Abstract

A generalized logistic function has been proposed as a kinetic analysis method that is superior to traditional methods. In fact, the parameter τ in the generalized logistic function has an effect on the reaction profile similar to the parameter n in the extended Prout–Tompkins model for autocatalytic reactions. Furthermore, the comparisons made in some papers to traditional methods were made by using the discredited method of determining kinetic parameters from a single heating rate, so they are misleading compared to proper kinetic analysis methods that simultaneously analyze multiple thermal histories. In addition, the current implementation of the generalized logistic function of fitting each experiment individually is prone to introduce errors in the kinetic parameters. Guidance is given on how the generalized logistic function might be used for proper chemical kinetic analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The application of the S-shaped (sigmoidal or logistic) curve to describe population growth dates back nearly 180 years [1] and is a standard topic in elementary biology. The logistic curve is given by

where α is the population, t is time, k is a growth constant, and c is a constant.

Although this form is also frequently observed for chemical reactions, use of the logistic curve is not commonly treated in elementary chemistry even though it has a long history of application in chemical kinetics. Despite several earlier uses of the autocatalytic logistic reaction model, this approach is often referred to as the Prout–Tompkins model [2, 3], which in differential form is

In this case, α is the fraction reacted (growth of product) and k is the reaction rate constant.

More than a century ago, Lewis [4] used the autocatalytic logistic equation to describe the thermal decomposition of silver oxide. Austin and Rickett [5] used the logarithmic form of the logistic equation to characterize the thermal decomposition of austenite. Akulov [6] in the Russian literature and Young [7] in the English literature used an extended form of the autocatalytic equation with reaction orders to model chemical reactions:

where n is the traditional reaction order and m is a “growth” parameter than can be correlated with the growth dimensionality of the geometric JMAEK nucleation-growth model [8, 9], although the precise relationship is more complicated [10, 11] and will not be detailed here. Variations of this form have been used in many papers in the kinetics literature.

Prout and Tompkins used the linear [2] and logarithmic [12] forms of the logistic equation to describe the thermal decomposition of potassium and silver permanganate, respectively. The logarithmic form is:

The autocatalytic reaction form was also recognized early for the decomposition of organic crystals, particularly energetic materials [13], and the self-ignition of energetic materials has been successfully modeled with an extended form of the autocatalytic reaction [14]. It has also been used to model polymer decomposition [8, 15], a wide variety of solid-state reactions [16], and in equilibrium-limited form, the phase transition of polymorphs of an energetic material [17]. It also figured prominently in two recent guidance papers of the International Confederation for Thermal Analysis and Calorimetry (ICTAC) kinetics committee [18, 19]. Dozens if not hundreds of other papers using this approach could be cited.

Recently, the logistic equation has been used to analyze chemical reaction data in a manner that is best described as a step backward. Both the simple [20–22] and a generalized form [23, 24] are fitted to a single experiment, either at isothermal or at a constant rate of heating. The generalized form has an additional parameter that can make the logistic function asymmetric, but that capability is not unique. Although the generalized logistic equation is potentially interesting for some cases if properly used, fitting the curve to single experiments and then deriving Arrhenius parameters therefrom is weak compared to methods that use simultaneous nonlinear regression of multiple experiments with diverse thermal histories [25].

Although the generalized form is claimed to be a substantial advance, it actually has similar capabilities to the commonly used extended form of the Prout–Tompkins model (also sometimes called a simplified or truncated form of the Šesták–Berggren equation [10]). Unfortunately, this fact is obscured in the papers of Artiaga et al. because they make inappropriate comparisons to kinetic parameters derived by fitting models to a single heating rate experiment. This discredited approach plagued the thermal analysis field in the late twentieth century and motivated the 2000 and 2011 ICTAC committee kinetics papers [18, 19], even though the problem with using a single heating rate was recognized as early as 1976 [26].

Chemical kinetics theory

Most reactions have to go over a barrier to change from one structure to another, and E f and E r characterize the forward and reverse activation energies. A reaction can be unimolecular (one chemical breaking down) or multi-molecular. It can either absorb heat (endothermic) by forming products with weaker bonds or emit heat (exothermic) by forming products with stronger bonds. The amount of heat absorbed or emitted is the enthalpy, and difference between the forward and reverse activation energies is equal to the enthalpy, ΔE.

