Abstract

External (in-air) Particle Induced Gamma-ray Emission (PIGE) setup of FOlded Tandem Ion Accelerator (FOTIA), Bhabha Atomic Research Centre (BARC) was utilized for determining concentrations of low Z elements (Si, Na, Al and F) in geological samples by a simple and novel sample preparation method using thin Mylar films to pack direct solid samples. Low energy proton beam was utilized and the current-normalized count rates of analytes were obtained using the count rate of tantalum, the beam exit window material. Meticulousness of the method was ascertained by analysing different CRMs and compared with conventional pelletisation method. Proposed method was adopted for elemental analysis in uranium ore samples for possible nuclear forensic applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chemical characterisation of geological matrices is important in various fields including nuclear forensics. Both destructive and non-destructive methods were adopted by chemists for their characterisation. The method that can analyse these samples non-destructively with accuracy is preferred especially for application in forensic science. Conventional spectroscopic methods are destructive in nature and required sample dissolution, elemental pre-concentration, radiochemical separation followed by estimation of elements. The most challenging process among these steps is the sample dissolution, especially in case of materials of geological origin. Routinely adopted sample dissolution methods are the conventional open vessel wet acid digestion followed by extraction with concentrated reagents, alkali fusion methods and microwave digestion methods. All these methods involve the usage of reagents to break the sample matrix and hence susceptible to reagent blank. Preparation and analysis of reagent blank is warranted in these dissolution procedures to tackle the actual elemental concentration in the samples since these elements may be present in the reagents in trace levels. Moreover, sample dissolution is carried out at high temperatures that may result in loss of volatile element of interest. This is more crucial in case of absorption, emission and mass spectrometric techniques where ultra-trace levels of elements are needed to be estimated. Hence the sample dissolution procedure should be stringent in case of destructive analysis. To overcome these setbacks, non-destructive methods for sample analysis is preferred. Nuclear analytical techniques like Neutron Activation Analysis (INAA), Particle Induced Gamma Emission (PIGE) and Particle Induced X-ray Emission (PIXE) are non-destructive in nature. In case of INAA, the interaction of neutrons with the element of interest in the target samples followed by measurement of the emitted characteristic delayed gamma rays from corresponding activation product by a High Purity Germanium detector (HPGe) are considered. In case of PIGE and PIXE, instead of neutrons, accelerated charged projectiles preferably proton or deuteron of a few MeV energy are bombarded onto the target samples and the emitting characteristic prompt gamma rays are quantified using an online HPGe detector simultaneously. INAA and PIXE methods are best suitable for high Z elements because of its higher sensitivities towards higher Z elements. PIGE technique using low energy proton beam (2–5 MeV) is used for quantifying low Z elements (typically, Z < 16), and medium energy proton beam (7–9 MeV) is used for quantifying medium to higher Z elements [1,2,3]. The conventional (in vacuum) PIGE setup at FOTIA, BARC is extensively used for quantification of low Z elements in geological, archaeological, and forensically important samples including glass and ceramics. Some of the typical applications utilising PIGE technique are listed in the references [4,5,6,7,8,9,10,11,12,13,14,15]. In case of geological samples, the conventional sample preparation is done by hydraulic pelletisation method. A suitable weight (typically, 200 mg) of finely powdered sample is homogenously mixed with cellulose along with an in-situ proton beam current normaliser (Li or F, ~ 2750 ppm). The mixture is then transferred to a hydraulic press and a force of about 2.5 tonnes is applied to confine the powdered sample into a disc shape pellet of 1 mm thickness and 20 mm diameter (Fig-1(A)). This pellet is then exposed to proton beam using particle accelerator and the prompt gamma rays from the elements are utilized for their quantification. The advantage of samples mixing in cellulose matrix is that it nullifies many parameters required for their quantification like stopping power/geometry effect. The selection criteria for the in-situ current normaliser element is that it should be absent in the sample and its current sensitivity should be high. In Nuclear Forensic point of view, estimation of metallic impurities could give insights about the source and chemical processing history of those confiscated nuclear materials which are out of regulatory control [16,17,18,19,20,21,22,23,24,25]. Though many analytical techniques are used for elemental composition analysis, non-destructive techniques find an edge over others. It will also be beneficial if the sample could be preserved after the elemental analysis as material evidence. One of the main advantages of non-destructive sample analysis is that the sample itself can be retained for further analysis or can even be presented as evidence when required by the law authorities.

