode. The samples were analyzed at 2θ an angle range of 3–45°. Samples were prepared on glass substrates with a thin layer of powdered material without solvent.

Fourier transform infrared spectroscopy (FTIR)

The absorption spectra in the infrared region were obtained using PerkinElmer® (Spectrum 400) equipment with an attenuated total reflectance (ATR) device with a selenium crystal. Samples of TDF, excipients and the analyzed BM (1:1, w/w) were directly transferred to the ATR device compartment and the results were obtained with 16 scanning and a 4 cm−1 resolution in the region comprising 4000–650 cm−1.

Non-isothermic decomposition kinetic study

The investigation of non-isothermal degradation kinetics was obtained with TG by applying the Ozawa method. Heating rates of 5, 10, 20 and 40 °C min−1 were used in a temperature range of 25–600 °C, in a platinum sample holder with approximately 6 mg (±0,3) of samples and a dynamic nitrogen atmosphere at flow rate of 50 mL min−1.

Results and discussion

TDF compatibility study with excipients using thermal analysis

The determination of the purity by DSC is explained by the theory of nonlinearity, i.e., the area where the event is started normally results from the fusion of impurities, justifying a nonlinear process, by applying the Van’t Hoff equation. Based on this, the purity found for TDF was 98.28%.

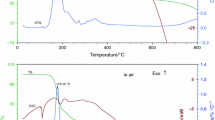

The obtained curves of TDF showed two endothermic events, in which the first one (T 112.30 °C) represents water loss and the second one (T = 117.53 °C) is the melting point of this compound, followed by the main degradation event of the drug at 146.49 °C. Table 1 presents the results obtained for the compatibility study by means of evaluation of the fusion peak temperature (T peak fusion) and the degradation temperature of TDF in BMs and tablet Viread® by DSC and TG/DTG, respectively. In the DSC analysis, the most part of the BMs showed small variations in terms of fusion peak temperature with exception of the BM TDF + MgS, which presents a reduction of 19.79 °C in relation to the fusion peak temperature of the isolated TDF.

According to the DSC curves of the BM TDF + MgS and the isolated TDF (Table 1 and Fig. 2), since was observed the absence of the fusion peak of TDF and the fusion event was anticipated in this BM compared to isolated TDF, the excipient magnesium stearate (MgS) can be previous dissolving of the drug in the liquified excipient, assuming that both present a certain miscibility [7]. The anticipation of the T onset (fusion) observed in Table 1 is an indicative that this solubilization process is related to a possible interaction between these compounds, therefore it demonstrates that there is weakening of intermolecular interactions between the components and that TDF crystals become fragile, making it more susceptible to fusion in the presence of this excipient, since a minor amount of energy is necessary to undo the crystalline network (fusion). On the other hand, weakening the crystalline structure also reflects in an increase in aqueous solubility of the substance [9], a beneficial consequence for TDF since it presents a very low solubility in water [10, 11].

A similar fact was described by Chaves [7], who detected the disappearance of the fusion event of diethylcarbamazine citrate in the presence of MgS. It can also be observed that, although MgS modifies the T onset (fusion) of TDF, the initial decomposition temperature of the drug [T onset (degradation)] was not modified, as demonstrated in TG curves (Table 1 and Fig. 3). Despite this, the pattern TG curve is not the same as is in TDF alone due to the interference of the MgS in this mixture, modifying the final TG curve of the BM.

The literature describes diverse interactions between MgS with other drugs, as glibenclamide and aciclovir [12, 13]. With captopril, a decrease in the fusion temperature was verified, besides changes in the form of this peak [14]. With aceclofenac, the drug endothermic fusion peak disappeared and the signs of MgS were modified [15].

In the BM TDF + Lactose monohydrate was verified a significant change in the T onset (fusion) of the drug (Table 1); however, it was not possible to analyze with exactness the T onset (degradation), since there was an expansion of the sample after heating to 219 °C, resulting in a slightly poorly defined curve and a non-conclusive result.

Lactose is used in the pharmaceutical industry as a diluent and agglutinate, creating nicely formed tablets. However, due to its characteristic of reducing sugar, its carbonyls easily react with compounds that possess a primary and/or secondary aliphatic amine in its chemical structure, resulting in the called Maillard reaction [16]. Soares-Sobrinho et al. (2010) noticed this interaction [17] with the antichagasic drug benznidazole, which presents a primary amine, besides occurring in other drugs such as aciclovir [13, 18], ivermectin [19], diethylcarbamazine citrate [7], glimepiride [12], and metformin [20]. Thus, it can be seen that this reaction possesses a great probability of occurring between TDF and lactose, since the drug possesses primary and secondary amines in its chemical structure.

