Abstract

This paper discusses the development of a separation method for isolation of 171Tm from a half-gram irradiated erbium target in support of stockpile stewardship and astrophysics research. The developed procedure is based on cation exchange separation using alpha-hydroxyisobutyric acid (α-HIBA) as chelating agent. It is able to achieve either a decontamination factor of 1.4(4) × 105 with 68.9(3) % recovery or 95.4(3) % recovery with a decontamination factor of 5.82(7) × 103 for a mock 500-mg target containing 17.9 mg thulium in a single pass-through at room temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thulium has been used as a diagnostic tracer in some nuclear weapon experiments [1]. By measuring the products of neutron induced reactions on radiochemical tracers in the samples collected after detonation, the differential performance of the device could be determined [2]. This data was used to develop and verify computer simulations of the events. The accuracy of results obtained by the codes depends heavily on the accuracy of the neutron capture cross section data used [1]. Since the end of underground nuclear testing in 1992, computer simulations have become much more important [3]. In astrophysics, 171Tm is also a branching point in the s-process of nucleosynthesis [4]. At branching points (radioactive isotopes lying close to the valley of stability with half lives on the order of one to few years) neutron capture competes with beta decay and such points can provide the most information on the burning process [1, 5]. Measurement of the neutron capture cross section of 171Tm can therefore provide better insight into physical processes in stars and nuclear devices.

171Tm is a radioisotope with a half-life of 1.92 years that is not present in nature. It can be produced in a high-flux nuclear reactor by neutron irradiation of 500 mg of isotopically enriched 170Er. When 170Er captures a neutron, it turns into 171Er, which beta decays to 171Tm with a half-life of 7.52 h. Assuming a neutron flux of 2 × 1015 n cm−2 s−1 and about 50 days of irradiation, the irradiated material will still contain 27 times more erbium than thulium [6]. The produced 171Tm must be separated from the unreacted 170Er to fabricate a 171Tm target for the cross section measurement. For accurate cross section determination, the 171Tm used must have 99 % or greater purity. The separation of Tm from Er is challenging, especially on the preparative scale, due to the physical and chemical similarities of the two elements. Due to the shielding of the 4f orbital by the 6s and 5d orbitals, both thulium and erbium only exist in the trivalent oxidation state in solution, and their ionic radii are very similar. To meet the purity requirement and due to the high cost of enriched 170Er, a highly selective and efficient separation is needed.

Lanthanide separations on the analytical scale have been extensively studied in the past and several review articles cover the topic [7–11]. However, on the semi-preparative and preparative scale (hundreds of μg to g) only a small number of publications exist. Most of them deal with separation of similar masses of lanthanides [12, 13]. There are no publications on the one-step separation of few milligrams of a lanthanide from hundreds of milligrams of its immediate neighbor. If samples fall into this range, they are generally divided into subsamples or only a fraction of them is processed [14–16]. A few of these articles deal with activated targets [13–16]. Larger, industrial scale, preparative lanthanide separations use counter current solvent extraction and/or ion exchange chromatography on industrial scale columns. They cannot be applied directly to the relatively “small” amounts of interest for this work without scaling them down nor are details on their process parameters available publicly.

Without a complexing agent, the rare earth elements are strongly retained on cation exchange resins. Lanthanides with smaller ionic radii (and therefore larger charge density) form stronger complexes with ligands and elute first from the column. α-HIBA was first used in lanthanide separations in 1956, and is still the most effective reagent overall [10]. For the separation of specific lanthanide pairs other complexing agents may however be more useful [8, 17]. Gharibyan [18] tested five different chelating agents for the separation of the thulium-erbium pair on the analytical scale and concluded that α-HIBA provided the best resolution. Therefore use of cation exchange resin and α-HIBA as chelating agent were chosen for this work, because eluting thulium before erbium minimizes the loss of the 171Tm product and maximizes the achievable decontamination factor.

The goals of this study were to (1) scale up the optimized analytical-scale separation of Gharibyan et al. [18] to allow a single pass-through separation of a full 500-mg Er target with a decontamination factor of at least 2700, (2) develop a separation of lanthanides from the chelating agent, and (3) verify that the amount of erbium in the collected fraction is less than 1 %. In this paper the results of these experiments are presented, showing that the procedure will allow collection of 171Tm that exceeds the purity requirements for the cross section measurement. Throughout this study inactive mock targets were used.

