Abstract

The term spontaneous combustion will be used here to refer to the general phenomenon of an unstable (usually oxidizable) material reacting and evolving heat, which to a considerable extent is retained inside the material itself by virtue of poor thermal conductivity of either the material or its container. Under some circumstances this process can lead to flaming combustion and overt fire, in which case it is properly called spontaneous ignition, which here is regarded as a special case of spontaneous combustion. This has been responsible for significant losses of life and enormous losses of property. Fire loss statistics from many sources show that spontaneous ignition is quoted as the cause in a much greater proportion of cases with multimillion-dollar losses than in smaller fires. Of course, one should also note that the proportion of “cause unknown” results follows a similar trend, probably due to the greater degree of destruction, and hence evidence loss, in larger fires.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Heat Transfer Coefficient

- Critical Condition

- Biot Number

- Continuous Stir Tank Reactor

- Spontaneous Combustion

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

The term spontaneous combustion will be used here to refer to the general phenomenon of an unstable (usually oxidizable) material reacting and evolving heat, which to a considerable extent is retained inside the material itself by virtue of poor thermal conductivity of either the material or its container. Under some circumstances this process can lead to flaming combustion and overt fire, in which case it is properly called spontaneous ignition, which here is regarded as a special case of spontaneous combustion. This has been responsible for significant losses of life and enormous losses of property. Fire loss statistics from many sources show that spontaneous ignition is quoted as the cause in a much greater proportion of cases with multimillion-dollar losses than in smaller fires. Of course, one should also note that the proportion of “cause unknown” results follows a similar trend, probably due to the greater degree of destruction, and hence evidence loss, in larger fires.

In other circumstances, clearly delineated from the former, only relatively mild self-heating occurs. This may be referred to as self-heating, spontaneous combustion, or by research scientists as subcritical behavior. By the same token, spontaneous ignition would be referred to as supercritical behavior. The well-defined boundary between the two types of behavior is referred to as the critical condition, and it plays an absolutely central role in the area, both conceptually and pedagogically. It can crudely but pictorially be thought of as a watershed.

The critical condition is actually a whole set of combinations of parameters that affect the behavior. The most important of these are the ambient (surrounding) temperature, and the size and shape of the body of material involved. Thus for a given body of a particular material we would normally talk about the critical ambient temperature (CAT). If we were dealing with a situation where the size of the body were always fixed by commercial practice, for instance, this would be the normal statement of the critical condition. However, in the case of storage of a variable amount of material in a constant temperature environment, then one would talk about the critical size or the critical diameter of the body for a given fixed temperature. The CAT is the most commonly used and stated critical condition.

For both fire prevention and fire cause investigation, it is essential to be able to identify the critical condition if spontaneous ignition is a possibility either before or after the event. It is also important to be aware of other possible factors operating in particular cases, such as solar irradiation in outdoor storage and preheating if recently manufactured or processed goods are involved. In such cases as hot laundry; hot new chipboard; hot, oily, porous food products (instant noodles, fried fish scraps); bagasseFootnote 1; and the like, the temperature of the material itself is a most important parameter affecting criticality in addition to the usual ones. In such cases we have to deal with and determine a critical stacking temperature (CST), which refers to the temperature of the material itself not the ambient temperature. The CST is dependent on the CAT and the size of the body so such cases are a degree more complicated than the traditional ones involving usually agricultural materials stacked at ambient temperature. In addition, in such cases with preheated materials the time to ignition (defined precisely later) is usually very much shorter than it is where the material is stacked at ambient temperature.

Because the basic processes competing with each other in spontaneous combustion are heat generation by chemical reaction and heat loss to the surroundings mainly by conduction, it is easy to see qualitatively why both a larger body and a higher ambient temperature will favor ignition rather than subcritical behavior as they both decrease the rate of heat loss. Generally the temperature profile across the body itself is roughly parabolic in shape with a peak at the center. Most chemical reaction rates increase almost exponentially with temperature, whereas heat loss processes such as conduction increase only linearly. Thus the center of the body where the temperature is highest is the region where ignition, or thermal runaway, will commence if it is going to take place at all. Many bodies that have undergone spontaneous ignition show this telltale signature of charring or complete destruction to ash in the center while retaining an almost pristine appearance on the outside, sometimes presenting rather dangerous situations for fire fighters in large-scale examples such as bagasse, woodchip, or peat piles. Similarly, the deep-seated nature of the burning started by spontaneous ignition can be difficult to extinguish completely, often reigniting days after apparent extinction.

The purpose of this article is to expound the detailed nature of the situations described above in a manner that approaches the principles involved in a way that minimizes mathematical formulation as far as is reasonable. The subject will be approached from the point of view of its relevance to fire cause and fire investigation and as such will refer mainly to solid systems. Many of the basic principles used were actually clarified by experimental work on gaseous systems; such systems still play a central role in current research on this topic, particularly ones where the chemical kinetics are simple and well understood in their own right.

A closely related aspect to be discussed here is the subject of runaway reaction, or thermal runaway. In the past two decades this topic has developed a literature of its own [1] and threatened to lose contact with the extensive literature on spontaneous combustion. These two terms, which can be taken as synonymous, are applied to supercritical conditions as defined above but only in the context of a chemical reactor. The reactor may be of batch, semibatch, or continuous flow type, but it will almost invariably be well stirred either mechanically or by deliberate turbulent mixing. Therein lies the attraction from a pedagogical point of view of such studies because the main difficulties in mathematical modeling of solid spontaneous combustion arising from spatial temperature variation and gradually decreasing concentration of reacting material are not present. Thus a mathematical theory describing such processes exactly serves as a first approximation, and a tractable one at that, to the more complex topic of solid spontaneous combustion. In addition, the difficult and messy “corrections” to the simplest possible theories due to Semenov [2] and Frank-Kamenetskii [3] are often impossible to apply in practical situations due to the dearth of data and/or their numerical uncertainties.

In addition, in the rare event that precise input data are available and detailed chemical kinetics are known, it is now entirely feasible for particular cases to invoke numerical integration of the relevant equations directly without use of the empirical and semiempirical curve fits involved in the classical corrections to the simplest theories. At the time of writing, average laptop computers are quite capable of such calculations for all but the most irregularly shaped bodies where finite element methods need to be invoked and custom written.

Accordingly we will spend some time here expounding the simplest possible theory (Semenov), which contains all the essential concepts for the understanding of criticality, the tangency between heat release and heat loss curves, and the existence (or otherwise) of stable and unstable steady states. We then move on briefly to the application of such ideas to more complex chemistry and the idea of thermal runaway in continuous stirred tank reactors (CSTR).

We then discuss the Frank-Kamenetskii version of thermal explosion theory, which considers temperature gradients within the self-heating body (thereby generalizing Semenov) and often gives better agreement with experiment for solid bodies with low thermal conductivity. For this reason it is much used in fire investigations, particularly when it is necessary to predict the CAT for a large-scale industrial body from small-scale laboratory tests. However, this type of extrapolation requires great care in its application to all but the simplest chemistry.

We then present some ways in which corrections can be made to the predictions of the Frank-Kamenetskii theory occurring under conditions where some of its assumptions are not sufficiently accurate. This occurs when the heat of reaction is relatively small and/or when the resistance to heat flow in the boundary of the body (or container wall) is relatively large compared to that inside the body itself (case of small Biot number). Corrections are also necessary when more than one chemical reaction generates heat and when oxygen diffusion into the interior of the body is rate limiting.