As to the thermal behavior of TDF in the Viread® commercial coated tablet, there was a reduction in T onset (fusion) from 114.26 to 105.91 °C justified by the presence of MgS as an excipient in this dosage form. Moreover, in this formulation was verified a delay in the T onset (degradation) from 146.49 to 157.88 °C. In this case, it was seen that the mutual association of the excipients protects the TDF from the thermal degradation, thus giving it stability. The excipients that make up the coating in this pharmaceutical dosage form can still take part in this protection against thermal degradation: Opadry II Y-30-10671 (which contains FD & C Blue n°2 aluminum lacquer, hydroxypropyl methylcellulose 2910, mono-hydrated lactose, titanium dioxide and triacetin).

For the other excipients, significant alterations in the fusion and degradation temperatures of TDF were not verified, thus discarding the possibility of interaction between them. Thus XRD and FTIR techniques were used as complementary techniques to understand the type of interaction between TDF + MgS and TDF + lactose monohydrate.

Compatibility study of TDF with excipients by XRD and FTIR

The XRD interactions were observed as to the presence of the main peak at 24.43° and of the secondary peaks at 4.96°, 10.29°, 19.89° and 24.29°, which are characteristic of TDF. In both BM evaluated was not observed alteration in the degree of crystallinity of the drug, confirmed by the maintenance of all the characteristic peaks of TDF [21]. However, after heating, the BM TDF + MgS and TDF + Lactose, respectively, at 100 and 140 °C, so at temperatures above their fusion events visualized by DSC curves (Table 1 and Fig. 2), were observed some loss of drug crystallinity in the BM profiles, as shown in Figs. 4 and 5. This last result is in agreement with the thermal analysis previously showed (Table 1 and Fig. 2). The differences verified in terms of intensity of these TDF peaks are due to a lower amount of the drug present in the mixture compared to the isolated drug sample.

Different studies have used the XRD analysis to elucidate the drug-excipient compatibility in the pre-formulation phase, as in the example of the analysis of ketoprofen with different pharmaceutical excipients [22].

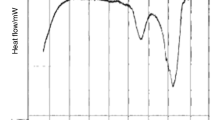

A FTIR was used as a complementary technique in order to investigate a possible chemical interaction between the mentioned BMs. Both mixtures demonstrate the presence of the characteristic bands of the drug and the excipients (Figs. 6 and 7).

The TDF alone (Figs. 6 and 7) shows characteristic FTIR absorption bands, as described: at 3600–3200 cm−1, a stretching in aromatic secondary amine; at 1400–1200 cm−1 and 1650–1580 cm−1, a bending N–H from primary amine; at 1250–1020 cm−1, a bending C–N from aliphatic tertiary amine; at 1800–1600, a stretching C=O from ester.

Regarding BM TDF + MgS (25 °C) (Fig. 6), a band shift of 13 cm−1 (from 1560.14 to 1573.68 cm−1) in the C=O region of stearate from MgS in comparison with the FTIR spectrum of the pure MgS was observed. Although this band shift is visualized only for MgS, it means that the excipient is interacting, under some degree, with the drug. Probably, this band shift characterizes the formation of a weak intermolecular hydrogen binding [23] involving the primary amine of TDF and this C=O from MgS. This same band shift was also verified in this BM heated after 100 °C. Regarding the other bands, there were no significant alterations.

In the BM TDF + Lactose under room temperature was not observed some interaction signal by FTIR. However, after heating to 140 °C, FTD’s amine band has shifted from 1622.98 to 1612.32 cm−1. This behavior is probably due to Maillard reaction between FTD’s amine group and lactose’s carbonyl group. Once lactose’s carbonyl group is covered by other vibrational groups, it was not possible to check its behavior; however, after heating the sample, it became light brown, which is characteristic of Maillard reaction (Fig. 7) [24].

Non-isothermic Decomposition Kinetic Study

The thermal analysis and its application to the kinetic analysis of the solid-state processes were used based on the theoretical basis of Ozawa’s kinetic method applied to thermoanalytical curves, as also applied in other works [25,26,27,28]. Thus the investigation of non-isothermal degradation kinetics was obtained from the degradation event of the drug analyzed by TG/DTG curves applying the Ozawa method. In this case, as the initial stage of the drug’s degradation event in the BM TDF + lactose was not possible to be measured as mentioned above, only the BM with MgS and the Viread® of was precisely investigated by the non-isothermal degradation kinetic.

By means of the data contained in Table 2, a comparative profile of stability between TDF, BM TDF + MgS and Viread® can be established. Among the data obtained in this study, the activation energy (Ae) presents a greater interest in the evaluation of the stability of pharmaceutical products, being useful in the establishment of a comparative profile between the drug and its associations with excipients, where the increase of the value of Ae means an increment in the stability of the system [26,27,28].