At any given temperature, molecules have a statistical distribution of energies, commonly a Boltzmann distribution. For most reactions, only a small fraction of the molecules have enough energy to get over the energy barrier of the reaction, and that fraction increases with temperature. Consequently, the reaction rate typically increases exponentially with an increase in temperature in a fashion first parameterized by Arrhenius in 1889 [27]. Specifically, the rate constant k increases according to the formula

where A is a frequency factor, as it has units of reciprocal time in addition to other units, depending on the kind of reaction, E is the activation energy for the reaction, R is the universal gas constant, and T is the absolute temperature. Multi-molecular gas-phase reactions typically have a power-law temperature dependence ranging from 0.5 to 1.5 in addition to the exponential dependence to account for collision frequency.

The reaction rate constant is often characterized by transition-state theory [28], which hypothesizes an activated complex at the peak of the reaction barrier. The enthalpy of formation of that activated complex is the activation energy. For unimolecular decomposition reactions, the frequency factor is related to the vibrational frequency of the bond to be broken in the active complex and is a function of Boltzmann’s constant, Planck’s constant, the absolute temperature, and the entropy of formation of the activated complex. For typical pyrolysis temperatures, the frequency factor neglecting the entropic term is a little over 1013 s−1. While some people studying complex reactions in a phenomenological or global manner refer to transition-state theory and activated complexes, such references are often ill-placed and may indicate naïveté concerning the huge simplifications involved in their work relative to fundamental reaction mechanisms. Nevertheless, transition-state theory does give qualitative guidance on what constitutes physically reasonable and unreasonable kinetic parameters.

For a simple unimolecular decomposition reaction, the activation energy is equal to the bond energy of the bond to be broken. However, such simple reactions are rarely of practical interest. Instead, reactions of interest often involve chains of reactions. For example, if a normal hydrocarbon splits into two fragments, the activation energy of that initiation reaction is equal to the strength of a carbon–carbon bond, or about 82 kcal mol−1. However, the molecular fragments are unstable and can either split an ethylene molecule off their end or start attacking their neighbors by abstracting a hydrogen atom from the middle of a neighboring chain, thereby converting a primary free radical to a more stable secondary free radical. In the latter case, the secondary free radical can decompose into an alkene and another primary free radical. These latter steps are called propagation reactions. Sometimes two free radicals combine to form a stable hydrocarbon. This is called a termination reaction and usually has zero activation energy. Since the breaking of one strong bond results through a chain reaction in breaking many bonds through the propagation reactions, which have lower activation energies, the overall activation energy for hydrocarbon cracking, depending on circumstances, is in the range of 50–60 kcal mol−1. Detailed mechanisms of polymer decomposition have been derived along with estimates of how the apparent activation energy relates to the activation energies of the elementary reactions [29, 30]. The average activation energy of polyethylene is in the 60 kcal mol−1 range as expected [25, 31].

Global kinetics, sometimes called phenomenological or engineering kinetics, do not try to deduce the detailed chemical reaction network, but they do try to pick a functional form that has the central defining feature of the reaction mechanism. In the thermal analysis community, a set of models (reproduced often as “The Table,” but not here) ranges from first-order to power-law, nucleation-growth, autocatalytic, and diffusion-limited reactions. These models have distinctively different reaction profiles. Even so, proper calibration requires data over a range of temperatures and times so that the effects of temperature and conversion are decoupled. In decades past, the analysis was often accomplished by graphical means, but digital computers enable the simultaneous analysis of all available experiments at any recorded thermal history by nonlinear regression. This analysis method is available in multiple commercial software programs. If done well, this procedure can derive models and kinetic parameters that have physical meaning and extrapolate outside the conditions of calibration.

The current paper focuses on global models that are related to the logistic equation. The simplest form is the conventional Prout–Tompkins model, which in exponential integral form is

Although c is often chosen to be zero, t is the time of maximum reaction rate (equal to half reacted for the traditional logistic equation), that means c is not truly a constant when one considers different temperatures. It makes more sense physically to choose t = 0 as the initial experimental time when the extent of reaction is arbitrarily small. Then, the parameter c relates to the initial fraction reacted by α 0 = 1/(1 + e−c), in which case

All experiments start with the same material, so it makes more physical sense to require α 0 to have the same value at all temperatures. Consequently, the time for half reaction at any given temperature is a function of α 0 and the value of k at that temperature. Equation (7) can be used to derive a rate equation as a function of time. Substituting the right-hand side of Eq. (7) into Eq. (2) gives