All of these factors are difficult to handle quantitatively, but fortunately none of them really alter the qualitative conceptual nature of what is going on. It is important in gaining an understanding of spontaneous combustion not to be confused by these corrections, although in certain cases they can be quite large.

We will then move on to discuss experimental testing methods, both on a laboratory and a larger scale where possible. A large array of calorimetric methods can be used to obtain relevant information, but not all of them, particularly differential scanning calorimetry (DSC) and differential thermal analysis (DTA), can give other than very general information and therefore can often be misleading. Nevertheless, such methods have their purpose when material of unknown origin and composition is involved. Sometimes one needs to know whether the unknown is capable of exothermic reaction at all as postulation of spontaneous ignition because a fire cause looks rather silly in its absence (this happens!). However, activation energies, in particular those obtained from DSC tests, should be treated with great suspicion.

A characteristic of fires where spontaneous ignition is suspected as the cause is that they often occur on premises that have been closed up or unoccupied for a significant period of time. A question of very great interest in such a context is, What is the time scale expected for a body of a given size in a given ambient temperature to reach ignition, that is, the appearance of overt flame? As one would expect, by application of Murphy’s law, this question is very difficult to answer with confidence except in the simplest of cases. The time to ignition is a parameter that is not only extremely sensitive to many factors that are often unknown but is also extremely sensitive to the degree of supercriticality, that is, how far the body is from the watershed. Not only does it depend on how far the body is from the watershed, but it depends sensitively on the direction as well. In other words, the term degree of supercriticality needs to be refined before any idea of time to ignition can be properly formulated.

A number of investigations of this problem have been carried out, and it is essential to recognize that most of the earlier ones addressed the question of time to ignition for the initial temperature of the body equal to the ambient temperature—such as would be the case in the building of a haystack. Hot stacked material requires totally different considerations for the evaluation of times to ignition, and classical formulas cannot be used in such situations. Such bodies can ignite in times that may be an order of magnitude shorter than predicted by uncritically using classical formulas.

In the penultimate section of this article, we move on to discuss the actual fire scene where spontaneous ignition has been the cause, or suspected cause, of the fire. We discuss factors that would be either positive or negative indicators of spontaneous ignition, and also the appropriate examination of the aftermath of the fire for pointers as to whether or not spontaneous ignition was the cause. We then proceed to illustrate all of the above with a number of case histories, some of them common and illustrative of the basic principles expounded here, others of a novel nature involving quite subtle and detailed investigations that nevertheless can give very definite results.

The Literature

There is a large and varied literature on the topic of spontaneous combustion ranging from sophisticated mathematical theory to technical measurements on industrial and agricultural products. It is scattered over a very wide range of journals, magazines, and disciplines. The most comprehensive publication is probably the book written by Bowes [4], Self-Heating: Evaluating and Controlling the Hazards. This book was published in 1984 and contains references to work published up to 1981, so at the present time it is in need of updating. However, it is the most useful reference available for those working, or commencing work, in the field from either an academic or a technical viewpoint. The Ignition Handbook by Babrauskas [5], published in 2003, contains a very useful chapter on self-heating and has become an indispensable reference for anyone working in the area of ignition.

Although much of the understanding of spontaneous combustion has come from the basic study of gas-phase reactions, where it is generally referred to as autoignition, this article will be limited to spontaneous combustion of solid materials generally. Many advances have been made in the field of gaseous autoignition over the last decade or so, stemming from accurate and detailed kinetic measurements and considerable advances in computing power. The critical condition for gaseous systems is a very complex locus in the parameter space characterized by ambient temperature (as for solids), pressure, and composition. Many organic materials, such as hydrocarbons, exhibit more than one autoignition temperature, and many also exhibit the phenomenon of igniting on decreasing ambient temperature. Many older tabulations of autoignition temperatures do not recognize these peculiarities and should be used with great caution. A detailed description of the reasons for such complexities and their importance in a hazard context is given by Griffiths and Gray [6] in the twenty-fourth Loss Prevention Symposium of the American Institute of Chemical Engineers (1990). A comprehensive list of references up to 1990 can be found in this article.

Reference to liquid reactions and related spontaneous ignitions and thermal instabilities will be given later in this article in the section on spatially homogeneous or “well-stirred” systems. Otherwise, references will be given at points throughout this text resulting in a reasonably complete bibliography.

Concept of Criticality

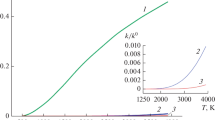

Over the last two decades the concept of criticality, which has been present in the thermal context for many years [7], has been recognized as a branch of bifurcation theory [8], an area of nonlinear applied mathematics that has grown rapidly and proven to be extremely powerful in solving nonlinear problems. In our case the nonlinearity comes from the temperature dependence of the chemical reaction (and therefore heat production) rate. The Arrhenius form for this for a single reaction is Ze −E/RT, where E is the activation energy and R is the universal gas constant. T is the absolute temperature, of course. At temperatures rather less than E/R (which can typically be 10,000 K or more), the Arrhenius function is very convex; that is, it curves upward rather rapidly with temperature. In contrast, the rate of heat loss from a reacting body is generally only a linear function of temperature, for example, conduction. Although radiation losses are nonlinear functions of temperature, they are much more weakly nonlinear than the Arrhenius function and also generally rather small at the low temperatures involved in solid spontaneous combustion although they are important in flame extinction. Typical heat generation per unit volume and heat loss (proportional to surface volume ratio as plotted) loci are shown in Fig. 20.1.

The low temperature range of the Arrhenius curve is seen here to be rather convex and rapidly increasing with temperature. The three straight lines represent the rate of heat loss from a body of fixed given size at various ambient temperatures T a,1 , T a,critical, and T a,2.

At T a,1 it can be seen that the heat production and loss curves intersect at two points. At T a,2 they do not intersect at all, and at T a,critical they intersect at only one point and, in fact, touch tangentially.

Because intersections represent conditions where heat production and loss balance exactly, we expect them to represent some sort of “equilibrium” or stationary point where the temperature of the body remains constant in time. It is important to remember that they do not represent equilibrium in any thermodynamic sense.

In the region of the lower intersection at T a,1 it can be seen from the diagram that the temperature of the body will increase up to the balance point from below as heat release is greater than heat loss in this region. On the other hand, just above this balance point the temperature of the body will move down to it because the heat release is lower than the heat loss in this region. Thus the lower balance point occurring at ambient temperature T a,1 is recognized as a stable balance, or stationary, point. Small perturbations from it will be nullified, and the body in this region will tend to stay at the balance point. Note that the temperature of the balance point is not T a,1 but slightly above it, usually by 5–20 °C. It represents subcritical self-heating and can cause loss of the material but not by overt ignition or fire. It can appear as degradation or discoloration of many materials, making them useless for their required purpose. For example, woodchips degraded in this way are not suitable for paper or cardboard production, and dried milk powder when discolored is unacceptable.

The second balance point at the ambient temperature T a,1 can be seen by a similar simple analysis to be unstable in the sense that, in the temperature region just below it, the heat production is lower than the heat loss, so the temperature tends to drop. In the temperature region just above it, the converse is true, so the body temperature tends to rise and leave the balance point. The latter acts as a watershed between two totally distinct types of behavior, that is, the temperature of the body dropping to the lower balance point or running away to the right of the diagram and much higher temperatures, representing ignition.

Here the temperature at the higher balance point would actually be the critical stacking temperature, or CST, for this particular body when stored at ambient temperature T a,1. We can immediately see that if the ambient temperature is increased, that is, the straight line is moved to the right with fixed slope (which is determined by the size and shape of the body as we shall see later), the CST will decrease, a physically reasonable and intuitive result.

