Abstract

The aim of this work was to develop novel polyvinyl alcohol (PVA) and polyethylene glycol (PEG) blends hydrogels via solution casting technique followed by γ-irradiation technique to crosslink and form a hydrogel material that contains a certain amount of water when the solution polymer was exposed to γ-radiation at a small dose rate at ambient temperature. The formation of the PVE: PEG cross-linked structure was confirmed by Fourier Transform Infrared Spectroscopy (FTIR) measurement. The degree of swelling increased with increases in PVA content in the PVA-PEG mixed gel. The drug released from the gel material was examined using drug model sodium sulfate. The drug release behavior from the hydrogel networks was influence by the PVA-PEG ratio in the hydrogel preparation. The released amount was influenced dramatically by the ratio of PVA in the initial feed. The kinetic of the drug released from the hydrogels in general was a non-Fickian diffusion type (anomalous) mechanisms, whereas the process is moderately affected by the viscoelastic relaxation of the chains through water penetration. The thermal stability behavior of the hydrogel was demonstrated by thermo-gravimetric analysis (TGA), the tensile strength and compressive strength were found to be increased with increasing PEG content under induced γ-radiation. Furthermore, biodegradability of the PVA: PEG polymer blends were estimated in phosphate buffer solutions (PBS) under different pH values and enzymatic solution at pH 7.4 through weight loss monitoring. The results indicated that the biodegradation was increased as a function of PEG content decreased. The gamma ray crosslinking of the PVA: PEG blend hydrogel can be a good candidate for applications in a drug career.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

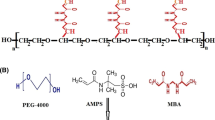

Hydrogels are hydrophilic macromolecular networks that are physically or chemically cross-linked, which allows the structures to swell in an aqueous environment and have been extensively applied in different application fields from intelligent carriers in controlled drug delivery systems to tissue engineering approaches [1–3]. Polyethylene glycol (PEG) is a hydrogel that has highly swollen biocompatible matrices and is approved by Food and Drug Administration (FDA) material with varied uses in the pharmaceutical and medical fields [4]. Its biocompatibility, tendency to absorb water, and flexibility make it one of the most widely used synthetic hydrogels. Additionally, PEG hydrogels have been used as drug carriers [5, 6]. Poly (vinyl alcohol) (PVA) must be cross-linked in order to be useful for a wide variety of applications, specifically in the areas of medicine and pharmaceutical science. PVA exhibits inferior mechanical properties, which can be improved by blending with other mechanically relative strong polymers. A wide range of materials properties can be obtained by merely changing the blend composition. Hydrogels based on PVA/PEG create unique opportunities to control biodegradability for biomedical and pharmaceutical applications [7], due to the advantages of the nontoxic, non-carcinogenic, and enhanced thermal stability of the hydrogel that indicate both PVA and PEG are cross-linked through a hydrogen bond (Fig. 1) [8, 9]. In general, the irradiation of polymer blends is a useful technique to crosslink or degrade the desired component polymer or to fix the blend morphology through free radical formation at the boundary surface in the polymer blend phase [10]. However, chemical cross-linked hydrogels have ionic or covalent bonds between polymer chains, and some of the crosslinking agents have proved to be toxic and give undesirable reactions [11]. In the radiation technique, the absorption of energy by the backbone polymer initiates the free radical process and the number of free radicals depends on the dose rate of the radiation [12, 13]. This has been known as a clean technique, because it does not require any extra substances, does not leave undesirable residues, and does not require any further purification.