The basic logistic equation is often called an autocatalytic model. The full autocatalytic reaction contains the reaction sequence is

which can be described mathematically by the relation dA/dt = −k 1 A − k 2 AB. The differential equation cast in terms of fraction reacted in the thermal analysis style is

The empirical reaction orders are added for flexibility. If we assume that n 1 = n 2, then

where z = k 1/k 2 ≈ 1 − q. The z and q factors allow the reaction to have a nonzero reaction rate in the absence of an explicit initiation reaction, analogous to α 0 in Eq. (7). This is important in modern applications that numerically integrate sets of differential equations that may include processes such as heat and mass transfer in addition to chemical reactions.

Artiaga et al. [23, 24] introduce a generalized logistic function that they claim is a major advance in fitting thermal decomposition profiles. It has the form

where b is a reaction rate parameter, t is either time or temperature, and c is the midpoint of the reaction in either time or temperature for a constant heating rate. (Note that c in Eq. (1) was dimensionless.) When differentiated, this equation gives

Comparing Eqs. (11) and (12) to Eqs. (6) and (8), respectively, indicates that if t is time, c is an arbitrary shift in time, b is the negative of the conventional rate constant, and τ is a new shape parameter.

Once more, we are faced with the physical meaning of the parameter c. If t = 0 is again defined as the time for maximum reaction rate, one could set the time derivative of Eq. (12) to zero and solve for c in terms of b and τ, and it would be different for each temperature per the temperature dependence of b. One could then solve for the implicit initial fraction reacted at each temperature with the experimentally derived time, but one is then faced with the physical unreality of the initial fraction reacted being different at each temperature. Similarly, if one allows c to be an arbitrary fitting parameter, it loses its intrinsic relationship to b and τ. Instead, it makes more physical sense to require the same initial fraction reacted for each experiment independent of temperature. That is what occurs in reality. So when properly cast in terms of a kinetic equation, Eq. (11) becomes:

where the initial fraction reacted now provides the time frame of reference.

For the rate equation, one can resubstitute Eq. (11) into Eq. (12) and obtain a differential equation for the reaction rate in terms of the fraction reacted:

One can see that Eq. (14) has a similar form to the standard approximation of the autocatalytic reaction model in Eq. (10). This form, however, still has a zero reaction at time zero and would require the introduction of a parameter such as z or q for numerical integration in systems of equations.

Numerical comparisons

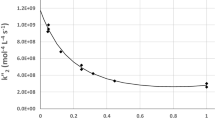

Asymmetric autocatalytic reaction profiles have been analyzed in the past by using the logarithmic form of the logistic curve, Eq. (4), which is asymmetric in linear time. It is perhaps not generally recognized that the extended form of the Prout–Tompkins model in linear time, Eq. (3), can fit data well that otherwise would require logarithmic time using non-unity values of the reaction order n and “growth” parameter m. This correspondence is shown in Fig. 1.

When the ambiguity of the parameter c is removed from the generalized logistic curve, Eq. (13) is also an improvement over the basic logistic equation for modeling autocatalytic reactions because of its ability to introduce reaction profile asymmetry. However, the real question is whether it is better than the commonly used extended Prout–Tomkins model. In fact, the parameter τ in Eq. (12) gives autocatalytic reaction characteristics similar to the reaction order n in the extended Prout–Tompkins model, as shown in Fig. 2 using the generalized reduced reaction rate formalism of Gotor et al. [32]. If fitted simultaneously to multiple thermal histories after substituting Eq. (5) for b, it would yield meaningful A and E values within the context of global kinetic modeling.

An alternative way of comparing the generalized logistic curve method to the extended Prout–Tompkins model is to see how well synthetic data from one can be fitted with the other when done properly by simultaneous regression of multiple thermal histories. Synthetic data were created with Eq. (13) for A = 1.0 × 1013, E/R = 25,164 K, τ equal to 2.0 and 0.1, and a 0 = 10−5 at temperatures of 623, 648, and 673 K. The three reaction curves for each value of τ were fitted simultaneously to the extended Prout–Tompkins model [Eq. (10)] using the kinetic analysis program Kinetics2015 (http://geoisochem.com/software/kinetics2015/index.html). The results are shown in Table 1 and Fig. 3. Slightly different parameters are obtained depending on one fits the fraction reacted, reaction rate, or both simultaneously. The correspondence between calculated and fitted reaction profiles is very good but not perfect, indicating that the models are close but not identical.