Thus this oversimplified but extremely useful model gives a simple understanding of what Bowes refers to as thermal ignition of the second kind, that is, what is probably better referred to as the hot stacking problem, a much more descriptive term. Not only that, but it also gives us a qualitatively correct picture of the more common or “normal” type of thermal ignition when the body self-heats from ambient to ignition without any preheating. At T a,1 if we very slowly increase the ambient temperature after the steady state has been reached, we can see that the now “quasi-steady state” will also slowly increase until at T a,critical the quasi-steady state and the CST merge at the point of tangency. Beyond this ambient temperature there is no balance point, and in this temperature region the heat release curve is now always above the loss line and therefore the temperature can only increase. Subsequent ignition will then occur. It will occur after some delay because the rate of temperature increase in this simple model is proportional to the imbalance between heat production and loss (i.e., the vertical distance between the two curves). This is initially quite small, increasing as the temperature rises. In this observation lie the seeds of the calculation of the ignition delay or time to ignition (TTI) to be examined later.

Even more insights can be obtained from this simple type of reasoning. As we shall see later, the slope of the heat loss line is dependent on the surface area/volume ratio of the body in question. Thus for a body of given shape the surface/volume ratio increases as the body gets smaller and decreases as the body gets larger. In Fig. 20.2 we can see the effect of increasing the size of a body at a fixed ambient temperature. For this fixed ambient temperature we can speak of subcritical, critical, and supercritical sizes for the body, depending on whether any balance points exist.

Thus for a body with characteristic dimension r sub we see the existence of both a CST and a balance point. For a larger body with dimension r super we see that neither exists and we expect temperature to rise to ignition. The critical condition, in this case expressed as a radius or body dimension, is given again by the tangency condition. This critical condition, of course, is identical with that obtained by thinking of the quasi-static variation of the ambient temperature as well. The critical radius for a given ambient temperature will be identical with the CAT for a body of that same radius. How we describe it is simply a matter of where we are coming from.

Of course, we do not usually continuously vary the size of a body but we do often stack bodies together, for example, bales of cotton, bales of hay, and so on, and allow larger than normal quantities to accumulate, for example, coal stockpiles. Even from the point of view of this very rudimentary theory, it is obvious that the CAT of two bales in contact will be considerably less than that for a single bale. Thus tests of the CATs of single bodies that are going to be stacked in groups for either transport or storage are useless unless a theory is available enabling calculation of the dependence of CAT on body size. The theory allowing this is thus extremely useful in relating practical tests on small bodies to be applied to storage of large numbers of them (with certain caveats to be discussed later).

To conclude this section it remains to show a convenient method of representing the behavior of the stable balance point and the unstable CST as a control parameter is varied (i.e., the ambient temperature or size of the body). This method enables a quick and convenient representation of the discussion given above on a single diagram (a bifurcation diagram) and also gives us a useful link to the mathematical developments of bifurcation theory.

Figure 20.3 shows what happens to the balance point temperature and the CST when T a is varied continuously from below its critical value to above it. This takes place at constant body size. In this case the ambient temperature is known as the bifurcation parameter. We should note that, even at very low ambient temperatures, the CST tends to a finite limit. In fact it becomes very insensitive to the ambient temperature, and no matter how cold the ambient temperature, there is no corresponding rise in the CST. Storing hot products in a cold warehouse does not help the problem much!

Conversely Fig. 20.4 shows how the CST rises indefinitely as the size of the body decreases at fixed ambient temperature. Regardless of ambient temperature it does pay to keep hot stored bodies small! Figure 20.4 also shows how, for sizes above the critical radius, there is no alternative but ignition. Of course the critical radius depends on the ambient temperature, and as the latter goes down the critical radius goes up. It is sometimes very useful to draw a critical radius versus critical ambient temperature graph, and we will see how to do this later.

The whole discussion above assumes that we are dealing with a given material so that the thermal and chemical properties do not vary. The effects of varying thermal conductivity, heat transfer coefficients, and density on the critical condition are also important but only when comparing different materials. The dependence of the critical condition on these properties will be enunciated in a later section.

One final point needs to be mentioned here. The Arrhenius function does actually level out to an asymptote at very high temperatures, which are off the scale in Figs. 20.1 and 20.2. Thus theoretically there is another balance point at very high temperatures, but in fact this point is not physically significant as it usually occurs at many thousands of degrees, well beyond the region where the assumptions of the model are valid. It also gives rise to a high temperature branch of the curves in Figs. 20.3 and 20.4, which is disjoint from the curves shown. Again it can be ignored from the point of view of low-temperature spontaneous ignition.

The Semenov (Well-Stirred) Theory of Thermal Ignition

The Semenov theory represents the simplest mathematical formulation of the ideas presented above in qualitative form. As such it is a valuable introduction to quantitative aspects of spontaneous ignition without introducing the technical difficulties associated with more elaborate forms of theory where spatial variations of temperature and reaction rate within the body are considered.

Assumptions of the Semenov Theory

The three assumptions of the Semenov theory are as follows:

-

1.

The temperature within the reacting body is spatially uniform: A spacially uniform temperature implies that either the material of the body is well stirred (i.e., it would have to be liquid or gas) or the resistance to heat flow within the body is so low compared to that within the container or boundary that it can all be assumed to be concentrated within the boundary. The latter results in a temperature discontinuity at the boundary of the material and is a good approximation in deliberately stirred fluids [9].

It is not a good approximation for materials of vegetable origin where thermal conductivities of materials such as cellulose are low and of the order of 0.05 W/mK. Nevertheless, even for such materials semiquantitative conclusions can be drawn from this theory if the spatially averaged temperature of the body is used.

-

2.

The heat generation is assumed to be due to a single chemical reaction: This assumption is often a reasonably good approximation, particularly when a “lumped” or empirically determined rate law has been measured independently. It does not mean that the chemical reaction taking place is only a single-step reaction. In fact this empirical approximation works quite well in many cases that are not single-step reactions.

-

3.

Both the heat of reaction and activation energy are assumed to be sufficiently large to support ignition behavior: The reasons for these assumptions will become clearer later, but it is intuitively obvious that if there is zero heat of reaction, ignition cannot occur. Likewise with zero activation energy (acceleration of reaction rate with temperature increase), ignition cannot occur either.

With these assumptions we can write down two equations that determine the temperature and fuel concentration as functions of time (but uniform in space). These are simply the conservation of energy and the kinetic rate law, respectively. They are

where

-

C v = Heat capacity at constant volume

-

ρ = Density

-

V = Volume

-

T = Temperature of the reacting material (in K)

-

T a = Ambient temperature of the surroundings (assumed constant in time)

-

Q = Heat of reaction per unit concentration of fuel

-

f(c) = Kinetic rate law

-

c = Concentration of fuel

-

E = Activation energy of the reaction

-

R = Universal gas constant

-

S = Surface area of the interface across which heat is lost to the surroundings

-

χ = Heat transfer coefficient

The independent variable is time.

The first term on the right-hand side of Equation 20.1 represents the rate of heat generation by the self-heating reaction. The second term represents the heat lost to the surroundings. The left-hand side represents the difference between these two. Equation 20.2 simply expresses the fact that as the reaction proceeds, the concentration c decreases as the fuel is used up. The commonest and simplest form for f(c) is Zc where Z is known as the pre-exponential factor, a constant. This case is known as a first-order reaction. These two terms are shown graphically in Fig. 20.1 for any particular value of c.

