Abstract

Brown coal-based materials are excellent adsorbents for reducing chromium(VI) to chromium(III) and afterward immobilizing these chromium(III) by the binding of oxygenic functional groups in adsorbents. In the study, the approach of pyrolysis is employed for the treatment of Cr-loaded solid waste. The effects of adsorbed chromium on the pyrolysis of Xilingol brown coal were studied, and the solid char residues were collected to characterize with XPS, XRD and SEM/EDX. For the pyrolysis in Ar, the mass loss rates of Cr-loaded samples were much higher than that of unloaded samples above 750 °C, together with the increase in CO and H2 emission. XPS spectra revealed that the increase in CO could be related to formation of [Cr–O–C]. For the pyrolysis in CO2, the presence of chromium was more favorable for the conversion of char, especially demineralized brown coal and kerogen. The maximum decomposition temperatures for the Cr-loaded samples were about 200 °C lower than that of unloaded samples. The char residue yields of Cr-loaded samples were obviously higher than that of corresponding unloaded samples (at 1200 °C). Finally, the chromium in the solid residue was recovered in the form of Cr2O3. The present study exploits an approach method for both brown coal waste treatment and chromium recovery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chromium(VI), a commonly identified contaminant in soils and ground water, is a well-known threat to human health. Researchers have studied the remediation of chromium(VI), and now various adsorption materials, such as waste biomass and humic acids, have been developed [1–4]. Recently, we found that the brown coal and its kerogen (obtained from brown coal by demineralization and extraction step) show an excellent ability to adsorb chromium(VI) under acidic condition, and most of the adsorbed chromium(VI) was reduced to less toxic chromium(III) [5]. Then, through further study to the above results, we concluded that reduced chromium(III) was bonded to oxygenic functional groups in brown coal-based adsorbent and it was difficult to desorb [6]. These results mean that the process performed by brown coal-based adsorbent not only detoxifies chromium(VI) to chromium(III), but chromium(III) is not also exposed to environment in the same adsorption condition. Therefore, the use of brown coal-based adsorbent could be promising for the chromium-contaminated wastewater treatment [7–9]. However, the further step associated with this process is how to deal with the large amounts of used Cr-loaded solid wastes. Unfortunately, this problem has received less attention, and no efficient action has been taken to deal with these industrial wastes after chromium(VI) adsorption [10–12]. Therefore, this research focuses on the treatment of the Cr-loaded solid waste together with chromium recovery.

Considering that brown coal is natural as fuel, the approach of pyrolysis is potential and hopeful way to treat the Cr-loaded solid waste [13–15]. It has been revealed that the inherent minerals (such as K, Ca and Na) of brown coal showed catalytic effects on its thermal properties [16–21]. In the Cr-loaded solid waste, there is a lot of chromium and it is interesting to know how the chromium will affect the thermal behavior of brown coal. However, reports about the effect of the chromium on the thermal behavior of the brown coal are still rare, and there is only little knowledge about the influence of chromium on the thermal properties of Cr-loaded brown coal. Therefore, it is interesting to reveal the influence of chromium on reaction mechanism and product distribution during the thermal treat of brown coal. This research could be useful for the potential utilization of Cr-loaded solid wastes by pyrolysis. And high-efficiency utilization could decrease the air pollutant emissions as well as provide fuels and recover chromium [22, 23].

In this paper, systematic studies about the raw brown coal samples, demineralized samples and the corresponding kerogen samples before and after chromium adsorption were performed in different atmosphere by the thermogravimetric analysis coupled with the online mass spectrometer (TG-MS). The solid char residues were characterized by X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD) and scanning electron microscopy with energy-dispersive spectroscopy (SEM/EDX). By examining the mass loss, gas components, the valence state and amount of chromium in char during the pyrolysis, essential information could be obtained for the utilization of the solid wastes from the chromium-contaminated water treatment and the recovery of chromium.

