Abstract

This communication presents the thermal performance evaluation of a direct flow evacuated tube collector-based solar water heater using energy, exergy analyses and some other thermodynamic parameters such as fuel depletion ratio, productivity lack, relative irreversibility and exergetic factor. The present solar water heating system was fabricated using total nine numbers of evacuated tubes having U-shape copper tubes being inserted inside the glass tube for flowing water through it. This arrangement was made for controlled flow rate of water having better heat and mass transfer mechanism. The experiments were carried out for different volume flow rates of water such as 10, 15, 20, 25 and 30 litres per hour (LPH) being supplied from the overhead tank directly. The performance of the present system is found to be the maximum for 15 LPH, while it is found to be the minimum for 30 LPH of volume flow of water among different volume flow rates analysed and presented in this study. It has also been found that the present water heating system performs better than those of other ETC water heating systems investigated by earlier. Also, the energy efficiency was found to be higher than that of the exergy efficiency for all the flow rates which is due to the fact that energy represents the quantity of energy, while exergy represents the quality of energy and also includes the irreversibilities associated with this system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to energy crisis worldwide and abundance of renewable energy sources particularly solar energy in the environment, it has become a major energy alternative. Use of solar energy depends upon type of application, and one of the most common applications of solar energy at low temperatures is heating of water for useful purposes. There are several types of solar water heating system; however, water heating systems based on the flat plate collectors (FPCs), evacuated tube collectors (ETCs) and compound parabolic collectors (CPCs) are very popular while flat plate and evacuated tube are mostly used collectors for residential and other water heating applications. Due to the usefulness and economic viability, many authors studied the advancement in these collectors [1–8]. The effect of single and double glazing and the selective absorbing surface of vacuum tubes was studied by Mason and Davidson [9]. Insulation is necessary to reduce the heat losses from the absorber so that the transparent insulating material was suggested by Goetzberger and Schmidt [10] over the absorber surface.

During the recent decades, the concept of exergy has been applied to various energy conversion systems by number of researchers [11–29]. Exergy can be defined as the maximum amount of useful work that can be obtained from the system, which is at a constant pressure and a temperature. Exergy is the measure of available energy, i.e. it tells about the quality of energy and based on the second law of thermodynamics, while energy is the quantity of energy and is first law practice. The concept of exergy, available energy, exergy consumption, irreversibility, exergy destruction is essentially the same. The maximum efficiency of heat withdrawal from a reservoir that can be converted into work is known as the Carnot efficiency [11, 12]. By using exergy analysis, losses associated with different components of the system can be identified, and therefore, a suitable design of the system can be given which will be ultimately useful for many engineers and scientists. Therefore, an exergy analysis has been found to be most promising tool in the design, simulation and performance evaluation of energy systems. It can also be said that the exergy analysis explores the possibilities of thermodynamic improvement of the system under consideration; however, the complete evaluation of the system is incomplete without economic analysis [15, 16].

Xiaowu and Ben [17] evaluated the domestic-scale solar water heater based on exergy analysis. They found that the exergetic efficiency of a domestic-scale water heater is small due to low quality of output energy, and also the maximum exergy losses were found to be in the storage barrel/tank. Gunerhan and Hepbasli [18] worked on the performance evaluation of solar water heating system based on exergy analysis. Their main objective was basically to analyse the different components of the system such as heat exchanger storage tank, circulating pump and flat plate solar collector. They also investigated the effect of variation of water inlet temperature on the exergy efficiency of individual components as well as the overall system. The values of exergy efficiency were found to be varying between 16 and 51.72 % for the heat exchanger, 10–16.67 % for the circulating pump and 2.02 and 3.37 % for the solar collector, while it was found to be in the range of 3.27–4.39 % for the overall system.