In recent years, there has been increasing interest in the synthesis of oral drugs in controlled-release pharmaceutical forms that allow once or twice-a-day dosage administration. Gamma irradiation has several advantages over conventional curing processes: I) no catalyst or additives are needed to initiate the reaction; II) the initiation is homogenous throughout the system; III) it can be performed at any temperature and be interrupted at a chosen reaction time; IV) the polymer can be analyzed at selected reaction stages; and V) the temperature during reaction initialization is maintained in contrast to highly exothermic curing without irradiation. In addition, the gamma irradiation applied to polymers causes three different processes: chain scission, crosslinking, or grafting. These processes are dependent on the nature of irradiation, the chemical nature of the polymer, and the applied dose [6, 14]. Many researchers have investigated the properties of PVA-based hydrogels for application in the biomedical field. In a study, Nouh et al. [15] prepared PVA/PEG copolymer irradiated with gamma irradiation at a low dose range (1.5 to 20Gy). Their results led to enhancements of the crosslinking mechanism that resulted in an increase in the average molecular mass. In another study, Park et al. [16] reported the effects of PEG addition on the PVA-based hydrogel by gamma ray. They concluded that the thermal and mechanical properties increased with PEG concentration. Machado et al. [17] prepared different hydrogels from two aqueous solutions of PVA (15 and 20 mass/mass %) by chemical reactions using citric acid as a cross-linking agent and by electron beam (EB) irradiation with doses from 25 to 100 kGy. Their main approach was to development a new material to be used as artificial articular cartilage. From their obtained experimental results, it can be summarized that the PVA hydrogels produced by the irradiation cross-linking process have lower water absorption capacity, better mechanical properties, and higher thermal stability. In this work, the gamma radiation technique was used to synthesize a hydrogel network by crosslinking polyvinyl alcohol and polyethylene glycol blends ratios. The swelling behavior of the produced hydrogel and the controlled release kinetics of the drug model were investigated and the thermal-mechanical properties of the PVA-based hydrogel were improved for applications in drug delivery.

Experimental

Materials

The polyvinyl alcohol (PVA) sample used in this study was purchased from the Sigma Aldrich Company. The polyethylene glycol (PEG) was supplied by Sigma Aldrich Co. and was used as received. The sodium sulfate (Riedel, Germany) was used without any purification. Doubly distilled and de-ionized water was used in the swelling and release studies.

Synthesis of hydrogel materials by γ-irradiation

Irradiation was held using the source of irradiation 60 Co cobalt γ-rays. The polymer blends of PVA/PEG have been prepared by the solution casting technique with 20:80, 50:50, and 80:20 weight ratios in 10 ml distilled water. The polymer solutions were then mixed with continuous stirring until complete miscibility and were subsequently cast onto glass dishes to form films with a thickness of ~0.4 mm. After drying the cast films was repeated by heating the polymer solutions at 60 °C several times to ensure complete miscibility between the two polymers. Irradiation was done at 25 °C with γ-rays at a dose rate of 10 kGy/h for various periods of time. Irradiated samples were kept in the sealed ampoules at 25 °C for at least a week to decay the radicals completely and dried in vacuum before the properties were measured. The total dose of 25 kGy at a dose rate of 10 KGy/h was used to produce a hydrogel crosslink material [16].

Analytical techniques

Fourier transform infrared spectroscopy

Fourier transform infrared (FTIR) spectrometry was carried out on a Perkin-Elmer Spectrum 2000 FTIR with an attenuated total reflectance (ATR) crystal accessory (Golden Gate). All spectra were calculated by means of 5 individual scans at 2 cm−1 resolution in the 500–4000 cm−1 interval with corrections for atmospheric water and carbon dioxide.

Degree of swelling

The swelling ratio of the PVA/PEG: 20:80, 50:50, 80:20 were carried out by using the weights method (before and after immersion in water) [17], and Specimens (dimensions 1 × 1 cm) were immersed in distilled water at room temperature to study swelling at a minimum of three samples (tested for each material). The hydrogel sample was removed from the water bath at each interval of time, dried with filter paper, weighed, and placed in the same bath until maximum swelling was obtained [18]. The swelling ratio (SR) was calculating by the following equation:

Release dynamics of the drug

The hydrogel samples were loaded with the drug model (Na2SO4) by soaking them in 40 ml of 0.1 M aqueous solution of the drug model for 2 days. The swollen drug-loaded hydrogels were dried at ambient temperature for several days and then at 50 °C until constant weight was achieved.

Kinetic modelling of drug release

To determine the quantity of drug released by the PVA: PEG hydrogel, the samples were set into a cell containing 50 mL of de-ionized water at 37 °C. The samples (1 mL) were withdrawn at fixed time intervals and the solutions were replaced by fresh release media. All release studies were conducted in a shaker at 100 rpm at 37 °C. Release studies were carried out in de-ionized water for 2 h, 4 h, and 6 h in a wide range of concentrations of Na2SO4 solution at 37 ± 1 °C. The drug concentration in each sample was then determined by spectrophotometrically at 280 nm. The cumulative percentage of drug release was calculated and the mean of three determinations was used in data analysis. The amount of salt released at any selected time (M t ) was calculated from the calibration curve. The maximum weight available for release (M∞) was determined in the same way as M t. after 24 h. The fractional salt released (Ft) was then calculated from the following formula [19].

