Abstract

Polycaprolactone is a biodegradable, biocompatible, and versatile polymer commonly used in the pharmaceutical and biomedical industry and the development of new catalysts that allow for the synthesis under milder reaction conditions and in shorter reaction times is an appealing alternative. The iron-containing imidazolium-based ionic liquid 1-n-butyl-3-methylimidazolium heptachlorodiferrate was able to efficiently catalyze the ring-opening polymerization of ε-caprolactone under mild reaction conditions. Polymerization yields higher than 80% were obtained after 4 h of reaction at temperatures up to 85 °C, using low ionic liquid:ε-caprolactone molar ratios (1:720 − 1:1500), in the absence of solvent and without an intentionally added alcohol as an initiator. Semi-crystalline polycaprolactones, with molecular weights up to 14 kDa and narrow molecular weight distributions were synthesized. The chemical structure of the polymer was confirmed by Nuclear Magnetic Resonance (1H NMR) and Fourier Transform Infrared (FTIR) spectroscopy, and its crystalline content was estimated from the enthalpy of melting of the differential scanning calorimetry (DSC) thermogram. Finally, a caprolactone-activated ROP mechanism mediated by the ionic liquid was suggested.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly(ε-caprolactone) (PCL) has been widely used as a drug delivery system and scaffolds for tissue engineering applications due to its biodegradability, biocompatibility, and tailorability; Also, its slow degradation rate, and its rubbery property makes it a preferable biomaterial for biomedical applications [1, 2]. However, the biodegradability and suitability for use in biomedical applications are tied to the degree of crystallinity and also molecular weight [3]. Usually, polymers with higher molecular weight display a lower rate of hydrolytic degradation. Functional PCL nanoparticles loaded with a biologically active agent and explored as drug delivery systems can be obtained by dispersion of preformed polymers or in-situ polymerization techniques; however, the choice of the encapsulation method is highly dependent on the physicochemical properties of the polymer and the biologically active agent [4], and also on the required nanoparticles characteristics, such as particle size which influence the biodistribution and cellular uptake [5]. Low molecular weight polymers facilitate the emulsification process decreasing the viscosity of the system and consequently promoting the achievement of smaller particles. PCL can be synthesized either by step-growth (polycondensation) or by chain-growth polymerization, in this latter case by the ring-opening polymerization (ROP) of the ε-caprolactone (CL) [1]; The mechanism for this ROP is generally classified according to the catalyst used: anionic, cationic, monomer-activated, or coordination–insertion ROP [6].

A large number of catalytic systems have been studied to improve the physical, thermal, and mechanical properties of the PCL, and also to soften the experimental synthesis conditions. Metal-based [7], enzymatic [8, 9], inorganic acid [10, 11], and organic systems [10, 12] are the most reported. Metal-based catalysts are commonly used due to their availability and assortment. Depending on their chemical properties they show some specific characteristics, such as high activity, and in some cases, low toxicity (e.g. alkaline earth-based); other metals like tin (post-transition metal) allow good control of the reaction when used together with a nucleophilic agent (alcohol) as an initiator, whereas the control of the reaction using alkali metal-based catalysts is hampered due to transesterification [1]. Enzymatic polymerization of CL using lipases has been proposed by several authors, including the physically immobilized form of Candida antarctica lipase B (CALB) – the commercial enzyme Novozyme-435 [13, 14]. Though the enzymatic polymerizations carry numerous environmental benefits and usually proceed under mild reaction conditions, the high cost, the large quantity of enzymes, and the formation of relatively low molecular weight polymers should be considered [15]. Less common catalytic systems, organic compounds and inorganic acids may not require the addition of an initiator if they have a hydroxyl group or amine group present on their chemical structures [1].