Experimental

Pretreatment and preparation of brown coal samples

Raw brown coal materials

The brown coal (denoted as XR) is collected from Xilingol, located in the middle of the Inner Mongolia Autonomous Region, China. The sample was ground to small particles with diameter <74 µm and then dried at 80 °C under vacuum for 24 h. XR was demineralized as follows: The mixture of 20 g XR in 135 mL 5 mol L−1 HCl aqueous solution was stirred for 1 h at 50–60 °C, and then, it was kept at ambient condition overnight. After filtering, 135 mL 40 % HF aqueous solution was added and the obtained slurry was stirred for 1 h before filtered again. The HF-removed solid residue was treated with 50 mL 37 % HCl aqueous solution again as above mentioned. The obtained sample was washed with hot deionized water until no chloride ion was detected and then dried at 80 °C under vacuum for 24 h to get the demineralized brown coal, which is designated as XD.

XD was further extracted with CHCl3 under reflux for 48 h, and the remained solid residue was kerogen and designated as XK (desiccation at 80 °C under vacuum for 24 h prior to use). The proximate and ultimate analysis results of XR, XD and XK are listed in Table 1. The ultimate analysis was carried out on the elemental analyzer (vario EL CUBE, Germany) in which C, H, N and S were determined by thermal conductivity detector and O was determined by IR detector separately. The proximate analysis was conducted according to the China national standard, proximate analysis of coal (GB/T212-2008).

Cr-loaded brown coal-based materials

Cr-loaded brown coal-based materials were collected from our previous wastewater treatment adsorption experiments [5]. Briefly, 5.0 g brown coal samples (including XR, XD and XK) were mixed with 250 mL 2600 mg L−1 chromium(VI) (K2Cr2O7) aqueous solution (the solution pH was adjusted to 1.0 using 0.1 M HCl) in a 500-mL flask and stirred at 40 °C for 48 h. The reaction mixture was filtered, and the filter cake was washed with distilled water until neutral pH and was dried at 80 °C under vacuum for 24 h. Chromium adsorbed brown coal, demineralized brown coal and kerogen were identified as XR-Cr, XD-Cr, XK-Cr, respectively.

The concentration of Cr in the filtrate was measured by ICP-OES (Thermo iCAP 6300). The concentration of Cr in the Cr-loaded samples was about 118.6 mg g−1 (mass%, 10.6) calculated by the difference between the initial total Cr in aqueous solution and Cr in the filtrate after adsorption experiments.

Preparation of char residues for XPS and SEM measurement

The XK-Cr samples were then heated at 400, 600 and 800 °C following the TG-MS temperature procedure, and then, samples were kept at this constant temperature for an additional 30 min. The char residues originated from XK-Cr treated at 400, 600 and 800 °C were denoted as XK-Cr-400, XK-Cr-600 and XK-Cr-800, respectively.

TG-MS experiments

Pyrolysis of the investigated samples in Ar and CO2 atmosphere was studied with the SETSYS Evolution thermogravimetric analyzer (TG, SETARAM, France) coupled with an online mass spectrometer (OMNI star/quadrupole mass analyzer; Pfeiffer Vacuum). Approximately 15 mg sample was loaded into the ceramic crucible and heated from room temperature to 1000 °C (in Ar) or 1200 °C (in CO2) at a constant heating rate of 10 °C min−1 and a flow rate of 60 mL min−1. The signals selected and identified corresponded to the mass spectra of 2, 16, 28 and 44 U, which were attributed to the main released components of gas H2, CH4, CO and CO2.

XPS, XRD and SEM/EDX analyses

The XK-Cr-400, XK-Cr-600 and XK-Cr-800 were analyzed by AXIS ULTRA DLD XPS. The X-ray excitation was provided by monochromatic Al Kα (1486.6 eV). Survey scans were obtained using pass energy of 100 eV, while high-resolution scans of specific elements were obtained using 20 eV pass energy. The detection of the emitted photoelectrons was performed perpendicular to the surface sample.

X-ray diffraction (XRD) analysis was carried out on D8 ADRANCE A25 (Germany) with Cu Kα radiation (λ = 1.5418 Å). The scans were performed with the 2θ range 10°–80° at a scanning speed of 1° min−1 and a step size of 0.02°.

A JEOL JSM-840A SEM/EDX was employed to observe the surface morphology and identify the elemental distribution at specific locations on the char surface.