Our study aims at developing a rapid methodology for non-destructive quantification of low Z elements (Si, Al, Na and F) in geological samples with least sample preparation. We have used thin Mylar films (a type of polyester film devoid of trace metals) to tightly pack the finely powdered geological samples of nearly 300 mg to expose to 3.75 MeV proton beam instead of using a pellet. Mylar films having an area of 25 cm2 and thickness of 25 μm were used for packing the samples. The characteristic prompt gamma rays were measured using an HPGe detector. The four elements namely Si, Al, Na and F were determined in all samples and geological reference materials using Ta as an external current normalizer by external PIGE method. The accuracy of results was confirmed by estimating Z-score with different certified/standard reference materials. The obtained results were also compared with the conventional PIGE method using sample pelletisation method.

Experimental

Materials

Certified reference materials (CRMs) USGS-G2, USGS-Syenite STM-1, NRCAN-REE-1 and NBS-SRM-1633a were analysed for quality assurance of the results. AR grade cellulose and Li2CO3 were obtained from Merck, India and used for making the sample pellets. The ore samples were obtained from Uranium Corporation of India Ltd (UCIL), Jharkhand, India. A jaw crusher was used to initially crush the samples to coarse aggregate. These coarse aggregates were then finely powdered in a ball mill and sieved with 75 µm pore size. Sieved samples were then ashed in a furnace at 450 oC to destroy moisture and organic matter (if any) and sealed in air tight containers until sample preparation.

Gamma-ray spectra were recorded using a liquid nitrogen cooled portable HPGe gamma detector having relative efficiency of 50 % and resolution of 2.0 keV at 1332 keV peak of 60Co coupled with an 8 k MCA. BARC developed PHAST software was used to analyse the spectra [26].

Sample preparation

About 25 cm2 sheets (weighing ~ 35 mg each) of Mylar were used to pack the samples. About 300 mg of finely powdered samples were taken in these sheets and tightly packed into a bulb shape (as shown in Fig-1(B)) and labelled after taping. The sample pellets were prepared in cellulose matrix as following for comparison of result. Constant amount of lithium (i.e. 2750 ppm) was added in these pellets to monitor the fluctuations in the proton beam current during experiment and to normalize the gamma spectrum for concentration calculation of element of interest in the targets. The mixture was then homogenously mixed manually with a mortar and pestle and later transferred to a 2.5 tonne hydraulic press to convert to disc shape (20 mm diameter and 1 mm thickness). CRMs were also prepared in Mylar films (USGS-G2, USGS-Syenite STM-1, NRCAN-REE-1 and SRM-1633a) and also as pellets (USGS CRM G2 and NRCAN-REE-1). Fig-1 represents the external (in air) PIGE setup installed at FOTIA, BARC. These samples were subjected to 3.75 MeV proton beam exposure for further analysis. Concordance of the results were ensured by replicate sample analysis.

External (in-air) PIGE setup

The experimental details of external (in-air) PIGE setup in Folded Tandem Ion Accelerator (FOTIA) installed at BARC were well explained in references [11,12,13,14]. The external PIGE experiment was carried out taking initial proton energy (5 MeV) from the accelerator with the terminal voltage of 2.5 MV. Briefly, 3 mm thick collimated proton beam is extracted to the air through a very thin tantalum window (25 μm) kept at the exit end of the stainless steel flange of vacuum chamber. The sample pellet as well as Mylar packed samples were placed in this end. All the targets including reference materials were irradiated with proton beam of 3.75 MeV energy (as calculated by SRIM 2010 software) [27]. The HPGe detector was kept at right angle with the proton beam direction and nearly 7 cm away from the sample (Fig-1). Necessary lead shielding was provided for minimising background radiation and human exposure. Typical sample exposure times were optimised in the range of 600 to 1800 s so that sufficient net peak areas were accumulated for better statistics. The samples were exposed and counted twice to ensure the reproducibility of results.