In agreement with the analysis carried out, was verified a decrease in the Ae of around 15% in the medicine Viread® compared to the isolated TDF; while this Ae variation was insignificant (5%) in relation to the BM TDF + MgS. Thus this result confirms the little interference of MgS on the degradation/stability of TDF, and on the other hand, the total others excipients, including those that make up the coating of Viread®, contribute negatively to the thermal stability of this drug, largely affecting its stability.

In addition, all kinetic decomposition indicated a reaction of the first-order (only one reaction contributes to the loss of mass), what means that there is only one significant reaction occurring and it is not affected by competing processes [8].

Conclusions

The thermal study carried out in this work allowed for detailed information about the existing interaction between TDF and the excipients contained in its formulation. Such information is important for dealing with the first compatibility study involving this drug, besides aiming to direct the delineation of other formulations containing TDF.

The results derived from the compatibility study by thermal analysis have identified the existing interaction between this drug and the excipients magnesium stearate and lactose monohydrate. These results were confirmed by FTIR, which showed a chemical interaction between these mixtures. The non-isothermal kinetic study occurred at a constant speed, indicating a reaction of the first-order and a lesser reaction Ae mainly for the commercial formulation, which presented a reduction of 15% in relation to isolated TDF. Based on this result, it can be concluded that the other components of the commercial dosage form are promoting a decrease in the drug’s stability.

In short, thermal analysis has shown to be a very useful technique in the drug-excipient compatibility study in view of the attainment of fast and convenient answers in the selection of excipient candidates which justifies its use in the pharmaceutical field to foresee, in the long run, the stability of the candidates for a pharmaceutical product, thus accelerating its commercialization.

References

Bellettia D, Tosia G, Fornia F, Gamberinib MC, Baraldib EC, Vandellia MA, Ruozia B. Chemico-physical investigation of tenofovir loaded polymeric nanoparticles. Int J Pharm. 2012;436(1–2):753–63.

Hu Cy, Liu Ym, Chen Q, Wang W, Wu K, Dong J, Li J, Jia Jy, Lu C, Sun Sx, Yu C, Li X. Pharmacokinetics and tolerability of tenofovir disoproxil fumarate 300 mg once daily: an open-label, single- and multiple-dose study in healthy Chinese subjects. Clin Therapeutics. 2013;35(12):1884–9.

Delahunty T, Bushman L, Fletcher CV. Sensitive assay for determining plasma tenofovir concentrations by LC/MS/MS. J Chromatogr B Analyt Technol Biomed Life Sci. 2006;830:6–12.

Rakhmanina N, Phelps BR. Pharmacotherapy of Pediatric HIV Infection. Pediatr Clin N Am. 2012;59:1093–115.

Guidelines for the Use of Antiretroviral Agents in Pediatric HIV Infection. Disponível em: http://aidsinfo.nih.gov/guidelines. Acesso em março de 2013.

MS, Ministério da Saúde. Protocolo clínico e diretrizes terapêuticas para adultos vivendo com HIV/AIDS. www.aids.gov.br. Acessed on: 11 October 2012.

Chaves LL, Rolim LA, Gonçalves MLCM, Vieira ACC, Alves LDS, Soares MFR, Soares-Sobrinho JL, Lima MCA, Rolim-Neto PJ. Study of stability and drug-excipient compatibility of diethylcarbamazine citrate. J Therm Anal Calorim. 2013;111:2179–86.

Costa SPM, Silva KER, Medeiros GCR, Rolim LA, Oliveira AJF, Lima MCA, Galdino SL, Pitta IR, Rolim-Neto PJ. Thermal behavior and compatibility analysis of the new chemical entity LPSF/FZ4. Thermochim Acta. 2013;562:29–34.

Vieira ACQM, Marques GS, Melo CM, Silva KER, Rolim LA, Lima MCA, Galdino SL, Pitta IR, Rolim-Neto PJ. Physical–chemical characterization of new anti-inflammatory agent (LPSF/GQ-130) and evaluation of its thermal compatibility with pharmaceutical excipients. J Therm Anal Calorim. 2013;. doi:10.1007/s10973-013-3358-y.

UNITED states phamacopea. 36 ed. Rockville: United state phamacopeial convention, 2011. Tenofovir Disoproxil Fumarate. Authorized USP Pending Monograph.

WHO, World Health Organization, Expert Comittee on Specification for Pharmaceutical Preparations, WHO Technical Report Series 953, Annex 2, Stability Testing of Active Pharmaceutical Ingredients and Finished Pharmaceutical Products, Geneva, Switzerland. 2009.

