Abstract

The growing environmental concern in all segments of society has aroused the interest of the scientific community in the search for alternatives to reduce the use of pesticides, getting highlighted the use of antagonists microorganisms, as species of Trichoderma. Despite many years of research, several challenges such as lack of formulations, storage and transport conditions, which reduce the viability of microorganisms, hamper the application of this technology in large scales. A polymeric formulation that retains the characteristics and properties of the antagonist is of fundamental importance for an efficient and effective control of the disease to be fought. Encapsulation into beads may be an alternative to provide protection and maintain the properties of these microorganisms. In this paper, applying the factorial design tool, was studied a formulation having as independent variables the proportion of sodium alginate, sodium polyphosphate and glycerol aiming to increase the water activity (aW) of the beads. The beads were prepared using the technique of drip by simple ionic gelation of biopolymers in solutions of CaCl2 (2M). Characterization of beads was held by FTIR spectrophotometer and thermogravimetric analysis. Results indicate that the greater proportion of polyphosphate formulation was more significant for a larger aW into the beads. Preliminary results show that beads formulation with alginate, polyphosphate and glycerol was able to maintain the viability of spores of Trichoderma sp. for 120 days when stored at room temperature.

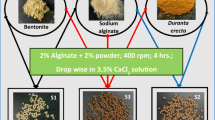

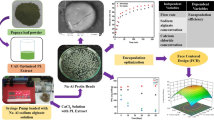

Graphical Abstract

The water activity (aW) of the samples was evaluated and had different responses that depended on the composition of granules. The surface chart represents the responses of aW for Ca-AGP beads. Figure shows the Pareto diagram, where it can be seen that only the concentration of polyphosphate was significantly variable in aW response. The distribution of the residuals (values predicted by the model vs. observed values) showed that the deviations were normally distributed and that there was a satisfactory correlation between the theoretical and experimental values.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Several species of microorganisms are employed in industrial applications such as probiotic cultures, enzymes producer and species used for biocontrol of plant diseases, such as species of Trichoderma. Despite many years of research and use of these microorganisms, there are still several challenges to apply this technology on a large scale. Among the challenges are the absence of formulations, which guarantee the viability of the biological agent during storage and transport, as well as facilitate the handling of the product to be applied in crops. Many formulations are marketed in the form in which they are produced, for example, spores suspensions in water or cereal impregnated with spores, normally, without proper registration in regulatory agencies (MAPA in Brazil), low storage time, loss or decrease in viability of biological control agent. To facilitate the storage and transport, these products are often dehydrated to suspend its metabolism and facilitate the handling. The techniques used are not always feasible for all species of microorganisms, causing injury or even loss of cell viability [1–3].

Naturally, the majority of microorganisms live aggregates in the colony form, forming biofilms or flakes, were usually surrounded by extracellular polymeric substances such as polysaccharides and proteins which confer protection from adverse environmental conditions [4]. To replace this natural protection, microencapsulation methods can be applied, providing protection during the dehydration process and prolonging viability during storage.

Microencapsulation is a technological process in order to protect the microorganisms involving them with a protective layer, usually biopolymers, as sodium alginate, favouring cell viability for long periods of time. To develop these capsules or granules, it is necessary to use a material that is nontoxic and which is not adversely reactive with the microorganism to be encapsulated. Several materials can be used as the encapsulating agent, among which are: agar, alginate, carrageen, starch, dextrin, sucrose, carboxymethylcellulose, gelatin, albumin and chitosan [5].

The most common technique for the encapsulation of microorganisms in capsules is called process of ionic gelation. In this process, the encapsulation can be performed by mixing the microorganisms in the anionic polymer solution (sodium alginate). This solution is extruding in a solution of multivalent cations (calcium chloride). In this process occurs formation of beads that protect the microorganisms into their structure [6].