Concentration calculation using tantalum as an external current normaliser in external PIGE method

Comparative method was adopted for the estimation of elemental concentration in the samples. In case of absolute method, characteristics of proton beam like energy, intensity and proton current should be known and maintained. Accurate determination of these parameters is difficult to obtain. The benefit of comparative/relative method is that the accurate determination of beam parameters is not warranted. In the two methods adopted for elemental determination, the current normalized count rate of elements of interest is used for the concentration calculations. The count rate of Li (added as in-situ in case of pellet targets) and count rate of Ta (in case of direct sample in Mylar) were used as the current normalizer. The count rate for Li i.e. proton induced nuclear reaction of lithium, 7Li (p, p′γ) 7Li – 478 keV is utilised for elemental concentration estimation. In case of direct sample analysis, count rate of the Ta (used as exit window) acts as the current normaliser. Here the count rate of prompt gammas emitting from Ta window due to the 181Ta (p, p′γ) 181Ta – 136 or 165 keV is recorded for current normalisation.

In the comparative method, the ratio of count rates (cps) of element ‘i’ in sample and standard \(\left[\frac{{\text{R}}_{\text{s}\text{m}\text{p}}^{\text{i}}}{{\text{R}}_{\text{s}\text{t}\text{d}}^{\text{i}}}\right]\) is given by Eqn-1.

Where \({\text{C}}_{\text{s}\text{m}\text{p}}^{\text{i}}\) and \({\text{C}}_{\text{s}\text{t}\text{d}}^{\text{i}}\)are the concentration of element ‘i’ in the sample and standard respectively. ‘I0’denotes the beam current and \({\upxi }\) denotes the stopping power. Suffixes ‘smp’ and ‘std’ stand for sample and standard respectively.

In case of pelletised samples, matrix matching reference materials with almost similar elemental constituents are used for analysis. Since the samples and reference materials are diluted in the cellulose matrix uniformly, the stopping powers in sample and standard may be considered as similar and is nullified. The Eqn-1 can be written as,

The ratio of beam current need not be estimated in case of comparative/relative method of PIGE analysis. In this method, the possible current variation during the sample exposure, if any, is monitored by the count rate of in-situ current normaliser added to the sample matrix (Li in our study). Any such fluctuation in beam current, the sensitivity (count rate per unit mass of current normaliser) can be used to counteract. The ratio of sensitivities of current normaliser in sample and standard is proportional to the absolute beam current ratio in sample and standard. Sensitivity of current normaliser \(\left[{\text{S}}_{\text{s}\text{m}\text{p}}^{\text{L}\text{i}}\right]\) in the sample is defined according to Eqn-3.

\({[\left(\text{C}\text{P}{\text{S}}_{\text{L}\text{i}}\right)}_{\text{s}\text{m}\text{p}}]\) and \(\left[{\left({\text{C}}_{\text{C}\text{N}}^{\text{L}\text{i}}\right)}_{\text{s}\text{m}\text{p}}\right]\) are the count rate (cps) and concentration of Li (mg kg− 1) in the sample. Similarly the sensitivity of current normaliser in the standard \({[\text{S}}_{\text{s}\text{t}\text{d}}^{\text{L}\text{i}}]\) is also estimated.

The concentration of analyte ‘i’ in the sample is calculated using Eqn-4.

Where, \({[\text{C}}_{\text{s}\text{t}\text{d}}^{\text{i}}]\)is the concentration of element ‘i’ in the standard (mg kg− 1).

In case of direct sample analysis, the current normaliser, Ta is fixed externally to sample and standard. As the concentration of Ta is the same, the ratio of count rates of gamma line of 136 keV would be sufficient for current normalisation. As the amount, matrix and major elemental constituents of sample and reference material are similar and the packing of samples in Mylar is tight, it can be assumed that the packing are thick and uniform to proton beam. The elemental concentration was estimated using Eqn-5.

\({[\text{R}}_{\text{s}\text{t}\text{d}}^{\text{T}\text{a}}]\) and \(\left[{\text{R}}_{\text{s}\text{m}\text{p}}^{\text{T}\text{a}}\right]\) are the count rates (cps) of Ta, 136 keV gamma line (window material of PIGE setup) in standard and sample respectively.

