Abstract

Cotton is a flammable material and some cottons would decompose or even self-ignite at bad storage and transport conditions. This paper studied the spontaneous combustion of cotton from the aspect of thermal decomposition temperature (TDT) and critical ambient temperature (CAT). From Fourier transform infrared spectroscopy analysis and chromatographic and mass spectrometric analysis, significant thermal decomposition was detected at the temperature of \(210\,^\circ \hbox {C}\), which indicated that the TDT of cotton was around \(210\,^\circ \hbox {C}\). From TG analysis and small-scale CAT test, activation energy of cotton and CAT of small cotton stack were obtained. Then, CATs of the cotton stacks with different dimensions were calculated based on Frank-Kamenetskii theory. With the dimensions l increased from 0.2 to 3.2 m, the CATs of cotton decreased from 195.0 to \(137.9\,^\circ \hbox {C}\). The TDT of cotton was higher than these CATs, and the differences between TDT and CAT of cotton varied from almost 15–\(70\,^\circ \hbox {C}\) (with the dimensions l increased from 0.2 to 3.2 m). As the experiments and calculation of the CATs were very complicated and time-consuming, the CATs of cotton can be estimated if the TDT was known. The result of this paper was especially meaningful for evaluating the risk of spontaneous combustion of cotton and speculating the reason of cotton fire.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton is a flammable material. Some kinds of cotton would decompose or even self-ignite at bad storage and transport conditions. For the bad storage and transport conditions, high ambient temperature is obviously one of the key reasons leads to cotton fire. So, it is very important to study the effect of temperature to the spontaneous combustion of cotton.

Previously, there were a number of studies on the thermal decomposition and spontaneous combustion of cotton. Many studies paid more attention to the thermal decomposition properties of different cottons (or cotton with different components). Ceylan et al. [1] studied the effect of water immersion on the thermal degradation of cotton fibers with thermogravimetric analysis. The maturity and variations in water-soluble content of the fiber were found to be important factors influencing the thermal behavior of raw cotton fibers. Wang et al. [2] studied the spontaneous combustion of stored wet cotton using a C80 calorimeter. The results indicated that the self-accelerating decomposition temperature (SADT) of wet cotton was lower than dry cotton and the risk of spontaneous combustion for wet cotton was higher than dry cotton. Zhao et al. [3] studied the spontaneous combustion risk of different cotton samples using a microcalorimeter technique. From their results, the self-heating oxidation temperatures (SHOTs) of some cotton samples are lower than others, and the self-heating and spontaneous combustion propensity of different cotton samples were different. Zhu et al. [4] studied the thermal decompositions of cotton and flame-retardant cotton fabrics by differential scanning calorimeter (DSC), thermogravimetry (TG) and pyrolysis–gas chromatography–mass spectroscopy (PY–GC–MS). The result was helpful in understanding of mechanisms of flame-retardant cotton fabrics. Gaan and Sun [5] studied the effect of phosphorus flame retardants on thermo-oxidative decomposition of cotton. Their results showed that diammonium phosphate (DAP), pyrovatex CP (PCP) and phosphoric acid (PA) chars maintain the surface morphology during the burning process, which might be due to the formation of a protective layer or crosslinking effect. Gaan and Sun [6] studied the effect of nitrogen additives on thermal decomposition of cotton. The thermal decomposition of the nitrogen compounds was different during the pyrolysis and combustion. On the effect of external conditions, Molto et al. [7] gave thermogravimetric analysis during the decomposition of cotton fabrics in an inert and air environment. Hagen et al. [8] studied the effect of boundary conditions to transition from smoldering to flaming fire for cotton.

