Abstract

Differential scanning calorimetry (DSC) and thermogravimetry (TG) were used in order to evaluate the thermal stability of an enalapril maleate formulation packaged in two types of packaging, polyvinyl chloride/aluminum blister and aluminum strip. Enalapril and the excipients employed in the formulation were also evaluated by TG and DSC. Tablets were analyzed before and after storage in an acclimatized room at 40 °C and relative humidity of 75 % for 90 days. The DSC and TG results were compared with the results of dosage of enalapril and related compounds obtained by high-performance liquid chromatography. These results indicate an occurrence of chemical interaction between enalapril maleate and the excipients during its storage. After storage, it was observed that the enalapril content reduced and the predominant degradation product was diketopiperazine for both types of packaging. The predominance of diketopiperazine could be related to the absence of sodium bicarbonate in the tablets, alkalinizing agent employed in the thermal stabilization of the drug.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The pharmaceutical formulation development requires knowledge of the drug physicochemical properties, but also of the excipients characterization and the drug–excipient compatibility. The compatibility between drug and excipients, and the thermal stability of the dosage form can be evaluated by thermal analysis methods, in which a physical or chemical property is measured as a function of temperature or time when the substance is subjected to a controlled temperature program [1].

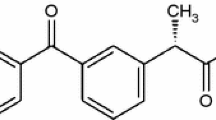

Enalapril is a pro-drug, an ethyl ester of a long-acting inhibitor of angiotensin-converting enzyme (ACE), enalaprilat. After its oral absorption, enalapril is metabolized for hydrolysis by liver yielding enalaprilat [2]. This drug is indicated for the treatment of essential and renovascular hypertension and congestive heart failure [3]. The main mechanism responsible for the antihypertensive effect of the ACE inhibitors is the reduction in the circulating angiotensin II concentration [4].

There are two main degradation pathways of enalapril maleate: the ester hydrolysis that leads to the formation of enalaprilat in the basic medium and the intramolecular cyclization in the acidic medium, which leads to the formation of diketopiperazine [2, 5, 6]. Enalapril maleate alone is very stable in temperature under dry and humid conditions, while the tablets are stable if protected from these same conditions [5]. The susceptibility of enalapril to these environmental conditions can affect the stability as well as bioavailability and the therapeutic efficacy of the drug [7].

Several techniques have been reported in the literature to monitor the degradation of enalapril. The methods include high-performance liquid chromatography (HPLC) [8–10], HPLC with mass spectrometry (HPLC-MS) [8], easy ambient sonic-spray ionization mass spectrometry (EASI-MS) [9] and Fourier transform infrared microspectroscopy equipped with a thermal analyzer (thermal FT-IR microscopic system) [11].

The thermoanalytical methods have many applications in the drug product studies, including the evaluation of stability of a pharmaceutical formulation [12]. The stability of a formulation may be affected by compatibility problems caused for interactions between pharmaceutical drugs and excipients [13]. Thermal analysis techniques can be applied in compatibility studies between drugs and excipients, providing an appropriate selection of excipients in order to prevent problems concerned to physical and chemical stability arising during late-stage product development [14].

Differential scanning calorimetry (DSC) is systematically employed for the compatibility studies. Rezende et al. [15] investigated the compatibility of enalapril maleate with excipients in a tablet formulation by DSC and thermogravimetry (TG). These authors observed an incompatibility between some of the components used in the formulation, such as colloidal silicon dioxide and sodium bicarbonate. Filho et al. [16] investigated the possible interactions between nifedipine and excipients as microcrystalline cellulose, magnesium stearate, monohydrated lactose, starch and hydroxypropyl methylcellulose by DSC and demonstrated that there is no evidence on incompatibility between nifedipine and these excipients.

The obtained data by DSC can be completed with the results of other thermal analysis techniques, such as TG, non-isothermal kinetics and isothermal stress testing, or spectroscopic (near-infrared spectroscopy—NIRS; Fourier transform infrared microspectroscopy—FT-IR) and chromatographic methods to assist in the proper interpretation of the results [17–19]. Simoncic et al. [20] investigated whether microcalorimetry could be used in the early stages of drug development for distinguishing between more and less stable substances or tablet dosage forms. In this study, it was shown that the heat output, which can be evaluated from the curves, can be correlated with the extent of enalapril degradation as confirmed by the HPLC.

