Abstract

Konjac Glucomannan (KGM) gels can be formed in the presence of organotitanium as crosslinkers which were chelated by different organic compounds. Organotitanium cross-linking agent is a chelate formed by coordination between tetrabutyl titanate and different organic compounds. The gel network was formed through the crosslinking reaction between titanium ions dissociated from organotitanium crosslinkers and the cis-diol hydroxyl groups on the mannose units of polysaccharide chains. Effect of concentration and species of ligands on rheological properties of the complex gels was studied by dynamic viscoelastic measurements. The gelation kinetics of the gels were investigated and the critical gelation points of the gels were accurately determined according to the Winter-Chambon criterion. The effects of kinds and concentrations of ligands on the shear storage modulus (G’), the loss modulus (G”), and the sol-gel transition points were studied. The sol-gel transition time varies with different ligands in the organotitanium crosslinkers. The sol-gel transition time and temperature were obviously observed and in good agreement with Winter–Chambon criterion.

Highlights

-

Konjac Glucomannan gels can be formed by crosslinking with organotitanium.

-

The sol-gel time and temperature were determined by Winter–Chambon criterion.

-

The sol-gel time varies with different ligands of organotitanium crosslinkers.

-

The so-gel transition time and temperature were controllable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Petroleum exploration has to develop in depth, and the formation temperature is getting higher and higher [1]. The more attention is paid to high temperature mining. Wells drilled in low-permeability reservoirs is often treated with hydraulic fracturing to increase their conductivity [2]. At present, ~70% of fracturing fluids use water-based fracturing fluid derived from guar gum [3]. The network structure of guar gum consisting of hydrogen bond interactions is broken at a higher temperature. Therefore, the study of high-temperature-resistant fracturing fluid has high practicality.

KGM is a non-ionic polysaccharide found in tubers of the Amorphophallus konjac, which consists of β-1, 4 linked D-mannose and D-glucose in a ratio of 1.6:1 [4]. Compared with other vegetable gum thickeners, KGM is not only easy to plant and process, but also has high yield, good salt resistance, and low water insoluble content. KGM aqueous solution has a high viscosity, and the viscosity of 0.6% aqueous solution is as high as 198–270 mPa·s [5]. KGM is known to form synergistic gels with other polysaccharides involving xanthan [6], κ-carrageenan [7] and acetan or deacetylated acetan [8]. KGM also can form thermoreversible gels in the presence of sodium alginate [9] or organic borate [10]. As a widely used fracturing thickener, KGM has little damage to the reservoir because of its low content of water-soluble matter, strong sand-carrying capacity and low residue. However, traditional KGM fracturing fluids only show good performance in medium and low temperature environments. The design of crosslinking agents that are resistant to high temperatures is significant. Ideally, the low-viscosity fluid is pumped to the underground formation, which is convenient for transportation and saves power and energy costs [11]. The method of delaying gel can be used to reduce frictional resistance. Therefore, the present study focuses on exploring high temperature-resistance organometallic crosslinkers and delayed cross-linking KGM gels.

Titanium (Ti, valence layer electron 3d24s2) is located in the IVB group of the fourth periods. It has the following characteristics: The energy of valence electron orbitals ((n-1)d, ns, np) is similar [12]. The smaller radius of atoms or ions can have a greater polarization effect on ligands and the ion itself has great deformability. Therefore, titanium has the tendency to accept empty orbitals of lone pair electrons and attract ligands to form complexes, which can be used to crosslink plant gum to form gel [13].