Gang et al. [19] worked on the performance analysis of solar water heater with compound parabolic concentrator for the higher temperature applications. They also found that when the water temperature increased from 26.9 to 55, 65, 75, 85 and 95 °C, the thermal efficiency was found to be in the decreasing in trend. Also, the lower thermal efficiency was found to be 49 % at 95 °C, while the exergetic efficiency was found to be increasing in nature. In other words, the highest exergetic efficiency was found to be at 55 °C, while it was found to be lowest at 40 °C. Ceylan [20] developed a parabolic trough collector (TCPTC) with temperature controlled mechanism and studied it based on the energetic and exergetic analyses. The experiments have been carried out at a temperature range of 40–100 °C at an interval of 10 °C. The performance of the system was found to be best at 70 °C with exergy efficiency of 63 %. Ayompe et al. [21] presented the performance evaluation of solar water heating systems with different types of collector’s, viz. flat plate and heat pipe ETC in temperate climate of Dublin, Ireland. The average collector efficiencies were found to be 46.1 and 60.7 %, respectively. However, the overall system efficiencies were found to be 37.9 and 50.3 % for the flat plate and ETCs, respectively.

In the present study, the performance evaluation of the designed and fabricated direct flow ETC-based water heating system was carried out. This study differs from the earlier ones not only in terms of the innovation in the design of the solar water heating system but also in terms of its analysis. The ETC-based water heating system has been designed by inserting the copper tubes inside the ETC tube in order to enhance the heat transfer of the flowing fluid inside the collector. Also, the designed and fabricated solar water heater has been analysed using energy, exergy efficiency and different thermodynamic parameters such as fuel depletion ratio, productivity lack, relative irreversibility and exergetic factor at different volume flow rates at different volume flow rates such as 10, 15, 20 25 and 30 litres per hour (LPH). It was found that the present system shows better performance at 15 LPH flow rate and also shows the better efficiency than those of other ETC-based water heating system investigated by earlier authors [18, 20].

Experimental set-up and procedure

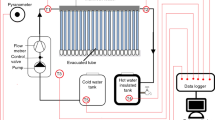

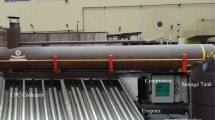

This study shows the experimental evaluation of ETC-based (length of 179.5 cm, inner diameter 44 mm and outer diameter 57.5 m) solar water heater system using energy and exergy analysis. Total of nine ETC tubes were arranged in series as shown in Fig. 1a, and the schematic diagram of the system is shown in Fig. 1b. On the other hand, the photographic view of the entire system is shown in Fig. 1c. In this system, copper tubes of suitable diameter have been inserted inside the evacuated tubes in U shape for continuous circulation of water in the entire arrangement. In order to enhance the performance of this system, a black absorbing coating is used on the outer surface of the inner tube enabling the absorption of the maximum possible solar radiation falling on the collector. As clear by name, there is a vacuum between the annular spaces of double-walled glass tubes so as to reduce the heat loss through different modes of heat transfer, viz. conduction and convection. Again, in order to reduce the heat loss from the exposed copper tubes to the ambient, the glass wool is used for insulation purposes. Also, the calibrated J-type of thermocouples having copper–constantan with temperature range of −200–1350 °C was used to measure the temperatures at different state points.

The arrangements for the inserted copper tubes inside the ETC tubes have been made in such a way that the outlet temperature of water for the first tube is the inlet of the second tube and so on. Also, to measure the flow rate of water, a rotameter with capacity up to 200 LPM is used and has been placed at the entrance of the first tube as can be seen from Fig. 1a–c. In this system, water from the overhead tank placed at the top of the nearby building was taken directly and the desired volume flow rate of the circulating fluid was set before it enters the collector. The solar radiation was measured by Suryamapi which was kept on the horizontal surface beside the experimental set-up. The data were measured, recorded using digital temperature displayer installed with the system as shown in Fig. 1c and were used for the analysis.

Analysis

Data for different parameters such as temperatures at inlet and outlet of the ETC volume flow rate of water and solar radiation were collected manually for different months at a typical of climatic condition of North India and energy, and exergy efficiencies have been calculated as given below:

Energy analysis

Based on the recorded data as mentioned above, the energy analysis has been made and the corresponding energy efficiency has also been calculated. Incident energy on the collector is given by [11–14, 29]:

where Q c (W) is the incident energy on the collector, A (m2) is the collector area, and I s (W m−2) is the incident solar radiation. The useful energy obtained can be written as [21–23, 29]:

where α is the absorptance of collector and τ is the transmittance of the collector. The useful energy absorbed by water inside the collector can be calculated by the following equation [21–23]:

where Q f (W) is the energy absorbed by water, Cpf (kJ kg−1-K) is the specific heat of water, ΔT (K) is the temperature difference between inlet and outlet temperature of water, and \( \dot{m} \) (kg s−1) is the mass flow rate of water. Therefore, the energy efficiency of the water heating system can be given as below [21–23]:

where η is the energy efficiency of the system.