The aim of this study was to evaluate the stability of an enalapril tablet formulation by DSC and TG compared with conventional accelerated stability study, in which tablets are subjected to stress conditions of heat and moisture. The influence of two types of packaging, polyvinyl chloride (PVC)/aluminum blister and aluminum strip, on the stability of enalapril maleate tablets was also evaluated.

Materials and methods

Materials

Active pharmaceutical ingredient (API): enalapril maleate (batch: 30111105083, Zhejiang).

Reference substances: enalapril maleate USP standard (batch: JIC267) and enalaprilat USP standard (batch: J1G349).

Excipients: spray-dried lactose (batch: 8612061661, Foremost Farms), microcrystalline cellulose 102 (batch: C1108036, Mingtai Chemical), pre-gelatinized starch (batch: IN523733, Colorcon), croscarmellose sodium (batch: D1202007, Mingtai Chemical), magnesium stearate (batch: 1167101, Magnesita) and colloidal silicon dioxide (batch: 3246904, Cabot).

Methods

Preparation of formulation

Tablets containing 5 mg of enalapril maleate were prepared by direct compression in a Lawes compressor (25 stations), and a group of matrices and biconcave punctures with 6 mm in diameter were used. The constituents in the formulation were as follows: spray-dried lactose, microcrystalline cellulose 102, pre-gelatinized starch, croscarmellose sodium, magnesium stearate and colloidal silicon dioxide.

Packaging

Tablets were packaged into two types of packaging: PVC colorless/aluminum blister and aluminum strip. The aluminum strips were formed on a standard machine (Fabrisul), and the blister manufacture was performed on a standard blister machine (Fabrima).

Storage experiments

Tablets of formulation developed were put into the two types of packaging described and placed for 90 days in a special acclimatized room that was equipped with a Mecalor air conditioner operating at 40 °C (±2 °C), and the relative humidity was kept at 75 % (±5 %).

Assay

The amount of enalapril maleate in the tablets was determined by HPLC according to the method described for the product monograph of enalapril maleate tablets in Brazilian Pharmacopeia [21]. This methodology is the same present in United States Pharmacopeia, USP-35 [22]. The liquid chromatograph was a Perkin Elmer Flexar Column Oven equipped with a 215-nm detector UV/DAD and a 4.6 mm × 25 cm column Perkin Elmer Brownlee Validated, containing 5-μm packing L7 and maintained at 50 °C. The flow rate was about 2.0 mL per minute, and the injection volumes for the samples into chromatograph were approximately 50 μL. The mobile phase was a filtered and degassed mixture of monobasic sodium phosphate buffer pH 2.2 and acetonitrile (75:25). Data acquisition was performed using TotalChrom Workstation software, version 6.3.2.

Related compounds

The related compounds content was taken using the methodology from the monograph of enalapril maleate tablets in Brazilian Pharmacopeia [21]. The chromatographic system was the same directed in the assay.

Thermal analysis

The TG was performed in a thermal analyzer, TGA/SDTA 851e from Mettler Toledo. A sample mass of 5–6 mg was used. The heating rate was 10 °C min−1, and the temperature range was from 25 to 600 °C. The nitrogen gas flow rate was 50 mL min−1.

The DSC curves were recorded using a Mettler Toledo 822e instrument. The nitrogen gas flow rate was 50 mL min−1. The heating rate was 10 °C min−1, and the temperature range was from 25 to 300 °C. The samples were weighed using aluminum crucibles. The initial mass of enalapril maleate and excipients was around 5 mg. The initial mass of enalapril maleate USP standard was about 1 mg. For the tablet analysis, a sample mass of 5–6 mg was used.