In these studies, most papers discussed the thermal decomposition of cotton with thermal analysis techniques (DSC, TG and so on). However, as the thermal decomposition would be different with the change of heating rates, it was not a good idea to obtain the thermal decomposition properties (especially the TDT and CAT discussed in this paper) of cotton with thermal analysis techniques directly. This paper paid more attention to the effects of temperature to thermal decomposition and spontaneous combustion of cotton. Thermal decomposition was a chemical decomposition caused by heat. The thermal decomposition temperature (TDT) of a substance was the temperature at which the substance chemically decomposed. In this paper, FTIR analysis and GC–MS analysis were used to obtain the TDT of cotton. For spontaneous combustion properties, the critical ambient temperature (CAT) can well reflect the effect of ambient temperature and volume to spontaneous combustion according to Frank-Kamenetskii [9] theory. However, the tranditional method according to Frank-Kamenetskii [9] theory was very complicated and time-consuming. In this paper, TG analysis and small-scale CAT test were used to calculate the CATs of cotton with different dimensions. Lastly, the relationship between TDT and CAT of cotton can be known preliminarily. As the experiments to calculate the CAT was still too complicated and time-consuming, the CAT of cotton can be estimated, while the TDT of cotton was known.

Experimental

Samples

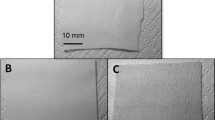

In this paper, there were four experiments: FTIR analysis, GC–MS analysis, TG analysis and small-scale CAT test. The cotton sample was typical seedless cotton which came from Hubei Province of China. Cotton sample was dried in the vacuum drying oven for 24 h at \(60\,^\circ \hbox {C}\) before the experiments of TG analysis and small-scale CAT test. For the FTIR analysis and GC–MS analysis, sealed glass bottles (1 l) with 2 g cotton were kept in constant temperature oven at temperatures 150, 170, 190, 210 and \(230\,^\circ \hbox {C}\) for another 1 h and five samples were obtained. The sealed glass bottles (1 l) which were used to collect the gases emitted at different oven temperatures for GC–MS analysis and the cotton samples were used for FTIR analysis (Fig. 1).

FTIR analysis

Fourier transform infrared spectroscopy (FTIR) was a technique which is used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. The instrument used in the experiments was Thermo Scientific Nicolet 6700. Attenuated total reflectance (ATR) accessory was used to determine the spectrum of a cotton samples (150, 170, 190, 210 and \(230\,^\circ \hbox {C}\)). Attenuated total reflectance (ATR) technique was very convenient for solid samples.

GC–MS analysis

Gas chromatographic and mass spectrometric (GC–MS) analysis was used to detect the gaseous products at different temperatures. A Supelco HPLC/SPME Column was used to absorb the released gases and then was analyzed with GC–MS equipments (Agilent 7890A and Agilent 5975C). The column was kept in bottle at \(40\,^\circ \hbox {C}\) for 15 min and heated up to 250\(\,^\circ \hbox {C}\) at a rate of 10\(\,^\circ \hbox {C}\) min\(^{-1}\) and then maintained at 250\(\,^\circ \hbox {C}\) for another 5 min. Testing conditions: carrier gas speed: 1 mL (He) min\(^{-1}\); injector temperature: 250\(\,^\circ \hbox {C}\); mass scanning range: 50–550; resulting EM voltage: 1282 V; MS source: 230\(\,^\circ \hbox {C}\) maximum 250\(\,^\circ \hbox {C}\); MS Quad: 150\(\,^\circ \hbox {C}\) maximum 200\(\,^\circ \hbox {C}\).

TG analysis

Thermogravimetry (TG) was a technique where the mass of materials was measured as a function of temperature or time, while the sample was subjected to a controlled temperature program in a controlled atmosphere. The instrument used for TG analysis in this paper was a simultaneous thermal analyzer (NETZSCH STA 449 F3). The mass of samples in the sample pan was about 5–7 mg. The cotton fiber was cut to short fiber as the length of cotton fiber was too long. The gaseous environment was air (gas flow: 30 mL min\(^{-1}\)) in the thermal analysis. The range of heating temperature was 30–500\(\,^\circ \hbox {C}\), and the heating rates for these experiments were 2, 3, 5, 10 and 15\(\,^\circ \hbox {C}\) min\(^{-1}\), respectively.