Thermal properties

Thermogravimetric analysis (TGA) was carried out using a Perkin Elmer Pyris 7 TGA analyzer (Waltham, MA, Germany) with scan ranges from 30 °C to 600 °C at a constant heating rate of 10 °C/min and continuous nitrogen flow. The thermal degradation temperatures taken into account were the temperature at (Tonset), the temperature of maximum weight loss (Tmax), and the temperature at 50 % weight loss (T50).

Mechanical properties

The tensile strength was measured using a universal mechanical tester (Instron, model 4451) according to ASTM D882. The tensile strength of each sample was tested at least five times, and the compressive strength of the hydrogel materials was measured using an Instron 5539. The strength was measured using 50 % compression and decompression of the hydrogel between the places of the test machine with a crosshead speed of 10 mm/min. The results reported are the mean values for five replicates.

Scanning electron microscopy (SEM)

The morphology of the fracture surfaces of the different PVA/PEG blend films was examined by SEM. The SEM micrographs were taken with a JSM-5400 electron microscope, JEOL, Japan. A sputter coater was used to pre-coat conductive gold onto the fracture surfaces before observing the micrographs at 30 kV.

Hydrolytic degradation of PVA: PEG polymer blends

The tests were performed to investigate the biodegradability of the PVA/PEG polymers. Hydrolytic degradation of films was carried out in PBS (pH = 7.4) and acidic PBS (pH = 2.0) both at 25 °C. The enzymatic degradation was performed in a solution mixture including PBS (20.0 mL, 150 mmol/L, pH = 7.4), 0.1 % MgC12 (5.0 mL) and 10 mg/mL Lipase AK, and the hydrolytic degradation was observed for one month, with measurements taken after 1, 3, 5, 7, 20 and 30 days. The samples were removed on the specified days and washed thoroughly with distilled water, dried in vacuum, and weighed to determine the weight loss.

Results and discussion

A crosslink is a bond that links one polymer chain to another and the degree of crosslinking is proportional to the radiation dose. Despite the kinetic of crosslinking by radiation dose has been studied since its initial discovery. However, there is still a debate about its particular naturel behavior. The comprehensively recognized mechanism includes the cleavage of a C-H bond on one polymer chain to eliminate the hydrogen atom from the polymer backbone along with the abstraction of a second hydrogen atom from a neighboring chain to create the hydrogen molecule [20]. Then the two adjacent polymeric radicals combine to form a crosslink. It can also lead to branch chains until, ultimately, a three-dimensional polymer network is formed. The formed network consists of at least two entangled cross-linked polymers. Figure 1 shows the mechanism of the hydrogel cross-linked for PVA and PEG blends by γ-irradiation technique.

Fourier transform infrared spectroscopy

The FTIR spectra of PVA and PEG at different feed ratios with irradiated are represented in Fig. 2. The FTIR spectrum of unirradiated PVA: PEG (50:50) was taken as a reference sample in spectra (A). Weak peaks were observed and compared with the irradiated PVA: PEG hydrogel. This clearly reveals that the major peaks associated with the poly (vinyl alcohol) induce γ-irradiation on the cross-linked PEG. It can also be observed that in general the peaks occurred for the C – H stretch at 2875–3015 cm−1 and the O - H stretch at 3200–3615 cm−1 and the C – O group at 1050–1200 cm−1. Intermolecular hydrogen bonding is expected to have occurred among PVA chains blends and PEG chains due to high hydrophilic forces with γ-irradiation effect as confirmed in the reaction (Fig. 1). Meanwhile, the decrease in intensity peaks at the hydroxyl group with a dramatic increase in the carbonyl group at (B), (C), and (D) demonstrates that the crosslink occurred due to the blending process as well as γ-irradiation [7, 21].

Swelling behavior

Swelling behavior can be determined by the amount of water in the three-dimensional hydrogel network structure. The hydrogels were immersed in distilled water for different times at room temperature until an equilibrium state of swelling was reached. As shown in Fig. 3, the swelling capability of PVA-PEG hydrogel increases progressively within the initial time of swelling up to 6 h and then shows a constant swelling, which indicates the maximum swelling. It is obvious that the maximum percentage of swelling increases when the PVA weight ratio in the hydrogel network is increased to 80 %. The maximum percentage of swelling value of ~70 % is obtained for the hydrogel prepared from the PVA-80 % weight ratio. This value decreases to 53 % with a weight ratio of PVA-20 %. The results obtained from the swelling behavior simply reflect the probability of network structure differences of these hydrogel systems [22, 23].