Despite their apparent simplicity these two equations are not soluble by classical methods, so we cannot write down their solution. Nevertheless, we can in fact write down the critical condition exactly (and other important quantities) using bifurcation theory. We will illustrate this for the simplest possible case only, remembering that it can also be done for more realistic and complicated cases as well within the confines of the Semenov theory.

First we write Equations 20.1 and 20.2 in dimensionless form (see nomenclature for details),

where

-

u = Dimensionless temperature

-

ν = Fuel concentration

-

ε = A dimensionless version of the ratio C ν /Q (i.e., a measure of the amount of fuel decomposition required to produce a temperature rise of 1 °C)

-

τ = A dimensionless time

-

ℓ = A dimensionless heat transfer coefficient

The most frequently used version of this theory, without fuel consumption, corresponds to taking the limit \( \upvarepsilon \to 0 \), thus maintaining ν at its initial value ν0. We have only a single equation to deal with now, that is,

Even this much-simplified equation is not analytically soluble. However, it relates exactly to Fig. 20.1 and can be used to calculate the critical condition readily. We first note that the balance points in Fig. 20.1 must satisfy the equation

For subcritical values of the ambient temperature, this equation will have three solutions for a given set of parameter values, ν0, u a , and ℓ. From Fig. 20.1 it can be seen that at the critical condition (T a,critical corresponding to u a,critical) not only do the two terms of Equation 20.6 balance, but their slopes also balance at this condition. Mathematically this means that their differential coefficients with respect to temperature must also be equal, that is,

The critical value of u s is then obtained by solving Equations 20.6 and 20.7 simultaneously, which interestingly can be done in closed form simply by eliminating the exponential, leaving a quadratic equation:

From our definition of u = RT/E and the general knowledge that R/E ≅ 0.0001 for most combustion reactions, we can see that at normal ambient temperatures for ignition we will have u a,critical ≅ 0.02, or in any case u a,critical ≪ 1. Using the standard formula for the solution of a quadratic equation and expanding the radical occurring, we can derive

which is the lower of the two roots (the upper one is unphysical).

If we substitute this back into either Equation 20.6 or 20.7 we get a relationship between the parameters of the problem, that holds at criticality only. Thus if we use Equation 20.6, we obtain, after some rearrangement,

We can interpret this equation in a number of ways. Since ℓ critical involves the size of the body as the only physically variable parameter, and ν0 is proportional to the bulk density of the material, we can take this equation to give us the critical size body for a given ambient temperature and bulk density. u a,critical is the only parameter here that cannot easily be made the argument of the equation.

Converting Equation 20.9 into dimensional form quickly gives us the relationship:

at the critical condition. ΔT critical would typically be 20–30 °C for ambient temperatures around 30–40 °C. Not surprisingly, it is independent of the body shape, being dependent only on the total surface area through which heat is lost. Nevertheless, even this oversimplified result can be very useful in an emergency situation. If E is not known, it is a useful rule of thumb (especially for agricultural cellulosic materials) that self-heating of more than 30° above ambient, that is, typically a body temperature of more than 60–70 °C, represents imminent spontaneous ignition, whereas an internal body temperature of 35–40 °C represents subcritical heating unlikely to run away but quite likely to lead to degradation of the material.

Two further points need to be made before leaving this simplified model. First, in order for Equation 20.8 to have real roots, it is necessary to require that

Physically this means that the chemical heat generation rate is sufficiently accelerative to produce the phenomenon of criticality. If it is not satisfied, there is only a single stable balance point for all conditions and no abrupt change in behavior can occur.

Second, if we examine Equation 20.10, the critical condition, we should note that where the concentration ν0 appears, in the case of gases we would normally convert this to pressure. Thus, in this case, Equation 20.10 gives a relationship between ambient temperature and pressure at the critical condition. This is the familiar explosion limit curve extensively used in the study of gaseous explosions.

Inclusion of Fuel Consumption

If we do not make the assumption \( \upvarepsilon \to 0 \) in Equation 20.4, the clear distinction between subcritical and supercritical behavior no longer exists. We can no longer define the critical condition as the disappearance of two balance points. Equations 20.3 and 20.4 possess only a single balance point, u = u a and c = 0 for all possible parameter values; and this refers to the equilibrium state when all fuel has been exhausted and nothing is happening—clearly a condition of no interest. For the definition of criticality in such a case it is helpful to examine the experimental or phenomenological definition. The experimentalist determines the critical condition by performing various tests at differing ambient temperatures (we will outline the details of test procedure in a later section) and by measuring the temperature-time history at the center of the sample. He or she will plot the maximum temperature attained against ambient temperature and will find there is a very steep increase in slope over a narrow region of ambient temperature. This is illustrated in Fig. 20.5.

The distinction between points 1 and 2 is very clear in terms of both the maximum temperature attained and the physical condition of the material itself after the test is finished. Typically at point 2 the material is hardly different visually from the initial condition, whereas at point 1 there is usually no more than a small amount of ash remaining. The temperature attained at point 1 is often of the order of hundreds of degrees above ambient compared with probably 30° above ambient at point 2.

It is impossible to get points between 1 and 2 experimentally without wasting a great deal of time due to the extreme sensitivity in this region, so the convention is to define the CAT as the arithmetic mean of T a,1 and T a,2 . With good equipment these will be only 3° or 4° apart at the most.

From the point of view of theoretical calculation of the CAT in this case, we note that the points in Fig. 20.5 can be joined by a smooth curve with a very steep region around an inflection point. It has been shown (Gray [10]) that this definition of the CAT, when fuel consumption is significant, leads to a relation between the usual parameters and this relation passes over smoothly to the one derived from the tangency condition as \( \upvarepsilon \to 0 \). For \( \upvarepsilon \cong 0.05 \) or less, which is the case for most practically important materials, the corrections arising from fuel consumption are not usually significant. This is especially the case in fire investigations where a posteriori numerical knowledge of parameter values is rather limited, and this correction (and others) is not justified.

Extensive discussion of earlier work on the fuel consumption correction is given in Bowes’s book [4]. Many empirical and semiempirical corrections were devised based on approximated integration of Equations 20.3 and 20.4. These corrections will not be discussed here because the advent of powerful PC and laptop computational capabilities has rendered them irrelevant. Equations 20.3 and 20.4 can be integrated with great speed and precision if accurate parameter values are available. Even so, it is necessary to have a definition of criticality when a computed or experimental version of Fig. 20.5 has been obtained. With the definition given in Gray [10] allied with numerical integration, the problem can be regarded as solved for all practical purposes.

Extension to Complex Chemistry and CSTRs

Complex Chemistry

Other than elementary gas-phase reactions, very few examples of chemical change occur via a single step as assumed above. As already remarked, the simple theory is more useful than might be expected because many complex chemical reactions behave as if they were a single step, over limited temperature ranges. This is usually because a single step does dominate the heat production rate, for example, when two reactions occur in parallel. If the activation energies are rather different, they will each in turn dominate the heat generation in two different temperature ranges, and in each of these ranges the simple theory will hold. Of course, it will not hold in the changeover region.

Another case where the simple theory can hold unexpectedly is when a number of reactions are in series and one is particularly slow. The slow reaction will determine the overall heat generation rate and its parameters will dominate the critical condition. If none of the above conditions hold, it is still possible to derive a generalization of the theory that is conceptually very closely related. It is possible to prove (Gray [11]) that if the heat release rate is defined as the sum of the heat release rates of all reactions taking place in the system, then the critical condition can be defined as the tangency of this quantity with the heat loss line. Thus a diagram like Fig. 20.1 can be drawn and the same constructions used, provided the total heat release curve for all the reactions is used.

