Abstract

Inorganic and hybrid organic–inorganic sol–gel coatings are one of the most interesting alternatives for the corrosion protection of metallic substrates based on the design possibilities offered by this processing method. These include the ability to combine the barrier function between the metal and the surrounding environment, and the self-healing effect by the incorporation of corrosion inhibitors into the coating itself. Electrochemical characterization is essential for the study of the corrosion process, and the techniques used are based on the movement of electric charges that takes place during the corrosion process. Some of these techniques perform measurements on a relatively large area of the coated metal, obtaining average results of the corrosion characteristics. The main techniques belonging to this group are electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization (PP). However, they do not provide details on the location of anodes, cathodes or defects. Other local electrochemical techniques are used to provide this type of information, necessary in many cases to determine the exact mechanism of protection offered by the coatings: scanning vibrating electrode technique (SVET), scanning ion-selective electrode technique (SIET), scanning Kelvin probe technique (SKP) and localized electrochemical impedance spectroscopy (LEIS). In this paper, a brief review of the particularities of these techniques in their application to sol–gel coatings on metals is included. The main part of the paper is focused on the analysis of some of the most representative examples of the application of these electrochemical techniques, trying to analyze different metal alloys.

Combination of electrochemical techniques is essential to accurately analyze the corrosion protection mechanism of sol–gel coatings, including passive and active protection, ion diffusion, delamination, etc.

Highlights

-

Corrosion protection using sol–gel coatings has been enhanced based on the design improvement.

-

Combination of electrochemical techniques for a precise evaluation of the protection mechanism.

-

SKP and OCP measurements are very promising electrochemical techniques for the corrosion analysis.

-

Influence of corrosion products on electrochemical results should be analyzed in a greater detail.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The main problem of the metals and alloys used today is their tendency to corrosion, defined as the spontaneous interaction of the metal with the environment causing the deterioration of its properties. When the metal is in an electrolyte, the process of natural deterioration is known as electrochemical corrosion. In this corrosion process, the oxidation of a metal and the reduction of species in the electrolyte, both associated with a charge transfer in the metal/electrolyte interface, are involved. As it is a thermodynamically favorable process, all methods to limit it are focused on reducing the kinetics of the oxidation and/or reduction reactions.

The coatings are one of the most interesting alternatives in the protection of metals; and in this context, sol–gel coatings can be prepared using techniques such as immersion, spinning and spraying. The sol–gel coatings allow combining the barrier function between the metal and the surrounding environment (passive protection), and the self-healing effect by incorporating corrosion inhibitors into the coating itself. The self-healing effect is based on the recovery of the original barrier properties of the coating after a sudden external impact (active protection). This impact can be produced by some type of object that generates a defect in the coating, such as a crack and partial delamination. This condition exponentially accelerates the corrosion process increasing the diffusion of the ions included in the oxidation and reduction reactions, which in turn can originate the activation of the self-healing effect.

The enormous design possibilities of the sol–gel process allow developing efficient coatings for each particular case of metal substrate and aggressive electrolyte. Among the most interesting sol–gel processing parameters for this type of application are the chemical composition (inorganic and organic–inorganic hybrid materials), surface tension, viscosity, density, coating thickness, hardness, incorporation of nanoparticles and corrosion inhibitors, type of interaction with the metal substrate, compatibility with polymer coatings, etc. There are different reviews in the literature focused on the effectiveness shown by the sol–gel coatings on different metals and alloys [1,2,3,4,5,6]. In these papers, the efficiency of the protection offered by the sol–gel coatings, both active and passive, is analyzed, according to their composition, thickness, residual porosity, adhesion to the metal substrate and type of inhibitors incorporated in the sol–gel coatings.

In addition to the physical–chemical and structural characterization, the electrochemical characterization is essential for the study of the corrosion process, and this can be done based on the movement of electric charges that takes place during this process. This circumstance allows the use of electrochemical techniques that evaluate the associated electrical parameters, both from the thermodynamic and kinetic points of view. This article focuses on the analysis of the main electrochemical techniques used in the characterization of sol–gel coatings for the corrosion protection of metallic substrates. Therefore, this manuscript highlights some of the most interesting publications from a “didactic” point of view.

2 Electrochemical techniques for the evaluation of the corrosion protection of sol–gel coatings

There are numerous articles and book chapters in the literature focused on the detailed analysis of the different electrochemical techniques that can be used in the common study of the corrosion process [3, 7,8,9,10,11]. In this section, we only intend to review the particularities of some of these techniques in their application to sol–gel coatings on metals.

Oxidation and reduction reactions on the surface of a metal in the presence of an electrolyte occur at the same time with a total current intensity equal to zero. This equilibrium situation is marked by a specific potential value (open circuit potential, OCP). The measurement of this potential as a function of the immersion time in the electrolyte can provide information on the evolution of the oxidation and reduction reactions. In the case of a metallic substrate protected with a sol–gel coating, the variation of this potential can provide information related to the development of defects in the coating, electrolyte absorption, balance between semi-corrosion reactions and coating delamination. In the case of incorporation of corrosion inhibitors, this potential variation can provide information on the initiation of the corrosion process, activation of the self-healing process and duration of the passivation period.