The gel with ideal cross-linking effect can be obtained by using inorganic ions such as titanium [14], zirconium [15] and borate [16, 17] directly as cross-linking agent. However, the inorganic ion has small size and the flow, permeability, diffusion of inorganic ion in aqueous solution are fast, resulting in uncontrollable time of gelation and greater friction when fracturing fluid gel is pumped [18]. Also due to the small size, the spatial distance of the KGM molecular chain needs to be shortened during the cross-linking process, and the KGM needs to be maintained at a higher concentration. Then large amounts of residues are left after the gel breaks, causing great damages to the reservoir and affecting [19]. Starting from tetrabutyl titanate and using triethanolamine and glycerol as organic ligands, Ma et al. [20] prepared an organotitanium crosslinking agent used simultaneously with organoboron. When the cross-linking ratio was 3.0–7.5%, the viscosity of the crosslinked hydroxypropyl guar gel fracturing fluid was maintained above 80mPa·s after 170 s−1 shearing at 80 °C for 1 h. Xu et al. [21] successfully prepared chitosan gel by organic titanium ionic crosslinking agent and investigated the viscoelastic properties of chitosan gel through rheological measurement. In our previous work, the rheology of KGM/ organic borate gels has been investigated, and the effect of crosslinking density on the critical gelation temperature and the elasticity of the gels were discussed [10]. However, the time of delaying cross-linking still cannot meet the current needs of oilfield exploitation.

In this study, tetrabutyl titanate was used as central ion reagents, L-Prolinol, Tris (hydroxymethyl) methyl aminomethane THAM (THAM) and Diisopropanolamine (DIPA) as organic ligands to investigate the temperature resistance and rheological properties of titanium ion complexes crosslinked KGM.

2 Experimental

2.1 Materials

The KGM sample was purchased from Hubei Qiangsen Industrial Co., Ltd., China and used without further purification. Tetrabutyl titanate was purchased from Xiya Reagent Chemical Technology Co., Ltd., China. Diisopropanolamine (DIPA), Tris(hydroxymethyl)methyl aminomethane THAM(THAM) and L-Prolinol were analytical reagents and purchased from Mreda Technology Co., Ltd., China. The structure of each ligand is shown in Fig. 1.

2.2 Preparation of KGM solutions

Powders of KGM samples were dispersed in distilled water by mechanical stirring at 75 °C for 2 h and maintained 1 h, then cooled to room temperature and stored for 1 day. The concentration of KGM affects the strength of the gel and even leads to the aggregation of chains [22, 23]. In this study, the concentration of KGM aqueous solution (Ck) was 4.0 g/L.

2.3 Preparation of organotitanium crosslinker

At room temperature, a certain proportion of isopropanol, glycerin, and organic ligands were sequentially added into a three-necked flask, and after stirring, a certain quality of tetrabutyl titanate was added. The temperature was raised to 70 °C, and the mixture was stirred magnetically for 5 h and then cooled to room temperature for later use. A series of organotitanium alcohol solutions with different concentrations of ligand were prepared. There were five different ratios of ligands to titanium (CL), which were 0.01, 0.02, 0.03, 0.04, and 0.05 wt%, respectively. When the ligands were L-Prolinol, THAM and DIPA, the crosslinking agents were recorded as I, II, and III in sequence.

The lone pair electrons on oxygen and nitrogen atoms as shown in Fig. 1 can be connected by coordination bonds in the electron holes in titanium atoms. At the same time, the organotitanium crosslinker is formed by the complexation of titanium ion with ligands containing two or more coordination atoms, which is a multinuclear complex with cyclic structure. Moreover, the titanium central ion can be combined with different atoms on the ligand. The composition of each chelate varies with the material ratio, reaction temperature and pH. Organic titanium chelate is a coordination compound with cyclic structure, which is synthesized by the complexation of metal ions with polyligand containing two or more coordination atoms. Among them, it is more inclined to generate the stable structure of five-membered or six-membered rings. Figure 2 shows the representative structures of each organic titanium crosslinking agent.

2.4 Preparation of KGM/organotitanium composite gels

The KGM aqueous solution and the organotitanium were mixed according to crosslinking ratio. In this experiment, the concentration of tetrabutyl titanate was 0.6 wt%. Then, after stirring quickly, the complex was immediately used to the following experiments. Figure 3 is schematic diagram of the structure of KGM gel in the presence of organictitanium [24].