Even with microencapsulation, drying processes very intense can affect cell viability. It is important to choose appropriate matrices to ensure the continued viability. Sodium alginate matrix has been most used in studies of microencapsulation due to the advantages of being biodegradable, nontoxic, biocompatible and abundant in nature [7, 8]. It is found in algae and in some bacterial exopolysaccharide [9]. Sodium alginate is a high molecular weight polysaccharide, unbranched formed by links (1–4) between acids β-d-mannuronic (M) and α-l-guluronic (G). According to Smidsrod cited by Workman et al. [10], alginates with different M/G ratios form gels with different properties. Bivalents ions, normally used in microencapsulation process, as Ca2+, connect selectively with homopolymeric GG-blocks and thus alginates with a low M/G ratio (high G content) form gels stronger than alginates with high M/G ratio (high M content).

However, only alginate beads produced may have distorted shapes, irregular sizes, poor strength and high porosity, and these defects can influence the stability and viability of microorganisms during storage [7]. The development of new matrices with other organic or inorganic materials can correct these distortions [11, 12], decrease the porosity and enable the beads humidity control even after the drying process, maintaining the integrity of cellular components and prolonging the viability of microorganisms or cells. As observed for Workman et al. [10] using the technique Bio-electrospraying, investigated the optimization parameters in order to allow stable production of size-controlled microspheres containing extracellular matrix material and human cells. It is observed in this study that although cell viability is minimally affected by encapsulation in all types of alginate tested, the addition of collagen and the optimization parameters, as well as, the cell density initial is important for proliferation and cell survival over the days.

Various environmental stress conditions can compromise the biological activity of cellular components. Naturally, some organisms use as strategy the accumulation of solutes known as osmolytes, which act as stabilizers of protein structure [13]. Some of these stabilizers are natural polyols such as glycerol, which are present in many species of microorganisms. These microorganisms exhibit this protective effect by establishing hydrogen bonds with proteins and may dispense the participation of water, which would normally be responsible for these connections [14]. These solutions promote a decrease in the movements of protein groups even at temperatures high enough to promote their aggregation and denaturation [15]. Besides osmoregulator is an important agent cryoprotectant because it allows the formation of ice crystals on the cell while maintaining the stability of cell wall [16, 17].

Another important osmoregulator is the polyphosphate that is present in most microorganisms such as bacteria, fungi and algae representing up to 20 % of its dry weight. In microbial cells, the inorganic polyphosphate plays a significant role in increasing the cell resistance to adverse environmental conditions and the biochemical regulation of various processes that are energy reserve, metal chelating, pH changes buffer, great importance in adjusting the physiological growth conditions of environmental stress, and in nutritional deficiency [18–20].

Both glycerol and polyphosphate are used in different strategies (cellular mechanisms) to maintain the integrity of the cell components under unfavorable environmental conditions. In addition, both have hydroxyl groups, which allow the formation of hydrogen bonds with water molecules and cell components, ensuring water activity (aW) necessary to maintain the metabolism and the cellular integrity [14–20]. Water activity is defined as the ratio of the vapor pressure of water in a material (p) to the vapor pressure of pure water (p o) at the same temperature. It is a measure of the energy status of the water in a system and is one of the most critical factors in determining quality and safety of the foods; it is also important to the stability of pharmaceutical and cosmetic formulations [21, 22].

Thus, we aimed to study the modification of sodium alginate matrix, with different proportions of sodium polyphosphate and glycerol through factorial design, seeking a resistant matrix with water-holding intramolecular capacity that guarantees the maintenance of cell viability of microorganisms during the storage period, to be applied in formulations for biological control with microorganisms of the specie Trichoderma sp.

2 Materials and methods

2.1 Factorial design of array compositions

In microencapsulation assay were used sodium alginate (Hansen®), sodium polyphosphate (Nuclear®) and glycerol (Vetec®) in different proportions. The proportions studied were established through a full factorial design 22 with three center points (level 0) and four axial (±α, where α = 1.4142), totaling 11 trials (Table 1). Assays were conducted randomly, and the data were analyzed using the Statistica 8.0 software (Statsoft®) at 95 % confidence level. The experimental error was obtained as the mean and standard deviation of the central points.

The proportions of sodium alginate varied according to the concentration of sodium polyphosphate, for a total of 2.00 % (w/v) polymer. The water activity (aW) of beads was analyzed (Aqualab® equipment) after the dehydration process, pursuing the conditions that favored the highest level of this variable.