Chromium recovery experiments

Cr-loaded samples were put in a horizontal quartz reactor with flowing CO2 (60 mL min−1), and the temperature was raised at the rate of 10 °C min−1 from room temperature to the given temperature (650, 750 and 850 °C). After 30, 90 or 150 min, samples within the reactor were cooled down to room temperature with continuous CO2 flowing and the solid residues were then collected for further analysis and weighed.

Results and discussion

TG-MS analysis

Pyrolysis in Ar

Thermogravimetric analysis (TG) is the main approach to study the pyrolysis [24, 25] since a multiplicity of physical process and chemical reactions could happen and followed during the process [26, 27]. To disclose the effect of adsorbed chromium on the thermal properties of this natural adsorbent, the pyrolysis of all six samples was investigated and the TG as well as the derivative thermogravimetry (DTG) curves is shown in Fig. 1. In order to compare with the mass loss between unloaded samples and Cr-loaded samples under the same basis, we have added 10.6 % to the total mass loss for all Cr-loaded samples, and the processed data are listed in Table 2. As shown in Fig. 1a, the mass loss of Cr-adsorbed samples was remarkably higher than the unloaded samples. Taking the char yield at 1000 °C for example, the total mass loss was 50.22 % at 1000 °C for XR-Cr, whereas the corresponding mass loss for XR was 33.24 % (Table 2).

Figure 1b shows the DTG curves for XR, XD, XK and their Cr-loaded samples including XR-Cr, XD-Cr and XK-Cr. Below 750 °C, DTG curves of all six studied samples were characterized by two separately peaks. The first peaks at about 90–110 °C corresponded to the removal of moisture and adsorbed gas from samples. As the temperature increased to around 200 °C, the volatiles were evaporated completely from the brown coal matrix. The second peak between 420 and 440 °C was originated from the devolatilization and decomposition of the organic matrix in brown coal [28–30]. At about 430 °C, the maximum mass loss rates of demineralized brown coal samples (XD and XD-Cr) and the corresponding kerogen samples (XK and XK-Cr) were similar, but both of them were much higher than that of XR and XR-Cr. Taken into account that the demineralized brown coal samples and the corresponding kerogen samples have low mineral content, the demineralization process could enhance the reactivity of brown coal samples during the pyrolysis. Similar results had also been reported by Bai et al. [31] who found that the total phenol yields of demineralized samples were higher than that of raw samples during coal pyrolysis. Moreover, there was an additional mass loss stage for all these Cr-loaded samples at about 850 °C according to Fig. 1b, which could be attributed to a catalytic effect of chromium for the pyrolysis of these brown coal samples.

Gas yields and composition of pyrolysis in Ar

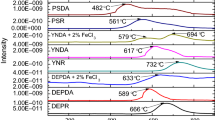

According to online mass data in Fig. 2, the main gas components released during pyrolysis of brown coal samples were H2, CH4, CO and CO2.

From Fig. 2a, it can be seen that H2 started being evolved when the temperature increased to 400 °C. Compared with unloaded samples, Cr-adsorbed samples can release H2 at a lower temperature with higher yield. For example, the temperature for releasing H2 started at about 400 °C for XK-Cr which was 100 °C lower than that of XK. The results suggested that chromium could promote H2 releasing from the brown coal during pyrolysis.

As shown in Fig. 2b, CH4 was produced from the beginning and reached the maximum amount at a lower temperature for Cr-loaded samples than it for unloaded samples (i.e., around 460 °C for XK-Cr and 560 °C for XK), which indicates that the chromium species decrease the release temperature of CH4 due to the catalytic effect. Meanwhile, it can be also observed that the Cr-loaded samples and XR sample produced less CH4 compared to demineralized samples (XD and XK), which can be concluded that chromium species and inherent ions in XR reduce the yield of CH4.

Figure 2c, d shows the evolution curves of CO and CO2, respectively. CO release for Cr-adsorbed samples was shifted toward the high-temperature zone (Fig. 2c). XD-Cr and XK-Cr produce a similar amount of CO, which was lower than the values of raw samples (XD and XK) until 750 °C, and then, the CO yield of XD-Cr and XK-Cr increased in the high-temperature zone (from 760 to 950 °C). Moreover, the CO2 yield for Cr-adsorbed samples was lower than that for the unloaded samples in the high-temperature range (Fig. 2d). Combining the additional mass loss peak in the DTG curves of XR-Cr, XD-Cr and XK-Cr about 850 °C (Fig. 1b), we believe that chromium catalyzes the reaction between CO2 and carbon (provided by the char residues) to form CO.