The mirror image comparison is to generate synthetic data from other models and fit them with the generalized logistic curve. Such data were generated from an extended Prout–Tompkins model and a Gaussian distributed activation energy model (DAEM). The former is appropriate for many inorganic materials and polymers, and the latter is appropriate for biomass, coal, and marine kerogen. The synthetic data were then analyzed using the methods of Kissinger [33] and Friedman [34] as well as the method of Artiaga et al.

The extended Prout–Tompkins model used Eq. (10) with A = 1.0 × 1013 s−1, E/R = 25,161 K, q = 0.999, m = 1, and n = 2 to generate the synthetic data. The kinetic parameters derived from the synthetic data are given in Table 2 and Fig. 4. The DAEM synthetic data were generated using A = 1.0 × 1013 s−1, E/R = 25,161 K, and σ = 2 % of E/R. The derived kinetic parameters are given in Table 3 and Fig. 5. In both cases, parameters for the generalized logistic equation were optimized for individual reaction curves using a grid-search method implemented in Excel. The Arrhenius parameters were then derived using an plot of ln(−b) versus 1/(c + 273.15).

A weakness of this two-step process for deriving A and E from the generalized logistic equation was exposed during this analysis. For the fastest heating rate, the optimal value of τ was actually 3.31, but the corresponding value of b caused the derived A and E values to be noticeably higher than the input values. The optimization was redone constraining the value of τ to the average of the other two values, which were quite close to each other, and the resulting A and E values were reasonable, as shown in Table 2. This would not be a problem if the method properly optimized all experiments simultaneously as has been done for many years in several commercial software packages. Furthermore, if properly implemented using Eq. (14), the generalized logistic curve parameters could be optimized for arbitrary thermal histories and not be restricted to isothermal and constant heating conditions.

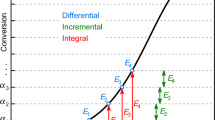

At this point, one might think the calibration procedure of the generalized logistic function works well, but one would be terribly wrong. The reason is quite simple in retrospect. Reaction profiles at a constant heating rate have four important characteristics: width, asymmetry, T max at a given heating rate, and the shift in T max with heating rate. Consequently, one needs four variables to fit them independently. As shown by Kissinger, the position of T max and its shift with heating rate determine A and E to an excellent approximation, but profile width and asymmetry are not addressed. However, methods have been developed to estimate m for autocatalytic reactions, σ for distributed reactivity reactions, and n for both from the profile width and from the asymmetry relative to a first-order reaction [8, 25]. If the reader does not understand how this works, they should study these references before proceeding because the explanations are too long to repeat here.

The generalized logistic equation contains only three parameters, so the optimization is underdetermined. Consequently, depending on how the model is calibrated, the parameters will be corrupted to fit at best three of the four characteristics at the expense of the fourth. One can see the practical consequences of this corruption in Figs. 6 and 7. The profiles calculated using time and temperature properly coupled to Eq. (14) show that the reaction profiles do not match the profiles used to calibrate the model. The problem is much worse for the Gaussian DAEM than for the extended Prout–Tompkins model for reasons to be explained forthwith.

The nature of the generalized logistic function is that reaction profile asymmetry is coupled to profile width. As τ increases, profile width and skewness to high temperature increase. As τ decreases, profile width decreases and skewness to low temperature increases. However, in all cases, the profile width is narrower than a first-order reaction, so it can only hope to work for a subset of all reactions.

The extended Prout–Tompkins model with m = 1 and n = 2 has a reaction profile narrower than a first-order reaction, so it is an appropriate candidate for generating synthetic data that can be successfully analyzed. Not surprisingly then, the agreement in Fig. 6 is fairly good. However, the generalized logistic model misses important details of the calibration data set: The temperature of the maximum reaction rate is missed slightly, and the high-temperature tail of the reaction is underestimated. Even so, the shift in the reaction profile with heating rate is properly captured, because as noted earlier, the method appears to capture the primary activation energy of the reaction correctly through an Arrhenius plot of the peak reaction rates. However, the peak of the reaction rate and the true temperature dependence of the reaction profile are missed due to the simplistic way the A and τ parameters are calibrated as well as some inherent discrepancy between the two models.