2.2 Preparation of beads

For the preparation of the beads, the different proportions of sodium alginate, sodium polyphosphate and glycerol were mixed during the preparation of the gelling solution. Then the method was used simple ionic gelation in that polymerizing solutions were extruded using a syringe in a solution of CaCl2 2.0 M. The formed beads were maintained in the CaCl2 solution under stirring on a magnetic stirrer for 30 min for stabilization. Subsequently, the beads were removed from the solution and washed with distilled water to remove excess calcium ions.

The beads were dehydrated in a circulating air oven at a controlled temperature at 40 °C until 12 h, with accompanying of mass loss at 1 h intervals until there stabilizing the mass.

For the microbiologic assays, a solution of spores of the fungi Trichoderma sp. was added at gelling solution and mixed for 15 min before of the be extruded, by following the procedure described earlier.

2.3 Beads characterization

The characterizations were conducted with the assay 5 (alginate/polyphosphate/glycerol), assay 6 (alginate/glycerol), assay 7 (alginate/polyphosphate) and assay 12 (alginate). The samples were subjected to analysis of FTIR spectra using an FTIR spectrophotometer (Perkin Elmer). The thermal stability was determined by thermogravimetric analysis (TA Shimadzu 60WS).

2.4 Microbiologic assays of viability Trichoderma sp. in beads

Aiming to evaluate the efficiency of polymer matrix, in maintaining cell viability of microorganisms during the dehydration process and storage period, was chosen four assays of the factorial design that were used for encapsulation Trichoderma sp. spores. After the encapsulation and dehydration process, the assays were stored at the room temperature (30 ± 2 °C) for 120 days. The assays were chosen: assay 5 (alginate/polyphosphate/glycerol), assay 6 (alginate/glycerol), assay 7 (alginate/polyphosphate) and assay 12 (alginate).

For production of Trichoderma sp. spores, we followed by the widely known methodology, with the cultivation in rice grains, previously moistened and sterilized, according to the methodology described by Jackisch-Matsuura and Menezes [23].

Microbiological analyses were performed by counting CFU/g (colony-forming units per gram of sample), with initial samples, during the drying process and the storage time of 120 days. For counting CFU/g was performed dilution of the beads in sodium citrate 2.0 % [24], following serial dilution in saline and counting on PDA medium (Potato, Dextrose and Agar).

3 Results and discussion

The general beads had formed with spherical appearance and white color with good transparency (Fig. 1). The samples were dehydrated, and the activity of water was checked each hour. After 12 h of dehydration, the aW of all beads formulation remained constant, as shown in Fig. 2. The response of water activity sought to verify the formulation with greater ability to maintain the viability of microorganisms.

3.1 Fourier transforms infrared spectroscopy analysis

The FTIR study revealed the functional groups of alginate–glycerol–polyphosphate—Ca-AGP (assay 5) beads, alginate–glycerol (assay 6) beads, alginate–polyphosphate (assay 7) beads and only alginate (assay 12) (Fig. 3). The broad peak observed at 3371 cm−1 was due to OH stretching [7, 25] present in all samples because all possess hydroxyl groups. The broad peak observed at 2940 cm−1 is attributed to CH stretching [25, 26] present in all samples due to the glycerol and alginate. The peak appearing at 1630 cm−1 is attributed to asymmetric stretching of group ν −(s,a)COO , present in the sodium alginate as well as deformation of hydroxyl groups of water molecules [25–27]. The peak appearing at 1595 and 1604 cm−1 refers to asymmetric and symmetric stretching vibrations of free carboxyl groups, respectively, ν −(a,s)COO . Characteristic peaks of phosphate groups appear between 1400 e 500 cm−1. The peak observed at 1030 cm−1 was attributed to the stretching of ν −(s,a)CO .and is found mainly in glycerol beads. The peaks observed at 952, 1109 and 1229 cm−1 were characteristic to beads with polyphosphate. It is possible to observe the intense band at 1011 cm−1 characteristic of ν(s,a) COC deformation of the rings present in the sodium alginate [25, 26]. The signal characteristic of phosphate groups ν(s,a) POH of sodium phosphate occurred in approximately 1031 cm−1 wavelength very close to the band observed for the group of sodium alginate ν(s,a) COC; therefore, these signals in the two groups may overlap after capsule formation.