Based on the data mentioned above, it can be concluded that the mass loss of Cr-loaded samples was remarkably higher than the unloaded samples, and Cr-loaded samples can produce more H2 and CO but less CH4 and CO2 which were transformed to CO during pyrolysis because of the chromium catalytic effect. However, considering that Ar is the inert atmosphere, it is also intriguing to explore the effect of chromium on the pyrolysis behavior of investigated sample in reducing atmosphere, i.e., CO2.

Pyrolysis in CO2

Figure 3 shows the TG and DTG curves of investigated samples in CO2 atmosphere, and the characteristic data of pyrolysis are summarized in Table 3. From TG and DTG profiles (Fig. 3a, b), it could be observed that three noticeable stages appeared in sequence. The first stage (stage 1, 80–200 °C) was attributed to the evaporation of physical adsorbed moisture and volatiles. The second mass loss stage (stage 2, 200–600 °C) was related to the emission of volatiles from decomposition reaction, which agreed with the trends obtained during the pyrolysis tests in Ar. Compared with pyrolysis in Ar, the additional mass loss in stage 3 (600–1200 °C) showed up because of the Boudouard reaction (C + CO2 = 2CO) [32]. The mass loss in CO2 was remarkably higher than that in Ar since the reaction of C with CO2 was more complete. Moreover, the maximum decomposition temperature in stage 3 was 1076.3 °C for XK, while it was 870.2 °C for XK-Cr, and the temperature for complete pyrolysis of XK-Cr (1000 °C) was lower compared to the result of XK (1100 °C). These results suggested that the Cr-loaded samples had higher thermal reactivity than that of unloaded samples. Therefore, the presence of chromium was favorable for the conversion of char during pyrolysis in CO2.

Gas yields and composition of pyrolysis in CO2

The evolution profiles of the gaseous species, including H2 and CH4 during pyrolysis in CO2, are shown in Fig. 4. It can be seen that the content of H2 first increased and then decreased (Fig. 4a). The increase could be due to the decomposition of brown coal (below 400 °C for Cr-loaded samples and below 600 °C for unloaded samples), while the decrease stage may due to the reaction of hydrogen with carbon dioxide. The start temperature of the second stage (the content of hydrogen emission decrease) for Cr-loaded samples was much lower than that of the unloaded samples due to the catalytic effect of chromium.

In Fig. 4b, CH4 emission stage of unloaded samples (XR, XD and XK) located between 400 and 700 °C with maximum peak at about 500 °C. But for the Cr-loaded samples (XR-Cr, XD-Cr and XK-Cr), no strong peaks could be observed in this temperature range, which is probably because the loaded chromium inhibits the break of aliphatic side chains to evolve into CH4, and more aromatic and aliphatic carbons react with CO2 to form CO in CO2 atmosphere.

Characterization of solid residues

To understand and characterize the process of pyrolysis in more detail, the solid residues of Cr-loaded kerogen collected at 400, 600 and 800 °C during pyrolysis were characterized by XPS, XRD and SEM/EDX.

Change in the valence state of chromium

XPS could disclose the surface element and chemical valence state information of the investigated samples [33, 34]. In this study, the XPS Cr (2p) spectra for solid char residues of XK-Cr obtained at 400, 600 and 800 °C were measured, and the spectra are presented in Fig. 5. In our previous work, we reported that the chemical valence state of chromium was mainly chromium(III) in the Cr-loaded solid brown coal waste [5]. According to the Cr (2p) spectra, chemical valence state of chromium was remained to chromium(III) in solid char residues of XK-Cr obtained at 400, 600, 800 °C. That is to say, in the present pyrolysis conditions, the valence of chromium is stable, and it was not reduced to chromium(0) or oxidized to toxic chromium(VI) [35, 36]. Moreover, according to the intensity of these peaks, the content of chromium(III) in the different samples increased with the increase in sample collection temperature, presumably due to losses of the organic component, such as hydrogen, carbon and oxygen, in XK.