Drug model release

Figure 4 presented the drug model releasing curves as a function of time from the PVA-PEG gel networks as having different weight ratios in de-ionized water. The degree of salt released was enhanced as the PVA weight ratio in the feed mixture for hydrogel network preparation increased. The releasing behaviors were almost consistent with the swelling behaviors (see Fig. 3). Generally, drug release from the network is based on controlled swelling and the out-diffusion rate is a function of the extent of hydration [24, 25]. Consequently, in this study, the result suggest that the drug releasing behaviors were controlled by the swelling behaviors.

Mechanism of drug release

The drug release behavior tends to be considered for the following simple exponential model (Zalipsky, 1995):

Where Mt./M∞ is a fraction of drug released at time t, k is the release rate constant, and n is the release exponent. The n value is used to characterize different releases for cylindrical shaped matrices. In this model, the value of n characterizes the release mechanism of the drug as described in Table 1. For the case of cylindrical tablets, 0.45 ≤ n corresponds to a Fickian diffusion mechanism, 0.45 < n < 0.89 to non-Fickian transport, n = 0.89 to Case II (relaxation) transport, and n > 0.89 to super case II transport. To determine the exponent of n, the portion of the release curve, where Mt./M∞ < 0.6, should only be used. To study the release kinetics, data obtained from in vitro drug release studies were plotted as log cumulative percentage drug release versus log time [26]. The frictional release of the drug model from the PVA-PEG hydrogels is shown in Fig. 4. Consequently, as can be seen in Fig. 5, the release of the drug model depends on the polymers blends ratio of the hydrogel network preparation. The results from the release indicate a smooth fit to a linear model. The slopes of the lines in Fig. 5 were obtained by a linear regression and the values of n are given in Table 1. The values of diffusion exponent ‘n’, gel characteristics constant ‘k’, and diffusion coefficients are summarized in Table 1. The release of the drug from the hydrogels occurred through a non-Fickian diffusion mechanism in all the mediums. In non-Fickian diffusion, the rate of diffusion of the drug from the polymer is comparable to the rate of polymer chain relaxation [27].

Thermogravimetric analysis (TGA)

Thermal stability is an important property for polymer blends with increased crosslinking. The relative thermal stabilities of the different hydrogels were assessed by comparing the weight loss within a temperature of 100–600 °C in Fig. 6. The major thermal decomposition occurs within the temperature range of 300–500 °C. However, the initial degradation temperature was due to water loss, as described in Table 2. The TGA curve showed that PVA-80 % was stable up to 250 °C and decomposition occurred above 300 °C. PEG-20 % hydrogel started to decompose 10 wt% of the total weight at 300 °C, whereas PEG-80 % hydrogel started to decompose at 315 °C, as shown in Fig. 6. The thermal stability of PVA-based hydrogel increases with PEG content. It can be seen that the decomposition temperature started at around 300 °C and rapidly continued until 600 °C. The PEG has a higher thermal stability. The improved thermal stability at 20:80 is probably due to the sufficient cross-linkage and interaction between PVA: PEG induced by γ-radiation. Meanwhile, the PEG-20 % showed a lower thermal stability after 300 °C compared to the highest weight ratio of PEG. This indicates that cross-linkage between PVA: PEG (20:80) increased thermal stability [28]. This phenomena demonstrated that the formed hydrogels could be processed at reasonably high weight ratio of PEG content.

Mechanical test

Figure 7 shows the tensile strength of PVA hydrogel as a function of PEG content induced by γ-irradiation. In general, the tensile strength was increased to reach 1050 kPa at PEG-80 % of the hydrogel materials, which was proportional to the fractional release displayed in Fig. 4. However, Fig. 7 indicates that gel strength increases with an increase in PEG content. That could be explained due to the elasticity of the gel and the plasticizing effect [29]. The lowest content of PVA-20 % led to increased compressive strength to reach at 430 kPa, which could be attributed to the presence of PEG promote a phase separation as the interaction of water with PEG is stronger than in PVA because of the effect of PEG chains on the higher crosslink density and relaxing crack energy [30].).