Thus, the FTIR spectra of the Ca-AGP beads confirmed the interaction between alginate, glycerol and polyphosphate. This interaction has showed the polyphosphate and glycerol part of the beads structure and is not released into the encapsulation and drying process.

3.2 Thermogravimetric analysis

The thermal behavior in TGA and DTG analysis of alginate–glycerol–polyphosphate Ca-AGP beads (assay 5), alginate–glycerol beads (assay 6), alginate–polyphosphate beads (assay 7) and only alginate beads (assay 12) was shown in Fig. 4. In general, the thermal decomposition of polysaccharides follows processes that include the desorption of physically absorbed water, dehydration and breaking the polymer chain [7, 28].

In the TGA curves of the assay 5, assay 6 and assay 7 (Fig. 4) can be observed three events during the increase in temperature–time zone. The first event (e1) occurred between 26 and 100 °C, with the maximum loss in mass (approximately 13 %) in all samples. It should be noted that this event occurred at a lower temperature as observed in the curve of the sodium alginate (70 °C). This first event of mass loss may be associated with loss of moisture [28–30]. In 150 °C occurred on the second event (e2) represented by an exothermic peak with a maximum at approximately 200 °C at this point, one can see a large mass loss, 44 % for assay 5, 6 and 7, and 15 % of mass loss for alginate. The third event is represented by an exothermic peak, initially occurring in 220 °C, may be noted at this point that the alginate had an exothermic peak cannot be observed in the assay 5, 6 and 7; this event was associated with mass loss of 30 % and then fell abruptly. These last two events represent transformations degradation of the material examined and the degradation temperature of the capsules.

It can be observed using thermogravimetric curves what the interaction occurred between both the polymers forming the matrix, and this interaction showed higher temperatures water loss and degradation compared to the alginate beads.

3.3 Water activity evaluation in factorial design

The water activity (aW) of the samples was evaluated and had different responses that depended on the composition of granules. The surface chart in Fig. 5a represents the responses of aW for Ca-AGP beads. Figure 5b shows the Pareto diagram, where it can be seen that only the concentration of polyphosphate was significant variable in aW response. The distribution of the residuals (values predicted by the model vs. observed values) showed that the deviations were normally distributed and that there was a satisfactory correlation between the theoretical and experimental values (Fig. 5c).

The aW increases with the increase in the percentage of polyphosphate and consequently to a decrease in alginate polymer for a total of 2.0 %. Although glycerol does not provide variable statistical significance in the variable response at higher concentrations of polyphosphate, higher concentrations of glycerol tend to positively affect the aW. Furthermore, it is observed that the optimal conditions between variables were not affected, but large amounts of polyphosphate and glycerol may affect the stability of the capsules [31].

3.4 Viability Trichoderma sp. into the beads

Figure 6a, b shows the Trichoderma sp. viability expressed in CFU/g (colony-forming unit per grams of samples), during dehydration process and storage period, respectively. It is possible to observe in Fig. 6a that all assays start with the same log value in CFU/g of sample (1010), but at the final dehydration process, only the assay 5 (alginate, polyphosphate and glycerol) maintains the log value initial. Already the other assays occurs decrease in the viability of spores during the dehydration period, with final log value assay 6 (108), assay 7 (106) and assay 12 (106). These results can be explained due to low protection offered by the beads to spores of trichoderma, and consequently the spores are affected by long exposure to dehydration temperature, such as observed for Cigdem and Merih, and related for Adzmi et al. [7].

After dehydration period, the assays were stored at room temperature (30 ± 2 °C) for 120 days, and the results of spores viability can be observed in Fig. 6b. At the final storage period, only the assay 5, formulation containing alginate, polyphosphate and glycerol, showed viability spores with log value 107 (CFU/g). On the other hand, all others assays did not show germination of spores after this period. In a study by Adzmi et al. [7], beads containing Trichoderma harzianum presented feasibility of three months, only under room temperature storage conditions. After this period, no viable cells of T. harzianum were detected. In the same study, when the beads were stored under refrigeration (5 ± 2 °C), the viability of the T. harzianum spore was maintained in 103 CFU/g. Another study involving T. harzianum, researchers obtained good results of germination after 60 days of storage at room temperature (26 ± 2 °C), employing other polymeric materials [3]. The above data indicate that the results obtained in this study, with the beads formulation containing alginate, glycerol and polyphosphate, feature an excellent alternative to encapsulate microorganisms and maintain its viability at room temperature for 120 days with more than 108 CFU/g of sample. These results are in excess of those achieved so far with other formulations.