Results and discussion

Figure 1 shows the TG, first derivate of thermogravimetric curve (DTG) and DSC curves of enalapril. From the comparison between these curves, it is observed that the thermal decomposition is subsequently initiated to the fusion of enalapril and continue until the approximate temperature of 330 °C. From the DTG, it was found that the decomposition occurred in two steps. In the temperature range of approximately 140 to 230 °C, there was a mass reduction of 25.7 %, and between 230 and 330 °C, the reduction was 73.8 % (Table 1), leading to an almost total loss of mass. Lin et al. [11] similarly observed a mass loss of 24.9 ± 2.4 % between 147 and 220 °C from TG curve of enalapril, which correlated with the formation of diketopiperazine. Decomposition of enalapril maleate begins with the loss of a maleic acid molecule and another of water, which are eliminated in an intramolecular cyclization reaction, causing the formation of diketopiperazine molecule [23].

The DSC curve of enalapril showed an endothermic peak with maximum about 150 °C associated with the fusion of substance, and this endothermic event was initiated at approximately 140 °C. Lin et al. [11] observed in the DSC curves of pure enalapril, an endothermic peak around 151 °C with the event starting at 147 °C, suggesting that the fusion of enalapril occurred in this range. Another partially overlapped endothermic peak at 163 °C related to the thermal decomposition was also observed in DSC curve, corresponding with changes in TG curve.

Figures 2 and 3 show the TG and DSC curves of tablets, packaged in PVC/aluminum blister and aluminum strip, respectively, before and after storage. Their thermal decomposition ranges are summarized in Table 1.

The DSC curves obtained for the tablets before storage were similar to the curves obtained after storage for both forms of packaging. From the TG curves for the formulation packaged in PVC/aluminum blister (Fig. 2) and data presented in Table 1, it was found that for this type of packaging, formulation did not maintain its thermal stability, since after storage the decomposition began at 60 °C, while before storage was initiated at 100 °C. For aluminum strip packaging, as shown by the TG curves in Fig. 3 and the data presented in Table 1, the thermal decomposition began at 60 °C before storage, suggesting that decomposition may have started during the packaging process due to the high temperatures used in the sealing of aluminum foil.

Figures 4 and 5 show the DSC curves of all components of the formulation compared with the curves of tablets packaged in PVC/aluminum blister and aluminum strip, respectively, before and after acclimatized exposure. The DSC curves of pre-gelatinized starch, microcrystalline cellulose and croscarmellose sodium showed endothermic events related to water loss beginning around 25 °C. In the DSC curves of tablets, there is an endotherm beginning about 30 °C, correlated with dehydration of these excipients. Magnesium stearate showed an endothermic event with a maximum around 110 °C, which was not evidenced in DSC curves of tablets probably due to the low amount of this excipient in the formulation. Silicon dioxide showed no thermal events until the temperature considered.

DSC curves of the pure components (drug and excipients) of tablets packaged in PVC/aluminum blister: enalapril maleate (A), spray-dried lactose (B), colloidal silicon dioxide (C), pre-gelatinized starch (D), microcrystalline cellulose (E), croscarmellose sodium (F), magnesium stearate (G) and tablets packaged in blister after storage (H)

DSC curves of the pure components (drug and excipients) of tablets packaged in aluminum strip: enalapril maleate (A), spray-dried lactose (B), colloidal silicon dioxide (C), pre-gelatinized starch (D), microcrystalline cellulose (E), croscarmellose sodium (F), magnesium stearate (G) and tablets packaged in aluminum strip after storage (H)

In the DSC curves of tablets, there is an endotherm in the temperature range 105–110 °C to 155 °C, with a maximum around 140–142 °C, where endothermic peaks for enalapril maleate and spray-dried lactose occur. The DSC curve of enalapril maleate shows an endothermic melting peak with maximum at 150 °C, and the DSC curve of spray-dried lactose presents a peak at 145 °C attributed to the conversion in anhydrous lactose.

As observed in studies evaluating the thermal stability of formulations by DSC, the maintenance of the thermal events observed for the pure drug in the DSC curve of formulation, without displacement of the temperature ranges, indicates the absence of interaction between drug and excipients. The main indicative of interactions are fusion event changes. The DSC curves of tablets (Figs. 2, 3) are constituted by two endothermic events. These DSC curves show an offset of starting of first event relating to the fusion of enalapril. Moreover, there was an anticipation of the endothermic peak of enalapril related to its fusion to 140–142 °C, notably shown in Figs. 1, 2 and 3. These results indicate an occurrence of chemical interaction between enalapril maleate and the excipients during its storage, which was confirmed by the results of the HPLC analysis. Indeed, the formulation had excipients that may cause the degradation of the drug, such as microcrystalline cellulose, croscarmellose sodium, magnesium stearate and silicon dioxide [5, 10, 24, 25].