Ionic liquids (ILs) used as solvents in polymerizations promote higher reaction rates and molecular weights, good yields, and the easy separation of products [16]. They are widely used as solvents and/or catalysts in many organic reactions; However, there are still few reports of their use as catalysts for polymerization reactions. Kaoukabi et al. [17] reported the ROP of ε-caprolactone (CL) in bulk using different ILs as catalysts and alcohols as initiators. The ILs 1-butyl-3-methylimidazolium hexafluorophosphate – [bmim][PF6] and 1-methyl-3-methylimidazolium hexafluorophosphate – [Memim][PF6] led to a linear increase of the molecular weight during the reaction, and low dispersity (up to 1.15 Ð). Using a CL:[bmim][PF6]:benzyl alcohol molar ratio of 200:1:1 at 120 °C for 48 h, PCLs of about 18.75 kDa (Mn) were obtained. Abdolmaleki and Mohamadi [18] also evaluated different ILs as catalysts using benzyl alcohol as an initiator in toluene (solvent); the IL morpholinium bisulfate [H-Mor]HSO4 promoted the synthesis of PCL of 13.6 kDa (Mv) after 48 h at 52 °C. Combining the previous data about the catalytic efficiency of the N,Nʹ-dialkylimidazolium-based ionic liquids for the ring-opening polymerization of CL [17], and the experience of our group related to the ability of the 1-n-butyl-3-methylimidazolium heptachlorodiferrate (BMI.Fe2Cl7) ionic liquid to mediate the cationic polymerization of styrene [19,20,21,22], this work aims to evaluate the efficiency of the iron-containing N,Nʹ-dialkylimidazolium-based ionic liquid BMI.Fe2Cl7 as a catalyst for the ring-opening polymerization of CL. Iron-containing catalysts are an attractive alternative to replace other toxic and more expensive metal-containing catalysts. Iron is an essential element of various metabolic processes in humans, then iron-containing catalysts can be considered resorbable [23]. Additionally, iron is one of the cheapest and most abundant metals on Earth.

Experimental section

Materials

Polymerization reactions were performed using ε-caprolactone (97%, Sigma-Aldrich) and the ionic liquid 1-n-butyl-3-methylimidazolium heptachlorodiferrate (BMI.Fe2Cl7), synthesized as reported by Rodrigues et al. [19]. After polymerization, the reaction medium was dissolved in chloroform (P.A. 99.8%, Neon Comercial) and the polymer obtained was precipitated in ice-cold ethanol (P.A. 99.8%, Neon Comercial). Tetrahydrofuran (HPLC Grade, J.T. Baker) and deuterated chloroform (99.8%, 0.5% TMS, Sigma-Aldrich) were used as solvents in the GPC and NMR analyses, respectively.

Polymerization reactions

Bulk polymerization reactions were performed under magnetic stirring and inert atmosphere in a Schlenk round-bottom flask (50 mL). BMI.Fe2Cl7 (20 μmol) was directly weighted into the reaction flask, and then the system was subjected to successive vacuum/argon cycles. CL (20 mmol) was added to the reaction flask with a syringe through the septum. After a predetermined time, the reaction medium was solubilized in chloroform. Then, the PCL was precipitated in ice-cold ethanol under magnetic stirring, filtered, and dried under reduced pressure at 50 °C until constant mass. Different reaction temperatures (60, 70 and 85 °C) and IL:CL molar ratios (1:720, 1:800, 1:1000, 1:1500, 1:1600 and 1:2000) were evaluated.

Characterization

Polymerization yield was determined by gravimetric analysis, discounting the mass of ionic liquid from the dry polymer mass. It is important to mention that the PCL recovery step via the precipitation in ethanol also acts as a purification step since the ionic liquid is soluble in the alcohol. However, the very low amount of IL used in these reactions does not affect the yield value.

Molecular weight distributions were determined by gel permeation chromatography (GPC). GPC analyses were conducted in a high-performance liquid chromatography instrument (HPLC, model LC 20-A, Shimadzu) equipped with a PLgel MiniMIX-C (PL1510-1500) guard column, and 2 × PLgel MiniMIX-C (PL1510-5500) HPLC column, from Agilent. Tetrahydrofuran (THF) was used as eluent with a volumetric flow rate of 0.3 mL‧min−1 at 40 °C. The PCL samples (0.02 g) were dissolved in THF (4 mL) and filtered through a nylon syringe filter (0.45 μm). The calibration was performed using polystyrene standards with molecular weights ranging from 580 to 9.225 × 106 g‧mol−1.

The polystyrene calibration was converted into one for PCL using the universal calibration method, by Eq. 1 [24]:

where \(K\) and \(a\) are the Mark-Houwink parameters. For polystyrene (PS), \(K\) = 0.932 × 10–4 dL‧g−1 and \(a\) = 0.740 and for polycaprolactone (PCL) \(K\) = 1.395 × 10–4 dL‧g−1 and \(a\) = 0.786.