Small-scale CAT test

The small-scale CAT test was designed to obtain the CAT of small-scale cotton stack directly. Figure 2 shows schematic diagram of the small-scale CAT test. In the experiment, the reference substance was the fiber of aluminum silicate (\(\hbox {Al}_2\hbox {SiO}_5\)) which was a typical high-temperature resistant fiber widely used in wall lining fillings of high-temperature furnace equipment. Constant temperature oven was used to provide isothermal environment. The internal dimension of the oven was \(45\,\hbox {cm} \times 35\,\hbox {cm} \times 45\,\hbox {cm}\). Agilent 34970A data acquisition and sheathed thermocouples were used in combination to acquire the data of temperature data. The oven temperatures were set at 155, 165, 175, 185 and 195\(\,^\circ \hbox {C}\), respectively. The sample and reference substance were kept on the electric oven at constant temperature for 10 h. In order to minimize the effect of convection to the experiment, two stainless steel vacuum bottles were used. The volume of the stainless steel vacuum bottle (no lid) was 500 mL with height of 22 cm, and the weight of cotton samples was 80–100 g.

Results and discussion

Thermal decomposition temperature

FTIR analysis

From the color of cotton samples, with the increasing in temperature, the color of samples changed from light yellow to dark yellow and then to black; at the temperature around 210\(\,^\circ \hbox {C}\), the color of cotton changed more significantly. FTIR analysis was used to detect the chemical reaction during thermal decomposition. FTIR spectroscopy of cotton samples is shown in Fig. 3. In the figure, the baselines of FTIR spectroscopies were 0 (150\(\,^\circ \hbox {C}\)), 0.05 (170\(\,^\circ \hbox {C}\)), 0.1 (190\(\,^\circ \hbox {C}\)), 0.15 (210\(\,^\circ \hbox {C}\)) and 0.2 (230\(\,^\circ \hbox {C}\)), respectively, for conveniently obtaining the differences of five cotton samples.

From the FTIR spectroscopy of cotton samples, it can be observed that the absorption peaks of these samples are similar except at the peak of 1722 cm\(^{-1}\) wavenumber. There was no peak at the wavenumber of 1722 cm\(^{-1}\) for 150, 170 and 190\(\,^\circ \hbox {C}\) cotton samples. The peak almost begins to develop around 210\(\,^\circ \hbox {C}\). At 230\(\,^\circ \hbox {C}\), there was an obvious peak at the wavenumber of 1722 cm\(^{-1}\).

Checking from infrared spectroscopy correlation table [10] (P. 29), the wavenumber of 1722 cm\(^{-1}\) reflects the bond of C=O (aldehyde or ketone). So, the appearance of C=O (aldehyde or ketone) can reflect the extent of thermal decomposition. Fras et al. [11] studied the oxidation of cellulose fibers (cotton fibers) by titration and XPS. They found that two processes take place when the oxidation method is applied (Fig. 4). From this paper, there was significantly oxidation of cotton samples when the ambient temperature was over 210\(\,^\circ \hbox {C}\).

GC–MS analysis

Gas chromatographic and mass spectrometric (GC–MS) analysis was used to detect the components of gaseous products at different temperatures. Previously, most papers paid more attention to compounds of gas by using the GC–MS. In this paper, GC–MS analysis provided more information about the thermal decomposition properties at different temperatures. GC–MS spectrum of cotton samples is shown in Fig. 5. In the figure, the baselines of GC–MS spectrum were 0 (150\(\,^\circ \hbox {C}\)), \(2\times 10^6\) (170\(\,^\circ \hbox {C}\)), \(4\times 10^6\) (190\(\,^\circ \hbox {C}\)), \(6\times 10^6\) (210\(\,^\circ \hbox {C}\)) and \(8\times 10^6\) (230\(\,^\circ \hbox {C}\)), respectively, for conveniently knowing the differences of five cotton samples. Table 1 lists typical compounds of thermal decomposition of cotton at different oven temperatures.