The results of the enalapril maleate content presented for tablets before packaging and storage were 97.1 % (m/m). After 90 days of acclimatized exposure, the enalapril content determination for tablets packaged in PVC/aluminum blister was 61.6 % (m/m) and for tablets packaged in aluminum strip was 81.2 % (m/m). When these results are analyzed in parallel to the test results of related compounds, there is a proportional increase in total impurities, indicating that the reduction in content of enalapril was related to the degradation of the drug.

The results of related compounds to the formulation packaged in blister PVC/aluminum before storage were 2.09 % and after 3 months of acclimatized exposure were 28.78 %, in which 1.43 and 21.76 % are the percentage of enalaprilat and diketopiperazine, respectively. The formulation packaged in aluminum strip presented 0.98 % for total impurities before storage and 11.81 % (0.73 % to enalaprilat and 10.15 % to diketopiperazine) after storage. Therefore, the predominant degradation product after storage was diketopiperazine for both types of packaging.

Diketopiperazine is formed in an acid medium by intramolecular cyclization at high-temperature conditions [5]. According to Rezende et al. [15], the reaction of enalapril maleate with an alkaline sodium compound such as NaOH, Na2CO3 or NaHCO3 is one of the methods described for the thermal stabilization of enalapril maleate [26, 27]. The predominance of diketopiperazine could be related to the absence of sodium bicarbonate in the tablets, resulting in a thermally non-stable formulation. In addition, the major degradation product in the presence of sodium bicarbonate is enalaprilat [5].

Conclusions

Thermogravimetry and DSC allowed the evaluation of the compatibility between drug and excipients and of the thermal stability of an enalapril maleate formulation. Furthermore, through these techniques, it was possible to verify the influence in stability of packaging used for the tablets (PVC/aluminum blister and aluminum strip), as determined in conventional stability study by enalapril content and related compounds tests. The instability against high-temperature conditions presented by the formulation may be related to the absence of sodium bicarbonate, alkalinizing agent employed in the thermal stabilization of the drug.

References

Gíron D. Contribution of thermal methods and related techniques to the rational development of pharmaceuticals—Part 1. Pharm Sci Technol Today. 1998;1:191–9.

Ip DP, Brenner GS. In: Florey K, editor. Analytical profiles of drug substances. London: Academic Press; 1987. p. 207–43.

Portóles A, Terleira A, Almeida S, García-Arenillas M, Caturla M, Filipe A, Vargas E. Bioequivalence study of two formulations of enalapril, at a single oral dose of 20 mg (tablets): a randomized, two-way, open-label, crossover study in healthy volunteers. Curr Ther Res. 2004;65:34–46.

Magalhães LBNC. Farmacologia cardiovasculorrenal: anti-hipertensivos. In: Silva P, editor. Farmacologia. Rio de Janeiro: Editora Guanabara Koogan; 2006. p. 691–702.

Al-Omari MM, Abdelah MK, Badwan AA, Jaber AMY. Effect of the drug-matrix on the stability of enalapril maleate in tablet formulations. J Pharm Biomed Anal. 2001;25:893–902.

Stanisz B. Evaluation of stability of enalapril maleate in solid phase. J Pharm Biomed Anal. 2003;31:375–80.

Lima DM, Santos LD, Lima EM. Stability and in vitro release profile of enalapril maleate from different commercially available tablets: possible therapeutic implications. J Pharm Biomed Anal. 2008;47:934–7.

Bhardwaj SP, Shing S. Study of forced degradation behavior of enalapril maleate by LC and LC–MS and development of a validated stability-indicating assay method. J Pharm Biomed Anal. 2008;46:113–20.

Amaral PH, Fernandes R, Eberlind MN, Hoehra NF. Direct monitoring of drug degradation by easy ambient sonic-spray ionization mass spectrometry: the case of enalapril. J Mass Spectrom. 2001. doi:10.1002/jms.2014.