2.5 Rheological measurements

Dynamic viscosity measurements were carried out using a rheometer (TA instruments Rheology Division, AR 2000, Great Britain) with a parallel plate geometry (40 mm in diameter and 1.5 mm in gap). To prevent dehydration during rheological measurement, a drop of low-viscosity mineral oil was added to the surface of the measured solution.

The dynamic temperature sweep measurements were conducted from 25 °C to 115 °C at a rate of 1.5 °C/min. The measuring frequencies were 1.00, 2.15, 4.64, 10.0, and 21.5 rad/s. Strain was 0.5%. The changes of storage modulus (G’), loss modulus (G”) and internal friction (tan δ) of samples with temperature (T) at different frequencies were observed.

2.6 Thermal stability analysis (DSC)

The thermal stability of KGM/ organotitanium composite gels (I, II, and III, CL = 0.03 wt%) were investigated with STA 449(NETZSCH, Germany) under the protection of nitrogen flowing at the rate of 10 ml · min−1. The samples weighed 10 mg, temperature rose from 25 to 150°C at heating rate of 5°C · min−1.

3 Results and discussion

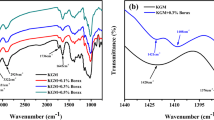

3.1 Titanate reaction pathways

People have previously studied guar gum and organic titanium, and believed that the cross-linking between guar and titanate involved a monomeric titanium molecule bridging the cis-hydroxyls on two guar chains [25]. The cis-o-hydroxyl groups in the mannose units can cross-link with the titanium ion of the butyl titanate. The presence of these crosslinks gives rise to gel-like properties. The titanium: hydroxyl bond has been confirmed to involve a true esterification reaction [26]. Accordingly, the chemistry of titanium esterification reactions is well documented [27]. The sequence of hydrolysis reactions is shown below (R represents different ligands and alkyl groups) [28]:

etc.

The equilibrium constant of the reaction k is determined by the concentration of alcohol in the solution and the strength of the ligand bond TiOR.

The esterification (crosslinking) reaction between an organotitanate and a hydroxyl group on KGM (HOR’) is given by [26, 28]:

The specific conditions of crosslinking between the polymer and the crosslinking agent are related to the reactivity of the hydroxyl group, the binding constant of the original titanate ligand, the ionic strength of the solution and the temperature.

3.2 Sol-gel transition points

Sol-gel transition is an important physical phenomenon with both considerable scientific and industrial importance [29]. It is of great significance to accurately judge the sol-gel transition, and determine the delay time of the cross-linked gels [30]. By exploring the changing trend of G’ and G” with time, the sol-gel transition was studied. The dynamic viscoelastic behavior of concentrated or sub-concentrated polymer solutions can be described by two parameters: the storage modulus (G’) characterizes the elastic loss modulus of the cross-linked network, and (G”) characterizes the friction resistance between polymer segments [31].

According to the change of the dynamic modulus of the polydimethylsiloxane chemical crosslinking gelation process, Chambon and Winter [32] proposed a method to determine the sol-gel transition point of the chemical crosslinked gels from the dynamic mechanical spectrum. For the gel transition point, there are two formulas defined at this point:

and

n represents the relaxation index. A system with n approaching 1 is defined as a purely viscous gel, whereas n approaching to 0 indicates a purely elastic gel [33]. This method indicates that the corresponding tanδ is a constant at the gel transition point, independent of frequency. The relaxation indexes corresponding to G’ and G” are the same at the sol-gel transition points, that is, the G’~ω and G”~ω curves are parallel. This equation has been widely used with chemical gels [34, 35], synthetic gels and natural physical gels [36, 37].

Figure 4 showed the time dependence of storage modulus (G’) and loss modulus (G”) for the KGM solutions in the presence of organotitanium (I) (CL = 0.03 wt%) at different frequencies and at 25 °C. G’ increased with time and G” grew slowly over time. It can be seen that G” was larger than G’ in the early stage, showing a liquid-like behavior, and both G’ and G” increase with the increase of frequency. With the increase of time, G’ was gradually larger than G”, and the gel behaved as a solid-like behavior. Thus, it can be proved that the gel was not immediately cross-linked in this system. The intersection time of G’ and G” varied at different frequencies, indicating that the time of intersection is a function of frequency [38].