Morphology study

Scanning electron microscopy images were taken at different feed ratios of PVA: PEG irradiation. As can be observed in Fig. 8, the structural surface morphology of hydrogel unirradiated PEG-50 % has been used as a reference compared with irradiated polymer blends. The change in the surface morphology of the cross-linked PVA: PEG hydrogel is clear in SEM. After blending with PEG a regular and parallel thin strains at blending ratios (PVA: PEG) of plasticized (80:20 %) and (50/50) as shown in micrograph (b) and (c). On the other hand, rough surface and relatively homogenous appearance was observed at PEG- 80 %, due to the compatibility performed after irradiation under 25 kGy with the highest percentage of PEG. In addition, the surface morphologies of the PVA/PEG blend became uneven and the phase-separation phenomenon occurred upon reduced PEG content. As displayed in Fig. 8, PVA segments and PEG segments could exert interaction by entanglement and by forming intermolecular hydrogen bonds [31], indicating that the blend of PEG into PVA changed the microstructure of the cross-linked PVA hydrogel. This phenomenon reveals that the change of the morphologies of PVA surface could be attributed to introduce of PEG segments [32–34].

Hydrolytic and enzymatic degradation of PVA: PEG polymer blends

To demonstrate the feasibility of PVA: PEG polymer blends for employ in biomaterials polymers, hydrolytic degradation tests were performed in PBS [35]. For this reason, PVA: PEG (20:80), (50:50) and (80:20) polymers were molded into samples with thicknesses of 1 mm the same conditions that were used for the mechanical tests. Then the samples were weighed 1 g and inserted into vials. During the degradation process, the samples were tested continuously in PBS at 25 °C for 30 says. Figure 9a shows the weight loss of the samples polymers as a function of time in the PBS, the degradation rate was dependent on the content of PEG in the blends, for example, PVA: PEG 80:20 which had a higher weight loss (27 %) for almost 30 days than PVA: PEG 50:50 (23 %) and the lower degradation behavior was observed for PVA: PEG 20:80 (13 %). The higher degree of chain entanglements in the high crosslinked could suppress the chain mobility significantly, thus decreasing the degradation rate compared with that of PVA: PEG 80:20.

Figure 9b was investigated in acidic PBS solution (pH = 2.0). All samples could be slowly hydrolyzed in the two solutions, and their final weight losses based on PVA: PEG were in the range of 20 % to 15 %, and 8 % upon increased PEG content respectively. Apparently, the polymers display a low degradation in acidic PBS solutions in compared to Fig. 9a, and there is not much difference among the samples, while the degradation rates of PEG-20 % and PEG-50 % in PBS 7.4 were considerably faster than those of PEG-20 % and PEG-50 % in PBS 2. These results indicate that the degradation behaviors are not only influenced by the contents of hydrophilic PEG in the polymers, but also closely related to their surface structures, bulk structures, degradation of PVA: PEG polymer blends mainly dependent on hydrophilic and hydroxyl group structure of PEG chains [35].

Moreover, Fig. 9c the enzymatic degradation of these obtained PVA: PEG polymer blends were carried out in PBS containing Lipase AK, due to the enzyme is substantially used to accelerate the degradation of PEG. Figure 9c describes the weight losses of PVA: PEG in enzymatic solution during a degradation period of 30 days. The changes of polymer weights in enzymatic solution are similar to those in weak base PBS solution. Almost, the final weight losses in the Lipase AK PBS are significantly superior to the weight losses of 30 days degradation in pH 7.4 PBS and pH 2 PBS [36, 37], showing that their enzymatic degradation is much faster than hydrolytic degradation.

Conclusion

In this paper, a series class of biodegradable PVA: PEG polymer blends were successfully prepared by using solution casting technique followed by γ-ray crosslinking to synthesized polymer hydrogels and the degree of swelling decreased as the composition of PEG increased in the blend that leads to increase number of intramolecular crosslinks. The hydrogels presented relatively different swelling capabilities in distilled water in the range of 53 %–70 %. The drug release from the produced PVA-PEG hydrogel was investigated and the kinetic of release was studied. The mechanism of the drug release tended to be non-Fickian (anomalous). The effect of PEG content was observed; the fraction release increased as the content of PVA increased. Also, the morphology of the blends affects the thermomechanical properties. The result obtained by SEM revealed that the surface of PEG-80 % sample became rough related to the crosslinked promoted by γ- radiation, pH value of degradation media and enzyme on the degradation rate of these PVA: PEG polymer blends were investigated. In addition, the high degree of crosslinking in PVA: PEG polymer blends have hindered the evaluation of their degradation behaviors,