The heat release curve in this case can have a complex shape, and thus more than one critical condition can occur. This state of affairs is extremely important in the ignition of most organic vapors, particularly hydrocarbons [6] where some critical conditions occur on decreasing the ambient temperature. Also in the ignition of some commonly occurring solids, particularly when wet, more than one heat-generating reaction can be important, for example, in the spontaneous ignition of moist bagasse [12]. In this case there are two critical conditions, one where a jump from virtually no self-heating to self-heating of ∼35 °C occurs, and a second critical condition where this intermediate state jumps to full-fledged ignition. Modelling of such situations is possible but beyond the scope of this chapter; however, similar behavior is likely to occur in other moist cellulosic materials, including hay, chipboard, and so forth.

At this stage it is worth pointing out that for bagasse at least, microbial “heat production” is not a factor in these phenomena. Although natural bagasse contains large numbers of microorganisms, sterilization by various methods does not affect heat production or self-heating at all, as measured by Dixon [13] and predicted on the basis of bacterial microcalorimetric data by Gray [14]. Similar work on hay is under way.

CSTRs and Thermal Runaway

Strangely, this topic has become uncoupled from work on spontaneous ignition over recent years even though the basic principles and mathematical methods used are similar. It is a huge problem in the chemical process industry and receives much attention. For example, in 1998 the Joint Research Centre of the European Commission, Institute for Systems Informatics and Safety, produced a book describing the proceedings of a European Union seminar held in Frankfurt in 1994 that managed to avoid almost completely any reference to the fundamentals of the problem or related material. Risk analysis appears to have replaced fundamental scientific understanding in some aspects of this problem.

We will confine ourselves here to writing down the basic equations governing a single exothermic chemical reaction taking place in a CSTR (continuously stirred tank reactor) to exhibit their similarity to the equation describing a spontaneously ignitable material, that is, Equations 20.3 and 20.4.

The appropriate equations for this case are in fact 3 and 4 with terms representing inflow and outflow of reactants and products, that is,

F is a volumetric flow rate and the subscript f refers to feed values. These equations can be cast in dimensionless form also. Here we simply note that they possess steady-state (balance point) solutions without making any approximations at all (such as neglect of fuel consumption), and Fig. 20.1 can be applied directly in slightly modified form. The critical condition referred to earlier occurs here also, but it can now be stated in terms of the CAT or a critical feed temperature or, indeed, a critical flow rate.

A critical size also occurs and this is particularly prominent in CSTR considerations where “scaleup” from prototype size to commercially viable size has resulted in exceeding the critical condition. Some references to this are given in Safety and Runaway Reactions [1], and there are many more in the chemical engineering literature and the study of self-heating in catalyst particles. See Aris [15] for an excellent discussion of this area.

The Frank-Kamenetskii Theory of Criticality

In its original form, the Frank-Kamenetskii theory included a more realistic model of heat transfer within the reacting solid, that is, by incorporating the heat conduction law of Fourier. This law allows a calculation of the variation of temperature within the self-heating body itself and allows comparison of measured and calculated self-heating to take place. However, it sacrifices the simple description of time-dependent behavior given by the Semenov model because such considerations involve the solution of partial differential equations. This is now much faster than even a few years ago, in terms of numerical computation, and improving day by day. Nevertheless, such numerical solutions do not lend themselves to simple interpretation even with the use of rapidly developing visualization techniques. Construction of appropriate meshes for finite element computation, necessary for practically occurring three-dimensional shapes, is also far from trivial.

As a result, the Frank-Kamenetskii theory is still mainly used for interpretation of testing experiments on self-heating and subsequent evaluation of parameters for individual systems. This is a viable proposition for materials with sufficiently large heats of reaction and activation energies. In such cases we shall see that the stationary (in time) conditions assumed in the Frank-Kamenetskii theory are indeed well approximated for the duration of typical tests in practical cases. In its original form this theory also neglects fuel consumption, as does the Semenov theory, with similar consequences. With these assumptions, the equation describing the theory is

with the boundary condition T = T a on the wall(s) of the body. T a is the ambient temperature of the surroundings. This boundary condition assumes instantaneous transfer of heat from the surface of the body to the surrounding medium (usually air). When this is not approximately correct, very important consequences follow, as we shall see in a later section on the interaction of self-heating bodies with each other. In this formulation the shape of the body and its size both enter the mathematical formulation through the boundary condition only.

As usual, Equation 20.15 is not analytically soluble. However for a one-dimensional infinite slab of material by using an approximation to the Arrhenius function (Frank-Kamenetskii [3]), the modified equation can be solved analytically. The same approximation was later shown to be analytically soluble for an infinite cylinder by Chambre [16].

With this approximation, Equation 20.15 takes the form

with θ = 0 on the boundary. θ is a dimensionless temperature defined by

that is, it is a measure of the temperature excess within the body at various points. The dimensionless parameter δ is defined by Equation 20.18:

where the symbols are already defined apart from r, which is usually one-half of the smallest dimension of the body, that is, the radius of a cylinder, the radius of a sphere, or the half-width of a slab. Mathematical treatment of Equation 20.16, whether it is exactly soluble or not, indicates that a solution satisfying the boundary conditions exists only when δ is less than or equal to δcritical where δcritical is some number depending on the shape of the body only. For an infinite slab of material δcritical = 0.878, and for an infinite cylinder it has the value 2.000. For other shape bodies, the critical value has to be obtained either numerically or by semiempirical methods outlined in some detail by Bowes [4]. For convenience, a few of the values are listed in Table 20.1.

The tabulation of figures for infinite slab or infinite square rod is useful insofar as they are often rather good approximations for real bodies, provided one or more of their dimensions are much larger than the others. Thus for the rectangular box, if we take r = l = 1, m = 10, we get δcritical = 1.75 compared to 1.700 for the infinite square rod. If we now look at Equation 20.18 for the particular case of a cube as an example, we get

at the critical condition. We have a number of choices as to interpretation of this equation depending on which parameter can be made the argument. If r is chosen as the argument, then the equation would be interpreted as giving a critical size for the body at a fixed ambient temperature T a . Because c 0 depends on the density of the material, Equation 20.19 could be rearranged to give a critical density for that particular size body at ambient temperature T a . What is not possible is isolation of T a as the argument of the equation, and this is often the most easily varied parameter in a typical test oven.

This complex dependence of the critical condition on T a is dealt with by rearranging Equation 20.18 and taking natural logarithms as follows:

from which it can be seen that a plot of ln[δcritical T 2a,critical /r 2] against 1/T a,critical will be a straight line with slope -E/R and intercept ln[QEf(c 0)/κRδcritical]. The traditional and recommended test protocol for spontaneous ignitions makes explicit use of this logarithmic form of the critical condition. Not only does it yield the activation energy from the slope, but the occurrence of a straight line plot assures us that the assumption of an Arrhenius temperature dependence for the heat-generating reaction is correct over the temperature range investigated.

Equation 20.20 can also be regarded as a scaling law, in principle enabling the prediction of CATs for large-scale bodies from measured CATs for much smaller laboratory-sized samples. However, as we shall see, it is necessary to ensure that the same chemical kinetics applies over the whole temperature range involved, that is, f(c 0) does not vary. Finally, if it becomes necessary to estimate the CAT for a complex shape, not included in Table 20.1, an excellent and comprehensive discussion of approximation methods is given by Boddington, Gray, and Harvey [17].