Prior to this work two attempts were made to measure the neutron capture cross section of 171Tm in the last two decades. In both cases 171Tm was produced the same way as described previously. Miller et al. [14] successfully separated 171Tm from a 500-mg Er target by dividing it after dissolution into ten 2-mL samples containing 50 mg target material each. The samples were passed through a 1 × 25 cm2 AG50x8 column three times followed by further purification on a 1 × 25 cm2 Capcell SCX column prior to target fabrication. The separation used a gradient of α-HIBA (0.07–0.40 M, pH 5.65) and it was performed at 80 °C for better resolution. Unfortunately the time-of-flight (TOF) cross section measurement had serious background issues [19]. After a better detector, the Detector for Advanced Neutron Capture Experiments (DANCE), was built at Los Alamos Neutron Science Center (LANSCE), Schwantes et al. [15] attempted the separation of a 250 mg target that had a less favorable 1:167 thulium:erbium ratio at the time of separation. They used a Dionex CG3 guard + CS3 analytical column system. Both columns were filled with CS3 resin. The guard column was 0.4 cm in diameter and 5 cm long, while the analytical column was 0.4 cm in diameter and 25 cm long. The mobile phase consisted of 0.1 M α-HIBA at pH 3.6. The sample was dissolved in 30 mL 0.5 M HCl and many separations, with 1 mL sample injected at a time, were performed to process all of the material. After separation from the chelating agent, a chromophore was used to detect the lanthanides using a UV/VIS spectrophotometric detector. The samples were passed through the system two more times for a total of three times at room temperature. The resulting thulium fraction contained 95 % thulium and 5 % erbium, and the Tm fraction was contaminated with significant amounts of stable 169Tm, which made an accurate neutron capture cross section measurement impossible.

Experimental

Reagents

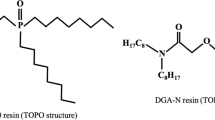

Glacial acetic acid (99.99+ %; Sigma-Aldrich and Optima; Fisher Scientific), ammonium hydroxide (99.99+ %; Sigma Aldrich and ACS Plus; Fisher Scientific), lithium hydroxide monohydrate (98.0+ %; Sigma Aldrich), sodium hydroxide (ACS; VWR International), potassium hydroxide (ACS; VWR International), rubidium hydroxide (99 % metals basis; Alfa Aesar), cesium hydroxide (99.9 %; Strem Chemicals), nitric acid (Baseline; Seastar Chemicals and Optima; Fisher Scientific), hydrochloric acid (Optima; Fisher Scientific), α-HIBA (99 %; Aldrich), 4-(2-pyridylazo)resorcinol monosodium salt monohydrate (PAR; ≥98 %; Sigma-Aldrich and >95 %; Dionex), a post-column reagent that allows spectrophotometric detection of lanthanides, erbium powder (99.9 % metal basis,~40 mesh; Aldrich), thulium powder (99.9 %, ~40 mesh; Aldrich), erbium oxide (99.99 %; Spex Industries) and thulium oxide (99.99 %; Research Chemicals) were used as received. All water used for the dilutions had a resistivity of >18 M Ω cm and was prepared by further purifying in-house deionized water using either a Barnstead E-pure Ultrapure Water Purification System or a Barnstead Nanopure Life Science UV/UF Ultrapure Water Purification System. The metals were dissolved in 1 M HNO3, carefully evaporated to dryness and the residue was dissolved in the desired concentration of HNO3. The oxides were dissolved in 15 mL of 6 M HCl and 0.5 mL of concentrated HNO3 mixture, evaporated to dryness, and then converted to nitrate form by evaporating and re-dissolving it three times in concentrated HNO3. After the final evaporation, it was taken up in the desired concentration of HNO3. To avoid decomposition of the residue to the oxides, evaporations were performed slowly while a constant flow of filtered in-house air was passed over the sample. Calibration of the inductively coupled plasma atomic emission spectrometer (ICP-AES; Shimadzu ICPE-9000) was performed using appropriate dilutions of an Alfa Aesar Specpure lanthanide/rare earth metals plasma standard solution Sc–Lu @ 100 μg/mL (Stock #: 14651) to obtain solutions with concentrations of 10 ppb, 100 ppb, 1 ppm and 10 ppm. AG50W-X8 cation exchange resin (200–400 mesh (37–74 μm), Bio-Rad Laboratories) and Dionex CS3 resin (10 μm) in pre-packed column from Dionex were used for the separations. For the separation of the lanthanides from α-HIBA, branched DGA resin (N,N,N′N′-tetrakis-2-ethylhexyl diglycolamide; Eichrom Technologies) was used. 0.4 M α-HIBA and 0.2 mM PAR solutions were prepared fresh daily according to a published method [20] with the exception of the pH adjustment of α-HIBA, for which LiOH was substituted with other hydroxides in some cases. When hydroxides other than LiOH were used, the pH of the solution was measured using a Piccolo Plus pH meter (Hanna Instruments, calibrated using pH 4.00 and 7.00 buffer solutions from VWR) while the hydroxide was added until the desired pH was reached. The eluent was either diluted from the 0.4 M α-HIBA solution or prepared fresh by using the appropriate amount of α-HIBA. Both α-HIBA and PAR solutions were filtered through 0.45 μm Nalgene cellulose nitrate filter and degassed by sonication prior to use.