The correspondence between the generalized logistic model and the Gaussian DAEM is best described as terrible even after multiplying A by five to get the T max value approximately correct. The reason is that the profile asymmetry of the Gaussian DAEM is skewed to low temperature, which forces τ to be less than one for fitting the profile shape in Fig. 5. The rate constant (−b) is then forced to be artificially low to fit the profile width. Although the Arrhenius plot recovers the proper mean activation energy, the frequency factor is off by a factor of several from what is actually required to match T max when the effects of the time-dependent temperature inherent in a ramped experiment are properly integrated with the distributed reactivity and the effect of τ on the absolute rate is included.

Discussion and conclusions

Due to improper kinetic analysis methods that had become common in the thermal analysis field, the ICTAC kinetics committee wrote a series of three papers that outline proper ways of collecting [35] and analyzing [18, 19] kinetic data in order to derive useful kinetic parameters. Both isoconversional and model fitting methods can work as long as they are properly structured. A key to success is to collect data over a variety of diverse thermal histories in order to decouple temperature and conversion and then analyze the data in such a fashion that one set of parameters work over a wide range of thermal histories.

The KineticsXX software series dating back to the late 1980s (reviewed by Burnham and Braun [8, 25]) used this philosophy, employing a combination of isoconversional and extended Kissinger kinetic analyses to select the proper model, which was then refined by nonlinear regression. More recently, Budrugeac [36] proposed a similar discernment scheme, which has been implemented in the TKS-SP software series [37]. Both these software packages (and perhaps others as well) use the extended form of the Prout–Tompkins equation (a.k.a. Akulov or truncated Šesták–Berggren models) to fit the decomposition profiles of diverse organic and inorganic materials.

Although the generalized logistic function has characteristics that might make it a good choice for some autocatalytic and nucleation-growth reactions, it is not as flexible as the extended Prout–Tompkins model. With only one parameter τ to account for both width and asymmetry deviations from the common logistic function, it cannot properly fit most reaction profiles. For example, linear polymers typically have reaction profiles narrower than a first-order reaction, but the degree of narrowness and the asymmetry are not likely to be correlated in the manner required by τ. In contrast, the m and n parameters in the extended Prout–Tompkins model enable those two profile features to be decoupled.

Not only is the generalized logistic equation limited in the types of reaction profiles it can fit, the proposed method of fitting individual experiments to a statistical function and then deducing a single activation energy from the peak reaction rate is a major step backward from the standard method of simultaneously fitting a diverse set of thermal histories simultaneously. As can be seen by comparing Figs. 5 and 7, a model can look like an excellent fit from one perspective but be completely wrong from another perspective. In order to qualify as a kinetic method, one must be able to write a chemical reaction rate law in terms of the chemical and physical processes and integrate that rate law either analytically or numerically for comparison to measured data. Merely fitting a statistical expression to a single reaction profile does not qualify as kinetic analysis.

Even worse than being a bad method, the assertion that the current implementation of the generalized logistic approach is superior to the Arrhenius method is incorrect and misleading. The kinetic parameters given in Table III of Naya et al. [20] are nonsensical and obviously derived by someone who does not understand proper kinetic analysis. Similarly, the fitting of biomass pyrolysis data at a single heating rate [22] violates proper kinetic determination protocol. Although both papers cite the first ICTAC kinetics paper [18], they clearly did not understand it.

A similar corruption of kinetic analysis is using the Weibull distribution to directly fit reaction profiles at a constant heating rate [38]. The Weibull distribution was originally used as a probability of mechanical failure. While it might seem plausible to use the distribution to fit a chemical reaction profile because a chemical bond might be considered the same as a failure of a mechanical member, any true chemical reaction model must be formulated in terms of a rate law with an Arrhenius dependence for the various rate processes. The proper way to use the Weibull distribution in chemical kinetics is to consider that the activation energy for a complex material will have a distribution of activation energies and that distribution can be parameterized in terms of a mathematical distribution such as Gaussian, Weibull, Gamma, or other distribution [25]. Fitting the Weibull or any other mathematical distribution function directly to the reaction profile is merely a curve-fitting exercise that has no physical meaning. There is no doubt that the additional shape flexibility of a Weibull distribution over a Gaussian distribution works better for this approach, but that does not mean it is proper kinetic analysis. At best, it would be a way of preconditioning kinetic data to remove noise and extrapolate the measured conversion in order to improve an isoconversional kinetic analysis, for example.