Exergy analysis

The exergy analysis has been performed based on the configuration of solar water heater. The amount of exergy received by the collector can be given as [11–29]:

where T a is ambient temperature and T S is the temperature of the source, while the exergy received by fluid is written as [11–29]:

where s O is output entropy, s in is input entropy, h O is output specific enthalpy, h in is input specific enthalpy, and \( \dot{m} \) is volume flow rate of water circulating through the ETC tubes. The enthalpy difference of moving fluid flowing through the tubes (water) is given by

and

However, the exergy received by fluid can also be given by

The exergy efficiency of the system can be written as [11–29]:

Using Eq. 9, the exergy efficiency can also be given as below [11–29]:

Thermodynamic parameters

The thermodynamics analysis of solar water heating systems may also be performed using the following set of parameters as given below [18, 23]:

Fuel depletion ratio:

where I i is the rate irreversibility and \( \mathop {F_{\text{T}} }\limits^{ \cdot } \) is the total exergy rate of fuel.

Relative irreversibility:

where \( \mathop {I_{\text{T}} }\limits^{ \cdot } \) is the total rate of irreversibility.

Productivity lack:

where \( \mathop {P_{\text{T}} }\limits^{ \cdot } \) is the total exergy rate of the product.

Exergetic factor:

where F i is the exergy rate of fuel.

Results and discussion

Present experimental study is an attempt to investigate the performance evaluation of direct flow ETC-based solar water heater using energy, exergy analyses and some other thermodynamic parameters as mentioned above. In conventional ETC-based solar water heating systems, the storage tank is at the top of the collectors and hot and cold water remains in the same tank. Hot water always remains at the top of the storage tank and cold water at the bottom level this is because of the density difference between hot and cold water. Solar water heaters based on ETC used in the present study is different from conventional ETC-based solar water heating system. In this system, water at the inlet is taken from the storage tank which is already situated at the roof of the building and hot water at the outlet is stored in properly insulated water tank so that to avoid heat losses.

The experiments were performed for typical climatic conditions at Katra (J&K), India. The experiments have been carried out in the winter season, i.e. in the month of January and February at different volume flow rates, viz. 10, 15, 20, 25 and 30 LPH. Data have been collected manually for a clear sky day of the months January and February. The measured data include solar radiation and temperatures at different state of points (inlet, outlet and ambient). Based on the collected data, calculations for energetic, exergetic efficiencies and other thermodynamic parameters as mentioned above have been analysed. Based on the collected data using above-mentioned set of Eqs. (1–15), calculations were made and graphs were plotted among different performance parameters as can be seen from Figs. 2–9. The variation in different parameters such as solar radiation, energy and exergy efficiencies are shown in Table 1, while the variation in other parameters such as fuel depletion ratio, productivity lack, relative irreversibility and exergetic factor with respect to time at different volume flow rates as mentioned above is shown in Table 2. The results obtained from the study are discussed as below:

Figure 2 illustrates the variation in solar radiation and energy and exergy efficiencies with respect to time for 10 LPH volume flow rate. From the figure, it can be seen that experiment starts at 11:30 a.m. when irradiation is quite good of about 500 W m−2. From the figure, it is also observed that solar radiation first increases with time then remains almost constant for some time then again decreases which is an obvious case in practice. It also seen that initially both the efficiencies are low which is due to the fact that initially solar radiation is also low and also temperature difference is less initially because it takes some time to warm the water. Input energy is low initially and the corresponding outlet temperature is also low; therefore, the temperature difference (∆T) is low, and hence, the corresponding energy and exergy output is also low. As solar radiation increases, both the efficiencies, i.e. energetic and exergetic, increases with time, while solar radiation starts decreasing after some point of time but both the efficiencies are still increasing in nature. These efficiencies attain peak at a particular point of time then decrease slowly afterwards. This variation in efficiencies with solar radiation can be explained in terms of increased outlet temperature due to copper tube inserted inside ETC tubes due to which temperature at the outlet does not drop suddenly.