There were nine typical compounds: furfural (C\(_5\)H\(_4\)O\(_2\)), octanal (C\(_8\)H\(_{16}\)O), nonanal (C\(_9\)H\(_{18}\)O), decanal (C\(_{10}\)H\(_{20}\)O), undecanal (C\(_{11}\)H\(_{22}\)O), dodecanal (C\(_{12}\)H\(_{24}\)O), tridecanal (C\(_{13}\)H\(_{26}\)O), tetradecanal (C\(_{14}\)H\(_{28}\)O) and pentadecanal (C\(_{15}\)H\(_{30}\)O). The area of peaks can well reflect the amount of compounds. In the table, N/A means the compounds cannot be detected or the concentration of these compounds was too low to be detected in the sealed glass bottles.

Not all the nine compounds can be detected at different temperatures. For the light gas compounds, furfural (C\(_5\)H\(_4\)O\(_2\)) and octanal (C\(_8\)H\(_{16}\)O), they were not detected at the temperature from 150–190\(\,^\circ \hbox {C}\). On the other hand, great amount of furfural (C\(_5\)H\(_4\)O\(_2\)) was detected at the temperature 230\(\,^\circ \hbox {C}\). Great amount of octanal (C\(_8\)H\(_{16}\)O) was detected at the temperature 210 and 230\(\,^\circ \hbox {C}\). For heavy gas compounds, tridecanal (C\(_{13}\)H\(_{26}\)O), tetradecanal (C\(_{14}\)H\(_{28}\)O) and pentadecanal (C\(_{15}\)H\(_{30}\)O), they were not detected at the temperature lower than 190\(\,^\circ \hbox {C}\). The amount of these heavy gas compounds increased quickly when the temperature was higher than 210\(\,^\circ \hbox {C}\).

There were four typical compounds (nonanal (C\(_9\)H\(_{18}\)O), decanal (C\(_{10}\)H\(_{20}\)O), undecanal (C\(_{11}\)H\(_{22}\)O) and dodecanal (C\(_{12}\)H\(_{24}\)O)) which can be detected in all experiments. Figure 6 shows the area change of four typical compounds in the GC–MS spectrum at different oven temperatures. From the figure, the area of four typical compounds increased rapidly around 210\(\,^\circ \hbox {C}\), while the amount of these components kept low below 210\(\,^\circ \hbox {C}\).

TDT of cotton

This paper also conducted the thermal analysis (TG analysis) with different heating rates, and there were different thermal decomposition rate curves at different heating rates (Fig. 8). There was no significant thermal decomposition property around the 210\(\,^\circ \hbox {C}\). Thermal analysis technique was not sensitive and suitable to obtain the thermal decomposition temperature (TDT).

Some significant thermal decomposition properties can be observed in FTIR analysis and GC–MS analysis at the temperature of 210\(\,^\circ \hbox {C}\). The color of cotton changed significantly at the temperature around 210\(\,^\circ \hbox {C}\), and the increasing in the bond C=O was the reason from the results of FTIR analysis. The produced gas components also increased significantly from the results of GC–MS analysis, which also indicated cotton sample chemically decomposed around 210\(\,^\circ \hbox {C}\). The TDT of cotton can be regarded as around 210\(\,^\circ \hbox {C}\).

Critical ambient temperature

Frank-Kamenetskii theory and small-scale CAT test

Frank-Kamenetskii theory reflected the variation of temperature within the stack of substances. In the theory of Frank-Kamenetskii, there was an important parameter—the dimensionless Frank-Kamenetskii parameter \(\delta\). The critical values of Frank-Kamenetskii parameters \(\delta _{cr}\) for some typical geometries could be known from Luo et al. [12] and Gray [13].