Experimental Testing Methods

Experimental testing methods are traditionally based on the scaling relationship (Equation 20.20). Appropriate containers (usually stainless steel gauze baskets) of various dimensions are used, being limited only by the size and heating capability of an accurately thermostatted oven, which must also have a spatially homogeneous ambient-temperature distribution (±0.5 °C is recommended). The gauze containers may be any convenient shape, equicylindrical or cubic being preferred due to ease of construction. The gauze does not restrict oxygen ingress through the boundary, nor does it restrict egress of carbon dioxide and other product gases during combustion. If the air inside the oven is sufficiently turbulent, usually the boundary conditions of the Frank-Kamenetskii theory will hold quite well.

The boundary condition is easier to satisfy when the thermal conductivity of the material inside the gauze baskets is relatively low, as it is with many agricultural materials containing cellulose (κ ∼ 0.05 W/mK). The efficacy of the boundary condition is determined by the heat transfer rate from the gauze to the oven air relative to the conduction rate within the material itself. This ratio (χr/κ) is known as the Biot number, and the larger it gets, the more accurate the Frank-Kamenetskii boundary condition (T = T a ) becomes. In practice a Biot number greater than 30 is effectively infinite as the CAT becomes extremely insensitive to it. We will return to this topic in a later section where the dependence of the critical condition on the Biot number will be outlined.

The test procedure involves starting with the smallest basket and a trial oven temperature. The sample is equipped with one or more fine thermocouples placed at the center of the sample and, if desired, at various places along a radius if a spatial profile is wanted (this is generally not necessary). The sample is placed in the preheated oven and the center temperature followed as a function of time. If the oven temperature is well below the CAT, the sample will simply approach the oven temperature asymptotically. If it is slightly below, but getting close, it will cross above the oven (ambient) temperature and attain a maximum of the order of 1–30 °C above ambient before declining. This represents the subcritical condition.

The sample is discarded and replaced with a fresh, similar one. If the previous run was subcritical, the oven temperature will be increased by usually 20 °C or less depending on the experience of the operator. The run is then repeated. If it is still subcritical, the procedure is again repeated until a supercritical oven temperature is attained. The arithmetic mean of the lowest supercritical temperature and the highest subcritical temperature is taken as the first estimate of the CAT. The uncertainty may be quite large at this stage so the process is usually continued by testing at the estimated CAT. The process is repeated, halving the difference between highest subcritical and lowest supercritical temperatures each time until the desired errors are obtained. Typical temperature-time plots showing the critical separation are shown in Fig. 20.6.

Two subcritical and one supercritical center temperature/time traces for a 0.175-m-radius equicylinder of hydrated calcium hypochlorite [17]

This reaction is an exothermic decomposition evolving oxygen [18]. From these measurements one would conclude that the CAT was 55.2 ± 1.34 °C. For greater accuracy the next test would be run at an ambient temperature of 55.2 °C. After at least four or five such sets of runs have been carried out in different size containers, giving four or five CATs at various radii, then the next step is to construct the Frank-Kamenetskii plot of the scaling Equation 20.20. A typical plot is shown in Fig. 20.7.

Recalculated Frank-Kamenetskii plot for the data of Uehara et al. on anhydrous calcium hypochlorite [19]

This plot shows a range of CATs for cylinders ranging in radius from 0.191 m down to 0.026 m, the larger radii corresponding to commercial containers. From the slope of this line, E/R can be read off directly, and, from the intercept, so can the dimensionless group occurring in the scaling equation. Sometimes components of this group may be known from independent measurements, for example, Q from calorimetry, κ from direct measurement, or f(c 0) from kinetic measurements, in which case all the parameters can be obtained.

Special Cases Requiring Correction

Presence of Water

When water is present in spontaneously combustible material, special considerations apply. First it is necessary to note that endothermic evaporation would be expected to partly offset some of the heat generation by the exothermic reactions taking place. Although this is true, it is often the case that at the high oven temperatures used in testing small samples, the low activation energy for evaporation (∼40 kJ/mol) leads to rapid evaporation before the exothermic process has got under way fully. Many spontaneous combustion reactions have activation energies around 100 kJ/mol, particularly the group of reactions of cellulosic materials.

As a result, the high-temperature CATs reflect the properties of the dry material, in particular the thermal conductivity. Consequently, extrapolations to temperatures well below 100 °C will be questionable for this reason alone. In the lower temperature range the heat transfer will be significantly affected by the presence of water and its transport from the hotter to the cooler regions of the body by evaporation, diffusion, and condensation.

Many cellulosic materials are known to exhibit a “wet reaction” [20, 21] in addition to the dry exothermic reaction. This reaction involves liquid water as a reactant and further complicates the picture as far as high-temperature testing is concerned. Simultaneous evaporation, diffusion, condensation, and reaction involving water have been modeled recently in connection with bagasse [22, 23], using an experimentally measured rate law for the wet reaction [24] giving results that are in good agreement with measured results for commercial-size piles of this material (minimum dimension 5–10 m).

The detailed nature of the wet reaction with a rate maximum around the 50–60 °C mark has led to false identification with microbial activity. In bagasse at least it has been shown [25] that microbial activity does not contribute to self-heating to any significant degree. Piles sterilized by various methods showed self-heating rates indistinguishable from those of nonsterile piles. Microbial counts were carried out in all cases and large decreases did not affect the self-heating rates. It would be rather surprising if similar results were not obtained from tests on hay and straw where microbiological activity (but not necessarily heating) are known to occur, and it is surprising that such tests have not yet been carried out.

Parallel Reactions

If more than one exothermic reaction can take place in the material, and these reactions have rather different activation energies, then each will dominate in its own temperature range. Thus the higher activation energy reaction will cut in at higher temperatures and be insignificant at lower temperatures when the low activation energy reaction will dominate the heat generation. The wider the divergence in activation energies, the sharper the discontinuity in slope, that is, the narrower the temperature range over which both will contribute. Hydrated calcium hypochlorite shows a clear example of this, and it is reflected in a sharp break in the slope of the Frank-Kamenetskii plot where the changeover occurs. Figure 20.8 shows this plot. The low temperature activation energy for this system is about 48 kJ/mol while that of the higher temperature reaction is around 125 kJ/mol, the transition temperature being around 120 °C [17]. Extrapolation of the high temperature line in this case gives CATs for large commercial-size containers that are seriously in error; that is, they are predicted to be much higher than they actually are. In the general case of two reactions with different activation energies, this will always be the case as the high activation energy reaction is “frozen out” at low temperatures, and the low activation energy reaction is “swamped” at higher temperatures.

The spontaneous decomposition of calcium hypochlorite has caused extensive container ship losses, particularly in the late nineties. Some due to hydrated calcium hypochlorite (UN 2880), defined by the International Maritime Organization [26] to contain not less than 5.5 % moisture and not more than 16 % moisture result from faulty extrapolation as can be seen from Fig. 20.8.

The discontinuity in slope of the F-K plot is undoubtedly due to the effect of moisture mediating chain reactions, the decomposition becoming extremely sensitive to trace metal concentrations.

This is confirmed by the work of Uehara et al. [19] on UN 1748 (“anhydrous”) calcium hypochlorite where the lower section of the line is missing. Thus the samples with lower moisture content (<1 %) are much less prone to thermal runaway. So are samples of UN 2880 tested in gauze baskets which allow rapid evaporation of moisture during the tests themselves, behaving in a very similar manner to Fig. 20.7.