In contrast to the non-physical application of the generalized logistic and Weibull functions, other groups have derived good global kinetic modeling methods for a variety of applications. Only two that I am very familiar with are mentioned here: petroleum exploration and safe storage of explosives. In both cases, there are substantial rewards and penalties at stake, and many years of effort has been applied toward optimizing the kinetic methods. Petroleum system modeling uses chemical kinetics derived from laboratory experiments over minutes to hours to predict the formation of oil and gas at hundreds of degrees cooler over millions of years [39, 40]. The rapid laboratory method agrees well with detailed mechanistic modeling in one study [41]. Similarly, chemical kinetics from thermal analysis experiments have been used successfully to model the self-heating and deflagration of warm energetic material. Both model fitting [14] and isoconversional [42] methods have been used, and both give similar results when properly done. Again, predictions of global kinetic methods have been compared favorably to more mechanistic models [43]. The point here is that there are robust global kinetic methods available in the literature, including some that are implemented in commercial software. Development of inferior statistical curve-fitting methods is counterproductive to advancing the application of global chemical kinetics.

In summary, recent methods of using statistical functions to fit single experimental curve shapes do not qualify as kinetic analysis methods. Unless the function can be converted to a chemical reaction rate law as a function of conversion and used for an arbitrary thermal history, these methods cannot derive parameters that have any clear physical meaning. They were not included in the ICTAC reports as recommended procedure for good reason.

References

Verhulst PF. Notice sur la loi que la population suit dans son accroissement. Corresp Math Phys. 1838;10:113–21.

Prout EG, Tompkins FC. The thermal decomposition of potassium permanganate. Trans Faraday Soc. 1944;40:488–98.

Brown ME. The Prout–Tompkins rate equation in solid-state kinetics. Thermochim Acta. 1997;300:93–106.

Lewis GN. Autocatalytic decomposition of silver oxide. Proc Am Acad Arts Sci. 1905;40:719–33.

Austin JB, Rickett RL. Kinetics of the decomposition of austenite at constant temperature. Trans AIME. 1938;135:396–415; AIME Technical publication 964, 20 pp.

Akulov NS. Basics of chemical dynamics. Moscow: Moscow State University; 1940 (in Russian).

Young DA. Thermal decomposition of solids. Oxford: Pergamon; 1966, p. 35.

Burnham AK. Application of the Šesták–Berggren equation to organic and inorganic materials of practical interest. J Therm Anal Calor. 2000;60:895–908.

Burnham AK, Braun RL, Coburn TT, Sandvik EI, Curry DJ, Schmidt BJ, Noble RA. An appropriate kinetic model for well-preserved algal kerogens. Energy Fuels. 1996;10:49–59.

Šesták J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperatures. Thermochim Acta. 1971;3:1–12.

Ng WL. Thermal decomposition in the solid state. Aust J Chem. 1975;28:1169–78.

Prout EG, Tompkins FC. The thermal decomposition of silver permanganate. Trans Far Soc. 1946;42:468–72.

Bawn CEH. The decomposition of organic solids. In: Garner WE, editor. Chemistry of the solid state, Chapter 10. London: Butterworths; 1955. p. 254–67.

Burnham AK, Weese RK, Wemhoff AP, Maienschein JL. A historical and current perspective on predicting thermal cookoff behavior. J Therm Anal Calor. 2007;89:407–15.

Burnham AK, Weese RK. Kinetics of thermal degradation of explosive binders Viton A, Estane, and Kel-F. Thermochim Acta. 2005;426:85–92.

Pérez-Maqueda LA, Criado JM, Sánchez-Jiménez PE. Combined kinetic analysis of solid-state reactions: a powerful tool for the simultaneous determination of kinetic parameters and the kinetic model without previous assumptions on the reaction mechanism. J Phys Chem A. 2006;110:12456–62.

Burnham AK, Weese RK, Weeks BL. A distributed activation energy model of thermodynamically inhibited nucleation and growth reactions and its application to the beta-delta phase transition of HMX. J Phys Chem B. 2004;108:19432–41.

Brown ME, Maciejewski M, Vyazovkin S, Nomen R, Sempere J, Burnham A, et al. Computational aspects of kinetic analysis. Part A: the ICTAC Kinetics Project—data, methods and results. Thermochim Acta. 2000;355:125–43.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Naya S, Cao R, Lopez de Ullibarri I, Artiaga R, Barbadillo F, Garcia A. Logistic mixture versus Arrhenius for kinetic study of material degradation by dynamic thermogravimetric analysis. J Chemom. 2006;20:158–63.