For self-heating and spontaneous combustion problems, the effect of reaction model \(f(\alpha )\) can be ignored, and only activation energy E and dimension l can affect the critical ambient temperature (CAT) of samples. Then, the CATs of cotton with different dimensions l can be calculated from Eq. (2). Luo et al. [14] also calculated the CATs of biomass and fishmeal successfully with this method.

The calculation of CATs was based on Frank-Kamenetskii theory with infinite Biot number boundary conditions. Thomas [15, 16] pointed out the effect of Biot number to the values of critical Frank-Kamenetskii parameter. The values of critical Frank-Kamenetskii parameter would decrease with the decreasing in Biot number. For Biot numbers greater than 30, the correction for critical Frank-Kamenetskii parameter \(\delta _{cr}\) was rather small but was significant for smaller values. Gray [13] (P.622) pointed out that for laboratory-size test bodies (\(l\approx 0.1\,\hbox {m}\)), the Biot number was rather large for typical cellulosic materials.

In the small-scale CAT test, as the bottom and sides (except the top) of bottle were almost heat-insulated, the height of bottle (22 cm) can be regarded as the characteristic dimension (l). The CAT of cotton with the characteristic dimension \(l=0.2\,\hbox {m}\) can be obtained from the small-scale CAT test. So, based on the small-scale CAT test, the calculation of the CATs of cotton for larger dimensions (l) according to Eq. (2) can be reliable.

Figure 7 shows the temperature changes of cotton sample and reference substance at different oven temperatures in the small-scale CAT test. Table 2 shows the temperature difference between cotton sample and reference substance at the end of the small-scale CAT test. It can be seen from the results that there were small differences between the temperatures of oven \({T_{\mathrm{a}}}\) and reference substance \({T_{\mathrm{r}}}\). As it is hard for the oven temperature to be kept constant, the small differences were acceptable. The temperature differences between cotton sample \({T_{\mathrm{s}}}\) and reference substance \({T_{\mathrm{r}}}\) can be observed. The difference \(T_{\mathrm{s}} - T_{\mathrm{r}}\) increased with the increasing in oven temperature and even reaches 15.4\(\,^\circ \hbox {C}\) at the oven temperature of 195\(\,^\circ \hbox {C}\). In other methods of spontaneous combustion and self-heating, such as the [17] (section: 28), the critical temperature was defined as the lowest oven temperature at which the sample temperature exceeds the oven temperature by 7\(\,^\circ \hbox {C}\) or more. Using similar benchmark, the CAT of cotton with the characteristic dimension (\(l=0.2\,\hbox {m}\)) was almost 195\(\,^\circ \hbox {C}\).

Kinetics and activation energy

From Eq. (2), the activation energy E of cotton should be calculated before the calculation of CATs of large dimensions. The activation energy E of cotton will be calculated with thermal analysis and kinetics. From the kinetics of solid-state reactions (or heterogeneous reactions), the extent of reaction \(\alpha\) was defined in terms of the mass fraction of solid that has decomposed. The non-isothermal kinetics equation of solid-state reaction is shown as follows.

where \(f(\alpha )\) was the reaction model. In previous studies, many kinetic methods were provided. However, the model-free methods, such as Friedman [18, 19] method and Ozawa [20] method, can eliminate the effect of model function, and they were more suitable for calculating activation energy. These methods were also recommended by International Confederation for Thermal Analysis and Calorimetry (ICTAC) [21, 22]. In this paper, Friedman method was used to calculate activation energy E. The equation of Friedman method was shown as follows.

Figure 8 shows the TG and DTG results of cotton sample at different heating rates. According to the research of Liu et al. [23] and Xu et al. [24], the reaction in the initial stage and the finished stage should not represent the whole process of thermal decomposition. It can be seen from the figure that reaction extent \(\alpha\) over 60% was different with that under 60%. So, in the thermal analysis, the extent of reaction \(\alpha\) of 20, 30, 40 and 50% was used, respectively.