Unfortunately the IMO has been inactive in defining moisture content limits for UN 1748 and some manufacturers have taken anything up to 5.5 % to be admissible resulting in large variations in the thermal stability of this product.

On the other hand the P and I (Protection and Indemnity) clubs have taken a proactive stance and largely refused to insure such cargoes unless they are shipped in refrigerated containers(reefers). The resultant increase in cost is probably leading to failure to declare some cargoes of this material as dangerous goods.

Also strategies have yet to be worked out to minimize the possibility of thermal runaway in the event of a power failure on board ship. The heat transfer coefficients of reefers are a fraction of those for normal containers, reducing the effective CATs of reefers without power to very low figures indeed. An obvious emergency strategy would be to open the doors of reefers in such a situation, but this would put serious restrictions on stowage possibilities.

Other examples of mechanism change are known and discussed by Bowes [4]. In such cases accurate predictions of CATs can still be made within each temperature range. This type of example emphasizes the need for tests covering as wide a range of temperatures as possible. Recent methods put forward as viable alternatives to the standard method, for example, Jones [27] and Chen [28], are restricted to either measurement at a single temperature or over a limited temperature range and can give dangerously flawed results. Empirical tests such as the Mackey test [29] and the crossover test [30] are not reliable and cannot be properly related to the basic principles of spontaneous ignition theory.

Finite Biot Number

The Biot number is defined as

where

-

χ = Surface heat transfer coefficient

-

r = Smallest physical dimension of the body

-

κ = Thermal conductivity of the material

It is the dimensionless measure of the ratio of the resistance to heat transfer within the body to that from the surface to the surroundings. Thus the Semenov theory is often referred to as zero Biot number and the Frank-Kamenetskii theory as infinite Biot number. They are both special cases of a more general (and more exact) formulation, as was originally pointed out by Thomas [31, 32].

In general the boundary condition at the edge of a self-heating body has the form of a continuity condition, which refers to the energy flux across the boundary. It states that the energy flux within the body (given by Fourier’s law) and the energy flux from the body surface to the surrounding air must be equal, that is,

In dimensionless form this becomes

This boundary condition does not hold if there exist any heat sources on the boundary of the body itself, as can occur when there is incidence of radiation or when there is heat generated by friction as can occur in pulverization of materials capable of self-heating. Such cases (in the shape of an infinite cylinder) have been treated and the modified critical condition obtained [33, 34]. Similarly modified boundary conditions must be used when surface reactions occur due to catalysis by surface material.

The values of the critical parameter δ quoted for the Frank-Kamenetskii theory are all for the limiting case \( Bi\to \infty \), and both Thomas and Barzykin have given semiempirical functions exhibiting the dependence of δcritical on Bi, which are detailed in the book by Bowes. As the Biot number decreases so does δcritical and hence so does the CAT, all compared with the standard Frank-Kamenetskii theory. For Biot numbers greater than 30, the correction is rather small but is significant for smaller values. Typical heat transfer coefficients from smooth solid surfaces to rapidly stirred air (in a test oven, for example) are of the order of 20 W/m2K, and thermal conductivities of typical cellulosic materials (such as sawdust) are around 0.05 W/mK, giving a ratio of 400/m. Clearly for laboratory-size test bodies (r ∼ 0.1 m), the Biot number is rather large.

For this reason a significant amount of work has simply assumed a sufficiently large Biot number without investigation of its actual numerical value. Sometimes the assumption is not justified, particularly where inorganic materials are involved, as their thermal conductivities can be quite large. For example, typical inorganic salt thermal conductivities lie in the range 0.2–3.0 W/m⋅K, giving for the ratio (χ/κ) a value of 7–100/m. Clearly for test bodies with r ∼ 0.1 m, the Biot number will be only 0.7–10. The effect of the small Biot number on δcritical is to reduce it by a factor ranging from 0.21 to 0.83, respectively. Clearly for such materials, the more general boundary condition suggested by Thomas must be used, and it is good practice for all but the most strongly insulating materials to estimate the thermal conductivity (particularly in the presence of water) independently of the standard testing regime.

A further important feature of self-heating bodies with a finite Biot number is that their CATs will be sensitive to the heat transfer coefficient from their surface to the surrounding air. Thus the value of the CAT obtained may well be test-oven sensitive and be strongly influenced by air movement. For example, it has been shown for hydrated calcium hypochlorite [18] that in stirred air in a typical test oven the CAT is 60 °C for a 0.175-m-radius container, but in still air the CAT is 55 °C.

This observation raises serious questions about the value of empirical testing methods such as the SADT test for shipping of self-heating materials [35] that determines criticality-related parameters under vaguely defined conditions of forced airflow in a test oven. The results are then used to determine “safe” conditions for shipping such materials in still air inside, for example, a shipping container. Almost invariably many self-heating bodies are stacked inside the same still air inside a container, and they will interact with each other to a very significant extent if the transfer of heat through the container wall is not very rapid. In practice such transfer is rather slow, involving two successive air-metal transfers. As a result the self-heating bodies collectively heat the air inside the container and produce a “cooperative CAT,” which can be tens of degrees lower than the CAT of a single body. The Semenov-type theory for this collective ignition has been formulated by Gray [36]. A more accurate version, where the individual bodies are assumed to obey the general boundary condition put forward by Thomas, has also been formulated. The predictions of this theory have been compared to the experimental CAT for eighteen 14 kg equicylinders packed in a rectangular steel box with good agreement [37]. The CAT was reduced from 62.5 °C for a single keg in still air to 54 °C for 18 kegs in still air.

Times to Ignition (Induction Periods)

The terms time to ignition and induction periods tend to be used synonymously. Here we will abbreviate using TTI. This represents the most difficult area of spontaneous combustion insofar as prediction is concerned. There are three principal reasons for this:

-

1.

The theoretical treatment is much more difficult than that of criticality itself.

-

2.

The actual definition has been greatly confused from case to case.

-

3.

The TTI, however defined, can be extremely sensitive to quantities that have hardly any effect on the position of the critical condition.

Theoretical Treatment

We refer the reader to Bowes [4] and Babrauskas [5] for discussion of earlier treatments. For illustrative purposes we will initially follow Bowes and define TTI from Equation 20.5 by integration from ambient temperature to some value u 1, say

This is, of course, in dimensionless form. Our present interest is the implicit use of u a as the lower limit; that is, it is the time for the sample to go from ambient temperature to some predetermined arbitrary figure, possibly the maximum temperature attained (it turns out that the integral is not sensitive to this limit, provided it is sufficiently high).

Although the maximum temperature attained is a meaningful figure for laboratory tests under some circumstances, it does not always correspond to practical large-scale circumstances. For example, it requires recording the time taken for the center of the sample to heat up in a test oven to ambient temperature and using this as the reference time for TTI. Unfortunately, when the center has reached this point, other parts of the body have often attained rather higher temperatures [38], and the subsequent TTI will be reduced compared to a large-scale body that may well have been built at ambient temperature and be quite uniform initially. Extrapolations of such laboratory tests will not then be reliable since the initial condition will not be appropriate.

The TTI for the hot stacking problem is qualitatively different from that in which the body is formed uniformly at ambient temperature. Generally this time is much shorter than the TTI for the more common case of initially ambient temperature throughout the body. The reasons have been given, with a comparison of the two cases, by Gray and Merkin [39]. Similar considerations apply when part of the body is at a high temperature (hot spot), and this case has been discussed in detail by Thomas [40].