Electrochemical impedance spectroscopy (EIS) is a technique based on the application of a sinusoidal potential signal in order to get the system out of the equilibrium state. The subsequent analysis of the relaxation process back to the initial state provides a sinusoidal current signal with the same frequency values but with different values of amplitude and phase angle. In order to obtain a linear response without irreversibly altering the system, the potential signal used is low (<±20 mV) and is usually applied at OCP. The impedance associated with the system is the relationship between the applied potential and the current response. In the case of metals protected with sol–gel coatings, the impedance value at each frequency range can be associated with different processes such as ion diffusion through layer defects, charge transfer in the metal/electrolyte interface, accumulation of electric charge on the coating surface, etc. The analysis of the impedance curves as a function of the immersion time in the electrolyte allows determining the corrosion kinetics and their mechanism, and evaluating the degree of protection offered by the coating under specific conditions. Possibly, EIS is the most common electrochemical technique used with sol–gel coatings since it allows studying the kinetics of the corrosion process in the case of passive and active protection or combination of both.

Other technique used in the characterization of sol–gel coatings is potentiodynamic polarization (PP). This technique is based on the external application of a potential to the coated metal substrate in order to place it in a specific range of the oxidation zone of the metal (potentials higher than OCP) or reduction of surrounding species (potentials lower than OCP). The most widely used modality is based on the variation of the potential over time at a constant speed. This technique allows evaluating the protection degree achieved with a specific coating under specific corrosion conditions (type of electrolyte and temperature) and the potential range at which the coating is stable. The technique is very useful for comparing sol–gel coatings with different compositions and/or thicknesses on the same metal by measuring the passivation current density and the breakdown potential.

The techniques listed up to now provide information on the kinetics of electrochemical corrosion of metals protected by coatings. This information is based on average measurements on the total tested area; however, they do not provide details on the location of anodes, cathodes or defects. For this reason, other local electrochemical techniques are used to provide this type of information, necessary in many cases to determine the exact mechanism of protection offered by the coatings. One of the most interesting local techniques is the scanning vibrating electrode technique (SVET) since it is very suitable to study the self-healing process of defects in sol–gel coatings on metals. The technique measures the current associated with the flow of ions in solution as a consequence of corrosion processes, distinguishing between anodic and cathodic areas. One of its most interesting features is the ability to evaluate the behavior change with the immersion time so the kinetics of the self-healing effect can be analyzed. Among the limitations of this technique for the study of sol–gel coatings is the defect size, since if it is less than one micron, the current generated in the corrosion process is small and difficult to detect by the equipment. The partial delamination of the coating is another limitation since the currents able to reach the coating outside are very small. Complementing SVET technique, scanning ion-selective electrode technique (SIET) is suitable for studying the phenomenon of self-healing of defects in coatings on metals. This technique identifies the ions integrated in the current flow during the corrosion process, such as protons, metal cations and electrolyte ions which allows establishing concentration maps as a function of time.

Scanning Kelvin probe technique (SKP) measures the distribution of Volta potential differences between the substrate and the measurement probe in the absence of electrolyte, making it a non-invasive technique. This characteristic makes possible the study of the delamination of the sol–gel coating and other processes that take place at the interface between the coating and the metallic substrate. The technique allows potential measurements at specific positions and distribution maps on sol–gel coatings with and without artificial defects under different temperature and relative humidity conditions.

Localized electrochemical impedance spectroscopy (LEIS) technique has the same physical basics as EIS but uses micro-electrodes to carry out impedance measurements at specific points on the surface of the sol–gel coating and compare the evolution of zones with and without artificial defects. The usual mode of operation is to measure at individual points in a given range of frequencies, but measurements can also be carried out at a fixed frequency to map an area of interest.

3 Some examples of application of electrochemical techniques to metal substrates protected with sol–gel coatings

Instead of reviewing the large number of articles related to sol–gel coatings for the protection of metals and alloys, this review is focused on evaluating only some of the most representative examples of the application of electrochemical techniques, trying to analyze different metal alloys.

Initially, the sol–gel coatings developed for the corrosion protection of metals pursued the design of a barrier effect against the electrolyte based on a high density and good adhesion. The most suitable electrochemical technique to analyze the average barrier properties provided by a sol–gel coating is the PP in its anodic zone. This technique allows comparing variations in the chemical composition of the coating and changes in its thickness for the same metallic substrate. In an interesting example [12], the influence of the content of zirconium in a silica-based hybrid sol–gel coating (partially replacing silicon in the oxide structure) is analyzed. The PP measurements were carried out in Harrison´s solution starting 250 mV negative to OCP, and increasing in the anodic direction. The results indicate that although a considerable improvement in corrosion resistance is generally observed with all coatings, the incorporation of zirconium causes a very significant reduction in the corrosion current density. This characterization technique also makes it possible to differentiate the specific barrier properties of each coating according to its zirconium content. The improvement provided by the incorporation of zirconium is based on the formation of Si–O–Zr bonds. In this way, the PP technique identifies the most suitable Si/Zr ratio from the point of view of corrosion protection, since an excess of zirconium reduces the barrier properties which is possibly associated with an increase of the fragility of the coating that generates more residual defects.