The variation of solar radiation and efficiencies against time for 15 LPH volume flow rate has been shown in Fig. 3. It is seen that initially the irradiance level is approximately 660 W m−2 which increases slowly and remains in a better level of irradiance for a long period of time and then decreases suddenly. As explained above, in this case also, both the efficiencies increase as solar radiation increases but drop suddenly as the corresponding solar radiation drops which is unlike the case of 10 LPH volume flow rate. At 10 LPH, after some time solar radiation decreases, but in this case, as the solar radiation decreases both the efficiencies suddenly decreases.

Figure 4 shows the variation in energy and exergy efficiencies and solar radiation with time at 20 LPH volume flow rate. From the figure, it is observed that for this particular day, solar radiation is very much fluctuating in nature. A mixed response in the variation of efficiencies with solar radiation has been found in this case. Sometimes as the solar radiation drops due to clouds, the corresponding efficiencies also decrease suddenly. However, sometimes solar radiation is high and the corresponding efficiencies are low. This mixed response in the variation of efficiencies is due to fluctuation in solar radiation which is intermittent in nature. Variation in solar radiation and efficiencies with time at 25 LPH and 30 LPH has been shown in Figs. 5 and 6, respectively. Same nature of variation in efficiencies with solar radiation has been found as that of 10 LPH volume flow rate.

The inlet and outlet temperatures against time for different volume flow rates (i.e. 10, 15, 20, 25, 30 LPH) has been manually recorded as given in experimental set-up and procedure section, and the performance has been illustrated in Figs. 7 and 8. General trend of variation in outlet temperature as obtained from Fig. 8 shows that the outlet temperature is the increasing function of time reaching its peak about mid of the day for different volume flow rates, viz. 10, 15, 20, 25 and 30 LPH and then decreases gradually in the evening time. The similar trend has been found for solar radiation but with some fluctuations throughout the daytime which is due to the intermittent nature of solar radiation as can be seen in Figs. 2–6. Therefore, it is found that outlet temperature is directly proportional to incident solar radiation. Optimum outlet temperature has been found for 15 LPH which is 79 °C.

Comparative variation in energetic and exergetic efficiencies at different flow rates is shown in Fig. 9. From the figure, it has been found that both the efficiencies for 15 LPH volume flow rate is highest among all the flow rates at which the present ETC-based SWH has been experimented and analysed. The average energetic and exergetic efficiencies at 15 LPH flow rate are 66.57 and 13.38 %, respectively. As can be seen from the figure, as the volume flow rate increases 15 LPH onwards both the efficiencies decreases. Both the efficiencies for 10 LPH flow rate are second best for the system and average energy, and exergy efficiency has been found to be 62.17 and 11.14 %, respectively. Energy and exergy efficiencies for 30 LPH flow rate have been found to be 30.36 and 2.22 %, respectively. Energy and exergy efficiencies for 20 LPH were 45.45 and 5.24 % and for 25 LPH flow rate were 35.49 and 3.30 %, respectively. Therefore, performance of direct flow ETC-based solar water heater with nine tubes has been found to be best at 15 LPH flow rate, i.e. 15 LPH is the optimum flow rate for nine tube ETC-based solar water heating system. This is due to the fact that at this flow rate output energy/exergy is better comparative to other flow rates presented in this study; therefore, losses are low and ultimately SWH works better at 15 LPH volume flow rate. Also performance of this SWH has been found to be better than that of other SWHs investigated by earlier authors [14, 16]. This better performance of the present system is due to the fact as explained above. Energy efficiency has been found to be always higher than those of exergy efficiency. This is due to the fact that energy efficiency is based on first law of thermodynamics and does not consider losses associated with the system. However, exergy efficiency is based on second law of thermodynamics and considers the losses/irreversibilities associated with the system. Therefore, exergy represents quality of energy rather than quantity.