Results and discussion

Standardisation and quality control of the proposed Mylar method

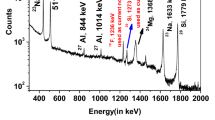

Table-1 summarises some of the physical characteristics of PIGE reactions relevant to our study. The concentration of elements in the samples were estimated using the following reactions, 29Si (p, p′γ) 29Si – 1273 keV, 28Si (p, p′γ) 28Si – 1779 keV, 27Al (p, p′γ) 27Al – 1014 keV, 23Na (p, p′γ) 23Na – 441 or 1636 keV, 19 F (p, p′γ) 19 F – 197 keV. Fig-2(A) and Fig-2(B) depicts a typical PIGE spectrum of a pelletised reference standard USGS-G2 irradiated in 3.75 MeV proton beam of FOTIA, BARC and the gamma spectrum of the same reference standard packed in Mylar sheet irradiated for almost the same period of time. The detection limits of elements (F, Na, Mg (585 keV), Al and Si in mg g− 1) estimated as described elsewhere [11] were 0.08, 0.4, 6.0, 1.3 and 2.0 respectively.

In case of pelletised samples, the current normalisation was carried out using Li added in-situ to the pellet utilising the reaction 7Li (p, p′γ) 7Li – 478 keV. The concentration of elements (Si, Al, Na and F) were estimated using Eqn-4. For Si, the concentrations determined by both 1273 and 1779 keV energies were in good agreement and the reported result was calculated using 1779 keV. Current normalisation in Mylar packed samples were estimated using the proton reaction 181Ta (p, p′γ) 181Ta – 136 keV, and the concentration of elements were calculated using Eqn-5. In case of external PIGE, the proton reaction of 181Ta results in two prompt gamma emissions, 136 and 165 keV. The ratio of count rates of 181Ta gammas [\(\frac{\text{C}\text{P}{\text{S}}_{136\text{k}\text{e}\text{V}}}{\text{C}\text{P}{\text{S}}_{165\text{k}\text{e}\text{V}}}]\) in the samples were in the range of 4.2 to 4.5. Hence any of the count rates of two gamma lines of 181Ta can be used for proton current normalisation. In present work, 136 keV gamma line from 181Ta was used for the concentration calculation due to better counting statistics.

Table-2 and Table-3 summarise the estimation of elemental concentration (± 2σ), deviation from the certified value and the Z-score (estimated using Eqn-6).

Where \({\upmu }\) and \(\stackrel{-}{\text{x}}\) are the mean certified concentration of element in CRM and experimentally estimated concentration respectively. [\({\text{U}}_{\text{C}\text{R}\text{M}}]\) and \(\left[{\text{U}}_{\text{e}\text{x}\text{p}}\right]\) denotes the certified and experimentally measured uncertainties (± 2σ) in CRM respectively.

The absolute deviation of elemental concentration estimated using Mylar package analysis were in the range of 0.3 to 4.4 % for both CRMs (USGS-G2 and NRCAN-REE-1). The corresponding deviation in estimated elemental concentrations using conventional in-situ current normalisation method varied from 0.03 to 4.1 %. The Z-scores for the standardised Mylar packing method and in-situ pelletisation methods were ≤ 2.2, indicating good accuracy for the newly adopted method.

Table-4 summarises the concentration estimation of elements in CRMs USGS-Syenite-STM-1 and SRM-NBS-1633a using Mylar packing. In case of NBM-SRM-1633a, the declared uncertainty does not specify the confidence level, hence it was assumed that the declared uncertainties are 95% for estimating Z-score. The Z-scores estimated using Eqn-6 for elemental concentration were ≤ 1.8. The results strongly indicate the feasibility of external in-air PIGE analysis using Mylar packing for rapid and accurate determination of low Z elements in case of geological materials, as compared to the conventional in-situ pelletisation method.

Application of proposed method for estimation of low Z elements in powdered ore samples for forensic applications.