On the other hand, the existence of small defects in the coating and the need for protection during long periods of immersion in the electrolyte led the design of the protection systems towards the combination of the barrier effect with a self-healing effect. The EIS technique is suitable for studying the self-healing effect of an inhibitor incorporated in a sol–gel layer because the different processes that can occur simultaneously (electrochemical transfer, ion diffusion, distribution of charges on the coating surface, etc.) are associated with different time constants located at different frequency ranges. However, when we have a sol–gel coating with very good barrier properties, the overlapping of the time constants can hinder an accurate assessment of the existence of a self-healing effect and its operating mechanism. An example of an analysis of the self-healing effect offered by cerium ions incorporated in a sol–gel coating is described in the article by Rosero Navarro et al. [13]. In this paper, the corrosion resistance of the AA2024 aluminum alloy protected with a methacrylate-silica sol–gel coating doped with different amounts of cerium ions is studied. The porosity generated in the coating, due to the incorporation of cerium ions, considerably limits the barrier properties, which allows, however, evaluating the effect of active protection provided by the cerium ions. The results of impedance obtained with the coating without cerium ions indicate values almost two orders of magnitude higher than those obtained with the coatings doped with cerium ions, behavior associated with the residual porosity produced by these ions. While in the case of the coating without cerium a reduction of the resistance associated to the charge transfer is observed when the immersion time increases, the incorporation of cerium in the coating leads to an increase of the total impedance to 0.01 Hz (Fig. 1). This behavior is related to a significant increase of the resistance associated with the charge transfer, more important if we consider that the resistances associated with the sol–gel coating and the natural layer of aluminum oxide decrease with the immersion time as a consequence of the degradation of both layers. On the other hand, the phase angle associated with the charge transfer presents an anomalous increase with the immersion time, contrary to what is commonly observed in sol–gel coatings. This behavior is associated with the activation of the self-healing mechanism that leads to the precipitation of cerium oxides/hydroxides in the area affected by corrosion, as is also confirmed by SEM-EDX. When the barrier behavior of the methacrylate-silica sol–gel coating on this same aluminum alloy is better, as in the case of doping with strontium aluminum polyphosphate [14], it is difficult to observe a clear differentiation between the time constants associated with the charge transfer and the natural layer of aluminum oxide. Consequently, the self-healing process could be associated with the “repair” effect of the inhibitor on the oxide layer instead of the formation of precipitates that heal the corrosion points.

Impedance diagrams (Bode plots) for the bare AA2024 aluminum alloy protected with TM-SiO2-5Ce coatings after different immersion times in 3.5 wt% NaCl solution [13] (reproduced with permission from Elsevier)

A complementary analysis of the self-healing effect provided by cerium ions immersed in a sol–gel coating is focused on the use of the LEIS technique. This technique allows a sweep through an artificial defect on the coating and performs impedance measurements at a specific frequency. In this example [15], it has been used with a hybrid sol–gel coating doped with zeolite particles loaded with cerium ions to protect the AA2024 aluminum alloy. The results of admittance modulus versus displacement in a direction perpendicular to the scratch length for undoped and doped coatings with cerium show the possible mechanism of action of cerium ions. While for the un-doped coating the admittance modulus increases steadily with the immersion time, in the case of the coating doped with cerium there is a reduction after 4 h of immersion. The authors suggest that this behavior is due to the activation of the self-healing effect of cerium ions after the beginning of the corrosion process. The cerium ions would leach out of the zeolite particles forming cerium hydroxide in the cathodic zones.

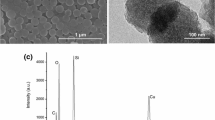

An alternative to the direct dispersion of the inhibitor in the sol–gel coating is focused on the use of nanocontainers incorporating the corrosion inhibitors. In this way it is intended to control the rate of leaching of the inhibitor, prolonging the active protection for a longer period of time. An interesting example in the protection of AA2024 aluminum alloys is the synthesis of mesoporous silica particles and their use to store the corrosion inhibitor, benzotriazole in this case [16]. The particles loaded with the inhibitor are dispersed in the solution by sonication, and the sol–gel coating on the aluminum alloy is prepared by immersion. The study of the corrosion process was carried out using three types of coatings: the sol–gel layer without inhibitors, with the inhibitor added directly to the precursor solution of the coating and with the inhibitor-loaded silica nanoparticles incorporated into the coating. In this case, the electrochemical technique used for the characterization of the corrosion process as a function of the immersion time in NaCl solutions is SVET, applying an artificial defect produced with a scalpel. Figure 2 shows current density maps on the aluminum substrate protected with the three types of coatings after 15 min and 10 h of immersion in the electrolyte. Likewise, the maximum and minimum value of current density is presented as a function of the immersion time. The current density increases with the immersion time in the cases of the coating without inhibitor and with the inhibitor incorporated directly to the coating, evidencing the absence of a self-healing mechanism. On the other hand, in the case of the coating loaded with silica nanoparticles incorporating the inhibitor, no increase in the current density is observed with the immersion time, a behavior that the authors associate to a self-healing effect. However, it is also necessary to indicate that the test only lasts 10 h, insufficient time to ensure active protection during a prolonged immersion time. On the other hand, the authors indicate that the load of inhibitor, calculated experimentally, is 409 mg per gram of silica nanoparticles. Evaluating the leaching kinetics of the inhibitor from these particles in aqueous suspensions, they showed that the leaching of the inhibitor under these conditions is very fast, concluding in less than 1 h. Although this fast leaching has the advantage of rapid action to slow down the corrosion process, it could also limit its action for prolonged immersion times in the electrolyte.