The chemical structure of the PCL was determined by 1H NMR spectroscopy acquired using a 600 MHz NMR spectrometer. Chemical shifts are reported in ppm relative to tetramethylsilane (TMS, δ = 0.00 ppm). All samples were solubilized in CDCl3 (δ = 7.26). The functional groups of the PCL were identified by infrared spectroscopy (IR). The attenuated total reflectance–Fourier transform infrared (ATR-FTIR) spectrum of the polymer samples in KBr pellets were collected on a Shimadzu spectrometer, model IRPrestige-21, in the range of wavenumber 4000 − 600 cm−1 by accumulating 32 scans at a resolution of 4 cm−1.

The PCL melting temperature (Tm) and melting enthalpy (ΔHm) were determined by differential scanning calorimetry – DSC (Jade-DSC, Perkin Elmer) using 5 mg of dried polymer. The samples were heated from 0 to 140 °C at a heating rate of 10 °C‧min−1, under a nitrogen atmosphere (20 mL‧min−1). Tm and ΔHm were recorded from the second heating ramp.

Results and discussion

The catalytic activity of the 1,3-dialkylimidazolium based ionic liquid BMI.Fe2Cl7 for the ring-opening polymerization of CL was evaluated. The homopolymerizations were carried out in bulk using different reaction conditions. Table 1 summarizes the yield of the polymerizations conducted at different temperatures (T) and reaction times (t) using different molar ratios between the IL and the ε-caprolactone (IL:CL), and the number-average molecular weight (Mn) and molecular-weight dispersity (Ð) of the polycaprolactones obtained. The molecular weight data are reported from the gel permeation chromatography analyses (GPC, polystyrene calibration), and also using the universal calibration method for PCL (Eq. 1). However, the results will be discussed concerning polystyrene calibration data.

Reaction yields show that the BMI.Fe2Cl7 efficiently catalyzed the CL polymerization under mild reaction conditions, this is at temperatures below 85 °C, using low IL:CL molar ratios (1:720 − 1:1600), in the absence of solvent and without an intentionally added alcohol as an initiator. Polymerization yields higher than 80% were obtained using IL:CL ratios of 1:720, 1:800, 1:1000, and 1:1500 at 70 and 85 °C for 4 h, Runs T1 and T3 – T6 (Table 1). Lower IL concentrations (1:2000, Run T8) were not able to catalyze these polymerizations, even increasing the reaction time to 72 h.

The effect of IL:CL molar ratio on polymerization yield and, therefore, on the PCL molecular weight was studied for the reactions conducted at 70 °C for 4 h (T1, T3, T4 and, T6). There were no substantial differences in polymerization yield and on PCL molecular weight when IL:CL molar ratios of 1:1000 or 1:1500 were used. However, increasing the amount of ionic liquid to 1:720, the polymerization yield decreased as described by Patrocinio et al. [21]. When the IL amount increased from 1:1500 to 1:720, yield and molecular weight decreased from 88 to 80% and from 13.7 to 8.2 kDa, respectively. Once water act as initiator, this behavior is partly due to the water content of ionic liquid and CL, and also due to the increase in intramolecular transesterification which led to cyclic oligomers formation, as observed by Abdolmaleki and Mohamadi [18]. Though some of these oligomers may not be recovered by precipitation, and also be smaller than the smallest polystyrene GPC standard (580 Da). Abdolmaleki and Mohamadi [18] obtained PCL with comparable molecular weight using different acidic ionic liquids as catalysts (pyrrolidinium bisulfate, pyrrolidinium chloride, and morpholinium bisulfate). The reactions were carried out in toluene at 52 °C, using benzyl alcohol (BnOH) as an initiator. However, these molecular weights were reached after longer reaction times (36 h), while reactions T1 to T6 in Table 1 were performed in only 4 h and without solvent.

Kaoukabi et al. [17] performed the PCL synthesis in bulk at 120 °C using BnOH as initiator and the ionic liquid [bmim][PF6] as catalyst, among others. Using a 50:1:1 ratio of CL:[bmim][PF6]:BnOH, the molecular weight (Mn) of PCL ranged from 3.2 to 6.6 kDa depending on reaction time which increased from 15 to 28 h. Decreasing the amount of ionic liquid and alcohol to a ratio of 200:1:1 and increasing the reaction time to 48 h, monomer conversion increased and the molecular weight reached 22.1 kDa. Although the molecular weights obtained with the ionic liquid BMI.Fe2Cl7, displayed in Table 1, were slightly lower, these were reached under milder reaction conditions, a 50 °C lower temperature (70 vs 120 °C), a considerably shorter reaction time (4 vs 48 h), and also a much smaller IL:CL ratio (1:1500 vs 1:200).