Fig-3(A) depicts a typical gamma spectrum of powdered ore pellet sample irradiated in PIGE setup and Fig-3(B) portrays the gamma spectrum of the same ore sample packed in Mylar sheet and irradiated for almost same period of time as that of pelletised sample. Table-5 summarises the comparison of estimated concentrations of four elements in mg g− 1 (± 2σ) (Si, Al, Na and F) in five different powdered ore samples by the new developed method as well as conventional pelletisation method. The concentrations estimated were well agreeing with each other. The result confirms feasibility of the newly developed method of packing finely powdered geological samples in Mylar films, showing it can well be used for the estimation of low Z elements in place of conventional cellulose pelletisation method, thereby avoiding lengthy sample preparation methods. Small sample size requirement and its non-destructive nature are more advantageous for this developed method which can be utilised in nuclear forensic applications.

Conclusion

The external (in-air) PIGE setup of FOTIA, BARC was used to develop a rapid, non-destructive and simultaneous multi-elemental analytical method for the estimation of concentration of low Z elements in geological samples (Si, Al, Na and F). Finely powdered geological samples were tightly packed in thin Mylar films (~ 25 cm2). The samples were irradiated in 3.75 MeV proton beam with a current of 10-15 nA. The developed method utilised the external Ta window installed in the PIGE setup as proton current normaliser. The relative method of analysis was used for the estimation of elemental concentration. The new method was also compared with the conventional pelletisation method which utilises added in-situ (Li) as current normaliser. The accuracy of the new method was ascertained by analysing matrix and constituent identical certified/standard reference materials. The Z-scores of the new procedure was ranged from 0.2 to 2.2 indicating good accuracy of the method. Average observed deviation from the certified value obtained for concentration estimation of low Z elements using Mylar packing was 3.3 %. The proposed method was also adopted for the estimation of elemental concentration of low Z elements in few ore samples and the results were compared with conventional cellulose pelletisation method. The concentrations of elements estimated by both methods were in good agreement. The developed method can be used for a rapid determination of low Z elements in geological samples like ore samples for possible forensic applications. In Nuclear Forensic view point, the low Z elements in the confiscated material could provide an insight of its provenance and the chemical procedure. Since the method is non-destructive, it is an added advantage that the analysed samples could be retained for future use or could be produced before law enforcing authorities if needed.

References

Räisänen J, Witting T, Keinonen J (1987) Absolute thick-target γ-ray yields for elemental analysis by 7 and 9 MeV protons, Nucl Instrum Methods Phys Res B 28(2):199–204. DOI:https://doi.org/10.1016/0168-583x(87)90105-4

Volfinger M, Robert J L (1994) Particle-induced-gamma-ray-emission spectrometry applied to the determination of light elements in individual grains of granite minerals. J Radioanal Nucl Chem 185:273–291. DOI:https://doi.org/10.1007/bf02041301

Valković O, Jakšić M, Fazinić S, Valković V, Moschini G, Menapace E (1995) Quality control of PIXE and PIGE nuclear analytical techniques in geological and environmental applications. Nucl Instrum Methods Phys Res B 99:372–375. DOI:https://doi.org/10.1016/0168-583X(95)00230-8

Chhillar S, Acharya R, Pai R V, Sodaye S, Mukerjee S K, Pujari P K (2012) A simple and sensitive particle induced gamma-ray emission method for non-destructive quantification of lithium in lithium doped Nd2Ti2O7 ceramic sample. J Radioanal Nucl Chem 293:437–441. DOI: https://doi.org/10.1007/s10967-012-1764-4

Dasari K B, Chhillar S, Acharya R, Ray D K, Behera A, Lakshmana Das N, Pujari P K (2014) Simultaneous determination of Si, Al and Na concentrations by particle induced gamma-ray emission and applications to reference materials and ceramic archaeological artifacts. Nucl Instrum Methods Phys Res B 39:37–41. DOI:https://doi.org/10.1016/j.nimb.2014.08.017

Srivastava A, Chhillar S, Singh D, Acharya R, Pujari P K (2014) Determination of fluorine concentrations in soil samples using proton induced gamma-ray emission. J Radioanal Nucl Chem 302:1461–1464. DOI:https://doi.org/10.1007/s10967-014-3661-5