Activation energy analysis for cotton with Friedman method is shown in Fig. 9 and Table 3. From Table 3, the differences among the values of activation energy E obtained at different reaction extent \(\alpha\) were comparable for the values of activation energy E. The mean value of activation energy E for the cotton sample was 159.01 kJ mol\(^{-1}\). Previously, Yao et al. [25] calculated the activation energy E of cotton with model-free methods, and the calculated activation energy E of cotton was 165.3 kJ mol\(^{-1}\) (Friedman method) and 169.9 kJ mol\(^{-1}\) (Ozawa method). Kim et al. [26] also calculated the activation energy E of cotton with model-free methods; the activation energy E they calculated was 159.3 kJ mol\(^{-1}\) (Ozawa method). The activation energy E they calculated was very close to the activation energy E calculated in this paper, which indicated that there was similar activation energy for different cottons. As the activation energy E of cotton was obtained with thermal analysis, CATs of cotton can be calculated based on Frank-Kamenetskii theory.

CATs of cotton

As it was very hard to obtain the activation energy with experiments according to Frank-Kamenetskii theory, this paper made a hypothesis that the activation energy of the cotton sample in Frank-Kamenetskii theory can be replaced and calculated with kinetic method of thermal analysis. Then, the CATs of cotton with different characteristic dimensions can be calculated from Eq. (2). The calculated CATs of cotton are shown in Table 4.

With the dimensions l increased from 0.2 m to 3.2 m, the CAT of cotton decreased from 195.0 to 137.9\(\,^\circ \hbox {C}\). Apparently, the larger dimensions of cotton stacks, the higher risk of spontaneous combustion.

Conclusions

This paper studied the thermal decomposition and spontaneous combustion of cotton from the aspect of thermal decomposition temperature (TDT) and critical ambient temperature (CAT). Four different experiments (FTIR analysis, GC–MS analysis, TG analysis and small-scale CAT test) were conducted. Based on the experiments, the following conclusions can be obtained.

-

1.

From FTIR analysis and GC–MS analysis, significant thermal decomposition was detected at the temperature of 210\(\,^\circ \hbox {C}\), which indicated cotton sample chemically decomposed around 210\(\,^\circ \hbox {C}\). Thus, the thermal decomposition temperature (TDT) of cotton can be regarded as around 210\(\,^\circ \hbox {C}\).

-

2.

From TG analysis and small-scale CAT test, activation energy of cotton and CAT of small cotton stack were obtained. CATs of large cotton stacks were calculated based on Frank-Kamenetskii theory. With the dimensions l increased from 0.2 m to 3.2 m, the CAT of cotton decreased from 195.0 to 137.9\(\,^\circ \hbox {C}\).

The TDT of cotton was higher than CATs of cotton, and the differences between TDT and CAT of cotton varied from almost 15–70\(\,^\circ \hbox {C}\) (with the dimensions l increased from 0.2 to 3.2 m). As the experiments and calculation of the CATs were much more complicated and time-consuming, the CATs of cotton can be estimated preliminarily if the TDT of cotton was obtained. That was especially meaningful for speculating the reason of cotton fire: whether it was caused by spontaneous combustion or arson.

Abbreviations

- \(\delta\) :

-

Frank-Kamenetskii parameter

- \(\delta _{\mathrm{cr}}\) :

-

Critical Frank-Kamenetskii parameter

- Q :

-

Reaction heat (J mol\(^{-1}\))

- \(\alpha\) :

-

Extent of reaction (mass fraction that has decomposed) (%)

- \(f(\alpha )\) :

-

Model function of solid-state reaction

- l or r :

-

Characteristic dimension (m)

- \({T_{\mathrm{a}} }\) :

-

Ambient temperature or temperature of oven (K)

- \({T_{\mathrm{s}}}\) :

-

The temperature of sample (K)

- \({T_{\mathrm{r}}}\) :