The results showed that alginate beads containing glycerol and polyphosphate presented a higher count of viable microorganisms. This result corroborates with the fact that glycerol and polyphosphate are used as hydrophilic agents, namely to assist in the process of water retention [14–20]. The results presented by the surface response and Pareto diagram (Fig. 5a, b) confirm such observations.

4 Conclusion

The results showed that the challenge to formulate beads with potential in maintaining viable microorganisms for a period exceeding 90 days at room temperature has been reached. Through this study, it can be seen that concentrations of about 1.0 % polyphosphate and 1.0 % alginate, for 2.0 % of total polymer, more 1.0 % glycerol can be used to immobilize spores of Trichoderma sp., ensuring the viability of spores for a long period of storage for up to 120 days at room temperature with more than 108 CFU/g of sample. This result can be justified due to the greater number of hydrogen bonds formed between water and the granules with higher concentrations of polyphosphate and glycerol. A water activity (aW) largest into the beads after drying favors the maintenance of cell viability.

References

Bae YR, Knudsen GR (2005) Soil microbial biomass influence on growth and biocontrol efficacy of Trichoderma harzianum. Biol Control 32:236–242

W Bettiol, MAB Morandi (2009) Biocontrole de doenças de plantas: uso e perspectivas. Embrapa Meio Ambiente, 341 p

IS Melo, FG Costa (2005) Desenvolvimento de uma Formulação Granulada a Base de Trichoderma harzianum para Controle de Fitopatógenos. Embrapa Comunicado Técnico, pp 1–4

Christensen BE, Characklis WG (1990) Physical and chemical properties of biofilms. In: Characklis WG, Marshall KC (eds) biofilms. Wiley, New York, p 93

Jackson LS et al (1991) Microencapsulation and food industry. LWT Food Sci Technol 24(4):289–297

Kruif CG, Weinbrecka F, Vries R (2004) Complex coacervation of proteins and anionic polysaccharides. Curr Opin Colloid Interface Sci 9:340–349

Adzmi F, Meon S, Musa MH, Yusu NA (2012) Preparation, characterization and viability of encapsulated Trichoderma harzianum UPM40 in alginate-montmorillonite clay. J Microencapsul 29(3):205–210

Naseby DC, Pascual JA, Lynch JM (2000) Effect of biocontrol strains of Trichoderma on plant growth, Pythium ultimum populations, soil microbiol communities and soil enzyme activities. J Appl Microbiol 88(1):161–169

Pawar SN, Edgar KJ (2012) Alginate derivatization: a review of chemistry, properties and application. Biomaterials 33:3279–3305

Workman VL, Tezera LB, Elkington PT, Jayasinghe SN (2014) Controlled generation of microspheres incorporating extracellular matrix fibrils for three-dimensional cell culture. Adv Funct Mater 24(2014):2648–2657

Rodrigues D, Rocha-Santos T, Sousa S, Gomes AM, Pintado MM, Malcata FX, Lobo JMS, Silva JP, Costa P, Amaral MH, Freitas AC (2011) On the viability of five probiotic strains when immobilized on various polymers. Int J Dairy Technol 64:137–144

Jiménez-Pranteda ML, Poncelet D, Náder-Macías ME, Arcos A, Aguilera M, Monteoliva-Sánchez M, Ramos-Cormenzana A (2012) Stability of lactobacilli encapsulated in various microbial polymers. J Biosci Bioeng 113(2):179–184

Yancey PH, Clark ME, Hand SC, Bowlus RD, Somero G (1982) Living with water stress: evolution of osmolyte systems. Science 21(4566):1214–1222

Viana YA, Garrote-Filho MS, Penha-Silva N (2005) Estabilização de proteínas por osmólitos. Biosci J 21(2):83–88