Left and middle: SVET current density maps of aluminum substrate coated with (a) SiOx/ZrOx film, (b) SiOx/ZrOx film with inhibitor, and (c) SiOx/ZrOx film containing inhibitor-loaded SiO2-NPs obtained after 15 min and 10 h. Right: Maximum and minimum current densities (j) versus time after immersion in 0.1 M NaCl over the scratched surface of the films with corresponding maps on the left and middle [16] (reproduced with permission from ACS Publications)

Another example of application of porous nanoparticles based on silica to incorporate corrosion inhibitors is carried out by Ding et al. [17]. In this case, the metal substrate to be protected is magnesium alloy AZ31B protected with a hybrid sol–gel coating. As corrosion inhibitors, 2-Hydroxy-4-methoxy-acetophenone is used doping the porous particles and dispersing them in the solution before making the coating; and 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane by immersion of the porous coating in a concentrated solution. The SVET results show interesting results since after 5 h of immersion in the NaCl solution there is evidence of corrosion in the artificial defect for coatings with and without inhibitors. However, the results after 24 and 72 h of immersion only show anodic and cathodic currents for the undoped coating. The authors justify this behavior to the effect of self-healing provided by the corrosion inhibitors. Again, it would be interesting to evaluate the SVET results after a longer immersion period. The results of EIS, up to 15 days of immersion in NaCl solution, only agree in part with these results (Fig. 3). There is an important improvement in the barrier function offered by the coatings when they are doped with the corrosion inhibitors, with a slower decreasing of the impedance values with the immersion time. However, no signal associated with the activation of the self-healing effect is observed; such as, for example, an increase of impedance after a previous decrease associated with the corrosion process, or a sudden variation in the time constants related to the inhibition effect. In this case, it would have been interesting to analyze the variation of the impedance diagrams during the first three days of immersion to compare these results with those obtained with the SVET technique.

Bode plots obtained on AZ31B magnesium coated alloy with SNAP coatings ((A(a) and B(b), MSNPs@SNAP coatings (B(a) and B(b)) and PFDS/MSNPs@SNAP coatings (C(a) and C(b)) after immersion for 5 h and 3, 7, 10, and 15 days in 0.05 M NaCl. Optical images of the SNAP coating (A(c)), MSNPs@SNAP coating (B(c)) and PFDS/MSNPS@SNAP coating (C(c)) taken after different immersion times [17] (reproduced with permission from RSCPublishing)

An alternative to porous silica nanoparticles in the protection of AA2024 aluminum alloy is the development of porous TiOx sol–gel coatings from the assembly of titania nanoparticles. This structure has also the ability to store corrosion inhibitors, benzotriazole in this case [18]. To complete the protection system, a hybrid sol–gel outer layer is incorporated using tetra-n-propoxy zirconium (TPOZ) and (3-glycidoxypropyl) trimethoxysilane (GPTMS). The study of the behavior against corrosion was carried out using EIS and SVET comparing the results of coatings with and without doping with the corrosion inhibitor. Figure 4 shows the impedance diagrams (Nyquist) as a function of the immersion time for the alloy protected with the porous layer of TiOx doped with benzotriazole plus the outer hybrid sol–gel layer (a), and the substrate protected only with the hybrid layer without doping (b). The difference between both is evident, and a continuous drop of the total impedance is observed with the immersion time in the system without inhibitor. On the other hand, a sequence of increases and decreases of the impedance is observed in the system including the inhibitor. The authors associate this behavior with the subsequent breakage and self-healing of the natural layer of aluminum oxide based on the inhibition effect provided by benzotriazole that is leached from the pores of the TiOx layer. In this case, it would have been very interesting to be able to analyze the corresponding Bode diagrams in order to observe more accurately the evolution of the different time constants as a function of the immersion time. The SVET tests were performed up to 3 h of immersion after the defects were carried out. The results indicate the absence of corrosion in the case of the substrate protected with the TiOx layer compared to the substrate coated with the sol–gel layer without inhibitor. These results are in agreement with those of EIS, although they do not show the complete process of corrosion initiation—inhibitor activation—self-healing, and are performed at very short immersion times which limit the analysis.