Conclusions

In the present study, direct flow ETC-based SWH with copper tubes inserted inside ETC has been designed and fabricated. The thermal performance of designed solar water heating system has been analysed experimentally using the concept of energy and exergy. From the study, it has also been found that after some point of time, solar radiation starts decreasing which is an obvious nature of solar radiation; ideal case is that as solar radiation decreases, the corresponding energy and exergy efficiency should also decrease as there is no thermal energy storage in the system. But with copper tubes inserted inside the ETC tubes increases the efficiencies for some time which ultimately enhances the overall performance of the system. The optimum outlet temperature for 15 LPH volume flow rate was found to be around 79 °C, while the optimum flow rate of the present solar water heating system for the same flow rate was found to be better among the other flow rates analysed and presented in this study. On the other hand, the energetic and exergetic efficiencies at 15 LPH flow rate were found to be 66.57 and 13.38 %, respectively. In the present solar water heating system, hot water at the outlet is directly collected to well-insulated storage tank and water at the inlet is taken from the storage tank already available at the roof of the building due to which no mixing of water occurs; as a result, we got enhanced efficiency. Also, the heat exchanger is made inside the hot water storage tank so that water remains hot for a longer duration of time and can be used in the night time when there is no availability of solar radiation. Besides, the storage tank can be insulated using a thick layer of phase change material to get hot water for a prolonged time period. This solar water heating system is very useful for domestic applications due to high efficiency and this can also be applied to larger scale applications which may be useful for industrial and commercial installations.

Abbreviations

- A :

-

Area of evacuated tube collector (m2)

- Cp :

-

Specific heat (kJ kg−1-K)

- Ex :

-

Exergy

- \( \mathop F\limits^{ \cdot } \) :

-

Exergy rate of fuel

- h :

-

Specific enthalpy (kJ kg−1)

- H :

-

Enthalpy (kJ)

- I :

-

Intensity of solar radiation (W m−2)

- \( \mathop I\limits^{ \cdot } \) :

-

Rate of irreversibility (kW)

- \( \dot{m} \) :

-

Volume flow rate of water (L H−1)

- \( \mathop P\limits^{ \cdot } \) :

-

Exergy rate of the product (kW)

- Q c :

-

Energy (W)

- s :

-

Entropy (kJ kg−1-K)

- ΔT :

-

Temperature difference (K)

- T :

-

Temperature (K)

- a:

-

Ambient

- c:

-

Collector

- f:

-

Fluid

- i:

-

Successive number of elements

- O:

-

Output

- in:

-

Input

- T:

-

Total

- S:

-

Sun

- α :

-

Absorptance of inner surface of evacuated tube collector

- τ :

-

Transmittance of the collector tube

- η :

-

Energy efficiency

- ψ :

-

Exergy efficiency

- δ :

-

Fuel depletion ratio

- χ :

-

Relative irreversibility

- ξ :

-

Productivity lack

- f :

-

Exergetic factor

References

Tiwari RC, Kumar A, Gupta SK, Sootha GD. Thermal performance of flat-plate solar collectors manufactured in India. Energy Convers Manag. 1991;31(4):309–13.

Alvarez A, Cabeza O, Muñiz MC, Varela LM. Experimental and numerical investigation of a flat-plate solar collector. Energy. 2010;35(9):3707–16.

Kumar R, Rosen MA. Thermal performance of integrated collector storage solar water heater with corrugated absorber surface. Appl Therm Eng. 2010;30(13):1764–8.

Mathioulakis E, Belessiotis V. A new heat-pipe type solar domestic hot water system. Sol Energy. 2002;72(1):13–20.

Lucia U. Entropy and exergy in irreversible renewable energy systems. Renew Sustain Energy Rev. 2013;20:559–64.

Kumar R, Rosen MA. Integrated collector-storage solar water heater with extended storage unit. Appl Therm Eng. 2011;31(2–3):348–54.

Harikrishnan S, Deepak K, Kalaiselvam S. Thermal energy storage behavior of composite using hybrid nanomaterials as PCM for solar heating systems. J Therm Anal Calorim. 2014;115(2):1563–71.

Hu Z, Li A, Gao R, Yin H. Effect of the length ratio on thermal energy storage in wedge-shaped enclosures. J Therm Analy Calorim. 2014;117:807–816.

Mason AA, Davidson JH. Measured performance and modeling of an evacuated-tube, integral-collector-storage solar water heater. J Sol Energy Eng. 1995;117(3):221–8.