Zoppi A, Garnero C, Linck YG, Chattah AK, Monti GA, Longhi MR. Enalapril: β-CD complex: stability enhancement in solid state. Carbohydr Polym. 2011;86:716–21.

Lin S-Y, Wang S-L, Chen T-F, Hu T-C. Intramolecular cyclization of diketopiperazine formation in solid-state enalapril maleate studied by thermal FT-IR microscopic system. Eur J Pharm Biopharm. 2002;54:249–54.

Gíron D. Applications of thermal analysis and coupled techniques in pharmaceutical industry. J Therm Anal Calorim. 2002;68:335–57.

Drebushchak VA, Shakhtshneider TP, Apenina SA, Medvedeva AS, Safronova LP, Boldyrev VV. Thermoanalytical investigation of drug–excipient interaction. Part II. Activated mixtures of piroxicam with cellulose and chitosan. J Therm Anal Calorim. 2006;86:303–9.

Narang AS, Rao VM, Raghavan KS. Excipient compatibility. In: Qiu Y, Chen Y, Zhang GGZ, Liu L, Porter WR, editors. Developing solid oral dosage forms: pharmaceutical theory and practice. Burlington: Academic Press; 2009. p. 125–45.

Rezende RLO, Santoro MIRM, Matos JR. Stability and compatibility study on enalapril maleate using thermoanalytical techniques. J Therm Anal Calorim. 2008;93:881–6.

Filho ROC, Franco PIBM, Conceição EC, Leles MIG. Stability studies on nifedipine tablets using thermogravimetry and differential scanning calorimetry. J Therm Anal Calorim. 2009;97:343–7.

Chaves LL, Rolim LA, Gonçalves MLCM, Vieira ACC, Alves LDS, Soares MFR, Sobrinho JLS, Lima MCA, Neto PJR. Study of stability and drug-excipient compatibility of diethylcarbamazine citrate. J Therm Anal Calorim. 2013;111:2179–86.

Pani NR, Nath LK, Acharya S, Bhuniya B. Application of DSC, IST, and FTIR study in the compatibility testing of nateglinide with different pharmaceutical excipients. J Therm Anal Calorim. 2012;108:219–26.

Kiss D, Zelkó R, Novák Cs, Éhen Zs. Application of DSC and NIRS to study the compatibility of metronidazole with different pharmaceutical excipients. J Therm Anal Calorim. 2006;84:447–51.

Simoncic Z, Zupancic P, Roskar R, Gartner A, Kogej K, Kmetec V. Use of microcalorimetry in determination of stability of enalapril maleate and enalapril maleate tablet formulations. Int J Pharm. 2007;342:145–51.

Brasil. Agência Nacional de Vigilância Sanitária. Farmacopeia Brasileira. Brasília, DF. 2010; v. II, p. 1109–10.

United States Pharmacopeia and National Formulary. USP35-NF30. 2012; p. 3033–4.

Ip DP, Brenner GS, Stevenson JM, Lindenbaum S, Douglas AW, Klein SD, Mccauley JA. High resolution spectroscopic evidence and solution calorimetry studies on the polymorphs of enalapril maleate. Int J Pharm. 1986;28:183.

Devi MV, Babu PSSK. Drug-excipient interaction studies on enalapril maleate. Int J Pharm Excip. 2000;2:153–8.

Sherman BC. Stable Solid Pharmaceutical Compositions Containing Enalapril Maleate. US Pat. 5562921, 08 out. 1996.

Sherman BC. Stable Solid Formulation of Enalapril Salt and Process for Preparation Thereof. EP Pat. 1637142(A2), 22 Mar. 2006.

Spireas S. Stable formulations of ace inhibitors, and methods for preparation thereof. US Pat. 2008221156(A1), 11 Sept. 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Souza, S.M.M., e Melo Franco, P.I.B., Leles, M.I.G. et al. Evaluation of thermal stability of enalapril maleate tablets using thermogravimetry and differential scanning calorimetry. J Therm Anal Calorim 123, 1943–1949 (2016). https://doi.org/10.1007/s10973-015-4648-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4648-3