Evolution of the Nyquist plots during immersion in 0.05 M NaCl obtained for AA2024-T3 treated with (a) benzotriazole-doped TiOx covered with sol–gel film and (b) undoped sol–gel coating [18] (reproduced with permission from Elsevier)

The results shown until now relate a drop in the anodic and cathodic currents observed with the SVET technique with a recovery of the barrier properties through the activation of a self-healing effect. However, it is important to note the influence of the deposition of corrosion products on the currents measured with this technique. In the case of AZ31 and ZE41 magnesium substrates protected with a bilayer sol–gel coating in simulated body fluid (SBF) [19], the SVET results show a reduction of the currents with the immersion time. On the other hand, the SIET results are in agreement with these results because a reduction of alkalinity by increasing the immersion time is observed. In the absence of an inhibitor, the explanation lies in the formation of corrosion products that include magnesium and calcium carbonates, which provide additional protection against corrosion.

Recloux et al. [20] also observed the important influence of the formation of corrosion products on SVET measurements when the immersion time in a NaCl solution increases. In this particular case, the aluminum alloy is protected with an inner layer of mesoporous silica doped with benzotriazole as inhibitor and an acrylic top coat, to which an artificial defect has been made. The results compare the bilayer system with and without corrosion inhibitor. In the case of the coating without benzotriazole, an increase in the current density is initially observed up to 4 h of immersion, decreasing for both, anodic and cathodic values, after this time (Fig. 5). The authors associate this behavior with the formation of corrosion products inside the artificial defect, whose are confirmed by microscopy. The analysis using the coatings doped with the inhibitor shows a different behavior, with no appreciable differences in the current density values when the immersion time increases. This behavior is associated by the authors to the effect of self-healing provided by benzotriazole. Also in this case, the test lasts 24 h, possibly insufficient time to evaluate the efficiency of the active protection at long immersion times, since it is likely that the leaching rate of the inhibitor to the electrolyte through the artificial defect is substantial. The electrochemical micro-cell was useful in this case to evaluate the self-healing process. The development of a film on the metal was verified by the presence of a passive region in anodic polarization curves.

2Dmaps of ionic currents above the defect of the undoped coating system and the corresponding optical images after different immersion times in 0.01 M NaCl: 2 h (a), 4 h (b), 14 h (c) and 24 h (d). The current density scale (e) is expressed in μA/cm2. The scan size is 2500 × 2080 μm and the defect size is 1.9 mm × 75 μm [20] (reproduced with permission from Elsevier)

Continuing with this analysis, the evaluation of AA2024 without coatings using the SVET technique shows a gradual reduction of the anodic current densities during the first 24 h of immersion in NaCl solution [21]. This behavior is associated with the formation of corrosion products on the metal surface, an important circumstance when this technique is used in the characterization of metals protected with sol–gel coatings. When it is analyzed the protection offered by a hybrid sol–gel coating doped with 8-hydroxyquinoline with an artificial defect, only the cathodic activity is appreciable after 24 h of immersion. The authors associate this behavior with active protection through the formation of insoluble complexes between the inhibitor (8-hydroxyquinoline) and the metal ions resulting from the corrosion process (Al3+ and/or Mg2+) on the artificial defect due to the local alkalization produced by the corrosion process.

In this context, the influence of corrosion products on the protection provided by the sol–gel coatings has also been studied by SKP; in particular, in the case of aluminum alloys 6016-T4 pre-treated with several sol–gel layers and an external epoxy coating [22]. For this analysis, filiform corrosion is produced through an artificial defect, and exposure to HCl vapors and high relative humidity. The SKP study establishes potential maps in the area of the defect and in the adjoining areas at different exposure times at high RH, which allows establishing the in-situ formation of galvanic cells under the coatings. The results indicate that the formation of corrosion products increases the potential of the exposed metal in the defect. They also indicate that the defect is surrounded by areas with more negative potentials under the coating close to the defect, which are anodic zones that will later generate corrosion filaments away from the defect (Fig. 6). This distribution of potentials indicates that galvanic cells are being formed between the cathode, in the defect, and the anodes, under the coating. By increasing the exposure time to high relative humidity, it is observed how the pretreatment using sol–gel layers considerably limits the expansion of the active area of corrosion from the defect. The measurements also make it possible to indicate anodic corrosion points that have been passivated by corrosion products and do not develop filaments. The results conclude that the anodic undermining is responsible for the adhesion loss of the coating to the substrate.

SKP potential profiles (air at 95% RH) of the electrocoated systems after 3 days of exposure in the air at 95% RH (A-Oxsilan, B-sol–gel based, C-APTES) [22] (reproduced with permission from Elsevier)