Equipment

HPLC

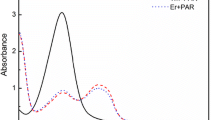

Two systems were used in this project. Experiments at the University of Nevada, Las Vegas (UNLV) were performed using a Dionex ICS-3000 with both isocratic (0–3 mL min−1) and gradient (0–10 mL min−1) pumps connected to a Dionex AS40 autosampler capable of delivering 0.5 or 5-mL samples, a Dionex PDA-100 photodiode array detector and a Dionex AXP pump (0–10 mL min−1) used for post column reagent delivery. The system was equipped with either a 25-μL or a 2-mL sample loop. The samples were filtered through either the 20-μm filter built into the cap of the Dionex PolyVial sample vials or a Pall 0.45-μm GHP syringe filter. The syringe filter was used in conjunction with manual sample loading for samples containing over 100 mg lanthanides to conserve sample. The effluent stream was split using a modified analytical scientific instruments (ASI) variable make-up flow splitter (690-PO10-50). Splitting is necessary as the flow cell in the detector cannot handle the higher flow rates used for the preparative separation as well as the high concentrations of lanthanides. The system used at Los Alamos National Laboratory (LANL) was assembled for this work using an Alltech 627 preparative HPLC pump (0–100 mL min−1), a Rheodyne Model 7000L two-position, six-port high-pressure switching valve, a 2-mL sample loop, an ASI custom-ordered variable make-up flow splitter (split ratio variable between 1:33 and 1:464), a Dionex AD25 UV–VIS spectrophotometric absorbance detector and for PAR delivery, an Eldex Labs Inc. Model B-100-S precision metering pump or a Dionex GP50 gradient pump in isocratic mode. The samples were filtered through a 0.2 μm Nalgene cellulose acetate syringe filter prior to injection. Both systems were connected to computers running the Dionex Chromeleon 6 software for data collection. The same columns, a Dionex preparative CS3 (2.2 × 25 cm2) and a 2.54 × 25 cm2 MODcol flanged stainless-steel column packed with the AG50W-X8 resin were used. The 2.2 cm diameter, 25 cm long preparative IonPac CS3 has an exchange capacity of 0.9 meq/column (calculated based on the capacity of the analytical IonPac CS3 column [21]), while the column filled with the BioRad resin has a much higher exchange capacity of 215 meq (calculated based on the 1.7 meq/mL wet capacity of the resin [22]). Since lanthanides have either no absorption in the UV/VIS region or their molar absorptivities are too low to be usable for detection, a chromophore PAR was used to enable detection [7, 10]. After post column derivatization, the Ln-PAR complex was detected between 510 and 520 nm (516 nm provided the greatest change in absorbance).

FT-IR

A Thermo Scientific Nicolet Fourier transform infrared (FT-IR) spectrometer equipped with an attenuated total reflectance (ATR) accessory was used to determine if α-HIBA was still present in the purified fractions using the carbon–hydroxyl stretching vibration (ν C–OH) at 1182 cm−1.

ICP-AES

A Shimadzu ICPE-9000 multitype ICP emission spectrometer was used to measure erbium and thulium individually in the collected fractions from the chromatographic separation.