Chhillar Sumit, Acharya R, Tripathi R, Sodaye S, Sudarshan K, Rout P C, Mukerjee S K, Pujari P K (2015) Compositional characterization of lithium titanate ceramic samples by determining Li, Ti and O concentrations simultaneously using PIGE at 8 MeV proton beam. J Radioanal Nucl Chem 305:463–467. DOI:https://doi.org/10.1007/s10967-015-4037-1

Tamilarasu S, Velraj G, Ray D K, Acharya R (2016) Chemical analysis of archaeological clay potteries by PIGE and PIXE methods using proton beams from tandem accelerator for provenance study. J Radioanal Nucl Chem 310:363–370. DOI:https://doi.org/10.1007/s10967-016-4842-1

Chhillar S, Acharya R, Mishra R K, Kaushik C P, Pujari P K (2017) Simultaneous determination of low Z elements in barium borosilicate glass samples by in-situ current normalized particle induced gamma-ray emission methods. J Radioanal Nucl Chem 312:567–576. DOI:https://doi.org/10.1007/s10967-017-5251-9

Acharya R, Pujari P K (2019) Potential of conventional and internal monostandard NAA and PGNAA and PIGE in forensic sciences: An overview. Forensic Chem 12:107–116. DOI:https://doi.org/10.1016/j.forc.2018.01.002

Sharma V, Acharya R, Hemlata K, Bagla, Pujari P K (2021) Standardization of an external (in-air) PIGE methodology using tantalum as a current normalizer in conjunction with INAA for rapid and non-destructive chemical characterization of “as-received” glass fragments towards forensic applications. J Anal At Spectrom 36:630–643. DOI: https://doi.org/10.1039/d0ja00482k

Sharma V, Acharya R, Samanta S K, Goswami M, Bagla H K, Pujari P K (2019) Chemical characterization of soda-lime glass samples by in-situ current normalised PIGE and conventional INAA methods for forensic applications. J Radioanal Nucl Chem 323:1451–1457. DOI:https://doi.org/10.1007/s10967-019-06926-7

Samanta S K, Sengupta A, Ghorui S, Acharya R, Pujari P K (2022) The standardization and application of an external (in air) particle induced gamma emission (PIGE) method for the rapid and non-destructive quantification of light elements at major to trace concentrations in coal, bottom ash and coke samples. J Anal At Spectrom 37:296–305. DOI:https://doi.org/10.1039/D1JA00309G

Wasim Raja S K, Vishal Sharma, Samanta S K, Acharya R, Tammana S R C, Murthy S, Majumdar, Pujari P K (2022) Development of an innovative external (in air) Particle Induced Gamma-ray Emission method for rapid non-destructive determination of isotopic composition of boron in “As received” boron based ceramic neutron absorbers. Anal Chim Act 1202:339686 DOI:https://doi.org/10.1016/j.aca.2022.339686

Sharma V, Sarkar A, Acharya R, Bagla H K, Pujari P K (2022) Utilization of accelerator and reactor based nuclear analytical techniques for chemical characterization of automobile windshield glass samples and potential of statistical analyses using trace elements towards glass forensics. Forensic Sci Int 334:111262. DOI:https://doi.org/10.1016/j.forsciint.2022.111262

Rosenberg R J, Zilliacus R (1993) Determination of impurities in nuclear fuel element components by neutron activation analysis. J Radioanal Nucl Chem Articles 169(1):113–124. DOI: https://doi.org/10.1007/bf02046789

Oliveira Junior O P, Sarkis J E S (2002) Determination of impurities in uranium oxide by inductively coupled plasma mass spectrometry (ICPMS) by the matrix matching method. J Radioanal Nucl Chem 254(3):519–526. DOI: https://doi.org/10.1023/a:1021642122066

Varga Zsolt,Wallenius Maria, Klaus M, Elizabeth K, Millet Sylvain (2009) Application of Lead and Strontium Isotope Ratio Measurements for the Origin Assessment of Uranium Ore Concentrates. Anal Chem 81:8327–8334. DOI:https://doi.org/10.1021/ac901100e