Figure 5 indicated the time dependence of loss tangent, tanδ for the KGM solutions in the presence of organotitanium (I) (CL = 0.03 wt%) at different frequencies and at 25 °C. The sol-gel transition of the aqueous solution was monitored by the change of tanδ with time. From the figure, it can be found that the tanδ~t curves at different frequencies intersect at one point. The critical gelation time (tcr) was determined to be 657 s, and n was calculated to be 0.61. The frequency dependence of moduli at various times at 25 °C was shown in Fig. 6. It was observed that the curves of G’, G”~ωn were parallel to each other at tcr = 657 s, where n = 0.61. The results obtained were in good agreement with formulas (1) and (2). The Winter–Chambon method was proved to be effective to determine the critical gelation time in the whole concentration range of KGM and organotitanium used in this study. The sol-gel transition time can be determined according to this method, independent of frequency.

As shown in Fig. 7 by the time dependence of loss tangent at different frequencies for the KGM/organotitanium(II) complex system (CL = 0.03 wt%), the tcr was determined to be 1327 s, and the corresponding n was calculated to be 0.18. And Fig. 8 also proved that the curve is indeed parallel at t = 1327 s. The sol-gel transition time of this system was longer compared with organotitanium(I), which should be attributed to the more stable coordination structure of the cross-linking agent. Similarly, the sol-gel transition time of the (III) cross-linking agent systems was determined according to this method, which was 1629s as shown in Figs. 9 and 10. The sol-gel transition time varies with different ligands in the organotitanium crosslinkers. In the KGM/ organotitanium system, most titanium ions were chelated by different coordination agents through coordinate linkage. The stability of organotitaniums varies with the structure of the ligand. When the structure of organictitanium is stable, it is difficult for titanium ions to dissociate from organictitanium, resulting in longer gel time.

Due to the introduction of organic compounds as ligands in the cross-linking agent, the system has the property of delayed cross-linking. The cross-linking process of organictitanium with KGM is akin to that of organic borate. The whole chemical equilibria involving dissociation of organictitanium in water, formation of titanium ions, and complexation between cis-diol sites on KGM chains and titanium ions determine the number of crosslinks. Once the subsistent free titanium ions were crosslinked with cis-diol hydroxyl groups of KGM, the coordinate linkage between the chelated titanium ions and the coordination agent was gradually destroyed. As a result, the coordinate balance was interrupted. There is a competition relationship between cis-diol hydroxyl groups and coordination agent. While more and more free titanium ions were released, the crosslinking points among KGM chains appeared and finally the gel formed. Therefore, the sol-gel transition of KGM solutions in the presence of organictitanium can be observed, attributing to the formation process of sufficient crosslinking points. This delayed cross-linking effect is of great significance in the transportation of fracturing fluid in oil field [11]. The organic coordination agent which was called delay additive served to mask the presence of at least a portion of the titanium ions at first, thereby providing a reserve of titanium ions for cross- linking the fluids as time went on. The sol-gel transition time of polymer solution is controllable, simultaneously. It reduces the friction consumption in the process of conveying fracturing fluid, thus saving energy.

3.3 Effect of concentration of ligands on sol-gel transition

In the preparation of each kind of organotitanium crosslinker, there were five different ratios of ligands to titanium (CL), which were 0.01, 0.02, 0.03, 0.04, 0.05 wt%, respectively. Figure 11 showed the value of tcr as a function of CL at various organotitanium crosslinkers. Apparently, the value of tcr of the complex gel increased with the increase of CL under a particular system. The growth rate becomes slow with the increase of ligand content, indicating that when the ligand content reaches a certain extent, its effect on the sol-gel transition tends to be stable. The sol-gel transition time varies with different ligands in the organotitanium crosslinkers. In the case of the same CL, the sol-gel transition time of KGM/ organic titanium crosslinker III is longer than that of other systems.