Column packing

AG50W-X8 200–400 mesh (74–37 μm) resin was suspended in water, and the finest resin beads were decanted off several times, until no more fines were left. The particle size distribution of the resin was determined before filling the column by imaging 220 particles using SEM and analizing the resulting images. The distribution is skewed with a mean of 58 μm and a sharp cut off on the low particle size side at 50 μm with only 1.4 % of the particles below that. The bottom plate of the column was assembled with the outlet plugged. Resin suspended in water was poured into the column until the cavity was filled. As the resin settled, the clear supernatant was removed using a transfer pipette and replaced with more slurry. This was repeated until the column was completely full. Then it was assembled and water was pumped through from top to bottom at high flow rates. Tubing with a small internal diameter was connected to the outlet to further increase the pressure above the pressures expected during normal operation. After two hours, the column was opened on the top for inspection. If void space above the resin bed was observed, additional resin slurry was added. This was repeated until absolutely no void volume was observed. Then the column was washed with 1 L of 1 M α-HIBA (pH 5.6–5.7), and opened and topped off with resin suspended in 1 M α-HIBA (pH 5.6–5.7). The resin shrinks somewhat in α-HIBA compared to its volume in water. Some extra resin was added to form a convex surface and the column was closed. At this point the column was ready to use, but it was periodically opened, inspected and topped off with 1 M α-HIBA (pH 5.6–5.7) suspended resin if any void volume was observed.

Scale-up of separation

Scale up was begun by replacing the 4 mm diameter, 250 mm long analytical column (used by Gharybian et al. [18]) with the 22 mm diameter 250 mm long preparative column. Other parameters such as sample loop size (25 μL), sample matrix (5 wt% HNO3) temperature (room temperature), eluent composition (0.056 M α-HIBA at pH 4.63 prepared using LiOH) or resin (Dionex CS3) were not changed. When scaling up a separation from a smaller to a larger diameter column, the linear flow rate should be kept the same to get the same retention times on the new column.

Using Eq. (1) to calculate the flow rate for the preparative CS3 column (\(\dot{V}_{2}\)) using the radii of the two columns (\(r_{1} , r_{2}\)) and the 1.2 mL min−1 flow rate from the analytical scale separation (\(\dot{V}_{1}\)) a result of 36.3 mL min−1 is obtained. This exceeds the capabilities of the Dionex ICS-3000 instrument used at the time, therefore the maximum flow rate of 10 mL min−1 was used as the starting point for the experiments on the preparative column. The ratio of the flow rates of the eluent to post column reagent was kept the same. During the preparative scale experiment and no guard column was used.

Although multiple authors reported improved separation at elevated column temperatures (e.g., [14]), the tests for this study were conducted at room temperature. The irradated erbium target will be highly radioactive and require handling in a hot cell. It was therefore decided to perform the separation at room temperature in order to keep the procedure as simple as possible.

During scale up, the flow rate, concentration and pH of the eluent, as well as the hydroxide used to set its pH were varied to improve the separation or save reagents. The resin was changed from Dionex CS3 to BioRad AG50W-X8 due to its higher capacity. The size of the sample loop was also increased to 2 mL to allow introduction of 500 mg lanthanides in a single injection and the nitric acid concentration of the injected sample was decreased to reduce the thickness of the band in which the lanthanides initially adsorb on the resin and therefore improve the separation.

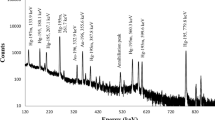

Purification of the lanthanides from α-HIBA

In addition to the ICP-AES measurement (carbon deposit on torch) employed during method development, α-HIBA would also cause interference with the manufacturing of the DANCE target (lowers efficiency of molecular plating) and therefore must be removed from the Tm fraction collected during chromatographic separation. A resin that can retain the lanthanides in high concentrations of HNO3, where the α-HIBA is protonated and does not complex the lanthanides, and allows elution of lanthanides in low acid concentrations, making it easy to adjust the sample matrix for further processing is desirable. There are four extraction chromatographic resins (TRU, RE, normal and branched DGA) from Eichrom Technologies that meet these criteria. Branched DGA was selected based on its published k′ values [23]. Both types of DGA resins show higher retentions than TRU or RE for trivalent lanthanides, and branched DGA has lower retention than normal DGA, making it less likely to cause elution problems. During the final full-scale separation, twelve 178-mL fractions across the Tm peak and over the beginning of the Er peak were collected. Each fraction was spiked with ~700 Bq 171Tm and acidified to 8 M HNO3. BioRad Poly-Prep columns with a diameter of 0.8 cm and a length of 4 cm were filled up to the 1.8-mL mark with branched-DGA resin wetted with 1.9 M HNO3 (0.1548 mmol capacity [23]) and preconditioned with 8 mL of 8 M HNO3. The fractions were each loaded onto a column, then the columns were washed with 20 mL of 8 M HNO3, followed by stripping of the lanthanides with 17 mL of 0.01 M HNO3. The strip solutions were gamma counted on a HPGe detector to determine the amount of lanthanide recovery. In addition, two of them were analyzed for α-HIBA using FT-IR.