Figure 6a shows the XPS O (1s) spectra and corresponding deconvolution peaks for the char residues of the XK-Cr obtained in Ar atmosphere. The assignments of their peaks are illustrated in Fig. 6b. O (1s) region in the spectra could be fitted with three components. Namely, O (1s) with a binding energy of 533.7 eV can be assigned to the [C(O)–O], and O (1s) value of 532.3 eV was characteristic for the [C–O]. O (1s) with a binding energy of 530.8 eV can unambiguously be attributable to chromium oxide [37]. It can be seen from Fig. 6b that the O (1s) spectrum in the “XK-Cr-800” was predominantly chromium oxide, such as the form of [Cr–O], while the “XK-Cr-400” mainly contained the oxygen of [C(O)–O] and [C–O]. These results disclosed that the temperature showed a significant influence on the oxygen species of the char residues. With the increase in collect temperature from 400 to 800 °C, the main oxygen components in the char residues switched from the organic [C(O)–O] and [C–O] to the inorganic [Cr–O]. The increase in CO might be attributed to large amounts of [Cr–O–C] above 750 °C. These XPS spectra were in agreement with the above pyrolysis results. The organic part of the samples diminished gradually, while the inorganic part was still remained in the solid char residues where it was main Cr2O3 (Fig. 7).

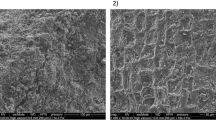

SEM/EDX analysis

SEM coupled with EDX could provide the surface morphology and element distribution of the investigated samples. The kerogen char residue of pyrolysis collected at 800 °C (XK-Cr-800) was selected and examined, and the obtained SEM images and EDX map are shown in Fig. 8. Small dark fragments were observed as the dominant morphology in the SEM image, which were mainly corresponding to the remained organic char matrix of XK-Cr residue. Interestingly, there were also bright spots (as shown in Fig. 8a, b) distributed uniformly on the char matrix fragments. As the natural mineral species of raw brown coal (such as Na, K or Si) have been removed in the demineralization step, these light spots corresponded to the adsorbed chromium (present as chromium oxide) which was concentrated and exposed to the surface of the char residue due to the shrink caused by the diminish of the organic part.

Proposal for chromium recovery

As described before, chromium showed the catalytic effect during pyrolysis of brown coal samples. Especially in CO2, only a small quantity of organic char residue was left; therefore, it is possible for complete recovery of the total amount of chromium, as chromium(III) purely.

XK-Cr samples were chosen for chromium recovery tests in CO2 atmosphere, and the results are listed in Table 4. After reaction at the lower temperature of 650 °C for 30 min, the mass fraction of Cr2O3 was only 29.1 %. When the reaction time increased to 150 min, the mass fraction of Cr2O3 increased to 42.4 %. However, it significantly increased to 63.7 % by raising the reaction temperature to 750 °C for 150 min, indicating that high temperature can enhance the conversion of char and hence increase the concentration of Cr2O3. Further, when the recovery experiment of chromium was carried out at 850 °C for 150 min, the maximum mass fraction of Cr2O3 climbed to 94.8 %, which means that almost all of the organic part in XK-Cr has decomposed and the residual 9.0 mg is nearly all the Cr2O3. The above results indicate that the chromium in Cr-loaded solid waste can be completely recovered.

Conclusions

This work was conducted to reveal the effect of adsorbed chromium on the pyrolysis behavior of brown coal-based adsorbents, and the obtained knowledge would further provide guidance for the treatment of the Cr-loaded solid waste together with chromium recovery. Our experimental results disclosed that adsorbed chromium shows an obviously catalytic activity for the pyrolysis of brown coal in both Ar and CO2 atmosphere and significantly promotes the reaction of CO2 with C to form CO. In the process of pyrolysis, the valence of chromium is stable and remains chromium(III), and finally the chromium in the solid residue was recovered in the form of Cr2O3 in CO2. The present study exploits a promising method for both brown coal waste treatment and chromium recovery, and it will pave the way for the application of this readily available brown coal adsorbent.

References

Garg UK, Kaur MP, Garg VK, Sud D. Removal of hexavalent chromium from aqueous solution by agricultural waste biomass. J Hazard Mater. 2007;140(1–2):60–8.