Schmidt C, Goetzberger A. Single-tube integrated collector storage systems with transparent insulation and involute reflector. Sol Energy. 1990;45(2):93–100.

Kotas TJ. The exergy method of thermal plant analysis. London: Butterworths; 1985.

Rosen MA, Dincer I. Exergy–cost–energy–mass analysis of thermal systems and processes. Energy Convers Manag. 2003;44(10):1633–51.

Szargut J, Morris DR, Steward FR. Exergy analysis of thermal, chemical, and metallurgical processes, New York: Hemishpere Publishing Corporation; 1988.

Rosen M, Dincer I. Exergy methods for assessing and comparing thermal storage systems. Int J Energy Res. 2003;27(4):415–30.

Rezaie B, Reddy BV, Rosen MA. Exergy analysis of thermal energy storage in a district energy application. Renew Energy. 2015;74:848–54.

Bahrehmand D, Ameri M. Energy and exergy analysis of different solar air collector systems with natural convection. Renew Energy. 2015;74:357–68.

Xiaowu W, Ben H. Exergy analysis of domestic-scale solar water heaters. Renew Sustain Energy Rev. 2005;9(6):638–45.

Gunerhan H, Hepbasli A. Exergetic modeling and performance evaluation of solar water heating systems for building applications. Energy Build. 2007;39(5):509–16.

Gang P, Guiqiang L, Xi Z, Jie J, Yuehong S. Experimental study and exergetic analysis of a CPC-type solar water heater system using higher-temperature circulation in winter. Sol Energy. 2012;86(5):1280–6.

Ceylan İ, Ergun A. Thermodynamic analysis of a new design of temperature controlled parabolic trough collector. Energy Convers Manag. 2013;74:505–10.

Ayompe LM, Duffy A, McKeever M, Conlon M, McCormack SJ. Comparative field performance study of flat plate and heat pipe evacuated tube collectors (ETCs) for domestic water heating systems in a temperate climate. Energy. 2011;36(5):3370–8.

Tyagi SK, Wang S, Singhal MK, Kaushik SC, Park SR. Exergy analysis and parametric study of concentrating type solar collectors. Int J Therm Sci. 2007;46(12):1304–10.

Xiang J, Cali M, Santarelli M. Calculation for physical and chemical exergy of flows in systems elaborating mixed-phase flows and a case study in an IRSOFC plant. Int J Energy Res. 2004;28(2):101–15.

Suleman F, Dincer I, Agelin-Chaab M. Energy and exergy analyses of an integrated solar heat pump system. Appl Therm Eng. 2014;73(1):557–64.

Chamoli S, Thakur N. Exergetic performance evaluation of solar air heater having V-down perforated baffles on the absorber plate. J Therm Analy Calorim. 2014;117:909–923.

Park SR, Pandey AK, Tyagi VV, Tyagi SK. Energy and exergy analysis of typical renewable energy systems. Renew Sustain Energy Rev. 2014;30:105–23.

Zafar S, Dincer I. Energy, exergy and exergoeconomic analyses of a combined renewable energy system for residential applications. Energy Build. 2014;71:68–79.

Tyagi SK, Pandey AK, Sahu S, Bajala V, Rajput JPS. Experimental study and performance evaluation of various cook stove models based on energy and exergy analysis. J Therm Analy Calorim. 2013;111(3):1791–9.

Tyagi VV, Pandey AK, Kothari R, Tyagi SK. Thermodynamics and performance evaluation of encapsulated PCM-based energy storage systems for heating application in building. J Therm Analy Calorim. 2014;115(1):915–24.

Acknowledgements

One of the authors (AKP) is thankful to the UM Power Energy Dedicated Advanced Centre (UMPEDAC), University of Malaya, Malaysia and Ministry of New and Renewable Energy (MNRE) Govt. of India for financial support. An Indian patent of the product has also been submitted/filled.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Pandey, A.K., Tyagi, V.V., Rahim, N.A. et al. Thermal performance evaluation of direct flow solar water heating system using exergetic approach. J Therm Anal Calorim 121, 1365–1373 (2015). https://doi.org/10.1007/s10973-015-4566-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4566-4