Verification of purity and recovery

The amount of erbium and thulium in the collected fractions were determined by ICP-AES. Each sample was diluted ten, hundred, and thousand fold following the branched-DGA column purification. Dilutions were measured three times from the most to the least dilute until an intensity over 10,000 counts was recorded. Results from the least dilute sample measured were averaged and reported. Thulium was detected at 313.126 nm, while erbium was measured at 337.271 nm.

Separation resolution (R s)

The separation resolution for Gaussian peaks is usually defined as the difference in the retention times over the sum of the full width of the peaks at either the half of the peak height (FWHM) or at the base of the peaks. However, in the case of this work, the shape of the peaks was not Gaussian. In order to better represent the ability of the separation to obtain a pure thulium fraction, the resolution was redefined as the difference in the retention times of thulium (t R,Tm) and erbium (t R,Er) over the sum of the full width of the thulium peak (w Tm, FWTM) and the left width of the erbium peak (w l,Er) both at 10 % peak height. The 10 % height was selected because due to tailing and overlapping of the peaks and drifting of the baseline in some cases the base width could not be determined reproducibly and the FWHM contains less information on the extent of the tailing than other widths much closer to the baseline.

More details on the definition of the separation resolution can be found in the work of Gharibyan et al. [18].

Results and discussion

Scale-up of separation

The optimized analytical scale separation of 25 μL 10 ppm Tm and 100 ppm Er sample in 5 % HNO3 at 25 °C (eluent of 0.056 M α-HIBA at pH 4.63 at 1.2 mL min−1 flow rate using Dionex GC3 4 mm diameter, 50 mm long and CS3 4 mm diameter, 250 mm long columns connected in series and mixing the effluent with 0.65 mL min−1 PAR solution [18]) was scaled-up to separate 0.5 g sample in a single pass through. Using the same eluent concentrations on the 22 × 250 mm2 preparative CS3 column at 10 mL min−1 eluent and 5 mL min−1 PAR flow rate, the amount of total lanthanide injected was increased stepwise from 72 to 718 μg/injection; the Tm:Er ratio was kept constant at 1:27. As expected, the resolution and retention times decreased with increased loading of the column. To improve the separation, the same study was repeated at lower eluent flow rate of 3 mL min−1. Again, the resolution decreased with higher mass loading, but there was a much more significant change in resolution compared to the higher flow rate separation, providing much better separation at low mass, but only a slight improvement at high mass loading (see Fig. 1). At the same time the higher flow rate yielded shorter separation times.

Next, the effect of different hydroxides used to adjust the pH of the eluent was studied by performing a series of seperations of 10.3 μg Tm from 277 μg Er in 25 μL 5 % nitric acid on the preparative CS3 column using 0.056 M α-HIBA eluent adjusted to pH 4.63(3). The effect of the following bases for pH adjustment was investigated: LiOH, NaOH, KOH, RbOH, CsOH and NH4OH. The flow rate of the eluent for all these tests was 3 mL min−1. The results are summarized in Table 1 and selected chromatograms of the hydroxides are shown on Fig. 2a, b. The uncertainties represent the standard deviation of triplicate measurements.

Comparison of the chromatograms recorded using different bases to adjust the pH of the eluent. a LiOH, NaOH and KOH, b NaOH, CsOH and NH4OH sample: 10 μg thulium + 277 μg erbium in 5 wt% HNO3; eluent: 0.056 M pH 4.63 α-HIBA at 3 mL min−1; Dionex CS3 2.2 × 25 cm2 column; 5 mL min−1 0.2 mM PAR; 25 μL sample loop; without flow splitter

Use of LiOH yielded far longer retention times than the rest of the hydroxides tested. All bases except CsOH gave similar resolution for the separation, with LiOH, NH4OH and NaOH performing slightly better than RbOH and KOH. Surprisingly, the use of CsOH resulted in a far inferior separation than its lighter alkali metal counterparts. For ease of use, NH4OH was selected over NaOH as the hydroxide of choice for further studies. Further investigation would be required in order to better understand the effect of the counter ion on resolution and retention time. Subsequently, the pH of the eluent was increased from 4.63(2) to 5.63(2) under identical conditions using either LiOH or NH4OH. In both cases the higher pH yielded significantly inferior separation and significantly shorter retention times. This is the same effect that increased α-HIBA concentration would yield. Raising the pH increases the concentration of the conjugate base α-HIB− (α-HIBA has a pKa of 4.01) significantly by deprotonating more α-HIBA. This could provide an opportunity for saving reagents if the pH increase is countered by a lowered α-HIBA concentration since the separation is not pH or α-HIBA concentration dependent but rather α-HIB− concentration dependent [19].