-

The temperature of reference substance (K)

- \(T_{\mathrm{a,cr}}\) :

-

Critical ambient temperature (CAT) (K)

- \(\lambda\) :

-

Thermal conductivity (W m K\(^{-1}\))

- R :

-

Universal gas constant (8.314 J mol\(^{-1}\) K\(^{-1}\))

- \(\beta\) :

-

Heating rate \(\beta = \hbox {d}T/\hbox {d}t\) (\(^\circ\hbox {C}\) min\(^{-1}\))

- A :

-

Frequency factor or pre-exponential factor

- E :

-

Reaction activation energy (kJ mol\(^{-1}\))

References

Ceylan ö, Van Landuyt L, Rahier H, De Clerck K. The effect of water immersion on the thermal degradation of cotton fibers. Cellulose. 2013;20(4):1603–12. doi:10.1007/s10570-013-9936-0.

Wang Q, Sun J, Guo S. Spontaneous combustion identification of stored wet cotton using a c80 calorimeter. Ind Crops Prod. 2008;28(3):268–72. doi:10.1016/j.indcrop.2008.02.014. http://www.sciencedirect.com/science/article/pii/S0926669008000344.

Zhao X, Xiao H, Wang Q, Ping P, Sun J. Study on spontaneous combustion risk of cotton using a micro-calorimeter technique. Ind Crops Prod. 2013;50:383–90. doi:10.1016/j.indcrop.2013.07.064. http://www.sciencedirect.com/science/article/pii/S0926669013004305.

Zhu P, Sui S, Wang B, Sun K, Sun G. A study of pyrolysis and pyrolysis products of ame-retardant cotton fabrics by DSC, TGA, and PY–GC–MS. J Anal Appl Pyrol. 2004;71(2):645–55. doi:10.1016/j.jaap.2003.09.005. http://www.sciencedirect.com/science/article/pii/S0165237003001554.

Gaan S, Sun G. Effect of phosphorus ame retardants on thermo-oxidative decomposition of cotton. Polym Degrad Stab. 2007;92(6):968–74. doi:10.1016/j.polymdegradstab.2007.03.009. http://www.sciencedirect.com/science/article/pii/S0141391007000857.

Gaan S, Sun G. Effect of nitrogen additives on thermal decomposition of cotton. J Anal Appl Pyrol. 2009;84(1):108–15. doi:10.1016/j.jaap.2008.12.004. http://www.sciencedirect.com/science/article/pii/S0165237008002143.

Molt J, Font R, Conesa JA, Martn-Gulln I. Thermogravimetric analysis during the decomposition of cotton fabrics in an inert and air environment. J Anal Appl Pyrol. 2006;76(12):124–31. doi:10.1016/j.jaap.2005.09.001.

Hagen BC, Frette V, Kleppe G, Arntzen BJ. Transition from smoldering to flaming fire in short cotton samples with asymmetrical boundary conditions. Fire Safe J. 2015;71:69–78. doi:10.1016/j.firesaf.2014.11.004. http://www.sciencedirect.com/science/article/pii/S0379711214001556.

Frank-Kamenetskii DA. Diffusion and heat transfer in chemical kinetics. New York: Plenum Press; 1969.

Pavia DL, Lampman GM, Kriz GS, Vyvyan JA. Introduction to spectroscopy. 5th ed. Connecticut: Cengage Learning; 2014.

Fras L, Johansson L-S, Stenius P, Laine J, Stana-Kleinschek K, Ribitsch V. Analysis of the oxidation of cellulose fibres by titration and XPS. Colloids Surf A Physicochem Eng Aspects. 2005;13:101–8. doi:10.1016/j.colsurfa.2005.01.035. http://www.sciencedirect.com/science/article/pii/S0927775705001810.

Luo Q, Liang D, Mo S. Numerical calculation of the critical parameters of Frank-Kamenetskii equation in spontaneous combustion theory. Numer Heat Transf Part B Fundam. 2015;68(5):403–17. doi:10.1080/10407790.2015.1036625.