When increasing concentration of ligands at a fixed concentration of tetrabutyl titanate, it became more difficult for titanium ions to dissociate. Thus, less free titanium ions were released in the mixture solution. Correspondingly, it’s difficult for titanium ions to attach cis-diol sites to form intermolecular complexes, so gel formation was obstructed. Therefore, the sol-gel transition time of the system became longer with the increase of CL. When CL increased to a certain value, the coordination number of titanium ions gradually reached saturation. Even with the addition of CL, the sol-gel transition time would not increase rapidly. As shown in the Fig. 11, the growth of the curve became slow at the end.

The number of ligand alkyl branches was related to the degree of molecular association. The more branches of the alkyl group, the stronger the shielding effect on the central titanium atom. This also prevents the occurrence of association [39]. It can be seen from Fig. 2 that the organotitanium crosslinker III has the most branches. Consequently, the dissociation of titanium ions is the most difficult in III systems. It follows that the sol-gel transition time of complex III was longer than others.

In a word, with the increase of CL, the probability of the cross- linking reaction between KGM and organotitanium decreased, resulting in slower gelation kinetics and the longer sol-gel transition time. Additionally, with the different structure of the ligand, the stability of the organotitanium structure is diversified, which could also lead to varied sol-gel transition times and network structures of KGM.

3.4 Determination of sol-gel temperature

For temperature resistant polymer gels used as fracturing fluids, the critical sol-gel temperature (Tsol) is an important factor that should be taken into consideration. In the present study, the validity of determination of Tsol by Winter–Chambon method was verified. Figure 12 showed the temperature dependence of G’ and G” of KGM/ organotitanium (I) solutions (Ck = 4.0 g/L, CL = 0.6 wt%) at different frequencies. It indicated that G” decreased gradually with the increase of temperature. G’ decreased gradually when the temperature was lower than 66 °C. When temperature ranged about 66 °C, there was a sharp rise of G’, and the increase of G’ became faster with the increase of temperature. It indicated that the fluidity of the solution increases as the temperature increases, when the temperature is below 66 °C. On the other hand, with increasing the temperature, the elasticity of the solution increased and the complex showed a solid-like behaviors. As can be seen, the solution undergoes a sol-gel transition when the temperature is greater than 66 °C, which is sufficient to resist the fluidity caused by the increase in temperature. The intersection point of G’ and G” can be observed in Fig. 12, but it strongly depends on the frequency. Figure 13 showed the temperature dependence of loss tangent (tan δ) for KGM/ organotitanium (I) solutions (CL = 0.03 wt%) at different frequencies. Like the determination of the time of tcr for KGM/organotitanium gels, the Winter–Chambon method is still effective in determining the Tsol. One can observe an intersection point (Tsol = 66.2 °C) from tanδ ~ temperature curves at various frequencies. This indicated that KGM/organotitanium can achieve high crosslinking density at higher temperatures.

3.5 Thermal analysis results

Thermal stabilities of KGM/ organotitanium composite gels (I, II, and III, CL = 0.03 wt%) were shown in Fig. 14. It can be seen that there was an obvious platform for all three curves at about 100 °C, which was caused by the evaporation of water. There was a peak value in the three curves, which was 108, 117, and 125 °C respectively, which represented the decomposition temperature of the KGM/ organotitanium composite gels I, II, and III. Consequently, the thermal stability of KGM/ organotitanium III gels was the most stable.

As mentioned above, KGM/ organotitanium III system had the best delayed crosslinking effect and the best temperature resistance at the same CL. Hence, organotitanium III was the best choice.