It was apparent that a 25-μL sample loop could not be used with the final sample size of 500 mg, since it is not possible to dissolve this quantity in such a small volume; therefore, the sample loop was replaced with a 2-mL sample loop made in-house using the appropriate length of 0.030-inch ID PEEK tubing. Injecting a sample with 287 μg total lanthanide (1:27 Tm:Er mass ratio, a step in the scale-up earlier) in this larger 2-mL volume led to a much inferior separation due to the 5 wt% nitric acid matrix used. Decreasing the nitric acid concentration the lanthanides are dissolved into 1 wt% significantly improved the separation. Additional smaller improvement was observed as the acid concentration was decreased to 0.63 wt% (0.1 M) without further improvement at even lower concentrations of 0.5 and 0.1 wt% as shown in Table 2.

A concentration of 0.1 M nitric acid (0.63 wt%) was selected for subsequent experiments to ensure that no sample was lost due to adsorption on the walls of the plastic containers.

It was calculated that even if the loading of the column is limited to 10 % of its total capacity, the preparative CS3 column can only handle about 5 mg total Tm–Er mass. Since the goal is a 0.5 g mass separation, a different cation exchange resin with a higher capacity, 200–400 mesh BioRad AG50W-X8, was selected for further scale up experiments due to its considerably higher capacity. A column with a slightly larger diameter 2.54 cm, and 25 cm height was packed with the AG50W-X8 resin. A test separation using the same 0.056 M eluent (pH 4.63, adjusted with NH4OH) and 287 μg total lanthanide mass resulted in no elution for thulium (or erbium) over the course of 110 min at 3 mL min−1 eluent flow rate on the HPLC system at LANL. To counter the effect of the greatly increased number of exchange sites, the concentration of the α-HIBA eluent was increased to 1 M, the pH was increased to 5.6–5.7 (NH4OH adjusted) and the flow rate was increased to 15 mL min−1. These conditions resulted in elution within 5 min, but no separation, therefore the α-HIBA concentration was lowered from 1 M to 0.0625 M in four steps, where in each step the concentration of the eluent was half of its concentration in the previous step. Since at 0.0625 M α-HIBA concentration baseline separation was achieved, next a series of experiments was performed with increasing lanthanide masses in the samples ranging from 277 μg Er + 10 μg Tm to 20 mg Er + 20 mg Tm. This increase was carried out in the following steps: 277 μg Er + 280 μg Tm; 5 mg Er + 5 mg Tm and 20 mg Er + 20 mg Tm. Increasing sample loading decreased the separation, therefore at this sample loading the eluent concentration was further reduced in 10 % increments from 0.0625 through 0.0563 to 0.0506 M (Fig. 3). Both of the lower concentrations yielded near baseline separation. These tests showed that lowering the concentration of α-HIBA improved the separation but also increased the retention times, while increasing the amount of lanthanides injected decreased the separation and slightly shortened the retention times.

The next set of experiments tested the same range of decreasing α-HIBA concentrations but at an even higher mass loading of 200 mg erbium and 7.4 mg thulium injected in 0.63 % HNO3. (Fig. 4) At the lowest α-HIBA concentration, the eluent flow rate was reduced to 8.9 mL min−1, providing even better, near baseline, separation between thulium and erbium.

Since baseline resolution was achieved, these final conditions were used for a single pass separation of a full mock target containing 482.1 mg erbium and 17.9 mg thulium. Sufficient separation of this 500 mg target was achieved using the lowest eluent concentration of 0.0506 M and flow rate of 8.9 mL min−1. Twelve 20-minute fractions were collected starting at 281.5 min past injection for purity analysis using ICP-AES covering the full thulium peak and spanning over to the beginning of the erbium peak.

Near baseline separation of the full-scale target was first achieved on the system at LANL. It was subsequently replicated three times at UNLV using a different HPLC system, chemicals from different manufacturers (except α-HIBA and AG50W-X8) and a newly packed column, but by the same analyst. The baseline separation between Tm and Er was better using the system at UNLV at the cost of slightly longer retention times. Chromatograms of the full-scale separations are shown on Fig. 5. Between the three chromatograms recorded at UNLV the only difference was the temperature of the laboratory, which varied several degrees between and during runs. In case of UNLV #3 the splitting ratio on the flow splitter was slightly higher yielding slightly lower absorbance values. The HPLC was set up identically, separations were performed on aliquots of the same sample and reagents were prepared using chemicals from the same lots. The observed variation in retention times can be compensated for in case of the irradiated material by monitoring the start of the Tm peak using a suitable radiation detector and shift the start of the fraction collection accordingly.