Gray B. Spontaneous combustion and self-heating. In: Hurley MJ, et al., editors. SFPE handbook of fibre protection engineering. 5th ed. New York: Springer; 2016. p. 604–32. doi:10.1007/978-1-4939-2565-0.

Luo Q, Liang D, Shen H. Evaluation of self-heating and spontaneous combustion risk of biomass and fishmeal with thermal analysis (DSC-TG) and self-heating substances test experiments. Thermochimica Acta. 2016;635:1–7. doi:10.1016/j.tca.2016.04.017. http://www.sciencedirect.com/science/article/pii/S0040603116300879.

Thomas PH. Some approximations in the theory of self-heating and thermal explosion. Trans Faraday Soc. 1960;56:833–9. doi:10.1039/TF9605600833.

Thomas PH. On the thermal conduction equation for self-heating materials with surface cooling. Trans Faraday Soc. 1958;54:60–5. doi:10.1039/TF9585400060.

UN. Recommendations on the transport of dangerous goods: manual of tests and criteria, 6th ed. United Nations, New York and Geneva (2015)

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 1964;6(1):183–95. doi:10.1002/polc.5070060121.

Friedman HL. Kinetics and gaseous products of thermal decomposition of polymers. J Macromol Sci Part A- Chem. 1967;1(1):57–79. doi:10.1080/10601326708053917.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(11):1881–6. doi:10.1246/bcsj.38.1881.

Brown M, Maciejewski M, Vyazovkin S, Nomen R, Sempere J, Burnham A, Opfermann J, Strey R, Anderson H, Kemmler A, Keuleers R, Janssens J, Desseyn H, Li C-R, Tang TB, Roduit B, Malek J, Mitsuhashi T. Computational aspects of kinetic analysis: Part a: The ic357 tac kinetics project-data, methods and results. Thermochim Acta. 2000;355(12):125–43. doi:10.1016/S0040-6031(00)00443-3. http://www.sciencedirect.com/science/article/pii/S0040603100004433.

Vyazovkin S, Burnham AK, Criado JM, Prez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(12):1–19. doi:10.1016/j.tca.2011.03.034.

Liu X, Feng Y, Li H, Zhang P, Wang P. Thermal decomposition kinetics of magnesite from thermogravimetric data. J Therm Anal Calorim. 2012;107(1):407–12. doi:10.1007/s10973-011-1841-x.

Xu M, Guo H, Li F, Qin Z. Thermal analysis kinetics of thermal decomposition of nickelviscose composite fiber. J Therm Anal Calorim. 2014;118(1):153–63. doi:10.1007/s10973-014-4006-x.

Yao F, Wu Q, Lei Y, Guo W, Xu Y. Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2008;93(1):90–8. doi:10.1016/j.polymdegradstab.2007.10.012. http://www.sciencedirect.com/science/article/pii/S0141391007003217.

Kim U-J, Eom SH, Wada M. Thermal decomposition of native cellulose: In uence on crystallite size. Polym Degrad Stab. 2010;95(5):778–81. doi:10.1016/j.polymdegradstab.2010.02.009. http://www.sciencedirect.com/science/article/pii/S0141391010000637.

Acknowledgements

This work was supported by International Program for Ph.D. candidates of Sun Yat-Sen University and by funds from Guangdong Provincial Scientific and Technological Project (Nos. 2013B090800008 and 2014B030301034) and ShenZhen Scientific and Technological Innovation Committee (No. JCYJ20130401161052963). Lastly, we also express our appreciation to the support of University of Wollongong.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, Q., Ren, T., Liang, D. et al. A study on the thermal decomposition temperature (TDT) and critical ambient temperature (CAT) of cotton. J Therm Anal Calorim 128, 1617–1625 (2017). https://doi.org/10.1007/s10973-017-6090-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6090-1