A temperature increase of 10 °C, from 60 to 70 °C, using an IL:CL molar ratio of 1:800 (T2 and T3) led to an increase in the polymerization yield, and as expected, also increased the molecular weight of the PCL. However, using an IL:CL molar ratio of 1:1000, a temperature increase of 15 °C, from 70 to 85 °C (T4 and T5), did not increase the reaction yield which was close to 86 – 87%. Thus, the polymer molecular weight that is conversion-dependent did not increase either. The effect of temperature on polymerization yield and thus on the molecular weight of the polymer was also described by Sobczak [25]. Using a molar ratio of CL:SnOct2:choline of 100:0.5:1 for 24 and 48 h and increasing the reaction temperature from 120 to 160 °C the author reported a sharp increase in the polymerization yield that was reflected in an increase of the molecular weight of the polymer. However, for 72 h of reaction, the temperature increase did not affect the polymerization yield, which was already close to 87%, keeping the polymer molecular weight constant at about 10 kDa.

Reaction T7 was conducted with half of the monomer added at the beginning of the reaction and the other half after 4 h. As the ionic liquid was entirely added at the beginning of the reaction, during the first 4 h the real IL:CL ratio was 1:800 such as in reaction T3, and then decreased to 1:1600. The reaction yields of T3 and T7 were 80% and 55%, respectively. Supposing that in the first 4 h 80% of the monomer polymerized, then 40% of the monomer polymerized in the first half and the other 15% in the second half. Although the yield of T7 was lower than that of T3, the molecular weight of the PCLs was similar, around 8 kDa. Figure 1 shows the molecular weight distribution of PCL of T3 and T7.

Molecular weight distributions of PCL obtained by ROP of CL mediated by BMI.Fe2Cl7 at 70 °C, using a molar ratio IL:CL of 1:800 for 4 h (sample T3, Table 1), and using a molar ratio IL:CL of 1:1600, with the half of the monomer added at the beginning of the reaction and the other half after 4 h (sample T7, Table 1)

The PCL synthesized under the conditions of reaction T3 displayed a monomodal and narrow distribution, characteristic of controlled polymerization reactions, whereas the PCL synthesized by T7 presented a wider distribution, with a low molecular weight shoulder.

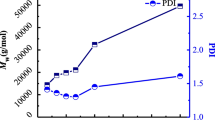

The kinetic behavior of the ε-caprolactone ROP mediated by BMI.Fe2Cl7 was evaluated at 70 °C for 4 h using an IL:CL molar ratio of 1:1000 (sample T4, Table 1), Fig. 2.

Yield evolution of ε-caprolactone ROP mediated by BMI.Fe2Cl7 at 70 °C for 4 h using an IL:CL molar ratio of 1:1000 (sample T4, Table 1)

In the first hour of reaction, approximately half of the mass of the final product is formed, and then the yield increases almost linearly between the first and third hours. After this time the yield increases slightly, reaching 86% at 4 h. Figure 3 shows a displacement of the molecular weight distribution of PCL samples to higher values when the reaction time increases.

Effect of the reaction time on molecular weight distributions of PCL obtained by ROP of CL mediated by BMI.Fe2Cl7 at 70 °C using an IL:CL molar ratio of 1:1000 (sample T4, Table 1)

The number-average molecular weight (Mn) and the dispersity (Ð) are summarized in Table 2.

The DSC thermogram of PCL (sample T4, Table 1), Fig. 4, shows a crystalline profile, with a crystalline content of 60%. The crystalline content was estimated from the enthalpy of melting (ΔHm) of the DSC thermogram using the heat of fusion of a 100% crystalline PCL sample, obtained from the literature [26]. The synthesized PCL presented a melting temperature (Tm) of 55 °C, in good agreement with the range (56 – 65 °C) described in the literature [1].

DSC thermogram of the PCL obtained by ROP of CL mediated by BMI.Fe2Cl7 at 70 °C using an IL:CL molar ratio of 1:1000 (sample T4, Table 1)

A typical 1H NMR spectrum of the resulting polymer (Fig. 5) shows the signals assignable to the hydrogens of the CH2OH end group (a) at 3.65 ppm and the hydrogen signals of the methylene unit near to the ester group (–CH2–O–CO–, b) at 4.06 ppm. The peaks between 1.3 and 1.7 ppm are assigned to the methylene hydrogens (CH2), and the peaks around 2.31 ppm are assigned to the α-carboxyl methylene hydrogens.