References

Rosiak JM, Yoshii F (1999) Hydrogels and their medical applications. Nucl. Inst. Methods Phys. Res. B 151:56–64

Zhao L, Mitomo H, Zhai M, Yoshii F, Nagasawa N, Kume T (2003) Radiation synthesis and characteristic of the hydrogels based on carboxymethylated chitin derivatives. Carbohydr. Polym. 51:169–175

Cascone MG, Sim B, Downes S (1995) Blends of synthetic and natural polymers as drug delivery systems for growth hormone. Biomaterials 16:569–574

Mellott MB, Searcy K, Pishko MV (2001) Release of protein from highly cross-linked hydrogels of poly(ethylene glycol) diacrylate fabricated by UV polymerization. Biomaterials 22:929–941

Sagle AC, Ju H, Freeman BD, Sharma MM (2009) PEG-based hydrogel membrane coatings. Polymer 50:756–766

Hassan CM, Peppas NA (2000) Structure and applications of poly(vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Adv. Polym. Sci. 153:37–65

Mansur HS, Orefice RL, Mansur AAP (2004) Characterization of poly(vinyl alcohol)/poly(ethylene glycol)hydrogels and PVA-derived hybrids by small-angle X-ray scattering and FTIR spectroscopy. Polymer 45:7193–7202

Wu M, Bao B, Yoshii F, Makuuchi K (2001) Irradiation of crosslinked, poly(vinyl alcohol) blended hydrogel for wound dressing. J. Radioanal. Nucl. Chem. 250:391–395

Park KR, Nho YC (2003) Synthesis of PVA/PVP hydrogels having two-layer by radiation and their physical properties. Radiat. Phys. Chem. 67:361–365

Abdel Moneam YA, Sakr HAA, Ali HE, Khalil SA, El-Naggar AWM (2014) Characterization and antimicrobial properties of gamma synthesized plasticized starch/poly(vinyl alcohol)/ZnO composites as protective coating for papers. International Journal of Chem Tech Research 6:2583–2597

Zakuraeva OA, Nesterov SV, Shmakova NA, Semenova GK, Sozontova EO, Feldman VI (2007) Radiation-chemical synthesis of poly(vinyl alcohol) hydrogel dicyclohexano-18-crown-6. Nucl. Inst. Methods Phys. Res. B 265:356–361

Yang X, Yang K, Wu S, Chen X, Yu F, Li J, Ma M, Zhu Z (2010) Cytotoxicity and wound healing properties of PVA/ws-chitosan/glycerol hydrogels made by irradiation followed by freeze–thawing. Radiat. Phys. Chem. 79:606–611

Gwon HJ, Lim YM, Nho YC, Baik SH (2010) Humectants effect on aqueous fluids absorption of γ-irradiated PVA hydrogel followed by freeze thawing. Radiat. Phys. Chem. 79:650–653

Dutta J (2012) Synthesis and characterization of γ-irradiated PVA/PEG/CaCl2 hydrogel for wound dressing. Am. J. Chem. 2:6–11

Nouh SA, Nagla AG, Othman MH, Eman SA, Lotfi ZI (2012) Thermal, structural, and optical properties of γ-irradiated poly(vinyl alcohol)/poly(ethylene glycol) thin film. J. Appl. Polym. Sci. 124:654–660

Park J-S, Kim H, Choi J-B, Gwona H-J, Shin Y-M, Lim Y-M, Khil MS, Nho Y-C (2012) Effects of annealing and the addition of PEG on the PVA based hydrogel by gamma ray. Radiat. Phys. Chem. 81:857–860

Machado LDB, Bavaresco VP, Pino ES, Zavaglia CAC, Reis MC (2004) TA of pval of hydrogen cross-linked by chemical and eb irradiation process used as artificial articular cartilage. J. Therm. Anal. Calorim. 75:445–451

Nugroho P, Mitomo H (2008) Study of biodegradation and improvement of heat stability of poly(lactic acid) by irradiation at high temperature. Malaysian Polymer Journal 3:27–37