Purification on branched DGA column

The chemical recovery from the final purification step was determined using 171Tm tracer. Each of the fractions collected from the LANL full-scale separation was spiked prior to removal of the HIBA by passing through a small, 1.8 mL bed volume, branched-DGA column. A standard containing the same amount of spike was prepared as well. After the lanthanides were eluted from the column, the resulting solutions were counted on an Ortec HPGe detector and compared to the standard. The average recovery of the thulium was 94(6) % based on separation of ten fractions. The large uncertainty was mainly due to the low activity of the spike, its low gamma yield and the relatively short counting times. The purified solutions were also measured using an FT-IR to verify the separation from α-HIBA. Two out of the twelve solutions were analyzed and the amount of α-HIBA was found to be below the detection limit of about 0.01 M in both of them.

ICP-AES analysis

Concentrations of erbium and thulium in the purified fractions were established using ICP-AES. Using the volume ratio of the eluate and load solutions, the original concentrations in the collected fractions were back calculated and overlaid on the chromatogram, Fig. 6.

When the thulium fraction was collected for 100 min, a decontamination factor of 1.4(4) × 105 with a recovery of 68.9(3) % was achieved. To achieve higher recovery while still having less than 1 % erbium contaminant, a recovery of 95.4(3) % was obtained by collecting for 140 min with a decontamination factor of 5.82(7) × 103, which is still more than double that of the required 2700. After this point not much more thulium is recovered, but the amount of erbium in the fraction rapidly increases. Longer collection times should only be used if an additional separation step is planned, e.g., on the preparative CS3 prior to cross section measurement target fabrication. The 140 min thulium fraction had a volume of 1241 mL which was reduced to generate a final sample of 0.135 mg/mL Tm in 119 mL.

Conclusions

The developed separation was capable of isolating milligrams of thulium from the required target mass of erbium with a purity of >99 % and a recovery of >95 % in a single pass-through. If an even greater purity becomes necessary, it could be achieved by sacrificing recovery or by passing the sample through a second, smaller column. The isolated thulium was successfully separated from the complexing agent on a branched-DGA column with a recovery of 94(6) %. The purity of the collected fractions was confirmed by ICP-AES measurements. The final separation using 0.0506 M α-HIBA pH 5.63 (NH4OH adjusted) at 8.9 mL min−1 flow rate was able to separate 17.9 mg thulium from 482.1 mg erbium dissolved in 2 mL 0.1 M HNO3 within 500 min on a 2.54 × 25 cm2 column filled with 200–400 mesh BioRad AG50W-X8. The 1241 mL thulium fraction was passed in increments through columns containing branched-DGA resin to remove the complexing agent. These eluates were combined and yielded 119 mL final volume with a concentration of 0.135 mg Tm/mL. The developed separation meets all the requirements and is ready to be applied to an irradiated 170Er target.

References

Wilhelmy JB, Ullmann JL, Lougheed RW, Koehler PE (1998) A proposal for an SBSS-astrophysics instrument at LANSCE: DANCE-device for advanced neutron capture experiments. Los Alamos National Laboratory, Los Alamos

Stoyer MA, McNabb DP, Burke JT, Bernstein LA (2009) Science based stockpile stewardship, uncertainty quantification, and surrogate reactions. Lawrence Livermore National Laboratory, Livermore, LLNL-TR-415408. https://e-reports-ext.llnl.gov/pdf/376635.pdf. Accessed 7 Apr 2015

Juzaitis RJ (2003) Science-based stockpile stewardship—an overview. Los Alamos Sci 28:32–37

Rundberg R, Ullmann JL, Wilhelmy JB, Fowler MM, Haight RC, MiIler GG, Palmer PD, Käppeler F, Koehler P (2000) Neutron capture cross section measurements for the analysis of the s-process. In: Manuel O (ed) Origin of elements in the solar system: implications of post-1957 observations. Kluwer Acad Publishers, New York

Reifarth R (2006) Stardust and the secrets of heavy-element production. Los Alamos Sci 30:70–77