The FTIR spectrum of the polymer, Fig. 6, is in good agreement with the PCL structure. FTIR (KBr, cm−1): 2946 νas(CH2), asymmetric CH2 stretching; 2864 νs(CH2), symmetric CH2 stretching; 1726 ν(C=O), carbonyl stretching; 1294 νcr, C−O and C−C stretching in the crystalline phase; 1239 νas(COC), asymmetric COC stretching; 1195 ν(OC−O), OC−O stretching [27].

According to the IR and NMR spectra of PCL, a monomer-activated ROP mechanism involving the activation of the caprolactone molecules by the ionic liquid is suggested (Scheme 1). The polymerization reaction initiates by the formation of the primary alcohol from the lactone by water in an acidic medium. The primary alcohol may be found in equilibrium with the cyclic ester (lactone), especially under acidic reaction conditions. Upon substrate activation by the imidazolium-based dual activation catalyst, the alcohol performs an addition reaction with the activated lactone. Anion-cation cooperative catalysis is commonly noted for several ionic liquids [28]. In the current work, both the cation and the anion may help in the C=O activation, in accordance with the literature [29,30,31,32]. The processes take place repeatedly affording the desired polymer.

Other ionic liquids have already been tested to promote the polymerization of CL [17]. The reaction required benzyl alcohol as the initiator and to enable breaking the ionic liquid H-bond network and then to facilitate the catalytic action of the ionic fluid. This breaking of the ionic liquid H-bond network causes a significant induction reaction period. In this work, however, significant differences should be highlighted. The developed catalytic system required no intentionally added alcohol as an initiator mostly because the anions have an acidic character instead of a basic character noted for the commonly tested ionic liquids [17]. The cation-anion interactions are therefore less energetic than those with basic anions rendering the tested ionic liquid in this work a more effective availability to promote the polymerization reactions. Metal-containing (as anions) ionic liquids are known to display weaker H-bonds [28].

Conclusions

The iron-containing imidazolium-based ionic liquid BMI.Fe2Cl7 efficiently catalyzed the synthesis of PCL by the ring-opening polymerization of ε-caprolactone under mild reaction conditions in bulk, even at low IL concentrations (up to 1:1500 IL:CL molar ratio), and without an intentionally added alcohol as an initiator. High yields were observed in 4 h of reaction at 70 °C. Under these reaction conditions and using a molar ratio IL:CL of 1:1000, a semi-crystalline PCL (60% of crystalline content) was obtained with narrow molecular weight distribution and number-average molecular weight (Mn) and dispersity (Ð) of 12.7 kDa and 1.3, respectively. It was observed that the polymer molecular weight was conversion-dependent, and the lower the amount of IL the higher the yield, and thus the molecular weight. However, no substantial differences were observed between 1:1000 and 1:1500 IL:CL molar ratios. Besides, when an IL:CL molar ratio of 1:800 was used, a temperature increase from 60 to 70 °C affected the yield and the molecular weight, but when the IL:CL molar ratio was decreased to 1:1000 no effect was observed when the reaction temperature was increased from 70 to 85 °C, as the yield was already around 86% in the reaction at 70 °C. A caprolactone-activated ROP mechanism mediated by the ionic liquid was suggested based on the imidazolium-based dual activation mode (anion-cation cooperative catalysis), and without any intentionally added alcohol as an initiator mostly due to the acidic character of the anion and weaker H-bond networks.

Availability of data and material

The datasets generated during the current study are available from the corresponding author on request.

Code availability

Not applicable.

References

Labet M, Thielemans W (2009) Synthesis of polycaprolactone: A review. Chem Soc Rev 38:3484–3504. https://doi.org/10.1039/b820162p

Malikmammadov E, Tanir TE, Kiziltay A, Hasirci V, Hasirci N (2018) PCL and PCL-based materials in biomedical applications. J Biomater Sci Polym Ed 29:863–893. https://doi.org/10.1080/09205063.2017.1394711

Jenkins MJ, Harrison KL (2006) The effect of molecular weight on the crystallization kinetics of polycaprolactone. Polym Adv Technol 17:474–478. https://doi.org/10.1002/pat.733