4 Conclusions

The crosslinking of the cis-diol groups on man- nose units of KGM in aqueous solution with free titanium ions coming from the dissociation of organotitanium alcohol solutions formed thermoreversible gels. Different organotitanium crosslinking agents can delay the critical gelation time tcr of KGM in a similar chelating manner. L-Prolinol, THAM and DIPA were selected as ligands. In the process of cross-linking, ligands participated in the competition between cis-hydroxyl groups and titanium ions, which was characterized by delayed gelation. The critical gelation time tcr can be exactly determined by using Winter–Chambon criterion based on the results of rheological measurements. The value of tcr was lengthened by increasing the concentration of ligands and the stability of chelates. It was found that the critical sol-gel temperature (Tsol) of the solutions can also be elucidated by Winter–Chambon criterion based on the results of temperature dependence of rheological properties. KGM/ organotitanium- DIPA (III) system had the best delayed crosslinking effect and the best temperature resistance at the same CL. In the following work, effect of concentration of KGM and organotitanium on rheological properties will be investigated.

References

McGlade CE (2012) A review of the uncertainties in estimates of global oil resources. Energy 47:262–270

Legemah M, Guerin M, Sun H et al. (2014) Novel high-efficiency boron crosslinkers for low-polymer-loading fracturing fluids. SPE J 19:737–743

Liu J, Wang S, Wang C et al. (2020) Influence of nanomaterial morphology of guar-gum fracturing fluid, physical and mechanical properties. Carbohydr Polym 234:115915

Kato K, Matsuda K (1969) Studies on the chemical structure of konjac mannan. Part I. Isolation and characterization of oligosaccharides from the partial acid hydrolyzate of the mannan. Agriculture Biol Chem 33:1446–1453

Kishida N, Okimasu S, Kamata T (1978) Molecular weight and intrinsic viscosity of konjac glucomannan. Agric Biol Chem 42:1645–1650

Annable P, Williams PA, Nishinari K (2002) Interaction in xanthan-glucomannan mixtures and the influence of electrolyte. Macromolecules 27:4204–4211

Williams PA, Clegg SM, Langdon MJ et al. (1993) Investigation of the gelation mechanism in k-carrageenan/konjac mannan mixtures using differential scanning calorimetry and electron spin resonance spectroscopy. Macromolecules 26:0024–9297

Ridout MJ, Gunning AP, Morris VJ et al. (1998) Characterisation of the polysaccharide produced by Acetobacter xylinum strain CR1/4 by light scattering and atomic force microscopy. Int J Biol Macromolecules 23:287–293

Gao S, Wu C, Nishinari K (2008) In situ pH-decrease-induced gelation of sodium alginate/carboxymethylated konjac glucomannan. J Appl Polym Sci 108:2825–2832

Gao S, Guo J, Wu L et al. (2008) Gelation of konjac glucomannan crosslinked by organic borate. Carbohydr Polym 73:498–505

Goel N, Shah SN, Yuan W et al. (2001) Suspension characteristics of borate-crosslinked gels: Rheology and atomic force microscopy measurements. J Appl Polym Sci 8229:78–2990

Li R, Zeng H, Zhou X (2013) Inorganic chemistry (21th ed.). Beijing: Chemical Industry Press

Dai C, Zhao G, You Q et al. (2014) A study on environment‐friendly polymer gel for water shut-off treatments in low-temperature reservoirs. J Appl Polym Sci 131:1–7

Allain C, Salome L (1987) Sol-gel transition of hydrolyzed polyacrylamide –chromium (III): Rheological behavior versus cross-link concentration. Macromolecules 20:2957–2958

Ahad E (1974) Differential scanning calorimetry of aqueous polymer solutions and gels. J Appl Polym Sci 18:1587–1602

Li C (2011) Preparation of Organic Zirconium Composite Crosslinking Agent and Research on Crosslinking. Xi’an Shiyou University

Gao S, Nishinari K, Guo J (2007) Thermoreversible konjac glucomannan gel crosslinked by borax. Carbohydr Polym 72:315–325

Brannon H, Ault M (1991) New delayed borate-crosslinked fluid provides improved fracture conductivity in high-temperature applications. SPE 22838

Li X, Liu H, Jiang A et al. (2012) Research and application of ultra-high temperature organic boron crosslinking agent. Oilfield Chemistry 29:80–82