Schwantes JM, Rundberg RS, Taylor WA, Vieira DJ (2006) Rapid, high-purity, lanthanide separations using HPLC. J Alloy Compd 418:189–194

Robards K, Clarke S, Patsalides E (1988) Advances in the analytical chromatography of the lanthanides. Analyst 113:1757–1779

Kumar M (1994) Recent trends in chromatographic procedures for separation and determination of rare earth elements. Analyst 119:2013–2024

Sarzanini C (1999) Liquid chromatography: a tool for the analysis of metal species. J Chromatogr A 850:213–228

Nash KL, Jensen MP (2001) Analytical-scale separations of the lanthanides: a review of techniques and fundamentals. Sep Sci Technol 36:1257–1282

Vasudeva Rao PR, Srinivasan TG, Sivaraman N (2009) Lanthanides: HPLC separation. In: Cazes J (ed) Encyclopedia of chromatography. CRC Press, Boca Raton

Quaim SM, Ollig H, Blessing G (1979) Separation of lanthanides by high pressure liquid chromatography. Radiochim Acta 26:59–62

Shuheng Y, Fa L, Hongdi Z, Xueliang L, Shulan Z (1988) Applications of pressurized cation exchange chromatography for fission yield determination. J Radioanal Nucl Chem 124:187–195

Miller GG, Rogers PZ, Palmer P, Dry D, Rundberg R, Fowler M, Wilhelmy J (2005) Preparation of radioactive rare earth targets for neutron capture study. J Radioanal Nucl Chem 263:527–530

Schwantes JM, Taylor WA, Rundberg RS, Vieira DJ (2008) Preparation of a one-curie 171Tm target for the detector for advanced neutron capture experiments (DANCE). J Radioanal Nucl Chem 276:533–542

Mocko V, Taylor WA, Nortier FM, Engle JW, Barnhart TE, Nickles RJ, Pollington AD, Kunde GJ, Rabin MW, Birnbaum ER (2015) Isolation of 163Ho from dysprosium target material by HPLC for neutrino mass measurements. Radiochim Acta 103:577–585

Campbell DO (1976) Separation of lanthanides and trivalent actinides with pressurized ion exchange. Sep Purif Method 5:97–138

Gharibyan N, Bene B, Sudowe R (2016) Chromatographic separation of thulium from erbium for neutron capture cross section measurements–part I: trace scale optimization of ion chromatography method with various complexing agents. J Radioanal Nucl Chem (under review)

Reifarth R, Haight R, Heil M, Fowler MM, Käppeler F, Miller GG, Rundberg RS, Ullmann JL, Wilhelmy JB (2003) Neutron capture measurements on 171Tm. Nucl Phys A 718:478c–480c

Dionex Technical Note 23 (1991) http://www.dionex.com/en-us/webdocs/4417-TN23_LPN032889-01.pdf. Accessed 7 Apr 2015

Product Manual IonPac CG3 Guard Column IonPac CS3 Analytical Column, Dionex Corp, Sunnyvale. http://www.dionex.com/en-us/webdocs/4398-32654-07_CS3_V17.pdf. Accessed 7 Apr 2015

AG 50W and AG MP-50 Cation Exchange Resins Instruction Manual, Bio-Rad Laboratories, Hercules. http://www.bio-rad.com/webroot/web/pdf/lsr/literature/9118_AG_50.pdf. Accessed 7 Apr 2015

Horwitz EP, McAlister DR, Bond AH, Barrans RE Jr (2005) Novel extraction chromatographic resins based on tetraalkyldiglycolamides: characterization and potential applications. Solvent Extr Ion Exch 23:319–344

Acknowledgments

The authors would like to thank Kenneth R. Ashley and Scott M. Bowen for their advice and sharing their extensive experience in lanthanide separations as well as David J. Vieira, Todd A. Bredeweg, Kevin D. John and Mary Turner for their support. This work was funded by the National Nuclear Security Administration Stewardship Science Academic Alliances Program under grant DEFG52-10NA29658, the United States Department of Energy Office of Science via the Isotope Development and Production for Research and Applications subprogram in the Office of Nuclear Physics and by the Seaborg Institute for Transactinium Science through the Seaborg Summer Research Fellowship. LA-UR-16-22041.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bene, B.J., Taylor, W.A., Birnbaum, E.R. et al. Chromatographic separation of thulium from erbium for neutron capture cross section measurements—Part II: Preparative scale separation. J Radioanal Nucl Chem 311, 155–163 (2017). https://doi.org/10.1007/s10967-016-4889-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-016-4889-z