Nava-Arzaluz MG, Piñón-Segundo E, Ganem-Rondero A, Lechuga-Ballesteros D (2012) Single emulsion-solvent evaporation technique and modifications for the preparation of pharmaceutical polymeric nanoparticles. Recent Pat Drug Deliv Formul 6:209–223. https://doi.org/10.2174/187221112802652633

Danaei M, Dehghankhold M, Ataei S, Hasanzadeh Davarani F, Javanmard R, Dokhani A, Khorasani S, Mozafari M (2018) Impact of particle size and polydispersity index on the clinical applications of lipidic nanocarrier systems. Pharmaceutics 10:57. https://doi.org/10.3390/pharmaceutics10020057

Oshimura M, Okazaki R, Hirano T, Ute K (2014) Ring-opening polymerization of ɛ-caprolactone with dilithium tetra-tert-butylzincate under mild conditions. Polym J 46:866–872. https://doi.org/10.1038/pj.2014.76

Arbaoui A, Redshaw C (2010) Metal catalysts for ε-caprolactone polymerisation. Polym Chem 1:801–826. https://doi.org/10.1039/b9py00334g

Varma IK, Albertsson A-C, Rajkhowa R, Srivastava RK (2005) Enzyme catalyzed synthesis of polyesters. Prog Polym Sci 30:949–981. https://doi.org/10.1016/j.progpolymsci.2005.06.010

Kobayashi S (2015) Enzymatic ring-opening polymerization and polycondensation for the green synthesis of polyesters. Polym Adv Technol 26:677–686. https://doi.org/10.1002/pat.3564

Gazeau-Bureau S, Delcroix D, Martín-Vaca B, Bourissou D, Navarro C, Magnet S (2008) Organo-catalyzed ROP of ϵ-caprolactone: Methanesulfonic acid competes with trifluoromethanesulfonic acid. Macromolecules 41:3782–3784. https://doi.org/10.1021/ma800626q

Shibasaki Y, Sanada H, Yokoi M, Sanda F, Endo T (2000) Activated monomer cationic polymerization of lactones and the application to well-defined block copolymer synthesis with seven-membered cyclic carbonate. Macromolecules 33:4316–4320. https://doi.org/10.1021/ma992138b

Zhu N, Liu Y, Liu J, Ling J, Hu X, Huang W, Feng W, Guo K (2018) Organocatalyzed chemoselective ring-opening polymerizations Sci Rep 8:3734. https://doi.org/10.1038/s41598-018-22171-6

Veneral JG, de Oliveira D, Ferreira SRS, Oliveira JV (2018) Continuous enzymatic synthesis of polycaprolactone in packed bed reactor using pressurized fluids. Chem Eng Sci 175:139–147. https://doi.org/10.1016/j.ces.2017.09.037

Zhao H, Nathaniel GA, Merenini PC (2017) Enzymatic ring-opening polymerization (ROP) of lactides and lactone in ionic liquids and organic solvents: Digging the controlling factors. RSC Adv 7:48639–48648. https://doi.org/10.1039/C7RA09038B

Albertsson A-C, Srivastava RK (2008) Recent developments in enzyme-catalyzed ring-opening polymerization. Adv Drug Deliv Rev 60:1077–1093. https://doi.org/10.1016/j.addr.2008.02.007

Vijayakrishna K, Manojkumar K, Sivaramakrishna A (2015) In: Mecerreyes D (ed) Applications of ionic liquids in polymer science and technology, Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-44903-5_13

Kaoukabi A, Guillen F, Qayouh H, Bouyahya A, Balieu S, Belachemi L, Gouhier G, Lahcini M (2015) The use of ionic liquids as an organocatalyst for controlled ring-opening polymerization of ϵ-caprolactone. Ind Crops Prod 72:16–23. https://doi.org/10.1016/j.indcrop.2015.02.002

Abdolmaleki A, Mohamadi Z (2013) Acidic ionic liquids catalyst in homo and graft polymerization of ε-caprolactone. Colloid Polym Sci 291:1999–2005. https://doi.org/10.1007/s00396-013-2941-x

Rodrigues TS, Machado F, Lalli PM, Eberlin MN, Neto BAD (2015) Styrene polymerization efficiently catalyzed by iron-containing imidazolium-based ionic liquids: Reaction mechanism and enhanced ionic liquid effect. Catal Commun 63:66–73. https://doi.org/10.1016/j.catcom.2014.11.002