Ma G, Shen Y, Wei Z (2013) An organic titanium crosslinking agent and its preparation method and use method. China Patent CN103113874A May 22

Xu Y, Shen C, Gao S (2015) Preparation and characterization of chitosan gel beads crosslinked by organic titanium. J Polym Res 22:53

Gao S, Nishinari K (2004) Effect of deacetylation rate on gelation kinetics of konjac glucomannan. Colloids Surf B: Biointerfaces 38:241–249

Gao S, Nishinari K (2004) Effect of degree of acetylation on gelation behavior of konjac glucomannan. Biomacromolecules 5:175–185

Xie W, Song Z, Liu Z (2016) Surface modification of PCC with guar gum using organic titanium ionic crosslinking agent and its application as papermaking filler. Carbohydr Polym 150:114–120

Driscoll P, Bowen J, Mark A(1980) Oil Base Foam Fracturing Applied to The Niobrara Shale Formation. SPE 9335

DuPont Inc, Versatile Tyzor Organic Titanates, Product brochure, Wilmington, Delaware

Rondesvadt C (1976) Titanium Compounds (Organic), Kirk-Othmer Encyclopedia of Chemical Technology, Vo123, 3rd ed

Kramer J, Prud’Homme R, Wiltzius P et al. (1988) Comparison of galactomannan crosslinking with organotitanates and borates[J]. Colloid Polym Sci 266:145–155

Nishinari K, Zhang H, Ikeda S (2000) Hydrocolloid gels of polysaccharides and proteins. Curr Opin Colloid Interface Sci 5:195–201

Nishinari K, Takahashi R (2003) Interaction in polysaccharide solutions and gels. Curr Opin Colloid Interface Sci 8:396–400

M Doi (1980) Molecular rheology of concentrated polymer systems. I. J Polym Sci Polym Phys Ed 18:1005–1020

Chambon F, Winter HH (1985) Stopping of crosslinking reaction in a PDMS polymer at the gel point. Polym Bull 13:499–50

Koike A, Takada A, Nemoto N (1998) Structure and dynamics of ovalbumin gels: II. Gels induced by heat treatment at 80 °C. Polym Gels Netw 6:257–271

Chambon F, Winter HH (1985) Stopping of crosslinking reaction in a PDMS polymer at the gel point. Polym Bull 13:499–50

Hellio-Serughetti D, Djabourov M (2006) Gelatin hydrogels cross- linked with bis(vinylsulfonyl)methane (BVSM): 1. The chemical networks. Langmuir 22:8509–8515

Te Nijenhuis K, Winter HH (1989) Mechanical properties at the gel point of crystallizing poly vinyl chloride solutions. Macromolecules 22:411–414

Rodd AB, Dunstan DE, Ross-Murphy SB et al. (2001) Dependence of linear viscoelastic critical strain and stress values on extent of gelation for a thermally activated gelling system. Rheologica Acta 40:23–29

Huang L, Takahashi R, Kobayashi S et al. (2002) Gelation behavior of native acetylated konjac glucomannan. Biomacromolecules 3:1296–130

Shinzo Y, Toshisuke K (1990) Cross-linking agent manual (8 th ed.). Beijing: Chemical Industry Press

Acknowledgements

We gratefully acknowledge the financial support by the National Natural Science Foundation of China (50703031).

Author contribution

ZZ: Validation, Formal analysis, Investigation, Data Curation, Writing- Original Draft, Writing- Review & Editing. SG: Conceptualization, Resources, Writing - Review & Editing, Visualization, Project administration, Funding acquisition, Supervision. YL: Validation, Investigation. FW: Validation, Investigation. CS: Resources, Visualization, Project administration, Supervision.

Funding

National Natural Science Foundation of China (50703031).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent to participate (Ethics)

Yes.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, Z., Gao, S., Li, Y. et al. Gelation of Konjac glucomannan crosslinked by organotitanium chelated with different ligands. J Sol-Gel Sci Technol 98, 401–410 (2021). https://doi.org/10.1007/s10971-021-05517-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-021-05517-x