Keegan E, Richter S, Kelly I, Wong H, Gadd P, Kuehn H, Adolfo Alonso-Munoz (2008) The provenance of Australian uranium ore concentrates by elemental and isotopic analysis. Appl Geochem 23:765–777. DOI:https://doi.org/10.1016/j.apgeochem.2007.12.004

Keegan Elizabeth M, Wallenius K, Mayer Z, Varga G Rasmussen (2012) Attribution of uranium ore concentrates using elemental and anionic data. Appl Geochem 27:1600–1609. DOI: https://doi.org/10.1016/j.apgeochem.2012.05.009

Keegan Elizabeth, Kristo Michael J, Colella Michael, Robel Martin, Williams Ross, Lindvall Rachel, Eppich Gary, Roberts Sarah, Borg Lars, Gaffney Amy, Plaue Jonathan, Wong Henri, Davis Joel, Loi Elaine, Reinhard Mark, Hutcheon Ian (2014) Nuclear forensic analysis of an unknown uranium ore concentrate sample seized in a criminal investigation in Australia. Foren Sci Int 240:111–121. DOI: https://doi.org/10.1016/j.forsciint.2014.04.004

Kristo Michael Joseph, Keegan Elizabeth, Colella Michael, Williams Ross, Lindvall, Rachel, Eppich Gary, Roberts Sarah, Borg Lars, Gaffney Amy, Plaue Jonathan, Knight Kim, Loi Elaine, Hotchkis Michael, Moody Kenton, Singleton Michael, Robel Martin, Hutcheon Ian (2015) Nuclear forensic analysis of uranium oxide powders interdicted in Victoria, Australia. Radiochim Acta 103(7):487–500. DOI: https://doi.org/10.1515/ract-2014-2363

Kristo Michael J, Gaffney Amy M, Marks Naomi, Knight Kim, Cassata William S, Hutcheon Ian D (2016) Nuclear Forensic Science: Analysis of Nuclear Material Out of Regulatory Control. Annu Rev Earth Planet Sci 44:555–579. DOI: https://doi.org/10.1146/annurev-earth-060115-012309

Balboni Enrica, Nina Jones, Tyler Spano, Antonio Simonetti, Burns Peter (2016) Chemical and Sr isotopic characterization of North America uranium ores: Nuclear forensic applications. Appl Geochem 74:24–32. DOI:https://doi.org/10.1016/j.apgeochem.2016.08.016

Apostol A I, Pantelica A, Ortega-Feliu I, Marginean N, Sima O, Straticiuc M, Jimenez-Ramos M C, Fugaru V (2017) Ion beam analysis of elemental signatures in uranium dioxide samples: importance for nuclear forensics. J Radioanal Nucl Chem 311:1339–1346. DOI:https://doi.org/10.1007/s10967-016-5136-3

Mukhopadhyay P K (2001) The operating software of the PHAST PC-MCA card, Proc. of Symposium on Intelligent Nuclear Instrumentation (INIT-2001), Mumbai, India, 307–310.

James Ziegler F, Ziegler M D, Biersack J P (2010) SRIM – The stopping and range of ions in matter. Nucl Instrum Methods Phys Res B: Beam Interact Mater At 268(11–12):1818–1823. DOI:https://doi.org/10.1016/j.nimb.2010.02.091

Acknowledgements

The authors would like to thank Dr. D K Aswal, Director, HS&EG, BARC, Dr. P K Pujari, Former Director, RC&IG, BARC, Head, RCD, Head, RSSD and Head, EMAD for their support and encouragements. Authors thank FOTIA operation members, OIC, FOTIA, Head, FOTIA, Section and AD, MRG and Head, IADD, BARC for their support during experiment.

Author information

Authors and Affiliations

Ethics declarations

Conflict of interest

The authors have no conflicts of interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ravi K, P., Sreejith, S.R., Mishra, S. et al. Development of a simple non-destructive method to quantify low Z elements in ore samples using tantalum as an external current normalizer in external (in-air) PIGE method for Nuclear Forensic applications. J Radioanal Nucl Chem 331, 4369–4376 (2022). https://doi.org/10.1007/s10967-022-08506-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08506-8