The SKP technique also has an important application in the study of the effect of self-healing in sol–gel coatings doped with corrosion inhibitors, always considering the formation of corrosion products and their influence on the values of work function distribution (mV). In the case of magnesium alloy AZ31B protected with a hybrid sol–gel coating doped with encapsulated 8-hydroxyquinoline with an artificial defect, the variation of the potential as a function of the measurement time allows the evaluation of the self- healing effect [23]. In this particular case, the defect was coated with a drop of NaCl solution and the potential measurement was performed exactly on the defect. Comparing the undoped coatings with those doped with the inhibitor, the potential values are similar for both and close to the bare magnesium alloy (−1.50 V vs. SHE) at the beginning of the immersion. By increasing the measurement time, the undoped coating shows no change in the potential indicating that the corrosion continues without variations. However, in the case of the coating doped with the inhibitor, an abrupt increase in the potential is observed up to values around −1.05 V vs. SHE that is associated with the self-healing effect provided by the inhibitor. This behavior is maintained until the end of the test (56 h), perhaps insufficient time to check the efficiency of the protection system at prolonged times of exposure to the aggressive electrolyte. On the other hand, the impedance values are gradually reduced with the immersion time, which would be partially in disagreement with the results obtained with SKP. Although it is difficult to compare results from techniques as different as EIS and SKP, it would have been of great interest to analyze the impedance curves obtained at times less than 5 h to study the variation of time constants and the associated impedance values, and try to detect the beginning of corrosion process and activation of the self-healing. This technique is also particularly suitable for studying the interface between the coating and the metal substrate when there are no artificial defects. In addition, its spatial resolution allows detecting the location of contamination in the coating or delamination areas. In the analysis of hybrid sol–gel coatings on carbon steel, the Surface work function distribution (mV) can be measured, so the potential values can be related to the interaction between the metal substrate and the coating [24]. An increase in potential towards more positive values indicates a stronger interaction of the coating with the substrate. On the other hand, the variation of the potential values in the measured area is an indication of the homogeneity of the coating, which also allows locating the presence of defects and even the localized inhibition of the anodic reaction if the potential increases towards more positive values. The interesting information provided by this non-contact technique of high spatial resolution is evident, which complements the information provided by other techniques that study average properties over large areas and with direct interaction with the sample, as in the case of EIS.

The combination of OCP and EIS techniques can be an interesting option to analyze the self-healing effect provided by the incorporation of cerium ions in sol–gel coatings with a good barrier behavior [25]. In this case, a sol–gel bilayer system of hybrid composition was designed for the protection of carbon steel. The bilayer system is formed by an inner layer (next to the steel) doped with cerium ions and an outer layer without cerium. In this way, the deterioration of the barrier properties of the sol–gel layer by incorporating cerium ions is prevented from affecting the entire protective system. The defect in the coating has been induced through successive polarization curves applied on the same test area until a sudden increase in current density is observed. From that moment, continuous OCP and EIS measurements are carried out alternately. Figure 7 shows the OCP measurements against the immersion time, indicating the temporary position where the EIS measurements have been performed, which are shown in Fig. 8. The strong potential variation (Fig. 7) between −0.60 V, a value similar to that obtained with bare steel, and +0.20 V, characteristic value of a crack-free coating, is an indication of the possible activation of the self-healing effect provided by the cerium ions. The values of reduced potential correspond to a stage where the corrosion predominates, activating then the self-healing process. As a result, the defect is healed and the potential increases, remaining until the corrosion process is reactivated, reducing the potential again. The impedance measurements (Fig. 8) are in agreement with this explanation, since the curves obtained in areas of low OCP show lower values of total impedance (107 ohm cm2) than the curves performed in sections of higher OCP (1010 ohm cm2). In the first case, the system is very capacitive with a single time constant related to the sol–gel coating. However, the curves obtained in low OCP sections have three time constants associated with the sol–gel coating, the active protection process and the electrochemical corrosion on the exposed metal surface through the defects. This successive and alternating variation of impedance values and number of time constants is clearly associated with the self-healing process when corrosion takes place. The SEM-EDX and Confocal Micro-Raman studies complement the electrochemical study, providing new evidence of the activation of the self-healing effect.

Corrosion potential versus immersion time of the coated steel substrate after increasing immersion time in 3.5 wt% NaCl solution on the same test area after the polarization-impedance measurements made during 354 days of immersion [25] (reproduced with permission from Royal Society of Chemistry)

Electrochemical Impedance Spectroscopy (EIS) of the bare and coated steel substrate after increasing immersion time in 3.5 wt% NaCl solution on the same test area after the polarization-impedance measurements made during 354 days of immersion [25] (reproduced with permission from Royal Society of Chemistry)

An alternative to the traditional sol–gel coatings used in the protection against corrosion of metals are those obtained from melting gels. These sol–gel materials have been prepared from the combination of mono and di-substituted silanes for the protection of stainless steel [26, 27]. The main characteristic of these hybrid organic–inorganic materials is their particular softening behavior, since they are solid at room temperature, they become liquid at temperatures around 110 °C, and return to the solid state when the temperature is reduced to the environment. The gels become “hybrid glasses” when the increase in temperature exceeds the consolidation temperature (135–160 °C), and no longer return to the liquid state in a subsequent heating. This behavior has its origin in the reaction between residual alkoxide and/or hydroxyl groups during the consolidation treatment. The main advantage of this type of coatings for the protection against corrosion of metals is that the water and solvents used during the preparation of the sol–gel solution are eliminated before the coating deposition. The consolidation treatment results in a hydrophobic, non-porous and defect-free coating as a consequence of a very limited volumetric shrinkage. Coatings prepared from melting gels can reach very high thicknesses (up to 1 mm) without defects, something totally unusual in traditional sol–gel coatings, either inorganic or organic–inorganic hybrids. For this reason, the barrier effect provided is significant, leading to impedance values as high as 1011 Ohm cm2 and a single time constant associated with the coating (Fig. 9). After four months of immersion, no appreciable changes were seen in the impedance values, which are associated with a quasi-ideal coating [26].