Alves RC, Agner T, Rodrigues TS, Machado F, Neto BAD, da Costa C, de Araújo PHH, Sayer C (2018) Cationic miniemulsion polymerization of styrene mediated by imidazolium based ionic liquid. Eur Polym J 104:51–56. https://doi.org/10.1016/j.eurpolymj.2018.04.035

Patrocinio VMB, Agner T, Dutra GVS, Machado F, Neto BAD, Araújo PHH, Sayer C (2019) High molecular weight polystyrene obtained by cationic emulsion polymerization catalyzed by imidazolium-based ionic liquid. Macromol React Eng 13:1800061. https://doi.org/10.1002/mren.201800061

Agner T, Zimermann A, Machado F, Neto BAD, Araújo PHH, Sayer C (2020) Thermal performance of nanoencapsulated phase change material in high molecular weight polystyrene. Polímeros Ciência e Tecnol 30:e2020013. https://doi.org/10.1590/0104-1428.01320

Kricheldorf HR, Kreiser-Saunders I, Damrau D-O (1999) Resorbable initiators for polymerizations of lactones. Macromol Symp 144:269–276. https://doi.org/10.1002/masy.19991440124

Schindler A, Hibionada YM, Pitt CG (1982) Aliphatic polyesters. III. Molecular weight and molecular weight distribution in alcohol-initiated polymerizations of ε-caprolactone. J Polym Sci Polym Chem Ed 20:319–326. https://doi.org/10.1002/pol.1982.170200206

Sobczak M (2012) Ring-opening polymerization of cyclic esters in the presence of choline/SnOct2 catalytic system. Polym Bull 68:2219–2228. https://doi.org/10.1007/s00289-011-0676-8

Ikada Y, Tsuji H (2000) Biodegradable polyesters for medical and ecological applications. Macromol Rapid Commun 21:117–132. https://doi.org/10.1002/(sici)1521-3927(20000201)21:3%3c117::aid-marc117%3e3.0.co;2-x

Elzein T, Nasser-Eddine M, Delaite C, Bistac S, Dumas P (2004) FTIR study of polycaprolactone chain organization at interfaces. J Colloid Interface Sci 273:381–387. https://doi.org/10.1016/j.jcis.2004.02.001

Zhong C, Sasaki T, Jimbo-Kobayashi A, Fujiwara E, Kobayashi A, Tada M, Iwasawa Y (2007) Syntheses, structures, and properties of a series of metal ion-containing dialkylimidazolium ionic liquids. Bull Chem Soc Jpn 80:2365–2374. https://doi.org/10.1246/bcsj.80.2365

Zhang L, Fu X, Gao G (2011) Anion-cation cooperative catalysis by ionic liquids. ChemCatChem 3:1359–1364. https://doi.org/10.1002/cctc.201100016

de Oliveira VM, Silva de Jesus R, Gomes AF, Gozzo FC, Umpierre AP, Suarez PAZ, Rubim JC, Neto BAD (2011) Catalytic aminolysis (amide formation) from esters and carboxylic acids: Mechanism, enhanced ionic liquid effect, and its origin. ChemCatChem 3:1911–1920. https://doi.org/10.1002/cctc.201100221

Sarkar A, Roy SR, Chakraborti AK (2011) Ionic liquid catalysed reaction of thiols with α, β-unsaturated carbonyl compounds—remarkable influence of the C-2 hydrogen and the anion. Chem Commun 47:4538–4540. https://doi.org/10.1039/c1cc10151j

Ramos LM, Guido BC, Nobrega CC, Corrêa JR, Silva RG, de Oliveira HCB, Gomes AF, Gozzo FC, Neto BAD (2013) The Biginelli reaction with an imidazolium-tagged recyclable iron catalyst: Kinetics, mechanism, and antitumoral activity. Chem - A Eur J 19:4156–4168. https://doi.org/10.1002/chem.201204314

Acknowledgements

The authors thank the financial support from CAPES − Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Finance Code 001 and CAPES PRINT Program (Project Number: 88887.310560/2018-00), and CNPq − Conselho Nacional de Desenvolvimento Científico e Tecnológico. The authors also thank the Analysis Center of Chemical Engineering and Food Engineering Department from the Federal University of Santa Catarina for the DSC analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Leite, M.J., Agner, T., Machado, F. et al. ε-caprolactone ring-opening polymerization catalyzed by imidazolium-based ionic liquid under mild reaction conditions. J Polym Res 29, 56 (2022). https://doi.org/10.1007/s10965-022-02891-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-02891-0