Cides LCS, Araújo AAS, Santos-Filho M, Matos JR. Thermal behaviour, compatibility study and decomposition kinetics of glimepiride under isothermal and non-isothermal conditions. J Therm Anal Calorim. 2006;84(2):441–5.

Barboza F, Vecchia DD, Tagliari MP, Silva MAS, Stulzer HK. Differential scanning calorimetry as a screening technique in compatibility studies of acyclovir extended release formulations. Pharm Chem J. 2009;43:6.

Bazzo GC, Silva MAS. Estudo termoanalítico de comprimidos revestidos contendo captopril através de termogravimetria (TG) e calorimetria exploratória diferencial (DSC). Rev Bras Cienc Farm. 2005;41(3):315–22.

Aigner Z, Heinrich RS, Farkas G, Ciurba A, Berkesi O, Szabó-Révész P. Compatibility studies of aceclofenac with retard tablet excipients by means of thermal and FT-IR spectroscopic methods. J Therm Anal Calorim. 2011;104:265–71.

Narang AS, Desai D, Badawy S. Impact of Excipient Interactions on Solid Dosage Form Stability. Pharm Res. 2012;29(10):2660–83.

Soares-Sobrinho JL, Soares MFR, Lopes PQ, Correia LP, Souza FS, Macêdo RO, Rolim-Neto PJA. Preformulation study of a new medicine for chagas disease treatment: physicochemical characterization, thermal stability, and compatibility of benznidazole. AAPS Pharm Sci Tech. 2010;. doi:10.1208/s12249-010-9495-8.

Monajjemzadeh F, Hassanzadeh D, Valizadeh H, Siahi-Shadbad MR, Mojarrad JS, Robertson TA, Roberts MS. Compatibility studies of acyclovir and lactose in physical mixtures and commercial tablets. Eur J Pharm Biopharm. 2009;73:404–13.

Rolim LA, Santos FCM, Chaves LL, Gonçalves MLCM, Freitas-Neto JL, Nascimento ALS, Soares-Sobrinho JL, Albuquerque MM, Lima MCA, Rolim-Neto PJ. Preformulation study of ivermectin raw material. J Therm Anal Calorim. 2014;. doi:10.1007/s10973-014-3691-9.

Santos AFO, Basilio ID Jr, Souza FS, Medeiros AFD, Pinto MF, Santana DP, Macedo RO. Application of thermal analysis in study of binary mixtures with metformin. J Therm Anal Calorim. 2008;93:361–4.

Johnsona TJ, Guptaa MJF, Albrighta TH, Kiser PF. Segmented polyurethane intravaginal rings for the sustained combined delivery of antiretroviral agents dapivirine and tenofovir. Eur J Pharm Sci. 2010;39(4):203–12.

Tita B, Fulias A, Bandur G, Marian E, Tira D. Compatibility study between ketoprofen and pharmaceutical excipientes used in solid dosage forms. J Pharm Biomed Anal. 2011;56:221–7.

Silverstein RM, Webster FX, Kiemle DJ. Identificação Espectrométrica de Compostos. 7st ed. 2007: 70–104.

Rowe RC. Lactose. In: Handbook of Pharmaceutical Excipients, 15nd ed. American Pharmaceutical Association: Washington: DC; 2006:389–91.

Ghaderi F, Nemati M, Siahi-Shadbad MR, Valizadeh H, Monajjemzadeh F. J Therm Anal Calorim. 2016;123:2081.

Sovizi MR. Investigation on decomposition kinetic of naproxen and celecoxib. J Therm Anal Calorim. 2010;102:285–9.

Soares MFR, Soares-Sobrinho JL, Silva KER, Alves LDS, Lopes PQ, Correia LP, Souza FS, Macêdo RO, Rolim-Neto PJ. Thermal characterization of antimicrobial drug ornidazole and its compatibility in a solid pharmaceutical product. J Therm Anal Calorim. 2011;104:307–13.

Oliveira MA, Yoshida MI, Gomes ECL. Análise térmica aplicada a fármacos e formulações farmacêuticas na indústria farmacêutica. Quim Nova. 2011;34(7):1224–30.

Acknowledgements

Thanks to Cristália Produtos Químicos Farmacêuticos Ltd. for the donation of the raw material, tenovir disoproxil fumarate.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, J.P.A., Figueirêdo, C.B.M., de Medeiros Vieira, A.C.Q. et al. Thermal characterization and kinetic study of the antiretroviral tenofovir disoproxil fumarate. J Therm Anal Calorim 130, 1643–1651 (2017). https://doi.org/10.1007/s10973-017-6477-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6477-z