Bode plots (log/Z/ vs. log frequency and phase angle vs. log frequency) of the bare and coated metal substrates during the first day and after four months of immersion in 3.5 wt. % NaCl solution [26] (reproduced with permission from Elsevier). Coating composition is based on methyltriethoxysilane (MTES) and dimethyldiethoxysilane (DMDES)

Other times, as for example in the use of stainless steel in biomedical applications, the objective of the sol–gel coating is not only to obtain a good barrier effect and/or a self-healing effect, but also to reach a compromise between these properties and an adequate residual porosity to contain bioactive particles. The use of a bilayer sol–gel system pursues this objective [28]. The inner layer provides a good barrier against corrosion and against the leaching of potentially toxic ions from steel. On the other hand, the outer layer has interconnected and open porosity that can enclose bioactive particles able to react with the body fluid to produce hydroxyapatite. The use of the EIS technique for the study of this bilayer system in comparison with each type of coating separately, and its fitting to equivalent circuits, allows an accurate evaluation of the characteristics of each layer in SBF. Although the total impedance at 0.01 Hz is similar for the three layer configurations, the resistance associated with the coating in the case of the outer layer alone is very low as a consequence of its high residual porosity and marked hydrophilic behavior. However, this resistance is high in the case of coatings formed only with the inner layer or with bi-layers based on the high barrier effect provided by the inner layer. In this way, the EIS technique makes it possible to clearly differentiate between dense and porous layers.

4 Conclusions

The corrosion protection of metals and alloys provided by sol–gel coatings has been gradually enhanced based on the improvements incorporated in the design of these coatings, such as, for example, optimization in the hybrid organic–inorganic nature of the coating, combination of different metals, thicknesses, residual processing defects, coating adhesion and incorporation of nanoparticles and corrosion inhibitors. EIS is the electrochemical technique most used in the characterization of the corrosion protection, since it allows discriminating between several processes (charge transfer, ion diffusion, charge accumulation on coating surface, etc.) that occur simultaneously during the corrosion process. However, this technique belongs to the group of area techniques and does not allow the location of anodes, cathodes and defects, which complicates the analysis of the corrosion protection mechanism. For this reason, different techniques of local analysis (SVET, SIET, SKP, LEIS) have been developed and used mainly for the study of the self-healing effect, allowing the evaluation of different corrosion inhibitors in specific conditions. However, in general, these techniques also have limitations related to low current densities because of the size of the defect or because corrosion occurs below the coating. A separate mention deserves the SKP technique as it is non-invasive and can evaluate the delamination of the sol–gel coating and other processes in the metal-coating interface. In short, an adequate study of corrosion protection makes it necessary to combine several electrochemical techniques in order to determine the mechanism of protection and inhibition of corrosion. The analysis of the open circuit potential (OCP) shifts with the immersion time is not usual in the literature; although these values can give indications about the evolution of the corrosion process, even of the activation of the self-healing effect. A critical point, possibly not very studied in the literature, is the significant influence of the corrosion products on the results provided by these electrochemical techniques. In most cases, their presence is unavoidable, and their influence on the values of impedance (EIS), current density (SVET) and potential (SKP) is considerable, and variations in these parameters can be imprecisely associated with a self-healing effect. For this reason, the combination of several electrochemical techniques with chemical and structural analysis is necessary to perform accurately the study of the corrosion protection offered by sol–gel coatings.

References

Durán A, Castro Y, Aparicio M, Conde A, de Damborenea JJ (2007) Protection and surface modification of metals with sol–gel coatings. Int Mater Rev 52:175–192

Yasakau KA, Ferreira MGS, Zheludkevich ML (2017) Sol–gel coatings with nanocontainers of corrosion inhibitors for active corrosion protection of metallic materials. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of sol–gel science and technology. Springer, Cham

Durán A, Castro Y, Conde A, de Damborenea JJ (2016) Sol–gel protective coatings for metals. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of sol–gel science and technology. Springer, Cham

Wang D, Bierwagen GP (2009) Sol–gel coatings on metals for corrosion protection. Progress Org Coat 64:327–338

AbdolahZadeh M, van der Zwaag S, Garcia SJ (2016) Self-healing corrosion-protective sol–gel coatings based on extrinsic and intrinsic healing approaches. Adv Polym Sci 273:185–218

Zheng SX, Li JH (2010) Inorganic–organic sol gel hybrid coatings for corrosion protection of metals. J Sol–Gel Sci Technol 54:174–187

Andreatta F, Fedrizzi L (2016) The use of electrochemical techniques for the characterization of the corrosion behavior of sol–gel-coated metals. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of sol–gel science and technology. Springer, Cham

Bard J, Faulkner LR (2001) Electrochemical methods: fundamentals and applications, 2nd edn. Wiley, New York, NY