Gode F, Atalay ED, Pehlivan E. Removal of Cr(VI) from aqueous solutions using modified red pine sawdust. J Hazard Mater. 2008;152(3):1201–7.

Arslan G, Edebali S, Pehlivan E. Physical and chemical factors affecting the adsorption of Cr(VI) via humic acids extracted from brown coals. Desalination. 2010;255(1–3):117–23.

Prado AGS, Moura AO, Andrade RDA, Pescara IC, Ferreira VS, Faria EA, et al. Application of Brazilian sawdust samples for chromium removal from tannery wastewater. J Therm Anal Calorim. 2009;99(2):681–7.

Zhao T, Ge W, Nie Y, Wang Y, Zeng F, Qiao Y. Highly efficient detoxification of Cr(VI) by brown coal and kerogen: process and structure studies. Fuel Process Technol. 2016;150:71–7.

Zhao T, Ge W, Yue F, Wang Y, Pedersen C, Zeng F, Qiao Y. Mechanism study of Cr(III) immobilization in the process of Cr(VI) removal by Huolinhe lignite. Fuel Process Technol. 2016;152:375–80.

Gode F, Pehlivan E. Chromium(VI) adsorption by brown coals. Energy Sources Part A. 2006;28(5):447–57.

Arslan G, Pehlivan E. Batch removal of chromium(VI) from aqueous solution by Turkish brown coals. Bioresour Technol. 2007;98(15):2836–45.

Arslan G, Pehlivan E. Uptake of Cr3+ from aqueous solution by lignite-based humic acids. Bioresour Technol. 2008;99(16):7597–605.

Gode F, Pehlivan E. Adsorption of Cr(III) ions by Turkish brown coals. Fuel Process Technol. 2005;86(8):875–84.

Pehlivan E, Arslan G. Removal of metal ions using lignite in aqueous solution—low cost biosorbents. Fuel Process Technol. 2007;88(1):99–106.

Uçurum M. A study of removal of Pb heavy metal ions from aqueous solution using lignite and a new cheap adsorbent (lignite washing plant tailings). Fuel. 2009;88(8):1460–5.

Rouff AA. The use of TG/DSC–FT-IR to assess the effect of Cr sorption on struvite stability and composition. J Therm Anal Calorim. 2011;110(3):1217–23.

Luzon M, Corrales T. Thermal studies and chromium removal efficiency of thermoresponsive hyperbranched copolymers based on PEG-methacrylates. J Therm Anal Calorim. 2013;116(1):401–9.

Varitis S, Pavlidou E, Kavouras P, Vourlias G, Chrissafis K, Xenidis A, et al. Devitrification routes of a vitrified chromium-loaded ash. J Therm Anal Calorim. 2015;121(1):203–8.

Wang XJ, Zhu HL, Wang XM, Liu HF, Wang FC, Yu GS. Transformation and reactivity of a potassium catalyst during coal-steam catalytic pyrolysis and gasification. Energy Technol. 2014;2(7):598–603.

Liu QR, Hu HQ, Zhou Q, Zhu SW, Chen GH. Effect of inorganic matter on reactivity and kinetics of coal pyrolysis. Fuel. 2004;83(6):713–8.

Ohtsuka Y, Wu ZH, Furimsky E. Effect of alkali and alkaline earth metals on nitrogen release during temperature programmed pyrolysis of coal. Fuel. 1997;76(14–15):1361–7.

Beamish BB, Shaw KJ, Rodgers KA, Newman J. Thermogravimetric determination of the carbon dioxide reactivity of char from some New Zealand coals and its association with the inorganic geochemistry of the parent coal. Fuel Process Technol. 1998;53(3):243–53.

Quyn DM, Wu H, Li C-Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part I. Volatilisation of Na and Cl from a set of NaCl-loaded samples. Fuel. 2002;81(2):143–9.

Kabir KB, Tahmasebi A, Bhattacharya S, Yu J. Intrinsic kinetics of CO2 gasification of a Victorian coal char. J Therm Anal Calorim. 2015;123(2):1685–94.