Diamant S, Eliahu N, Rosenthal D, Goloubinoff P (2001) Chemical chaperones regulate molecular chaperones in vitro and in cells under combined salt and heat stresses. J Biol Chem 276(43):39586–39591

Arruda PV, Rodrigues RCLB, Felipe MGA (2007) Glicerol: um subproduto com grande capacidade industrial e metabólica. Rev Anal 26:56–62

Nevoigt E, Stahl U (1997) Osmoregulation and glycerol metabolism in the yeast Saccharomyces cerevisiae. FEMS Microb Rev 21:231–241

Shari’a AEN, Nascimento AE, Lima MAB, Campos-Takaki GM, Souza W (2002) Polyphosphate in Zygomycetes: a cytochemical study. Braz J Microbiol 33:119–126

Kulaev IS, Vagabov VM (1983) Polyphosphate metabolism in microorganisms. Adv Microbiol Physiol 24:83–169

Harold FM (1966) Inorganic polyphosphate in biology: structure, metabolism and function. Bacteriol Rev 13:772–794

FM Harold (2015) Water activity. Replacing myths with science. http://www.wateractivity.org/. Accessed 16 Feb 2015

Björklund S, Wadsö L (2011) A calorimetric method to determine water activity. Rev Sci Instrum 82:114903

Jackisch-Matsuura A, Menezes M (1999) Efeito de Trichoderma spp. no controle de Pythium aphanidermatum em fumo (Nicotiana tabacum). Summa Phytopathologuca 25(2):161–164

Lima JR, Locatelli GO, Finkler L, Luna-Finkler CL (2014) Incorporação de Lactobacillus casei microencapsulado em queijo tipo coalho. Revista Ciência & Saúde 7(1):27–34

Carta D, Knowles JC, Smith ME, Newport RJ (2007) Synthesis and structural characterization of P2O5–CaO–Na2O sol–gel materials. J Non-Cryst Solids 353:1141–1149

Narra K, Dhanalekshmi U, Rangaraj G, Raja D, Kumar CS, Reddy PN, Mandal AB (2012) Effect of formulation variables on rifampicin loaded alginate beads. Iran J Pharm Res 11(3):715–721

Pongjanyakul T, Puttipipatkhachorn S (2007) Modulating drug release and matrix erosion of alginate matrix capsules by microenvironmental interaction with calcium ion. J Non-Cryst Solids 353:1141–1149

Parikh A, Madamwar D (2006) Partial characterization of extracellular polysaccharides from cyanobacteria. Bioresour Technol 97:1822–1827

Marinho-Soriano E, Bourret E (2005) Polysaccharides from the red seaweed Gracilaria dura (Gracilariales, Rhodophyta). Bioresour Technol 96:379–382

Wang Y, Li C, Liu P, Ahmed Z, Xiao P, Bai X (2010) Physical characterization of exopolysaccharide produced by Lactobacillus plantarum KF5 isolated from Tibet Kefir. Carbohydr Polym 82:895–903

Morrison LR (1994) Glycerol. Encyclopedia of chemical technology. Wiley, New York, pp 921–932

Acknowledgments

The financial support for this research by CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico—Grant Number 486589/2013-7) and FACEPE (Fundação de Amparo a Ciência e Tecnologia do Estado de Pernambuco—Grant Number APQ-0227-1.06/11) is gratefully acknowledged. Tibério Vasconcelos was supported by a studentship from CAPES (Coordenação de Aperfeiçoamento de Pessoal de Ensino Superior), and Magali Amorim, Gabriel dos Santos and Priscilla Botelho were supported by a studentship from FACEPE. Luciano Avallone Bueno would like to thank the support of UFRPE (Universidade Federal Rural de Pernambuco), Rede Nordeste de Biotecnologia (RENORBIO) and Universidade de Sorocaba (UNISO).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

dos Santos, G.F., Locatelli, G.O., Coêlho, D.A. et al. Factorial design, preparation and characterization of new beads formed from alginate, polyphosphate and glycerol gelling solution for microorganism microencapsulation. J Sol-Gel Sci Technol 75, 345–352 (2015). https://doi.org/10.1007/s10971-015-3705-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3705-5