Kelly RG, Scully JR, Shoesmith DW, Buchheit RG (2002) Electrochemical techniques in corrosion science and engineering. Marcel Dekker, New York, NY

Bastos A (2017) Application of SVET/SIET techniques to study healing processes in coated metal substrates. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of sol–gel science and technology. Springer, Cham

Bastos AC, Quevedo MC, Karavai OV, Ferreira MGS (2017) Review—on the application of the scanning vibrating electrode technique (SVET) to corrosion research. J Electrochem Soc 164:C973–C990

Rodič R, Iskra J, Milošev I (2014) A hybrid organic–inorganic sol–gel coating for protecting aluminium alloy 7075-T6 against corrosion in Harrison’s solution. J Sol–Gel Sci Technol 70:90–103

Rosero-Navarro NC, Pellice SA, Durán A, Aparicio M (2008) Effects of Ce-containing sol–gel coatings reinforced with SiO2 nanoparticles on the protection of AA2024. Corros Sci 50:1283–1291

Raps D, Hack T, Wehr J, Zheludkevich ML, Bastos AC, Ferreira MGS, Nuyken O (2009) Electrochemical study of inhibitor-containing organic–inorganic hybrid coatings on AA2024. Corros Sci 51:1012–1021

Dias SAS, Marques A, Lamaka SV, Simões A, Diamantino TC, Ferreira MGS (2013) The role of Ce(III)-enriched zeolites on the corrosion protection of AA2024-T3. Electrochim Acta 112:549–556

Borisova D, Möhwald H, Shchukin DG (2011) Mesoporous silica nanoparticles for active corrosion protection. ACS Nano 5:1939–1946

Ding CD, Liu Y, Wang MD, Wang T, Fu JJ (2016) Self-healing, superhydrophobic coating based on mechanized silica nanoparticles for reliable protection of magnesium alloys. J Mater Chem A 4:8041–8052

Lamaka SV, Zheludkevich ML, Yasakau KA, Montemor MF, Cecílio P, Ferreira MGS (2006) TiOx self-assembled networks prepared by templating approach as nanostructured reservoirs for self-healing anticorrosion pre-treatments. Electrochem Commun 8:421–428

Córdoba LC, Marques A, Taryba M, Coradin T, Montemor F (2018) Hybrid coatings with collagen and chitosan for improved bioactivity of Mg alloys. Surf Coat Technol. 341:103–113

Recloux I, Gonzalez-Garcia Y, Druart ME, Khelifa F, Dubois Ph, Mol JMC, Olivier MG (2016) Active and passive protection of AA2024-T3 by a hybrid inhibitor doped mesoporous sol–gel and top coating system. Surf Coat Technol 303:352–361

Tian Z, Shi H, Liu F, Xu S, Han EH (2015) Inhibiting effect of 8-hydroxyquinoline on the corrosion of silane-based sol–gel coatings on AA 2024-T3. Progress Org Coat 82:81–90

Nazarov A, Romano AP, Fedel M, Deflorian F, Thierry D, Olivier MG (2012) Filiform corrosion of electrocoated aluminium alloy: role of surface pretreatment. Corros Sci 65:187–198

Ding CD, Xu JH, Tong L, Gong GC, Jiang W, Fu J (2017) Design and fabrication of a novel stimulus-feedback anticorrosion coating featured by rapid self-healing functionality for the protection of magnesium alloy. ACS Appl Mater Interfaces 9:21034–21047

Kannan AG, Choudhury NR, Dutta NK (2010) Electrochemical performance of sol–gel derived phospho-silicate-methacrylate hybrid coatings. J Electroanal Chem 641:28–34

Mosa J, Rosero-Navarro NC, Aparicio M (2016) Active corrosion inhibition of mild steel by environmentally-friendly Ce-doped organic–inorganic sol–gel coatings. RSC Adv 6:39577–39586

Aparicio M, Jitianu A, Rodriguez G, Degnah A, Al-Marzoki K, Mosa J, Klein LC (2016) Corrosion protection of AISI 304 stainless steel with melting gel coatings. Electrochim Acta 202:325–332

Aparicio M, Jitianu A, Rodriguez G, Al-Marzoki K, Jitianu M, Mosa J, Klein LC (2017) Thickness-properties synergy in organic–inorganic consolidated melting-gel coatings for protection of 304 stainless steel in NaCl solutions. Surf Coat Technol 315:426–435

López DA, Rosero-Navarro NC, Ballarre J, Durán A, Aparicio M, Ceré S (2008) Multilayer silica-methacrylate hybrid coatings prepared by sol–gel on stainless steel 316L: electrochemical evaluation. Surf Coat Technol 202:2194–2201

Acknowledgements

The authors would like to acknowledge the financial support from Ministerio de Economía y Competitividad, Spain (PCIN-2013-030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Aparicio, M., Mosa, J. Electrochemical characterization of sol–gel coatings for corrosion protection of metal substrates. J Sol-Gel Sci Technol 88, 77–89 (2018). https://doi.org/10.1007/s10971-018-4785-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4785-9