Cao R, Naya S, Artiaga R, Garcia A, Varela A. Logistic approach to polymer degradation in dynamic TGA. Poly Degrad Stab. 2004;85:667–74.

Barbadillo F, Fuentes A, Naya S, Cao R, Mier JL, Artiaga R. Evaluating the logistic mixture model on real and simulated TG curve. J Therm Anal Calorim. 2007;87:223–7.

Rios-Fachal M, Garcia-Fernandez C, Lopez-Beceiro J, Gomez-Barreiro S, Tarrio-Saavedra J, Ponton A, Ariaga R. Effect of nanotubes on the thermal stability of polystyrene. J Therm Anal Calorim. 2013;113:481–7.

Tarrio-Saavedra J, Lopez-Beceiro J, Naya S, Francisco-Fernandez M, Artiaga R. Simulation study for generalized logistic function in thermal data modeling. J Therm Anal Calorim. 2014;118:1253–68.

Burnham AK, Braun RL. Global kinetic analysis of complex materials. Energy Fuels. 1999;13:1–22.

Craido JM, Morales J. Defects of thermogravimetric analysis for discerning between first order reactions and those taking place through the Avrami–Erofeev’s mechanism. Thermochim Acta. 1976;16:382–7.

Arrhenius S. Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Z Phys Chem. 1989;4:226.

Laidler KJ, King MC. The development of transition-state theory. J Phys Chem. 1983;87:2657–64.

Jellinek HHG. Degradation and stabilization of polymers. Amsterdam: Elsevier; 1983.

Flynn JH, Florin RE. Degradation and pyrolysis mechanisms. In: Liebman SA, Levy EJ, editors. Pyrolysis and GC in polymer analysis. New York: Marcel Dekker; 1985. p. 149–208.

Budrugeac P. Theory and practice in the thermoanalytical kinetics of complex processes: application for the isothermal and nonisothermal thermal degradation of HDPE. Thermochim Acta. 2010;500:30–7.

Gotor FJ, Criado JM, Malak J, Koga N. Kinetic analysis of solid-state reactions: the Universality of Master Plots for analyzing isothermal and nonisothermal experiments. J Phys Chem A. 2000;104:10777–82.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C. 1964;(6):183–95.

Vyazovkin S, Chrissafis K, Di Lorenzo ML, Koga N, Pijolat M, Roduit B, Sbirrazzouli N, Sunol JJ. ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta. 2014;590:1–23.

Budrugeac P. Some methodological problems concerning the kinetic analysis of non-isothermal data for therm-oxidative degradation of polymers and polymeric materials. Poly Degrad Stab. 2005;89:265–73.

Rotaru A, Goąa M. Computational thermal and kinetic analysis: complete standard procedure to evaluate the kinetic triplet from non-isothermal data. J Therm Anal Calor. 2009;2:421.

Cai J, Liu R. Weibull mixture model for modeling nonisothermal kinetics of thermally stimulated solid-state reactions: application to simulated and real kinetic conversion data. J Phys Chem B. 2007;111:10681–6.

Peters KE, Walters CC, Mankiewicz PJ. Evaluation of kinetic uncertainty in numerical models of petroleum generation. AAPG Bull. 2006;90:1–19.

Stainforth JG. Practical kinetic modeling of petroleum generation and expulsion. Mar Pet Geol. 2009;26:552–72.

Walters CC, Freund H, Kelemen SR, Peczak P, Curry DJ. Predicting oil and gas compositional yields via chemical structure-chemical yield modeling (CY-CYM): part 2—application under laboratory and geologic conditions. Org Geochem. 2007;38:306–22.

Roduit B, Folly P, Berger B, Mathieu J, Sarbach A, Andres H, Ramin M, Vogelsanger B. Evaluating SADT by advanced kinetics-based simulation approach. J Therm Anal Calor. 2008;93:153–61.

Wemhoff AP, Howard WM, Burnham AK, Nichols AL. An LX-10 kinetic model calibrated using simulations of multiple small-scale thermal safety tests. J Phys Chem A. 2008;112:9005–11.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Burnham, A.K. Use and misuse of logistic equations for modeling chemical kinetics. J Therm Anal Calorim 127, 1107–1116 (2017). https://doi.org/10.1007/s10973-015-4879-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4879-3