Gulsen D, Chauhan A (2006) Effect of water content on transparency, swelling, lidocaine diffusion in p-HEMA gels. J. Membr. Sci. 269:35–48

Kaity S, Isaac J, Ghosh J (2013) Interpreting polymer network of locust bean gum-poly (vinyl alcohol) for controlled release drug delivery. Carbohydr. Polym. 94:456–467

Satish CS, Satish KP, Shivakumar HG (2006) Hydrogels as controlled drug delivery systems: synthesis, crosslinking, water and drug transport. Indian Journal of Pharmaceutical Sciences 68:133–140

Singh B, Pal L (2011) Radiation crosslinking polymerization of sterculia polysaccharide-PVA-PVP for making hydrogel wound dressings. Int. J. Biol. Macromol. 48:501–510

Wang, M., Xu, L., Hui, H., Zhai, M., Peng., J., Nho, J., Li, J., and Wei, G (2007) Radiation synthesis of PVP/CMC hydrogels as wound dressing. Nucl. Inst. Methods Phys. Res. B 265: 385–389.

Singh B (2007) Psyllium as therapeutic and drug delivery agent. Int. J. Pharm. 334:1–14

Zalipsky S (1995) Chemistry of polyethylene glycol conjugates with biologically active molecules. Adv. Drug Deliv. Rev. 16:157–182

González-Rodrígues ML, Maestrelli F, Mura P, Rabasco AM (2003) In vitro release of sodium diclofenac from a central core matrix tablet aimed for colonic drug delivery. Eur. J. Pharm. Sci. 20:125–131

Rao KVR, Devi KP, Buri P (1990) Influence of molecular size and water solubility of the solute on its release from swelling and erosion controlled polymer matrices. J. Control. Release 12:133–141

Bourke SL, Al-Khalili M, Briggs T, Michniak BB, Kohn J, Poole-Warren LA (2003) A photo-crosslinked poly(vinyl alcohol) hydrogel growth factor release vehicle for wound healing applications. AAPS Pharm Sci 5:101–111

Lugao AB, Rogero SO, Malmonge SM (2002) Rheological behaviour of irradiated wound dressing poly(vinyl pyrrolidone) hydrogels. Radiat. Phys. Chem. 63:543–546

Yusong P, Dangsheng X, Xiaolin C (2007) Mechanical properties of nanohydroxyapatite reinforced poly(vinyl alcohol) gel composites as biomaterial. J. Mater. Sci. 42:5129–5134

Jin L, Bai RB (2002) Mechanisms of lead adsorption on chitosan/PVA hydrogel beads. Langmuir 18:9765–9770

Minhas MU, Ahmad M, Ali L, Sohail M (2013) Synthesis of chemically cross-linked polyvinyl alcohol-co-poly (methacrylic acid) hydrogels by copolymerization; a potential graft-polymeric carrier for oral delivery of 5-flourouracil. J. Pharm. Sci. 21:44

Leitão AF, Silva JP, Dourado F, Gama M (2013) Production and characterization of a new bacterial cellulose/poly(vinyl alcohol) nanocomposite. Materials 6:1956–1966

Bodugoz-Senturk H, Macias CE, Kung JH, Muratoglu OK (2009) Poly(vinyl alcohol)-acrylamide hydrogels as load-bearing cartilage substitute. Biomaterials 30:589–596

Huang SJ (1985) Biodegradable polymers, in encyclopedia of polymer science and engineering, vol 2. Wiley, New York, p. 220

Ding M, Zhang M, Yang J, Qui JH (2012) Study on the enzymatic degradation of PBS and its alcohol acid modified copolymers. Biodegradation Epub 23:127–132

Chan Woo Lee, Kimura. Jin-Do Chung (2008) Mechanism of enzymatic degradation of poly (butylone succinate). Macromol. Res. 16: 651–658.

Acknowledgments

The authors acknowledge the financial support of the Libyan Authority for Research, Science & Technology-Tripoli, and the authors are also indebted to Nanocomposites Biomaterials Laboratory in the Faculty of Engineering - Architectural Science at Ryerson University in Toronto, Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abu Ghalia, M., Dahman, Y. Radiation crosslinking polymerization of poly (vinyl alcohol) and poly (ethylene glycol) with controlled drug release. J Polym Res 22, 218 (2015). https://doi.org/10.1007/s10965-015-0861-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0861-9