With the ready availability of powerful and fast numerical techniques, it is now feasible to integrate routinely the time-dependent heat conduction equation for this problem, which is probably the best solution. Zinn and Mader [41] were early participants in this effort, and more recently Gray, Little, and Wake [38] have noted that such numerical results can be usefully used to predict a very good lower bound to the TTI. These results are desirable as they err on the side of safety.

Very close to criticality, perturbation treatments have been formulated [42–46], but these are mainly of theoretical interest. At the critical condition the TTI becomes infinite, and close to this condition it is extremely sensitive to the degree of criticality, so unless this is known accurately (hardly ever the case), use of such formulas is not advised.

Other, Largely Chemically Kinetic, Difficulties

In addition to the difficulties discussed above, which apply even when only a single simple reaction is assumed, there are others that are largely chemically kinetic. It has long been known that chain reactions, whether branching or not, can exhibit very long induction periods followed by very rapid onset of (sometimes nonexplosive) reaction. Many exothermic spontaneous ignition reactions do possess some chain characteristics even though these do not manifest themselves once the reaction is well underway. Thus it is feasible for complex chain mechanisms to determine the details of the TTI but not be at all important in determining the critical condition where gross heat balance considerations are crucial. In many cases this leads to extremely irreproducible TTIs without similar variation of CATs or other properties. In case this list of difficulties leads to an overly pessimistic view of the topic of TTI, there are some things that can generally be relied on as far as the practical situation of fire investigation is concerned.

Very crudely speaking, notwithstanding the above discussion, the larger the body, the longer the TTI will usually be. Thus a fire thought to have been caused by spontaneous ignition of a pile of linseed oil–contaminated rags contained in a wastepaper basket will usually appear within a few hours of the rags being placed there. On the other hand, a fire resulting from spontaneous ignition of thousands of metric tons of woodchips would occur only after some months of assembly, assuming the pile was assembled at ambient temperature. For such bodies it is generally true that the TTI increases with size in this manner. Accordingly haystacks tend to ignite (if they are supercritical) after a few weeks and coal stockpiles after a few months. However, the TTI can decrease dramatically if the body is very far beyond the CAT.

For hot stacked bodies, on the other hand, times are generally much shorter and not particularly sensitive to the ambient temperature. Thus stacks of freshly manufactured chipboard with a volume of a few cubic meters can ignite much more quickly—that is, hours rather than days—than a similarly sized body self-heating from ambient. Beyond these general comments one has to treat each separate case on its merits with a careful eye for exceptions to any general rules. For example, the presence of any catalytic material, such as rusty metal (a common contaminant of many materials), can dramatically decrease the TTI. This indicates the presence of free-radical or chain reactions and is fairly common, although the CATs and CSTs are only slightly affected.

In summary, in fire cause investigation, where spontaneous ignition is suspected, it is wise to be very circumspect about time factors without very thorough investigation and detailed knowledge of the initial conditions likely to have existed when the body was put in place. Even the traditional linseed-oil rag example can be thrown out of the normal pattern by the presence of mineral turpentine, a very common diluent for oil-based stains. The evaporation of this from the rags can greatly prolong the TTI by virtue of the consequent cooling effect and also the exclusion of air by the vapor. Depending on the circumstances, these factors could add 2 or 3 days to a TTI that would normally be no more than a few hours.

Investigation of Cause of Possible Spontaneous Ignition Fires

From the investigative point of view, it is helpful to list the practical factors that enhance the possibility of spontaneous ignition as a possible fire cause.

The Size of the Body of Material

The larger the size of the body of material, the greater the likelihood of spontaneous ignition. By size of the body we mean the parts that are in thermal contact. A large pile of cotton bales with aisles through it would not necessarily be a large body in the thermal sense used here. This classification would be true even if (as often happens), once ignited, fire could spread easily from one section to the next.

High Ambient Temperatures

Because the air around the body in question has to act as a heat sink, the higher the ambient temperature, the more inefficient is the air as a coolant. Also direct placement underneath a metal roof or adjacent to a northwest- (southern hemisphere) or southeast- (northern hemisphere) facing wall is a positive factor.

Thermal Insulation

Sometimes spontaneously ignitable materials are stored in chemical warehouses or elsewhere packed against inert solids that prevent free airflow over the surface, thus reducing heat losses. This effect is evidenced by the appearance of maximum charring or self-heating that is off center and closer to the insulated side of the body. It also results in a reduced CAT.

Fibrous Nature and Porosity of Material

Fibrous or porous materials allow greater access of air than otherwise (solid wood is not subject to spontaneous ignition at normal ambient temperatures, but woodchips and sawdust certainly are!). The concept that packing such porous materials by compression will increase the CAT by oxygen exclusion is badly flawed. This procedure increases the density (thus lowering the CAT) and has virtually no effect on the availability of oxygen. During the preflame development, the oxygen requirement is very low; by the time overt flame is observed, there are usually broad channels of destroyed material (chimneys) that will allow ready access.

Pure cotton in a test oven with a nitrogen atmosphere has been shown to undergo spontaneous ignition but with a longer induction period than in the presence of air [47]. This could be due to adsorbed oxygen on the cellulose fibers or due to exothermic decomposition of the cellulose in the absence of air [48].

Otherwise “harmless” materials (i.e., liquids with very high flashpoints) can undergo spontaneous ignition at temperatures more than a hundred degrees below either their flashpoints or their so-called autoignition temperatures. The familiar drying oils (flashpoints around 230 °C) spread on cotton afford such an example, igniting sometimes at room temperature under the appropriate conditions. In bulk such oils pose little threat of fire causation.

Similarly, hydraulic fluids, specifically designed for nonflammability and with extremely high flashpoints, can undergo spontaneous ignition if allowed to leak onto thermal lagging, such as mineral wool, fiberglass, and so forth, which are characterized by having particularly high surface areas. Practical cases of this and experimental tests have been reported by Britton [49], with particular reference to ethylene oxide fires. More recently a modeling project has been carried out [50, 51] based on adaptation of the Semenov theory of ignition to a porous solid that was wetted with combustible liquid.

Temperature of Stacking

The factor of temperature of stacking is simple—the hotter the worse! The main question is, How hot? The CST (critical stacking temperature) is only weakly dependent on the ambient temperature at low ambient temperatures, but it is sensitive to the size of the hot body. This situation arises with freshly manufactured products such as foodstuffs (milk powder, flour, instant noodles, fried batter, etc.), synthetic materials such as chipboard, cotton bales straight from the ginning process, bagasse straight from the sugar mill, fresh laundry (usually in commercial quantities), and so on.

To evaluate the CST requires full testing to obtain the parameters for the material (such as E, Q, κ, etc.) and then application of one of the methods in the literature for its calculation. Thomas [40] has given a method for hot spots of material, and Gray and Scott [52] have given a generalization of this, removing the approximation to the Arrhenius function made by Thomas. A simpler method of calculation of the CST has been given by Gray and Wake [53]. It uses a spatially averaged temperature in the Arrhenius function and then obtains exact results for this simplified problem.

Length of Time Undisturbed

Material that has been in place for longer than usual is reason to suspect spontaneous ignition as a fire cause. Many industrial procedures involve the temporary storage of materials that are normally above their CAT but that are not left undisturbed for a period longer than or equal to their TTI. Thus under normal circumstances fire does not occur even though the TTI is regularly exceeded. If processes are slowed down for some reason, or storage is prolonged due to vacation, fire can occur even though no other parameters have been changed.

The Aftermath