Irfan MF, Usman MR, Kusakabe K. Coal gasification in CO2 atmosphere and its kinetics since 1948: a brief review. Energy. 2011;36(1):12–40.

Vasireddy S, Morreale B, Cugini A, Song C, Spivey JJ. Clean liquid fuels from direct coal liquefaction: chemistry, catalysis, technological status and challenges. Energy Environ Sci. 2011;4(2):311–45.

Kizgut S, Yilmaz S. Characterization and non-isothermal decomposition kinetics of some Turkish bituminous coals by thermal analysis. Fuel Process Technol. 2004;85(2–3):103–11.

Çakal GÖ, Yücel H, Gürüz AG. Physical and chemical properties of selected Turkish lignites and their pyrolysis and gasification rates determined by thermogravimetric analysis. J Anal Appl Pyrolysis. 2007;80(1):262–8.

Giroux L, Charland JP, MacPhee JA. Application of thermogravimetric Fourier transform infrared spectroscopy (TG-FTIR) to the analysis of oxygen functional groups in coal. Energy Fuels. 2006;20(5):1988–96.

Xu Y, Zhang Y, Zhang G, Guo Y, Zhang J, Li G. Pyrolysis characteristics and kinetics of two Chinese low-rank coals. J Therm Anal Calorim. 2015;122(2):975–84.

Canel E, Misirlioglu Z, Canel M, Ballice L. Temperature programmed pyrolysis and supercritical extraction of Turkish lignites. Energy Sources Part A Recovery Util Environ Eff. 2010;32(14):1261–72.

Domazetis G, James BD, Liesegang J, Raoarun M, Kuiper M, Potter ID, et al. Experimental studies and molecular modelling of catalytic steam gasification of brown coal containing iron species. Fuel. 2012;93(1):404–14.

Jayaraman K, Gokalp I. Thermogravimetric and evolved gas analyses of high ash Indian and Turkish coal pyrolysis and gasification. J Therm Anal Calorim. 2015;121(2):919–27.

Bai YH, Yan LJ, Li GL, Zhao RF, Li F. Effects of demineralization on phenols distribution and formation during coal pyrolysis. Fuel. 2014;134:368–74.

Duan L, Zhao C, Zhou W, Qu C, Chen X. Investigation on coal pyrolysis in CO2 atmosphere. Energy Fuels. 2009;23(7):3826–30.

de Godoi FC, Rodriguez-Castellon E, Guibal E, Beppu MM. An XPS study of chromate and vanadate sorption mechanism by chitosan membrane containing copper nanoparticles. Chem Eng J. 2013;234:423–9.

Murphy V, Tofail SAM, Hughes H, McLoughlin P. A novel study of hexavalent chromium detoxification by selected seaweed species using SEM-EDX and XPS analysis. Chem Eng J. 2009;148(2–3):425–33.

Lakatos J, Brown SD, Snape CE. Coals as sorbents for removal and reduction of hexavalent chromium from aqueous waste streams. Fuel. 2002;81:691–8.

Chen J, Jiao F, Zhang L, Yao H, Ninomiya Y. Use of synchrotron XANES and Cr-doped coal to further confirm the vaporization of organically bound Cr and the formation of chromium(VI) during coal oxy-fuel combustion. Environ Sci Technol. 2012;46(6):3567–73.

McCafferty E, Wightman JP. Determination of the concentration of surface hydroxyl groups on metal oxide films by a quantitative XPS method. Surf Interface Anal. 1998;26(8):549–64.

Acknowledgements

This work was the Research Project Supported by Shanxi Scholarship Council of China (2015-123). Professor Yan Qiao thanks the Chinese Academy of Sciences (2013YC002) and the Youth Innovation Promotion Association of Chinese Academy of Sciences (2011137) for financial support. We thank Professor Zongqing Bai for help with preparing manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Wenzhi Ge and Tingting Zhao have contributed equally to this work and should be considered co-first authors.

Rights and permissions

About this article

Cite this article

Ge, W., Zhao, T., Chen, S. et al. The effect of adsorbed chromium on the pyrolysis behavior of brown coal and the recovery of chromium. J Therm Anal Calorim 128, 513–522 (2017). https://doi.org/10.1007/s10973-016-5890-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5890-z